Discover the Benefits of Flat Washers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for flat washer

In today’s global marketplace, sourcing the right flat washer can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and the UAE. With various materials, sizes, and applications, understanding the nuances of flat washers is essential for maintaining the integrity and longevity of mechanical assemblies. This guide serves as a comprehensive resource, delving into the different types of flat washers available, their specific applications across industries, and critical factors for supplier vetting.

B2B buyers will benefit from actionable insights on cost considerations, material properties, and sourcing strategies tailored to their regional needs. By addressing common challenges such as quality assurance, compliance with international standards, and logistical considerations, this guide empowers businesses to make informed purchasing decisions. Whether you are involved in manufacturing, construction, or automotive sectors, understanding the intricacies of flat washers can enhance operational efficiency and reduce downtime.

Navigating the complexities of the flat washer market requires not just product knowledge but also strategic sourcing practices. This guide is designed to equip international B2B buyers with the necessary tools and insights to optimize their procurement processes, ensuring they can confidently select the right components for their projects while maximizing value.

Understanding flat washer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Flat Washer | Thin, flat disc with a center hole, available in various materials and sizes | General fastening applications in construction and manufacturing | Pros: Versatile, widely available; Cons: May not provide optimal grip for dynamic loads. |

| Fender Washer | Larger outer diameter compared to the inner hole, designed to distribute load | Automotive and heavy machinery applications | Pros: Excellent load distribution; Cons: Bulkier, may not fit in tight spaces. |

| Lock Washer | Features a split design to create tension, preventing loosening | High-vibration environments, such as machinery and automotive | Pros: Effective against loosening; Cons: Can be more expensive than standard washers. |

| Nylon Flat Washer | Made from nylon, providing a non-conductive option for sensitive applications | Electrical and electronic applications | Pros: Lightweight, corrosion-resistant; Cons: Limited temperature resistance compared to metals. |

| Stainless Steel Washer | Corrosion-resistant, available in various grades, ideal for harsh environments | Marine, chemical processing, and outdoor applications | Pros: Durable and long-lasting; Cons: Higher cost than standard steel options. |

What are the Characteristics of Standard Flat Washers?

Standard flat washers are essential components in many fastening systems, offering a broad bearing surface that helps distribute load evenly across the fastened material. They are typically made from materials such as steel, stainless steel, or brass and come in various sizes to accommodate different bolt diameters. When sourcing standard flat washers, B2B buyers should consider the material’s strength and corrosion resistance, especially for applications in construction and manufacturing, where durability is crucial.

How Do Fender Washers Differ from Other Types?

Fender washers are characterized by their larger outer diameter relative to the inner hole, which allows for better load distribution over a wider area. This feature makes them particularly useful in automotive and heavy machinery applications, where uneven surfaces can lead to fastening issues. B2B buyers should evaluate the space constraints of their projects, as fender washers can be bulkier than standard options but provide enhanced stability.

Why Choose Lock Washers for High-Vibration Applications?

Lock washers are designed with a split or bent shape that creates tension when compressed, helping to prevent loosening due to vibration. They are ideal for use in high-vibration environments, such as automotive and machinery applications, where maintaining a secure fastener connection is critical. When purchasing lock washers, buyers should consider the specific vibration levels in their applications to ensure they select an appropriate type.

What Advantages Do Nylon Flat Washers Offer?

Nylon flat washers are a non-conductive option that provides insulation in electrical and electronic applications. Their lightweight nature and resistance to corrosion make them an excellent choice for sensitive environments where metal washers may not be suitable. B2B buyers should assess the temperature and chemical exposure in their applications, as nylon washers may have limitations compared to metal options.

When Should B2B Buyers Opt for Stainless Steel Washers?

Stainless steel washers are known for their exceptional corrosion resistance and durability, making them suitable for use in harsh environments such as marine and chemical processing applications. They are available in various grades, allowing buyers to select the right type based on their specific needs. While the cost is generally higher than standard steel washers, the long-term benefits in terms of performance and longevity often justify the investment.

Key Industrial Applications of flat washer

| Industry/Sector | Specific Application of Flat Washer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine assembly and chassis connections | Enhances stability and reduces vibration-related failures | Material selection (stainless steel vs. carbon steel), corrosion resistance, and size specifications |

| Construction | Structural support in beams and columns | Distributes load evenly, preventing structural failure | Compliance with local building codes, size and load specifications, and material durability |

| Manufacturing | Machinery assembly in production lines | Reduces wear and tear, ensuring longer equipment life | Availability of bulk orders, compatibility with existing machinery, and specific material requirements |

| Electronics | Circuit board assembly | Provides a stable connection for components, minimizing signal loss | Precision in size and thickness, material compatibility, and sourcing from reliable suppliers |

| Renewable Energy | Solar panel and wind turbine installations | Improves durability and performance of renewable systems | Weather resistance, material quality, and compliance with international standards |

How is Flat Washer Used in the Automotive Industry?

