Discover Key Benefits: Tool Case Description Simplified (2025)

Introduction: Navigating the Global Market for tool case description

Navigating the global market for tool cases can be daunting for international B2B buyers, especially when sourcing durable and reliable options that meet diverse industry needs. The challenge lies not only in identifying the right tool case but also in ensuring it withstands the rigors of various working environments—from the arid conditions of Africa to the humid climates of South America and the varied climates across Europe and the Middle East. This comprehensive guide on tool case descriptions addresses these challenges by offering an in-depth look at the different types of tool cases available, their applications, and the critical factors to consider when making a purchasing decision.

In this guide, we will explore essential aspects such as the construction materials that enhance durability, the importance of waterproofing for extreme conditions, and the advantages of customizable interiors for specific tool organization. We will also provide actionable insights on supplier vetting processes, cost considerations, and warranty options, equipping buyers with the knowledge necessary to make informed choices.

By understanding the nuances of tool case features and functions, B2B buyers from regions such as Poland and Brazil can confidently navigate the market, ensuring they select products that not only meet their operational needs but also offer long-term value. This guide serves as a vital resource for businesses aiming to optimize their tool storage solutions while enhancing efficiency and productivity in their respective fields.

Understanding tool case description Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hard-Sided Tool Cases | Watertight, impact-resistant, and durable construction. | Field service, construction, and biomedical. | Pros: Excellent protection; Cons: Heavier and bulkier. |

| Modular Tool Cases | Customizable interiors and modular connectivity with other cases. | Telecom, datacom, and renewable energy. | Pros: Versatile and adaptable; Cons: More complex setup. |

| Portable Tool Cases | Lightweight and easy to transport; often feature wheels. | General trade, maintenance, and repair. | Pros: Easy mobility; Cons: May lack durability. |

| Tool Cases with Inserts | Foam inserts for custom tool organization and protection. | Audio/video, field service, and utilities. | Pros: Customizable for various tools; Cons: Inserts may wear out. |

| Steel Tool Boxes | Robust steel construction with high weight capacity. | Heavy-duty industrial applications. | Pros: Extremely durable; Cons: Prone to rust if not treated. |

What Are Hard-Sided Tool Cases and Their Benefits for B2B Buyers?

Hard-sided tool cases are designed for maximum durability and protection, often featuring watertight seals and impact-resistant materials. They are ideal for industries such as field service, construction, and biomedical, where tools are exposed to harsh environments. When considering these cases, buyers should evaluate the weight and bulkiness, as these factors can influence transport efficiency.

How Do Modular Tool Cases Enhance B2B Operations?

Modular tool cases offer customizable interiors and the ability to connect with other storage components. This flexibility is particularly valuable in sectors like telecom and renewable energy, where tools and equipment frequently change. Buyers should consider the complexity of setup and the initial investment, as these cases can require a more significant upfront cost compared to traditional options.

What Advantages Do Portable Tool Cases Offer for Tradespeople?

Portable tool cases are lightweight and designed for easy transport, often equipped with wheels for added convenience. They are suitable for general trade work, maintenance, and repair tasks. While their mobility is a significant advantage, buyers should be aware that these cases may not provide the same level of durability as hard-sided options, potentially leading to quicker wear and tear.

Why Choose Tool Cases with Inserts for Customization?

Tool cases with customizable foam inserts allow for tailored organization and protection of tools, making them ideal for sectors like audio/video and utilities. The ability to create specific pockets for each tool enhances efficiency and reduces damage during transport. However, buyers should consider the longevity of the foam inserts, as they may degrade over time and require replacement.

What Are the Key Features of Steel Tool Boxes for Heavy-Duty Needs?

Steel tool boxes are known for their robustness and high weight capacity, making them suitable for heavy-duty industrial applications. They provide excellent protection against physical damage, but buyers must consider potential rust issues if the boxes are not properly treated or maintained. The durability offered by steel can justify the investment for companies that require long-lasting storage solutions.

Key Industrial Applications of tool case description

| Industry/Sector | Specific Application of Tool Case Description | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Field Service | Transporting specialized tools to remote job sites | Ensures tools are protected from environmental hazards | Durability, waterproof features, weight capacity |

| Biomedical | Secure storage of sensitive medical equipment | Protects valuable equipment from damage and contamination | Compliance with health standards, customizable inserts |

| Renewable Energy | Organizing tools for installation and maintenance of solar panels | Facilitates efficient workflows and reduces downtime | Portability, weather resistance, compatibility with tool kits |

| Oil & Gas | Storing tools for drilling and extraction processes | Enhances safety and efficiency in hazardous environments | Corrosion resistance, heavy-duty construction |

| Telecom | Carrying equipment for network installations and repairs | Streamlines operations and minimizes equipment loss | Modular design, ease of transport, protective features |

How is Tool Case Description Utilized in Field Service Applications?

In the field service industry, tool cases are crucial for transporting specialized tools to remote job sites. These cases must be durable and capable of withstanding various environmental conditions, such as extreme temperatures or moisture. By investing in high-quality, watertight cases, companies can ensure that their tools remain protected, reducing the risk of damage and minimizing operational downtime. International buyers, particularly in Africa and South America, should prioritize features like telescoping handles and wheels for ease of mobility across rugged terrains.

