Discover Power Socket Types by Country: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for power socket types by country

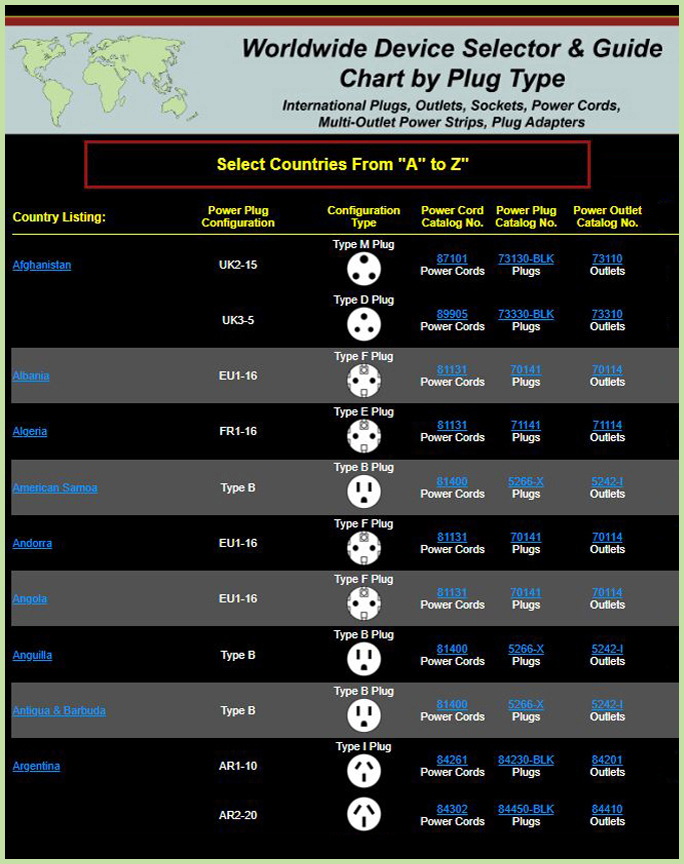

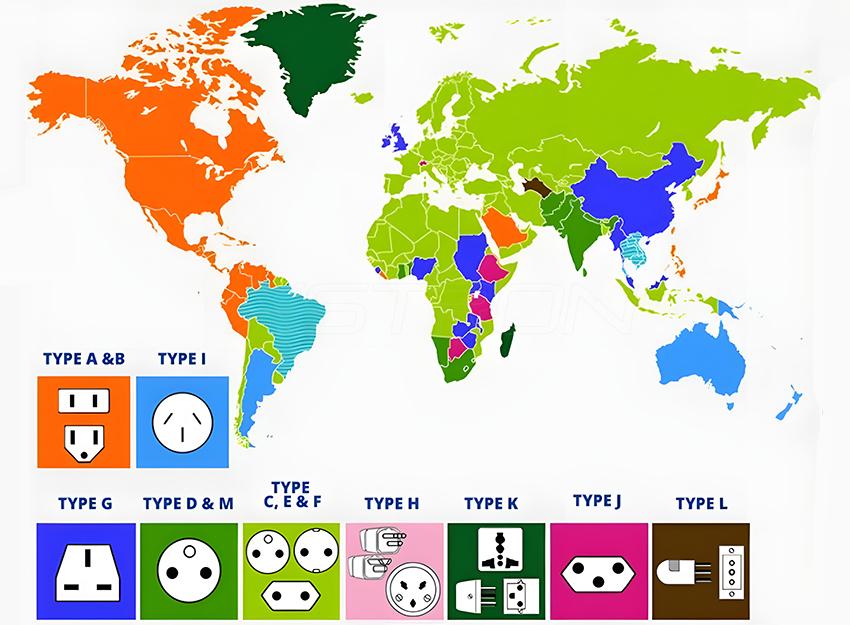

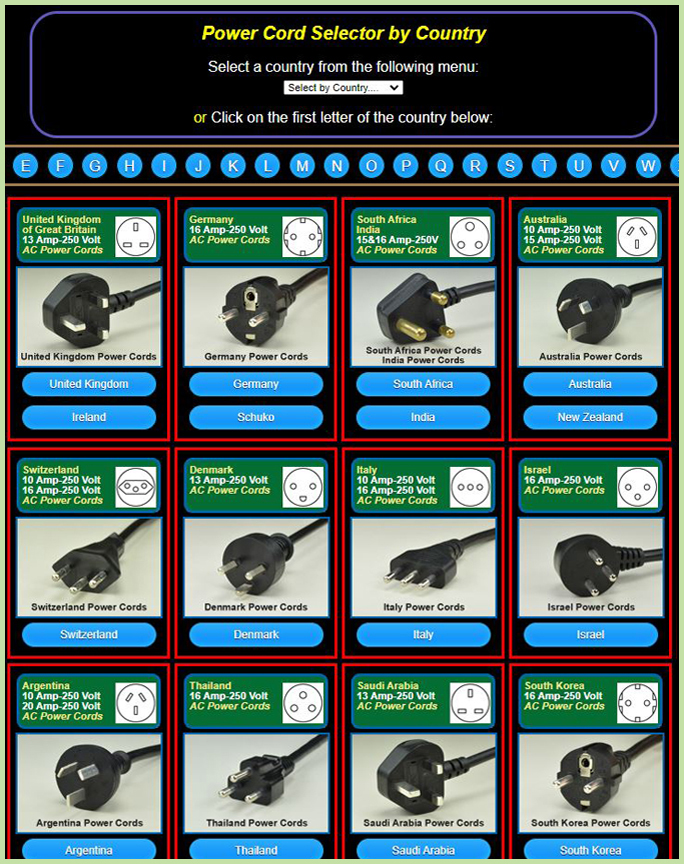

As international B2B buyers increasingly navigate the complexities of the global market, understanding the various power socket types by country becomes a crucial factor in ensuring seamless operations and compatibility. Sourcing the right electrical components can be a daunting task, especially for businesses looking to expand into regions like Africa, South America, the Middle East, and Europe. This guide provides a comprehensive overview of power socket types, voltage standards, and their applications across different countries, enabling buyers to make informed purchasing decisions.

In this resource, you’ll find an extensive analysis of socket types, including the most commonly used configurations, their voltage specifications, and frequency variations. We delve into supplier vetting processes, helping you identify reliable manufacturers and distributors who meet international standards. Additionally, we provide insights into cost considerations, ensuring you have a clear understanding of budget implications when sourcing electrical equipment.

By equipping B2B buyers with the knowledge needed to navigate the intricacies of global power standards, this guide empowers businesses to mitigate risks associated with electrical compatibility issues. Whether you are sourcing equipment for a new project in Kenya or expanding your operations in Brazil, understanding local requirements is essential for ensuring operational efficiency and compliance.

Understanding power socket types by country Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Flat parallel blades, 15A, 125V | North America, electronics | Pros: Widely used in North America; Cons: Limited to lower voltage applications. |

| Type C | Two round pins, 2.5A, 220-240V | Europe, appliances, tools | Pros: Common in Europe; Cons: Not compatible with Type E/F. |

| Type G | Three rectangular pins, 13A, 230V | UK, heavy appliances, industrial | Pros: High safety standards; Cons: Bulkier design may limit portability. |

| Type I | Two flat pins in a V-shape, 10A/15A, 230V | Australia, machinery, electronics | Pros: Suitable for high power; Cons: Incompatibility with other types outside Australia. |

| Type N | Two round pins and a grounding pin, 10A/20A, 127V/220V | Brazil, appliances, consumer electronics | Pros: Versatile voltage options; Cons: Limited global adoption. |

What Are the Characteristics of Type A Power Sockets?

Type A sockets feature two flat parallel blades and are primarily used in North America and parts of Central and South America. They are rated for 15A at 125V, making them suitable for low-power appliances like lamps and phone chargers. B2B buyers should consider the compatibility with existing infrastructure when sourcing equipment, as Type A is not suitable for higher voltage applications.