In the automotive sector, flat washers are critical components in engine assemblies and chassis connections. They are used to distribute the load of fasteners, reducing the risk of vibration-related failures that can lead to costly repairs and safety issues. Buyers in this industry must consider the material properties, particularly corrosion resistance, as vehicles are often exposed to harsh environmental conditions. Sourcing washers that meet specific size and material standards can significantly enhance the longevity and reliability of automotive components.

What Role Do Flat Washers Play in Construction?

In construction, flat washers are essential for providing structural support in beams and columns. By distributing loads evenly, they help to prevent structural failures that could endanger safety and lead to costly repairs. When sourcing flat washers for construction projects, businesses must ensure compliance with local building codes and material standards. Durability and load specifications are critical factors, especially in regions prone to extreme weather conditions.

How Are Flat Washers Utilized in Manufacturing?

Manufacturing relies heavily on flat washers for machinery assembly within production lines. These washers help reduce wear and tear on machinery by providing a stable surface for bolts and screws, which ultimately extends the equipment’s lifespan. International B2B buyers should focus on the availability of bulk orders and ensure compatibility with existing machinery. Selecting the right material is also crucial, as it affects the performance and durability of the assembly.

Why Are Flat Washers Important in Electronics?

In the electronics industry, flat washers are used during circuit board assembly to ensure stable connections for components. They help minimize signal loss and improve overall functionality. Buyers must pay attention to the precision of size and thickness when sourcing flat washers, as even minor discrepancies can lead to performance issues. Additionally, sourcing from reputable suppliers ensures that the washers meet the stringent quality standards required in electronics.

How Do Flat Washers Contribute to Renewable Energy Systems?

Flat washers play a vital role in renewable energy systems, such as solar panel and wind turbine installations. They enhance the durability and performance of these systems by providing reliable connections that withstand environmental stresses. When sourcing flat washers for renewable energy applications, businesses should prioritize weather resistance and material quality, as these factors directly impact the efficiency and longevity of energy systems. Compliance with international standards is also essential to ensure reliability and safety in these critical applications.

3 Common User Pain Points for ‘flat washer’ & Their Solutions

Scenario 1: Sourcing the Right Size Flat Washers for Specific Applications

The Problem:

B2B buyers often face difficulties when sourcing flat washers that meet the specific size requirements for their projects. In sectors such as construction or manufacturing, the correct fit is crucial for ensuring structural integrity and safety. A buyer might discover that the washers available locally do not match the needed dimensions, such as inner or outer diameters, thickness, or material specifications. This misalignment can lead to project delays, increased costs, and potential safety risks if inappropriate components are used.

The Solution:

To avoid these pitfalls, buyers should invest time in understanding the exact specifications required for their applications. This includes measuring the diameter of the bolts or screws and determining the load distribution needs. Once the specifications are clear, utilize reputable suppliers that provide detailed product descriptions and offer a wide range of flat washers, including custom options if necessary. For international buyers, leveraging online platforms that allow for bulk ordering and comparison of materials can significantly streamline the sourcing process. Furthermore, establishing a good relationship with suppliers can lead to better pricing and availability of the exact sizes needed.

Scenario 2: Addressing Corrosion Issues with Flat Washers

The Problem:

Corrosion is a prevalent issue for flat washers, especially in humid or chemically aggressive environments. B2B buyers in industries like agriculture or marine applications often find that standard steel washers fail prematurely due to rust and degradation. This can result in equipment malfunction, increased maintenance costs, and even project failures, as corroded washers can compromise the integrity of the fastening system.

The Solution:

To combat corrosion, buyers should consider selecting flat washers made from corrosion-resistant materials such as stainless steel or specialized coatings like galvanized or epoxy finishes. It’s essential to evaluate the environmental conditions the washers will be exposed to and choose a material that aligns with these conditions. Additionally, buyers can consult with manufacturers to receive guidance on the best materials for their specific applications. Implementing regular maintenance checks can also help in identifying and replacing corroded washers before they lead to significant issues. Investing in higher-quality, corrosion-resistant washers upfront can save costs in the long run and ensure the reliability of equipment.

