Discover Membrane Button Benefits: A Complete Buying Guide (2025)

Introduction: Navigating the Global Market for membrane button

In today’s competitive landscape, sourcing high-quality membrane buttons can be a daunting challenge for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. These versatile components serve as the interface between users and electronic devices, providing essential functionality across numerous industries, from medical to consumer electronics. This comprehensive guide aims to demystify the complexities of membrane buttons, offering insights into their various types, applications, and design considerations.

As buyers navigate the global market, understanding the distinctions between tactile and non-tactile switches, and the importance of durability and environmental resistance, is crucial. This guide covers critical aspects such as supplier vetting processes, cost factors, and trends impacting membrane switch technology. By providing a thorough overview, it empowers B2B buyers to make informed purchasing decisions, ensuring they select the right membrane buttons that meet their specific operational needs.

Whether you’re looking to enhance user experience in medical devices or streamline controls in industrial applications, this guide is designed to equip you with the knowledge necessary to effectively assess options and engage with suppliers. Embrace the opportunity to optimize your sourcing strategy and drive innovation in your product offerings with the insights provided in this essential resource.

Understanding membrane button Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactile Membrane Switch | Provides tactile feedback with a “click” or “snap” | Medical devices, consumer electronics, industrial controls | Pros: Enhanced user experience; Cons: Slightly less durable than non-tactile options. |

| Non-Tactile Membrane Switch | No tactile feedback; relies on visual/auditory cues | Laboratory instruments, consumer electronics, HVAC systems | Pros: Highly durable; Cons: Lack of physical feedback may confuse users. |

| Backlit Membrane Switch | Illuminated buttons for visibility in low-light conditions | Medical devices, control panels, consumer products | Pros: Improved usability in dim environments; Cons: More complex and potentially costly. |

| Capacitive Touch Switch | Activated by touch; no pressure needed | Smartphones, tablets, high-end consumer electronics | Pros: Sleek design, highly durable; Cons: Cannot be activated with non-conductive objects. |

| Metal Dome Array Switch | Uses metal domes for tactile feedback; long lifespan | Industrial equipment, medical devices, consumer electronics | Pros: Robust and reliable; Cons: May require additional space for installation. |

What Are the Characteristics of Tactile Membrane Switches?

Tactile membrane switches offer a physical response when pressed, typically producing a “click” sound or a noticeable snap. This feature is essential in applications such as medical devices, where user feedback is critical for accessibility. Buyers should consider the required activation force and cycle durability, as these factors will influence user satisfaction and device longevity.

How Do Non-Tactile Membrane Switches Work?

Non-tactile membrane switches lack physical feedback but compensate with visual or auditory signals. They are ideal for environments where durability is paramount, such as laboratory instruments or HVAC systems. When purchasing, businesses should evaluate the expected usage frequency, as these switches often have a higher activation lifespan compared to tactile options.

What Benefits Do Backlit Membrane Switches Provide?

Backlit membrane switches enhance visibility in low-light conditions, making them invaluable in medical devices and control panels. The incorporation of LED technology allows for creative branding and user interface design. Buyers must assess the complexity and cost associated with backlighting, balancing these with the enhanced user experience in their specific applications.

Why Choose Capacitive Touch Switches?

Capacitive touch switches are activated by the natural conductivity of the human finger, eliminating the need for mechanical pressure. This design is particularly suited for sleek, modern devices like smartphones and tablets. When considering capacitive switches, buyers should take into account the need for conductive activation, as these switches may not function with gloves or styluses.

What Makes Metal Dome Array Switches a Reliable Choice?

Metal dome array switches provide tactile feedback through durable metal domes, making them suitable for high-use environments such as industrial equipment and medical devices. Their robustness ensures long life cycles, often exceeding a million activations. Buyers should consider the installation space required, as these switches may necessitate a larger footprint compared to other types.

Key Industrial Applications of membrane button

| Industry/Sector | Specific Application of Membrane Button | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Electronics | User interface for diagnostic equipment | Enhances user experience and accuracy in diagnostics | Compliance with medical standards, durability, and ease of cleaning |

| HVAC Systems | Control panels for temperature regulation | Streamlined operations and improved energy efficiency | Resistance to environmental factors, tactile feedback options |

| Consumer Electronics | Keypads for smart home devices | Cost-effective, space-saving interface solutions | Customization options for branding, integration with existing tech |

| Industrial Machinery | Control interfaces in manufacturing equipment | Increased reliability and reduced maintenance costs | Robustness against dust and contaminants, IP ratings for protection |

| Agricultural Equipment | Operator controls in tractors and farm machinery | Improved ergonomics and user-friendly operation | Resistance to harsh outdoor conditions, customizable layouts |

How is Membrane Button Technology Used in Medical Electronics?

In the medical field, membrane buttons serve as critical user interfaces for diagnostic equipment such as ultrasound machines and patient monitoring systems. These interfaces are designed to be intuitive, allowing healthcare professionals to operate complex machinery with ease. The membrane buttons help prevent contamination, which is essential in medical environments. Buyers should prioritize suppliers who comply with strict medical device regulations, ensuring that the switches are durable and easy to clean, as these factors are crucial for maintaining hygiene and functionality.