What Role Does Tool Case Description Play in the Biomedical Sector?

In the biomedical sector, tool cases serve as secure storage solutions for sensitive medical equipment. These cases help protect valuable instruments from damage and contamination during transport and storage. For international B2B buyers, especially in the Middle East and Europe, compliance with health and safety standards is paramount. Therefore, selecting tool cases that offer customizable inserts for specific medical tools can enhance organization and ensure that equipment is readily available when needed.

How is Tool Case Description Applied in Renewable Energy Projects?

Tool cases are essential in the renewable energy industry for organizing tools required for the installation and maintenance of solar panels and wind turbines. These cases facilitate efficient workflows, allowing technicians to quickly access the necessary tools, thus reducing downtime. Buyers in Europe and South America should consider sourcing tool cases that are portable and weather-resistant to withstand outdoor conditions, ensuring that tools remain functional and protected during use.

Why is Tool Case Description Important in the Oil & Gas Industry?

In the oil and gas sector, tool cases are vital for storing equipment used in drilling and extraction processes. These cases must be designed to enhance safety and efficiency in hazardous environments, often requiring corrosion-resistant materials and robust construction. For international buyers, particularly in regions with extreme weather conditions, it is essential to select tool cases that provide maximum protection against environmental elements while ensuring easy transport and accessibility to tools.

How Does Tool Case Description Benefit Telecom Operations?

In the telecom industry, tool cases are used to carry equipment necessary for network installations and repairs. These cases help streamline operations and minimize the risk of equipment loss during transportation. For B2B buyers, particularly in Africa and Europe, selecting tool cases with a modular design can offer flexibility in organizing various tools and accessories, making it easier to adapt to different project requirements while ensuring that all necessary items are readily available.

3 Common User Pain Points for ‘tool case description’ & Their Solutions

Scenario 1: Inadequate Protection Against Harsh Conditions

The Problem: For B2B buyers operating in industries such as oil and gas or renewable energy, tools are often exposed to extreme conditions, including moisture, dust, and temperature variations. A frequent challenge arises when the chosen tool case fails to provide adequate protection, leading to tool damage and increased replacement costs. Buyers may find that standard tool cases do not withstand environmental stressors, resulting in operational downtime and loss of productivity.

The Solution: To overcome this challenge, B2B buyers should prioritize sourcing tool cases designed specifically for harsh conditions. Look for features such as watertight seals, impact-resistant materials, and corrosion resistance. For instance, cases like the SKB Custom Made Tool Case offer superior durability and a lifetime warranty, ensuring longevity even in extreme environments. When specifying tool cases, consider investing in models with customizable foam inserts, which can securely hold tools in place and protect them from impact. This proactive approach not only protects your investment but also enhances operational efficiency by minimizing tool replacement and downtime.

Scenario 2: Difficulty in Organizing Tools Efficiently

The Problem: Many B2B buyers face the issue of disorganization within their tool storage solutions. An unorganized tool case can lead to wasted time during projects, as workers struggle to find the right tools. This inefficiency can be particularly problematic in fast-paced environments, where time is money. Buyers often report frustration when they have to sift through a jumbled collection of tools, leading to mistakes and accidents on the job site.

The Solution: To address this pain point, buyers should consider modular tool cases with customizable inserts, such as the Milwaukee PACKOUT™ Tool Case. These systems allow users to create tailored compartments for each tool, making it easy to locate and access them quickly. Additionally, investing in cases that integrate with a modular storage system ensures compatibility and ease of transport. Implementing a standardized labeling system for tools and compartments can further enhance organization. By taking these steps, buyers can significantly improve their workflow, reduce time wastage, and increase overall productivity on the job site.

Scenario 3: High Shipping Costs and Logistical Challenges

The Problem: International B2B buyers, particularly those in Africa and South America, often encounter high shipping costs and logistical hurdles when sourcing tool cases. These challenges can lead to delays in project timelines and increased expenses. Buyers may find themselves paying premium rates for shipping bulky tool cases, which can negate the savings gained from purchasing high-quality products.

The Solution: To mitigate these costs, buyers should explore local suppliers or manufacturers that offer competitive pricing on tool cases without compromising quality. Building relationships with regional distributors can provide access to bulk purchasing options, which often come with discounts. Additionally, consider sourcing lightweight and stackable tool cases that minimize shipping volume. For example, selecting tool cases with collapsible designs can significantly reduce shipping dimensions. Buyers should also evaluate freight forwarders who specialize in handling logistics for tools and equipment, ensuring better rates and more efficient shipping processes. By optimizing the sourcing strategy, buyers can reduce overall costs while ensuring timely delivery of their tool cases.

Strategic Material Selection Guide for tool case description

When selecting materials for tool cases, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Here, we analyze four common materials used in tool case manufacturing: polypropylene, aluminum, steel, and high-density polyethylene (HDPE). Each material has unique properties, advantages, and limitations that can significantly impact the end product’s suitability for various applications.

