Discover the Benefits of Hot Water Pressure Washer (2025)

Introduction: Navigating the Global Market for hot water pressure washer

In a competitive global marketplace, sourcing the right hot water pressure washer is crucial for businesses seeking efficiency and reliability in their cleaning operations. With a diverse range of models available, international B2B buyers face the challenge of identifying the best solutions that align with their specific needs and regional conditions. This guide is designed to navigate you through the complexities of the hot water pressure washer market, offering insights into various types, their applications across industries, and practical tips for supplier vetting.

Understanding the intricacies of hot water pressure washers can directly impact operational efficiency, especially in regions such as Africa, South America, the Middle East, and Europe, including countries like Spain and the UAE. This comprehensive resource will cover essential topics such as cost considerations, maintenance requirements, and performance metrics. We aim to equip you with the knowledge to make informed purchasing decisions that not only meet your immediate cleaning needs but also ensure long-term value for your investment.

By leveraging the insights provided in this guide, you will be better positioned to evaluate suppliers, compare product offerings, and select hot water pressure washers that enhance your operational capabilities. Join us as we explore the key factors that will empower your organization to thrive in an increasingly globalized economy.

Understanding Search Intent for ‘hot water pressure washer’

When users search for **”hot water pressure washer”**, Google’s results indicate a strong **informational intent**. This means users are primarily looking to learn and understand the topic. They want definitions, explanations, and foundational knowledge about ‘hot water pressure washer’.

Our analysis of the search engine results page (SERP) reveals several key features that shape this article:

* **Presence of Video Content:** No.

* **Shopping Ad Integration:** No.

* **’People Also Ask’ Questions:** We found 0 relevant user questions, which we have directly addressed in our FAQ and other sections to resolve common user queries.

This data-driven approach ensures our content directly matches what users are looking for, providing a more professional and helpful resource.

Understanding hot water pressure washer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Hot Water Pressure Washer | Compact, quieter operation, lower maintenance | Indoor cleaning, food processing, hospitals | Pros: Low noise, energy-efficient. Cons: Limited power for heavy-duty tasks. |

| Diesel Hot Water Pressure Washer | High power output, portable, rugged design | Construction sites, outdoor cleaning, agriculture | Pros: High mobility, suitable for tough jobs. Cons: Higher fuel costs, more emissions. |

| Gas-Powered Hot Water Pressure Washer | Powerful, versatile, ideal for remote locations | Industrial cleaning, fleet maintenance | Pros: High pressure and flow rates. Cons: Requires more maintenance, noise levels. |

| Trailer-Mounted Hot Water Pressure Washer | Mobile, large capacity, built for heavy use | Large-scale industrial cleaning, municipalities | Pros: High efficiency, large water supply. Cons: Requires a towing vehicle, higher initial investment. |

| Skid-Mounted Hot Water Pressure Washer | Fixed installation, space-saving, customizable | Permanent installations, manufacturing plants | Pros: Optimized for specific tasks, durable. Cons: Less portable, installation costs. |

What Are the Characteristics of Electric Hot Water Pressure Washers?

Electric hot water pressure washers are designed for operations requiring lower noise levels and minimal maintenance. They are ideal for indoor use, such as hospitals, food processing facilities, and other environments where cleanliness is paramount. When considering an electric model, B2B buyers should evaluate the power requirements and ensure that the facility’s electrical infrastructure can support the machine’s operation. Additionally, the lower emissions make them suitable for businesses focused on sustainability.

How Do Diesel Hot Water Pressure Washers Stand Out?

Diesel hot water pressure washers are known for their high power output and rugged design, making them ideal for construction sites and outdoor cleaning applications. Their portability allows for use in remote locations without access to electricity. However, buyers should consider the higher fuel costs and environmental impact associated with diesel engines. Companies in sectors requiring mobility and power for tough cleaning tasks will find diesel models particularly beneficial.

What Benefits Do Gas-Powered Hot Water Pressure Washers Offer?

Gas-powered hot water pressure washers combine versatility with high pressure and flow rates, making them suitable for industrial cleaning and fleet maintenance. They excel in remote or outdoor conditions where electrical connections may not be available. However, potential buyers should factor in the maintenance requirements and noise levels associated with gas engines. For businesses that demand robust cleaning solutions, gas-powered models represent a compelling option.

Why Choose a Trailer-Mounted Hot Water Pressure Washer?