What Role Do Membrane Buttons Play in HVAC Systems?

In HVAC systems, membrane buttons are integral to control panels that regulate temperature and airflow. They provide a low-profile, user-friendly interface that can withstand the rigors of continuous use in various environments. The tactile feedback from these buttons enhances user interaction, ensuring precise adjustments. For international buyers, especially in regions with extreme climates, sourcing membrane buttons that are resistant to humidity and temperature fluctuations is vital to maintaining operational efficiency and longevity.

How Are Membrane Buttons Utilized in Consumer Electronics?

Membrane buttons are extensively used in smart home devices, such as thermostats and home automation systems. Their sleek design allows for versatile placement without taking up excessive space, making them ideal for modern consumer electronics. Additionally, they can be customized with branding and graphics, enhancing the product’s marketability. When sourcing these components, buyers should consider the ease of integration with existing technologies and the potential for customization to meet specific consumer demands.

What Is the Importance of Membrane Buttons in Industrial Machinery?

In industrial settings, membrane buttons act as control interfaces for machinery, providing a reliable means of operation. Their design minimizes the risk of malfunction due to dust or debris, which is critical for maintaining productivity. By opting for membrane buttons, businesses can achieve significant cost savings through reduced maintenance and increased equipment longevity. Buyers in this sector should focus on sourcing switches with high IP ratings to ensure they can withstand the harsh conditions often found in manufacturing environments.

How Do Membrane Buttons Enhance Agricultural Equipment?

In agricultural machinery, membrane buttons are used for operator controls in tractors and other equipment. They are designed for ease of use, allowing operators to make quick adjustments while working in challenging outdoor conditions. The ergonomic design reduces operator fatigue and enhances efficiency. Buyers from regions like Africa and South America should seek membrane buttons that can endure exposure to dust, moisture, and varying temperatures, ensuring reliability and performance in the field.

3 Common User Pain Points for ‘membrane button’ & Their Solutions

Scenario 1: Durability Issues in Harsh Environments

The Problem: B2B buyers in industries such as agriculture or medical equipment often face challenges with membrane buttons failing in harsh environments. Factors like moisture, dust, and extreme temperatures can lead to malfunctions. This not only causes delays in production but also raises safety concerns, especially in medical devices where reliable functionality is crucial. The cost of frequent replacements and repairs can also significantly impact operational budgets.

The Solution: To combat durability issues, buyers should consider membrane switches with enhanced sealing options, such as sealed gaskets or IP-rated designs that provide protection against contaminants. When sourcing membrane buttons, it’s essential to communicate the specific environmental conditions they will face. Look for manufacturers that offer custom solutions tailored to these needs, such as backlit options that remain functional in low-light conditions. Additionally, ensure that the chosen membrane buttons undergo rigorous testing for durability against factors like water spray, immersion, and chemical exposure. Regular maintenance and cleaning protocols can also extend the lifespan of these components.

Scenario 2: User Interface Confusion

The Problem: In sectors like consumer electronics and industrial controls, poorly designed user interfaces can lead to confusion and operational errors. Membrane buttons that lack clear labeling or intuitive layouts can frustrate users, resulting in decreased efficiency and increased training costs. This challenge is particularly evident in multinational companies where users come from diverse backgrounds and may have varying levels of familiarity with the technology.

The Solution: To enhance user experience, invest in membrane buttons with high-quality graphic overlays that include clear, multilingual labeling and intuitive iconography. Collaborate with design experts who specialize in user interface (UI) and user experience (UX) to ensure that the button layout aligns with user expectations. Additionally, consider tactile feedback options that provide users with a physical response upon activation, reducing the likelihood of errors. Conduct usability testing with actual end-users to gather insights that can inform further refinements in the design. This proactive approach not only improves user satisfaction but also minimizes the risk of operational errors.

Scenario 3: Cost vs. Quality Dilemma

The Problem: B2B buyers often grapple with the trade-off between cost and quality when selecting membrane buttons. While cheaper options may seem appealing, they can lead to higher long-term costs due to failures or replacements. This is a critical issue for businesses looking to maintain profit margins while ensuring product reliability, especially in competitive markets like automotive or consumer goods.

The Solution: To navigate the cost versus quality dilemma, buyers should focus on total cost of ownership (TCO) rather than just upfront pricing. Engage with suppliers who provide transparent information about the lifecycle of their membrane buttons, including expected durability and warranty terms. Look for manufacturers that offer customization options, allowing for the selection of materials and features that meet specific performance requirements without unnecessary expenses. Additionally, consider forming strategic partnerships with reputable suppliers who can provide insights into the best practices for integrating membrane buttons into your products, ensuring that quality is not compromised for the sake of cost. This approach fosters long-term relationships that can lead to better pricing and support in the future.

Strategic Material Selection Guide for membrane button

What Are the Common Materials Used for Membrane Buttons?

When selecting materials for membrane buttons, it’s crucial to consider their properties, advantages, and limitations. Below is an analysis of four common materials used in the manufacturing of membrane buttons, tailored for international B2B buyers.