How Do Type C Sockets Differ from Other Types?

Type C sockets, characterized by two round pins, are widely used across Europe and are rated for 2.5A at 220-240V. They are commonly found in appliances and tools. Buyers should note that while Type C is prevalent, it is not compatible with Type E or F sockets, which may require additional adapters for businesses operating across different countries.

What Advantages Does Type G Offer for B2B Buyers?

Type G sockets feature three rectangular pins and are rated for 13A at 230V, primarily used in the UK and several other countries. They are suitable for heavy appliances and industrial equipment, offering high safety standards due to their fuse protection. However, their bulkier design may pose challenges for portability, making them less ideal for travel or mobile applications.

Why Choose Type I for Australian Applications?

Type I sockets have two flat pins arranged in a V-shape and can handle 10A or 15A at 230V. They are primarily used in Australia and are suitable for high-power applications, including machinery and electronic devices. B2B buyers should be aware of the potential incompatibility with other socket types outside Australia, which may necessitate the use of adapters.

What Makes Type N Unique in the Global Market?

Type N sockets are distinguished by their two round pins and a grounding pin, rated for either 10A or 20A at 127V or 220V. They are primarily found in Brazil and are suitable for a range of appliances and consumer electronics. Although Type N offers versatility with its voltage options, its limited adoption globally means that buyers may face challenges when integrating equipment across different markets.

Key Industrial Applications of power socket types by country

| Industry/Sector | Specific Application of power socket types by country | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of Type C and Type F sockets in European factories | Ensures compatibility with European machinery and equipment | Buyers must verify voltage and frequency standards for machinery. |

| Hospitality | Implementation of Type G sockets in hotels across the UK | Provides reliable power for guest services and amenities | Consider the need for universal adapters for international guests. |

| Construction | Use of Type M sockets in construction sites in South Africa | Supports heavy machinery and tools with high power requirements | Assess local voltage compatibility and safety standards. |

| Telecommunications | Installation of Type D and Type M sockets in African telecom towers | Facilitates reliable power supply for telecommunications equipment | Evaluate the availability of local power infrastructure. |

| Healthcare | Integration of Type B sockets in medical facilities in the USA | Ensures safety and compatibility for medical devices and equipment | Ensure compliance with local health regulations and standards. |

How Are Power Socket Types Used in Key Industries?