What are the Key Properties of Polypropylene for Tool Cases?

Polypropylene is a thermoplastic polymer known for its lightweight and flexible characteristics. It has a good temperature resistance, typically rated up to 100°C (212°F), and exhibits excellent chemical resistance, making it suitable for various environments.

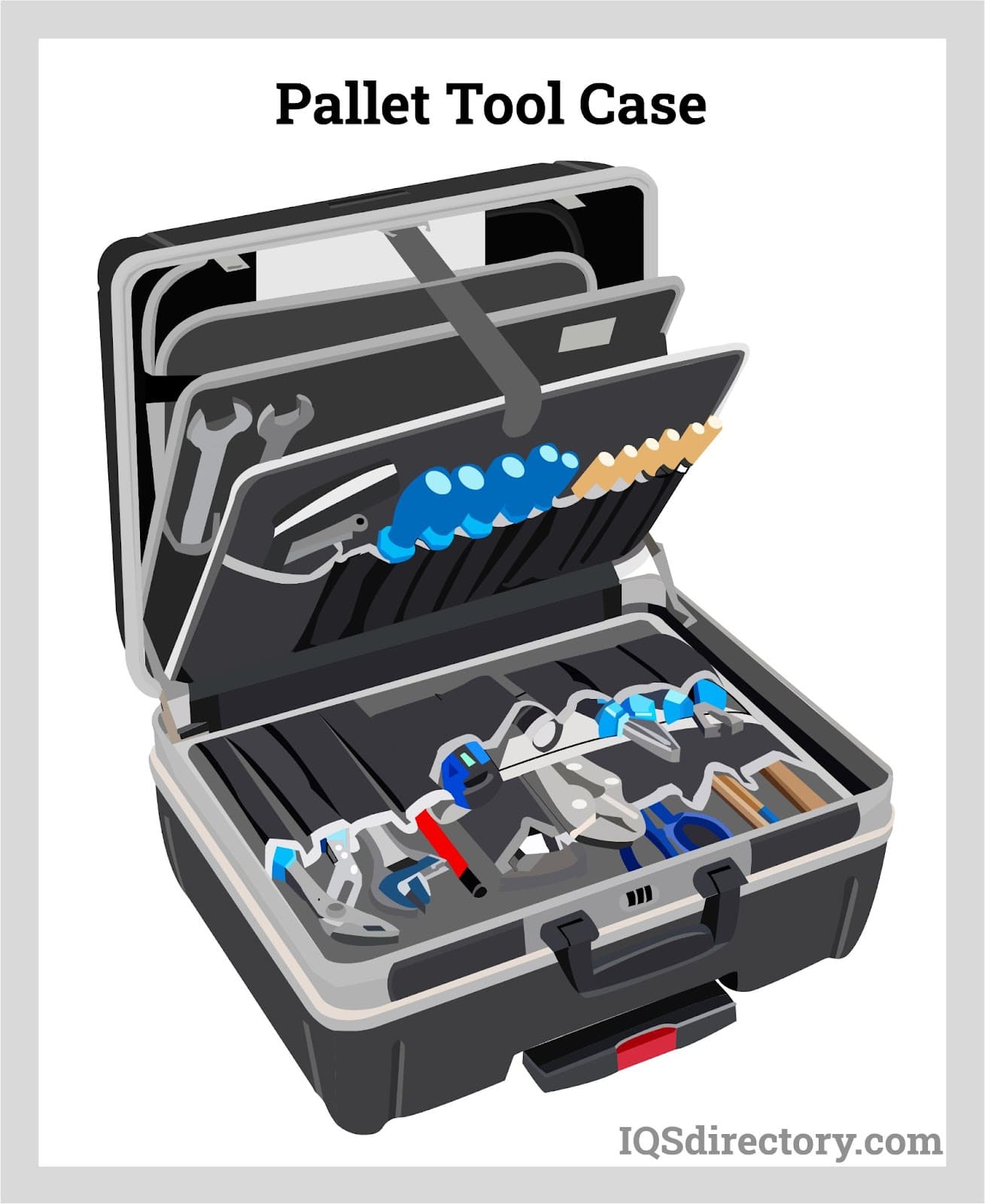

A stock image related to tool case description.

Pros: Polypropylene tool cases are cost-effective, lightweight, and resistant to impact and corrosion. They are also easily molded into complex shapes, allowing for customizable designs.

Cons: While polypropylene is durable, it may not withstand extreme temperatures as well as metals. It can become brittle in very low temperatures, which may limit its use in colder climates.

Impact on Application: Polypropylene is ideal for applications where weight is a concern, such as in the field service industry, but may not be suitable for heavy-duty industrial environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local environmental regulations regarding plastic use. Additionally, understanding the material’s performance in local climates is crucial.

How Does Aluminum Perform in Tool Case Applications?

Aluminum is a lightweight metal known for its strength-to-weight ratio and corrosion resistance. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F), making it versatile for various applications.

Pros: Aluminum tool cases are highly durable, resistant to corrosion, and provide excellent protection against physical impacts. They can also be anodized for additional surface protection.