1. Polyester (PET)

Key Properties: Polyester (PET) is known for its excellent chemical resistance and durability. It can withstand temperatures ranging from -40°C to 125°C, making it suitable for various environments. Its tensile strength is high, which contributes to its longevity.

Pros & Cons: The primary advantage of polyester is its cost-effectiveness and ability to print high-resolution graphics. However, it may not perform well in extreme temperatures and can become brittle over time if exposed to UV light. Additionally, while it is durable, it may not be suitable for applications requiring high tactile feedback.

Impact on Application: Polyester is often used in consumer electronics and medical devices. Its compatibility with a wide range of chemicals makes it ideal for environments where spills are a concern.

Considerations for International Buyers: Buyers from regions like Africa or South America should ensure compliance with local standards, such as ASTM or ISO certifications. In Europe, the RoHS directive may also apply, limiting certain hazardous substances in electronic products.

2. Polycarbonate (PC)

Key Properties: Polycarbonate is highly resistant to impact and has a temperature rating of -40°C to 120°C. It also offers excellent optical clarity, making it suitable for applications where visibility is essential.

Pros & Cons: The main advantage of polycarbonate is its robustness and resistance to breakage, which is ideal for rugged applications. However, it is generally more expensive than polyester and can be prone to scratching unless treated with a hard coat.

Impact on Application: Polycarbonate is commonly used in industrial controls and high-end consumer electronics. Its resistance to extreme conditions makes it suitable for outdoor applications.

Considerations for International Buyers: Compliance with safety standards is crucial, especially in the medical and aerospace sectors. Buyers should verify that polycarbonate materials meet relevant certifications in their respective markets.

3. Silicone

Key Properties: Silicone offers exceptional flexibility and temperature resistance, functioning effectively between -60°C and 200°C. It is also highly resistant to UV light and ozone, making it suitable for outdoor use.

Pros & Cons: The flexibility of silicone allows for excellent tactile feedback, making it a preferred choice for tactile membrane switches. However, it tends to be more expensive and may require specialized manufacturing techniques, increasing production complexity.

Impact on Application: Silicone is often used in applications requiring high durability and tactile response, such as medical devices and automotive controls.

Considerations for International Buyers: Buyers should consider the higher costs associated with silicone and ensure that their suppliers can meet the necessary quality standards. Additionally, understanding local regulations regarding silicone materials is essential, particularly in the EU.

4. Metal Dome Arrays

Key Properties: Metal dome arrays are made from stainless steel or other metals, providing excellent durability and a tactile response. They can withstand high cycles of use, often exceeding one million actuations.

Pros & Cons: The primary advantage of metal dome arrays is their longevity and reliability in providing tactile feedback. However, they can be more expensive than other materials and may require more complex assembly processes.

Impact on Application: These are commonly used in high-performance applications, including medical devices and industrial controls, where tactile feedback is critical.

Considerations for International Buyers: Buyers must ensure that metal dome arrays comply with relevant industry standards, especially in sectors like medical and aerospace. Additionally, understanding the supply chain for metal components is crucial in regions with varying availability.

Summary Table of Material Selection

| Material | Typical Use Case for Membrane Button | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester (PET) | Consumer electronics, medical devices | Cost-effective, high-resolution graphics | Limited UV resistance, brittleness | Low |

| Polycarbonate (PC) | Industrial controls, outdoor devices | High impact resistance, clarity | Higher cost, prone to scratching | Med |

| Silicone | Medical devices, automotive controls | Excellent tactile feedback, durability | Higher cost, complex manufacturing | High |

| Metal Dome Arrays | Medical devices, industrial controls | Longevity, reliable tactile response | Higher cost, complex assembly | Med |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for membrane button