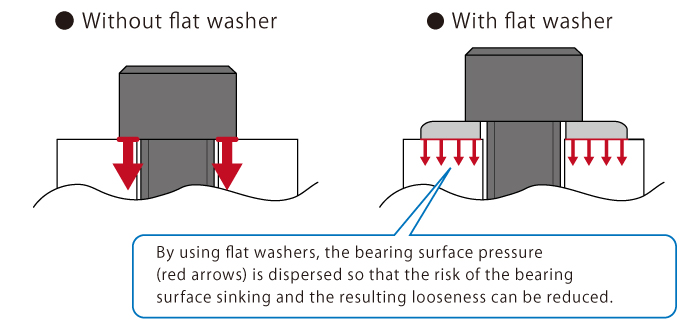

Scenario 3: Preventing Fastener Loosening Over Time

The Problem:

Fastener loosening is a common challenge faced by B2B buyers, particularly in applications involving vibrations, such as in automotive or heavy machinery industries. Flat washers can help distribute load and reduce friction, but if they are not the right type or installed correctly, the risk of loosening increases. This can lead to safety hazards and costly repairs if components fail due to inadequate fastening.

The Solution:

To effectively prevent fastener loosening, buyers should consider using flat washers designed specifically for high-vibration applications, such as lock washers or split washers, in conjunction with standard flat washers. Proper installation techniques are equally important; ensure that washers are installed flat and that the correct torque specifications are adhered to when tightening bolts and screws. Regular inspections should be part of the maintenance routine to check for any signs of loosening and to replace any washers that show signs of wear or damage. Educating team members on the importance of washer selection and installation can help enhance the longevity and safety of assemblies in vibration-prone environments.

Strategic Material Selection Guide for flat washer

What Are the Key Properties of Stainless Steel Flat Washers?

Stainless steel flat washers are widely recognized for their excellent corrosion resistance, making them suitable for various applications, especially in humid or corrosive environments. They can withstand high temperatures, typically rated up to 1,000°F (538°C), depending on the specific grade. The most common grades used in flat washers are 304 and 316, with 316 offering superior resistance to chlorides, making it ideal for marine applications.

Pros & Cons:

Stainless steel washers are durable and provide long-lasting performance, but they can be more expensive than other materials. The manufacturing process can also be complex, leading to higher costs. However, their resistance to rust and corrosion makes them a preferred choice for applications in the Middle East and coastal regions of Africa and South America.

Impact on Application:

These washers are compatible with a variety of media, including water and chemicals, making them versatile for industrial use. They are often required in compliance with ASTM standards, which are recognized globally.

How Do Carbon Steel Flat Washers Compare?

Carbon steel flat washers are known for their strength and load-bearing capacity. They are typically coated with zinc or other finishes to enhance corrosion resistance, but they are not as resistant as stainless steel. The temperature rating for carbon steel washers is generally lower, around 400°F (204°C).

Pros & Cons:

The primary advantage of carbon steel washers is their cost-effectiveness, making them a popular choice for large-scale projects. However, their susceptibility to rust and corrosion limits their use in harsh environments. This can be a significant consideration for buyers in humid or coastal regions.

Impact on Application:

Carbon steel washers are suitable for general-purpose applications but may not be ideal for use with aggressive chemicals. Buyers should consider the environmental conditions of their specific applications and whether they need to comply with local standards.

What Are the Benefits of Nylon Flat Washers?

Nylon flat washers offer unique properties, such as lightweight and excellent insulation. They are resistant to chemicals and moisture, making them suitable for electrical applications. Nylon washers can typically handle temperatures up to 185°F (85°C).

Pros & Cons:

While nylon washers are non-conductive and prevent galvanic corrosion, they are not as strong as metal washers. Their cost is generally moderate, but they may not be suitable for high-load applications due to their lower tensile strength.

Impact on Application:

These washers are ideal for applications where electrical insulation is crucial, such as in electronics or automotive industries. Buyers should ensure compliance with relevant standards, particularly in Europe, where regulations on materials can be stringent.

What Makes Brass Flat Washers a Unique Choice?

Brass flat washers are known for their aesthetic appeal and corrosion resistance, particularly in marine environments. They can withstand moderate temperatures and pressures, making them suitable for plumbing and electrical applications.

Pros & Cons:

Brass washers are durable and resistant to corrosion; however, they can be more expensive than carbon steel options. Their softness can lead to deformation under high loads, which may limit their use in heavy-duty applications.