Cons: The cost of aluminum is generally higher than plastic materials, and while it offers good strength, it can be prone to dents and scratches.

Impact on Application: Aluminum is well-suited for industries such as aerospace and automotive, where durability and weight are critical.

Considerations for International Buyers: Buyers in Europe, particularly Poland, should be aware of compliance with EU regulations regarding material sourcing and recycling. Understanding the local market’s demand for aluminum cases can also guide purchasing decisions.

What are the Advantages of Steel in Tool Case Manufacturing?

A stock image related to tool case description.

Steel is known for its exceptional strength and durability, making it a common choice for heavy-duty tool cases. It can handle extreme temperatures and pressures, withstanding conditions that would damage lighter materials.

Pros: Steel offers unparalleled protection against impacts, making it ideal for industrial applications. It is also resistant to fire and can be treated to prevent rust.

Cons: Steel cases are heavier and more expensive than their aluminum or plastic counterparts. They may also require additional coatings to prevent corrosion in humid environments.

Impact on Application: Steel tool cases are perfect for the oil and gas industry, where tools are often exposed to harsh conditions.

Considerations for International Buyers: Buyers from the Middle East should consider the impact of high humidity and temperature on steel products. Compliance with international standards for safety and quality is also essential.

How Does High-Density Polyethylene (HDPE) Compare?

HDPE is a robust plastic known for its high impact resistance and durability. It maintains its integrity in temperatures ranging from -40°C to 60°C (-40°F to 140°F).

Pros: HDPE is lightweight, resistant to chemicals, and offers excellent protection against moisture and UV rays. It is also recyclable, which can be a selling point for environmentally conscious buyers.

Cons: While HDPE is durable, it can be less rigid than aluminum or steel, potentially leading to deformation under heavy loads.

Impact on Application: HDPE is suitable for industries like renewable energy and telecommunications, where moisture resistance is critical.

Considerations for International Buyers: Buyers in South America should be aware of local recycling initiatives and the demand for eco-friendly materials. Understanding regional preferences for tool case materials can influence purchasing decisions.

Summary Table of Material Selection for Tool Cases

| Material | Typical Use Case for Tool Case Description | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Lightweight field service applications | Cost-effective and flexible | Brittle in low temperatures | Low |

| Aluminum | Aerospace and automotive industries | Durable and corrosion-resistant | Higher cost and prone to dents | Med |

| Steel | Oil and gas industry | Exceptional strength and impact resistance | Heavier and requires rust prevention | High |

| High-Density Polyethylene (HDPE) | Renewable energy and telecommunications | Lightweight and moisture-resistant | Less rigid under heavy loads | Med |

This comprehensive analysis of materials provides B2B buyers with actionable insights to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for tool case description

What Are the Main Stages of Tool Case Manufacturing?

The manufacturing process for tool cases typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help international B2B buyers assess the quality and durability of the tool cases they are considering for purchase.

Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing tool cases is selecting the right materials. Common materials include:

- High-Density Polyethylene (HDPE): Known for its durability and resistance to impact and moisture, making it ideal for rugged environments.

- Polypropylene (PP): Lightweight and resistant to chemical corrosion, suitable for portable tool cases.

- Aluminum: Offers a balance of strength and weight, often used in high-end or specialized cases.

- Steel: Provides exceptional strength and security, typically used in heavy-duty applications.

These materials undergo rigorous quality checks to ensure they meet the necessary specifications before moving to the next stage.

How Are Tool Cases Formed?

Once the materials are prepared, the next step is forming. This involves shaping the materials into the desired form using techniques such as:

- Injection Molding: Widely used for plastic cases, this process allows for complex shapes and high-volume production.

- Die-Casting: Commonly used for aluminum cases, providing high precision and strength.

- Sheet Metal Fabrication: Involves cutting and bending steel sheets to create robust tool cases.

Each technique has its advantages, and the choice depends on the intended use and required durability of the tool case.

What Is Involved in Assembly and Finishing Processes?

The assembly stage involves joining various components, such as handles, latches, and internal dividers. Techniques such as welding, riveting, and adhesive bonding are used to ensure a strong and durable structure.

Finishing processes include:

- Surface Treatments: Such as powder coating or anodizing for aluminum cases, which enhance corrosion resistance and aesthetic appeal.

- Quality Control Checks: Conducted throughout the assembly and finishing stages to ensure compliance with specifications.

These processes not only improve the functionality of the tool cases but also enhance their visual appeal, which is crucial for B2B buyers looking for quality products.

A stock image related to tool case description.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is essential in the manufacturing of tool cases, particularly for international B2B buyers who may require compliance with various standards. The following international standards are relevant:

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization, regardless of size or industry. Compliance indicates that the manufacturer consistently provides products that meet customer and regulatory requirements.

-

CE Marking: For products sold within the European Economic Area (EEA), CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For tool cases used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is critical.

What Are the Key Quality Control Checkpoints in Tool Case Manufacturing?