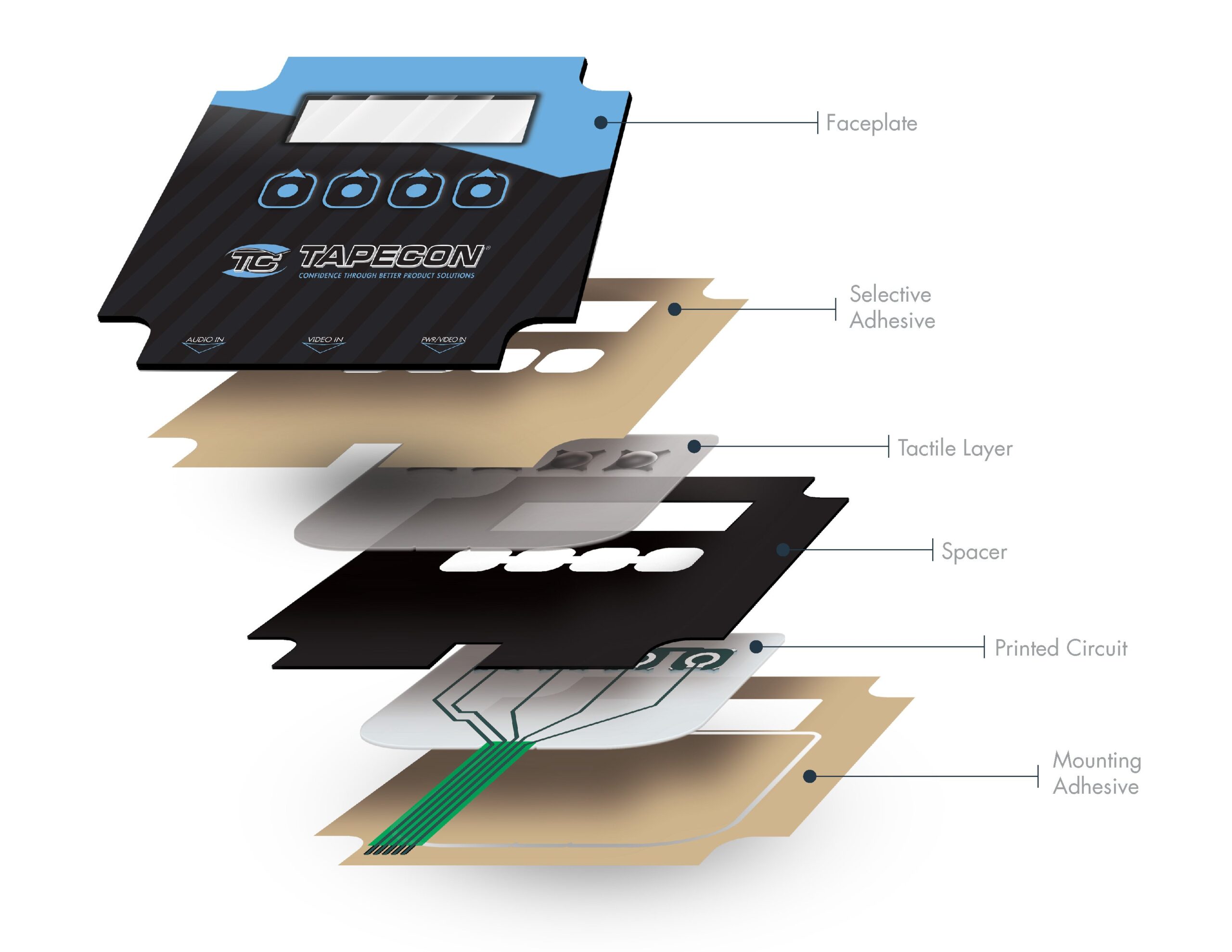

What Are the Key Stages in the Manufacturing Process of Membrane Buttons?

The manufacturing process for membrane buttons involves several critical stages, each designed to ensure the final product meets both functional and aesthetic requirements. Here’s a breakdown of the main stages:

A stock image related to membrane button.

Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing membrane buttons is the selection and preparation of materials. Typically, manufacturers use flexible materials such as polyester or polycarbonate for the graphic overlay. These materials are chosen for their durability and ability to withstand environmental factors, including moisture and abrasion.

Adhesives play a crucial role as well, bonding different layers together. Conductive inks or foils are also used to create the necessary circuits within the button. Quality control begins at this stage, as the choice of materials directly impacts the performance and longevity of the membrane button.

How Are Membrane Buttons Formed?

Once the materials are prepared, the next stage is forming. This involves processes such as printing graphics onto the overlays and applying conductive materials. Techniques like screen printing or digital printing are commonly used, ensuring that the designs are clear and durable. For tactile buttons, metal dome arrays may be incorporated, which provide the necessary tactile feedback when pressed.

After printing, layers are cut to precise dimensions using laser cutting or die-cutting techniques, ensuring uniformity and accuracy across all products. This stage is crucial for maintaining consistency, especially for B2B buyers who require large volumes of products.

What Does the Assembly Process Involve?

The assembly stage is where various components are brought together. Typically, this includes layering the graphic overlay, adhesive, circuit layers, and any additional elements like rigid support layers. Automated assembly lines are often employed for efficiency, although manual assembly may be utilized for more complex designs.

During this stage, manufacturers ensure proper alignment of all layers to avoid any functional discrepancies. Quality checks are often integrated into the assembly process, allowing for the immediate identification of defects.

What Finishing Techniques Are Applied?

A stock image related to membrane button.

The final stage in the manufacturing process is finishing, which involves applying protective coatings or lamination to enhance durability and aesthetics. This step may also include testing for functionality, ensuring that all circuits are operational and that the button responds correctly to user input.

Finishing processes can include UV coating or anti-glare treatments, which improve the product’s usability in various environments. A thorough inspection is conducted at this stage to confirm that the membrane buttons meet the required specifications.

What International Quality Standards Should B2B Buyers Be Aware Of?

Quality assurance is paramount in the manufacturing of membrane buttons, especially for international B2B transactions. Compliance with international standards ensures that products are safe, reliable, and of high quality. Here are some key standards and certifications to consider:

A stock image related to membrane button.

How Does ISO 9001 Certification Impact Quality Control?

