Discover the Benefits of Capacitive Touch Screen Technology (2025)

Introduction: Navigating the Global Market for capacitive touch screen

In today’s rapidly evolving technological landscape, sourcing high-quality capacitive touch screens presents a significant challenge for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. Capacitive touch screens, renowned for their responsiveness and precision, are integral to a variety of applications, from mobile devices to industrial control panels. However, navigating the complexities of supplier selection, understanding the nuances of different types, and evaluating costs can be daunting.

This comprehensive guide aims to demystify the global market for capacitive touch screens, offering actionable insights tailored for international B2B buyers. We will explore the various types of capacitive touch screens, including projected capacitive options that enhance performance and durability. Additionally, we will delve into their applications across industries, supplier vetting processes to ensure quality and reliability, and cost considerations that can impact your bottom line.

By providing an in-depth analysis of these aspects, this guide empowers B2B buyers to make informed purchasing decisions, helping them to select the right products that align with their specific operational needs. Whether you are a business in Poland seeking advanced touchscreen technology or a distributor in Turkey looking to expand your product offerings, understanding the intricacies of capacitive touch screens is crucial for maintaining a competitive edge in the global market.

Understanding capacitive touch screen Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Projected Capacitive Touchscreen | Utilizes a matrix of electrodes for multi-touch; high resolution | Smartphones, Tablets, Industrial Control | Pros: High accuracy, supports multi-touch; Cons: More expensive than other types. |

| Surface Capacitive Touchscreen | Senses touch through the surface; requires a conductive object | Retail Kiosks, ATMs | Pros: Good durability, simple design; Cons: Limited to single touch. |

| Mutual Capacitive Touchscreen | Uses a grid to detect touch; supports multiple simultaneous touches | Medical Devices, Interactive Displays | Pros: Excellent for complex input; Cons: Can be sensitive to environmental factors. |

| Flat Capacitive Touchscreen | Thin design with a flat surface; ideal for sleek devices | Consumer Electronics, Automotive | Pros: Aesthetic appeal, space-efficient; Cons: May lack robustness in harsh environments. |

| Multi-Touch Capacitive Touchscreen | Designed for simultaneous multiple inputs; enhanced user interaction | Gaming Devices, Advanced Point of Sale | Pros: Enhanced user experience; Cons: Higher complexity and cost. |

What Are the Characteristics of Projected Capacitive Touchscreens?

Projected capacitive touchscreens are characterized by their use of a grid of tiny electrodes beneath the surface, allowing them to detect touch through changes in capacitance. This technology enables high-resolution displays and supports multi-touch functionality, making it ideal for smartphones and tablets. For B2B buyers, the suitability of this type hinges on the need for precision and responsiveness, especially in applications like industrial control and consumer electronics. However, the higher cost may be a consideration for budget-conscious buyers.

How Does Surface Capacitive Touchscreen Functionality Benefit Businesses?

Surface capacitive touchscreens operate by sensing touch through the conductive properties of the human body. They are commonly used in retail kiosks and ATMs, where durability and ease of use are paramount. The design is straightforward, and while it offers good performance, it is limited to single touch inputs, which may not meet the needs of interactive applications. B2B buyers should weigh the benefits of durability against the need for more advanced touch capabilities.

What Makes Mutual Capacitive Touchscreens Suitable for Complex Applications?

Mutual capacitive touchscreens are designed to detect touch through a grid layout that allows for multiple simultaneous touch points. This capability makes them particularly effective in medical devices and interactive displays where complex input is required. While they offer excellent functionality, buyers should consider environmental factors, as these screens can be sensitive to humidity and temperature changes, impacting their performance in certain settings.

Why Choose Flat Capacitive Touchscreens for Sleek Designs?

Flat capacitive touchscreens are known for their slim profile and modern aesthetic, making them an excellent choice for consumer electronics and automotive applications. Their design allows for space-efficient integration into devices. However, while they enhance visual appeal, buyers should consider their robustness, as these screens may not perform well in rugged environments. Evaluating the intended application is crucial for making an informed purchasing decision.

What Advantages Do Multi-Touch Capacitive Touchscreens Offer for User Interaction?

Multi-touch capacitive touchscreens are engineered to recognize multiple touch points simultaneously, enhancing user interaction and experience. They are commonly used in gaming devices and advanced point-of-sale systems, where intuitive control is essential. Although they provide a superior user experience, the increased complexity and cost may be a drawback for some buyers. Businesses must assess their specific needs and budget when considering this type of touchscreen technology.

Key Industrial Applications of capacitive touch screen

| Industry/Sector | Specific Application of Capacitive Touch Screen | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient Monitoring Systems | Enhanced user interface for real-time data access | Compliance with medical standards; durability |

| Retail | Interactive Kiosks and Point of Sale Systems | Improved customer engagement and transaction speed | Customization options; integration with existing tech |

| Industrial Automation | Control Panels for Machinery | Increased precision in operational controls | Environmental resistance; scalability |

| Transportation | Fleet Management Displays | Streamlined information access for drivers | Ruggedness for outdoor use; multi-touch capabilities |

| Education | Smart Classroom Solutions | Interactive learning experiences | Compatibility with various educational software |

How is Capacitive Touch Screen Used in Healthcare Applications?