In the manufacturing sector, particularly in Europe, Type C and Type F sockets are prevalent due to their compatibility with most machinery. These sockets help avoid operational delays caused by electrical mismatches, ensuring smooth production processes. For international buyers, understanding local voltage and frequency standards is crucial to avoid equipment damage and ensure compliance with regulations.

The hospitality industry, especially in the UK, predominantly uses Type G sockets. These sockets provide reliable power for essential services such as lighting, air conditioning, and electronic devices in hotels. International buyers should consider the necessity for universal adapters to accommodate guests from various regions, enhancing their experience and ensuring service continuity.

In construction, Type M sockets are commonly used in South Africa to power heavy machinery and tools. These sockets support the high power requirements typical in construction environments. Buyers must assess local voltage compatibility and safety standards to ensure that their equipment operates efficiently and safely on-site.

The telecommunications sector in Africa frequently utilizes Type D and Type M sockets for powering telecom towers. These sockets ensure a reliable power supply for critical telecommunications infrastructure, which is essential for maintaining connectivity. Buyers should evaluate the availability of local power infrastructure and consider potential power fluctuations that could impact operations.

Lastly, in the healthcare sector in the USA, Type B sockets are integral to medical facilities. They provide a safe and compatible power source for sensitive medical devices and equipment, ensuring patient safety and operational efficiency. International buyers must ensure compliance with local health regulations and standards to avoid legal issues and maintain high service quality.

A stock image related to power socket types by country.

3 Common User Pain Points for ‘power socket types by country’ & Their Solutions

Scenario 1: Navigating Incompatible Power Socket Types in International Markets

The Problem: International B2B buyers often face challenges when sourcing electrical equipment for various regions, especially when the power socket types vary significantly between countries. For example, a company planning to expand operations into multiple African nations may find that while some countries use Type C and E sockets, others rely on Type G. This diversity can lead to confusion and potentially expensive delays if the right adapters or equipment aren’t sourced prior to deployment.

The Solution: To mitigate this problem, B2B buyers should conduct thorough research on the specific power socket types in each target country. Utilizing resources such as the World Standards website or the International Electrotechnical Commission (IEC) can provide a comprehensive overview of plug types and voltages. Buyers should create a detailed compatibility chart that includes the plug types and voltages for each destination. Furthermore, when sourcing electrical equipment, ensure that the suppliers provide products compatible with the specific power requirements of each market. Including multi-type sockets or universal adapters in bulk orders can also provide flexibility and prevent operational hiccups.

Scenario 2: Voltage Variations Leading to Equipment Damage

The Problem: Voltage inconsistencies across different countries can be a significant concern for B2B buyers. For instance, a company importing electrical appliances from Europe, which typically operates at 230V, might encounter issues when attempting to use these appliances in countries like the United States, where the standard is 120V. This mismatch can not only lead to operational failures but also damage expensive equipment.

The Solution: B2B buyers need to ensure that all electrical equipment is rated for the correct voltage before making international purchases. One actionable strategy is to invest in voltage converters or transformers that can adapt the voltage supply to meet the equipment requirements. Additionally, buyers should work with manufacturers who can provide dual-voltage appliances or specify that products must be compatible with both 110V and 230V systems. Establishing relationships with local suppliers who understand the regional voltage standards can also provide valuable insights and ensure compliance with local regulations.

Scenario 3: Supply Chain Disruptions Due to Adapter Shortages

The Problem: As businesses expand globally, they may encounter supply chain disruptions related to the availability of power adapters compatible with local sockets. For example, a South American company might import machinery that requires specific types of plugs, only to find that the necessary adapters are either unavailable or significantly overpriced in their region. This can result in delays and increased costs, hampering business operations.

The Solution: To prevent such disruptions, B2B buyers should proactively stock up on essential adapters and ensure they are part of their procurement strategy. Establishing partnerships with manufacturers or suppliers that specialize in power solutions can help secure a steady supply of the required adapters. Additionally, implementing a just-in-time inventory system can streamline the process of acquiring adapters as needed, while bulk purchasing can reduce costs. Buyers should also consider including adaptable equipment in their procurement lists, such as machines that feature interchangeable plugs, thereby enhancing their operational flexibility and reducing dependency on specific adapter types.

Strategic Material Selection Guide for power socket types by country

What are the Key Materials Used in Power Socket Manufacturing?

When selecting materials for power sockets, international B2B buyers must consider various factors, including performance properties, cost, and compliance with regional standards. Below is an analysis of four common materials used in power socket manufacturing, focusing on their properties, advantages, disadvantages, and implications for buyers in different regions, particularly Africa, South America, the Middle East, and Europe.

How Does Polycarbonate Perform in Power Socket Applications?

Key Properties: Polycarbonate is a thermoplastic polymer known for its high impact resistance and excellent electrical insulation properties. It can withstand temperatures up to 130°C (266°F) and offers good resistance to UV light and chemicals.

Pros & Cons: The durability of polycarbonate makes it a popular choice for power sockets, especially in environments prone to physical stress. It is relatively lightweight and can be molded into complex shapes, which simplifies manufacturing. However, polycarbonate can be more expensive than other plastics and may not perform well in extreme temperatures.