ISO 9001 is a widely recognized quality management standard that focuses on meeting customer expectations and delivering customer satisfaction. Manufacturers that are ISO 9001 certified must adhere to strict quality management principles, which include a strong customer focus, the involvement of top management, and a process approach to quality assurance.

For B2B buyers, partnering with ISO-certified manufacturers can provide assurance that the production processes are robust and that products will consistently meet quality standards.

What Industry-Specific Certifications Should Be Considered?

Depending on the application of the membrane buttons, other certifications may be relevant. For instance, CE marking is crucial for products sold within the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

In the medical field, certifications from organizations like the FDA or specific ISO standards related to medical devices (ISO 13485) may be required. B2B buyers in industries such as aerospace or automotive may also look for certifications like AS9100 or IATF 16949, respectively.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process for membrane buttons. Key checkpoints include:

What Are Incoming Quality Control (IQC) Procedures?

Incoming Quality Control (IQC) involves inspecting raw materials and components before they enter the production process. This stage ensures that only materials that meet specified standards are used, reducing the likelihood of defects.

How is In-Process Quality Control (IPQC) Conducted?

In-Process Quality Control (IPQC) is conducted during the manufacturing stages. This includes monitoring critical parameters such as adhesive curing times and alignment during assembly. Regular checks help identify any potential issues early, allowing for immediate corrective actions.

What Role Does Final Quality Control (FQC) Play?

Final Quality Control (FQC) occurs after the finishing stage and involves a comprehensive inspection of the finished membrane buttons. This can include functionality tests, visual inspections for defects, and verification against customer specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some effective methods:

What Should Be Included in Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control processes. Buyers should look for evidence of ISO certifications, review quality management systems, and evaluate the supplier’s ability to meet delivery timelines and product specifications.

How Can Buyers Utilize Quality Reports?

Requesting detailed quality reports can provide insights into the supplier’s QC performance. These reports should include data on defect rates, results from testing procedures, and any corrective actions taken in response to quality issues.

What is the Role of Third-Party Inspections?

Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can conduct audits and inspections at various stages of the manufacturing process, providing unbiased assessments of quality control measures.

What Are the Unique Quality Control Nuances for International B2B Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific quality control nuances that may affect their procurement strategies:

- Cultural Differences: Understanding local business practices and cultural expectations is essential when assessing suppliers.

- Regulatory Compliance: Different regions may have varying regulatory requirements, and it’s crucial to ensure that the supplier complies with both local and international standards.

- Logistics and Supply Chain Considerations: Buyers should evaluate the supplier’s logistics capabilities to ensure timely delivery of quality products.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing membrane buttons, ensuring they partner with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘membrane button’

When sourcing membrane buttons for your business, having a structured approach is essential to ensure you select the right product that meets your needs. This guide provides a step-by-step checklist for international B2B buyers, focusing on key considerations that will facilitate an effective procurement process.

Step 1: Define Your Technical Specifications

Before you start looking for suppliers, clearly outline the technical requirements of your membrane buttons. Consider factors such as size, shape, tactile feedback (tactile vs. non-tactile), and environmental conditions (e.g., exposure to moisture or dust). This step is crucial as it sets the foundation for your search and helps you communicate effectively with potential suppliers.

Step 2: Research Industry Applications

Understand the specific applications of membrane buttons in your industry. Membrane switches are used across various sectors including medical, industrial controls, and consumer electronics. Knowing the common applications can help you identify the right type of membrane switch that aligns with your product’s requirements, ensuring optimal functionality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Look for suppliers with a strong reputation in the industry, and request company profiles, case studies, and references from existing clients. Ensure that they have experience in your specific sector to mitigate risks and ensure quality.

- Check for Certifications: Verify if the supplier holds relevant certifications such as ISO or CE, which can indicate adherence to quality and safety standards.

Step 4: Request Prototypes for Testing

Once you have shortlisted potential suppliers, request prototypes of their membrane buttons. Testing prototypes allows you to assess the quality, durability, and performance under real-world conditions. This step is vital as it helps you identify any potential issues before committing to a larger order.

Step 5: Negotiate Pricing and Terms

Discuss pricing structures and payment terms with your chosen suppliers. Be transparent about your budget and expected order volume, as many suppliers offer discounts for bulk purchases. Understanding the total cost of ownership, including shipping and potential duties, is essential for accurate budgeting.

Step 6: Assess After-Sales Support and Warranty

Inquire about after-sales support and warranty policies. A reliable supplier should offer ongoing support, including installation guidance and troubleshooting assistance. A solid warranty can protect your investment and provide peace of mind, especially if the membrane buttons are critical to your operations.

Step 7: Finalize Order and Monitor Production

Once you’ve selected a supplier, finalize your order with clear documentation outlining all specifications and expectations. Maintain regular communication throughout the production process to ensure timelines are met and any issues are promptly addressed. This proactive approach can help ensure that your membrane buttons meet your quality standards upon delivery.

By following these steps, you can streamline your sourcing process for membrane buttons, ensuring that you make informed decisions that align with your business objectives and operational requirements.

Comprehensive Cost and Pricing Analysis for membrane button Sourcing

What Are the Key Cost Components in Membrane Button Sourcing?