In healthcare, capacitive touch screens are integral to patient monitoring systems, providing a user-friendly interface for medical staff to access and input data swiftly. These systems are designed to withstand rigorous cleaning protocols and are often required to meet strict regulatory standards. For international buyers, especially in regions like Africa and South America, sourcing high-quality, compliant touch screens can enhance operational efficiency and improve patient outcomes.

What Role Does Capacitive Touch Screen Play in Retail?

Retail environments utilize capacitive touch screens in interactive kiosks and point-of-sale systems to enhance customer experiences. These devices allow for quick transactions and easy access to product information, driving sales and improving customer satisfaction. B2B buyers from Europe and the Middle East should consider sourcing touch screens that offer customization options to align with brand aesthetics and integrate seamlessly with existing sales platforms.

How is Capacitive Touch Screen Impacting Industrial Automation?

In industrial automation, capacitive touch screens are used in control panels for machinery, enabling operators to manage complex systems with precision. The ability to respond to touch without the need for physical pressure reduces wear and tear on equipment, leading to lower maintenance costs. Buyers should prioritize sourcing touch screens that are environmentally resistant and scalable to accommodate various machinery types, especially in sectors with fluctuating demands.

Why Are Capacitive Touch Screens Essential for Transportation?

Capacitive touch screens are critical in fleet management displays, allowing drivers to access vital information while on the move. These screens provide a streamlined interface for navigation, communication, and vehicle diagnostics, improving safety and efficiency. When sourcing for this application, businesses should focus on rugged designs that can withstand outdoor conditions and offer multi-touch capabilities for enhanced functionality.

How Do Capacitive Touch Screens Enhance Education?

In educational settings, capacitive touch screens facilitate smart classroom solutions that promote interactive learning. They enable teachers to engage students through dynamic presentations and collaborative activities. B2B buyers in this sector should ensure compatibility with various educational software and consider sourcing screens that offer durability and ease of use, catering to the diverse needs of educational institutions across different regions.

3 Common User Pain Points for ‘capacitive touch screen’ & Their Solutions

Scenario 1: Difficulty in Operating in Extreme Environments

The Problem: Many B2B buyers in sectors like logistics and public safety require capacitive touch screens to function reliably in extreme environmental conditions, such as high temperatures, humidity, or dust. For instance, a logistics company operating in the Middle East may find that their touch screens fail to register inputs due to intense heat or sand infiltration. This not only disrupts workflow but can lead to costly delays and equipment failures.

The Solution: To mitigate this challenge, buyers should prioritize sourcing capacitive touch screens that are specifically designed for rugged environments. Look for models with a high Ingress Protection (IP) rating, such as IP65 or higher, which indicates resistance to dust and water. Additionally, choose screens that have been tested to MIL-STD 810G standards for temperature extremes. For example, a touch screen that operates effectively in temperatures ranging from -20°C to +70°C would be ideal. When specifying these screens, ensure that they also include anti-glare and anti-reflective coatings to enhance visibility under bright sunlight. Working closely with suppliers to understand the specifications and testing results of these devices will ensure that they meet your operational needs.

Scenario 2: Inaccurate Touch Response Leading to User Frustration

The Problem: B2B buyers may encounter issues with capacitive touch screens that do not respond accurately to user inputs, leading to frustration and decreased productivity. For example, in a retail environment in South America, employees might find that the screen frequently misinterprets gestures or fails to register touches, resulting in slow check-out processes and unhappy customers.

The Solution: To address this issue, it is crucial to select capacitive touch screens that utilize projected capacitive technology, which offers higher accuracy and supports multi-touch inputs. Buyers should seek out screens with a response time of less than 40 ms and a minimum touch resolution of 1920 x 1080 pixels to ensure precision. Additionally, when integrating these screens into your existing systems, conduct thorough testing during the installation phase. This includes calibrating the screens to match the typical usage patterns of staff and ensuring that they are compatible with the operating systems in use. Regular training for employees on the best practices for using these screens can also help minimize errors and enhance overall user satisfaction.

Scenario 3: Screen Damage and Maintenance Challenges

The Problem: Capacitive touch screens are susceptible to scratches and other forms of damage, especially in industries like manufacturing and construction, where tools and equipment are frequently handled. For instance, a buyer in the Middle East may find that touch screens in their machinery are often damaged, leading to expensive replacements and increased downtime.