Impact on Application:

Brass washers are often preferred in decorative applications or where low electrical conductivity is desired. Buyers in Europe and the UAE should ensure that brass materials meet local standards, as regulations can vary significantly.

Summary Table of Material Properties for Flat Washers

| Material | Typical Use Case for flat washer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine applications, chemical processing | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | General-purpose fastening | Cost-effective for bulk orders | Susceptible to rust and corrosion | Low |

| Nylon | Electrical insulation, light-duty applications | Lightweight and non-conductive | Lower load-bearing capacity | Med |

| Brass | Plumbing, decorative applications | Aesthetic appeal and corrosion resistance | Softer material, prone to deformation | Med |

This guide provides a detailed overview of the properties, advantages, and limitations of various flat washer materials, tailored for international B2B buyers. Understanding these factors can significantly impact purchasing decisions and application suitability, especially in diverse markets across Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for flat washer

What Are the Key Stages in the Manufacturing Process of Flat Washers?

The manufacturing of flat washers involves several key stages that ensure the final product meets the required specifications and quality standards. Understanding these stages can help international B2B buyers assess suppliers more effectively.

Material Preparation: How Is the Right Material Chosen?

The manufacturing process begins with selecting the appropriate materials. Flat washers are typically made from various materials including stainless steel, carbon steel, and nylon, depending on their intended application. Buyers should consider the specific requirements of their projects, such as corrosion resistance, load-bearing capacity, and environmental conditions. Common materials include:

- Stainless Steel: Known for its corrosion resistance and strength, ideal for outdoor applications.

- Carbon Steel: Often used for its strength but may require additional coatings for corrosion protection.

- Nylon: Used in applications requiring insulation or non-conductivity.

Once the material is selected, it is cut into sheets or strips, depending on the washer’s final dimensions.

Forming: What Techniques Are Used to Shape Flat Washers?

The forming stage involves shaping the flat washers using several techniques:

- Stamping: This is the most common method for producing flat washers. Metal sheets are fed into a stamping press, where a die cuts out the washer shape. This method allows for high-volume production and consistency in size.

- Laser Cutting: For more complex shapes or lower volume runs, laser cutting can be employed. It offers precision and flexibility in design.

- Punching: Similar to stamping, this method uses a punch press to create washers from sheet metal. It is suitable for producing washers with specific dimensions or features.

These techniques ensure that the washers have uniform thickness and precise dimensions, which are crucial for their performance.

Assembly and Finishing: How Are Flat Washers Prepared for Use?

After forming, the washers undergo assembly and finishing processes:

- Deburring: Edges are smoothed to remove sharp edges, which can prevent injury during handling and installation.

- Surface Treatment: Depending on the application, flat washers may receive surface treatments such as galvanization, powder coating, or passivation to enhance corrosion resistance. This is particularly important for washers that will be exposed to harsh environments.

Finally, the washers are packaged for shipping, ready for distribution to customers.

What Quality Assurance Measures Are Essential for Flat Washers?

Quality assurance (QA) is critical in ensuring that flat washers meet international standards and buyer specifications. B2B buyers should be aware of various QA measures employed by manufacturers.

Which International Standards Should Flat Washer Manufacturers Adhere To?

International standards such as ISO 9001 set the framework for quality management systems. Manufacturers should have certifications that demonstrate their commitment to quality and continuous improvement. Specific standards relevant to flat washers include:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Particularly relevant for washers used in oil and gas applications, ensuring they meet industry-specific requirements.

These certifications help buyers verify that the products are manufactured to recognized quality standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is implemented at various checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing ensure that the processes are producing components within tolerance limits.

- Final Quality Control (FQC): The completed washers are subjected to final inspections, including dimensional checks, visual inspections, and functional tests.

These checkpoints are essential for maintaining quality throughout the manufacturing process.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure their suppliers maintain robust quality control practices:

- Supplier Audits: Conducting regular audits of suppliers’ facilities can provide insights into their manufacturing processes and QC practices.

- Requesting Quality Reports: Buyers should ask for documentation of quality control measures, including inspection reports and compliance certifications.

- Third-Party Inspections: Engaging third-party inspection services can provide unbiased verification of the supplier’s quality control processes and product quality.

What Testing Methods Are Commonly Used for Flat Washers?

Several testing methods are employed to ensure that flat washers meet the required specifications:

- Dimensional Testing: Measurements are taken to ensure that the washers conform to specified dimensions.

- Material Testing: Tests such as tensile strength and hardness tests confirm that the materials used meet industry standards.