When sourcing membrane buttons, understanding the underlying cost structure is crucial for B2B buyers. The primary components influencing the total cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials—such as polyester, polycarbonate, conductive inks, and adhesives—can significantly impact costs. Higher-quality materials may lead to a higher price but often provide better durability and performance.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Regions with lower labor costs may offer more competitive pricing, but it’s important to balance this with the quality of workmanship.

-

Manufacturing Overhead: This includes expenses related to equipment, utilities, and facility maintenance. Understanding the manufacturer’s overhead can help buyers gauge the pricing strategy and ensure they are not overpaying.

-

Tooling: Custom tooling can be a significant upfront cost. Buyers should inquire about tooling costs, especially if they require unique designs or specifications.

-

Quality Control (QC): Implementing a robust QC process ensures product reliability and compliance with industry standards. This may add to the overall cost but is essential for high-stakes applications, particularly in sectors like medical or aerospace.

-

Logistics: Shipping costs can vary widely based on the supplier’s location, the shipping method, and the destination. International buyers must also consider customs duties and taxes.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the standard margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect Membrane Button Sourcing?

Several factors can influence the pricing of membrane buttons, making it vital for buyers to be aware of these elements:

-

Volume/MOQ: Minimum Order Quantity (MOQ) significantly impacts pricing. Larger orders often yield better pricing per unit due to economies of scale. Buyers should assess their needs and negotiate MOQs that align with their production requirements.

-

Specifications and Customization: The more customized the membrane switch, the higher the cost. Buyers should define their specifications clearly to avoid unnecessary expenses.

-

Materials: As mentioned, the choice of materials affects pricing. Buyers should consider the long-term benefits of investing in high-quality materials versus cheaper alternatives.

-

Quality and Certifications: Products that meet specific industry certifications (e.g., ISO, UL) may cost more. However, these certifications can enhance product reliability and market acceptance, offering long-term cost benefits.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence price. Established suppliers may charge a premium but often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is critical for international buyers. These terms define the responsibilities of buyers and sellers in shipping, which can affect the overall cost. For instance, choosing FOB (Free On Board) terms might shift some shipping costs to the buyer, impacting the total cost of ownership.

What Are Some Tips for Negotiating Costs Effectively?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings:

-

Total Cost of Ownership (TCO): Consider not just the upfront costs but the entire lifecycle costs associated with the product. This includes maintenance, potential downtimes, and replacement costs.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Suppliers may be more willing to negotiate with partners they trust.

-

Request Detailed Quotes: Ask for itemized quotes that break down costs. This transparency helps identify areas where you can negotiate or find cost efficiencies.

-

Leverage Market Research: Understanding market trends and average pricing can empower buyers during negotiations. Use this knowledge to argue for fair pricing.

-

Be Flexible with Specifications: If possible, consider being flexible with your specifications or materials. This may allow for cost savings without compromising essential functions.

Conclusion

When sourcing membrane buttons, a comprehensive understanding of cost structures, pricing influencers, and effective negotiation strategies can empower B2B buyers to make informed decisions. While prices can vary widely, being proactive in these areas can lead to better procurement outcomes. Always remember that indicative prices may fluctuate based on market conditions, so continuous market monitoring is essential for optimal sourcing.

Alternatives Analysis: Comparing membrane button With Other Solutions

When evaluating user interface solutions for electronic devices, it is essential for international B2B buyers to consider various options. Membrane buttons are popular due to their versatility and low profile, but alternatives like mechanical switches and capacitive touch technology may also suit specific applications. This analysis will compare membrane buttons with mechanical switches and capacitive touch interfaces, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Membrane Buttons and Alternatives

| Comparison Aspect | Membrane Button | Mechanical Switch | Capacitive Touch Interface |

|---|---|---|---|

| Performance | Reliable in various environments | High durability and tactile feedback | Sensitive to touch, not pressure-based |

| Cost | Generally low-cost | Moderate to high-cost | Higher initial investment |

| Ease of Implementation | Simple integration with designs | Requires more space and wiring | Requires sophisticated electronics |

| Maintenance | Low maintenance; sealed options available | Regular maintenance needed | Minimal maintenance, but sensitive |

| Best Use Case | Ideal for compact devices, medical equipment | Heavy machinery, consumer electronics | Smart devices, modern control panels |

What Are the Advantages and Disadvantages of Mechanical Switches?

Mechanical switches are traditional alternatives that provide a tactile response, making them suitable for applications where user feedback is essential. They are typically more durable than membrane buttons, especially in high-usage environments, and can withstand harsh conditions. However, their bulkiness requires more space, which may not be suitable for compact devices. Additionally, the cost can be higher due to the materials used and the need for more complex wiring.

How Does Capacitive Touch Technology Compare to Membrane Buttons?