The Solution: To prevent damage, it is advisable to invest in capacitive touch screens with durable glass, such as Gorilla Glass or similar materials that provide enhanced resistance to scratches and impacts. Additionally, implementing protective measures such as screen guards or enclosures can significantly extend the lifespan of the screens. When specifying touch screens, inquire about features like anti-glare coatings that not only improve visibility but also provide an extra layer of protection. Regular maintenance checks should also be scheduled to identify any wear and tear early on, allowing for proactive repairs or replacements. Moreover, working with suppliers who offer comprehensive warranties and support services can ensure quick resolutions to any issues that may arise, minimizing operational disruptions.

Alternatives Analysis: Comparing capacitive touch screen With Other Solutions

Introduction: Exploring Alternatives to Capacitive Touch Screens

In the fast-evolving landscape of display technology, capacitive touch screens have emerged as a popular choice for many applications due to their responsiveness and clarity. However, several alternative technologies can fulfill similar roles, each with unique advantages and disadvantages. This analysis aims to provide international B2B buyers with a comparative overview of capacitive touch screens against resistive touch screens and infrared touch screens, enabling informed decision-making based on specific operational needs.

Comparison Table: Capacitive Touch Screen vs. Alternatives

| Comparison Aspect | Capacitive Touch Screen | Resistive Touch Screen | Infrared Touch Screen |

|---|---|---|---|

| Performance | High sensitivity, multitouch capabilities | Moderate sensitivity, single touch | High sensitivity, multitouch capabilities |

| Cost | Higher initial investment | Lower initial investment | Moderate to high investment |

| Ease of Implementation | Requires specialized hardware | Easier to implement; less complex | Moderate complexity, requires precise alignment |

| Maintenance | Lower maintenance; durable | Higher maintenance; susceptible to wear | Moderate maintenance; sensitive to dust and dirt |

| Best Use Case | Mobile devices, kiosks, high-traffic areas | Industrial applications, environments with heavy use | Public spaces, interactive displays |

Detailed Breakdown of Alternatives

What are the advantages and disadvantages of resistive touch screens?

Resistive touch screens operate by sensing pressure applied to the screen, making them suitable for environments where users may wear gloves or use styluses. Their lower initial cost makes them appealing for budget-conscious buyers. However, they generally offer less clarity and responsiveness compared to capacitive screens. Over time, the pressure-sensitive layers may wear out, necessitating more frequent maintenance and replacements. This technology is best suited for industrial applications or environments where durability and cost are prioritized over performance.

How do infrared touch screens compare to capacitive touch screens?

Infrared touch screens utilize an array of infrared light emitters and sensors around the screen’s edges to detect touch by measuring interruptions in the light beams. This technology offers high sensitivity and supports multitouch functionality, making it an attractive alternative for interactive displays in public settings. However, infrared screens can be more sensitive to environmental factors such as dust and dirt, which may require regular cleaning and maintenance. Additionally, their installation can be more complex compared to capacitive and resistive screens, making them less ideal for all applications.

Conclusion: Choosing the Right Touch Screen Technology for Your Business

When selecting a touch screen solution, B2B buyers must carefully consider their specific use case, budget constraints, and operational environment. Capacitive touch screens excel in scenarios demanding high responsiveness and clarity, making them ideal for consumer-facing devices. On the other hand, resistive touch screens may serve better in industrial settings where durability and cost-efficiency are crucial. Infrared touch screens are well-suited for interactive applications in public spaces but come with higher maintenance requirements. By evaluating these factors, businesses can make informed decisions that align with their operational needs and customer expectations.

Strategic Material Selection Guide for capacitive touch screen

What Are the Key Materials Used in Capacitive Touch Screens?

When selecting materials for capacitive touch screens, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the final product. Below, we analyze four common materials used in capacitive touch screens from a B2B perspective, focusing on insights relevant to international buyers, particularly in Africa, South America, the Middle East, and Europe.

How Does Glass Influence Capacitive Touch Screen Performance?

Key Properties:

Glass is the most common material used for the surface of capacitive touch screens. It offers excellent optical clarity, high scratch resistance, and good chemical stability. Tempered glass can withstand high temperatures and pressure, making it suitable for various environments.

Pros & Cons:

The primary advantage of glass is its durability and aesthetic appeal, providing a premium look and feel. However, it can be more expensive than other materials and may require complex manufacturing processes, such as tempering or coating for anti-glare properties.

Impact on Application:

Glass is compatible with most touch technologies, allowing for high-resolution displays. It is often used in smartphones, tablets, and industrial devices. However, it may not be suitable for extreme conditions where shattering could be a concern.

Considerations for International Buyers:

Buyers should ensure that the glass meets regional standards such as ASTM or DIN for safety and performance. In regions with high humidity or temperature fluctuations, selecting glass with appropriate thermal and humidity resistance is crucial.

What Role Does Polycarbonate Play in Touch Screen Design?

Key Properties:

Polycarbonate is a lightweight, impact-resistant plastic that can withstand significant stress. It has a lower temperature tolerance than glass but offers excellent transparency and can be treated to enhance scratch resistance.

Pros & Cons:

The main advantage of polycarbonate is its resilience and lower cost compared to glass. However, it is more prone to scratching and may yellow over time when exposed to UV light, potentially affecting the display quality.