- Corrosion Resistance Testing: For washers intended for use in corrosive environments, tests are conducted to evaluate their resistance to rust and degradation over time.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing flat washers internationally, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should consider several nuances:

- Understanding Regional Standards: Different regions may have varying quality standards and certifications. Familiarizing oneself with these can prevent compliance issues.

- Language and Communication Barriers: Ensure that communication with suppliers is clear, especially regarding quality expectations and specifications.

- Cultural Differences: Be aware of cultural differences that may affect business practices and negotiations.

By taking these factors into account, B2B buyers can enhance their procurement processes and ensure they are sourcing high-quality flat washers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flat washer’

To successfully procure flat washers for your business needs, following a structured sourcing checklist is essential. This guide will help international B2B buyers, especially from Africa, South America, the Middle East, and Europe, navigate the complexities of sourcing flat washers effectively.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for flat washers is the first step in the procurement process. Consider factors such as:

– Material: Choose from stainless steel, galvanized, nylon, or carbon steel based on corrosion resistance and strength needs.

– Dimensions: Specify inner and outer diameters, as well as thickness, to ensure compatibility with bolts and screws.

Step 2: Research Market Prices and Trends

Conduct thorough research to understand the current market rates for flat washers. This includes:

– Comparing Suppliers: Look at various suppliers across different regions to gauge pricing.

– Monitoring Trends: Stay informed about any fluctuations in material costs or changes in demand that could affect pricing.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, it’s crucial to vet them thoroughly. Consider the following:

– Company Profile: Request detailed information about the supplier’s history, capabilities, and production processes.

– Client References: Seek testimonials from other businesses, particularly those in your industry or region, to assess reliability and quality.

Step 4: Verify Supplier Certifications

Ensuring that suppliers meet industry standards is vital for quality assurance. Look for:

– ISO Certification: This indicates adherence to international quality management standards.

– Material Certifications: Check for compliance with standards like ASTM or SAE, especially if you are sourcing for specific applications like automotive or construction.

Step 5: Request Samples for Testing

Before committing to a large order, always request samples. This allows you to:

– Test Quality: Evaluate the flat washers for durability, size accuracy, and material properties.

– Assess Compatibility: Ensure the washers fit perfectly with your existing bolts or screws during assembly.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate favorable terms. Focus on:

– Pricing Structures: Discuss bulk order discounts or long-term contracts for better pricing.

– Delivery and Lead Times: Confirm lead times to ensure they align with your project timelines.

Step 7: Establish a Reliable Communication Channel

Effective communication is key to successful sourcing. Ensure you:

– Set Regular Check-Ins: Establish a schedule for updates on order status, production timelines, and any potential issues.

– Utilize Multiple Channels: Engage through email, phone calls, or even video conferencing for clarity and responsiveness.

By following this checklist, B2B buyers can ensure a streamlined and effective sourcing process for flat washers, ultimately leading to successful procurement and project execution.

Comprehensive Cost and Pricing Analysis for flat washer Sourcing

What Are the Key Cost Components in Flat Washer Sourcing?

Understanding the cost structure of flat washers is essential for international B2B buyers. The primary components influencing the total cost include:

-

Materials: The type of material significantly impacts the price. Stainless steel, for instance, is generally more expensive than carbon steel or nylon. Prices can also vary based on the quality of the material, such as corrosion resistance or specific certifications like ASTM.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. These costs can vary based on the location of the manufacturing facility, with regions like Europe often having higher labor costs compared to some parts of Africa or South America.

-

Manufacturing Overhead: This includes costs associated with the production facility, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Depending on the complexity of the flat washer design, tooling costs can vary significantly. Custom designs may require specialized molds or machinery, increasing the upfront investment.

-

Quality Control (QC): Ensuring product quality incurs additional costs. Rigorous testing and certification processes, particularly for high-spec applications in industries like automotive or aerospace, can increase overall expenses.

-

Logistics: Transportation costs, including shipping, customs duties, and warehousing, are critical, especially for international buyers. These costs can fluctuate based on distance, shipping method, and current market conditions.

-

Margin: Supplier margins can vary based on market demand and competition. Understanding the supplier’s pricing strategy is vital for effective negotiation.

How Do Price Influencers Affect Flat Washer Costs?

Several factors can influence the pricing of flat washers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should negotiate terms that align with their purchasing power.

-

Specifications and Customization: Customized flat washers designed for specific applications may incur additional charges. Buyers should clearly outline their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, ASME) can elevate prices but are crucial for applications requiring reliability. Buyers should weigh the cost against the benefits of enhanced durability and performance.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Local suppliers may offer better logistics and lower shipping costs, while overseas suppliers might provide lower material costs.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential as they define the responsibilities of buyers and sellers in shipping and logistics. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total costs.