Impact on Application: Polycarbonate’s excellent insulating properties make it suitable for high-voltage applications, ensuring safety and reliability. It is compatible with various media, including air and moisture, making it ideal for indoor and outdoor use.

Considerations for International Buyers: Buyers should ensure that polycarbonate sockets comply with international standards such as IEC 60884 and ASTM D635. In regions like Africa and South America, where electrical systems may vary, understanding local compliance is crucial.

What Role Does Thermoplastic Elastomer (TPE) Play in Power Sockets?

Key Properties: TPE is a versatile material that combines the properties of rubber and plastic. It offers excellent flexibility, temperature resistance (up to 90°C or 194°F), and is resistant to various chemicals.

Pros & Cons: TPE’s flexibility allows for easy handling and installation, making it user-friendly. It also provides good weather resistance, which is beneficial for outdoor applications. However, TPE can be more costly than traditional plastics and may not be as durable under mechanical stress.

Impact on Application: TPE is often used in power cords and flexible connectors where movement and bending occur. Its compatibility with various media makes it suitable for diverse environments, including humid conditions found in tropical regions.

Considerations for International Buyers: Compliance with standards like UL 62 for flexible cords is essential, especially in regions with stringent safety regulations. Buyers should also consider the environmental impact of TPE, as sustainability is becoming increasingly important in global markets.

Why is Metal (Copper and Aluminum) Important in Power Socket Manufacturing?

Key Properties: Metals like copper and aluminum are known for their excellent electrical conductivity, with copper offering superior performance. Both materials can withstand high temperatures and are resistant to corrosion when treated properly.

Pros & Cons: Metal sockets are highly durable and can handle heavy electrical loads, making them suitable for industrial applications. However, they are heavier and more expensive than plastic alternatives. Additionally, metal can be prone to rust if not properly coated, especially in humid environments.

Impact on Application: Metal sockets are ideal for high-power applications and environments where durability is critical. Their conductivity ensures efficient power transfer, reducing energy loss.

Considerations for International Buyers: Buyers must ensure that metal sockets comply with international standards such as IEC 60947 for low-voltage switchgear. In regions like the Middle East, where high temperatures are common, selecting corrosion-resistant coatings is vital.

How Does PVC (Polyvinyl Chloride) Fit into Power Socket Design?

Key Properties: PVC is a widely used thermoplastic known for its chemical resistance and good electrical insulation properties. It can handle temperatures up to 60°C (140°F) and is available in various formulations for different applications.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for budget-friendly sockets. However, its lower temperature resistance and potential for brittleness over time can be drawbacks, especially in extreme conditions.

Impact on Application: PVC is suitable for indoor applications where exposure to harsh conditions is limited. Its insulating properties make it effective for low to medium voltage applications.

Considerations for International Buyers: Buyers should check for compliance with standards such as ASTM D1784 for PVC materials. In regions like Europe, where environmental regulations are stringent, selecting lead-free PVC formulations may be necessary.

Summary Table of Material Selection for Power Sockets

| Material | Typical Use Case for power socket types by country | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | High-voltage applications, outdoor sockets | High impact resistance | Higher cost than other plastics | Medium |

| Thermoplastic Elastomer | Flexible connectors, power cords | Excellent flexibility | More expensive than traditional plastics | High |

| Metal (Copper/Aluminum) | Industrial applications, high-power sockets | Superior electrical conductivity | Heavier and prone to rust | High |

| PVC | Indoor low to medium voltage sockets | Cost-effective | Lower temperature resistance | Low |

A stock image related to power socket types by country.

This guide provides actionable insights for international B2B buyers, helping them make informed decisions about material selection for power sockets based on regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for power socket types by country

What Are the Main Stages in Manufacturing Power Sockets?

Manufacturing power sockets involves a systematic approach that includes several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring the final product meets both safety and performance standards.

-

Material Preparation: The first step is sourcing high-quality materials, primarily plastics and metals. Common materials include polycarbonate for insulation and copper for conductors. Suppliers must ensure that materials meet specific regulatory standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals).

-

Forming: This stage involves the shaping of materials into the desired socket components. Techniques such as injection molding are often used for plastic parts, while metal parts may be produced using stamping or die-casting. The choice of technique affects the durability and cost of the final product.

-

Assembly: After individual components are formed, they are assembled into the complete socket. This process may involve manual labor or automated machinery, depending on the production scale. Efficient assembly lines are essential for maintaining quality and reducing lead times.

-

Finishing: The final stage includes surface treatment and testing. This may involve applying coatings to enhance durability and aesthetics. It is crucial to ensure that all products are free from defects and meet international quality standards before packaging.

How Do Quality Control Processes Ensure the Reliability of Power Sockets?

Quality control (QC) is integral to manufacturing power sockets, ensuring that products are safe and functional. Various international and industry-specific standards guide these processes.

-

Relevant International Standards: Compliance with ISO 9001, a standard for quality management systems, is essential. Additionally, for electrical safety, standards such as IEC 60884 (for plugs and sockets) and CE marking (for products sold in Europe) are critical. These certifications demonstrate adherence to safety and performance requirements.

-

Key QC Checkpoints: Quality control is typically divided into three checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and identify defects early.