Impact on Application:

Polycarbonate is often used in rugged devices or environments where weight is a concern, such as handheld devices for fieldwork. Its flexibility allows for innovative designs but may limit the resolution compared to glass.

Considerations for International Buyers:

Buyers should check for compliance with international standards like JIS for impact resistance. In regions with high UV exposure, selecting polycarbonate with UV-stabilizing treatments can enhance longevity.

How Does ITO (Indium Tin Oxide) Affect Touch Screen Functionality?

Key Properties:

Indium Tin Oxide (ITO) is a transparent conductive material widely used in capacitive touch screens. It allows for high conductivity while maintaining optical transparency, crucial for touch sensitivity.

Pros & Cons:

ITO provides excellent touch sensitivity and is essential for multitouch capabilities. However, it is relatively expensive and can be brittle, leading to potential issues during manufacturing and end-use.

Impact on Application:

ITO is integral to the functionality of high-end devices, ensuring accurate touch response. Its brittleness may limit its use in flexible displays or devices subjected to stress.

Considerations for International Buyers:

Buyers should consider sourcing ITO from suppliers who comply with environmental regulations, as indium mining can have ecological impacts. Ensuring that suppliers meet international standards for electronic components is also vital.

What Benefits Does PET (Polyethylene Terephthalate) Offer for Touch Screens?

Key Properties:

PET is a thermoplastic polymer known for its strength, flexibility, and chemical resistance. It is often used as a substrate in capacitive touch screens due to its lightweight and durable nature.

Pros & Cons:

PET is cost-effective and can be produced in various thicknesses, making it versatile for different applications. However, it may not provide the same level of scratch resistance as glass or polycarbonate.

Impact on Application:

PET is commonly used in lower-cost devices or applications where weight and flexibility are prioritized, such as automotive displays or portable electronics.

Considerations for International Buyers:

When sourcing PET, buyers should ensure it meets relevant safety and performance standards, such as RoHS compliance. In regions with high temperatures, selecting PET with enhanced thermal resistance can prevent deformation.

Summary Table of Material Selection for Capacitive Touch Screens

| Material | Typical Use Case for capacitive touch screen | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Smartphones, tablets, industrial devices | High durability and optical clarity | Higher cost and complex manufacturing | High |

| Polycarbonate | Rugged handheld devices | Lightweight and impact-resistant | Prone to scratching and UV degradation | Medium |

| ITO (Indium Tin Oxide) | High-end smartphones and tablets | Excellent touch sensitivity and transparency | Expensive and brittle | High |

| PET (Polyethylene Terephthalate) | Automotive displays, portable electronics | Cost-effective and flexible | Lower scratch resistance compared to glass | Low |

This strategic material selection guide provides vital insights for international B2B buyers, enabling informed decisions tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for capacitive touch screen

What Are the Main Stages of Manufacturing Capacitive Touch Screens?

The manufacturing process of capacitive touch screens involves several key stages, each critical to ensuring the quality and functionality of the final product. Here’s an overview of the main stages:

Material Preparation

The first step in manufacturing capacitive touch screens is the preparation of raw materials. High-quality glass is selected for the display surface due to its durability and optical clarity. Conductive materials, such as indium tin oxide (ITO), are used to create the capacitive layers. The choice of materials significantly impacts the touch screen’s sensitivity, durability, and overall performance.

Forming

Once the materials are prepared, they undergo a forming process. This typically involves cutting the glass to the desired dimensions and applying the conductive layer. The ITO is deposited onto the glass through techniques like sputtering or chemical vapor deposition. This step must be executed with precision to ensure uniformity across the screen, as any inconsistencies can lead to performance issues.

Assembly

The assembly stage involves layering the various components of the touch screen. This includes the glass panel, the conductive layers, and protective coatings. During assembly, careful alignment is crucial, particularly for multi-touch screens that require precise positioning of sensors. The components are often bonded together using optical adhesives, which enhance durability and touch sensitivity.

Finishing

The final stage is finishing, where the touch screen undergoes various treatments to enhance its performance. This may include applying anti-glare or anti-fingerprint coatings, which improve user experience by maintaining clarity and reducing smudges. Additionally, the screens are tested for defects and calibrated to ensure accurate touch responses before packaging.

What Are the Key Quality Control Measures for Capacitive Touch Screens?

Quality control (QC) is essential throughout the manufacturing process to ensure that capacitive touch screens meet international standards and customer expectations. Here are the key QC measures typically implemented:

International and Industry-Specific Standards

B2B buyers should be aware of the relevant international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Additionally, certifications like RoHS (Restriction of Hazardous Substances) ensure that the materials used are safe and environmentally friendly.

QC Checkpoints: How Are They Implemented?

Quality control is often segmented into several checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers are required to provide documentation that proves material quality and compliance with specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production parameters. This ensures that any deviations from quality standards are identified and rectified promptly.