What Are Effective Buyer Tips for Cost-Efficient Flat Washer Sourcing?

To optimize sourcing costs and enhance value, consider the following strategies:

-

Negotiate Pricing: Leverage your purchasing volume and establish long-term relationships with suppliers to negotiate better rates. Highlighting your commitment can encourage suppliers to offer discounts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider long-term costs associated with maintenance, replacement, and logistics. Choosing a higher-quality flat washer may reduce the frequency of replacements.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, international tariffs, and trade agreements that may impact pricing when sourcing from different regions, particularly from Africa, South America, the Middle East, and Europe.

-

Conduct Market Research: Regularly assess market trends and pricing benchmarks to make informed decisions. Understanding the competitive landscape can provide leverage during negotiations.

Disclaimer on Pricing

Prices for flat washers can fluctuate based on market conditions, material availability, and supplier pricing strategies. Always request current quotations and consider multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing flat washer With Other Solutions

Introduction to Alternative Solutions for Flat Washers

When selecting fastening solutions, international B2B buyers must evaluate various options beyond the traditional flat washer. Alternatives can offer unique benefits that may better suit specific applications, environments, or budget constraints. Understanding these alternatives enables buyers to make informed decisions that optimize performance and cost-effectiveness.

Comparison Table of Flat Washers and Alternatives

| Comparison Aspect | Flat Washer | Split Lock Washer | Fender Washer |

|---|---|---|---|

| Performance | Distributes load effectively; enhances stability | Provides spring tension to prevent loosening | Increases load distribution; larger bearing surface |

| Cost | Generally low-cost, affordable | Similar price range, slightly higher due to complexity | Moderate cost, varies with size and material |

| Ease of Implementation | Easy to install with standard tools | Requires specific installation techniques | Simple installation, but may need larger holes |

| Maintenance | Minimal maintenance required; durable | May require periodic checks for tension | Low maintenance; corrosion resistance varies by material |

| Best Use Case | General applications; ideal for machinery | Automotive applications; vibration-prone environments | Situations needing a larger surface area, like decking |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Split Lock Washers?

Split lock washers are designed to provide a spring-like tension that helps to secure bolts and screws in place. Their unique design allows them to compress and expand, creating a tighter fit that is especially effective in environments prone to vibration, such as automotive and industrial applications. While they are slightly more expensive than flat washers, their added security may justify the cost. However, installation can be more complex, and periodic checks may be necessary to ensure they maintain adequate tension.

A stock image related to flat washer.

How Do Fender Washers Compare to Flat Washers?

Fender washers feature a larger outer diameter compared to standard flat washers, making them ideal for distributing loads over a wider surface area. This characteristic is particularly beneficial in applications like decking or thin materials where a standard washer might pull through. While fender washers offer excellent load distribution, they typically come at a moderate cost and may require larger holes for installation. Their maintenance is generally low, but the choice of material, especially regarding corrosion resistance, should be carefully considered based on the environment.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate fastening solution requires a thorough understanding of your specific application and requirements. Flat washers provide an economical and effective option for many general uses, while alternatives like split lock washers and fender washers can enhance performance in specialized scenarios. By evaluating factors such as performance, cost, ease of implementation, and maintenance, B2B buyers can confidently choose the best solution that aligns with their operational needs and budget constraints. Engaging with suppliers who can provide detailed product specifications and application advice will further ensure a successful procurement process.

Essential Technical Properties and Trade Terminology for flat washer

What Are the Essential Technical Properties of Flat Washers?

When sourcing flat washers, understanding their technical specifications is critical for ensuring compatibility and performance in your applications. Here are key properties to consider:

1. Material Grade: What Should You Choose?

Flat washers are typically made from materials like stainless steel, carbon steel, and nylon. The material grade affects corrosion resistance, strength, and application suitability. For instance, 304 and 316 stainless steel are commonly used for their superior corrosion resistance, making them ideal for outdoor or humid environments. Choosing the right material can enhance the longevity of your assembly, reducing replacement costs and downtime.

2. Washer Thickness: Why Does It Matter?

The thickness of a flat washer can significantly impact its load-bearing capacity and flexibility. Thicker washers can distribute loads more effectively, which is crucial in high-stress applications. However, excessive thickness may lead to difficulties in fitting or misalignment. Ensure that you select a washer thickness that aligns with the specifications of your bolts or screws for optimal performance.