– Final Quality Control (FQC): After assembly, each socket undergoes comprehensive testing to ensure it meets safety and performance standards. -

Common Testing Methods: Various tests are employed to assess socket safety and performance. These include:

– Dielectric Strength Tests: To ensure insulation can withstand high voltages.

– Temperature Rise Tests: To measure the heat generated under load.

– Mechanical Endurance Tests: To assess durability through repeated use.

A stock image related to power socket types by country.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to mitigate risks.

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to assess a supplier’s manufacturing processes and quality assurance practices. This allows buyers to evaluate compliance with international standards and identify any gaps in quality management.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes. Reports should include information on defect rates, testing results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These organizations can conduct independent assessments of manufacturing practices, material quality, and compliance with safety standards.

-

Certifications and Documentation: Buyers should request copies of all relevant certifications, such as ISO 9001, CE, and any other applicable standards. This documentation is crucial for verifying that suppliers adhere to the necessary quality control processes.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers face unique challenges when sourcing power sockets, especially regarding quality control.

-

Regional Compliance Differences: Different regions may have varying regulatory requirements for electrical products. For instance, sockets used in Europe must comply with stricter safety standards compared to those in some African countries. Understanding these differences is essential for ensuring compliance.

-

Cultural and Communication Barriers: When dealing with suppliers from different cultural backgrounds, communication can be a challenge. Buyers should be clear about their quality expectations and ensure that suppliers understand the importance of compliance with international standards.

-

Supply Chain Transparency: Establishing transparency in the supply chain is vital. Buyers should inquire about the sources of materials and the manufacturing processes to ensure that they align with their quality expectations. This can help in mitigating risks associated with substandard products.

-

Building Long-Term Relationships: Cultivating relationships with reliable suppliers can enhance quality assurance. Long-term partnerships often lead to better communication and collaboration on quality issues, ultimately benefiting both parties.

Conclusion

In summary, the manufacturing processes and quality assurance practices for power sockets are critical factors that B2B buyers must consider. By understanding the main stages of production, the importance of rigorous quality control, and the nuances of international sourcing, buyers can make informed decisions that ensure they receive safe and reliable products. This knowledge is particularly valuable for businesses operating in diverse markets across Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power socket types by country’

This guide aims to equip B2B buyers with a structured approach to sourcing power socket types by country. Understanding the various plug types and voltages is essential for ensuring compatibility and safety in electrical equipment, especially when operating in diverse international markets. Follow these steps to streamline your sourcing process.

Step 1: Identify Target Markets and Their Socket Standards

Begin by determining the specific countries where you plan to operate or sell your products. Each country may have different standards regarding plug types and voltage levels, which can affect product compatibility.

- Research the most common plug types: For example, Type C and Type G are prevalent in many regions, including Europe and parts of Africa.

- Understand voltage requirements: Know whether you need to accommodate 110V or 220V systems, as this will influence the design and safety features of your products.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications required for your products concerning power sockets. This includes the type of plugs, voltage compatibility, and any necessary adapters or converters.

- Consider product usage: Identify whether your products will be used in residential, commercial, or industrial settings, as this may dictate different requirements.

- Evaluate safety standards: Ensure that your specifications meet both international and local safety regulations to avoid compliance issues.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure they can meet your technical specifications and quality standards. This is crucial for maintaining product integrity and customer satisfaction.

- Request documentation: Ask for certifications, such as ISO or CE markings, which demonstrate compliance with international safety standards.

- Check references: Obtain case studies or testimonials from other businesses that have sourced similar products from the supplier.

Step 4: Assess Product Availability and Lead Times

Investigate the availability of the required products and their lead times. Timely procurement is essential to meet your operational timelines and avoid disruptions.

- Inquire about stock levels: Ensure that the supplier has adequate inventory to fulfill your orders promptly.

- Understand shipping options: Consider suppliers that offer reliable shipping methods, particularly for international shipments that may face customs delays.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms and pricing. This step is vital for optimizing your costs and ensuring long-term partnerships.

- Discuss volume discounts: Larger orders often qualify for better pricing, so assess your purchasing needs accordingly.

- Clarify payment terms: Establish clear payment terms to manage cash flow effectively, including deposits and payment timelines.

Step 6: Implement Quality Assurance Checks

Before finalizing any orders, implement quality assurance checks to ensure that the products meet your specifications and standards.

- Conduct sample testing: Request samples to evaluate their compatibility with your products and ensure they meet safety standards.

- Plan for inspections: Consider establishing a procedure for inspecting goods upon delivery to address any discrepancies immediately.

Step 7: Stay Informed on Regulatory Changes

Finally, maintain awareness of any changes in international regulations regarding electrical standards and socket types. This knowledge is crucial for adapting your sourcing strategies to remain compliant.

- Subscribe to industry newsletters: Keep up with updates that may impact your sourcing decisions.

- Engage with trade associations: Networking with industry professionals can provide insights into emerging trends and regulatory developments.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing power socket types by country, ensuring their products are compatible, safe, and compliant with international standards.

Comprehensive Cost and Pricing Analysis for power socket types by country Sourcing

What Are the Key Cost Components for Power Socket Types by Country?