Quality control checkpoints play a crucial role in ensuring that the tool cases meet the required specifications. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the predefined standards.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this stage includes checks for dimensional accuracy and adherence to specifications.

-

Final Quality Control (FQC): This final inspection ensures that the finished product meets all quality standards and is free from defects before shipping.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are actionable steps:

-

Conduct Supplier Audits: Schedule on-site audits to assess the manufacturing processes, quality control systems, and compliance with international standards.

-

Request Quality Assurance Reports: Suppliers should provide documentation detailing their quality control processes, including test results and compliance certifications.

-

Third-Party Inspections: Engage independent inspection agencies to evaluate the supplier’s products before shipment. This adds an extra layer of assurance regarding product quality.

What Testing Methods Are Commonly Used in Tool Case Manufacturing?

Various testing methods are employed to ensure the durability and reliability of tool cases, including:

- Drop Tests: Assessing the case’s ability to withstand impacts during transportation.

- Water Resistance Tests: Ensuring that the tool cases remain watertight under specified conditions.

- Temperature and Humidity Tests: Evaluating the case’s performance under extreme environmental conditions.

These tests are crucial for B2B buyers who require robust products capable of withstanding harsh working conditions.

What Are the QC Nuances for International B2B Buyers?

International B2B buyers should be aware of the nuances in quality control that may vary by region. For instance:

-

Cultural Differences in Quality Expectations: Buyers from different regions may have varying expectations regarding quality standards and finishes. Understanding these differences can help in selecting the right supplier.

-

Regulatory Compliance: Ensure that the supplier adheres to local regulations concerning product safety and environmental impact, which can vary significantly between countries.

-

Documentation and Traceability: Verify that suppliers maintain thorough documentation of their quality control processes, allowing for traceability in case of defects or recalls.

By considering these aspects, B2B buyers can make informed decisions that lead to successful procurement of tool cases that meet their quality requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tool case description’

In the competitive landscape of B2B sourcing, selecting the right tool case is crucial for ensuring the protection and organization of your valuable tools. This guide provides a practical checklist to assist international buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed purchasing decisions. By following these steps, you can streamline your sourcing process and secure a tool case that meets your operational needs.

Step 1: Define Your Technical Specifications

Before you start searching for suppliers, it’s essential to clearly outline your requirements. Consider factors such as size, weight capacity, material durability, and environmental resistance (e.g., waterproofing). Identifying these specifications upfront helps narrow down your options and ensures that the selected case aligns with your operational demands.

- Size and Dimensions: Ensure the tool case can accommodate your tools and accessories comfortably.

- Material Strength: Look for cases made from high-quality materials like impact-resistant polymers or injection-molded constructions.

Step 2: Research Market Trends and Innovations

Stay updated on the latest trends in tool case technology and features. Innovations such as customizable inserts, modular connectivity, and enhanced security features can significantly impact your selection. Understanding current market offerings helps you compare products effectively.

- Modular Systems: Investigate whether a modular storage system can provide versatility in your tool organization.

- Weather Resistance: Consider IP ratings that indicate the level of dust and water resistance.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet suppliers to ensure reliability and quality. Request company profiles, case studies, and references from buyers within your industry or region. A supplier’s reputation can significantly impact your overall satisfaction with the product.

- Supplier History: Investigate how long the supplier has been in the market and their experience with international buyers.

- Client Testimonials: Seek feedback from previous clients regarding the product quality and after-sales support.

Step 4: Verify Certifications and Compliance

Ensure that the tool case complies with international safety and quality standards. Look for certifications such as ISO, CE, or local compliance that can assure you of the product’s reliability.

- Quality Assurance: Check if the product undergoes rigorous testing for durability and safety.

- Warranty Information: A robust warranty can provide peace of mind regarding product longevity.

Step 5: Assess Customization Options

Customization can enhance the functionality of your tool case. Determine if the supplier offers options such as customizable foam inserts or specific sizes tailored to your tools. This step is crucial for maximizing the protection and accessibility of your tools.

- Foam Inserts: Ensure that the case allows you to create custom pockets for your tools.

- Color and Branding: Consider whether you need the case to reflect your company’s branding.

Step 6: Compare Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing models and payment terms. Look for transparency in pricing, including any additional costs such as shipping and customs fees. Understanding the total cost upfront can prevent budget overruns.

- Bulk Discounts: Inquire about discounts for larger orders which can lead to significant savings.

- Payment Flexibility: Assess payment options that suit your financial strategy, especially for international transactions.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics of shipping and delivery. Assess shipping times, costs, and the supplier’s capability to handle international shipping. Ensuring a smooth delivery process is vital for maintaining your operational timeline.

- Shipping Partners: Confirm if the supplier collaborates with reliable logistics partners.

- Delivery Tracking: Ensure the supplier provides tracking capabilities for your shipment.

By following this step-by-step checklist, you can effectively navigate the complexities of sourcing tool cases, ensuring that you select a product that meets your specific needs while fostering a reliable supplier relationship.

Comprehensive Cost and Pricing Analysis for tool case description Sourcing

What Are the Key Cost Components for Tool Case Sourcing?