-

Final Quality Control (FQC): Once the touch screens are assembled, they undergo a final inspection. This includes functional testing, visual inspections for defects, and performance evaluations to ensure that the screens meet predefined specifications.

What Common Testing Methods Are Used for Capacitive Touch Screens?

To ensure the quality and reliability of capacitive touch screens, various testing methods are employed:

-

Functional Testing: This involves checking the touch sensitivity and accuracy of the screen under different conditions. Multi-touch functionality is also evaluated to confirm that the screen can detect multiple simultaneous touches.

-

Environmental Testing: Capacitive touch screens must perform well under varying temperature and humidity conditions. Manufacturers often simulate extreme environments to test the screens’ resilience.

-

Durability Testing: This includes drop tests, scratch resistance tests, and other mechanical stress tests to evaluate how well the screens can withstand physical damage.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, ensuring quality from suppliers is critical. Here are some strategies to verify supplier quality control:

Conducting Supplier Audits

Buyers should perform regular audits of their suppliers’ manufacturing facilities. This allows them to assess compliance with quality standards, review processes, and ensure that the necessary QC measures are in place. Audits can also provide insights into the supplier’s capability to meet production demands and timelines.

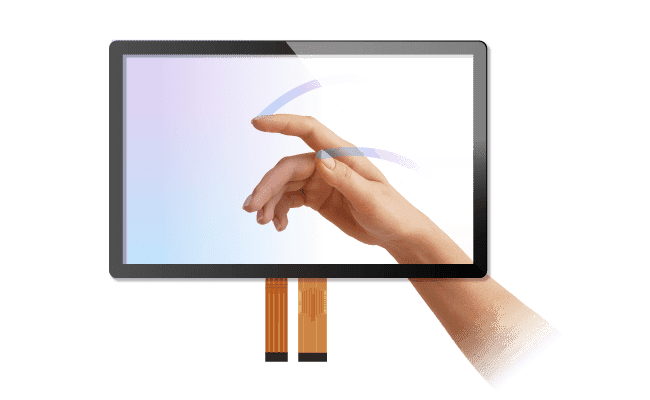

A stock image related to capacitive touch screen.

Requesting Quality Reports

Buyers can request detailed quality reports from suppliers. These reports should include information on testing methodologies, results of various quality checks, and certifications obtained. A transparent supplier will readily provide this documentation, demonstrating their commitment to quality.

Engaging Third-Party Inspection Services

A stock image related to capacitive touch screen.

Utilizing third-party inspection services can add an additional layer of assurance. These independent entities can conduct inspections and testing on behalf of the buyer, providing unbiased evaluations of product quality. This is particularly beneficial for buyers unfamiliar with local suppliers or those looking to mitigate risks.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing capacitive touch screens globally, buyers should consider the nuances of quality control and certification. Different regions may have varying standards, and understanding these can aid in making informed purchasing decisions.

For example, buyers from Europe must ensure that products are CE compliant, while those in Africa may need to consider local standards that differ from international ones. Additionally, awareness of import regulations and certification requirements is crucial to avoid delays and additional costs.

In conclusion, thorough knowledge of the manufacturing processes and quality assurance measures for capacitive touch screens is essential for B2B buyers. By understanding the stages of production, quality control checkpoints, testing methods, and verification strategies, buyers can make informed decisions that align with their business needs and ensure high-quality product procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘capacitive touch screen’

In today’s competitive landscape, sourcing a capacitive touch screen requires careful consideration and planning. This guide serves as a practical checklist for international B2B buyers, helping them make informed decisions when procuring this technology. Follow the steps below to ensure you select the right capacitive touch screen for your needs.

Step 1: Define Your Technical Specifications

Before beginning your search for a capacitive touch screen, it’s essential to outline your technical requirements. Consider factors such as screen size, resolution, and touch sensitivity. For example, a 13.3-inch screen with a resolution of 1920 x 1080 may be ideal for mobile office solutions, while applications in industrial settings may require larger sizes or rugged specifications.

- Consider Environmental Factors: Determine the operating conditions such as temperature range and exposure to dust or moisture. Ensure the screen meets relevant IP ratings (e.g., IP65) for your specific environment.

Step 2: Research Available Technologies

Capacitive touch screens come in various technologies, such as projected capacitive and surface capacitive. Understanding these options will help you choose a solution that best fits your application.

- Projected Capacitive Touch Screens: These screens offer better resolution and do not require backlighting, making them suitable for outdoor use. Evaluate whether multitouch capabilities are essential for your applications.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure they can meet your requirements. Request company profiles, case studies, and references from buyers in similar industries or regions.

- Assess Supplier Experience: Look for suppliers with a proven track record in delivering capacitive touch screens. Verify their experience with international shipping and compliance with local regulations in your region.

Step 4: Verify Supplier Certifications

It’s crucial to ensure that your suppliers meet industry standards and certifications. Common certifications include CE, FCC, RoHS, and REACH, which indicate compliance with safety and environmental regulations.