When sourcing power sockets internationally, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. For example, sockets made from durable plastics or metals may have higher upfront costs but offer better longevity. Countries with abundant raw materials can often provide lower material costs.

-

Labor: Labor costs vary widely between regions. For instance, manufacturing in countries with lower wage standards, such as some parts of Africa and South America, can yield substantial savings. However, it’s essential to consider the skill level of the workforce, which can affect production quality.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Regions with advanced manufacturing infrastructure may have higher overhead costs, which can influence the final price.

-

Tooling: The initial setup for manufacturing, including molds and dies, can be a significant one-time expense. Custom designs will require additional investment in tooling, impacting pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet international standards, which can lead to higher costs. However, this is crucial for avoiding costly recalls or reputational damage.

-

Logistics: Shipping costs can vary significantly based on the origin and destination. Factors such as distance, mode of transport, and customs duties play a pivotal role in the overall logistics cost.

-

Margin: Suppliers will add their markup based on market conditions and competition. Understanding the typical margin in different regions can help buyers negotiate better prices.

How Do Price Influencers Affect B2B Sourcing for Power Sockets?

Several factors influence the pricing of power sockets, particularly for international buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes typically lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to negotiate favorable terms.

-

Specifications and Customization: Custom designs or specifications may incur additional costs. Buyers should be clear about their requirements upfront to avoid unexpected charges later in the production process.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can influence both cost and price. For instance, sockets that comply with international safety standards may have higher material and testing costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their experience and quality assurance, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining who is responsible for shipping, insurance, and tariffs. This knowledge can help buyers calculate the total landed cost more accurately.

What Buyer Tips Can Enhance Cost-Efficiency in Power Socket Sourcing?

-

Negotiation Strategies: Leverage your purchasing power by negotiating terms based on volume and long-term partnerships. Establishing relationships with suppliers can lead to better pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the TCO, including shipping, installation, and maintenance costs. This approach can lead to more informed decisions.

-

Be Aware of Pricing Nuances: Prices can fluctuate based on global supply chain issues, tariffs, and currency exchange rates. Stay informed about market trends to anticipate changes that could affect your costs.

-

Conduct Market Research: Understanding regional market dynamics can provide insights into competitive pricing. Research local suppliers in Africa, South America, the Middle East, and Europe to identify potential cost-saving opportunities.

-

Leverage Technology: Utilize procurement software and platforms that can help streamline sourcing processes, track pricing trends, and manage supplier relationships effectively.

In conclusion, while sourcing power sockets internationally, B2B buyers must carefully consider the various cost components and price influencers to achieve optimal pricing and ensure successful procurement.

Alternatives Analysis: Comparing power socket types by country With Other Solutions

The global landscape of electrical systems is diverse, particularly regarding power socket types and their compatibility across various countries. For international B2B buyers, understanding these differences is crucial when sourcing electrical products or establishing operations in new regions. While traditional power socket types serve their purpose, alternative solutions exist that can address specific needs more effectively. Below, we compare the traditional “Power Socket Types by Country” against two viable alternatives: Universal Power Adapters and Wireless Charging Technologies.

Comparison Table of Power Socket Solutions

| Comparison Aspect | Power Socket Types By Country | Universal Power Adapters | Wireless Charging Technologies |

|---|---|---|---|

| Performance | Reliable and standardized | Variable performance based on design | High efficiency with compatible devices |

| Cost | Varies by country and type | Moderate, often a one-time purchase | Higher initial investment, but lower long-term costs |

| Ease of Implementation | Requires specific plugs | Simple plug-and-play | Requires compatible devices and infrastructure |

| Maintenance | Minimal maintenance required | Low maintenance, but can wear out | Low maintenance with durable systems |

| Best Use Case | Ideal for permanent installations | Travel and temporary setups | Modern devices and evolving tech environments |

What Are the Advantages and Disadvantages of Universal Power Adapters?

Universal power adapters provide flexibility for businesses that operate in multiple countries. They allow users to connect devices with different plug types to a single power source. The main advantage is their convenience, particularly for travelers or businesses setting up temporary operations abroad. However, their performance can vary based on the quality of the adapter, and they may not support all devices efficiently, especially those that require higher voltages or specific types of grounding.

How Do Wireless Charging Technologies Compare?

Wireless charging technologies are gaining traction as a modern alternative to traditional power sockets. They offer significant benefits, including the elimination of cables and connectors, which reduces wear and tear on devices. This technology is ideal for environments where multiple devices need to be charged simultaneously, such as in offices or public spaces. However, the initial investment can be higher, and not all devices are compatible, which can limit its adoption. Additionally, the efficiency of wireless charging can be less than that of wired connections, particularly over longer distances.

Conclusion: How Can B2B Buyers Choose the Right Power Solution?

For international B2B buyers, selecting the right power solution hinges on understanding the specific needs of their operations. If the requirement is for stable, long-term installations, adhering to the local power socket types is essential. Conversely, if flexibility and mobility are priorities, universal power adapters may be the better choice. For companies looking to innovate and adopt cutting-edge technologies, wireless charging presents an exciting opportunity, albeit with some compatibility considerations. Ultimately, evaluating the operational environment, budget constraints, and technological requirements will guide buyers in making the most informed decision.