When sourcing tool cases, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. High-quality plastics, metals, and weather-resistant materials may increase initial costs but can lead to longer-lasting products, reducing the Total Cost of Ownership (TCO).

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with higher labor costs, such as Europe, might lead to increased pricing, whereas sourcing from countries in Africa or South America may offer cost advantages due to lower labor rates.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: The initial investment in molds and tools for manufacturing can be significant, especially for customized tool cases. However, this is often a one-time cost that can be amortized over large production runs.

-

Quality Control (QC): Ensuring that products meet quality standards incurs additional costs. Investing in robust QC processes can prevent costly returns and enhance customer satisfaction.

-

Logistics: Transportation and handling costs vary based on the shipping distance and method. Incoterms play a vital role in determining who bears these costs, which can affect the overall pricing.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary significantly based on market competition and the supplier’s positioning.

What Influences Pricing in Tool Case Sourcing?

Several factors can influence the pricing of tool cases:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically receive better pricing due to economies of scale. Buyers should consider negotiating MOQs that align with their needs without overcommitting.

-

Specifications and Customization: Custom features, such as specific sizes, colors, or inserts, can increase costs. Buyers should evaluate whether customization is essential for their operations or if standard options suffice.

-

Material Quality and Certifications: Tool cases made from premium materials or those with industry certifications (like IP ratings for weather resistance) may command higher prices. Buyers should weigh the benefits of these features against their budget.

-

Supplier Factors: Relationships with suppliers can influence pricing. Long-term partnerships may lead to better terms and pricing flexibility.

-

Incoterms: Understanding the implications of Incoterms is vital for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping costs and risks, which can significantly impact the final price.

What Tips Can Help B2B Buyers Negotiate Better Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips for negotiating better prices:

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term savings associated with higher-quality tool cases against their upfront costs. This perspective can strengthen your negotiating position.

-

Leverage Volume Discounts: If your business can consolidate orders or increase volume, use this leverage to negotiate better pricing.

-

Request Multiple Quotes: Don’t settle for the first price you receive. Collect quotes from multiple suppliers to establish a competitive baseline for negotiations.

-

Build Relationships: Establishing rapport with suppliers can lead to better terms. Suppliers are often more willing to negotiate with trusted clients.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations, tariffs, and import duties that could affect the final cost. Being informed about these factors can enhance negotiation strategies.

Disclaimer on Indicative Prices

Prices for tool cases can vary widely based on the factors mentioned above. It is essential for buyers to conduct thorough market research and supplier assessments to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing tool case description With Other Solutions

When considering the optimal solution for tool storage and transportation, international B2B buyers should explore various alternatives to the traditional tool case description. Each solution offers unique features, performance metrics, and cost implications that can significantly impact operational efficiency and budget considerations. This analysis will compare the standard tool case with alternative storage solutions such as modular storage systems and heavy-duty tool boxes.

| Comparison Aspect | Tool Case Description | PACKOUT™ Tool Case with Customizable Insert | DeWALT ToughSystem® 2.0 Toolbox |

|---|---|---|---|

| Performance | Highly durable, water-resistant, and secure | Impact-resistant, weather-sealed, modular | Sturdy construction, adaptable storage |

| Cost | Moderate price for lifetime warranty | Higher initial investment | Competitive pricing, various sizes |

| Ease of Implementation | Simple setup and use | Requires initial customization | Easy to integrate with existing systems |

| Maintenance | Minimal upkeep required | Occasional cleaning needed | Durable materials reduce maintenance needs |

| Best Use Case | Field service in extreme conditions | Versatile for multiple trades | Construction and industrial environments |

What Are the Advantages and Disadvantages of the PACKOUT™ Tool Case?

The PACKOUT™ Tool Case from Milwaukee Tool is designed for versatility and durability, featuring an impact-resistant body and IP65 rated weather seal. This makes it an excellent choice for those working in harsh job site environments. Its customizable foam insert allows users to tailor the storage to their specific tool needs, enhancing protection and organization. However, the initial investment may be higher compared to traditional tool cases, and it may require some time to set up the customizable features.

How Does the DeWALT ToughSystem® 2.0 Toolbox Compare?

The DeWALT ToughSystem® 2.0 Toolbox is known for its robust construction and adaptability. This toolbox can accommodate a variety of tools and accessories, making it suitable for construction and industrial applications. Its design promotes easy integration with other ToughSystem products, allowing for a comprehensive storage solution. On the downside, while its price point is competitive, it may not offer the same level of weather resistance as other options, which could be a concern for outdoor use.

Conclusion: How to Choose the Right Tool Storage Solution?

Selecting the right tool storage solution depends on your specific operational needs, budget, and the environments in which you work. If durability and customization are priorities, the PACKOUT™ Tool Case is a solid option, while the DeWALT ToughSystem® 2.0 is ideal for those seeking a robust, adaptable solution. The traditional tool case description remains a reliable choice for those who prioritize straightforward functionality and maintenance. Evaluate each option’s performance, cost, and ease of use to ensure the best fit for your business requirements.