- Check Quality Assurance Processes: Inquire about the supplier’s quality control measures, including testing for durability and performance under various conditions. This ensures that you are investing in reliable products.

Step 5: Request Samples and Conduct Testing

Before making a bulk purchase, request samples to evaluate the product firsthand. Testing the screens in your specific environment is vital to assess their performance and compatibility with your systems.

- Evaluate User Experience: Focus on touch responsiveness, clarity under different lighting conditions, and ease of cleaning. This will help you gauge how well the screen will perform in real-world scenarios.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, enter into discussions about pricing, lead times, and payment terms. Be clear about your expectations regarding delivery timelines and after-sales support.

- Discuss Warranty and Support: Ensure the supplier offers a reasonable warranty period and reliable support channels. This will protect your investment and provide peace of mind.

Step 7: Finalize Purchase and Monitor Performance

After finalizing the purchase, keep track of the performance of the capacitive touch screens in your operations. Collect feedback from users to identify any issues early on.

- Continuous Improvement: Use this feedback to inform future purchases and supplier evaluations, ensuring that your sourcing strategy evolves with your business needs.

By following these steps, B2B buyers can make informed decisions and successfully source capacitive touch screens that enhance their operations.

Comprehensive Cost and Pricing Analysis for capacitive touch screen Sourcing

What Are the Key Cost Components in Capacitive Touch Screen Sourcing?

When sourcing capacitive touch screens, understanding the cost structure is essential for international B2B buyers. The main cost components include:

-

Materials: The primary materials for capacitive touch screens are glass, conductive coatings, and electronic components. High-quality materials enhance performance but can also increase costs. For instance, using specialized glass that offers better durability and clarity can significantly affect the overall price.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes lead to compromises in quality. In contrast, regions known for advanced manufacturing capabilities may have higher labor costs but provide superior craftsmanship.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, enabling suppliers to offer better pricing.

-

Tooling: Custom tooling for specific designs can incur substantial costs. Buyers should consider whether they require specialized shapes or sizes, as this can significantly impact the overall investment.

-

Quality Control (QC): Rigorous quality checks are essential for ensuring product reliability. While this adds to the cost, it is crucial for minimizing returns and maintaining customer satisfaction.

-

Logistics: Shipping and handling costs are often overlooked. The final price can be influenced by the chosen shipping method, distance from the supplier, and any tariffs or duties applicable to imports.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the competitive landscape can help buyers negotiate better terms.

How Do Price Influencers Affect Capacitive Touch Screen Costs?

Various factors can influence the pricing of capacitive touch screens:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts, making it essential to assess whether your purchasing strategy allows for bulk buying. Smaller orders might incur higher per-unit costs.

-

Specifications and Customization: Custom features such as size, resolution, and touch sensitivity can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The use of premium materials and obtaining certifications (like CE, FCC, RoHS) can enhance the product’s value but also increase costs. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: Supplier reputation, reliability, and location can all affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: The agreed Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can prevent additional costs and delays.

What Buyer Tips Can Help in Negotiating Capacitive Touch Screen Prices?

International buyers, particularly from Africa, South America, the Middle East, and Europe (including Poland and Turkey), should consider the following strategies to optimize their sourcing process:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Establishing a long-term relationship with suppliers can lead to better deals over time.

-

Focus on Total Cost of Ownership (TCO): Instead of just considering the purchase price, evaluate the total cost of ownership, including maintenance, potential failures, and energy consumption. This broader view helps in making informed purchasing decisions.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on geographic location, local regulations, and currency fluctuations. Researching the market and understanding regional pricing norms can provide leverage during negotiations.

-

Leverage Technology for Communication: Utilize digital tools for real-time communication with suppliers. This can expedite negotiations and lead to better outcomes.

Disclaimer on Indicative Prices

Prices for capacitive touch screens can vary widely based on specifications, quantities, and supplier agreements. The figures mentioned in this analysis serve as indicative examples and may not reflect current market conditions. Always seek updated quotes from suppliers to ensure accurate budgeting.

Essential Technical Properties and Trade Terminology for capacitive touch screen

What Are the Essential Technical Properties of Capacitive Touch Screens?

Understanding the technical specifications of capacitive touch screens is crucial for B2B buyers, especially when selecting products that meet specific operational needs. Here are some of the key properties to consider:

1. Resolution: What Does It Mean for Your Display Quality?

Resolution refers to the number of pixels displayed on the screen, commonly expressed as width x height (e.g., 1920 x 1080). Higher resolution means sharper images and clearer text, which are essential for applications requiring detailed visual information, such as in medical or industrial settings. For B2B buyers, choosing a display with appropriate resolution can enhance user experience and productivity.

2. Brightness (Nits): How Does It Affect Visibility?

Brightness, measured in nits, indicates how much light the screen emits. Displays with adjustable brightness levels, such as 1000 nits, are ideal for outdoor or high-glare environments. For buyers in sectors like logistics and public safety, screens that maintain visibility under various lighting conditions are critical for operational efficiency and safety.