Essential Technical Properties and Trade Terminology for power socket types by country

What Are the Essential Technical Properties of Power Socket Types?

When sourcing power sockets for international markets, understanding the technical specifications is crucial for ensuring compatibility and safety. Here are some essential properties to consider:

-

Material Grade

The material used in power sockets typically includes thermoplastics or thermosetting plastics. High-grade materials are crucial for durability and heat resistance, which are vital for preventing electrical fires. B2B buyers should prioritize sockets made from materials that comply with international safety standards, especially when sourcing from diverse regions like Africa or South America. -

Current Rating

The current rating (measured in amperes) indicates the maximum load the socket can handle. For instance, sockets rated for 10A are common in many countries, while others may require 16A ratings for higher power appliances. Understanding the current rating is essential for B2B buyers to ensure that the sockets can safely support the electrical load of devices used in their target market. -

Voltage Compatibility

Different countries operate on varying voltage levels, typically ranging from 100V to 240V. For example, while Europe generally uses 230V, North America operates at 120V. B2B buyers must ensure that the sockets they purchase are compatible with the voltage used in their specific markets to avoid damaging electrical devices and to ensure safety. -

Frequency

The frequency of the electrical supply, measured in hertz (Hz), can affect the performance of certain electrical devices. Most countries operate at either 50Hz or 60Hz. Buyers should verify the frequency requirements of their devices to ensure proper functionality and avoid potential malfunctions. -

Safety Standards

Compliance with international safety standards, such as IEC (International Electrotechnical Commission) or local regulations, is crucial. These standards help ensure that the sockets are safe for use and have undergone rigorous testing. B2B buyers should request certifications to verify compliance before making bulk purchases. -

Tolerance Levels

Tolerance levels refer to the acceptable variations in the physical dimensions and electrical characteristics of the sockets. These tolerances are critical for ensuring that plugs fit securely and function properly. Inconsistent tolerances can lead to connection issues or even electrical hazards, making this a key consideration for buyers.

What Are the Common Trade Terms Related to Power Sockets?

Understanding industry-specific terminology is essential for navigating international trade effectively. Here are some common terms B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of power sockets, buyers may source sockets from OEMs who can provide high-quality products tailored to specific requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and overall costs. Buyers should negotiate MOQs that align with their purchasing capabilities and market demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For power sockets, an RFQ should detail the required specifications, quantities, and delivery timelines to ensure that suppliers provide accurate and competitive quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to clarify shipping responsibilities, risk management, and costs associated with transporting power sockets across borders. -

Certification

Certification indicates that a product meets certain standards set by regulatory bodies. For power sockets, certifications may include safety and performance standards. B2B buyers should prioritize sourcing certified products to ensure safety and compliance in their target markets. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the context of power sockets, understanding lead times is essential for effective supply chain management and inventory planning, especially in markets with high demand fluctuations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that ensure product quality and compliance while navigating the complexities of international sourcing.

Navigating Market Dynamics and Sourcing Trends in the power socket types by country Sector

What Are the Current Market Dynamics and Key Trends in Power Socket Types?

The market for power socket types is witnessing significant changes driven by globalization, technological advancements, and increasing international trade. With the rise of e-commerce, international B2B buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly sourcing electrical products from various global suppliers. This trend is fueled by the need for compatible electrical solutions that cater to diverse power socket standards across countries. For instance, many African countries use plug types C and E, while South America shows a mix of types A, B, and C, leading to a demand for versatile and universal socket solutions.

Emerging technologies, such as smart home systems, are also reshaping the market. Buyers are now looking for power sockets that support smart functionalities, including USB ports for charging devices. Furthermore, sustainability is becoming a key concern, with B2B buyers increasingly prioritizing eco-friendly materials and manufacturing processes. This shift towards sustainable sourcing is not only beneficial for the environment but also enhances brand reputation and compliance with regulatory standards.

How Can Sustainability and Ethical Sourcing Impact B2B Transactions in Power Socket Types?

Sustainability and ethical sourcing are critical components in the power socket market, influencing buyer decisions significantly. The environmental impact of electrical components is substantial, from production to disposal. B2B buyers are now more conscious of the materials used in manufacturing power sockets. They are seeking suppliers who utilize recycled materials and environmentally friendly production techniques. Certifications such as ISO 14001 for environmental management and ENERGY STAR for energy efficiency are becoming essential for suppliers to demonstrate their commitment to sustainability.

Moreover, ethical supply chains are paramount in maintaining transparency and accountability. Buyers are increasingly demanding proof of ethical labor practices and fair trade conditions from their suppliers. This focus not only helps in building trust but also mitigates risks associated with supply chain disruptions. By sourcing from manufacturers who prioritize sustainability, businesses can enhance their corporate social responsibility (CSR) profiles, appealing to environmentally-conscious consumers and stakeholders alike.

What Is the Evolution and Historical Context of Power Socket Types?

The evolution of power socket types can be traced back to the early 20th century when electrical systems became standardized. Initially, various plug designs were used, leading to compatibility issues. The establishment of international standards by organizations such as the International Electrotechnical Commission (IEC) was crucial in harmonizing socket types. Today, there are over 15 different plug types globally, with types C and G being among the most common.