Essential Technical Properties and Trade Terminology for tool case description

What Are the Key Technical Properties of Tool Cases?

When evaluating tool cases, several technical specifications are critical for international B2B buyers. Understanding these properties ensures that you select a product that meets your operational needs and withstands various environmental conditions.

1. Material Grade: What Is the Best Material for Durability?

Tool cases are typically constructed from materials such as high-density polyethylene (HDPE), polypropylene, or aluminum. HDPE and polypropylene are resistant to impact and corrosion, making them suitable for harsh environments. Aluminum offers a lightweight yet robust option, ideal for high-end applications. Choosing the right material grade directly impacts the longevity and performance of the tool case, making it crucial for businesses that rely on durable and reliable storage solutions.

2. IP Rating: How Do You Ensure Weather Resistance?

The Ingress Protection (IP) rating indicates how well a tool case can resist dust and moisture. For example, an IP65 rating means the case is dust-tight and can withstand water jets. This is especially important for industries operating in extreme weather conditions, such as construction or outdoor maintenance. Understanding IP ratings helps buyers select cases that will protect their tools and equipment from environmental hazards, thereby reducing replacement costs.

3. Weight Capacity: What Load Can the Tool Case Handle?

Weight capacity is a crucial specification that determines how much weight a tool case can carry without compromising its integrity. Most tool cases specify a maximum weight limit, which can range from 50 lbs to over 100 lbs. Knowing the weight capacity helps buyers avoid overloading their cases, which can lead to damage and increased risk of accidents on job sites.

4. Dimensions: How Important Are Internal and External Measurements?

Internal and external dimensions are vital for ensuring that the tool case will accommodate the tools and accessories intended for storage. Buyers should consider both the size of the tools and any additional padding or inserts that may be required. Accurate measurements prevent issues related to tool fitment and allow for better organization within the case.

5. Warranty: What Does a Warranty Indicate About Quality?

A warranty, such as a lifetime warranty, signals a manufacturer’s confidence in their product’s durability and performance. Warranties can vary widely, so understanding the terms is essential for buyers. A robust warranty can protect your investment and provide peace of mind, especially for businesses that rely on their tools for income generation.

What Trade Terminology Should You Know When Buying Tool Cases?

Familiarizing yourself with industry-specific terminology can enhance your purchasing decisions and ensure smoother transactions.

1. OEM (Original Equipment Manufacturer): What Does It Mean for Sourcing?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tool cases, purchasing from an OEM can ensure high-quality, custom solutions tailored to specific industry needs. This can be crucial for businesses seeking specialized tool storage options.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ can help buyers negotiate better terms and manage inventory effectively. For businesses in Africa and South America, where supply chains can be complex, knowing the MOQ can prevent overstocking or stockouts.

3. RFQ (Request for Quotation): How Do You Get the Best Price?

An RFQ is a document that a buyer sends to suppliers to request pricing for specific products. Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal for tool cases. This is particularly useful in competitive markets like Europe and the Middle East.

4. Incoterms: What Shipping Terms Should You Understand?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for B2B buyers to understand shipping costs and liabilities. This knowledge can significantly impact total landed costs for tool cases.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing tool cases, ensuring they select products that meet their specific operational needs and budget considerations.

Navigating Market Dynamics and Sourcing Trends in the tool case description Sector

What Are the Key Market Dynamics and Trends in the Tool Case Sector for International B2B Buyers?

The tool case market has seen significant growth driven by various global factors. Increasing demand for portable and durable storage solutions is primarily fueled by the booming construction, telecommunications, and renewable energy sectors. These industries require robust tool cases that can withstand extreme environments while ensuring tools are organized and easily accessible. In regions like Africa and South America, rapid urbanization and infrastructural development are propelling the need for high-quality tool cases. Meanwhile, in Europe and the Middle East, a focus on innovation and efficiency is leading companies to seek customizable and modular solutions.

Another emerging trend is the integration of smart technology into tool cases, such as RFID tracking and mobile app connectivity. This tech-forward approach appeals to B2B buyers looking for enhanced inventory management and security features. Additionally, sustainability is increasingly becoming a priority; buyers are now favoring manufacturers who prioritize eco-friendly materials and practices. As supply chains become more global, buyers must navigate complex logistics and regulatory frameworks, making it essential to partner with reliable suppliers who understand local market dynamics.

How Is Sustainability Influencing Sourcing Trends in the Tool Case Sector?

Sustainability has become a critical consideration in the tool case sector, influencing sourcing strategies for B2B buyers. As businesses worldwide become more environmentally conscious, they are increasingly looking for suppliers that demonstrate a commitment to ethical sourcing and sustainable practices. This includes using recycled materials, reducing waste in manufacturing processes, and ensuring fair labor practices throughout the supply chain.

Buyers should look for tool cases certified by recognized environmental standards, such as ISO 14001 or those that use sustainable materials like biodegradable plastics or recycled metals. Such certifications not only mitigate environmental impact but also enhance brand reputation and align with consumer expectations for corporate responsibility. Furthermore, adopting sustainable sourcing practices can lead to cost savings in the long term, as energy-efficient production methods and reduced waste can lower overall operational costs.