Capacitive touch interfaces utilize the electrical properties of the human body to detect touch, allowing for a sleek design that does not require physical pressure. This technology offers a modern aesthetic and can support multi-touch functionality, which is increasingly desired in consumer electronics and smart devices. However, the initial investment is often higher than membrane buttons, as it requires advanced circuitry and programming. Furthermore, capacitive interfaces may struggle in environments where users wear gloves or use styluses.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate user interface solution, B2B buyers must assess their specific needs, including environmental conditions, user interaction requirements, and budget constraints. Membrane buttons are excellent for compact designs and low-cost applications, while mechanical switches are preferable for durability and tactile feedback. Capacitive touch technology is ideal for modern devices requiring a sleek interface but comes with a higher cost. Ultimately, understanding the unique demands of the application will guide buyers in making an informed decision that aligns with their operational requirements.

Essential Technical Properties and Trade Terminology for membrane button

What Are the Essential Technical Properties of Membrane Buttons?

When considering membrane buttons for your B2B applications, understanding their technical properties is crucial. Here are some key specifications that directly impact functionality, durability, and suitability for various environments:

1. Material Grade

Membrane buttons are typically made from materials like polyester or polycarbonate. The material grade affects the button’s durability, flexibility, and resistance to chemicals and UV light. Higher-grade materials are essential for applications in harsh environments, such as medical devices or outdoor machinery, ensuring longevity and reliability.

2. Tolerance Levels

Tolerance in membrane switches refers to the allowable deviation from specified dimensions. It is critical to ensure that the buttons fit correctly within the intended device, preventing operational issues. Tight tolerances are essential for applications requiring precision, such as in medical or aerospace industries, where any misalignment can lead to failure.

3. Operating Temperature Range

The operating temperature range indicates the temperatures within which the membrane switch can function effectively. This is particularly important for international buyers, as products may be used in varied climates, from the heat of Africa to the colder regions of Europe. Selecting membrane buttons with an appropriate temperature range ensures consistent performance.

4. IP Rating (Ingress Protection)

The IP rating indicates the level of protection against dust and water ingress. For industries like food service or medical equipment, a higher IP rating (e.g., IP67) is vital to ensure that the membrane switch can withstand exposure to contaminants and moisture, thus maintaining functionality and hygiene.

5. Actuation Force

Actuation force is the amount of pressure required to activate the switch. This specification is important for usability, especially for applications where users may have physical limitations. Customizing the actuation force can enhance user experience, making products more accessible.

6. Lifecycle and Durability

Lifecycle refers to the number of actuations a membrane switch can endure before failure. Membrane buttons designed for high-usage environments must have a lifecycle of over a million presses, making them suitable for consumer electronics, industrial machinery, and medical devices. Understanding lifecycle specifications helps buyers select appropriate products based on expected usage.

What Are Common Trade Terms Related to Membrane Buttons?

Navigating the purchasing landscape for membrane buttons involves familiarizing yourself with specific trade terminology. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that may be marketed by another company. In the context of membrane switches, it is crucial for buyers to understand the OEM’s role to ensure compatibility and quality in the products being integrated into their devices.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, particularly small businesses, as it affects inventory costs and cash flow. Some manufacturers may offer flexibility on MOQ, which can be advantageous for international buyers looking to test products before committing to larger orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For B2B buyers, submitting an RFQ can streamline the purchasing process and ensure that they receive competitive pricing and terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for international buyers from Africa, South America, the Middle East, and Europe to understand their obligations regarding shipping, insurance, and delivery.

5. Customization Options

Customization refers to the ability to tailor membrane switches to specific requirements, such as size, design, and functionality. Understanding customization options is essential for B2B buyers to ensure that the membrane buttons meet their specific application needs, enhancing usability and brand identity.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing membrane buttons for their diverse applications.

Navigating Market Dynamics and Sourcing Trends in the membrane button Sector

What Are the Current Market Dynamics and Key Trends in the Membrane Button Sector?

The membrane button sector is witnessing significant transformations influenced by global drivers such as technological advancements, increasing demand for compact and user-friendly interfaces, and the growing trend towards automation across various industries. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are particularly focused on sourcing membrane switches that are not only cost-effective but also versatile in their applications. The rise of smart devices has accelerated the adoption of membrane switches in consumer electronics and medical devices, making them essential components in modern technology.

Emerging trends include the integration of capacitive touch technologies, which offer enhanced durability and a sleeker design, appealing to manufacturers looking for modern user interfaces. Additionally, the shift towards customization is notable, as buyers increasingly seek tailored solutions that meet specific functional and aesthetic requirements. Sustainability is becoming a key factor in purchasing decisions, with an emphasis on sourcing from manufacturers that prioritize eco-friendly materials and processes. Buyers from Europe, in particular, are driving this trend as regulations around environmental standards tighten.

How Can Sustainability and Ethical Sourcing Impact Your Membrane Button Purchases?

Sustainability and ethical sourcing are pivotal considerations for B2B buyers in the membrane button sector. The environmental impact of manufacturing processes, including waste generation and energy consumption, is under scrutiny. Buyers are encouraged to seek suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing emissions in their production processes.

Moreover, the importance of ethical supply chains cannot be overstated. Suppliers should be able to provide transparency regarding their sourcing practices and labor conditions. Certifications like ISO 14001 for environmental management and certifications for materials like RoHS compliance (Restriction of Hazardous Substances) are indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with ‘green’ certifications, businesses can not only enhance their brand reputation but also align with the increasing consumer demand for responsible products.