The historical context of power sockets reflects the broader trends in electrical infrastructure development. As countries modernized, the need for standardized electrical systems became apparent, facilitating international trade and travel. For B2B buyers, understanding this evolution is vital for making informed purchasing decisions, as it highlights the importance of compatibility and adaptability in electrical solutions across diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of power socket types by country

-

How do I solve compatibility issues with power sockets when importing electronics?

To solve compatibility issues, first, identify the power socket types and voltage specifications of the destination country. Utilize a comprehensive guide that details plug types, voltages, and frequencies by country. Next, source adapters or transformers that match the local standards. When selecting suppliers, inquire about their experience with international shipping and compliance with local electrical standards. Regular communication with your logistics provider can also help ensure that all products conform to the necessary specifications upon arrival. -

What is the best way to choose the right power socket type for my export products?

Choosing the right power socket type involves researching the target market’s electrical standards, including plug types and voltage. Use resources that provide detailed information on socket compatibility for various countries. Additionally, consult local partners or distributors to understand consumer preferences and regulatory requirements. Consider offering products with universal sockets or including adapters to enhance marketability. This proactive approach ensures your products meet local needs and reduces potential return rates due to compatibility issues. -

What are the minimum order quantities (MOQs) for power sockets when sourcing from international suppliers?

Minimum order quantities (MOQs) for power sockets can vary significantly depending on the supplier, product type, and manufacturing capabilities. Generally, MOQs range from 100 to 1,000 units for standard products. When negotiating with suppliers, express your expected sales volume and seek flexibility in MOQs, especially if you are a new buyer. Establishing a good relationship with suppliers can also help in negotiating lower MOQs or test orders to assess product quality before committing to larger quantities. -

How can I vet suppliers for power socket types effectively?

To vet suppliers effectively, conduct thorough background checks, including their reputation, experience in the industry, and compliance with international electrical standards. Request certifications such as ISO or IEC standards to ensure quality and safety. Additionally, seek references from other clients to gauge their reliability. Use online platforms to read reviews and check for any complaints. A site visit or virtual audit can provide insights into their manufacturing processes and quality control measures. -

What payment terms should I negotiate when sourcing power sockets internationally?

When negotiating payment terms, aim for conditions that protect your cash flow while providing the supplier with assurance. Common terms include a 30% deposit upfront and the remaining 70% upon delivery or before shipment. Consider using escrow services for larger transactions to ensure that funds are only released upon satisfactory receipt of goods. Additionally, discuss options for letters of credit (LC) or trade financing to mitigate risks, especially with new suppliers. -

What quality assurance (QA) practices should I implement when sourcing power sockets?

Implementing robust quality assurance practices involves establishing clear quality standards and specifications with your suppliers. Conduct pre-production inspections to ensure that materials and components meet your requirements. Post-production inspections are also critical; consider hiring third-party inspection services to verify product quality before shipment. Regular audits of the supplier’s manufacturing processes can help ensure compliance with safety standards and reduce the likelihood of defects in the final products. -

How do I manage logistics for importing power sockets from different countries?

Managing logistics for importing power sockets involves selecting a reliable freight forwarder experienced in international shipping. Ensure they understand the specific requirements for electrical goods, including customs regulations and documentation. Consider shipping terms like Incoterms to clarify responsibilities between you and the supplier. Additionally, monitor shipment timelines and have contingency plans for delays. Familiarize yourself with local import duties and taxes to avoid unexpected costs upon delivery. -

What are the common challenges faced when sourcing power sockets internationally?

Common challenges include navigating differing electrical standards, ensuring product quality, and managing logistics across borders. Variability in plug types and voltage requirements can complicate product compatibility. Additionally, quality control issues may arise if suppliers do not adhere to agreed specifications. To mitigate these challenges, conduct thorough market research, establish clear communication with suppliers, and implement stringent QA measures. Staying informed about local regulations can also help streamline the sourcing process and reduce risks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for power socket types by country

In today’s interconnected global marketplace, understanding the diversity of power socket types across countries is crucial for international B2B buyers. The disparities in plug types, voltages, and frequencies can significantly impact the efficiency of operations and supply chain logistics. Strategic sourcing of power sockets and related equipment not only ensures compliance with local standards but also enhances the safety and reliability of electrical installations.

What Are the Key Takeaways for B2B Buyers?

-

Standardization vs. Diversity: While many countries adhere to specific standards, regions like Africa and South America exhibit a mix of socket types, requiring careful assessment to avoid compatibility issues.

-

Regional Insights: Buyers from the Middle East and Europe must navigate various plug types, such as the prevalent Type C and Type G, to ensure seamless operations.

-

Future-Proofing: As technology evolves, investing in adaptable and universal power solutions can mitigate future disruptions and enhance operational flexibility.

How Can B2B Buyers Prepare for Global Operations?

International B2B buyers should prioritize comprehensive market research to identify the specific requirements of their target regions. Establishing relationships with local suppliers can facilitate smoother sourcing processes and provide insights into regional compliance standards.

As we move forward, embracing innovative solutions and fostering partnerships will be essential in navigating the complexities of global power standards. Equip your business today with the right knowledge and tools to harness the opportunities presented by diverse electrical systems worldwide.