3. Touch Sensitivity: Why Is It Important?

Touch sensitivity is the screen’s ability to accurately detect input from a finger or stylus. Capacitive touch screens typically support multi-touch, allowing for simultaneous inputs, which enhances user interaction. This is particularly beneficial for applications like point-of-sale systems or interactive kiosks, where quick and accurate touch responses are necessary.

4. Material Grade: What Should You Look For?

The material used for the touchscreen surface significantly impacts durability and user experience. For instance, anti-glare and anti-reflective coatings improve visibility and reduce fingerprints. Buyers should consider screens made from high-grade materials like Gorilla Glass, which provide resistance to scratches and impacts, essential for rugged environments.

5. Operating Temperature Range: Why It Matters

Operating temperature range defines the ambient temperatures within which the device can function optimally. A range of -20°C to +70°C is common for industrial-grade touch screens. Buyers in extreme climates or specific industries should ensure that their chosen screens can withstand the environmental conditions without performance degradation.

6. Ingress Protection (IP Rating): How Does It Ensure Longevity?

The Ingress Protection rating indicates how well a device is protected against dust and water. An IP65 rating means that the device is dust-tight and can withstand low-pressure water jets, making it suitable for outdoor or industrial applications. Buyers should prioritize screens with high IP ratings to ensure longevity and reliability in challenging conditions.

What Are Common Trade Terms Associated with Capacitive Touch Screens?

Navigating the world of capacitive touch screens involves understanding industry jargon. Here are some essential terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer): What Role Do They Play?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When buying capacitive touch screens, understanding the OEM can help buyers assess product quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost-effectiveness. Buyers should negotiate MOQ to align with their purchasing strategy.

3. RFQ (Request for Quotation): How Do You Use It?

An RFQ is a document sent to suppliers requesting pricing for specific products. For capacitive touch screens, an RFQ can help buyers obtain competitive pricing and terms, making it a vital tool in procurement processes.

4. Incoterms: What Do They Mean for Shipping?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is essential for B2B transactions, as they clarify who bears the costs and risks during transportation, especially for international orders.

5. Lead Time: How Does It Impact Your Operations?

Lead time refers to the time taken from placing an order to receiving it. For businesses that rely on capacitive touch screens for their operations, understanding lead time helps in planning and minimizing disruptions.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing capacitive touch screens tailored to their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the capacitive touch screen Sector

What Are the Key Market Dynamics and Trends in the Capacitive Touch Screen Sector?

The capacitive touch screen market is experiencing rapid growth due to several global drivers. Increasing demand for smart devices across various sectors, including consumer electronics, automotive, and industrial applications, is propelling the market forward. Notably, innovations in projected capacitive technology are enhancing user experience with improved responsiveness and clarity, which are essential for applications in mobile devices and kiosks. Furthermore, the rise of IoT (Internet of Things) devices is expected to escalate the demand for touch interfaces, as these devices often rely on intuitive user interactions.

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of emerging trends such as the integration of artificial intelligence and machine learning into touch screen interfaces. This technology is enabling more sophisticated user interactions and predictive behaviors, which can enhance operational efficiency in various business applications. Additionally, the trend towards customization and personalization in touch screen solutions is gaining traction, allowing companies to tailor products to specific industry needs, such as rugged touch screens for logistics or high-brightness displays for outdoor use.

How Can Sustainability and Ethical Sourcing Impact Capacitive Touch Screen Procurement?

Sustainability is becoming a critical consideration for B2B buyers in the capacitive touch screen market. The environmental impact of electronics manufacturing is significant, and companies are increasingly focusing on ethical sourcing practices. This includes ensuring that materials used in capacitive touch screens, such as indium and tin, are obtained from sustainable sources. Buyers should seek suppliers that adhere to environmental standards and certifications, such as ISO 14001, which signify a commitment to reducing environmental impact.

Furthermore, the demand for ‘green’ certifications is rising, as businesses recognize the importance of sustainable products in their supply chain. Companies can differentiate themselves by sourcing capacitive touch screens that utilize recycled materials or environmentally friendly manufacturing processes. Engaging with suppliers who have transparent supply chains and ethical labor practices not only enhances corporate responsibility but can also improve brand reputation and customer loyalty.

What Is the Historical Context of Capacitive Touch Screen Technology?

Capacitive touch screen technology has evolved significantly since its inception in the 1970s. Initially, it was primarily utilized in specialized applications, but advancements in materials and electronics have transformed it into a mainstream technology. The introduction of projected capacitive touch screens in the early 2000s marked a turning point, offering enhanced performance and multi-touch capabilities that set it apart from resistive technologies. This evolution has paved the way for capacitive touch screens to become ubiquitous in consumer electronics, ranging from smartphones to tablets, and has enabled their adoption in various industrial applications.