What is the Evolution of the Membrane Button Technology?

The evolution of membrane button technology has been marked by significant advancements since its inception. Initially used in basic applications, membrane switches have evolved to become integral components in sophisticated electronics, providing a reliable interface for users across various industries. The early designs were predominantly mechanical, but the shift towards electronic and digital solutions has allowed for greater design flexibility and functionality.

In the past decade, advancements in materials and manufacturing processes have led to the development of tactile and non-tactile switches, capacitive touch technology, and backlit options, enhancing usability and aesthetics. This evolution reflects the growing demand for more interactive and visually appealing interfaces, particularly in high-tech industries such as medical devices, automotive, and consumer electronics. As the technology continues to advance, international B2B buyers can expect even more innovative solutions that cater to their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of membrane button

-

How do I choose the right membrane switch for my application?

Choosing the right membrane switch involves assessing your specific application requirements, including environmental conditions, user interaction, and design constraints. Consider factors such as tactile feedback, durability, and whether you need features like backlighting or capacitive touch. Collaborate with manufacturers to customize the switch based on the intended use, ensuring it meets performance standards and regulatory compliance, especially for industries like medical or industrial controls. -

What is the best membrane switch design for outdoor use?

For outdoor applications, select membrane switches with enhanced durability features such as sealed gaskets, IP67 ratings for water and dust resistance, and UV-resistant overlays. Non-tactile switches are often preferable in harsh environments since they are less likely to be compromised by debris. Consult with suppliers to discuss specific environmental conditions your switches will face, ensuring they can withstand temperature variations and moisture exposure. -

What are the common customization options for membrane switches?

Customization options for membrane switches include graphic overlays, tactile feedback types (e.g., tactile vs. non-tactile), size, shape, and the inclusion of features like backlighting or capacitive sensing. Manufacturers can also tailor the materials used for overlays and adhesives to meet specific durability or aesthetic requirements. Engaging in a thorough design discussion with your supplier can help you achieve the optimal configuration for your needs. -

What is the minimum order quantity (MOQ) for membrane switches?

The MOQ for membrane switches varies by manufacturer, typically ranging from a few hundred to several thousand units. This quantity often depends on the complexity of the design and production capabilities of the supplier. It’s advisable to communicate your project scope and budget with potential suppliers to find a flexible arrangement that accommodates your needs while ensuring cost-effectiveness. -

What payment terms should I expect when sourcing membrane switches internationally?

Payment terms for international sourcing can vary widely among suppliers. Common options include upfront payments, net 30/60/90 days, or a letter of credit for larger orders. Discussing payment options upfront with potential suppliers can help establish trust and ensure smooth transactions. Be aware of additional costs such as import duties and taxes when calculating your total expenditure. -

How do I vet potential suppliers for membrane switches?

Vetting suppliers for membrane switches involves researching their industry experience, certifications, and customer reviews. Request samples to assess product quality and inquire about their manufacturing processes, lead times, and support services. Establishing communication with their existing clients can provide valuable insights into reliability and service levels. Additionally, consider suppliers who have experience in your specific industry to ensure they understand your unique requirements. -

What quality assurance measures should I expect from membrane switch manufacturers?

Reputable membrane switch manufacturers implement rigorous quality assurance (QA) measures, including material inspections, in-process quality checks, and final product testing. Look for suppliers that adhere to international standards, such as ISO 9001, to ensure consistent quality. Request documentation of their QA processes and any certifications to verify their commitment to product excellence. -

How is logistics managed for international shipments of membrane switches?

Logistics for international shipments of membrane switches typically involves coordinating with freight forwarders for transportation, customs clearance, and delivery. Discuss shipping options with your supplier, including air vs. sea freight, depending on your timeline and budget. Ensure that the supplier provides necessary documentation such as invoices, packing lists, and certificates of origin to facilitate smooth customs processing. Understanding the logistics framework will help you plan your inventory management effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for membrane button

How Can Strategic Sourcing Enhance Your Membrane Button Procurement?

In conclusion, strategic sourcing for membrane buttons offers significant advantages for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By focusing on quality, customization, and supplier reliability, businesses can ensure they acquire the most effective membrane switches tailored to their specific needs. The versatility of membrane switches across various industries—from medical devices to consumer electronics—highlights their value as a critical component in modern technology.

Investing in strategic sourcing not only minimizes costs but also enhances product performance and longevity, leading to improved user satisfaction and reduced maintenance. As you navigate the complex landscape of membrane button procurement, consider leveraging partnerships with manufacturers who offer comprehensive design and production capabilities.

Looking ahead, the demand for innovative and reliable membrane switches is expected to grow, driven by advancements in technology and an increasing focus on user-friendly interfaces. Now is the time for international buyers to align their sourcing strategies with these trends, ensuring they stay competitive and meet evolving market demands. Engage with reputable suppliers today to explore custom solutions that can elevate your product offerings and drive success in your industry.