What Is the Historical Context of the Tool Case Industry for B2B Buyers?

The tool case industry has evolved significantly over the past few decades, transitioning from simple, metal boxes to highly specialized, durable, and customizable solutions. Initially, tool cases were primarily designed for basic protection and portability. However, as industries advanced, so did the need for more sophisticated storage solutions. The introduction of materials like high-impact polymers and advancements in design technology allowed manufacturers to create tool cases that are not only lighter but also offer better protection against environmental factors.

Today, the market is characterized by a diverse range of products that cater to various sectors, including construction, telecommunications, and biomedical industries. This evolution reflects a broader trend in B2B procurement, where buyers are increasingly prioritizing functionality, durability, and customization in their sourcing decisions. As the industry continues to innovate, staying informed about historical trends can provide valuable insights into future developments and opportunities within the tool case market.

Frequently Asked Questions (FAQs) for B2B Buyers of tool case description

-

How do I choose the right tool case for my needs?

Choosing the right tool case depends on several factors including the type of tools you need to store, the environment in which you’ll be working, and the level of protection required. Consider features such as waterproofing, impact resistance, and customization options for tool organization. For international buyers, it’s also essential to assess the dimensions and weight for shipping, as well as the availability of replacement parts or additional inserts to maximize the utility of your investment. -

What is the best tool case for transporting tools internationally?

The best tool case for international transport should offer durability and security. Look for cases with features like watertight seals, impact-resistant materials, and heavy-duty latches. Cases that can accommodate customizable inserts are also beneficial, as they ensure tools are securely stored and organized during transit. Additionally, check for compliance with international shipping regulations to avoid delays or damage during customs clearance. -

What customization options should I consider when sourcing tool cases?

Customization options can vary significantly between manufacturers. Look for suppliers that offer customizable foam inserts to protect specific tools, as well as branding options for corporate identity. Consider cases that allow for internal layout adjustments, which can enhance organization based on your specific tool requirements. Lastly, ensure that customization does not compromise the case’s structural integrity or waterproof features. -

What are the typical minimum order quantities (MOQs) for tool cases?

Minimum order quantities (MOQs) can vary greatly depending on the supplier and the type of tool case. For standard models, MOQs might range from 50 to 100 units, while customized options could require larger quantities. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing strategy, especially if you are looking to test a new product line before committing to larger orders. -

What payment terms are common when purchasing tool cases internationally?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, net 30/60/90 days, or letters of credit for larger orders. It’s crucial to clarify terms prior to finalizing your order, especially considering exchange rates and potential additional fees for international transactions. Always ensure that payment methods are secure and offer buyer protection. -

How do I vet suppliers for tool cases in international markets?

Vetting suppliers is critical to ensure quality and reliability. Start by checking their industry reputation through reviews and testimonials. Request samples to evaluate product quality firsthand. Additionally, consider suppliers who have certifications such as ISO 9001, which indicates a commitment to quality management. Engaging in direct communication to discuss their manufacturing processes and logistics capabilities can also provide valuable insights into their reliability. -

What quality assurance measures should I look for in tool cases?

Quality assurance measures can include third-party testing for durability, waterproofing, and impact resistance. Inquire if the manufacturer conducts regular quality checks and if they offer warranties or guarantees on their products. A robust return policy is also a good indicator of a supplier’s confidence in their products. Ensure that any quality certifications are documented and accessible for review. -

What logistics considerations should I keep in mind when importing tool cases?

When importing tool cases, consider shipping options that align with your budget and timeline. Air freight is faster but more expensive, while sea freight is more economical for larger orders. Ensure that your supplier can provide all necessary shipping documents, including customs declarations and certificates of origin. Additionally, research local import regulations in your country to avoid unexpected tariffs or delays during customs clearance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tool case description

What Are the Key Takeaways for International B2B Buyers on Tool Cases?

In today’s competitive landscape, the strategic sourcing of tool cases is vital for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Investing in durable, customizable, and weather-resistant tool cases not only protects your valuable equipment but also enhances efficiency and productivity on the job. Features such as impact resistance, watertight designs, and modular connectivity systems are essential for meeting the diverse needs of various industries—from renewable energy to telecommunications.

How Can Strategic Sourcing Enhance Your Tool Case Procurement?

Strategic sourcing allows buyers to identify suppliers that align with their operational needs and budget constraints. By leveraging comprehensive market research and supplier evaluations, businesses can secure tool cases that offer optimal value and performance. This is particularly important for companies operating in harsh environments, where the quality of tool storage can significantly impact project outcomes.

What’s Next for B2B Buyers in Tool Case Acquisition?

As you consider your next procurement cycle, prioritize suppliers who demonstrate a commitment to quality, warranty offerings, and customer support. With the right tool case, your teams can operate more effectively, regardless of location or conditions. Take proactive steps today to enhance your tool storage solutions and drive your operational success into the future. Engage with reputable manufacturers and distributors to explore the latest innovations in tool case design, ensuring that you remain competitive and well-equipped for any challenge.