3. Inner and Outer Diameter: How to Ensure Proper Fit?

The inner diameter (ID) must match the bolt size, while the outer diameter (OD) should be sufficient to provide adequate load distribution. For example, a washer with an ID of 1/4 inch and an OD of 1 inch will fit a 1/4 inch bolt and provide a broader bearing surface. Proper sizing is essential to prevent damage to the surface being fastened and to maintain connection integrity.

4. Finish Type: Which One Should You Consider?

Flat washers come with various finishes, such as galvanized, zinc-plated, or uncoated. The finish affects the washer’s resistance to rust and wear. For example, galvanized finishes offer enhanced protection against corrosion, making them suitable for outdoor applications. Understanding the finish type is vital in selecting a washer that meets environmental and operational demands.

What Are Common Trade Terms Associated with Flat Washers?

Familiarizing yourself with trade terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms to know:

1. OEM (Original Equipment Manufacturer): What Does It Imply?

OEM refers to companies that manufacture products that are used as components in another company’s end product. Understanding OEM specifications helps buyers ensure that the washers meet the required standards for quality and compatibility.

2. MOQ (Minimum Order Quantity): How Does It Affect Pricing?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ can help you budget and plan your inventory more effectively. Suppliers may offer better pricing for larger orders, so consider your volume needs when negotiating.

3. RFQ (Request for Quotation): Why Is It Important?

An RFQ is a document sent to suppliers requesting a quote for specific products. It is crucial for B2B buyers to detail their requirements, including specifications and quantities, to receive accurate pricing and availability information.

4. Incoterms (International Commercial Terms): How Do They Impact Shipping?

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms can help you manage shipping costs, insurance, and risk during transit, ensuring a smoother purchasing process.

5. Lead Time: What Should You Expect?

Lead time refers to the time taken from placing an order to receiving the product. It can vary based on supplier location, order size, and production schedules. Knowing the lead time allows you to plan your projects more effectively and avoid delays.

By grasping these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions regarding flat washers, ultimately enhancing the efficiency and reliability of their operations.

Navigating Market Dynamics and Sourcing Trends in the flat washer Sector

What Are the Current Market Dynamics and Key Trends in the Flat Washer Sector?

The global flat washer market is witnessing significant growth driven by various factors, including the expansion of the construction and automotive industries. International B2B buyers from Africa, South America, the Middle East, and Europe should be aware of the increasing demand for high-quality fasteners, particularly flat washers, which are essential for ensuring stability and reliability in mechanical assemblies. One emerging trend is the integration of smart technology in manufacturing processes, enhancing production efficiency and quality control. For instance, the use of IoT devices in factories allows for real-time monitoring and data collection, enabling manufacturers to respond swiftly to market changes.

Moreover, the flat washer market is seeing a shift towards the utilization of advanced materials, such as corrosion-resistant stainless steel and environmentally friendly options. Buyers should prioritize suppliers who offer a diverse range of materials and finishes, as this flexibility can cater to various applications across sectors. Additionally, global supply chains are becoming more complex due to geopolitical factors and trade regulations, which necessitates thorough market research and risk assessment for sourcing strategies.

How Is Sustainability and Ethical Sourcing Reshaping the Flat Washer Industry?

Sustainability is increasingly at the forefront of business operations, influencing how B2B buyers approach sourcing flat washers. The environmental impact of manufacturing processes, particularly in the extraction of raw materials and energy consumption, is prompting companies to seek suppliers with robust sustainability practices. Ethical sourcing is essential not only for compliance with regulations but also for enhancing brand reputation and customer trust.

Buyers should look for suppliers that offer ‘green’ certifications or use recycled materials in their flat washer production. Certifications such as ISO 14001 for environmental management systems can provide assurance of a supplier’s commitment to sustainable practices. Furthermore, incorporating eco-friendly materials, such as biodegradable plastics or recycled metals, can significantly reduce the carbon footprint associated with the lifecycle of flat washers. This shift towards sustainability not only aligns with global environmental goals but also meets the growing demand from end-users for responsible sourcing.

What Is the Historical Context of Flat Washers in the B2B Market?

The evolution of flat washers traces back to the early days of mechanical fastening, where their primary function was to distribute load and reduce friction in bolted joints. Over the decades, advancements in manufacturing technology and materials science have significantly transformed the flat washer sector. Initially made from simple materials like iron, modern flat washers are now available in a variety of materials, including stainless steel, nylon, and composite materials, catering to diverse industrial needs.