As B2B buyers navigate this dynamic market, understanding the historical context of capacitive touch screens can provide valuable insights into future trends and innovations, ensuring they are well-positioned to leverage this technology for their business needs.

Frequently Asked Questions (FAQs) for B2B Buyers of capacitive touch screen

-

How do I solve compatibility issues with capacitive touch screens in different operating environments?

To address compatibility issues with capacitive touch screens, first, ensure that the screen is compatible with the operating systems you plan to use, such as Windows, Android, or Linux. Check the manufacturer’s specifications for supported platforms. Additionally, consider environmental factors such as temperature and humidity, as some screens are rated for extreme conditions. If you’re integrating the touch screen into existing systems, consult with suppliers for potential drivers or firmware updates that enhance compatibility. -

What is the best capacitive touch screen for outdoor use in varying light conditions?

The ideal capacitive touch screen for outdoor applications should feature high brightness levels (ideally above 1000 nits) and anti-glare coatings to enhance visibility in direct sunlight. Look for models with ambient light sensors that automatically adjust brightness based on environmental conditions. A rugged design with IP65 or higher ingress protection is also crucial to ensure durability against dust and moisture, making it suitable for harsh outdoor environments. -

How can I vet suppliers for capacitive touch screens in international markets?

Vetting suppliers involves checking their credentials, certifications, and customer reviews. Request samples to evaluate product quality and performance. Engage in direct communication to assess their responsiveness and willingness to provide technical support. Utilize platforms like Alibaba or Global Sources to find reputable suppliers, and consider conducting on-site visits if feasible. Additionally, verify their compliance with international standards such as CE, RoHS, and FCC to ensure product safety and reliability. -

What are the common minimum order quantities (MOQs) for capacitive touch screens?

Minimum order quantities for capacitive touch screens can vary significantly based on the supplier and the specific product. Generally, MOQs can range from 50 to 500 units for standard models. For customized screens, MOQs may be higher due to increased production costs. Always discuss your requirements directly with the supplier to negotiate MOQs that align with your business needs, especially if you are testing market demand in your region. -

What payment terms should I expect when sourcing capacitive touch screens internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit of 30-50% upfront with the balance paid upon shipment or delivery. Some suppliers may offer net 30 or net 60 terms for established businesses. Consider using secure payment methods like letters of credit or escrow services to mitigate risks. Clarify these terms during negotiations to ensure they meet your cash flow requirements and protect your investment. -

How do I ensure quality assurance (QA) for capacitive touch screens from international suppliers?

To ensure quality assurance, request detailed product specifications and test reports from suppliers. Establish a clear QA process that includes sample testing before large orders. Consider hiring a third-party inspection service to conduct quality checks at the manufacturing site. Additionally, ensure the supplier adheres to international quality standards, such as ISO 9001, which can provide further assurance of their commitment to quality control. -

What logistics considerations should I keep in mind when importing capacitive touch screens?

When importing capacitive touch screens, consider the shipping method (air vs. sea), as air freight is faster but more expensive. Evaluate the import duties, taxes, and customs regulations specific to your country, as these can impact overall costs. Work with a reliable logistics partner who understands international trade complexities. Additionally, ensure proper packaging to protect screens from damage during transit, and plan for any potential delays in customs clearance. -

Can capacitive touch screens be customized for specific business applications?

Yes, many manufacturers offer customization options for capacitive touch screens, including size, resolution, touchscreen technology (e.g., projected capacitive), and additional features like multi-touch capabilities or specific input ports. When discussing customization, provide detailed specifications regarding your application needs, such as environmental conditions or user interface requirements. Ensure to factor in lead times for production and delivery when planning your project timeline.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

A stock image related to capacitive touch screen.

Strategic Sourcing Conclusion and Outlook for capacitive touch screen

In today’s rapidly evolving technology landscape, capacitive touch screens stand out as a pivotal element in enhancing user interaction across various industries. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, strategic sourcing of capacitive touch screens can significantly impact product development and market competitiveness. Key takeaways include the importance of understanding the differences between capacitive and resistive touch technologies, recognizing the benefits of multitouch capabilities, and ensuring compliance with local regulations and standards.

Why is Strategic Sourcing Crucial for Capacitive Touch Screens?

Effective strategic sourcing enables businesses to identify reliable suppliers, negotiate favorable terms, and secure high-quality components that meet specific operational needs. This approach not only reduces costs but also enhances product reliability and performance, which is vital in sectors like retail, logistics, and public safety.

What is the Future Outlook for Capacitive Touch Screen Technology?

As demand for innovative, user-friendly interfaces continues to grow, capacitive touch screens are expected to evolve with advancements in technology. Buyers should remain vigilant in tracking trends such as enhanced durability, improved responsiveness, and integration with IoT devices.

In conclusion, by prioritizing strategic sourcing, international B2B buyers can position themselves for success in the competitive touchscreen market. Explore partnerships with reputable suppliers and stay ahead of technological advancements to maximize your operational efficiency and product offerings.