A stock image related to flat washer.

As industries evolved, so did the specifications and applications of flat washers. The automotive and aerospace sectors, in particular, have driven innovations in washer design, such as the introduction of specialized coatings for enhanced durability and corrosion resistance. Today, flat washers are not only integral to mechanical assemblies but also play a crucial role in ensuring safety and performance across various applications, making them a vital consideration for international B2B buyers. Understanding this evolution helps buyers appreciate the product’s value and make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of flat washer

-

How do I select the right flat washer for my application?

Selecting the appropriate flat washer involves considering the bolt size, material, and application environment. First, match the inner diameter of the washer to the bolt size to ensure a snug fit. For material, stainless steel is ideal for corrosion resistance, particularly in humid or coastal areas, while zinc-plated options provide good durability for general applications. Additionally, consider the washer’s thickness and outer diameter to ensure it can adequately distribute load and prevent damage to the surface being fastened. -

What is the best material for flat washers used in outdoor applications?

For outdoor applications, stainless steel flat washers are highly recommended due to their excellent corrosion resistance and durability. They withstand harsh weather conditions and exposure to moisture without degrading. If budget constraints are a concern, hot-dipped galvanized steel washers can be a cost-effective alternative, providing reasonable protection against rust and corrosion while being suitable for various outdoor settings. -

What are the key factors to consider when vetting international suppliers for flat washers?

When vetting international suppliers, consider their certifications, production capacity, and lead times. Look for suppliers with ISO certifications to ensure quality standards. Evaluate their responsiveness and customer service, as this can indicate reliability. Additionally, request samples to assess product quality firsthand. Finally, check their track record for on-time deliveries and compliance with international shipping regulations to mitigate supply chain risks. -

What are the typical payment terms for international flat washer orders?

Payment terms for international orders often vary based on supplier policies and buyer relationships. Common terms include advance payment, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that balance risk and cash flow. For new suppliers, consider starting with smaller orders and using secure payment methods like PayPal or escrow services to protect your investment until trust is established. -

How can I customize flat washers for specific applications?

Many suppliers offer customization options for flat washers, including variations in size, thickness, and material. To initiate customization, provide detailed specifications such as dimensions, material preferences, and any surface treatments required. Discuss your application needs with the supplier to ensure they can meet your requirements. Be aware that custom orders may have higher minimum order quantities (MOQs) and longer lead times. -

What is the minimum order quantity (MOQ) for flat washers in international trade?

The MOQ for flat washers can vary significantly between suppliers and depends on factors like material type and manufacturing capabilities. Typically, MOQs can range from 100 to 1,000 pieces. It’s crucial to confirm MOQs during the initial discussions with potential suppliers to ensure they align with your purchasing needs. Some suppliers may offer flexibility for larger orders or ongoing contracts. -

What quality assurance measures should I expect from flat washer suppliers?

Reputable flat washer suppliers should implement stringent quality assurance measures, including material inspections, dimensional checks, and load testing. Request documentation of their quality control processes and any certifications they hold, such as ISO 9001. Additionally, inquire about their return policy and warranty to ensure they stand behind their products in case of defects or inconsistencies. -

What logistics considerations should I keep in mind when importing flat washers?

When importing flat washers, consider shipping methods, customs clearance, and potential tariffs. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your timeline. Ensure you have a clear understanding of customs regulations in your country, including necessary documentation and duties. Partnering with a reliable logistics provider can help streamline the process and avoid unexpected delays or costs.

A stock image related to flat washer.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for flat washer

In conclusion, strategic sourcing of flat washers is essential for international B2B buyers aiming to enhance their supply chain efficiency and product quality. By understanding the diverse types, materials, and finishes available, businesses can select the right flat washers that meet their specific application requirements, whether in automotive, manufacturing, or construction sectors.

How Can Strategic Sourcing Benefit Your Business?

Investing in strategic sourcing not only reduces costs but also mitigates risks associated with supply chain disruptions. Buyers from Africa, South America, the Middle East, and Europe should leverage supplier relationships to secure favorable terms and ensure consistent quality. Additionally, considering local suppliers can lead to reduced lead times and improved service levels.

What’s Next for International B2B Buyers?

Looking ahead, international buyers are encouraged to stay informed about market trends and innovations in fasteners. Embracing digital platforms for sourcing can further enhance procurement processes. As the demand for reliable fastening solutions continues to rise, prioritizing strategic sourcing will position your business for success. Engage with suppliers today to explore sustainable options that align with your operational goals.