Trailer-mounted hot water pressure washers are designed for large-scale industrial cleaning and municipal applications. Their mobile nature and large water supply make them efficient for extensive cleaning tasks. When investing in this type, businesses should consider the need for a towing vehicle and the initial investment cost. This solution is ideal for companies that require high efficiency and mobility in their cleaning operations.

What Are the Advantages of Skid-Mounted Hot Water Pressure Washers?

Skid-mounted hot water pressure washers offer a space-saving solution that can be customized for specific applications, making them suitable for permanent installations in manufacturing plants. Their durability ensures long-term use, but buyers should be aware of the installation costs and the lack of portability. This type is best for businesses that have a fixed cleaning location and require tailored solutions for their operations.

Related Video: First Time Using Magnum 4000 Series Hot Water Pressure Washer

Key Industrial Applications of hot water pressure washer

| Industry/Sector | Specific Application of Hot Water Pressure Washer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Cleaning production equipment and surfaces | Ensures compliance with hygiene standards, reducing risk of contamination | Evaluate temperature control features and chemical compatibility |

| Automotive Manufacturing | Degreasing and cleaning machinery and components | Increases equipment lifespan and maintains production efficiency | Look for durability and ease of mobility in various environments |

| Construction and Heavy Equipment | Cleaning construction machinery and vehicles | Enhances operational efficiency and reduces downtime | Consider portability and adaptability to various surfaces |

| Agriculture | Cleaning livestock facilities and equipment | Improves animal health and farm hygiene | Assess water pressure and temperature settings for effectiveness |

| Oil and Gas | Cleaning pipelines and drilling equipment | Prevents corrosion and extends lifespan of assets | Ensure compliance with safety standards and environmental regulations |

How is a Hot Water Pressure Washer Used in Food Processing?

In the food processing industry, hot water pressure washers are essential for maintaining cleanliness in production areas and equipment. They effectively remove grease, food residues, and contaminants that can compromise hygiene. By utilizing high-temperature water, these machines not only clean but also sanitize surfaces, ensuring compliance with strict health regulations. International buyers should prioritize models that offer adjustable temperature settings and compatibility with food-safe detergents to meet local health standards in their regions, such as those in Africa and the Middle East.

What Role Does a Hot Water Pressure Washer Play in Automotive Manufacturing?

In automotive manufacturing, hot water pressure washers are employed to degrease and clean machinery, tools, and vehicle components. The combination of high pressure and hot water dislodges stubborn grime, enhancing machine performance and extending the lifespan of expensive equipment. For B2B buyers in Europe and South America, sourcing machines that are robust, portable, and equipped with quick-connect fittings can facilitate efficient cleaning processes, ultimately leading to reduced operational costs and improved productivity.

How Do Hot Water Pressure Washers Benefit Construction and Heavy Equipment Cleaning?

Construction and heavy equipment often accumulate dirt, mud, and grease, which can hinder performance. Hot water pressure washers are effective in cleaning these assets, improving operational efficiency and minimizing downtime due to maintenance. Buyers in regions like Africa and the Middle East should consider the machine’s mobility and versatility, as construction sites can vary greatly in terrain and accessibility. Evaluating models with adjustable pressure settings can also help tailor cleaning to specific equipment types, ensuring thorough cleanliness without damaging surfaces.

Why is a Hot Water Pressure Washer Important for Agriculture?

In agriculture, maintaining clean livestock facilities and equipment is crucial for animal health and productivity. Hot water pressure washers can effectively eliminate manure, feed residues, and pathogens, promoting a healthier environment for livestock. For international buyers, particularly in South America and Europe, it is important to assess the pressure and temperature capabilities of the washer to ensure it meets the specific needs of their operations. Additionally, ease of use and maintenance should be key considerations to ensure consistent application in the field.

How is a Hot Water Pressure Washer Used in the Oil and Gas Industry?

In the oil and gas sector, hot water pressure washers are vital for cleaning pipelines and drilling equipment. They help prevent corrosion and buildup that can lead to operational inefficiencies and costly repairs. B2B buyers in this industry should focus on sourcing machines that comply with safety standards and environmental regulations, especially in regions like the Middle East where strict compliance is mandatory. Features such as high-temperature capabilities and robust construction materials are critical to withstand the harsh working conditions typically found in oil and gas operations.

Related Video: How To Use A Hot Water Pressure Washer

3 Common User Pain Points for ‘hot water pressure washer’ & Their Solutions

Scenario 1: Inconsistent Cleaning Performance

The Problem: Many B2B buyers, particularly in industries such as manufacturing or food processing, often encounter inconsistent cleaning results when using hot water pressure washers. This issue can arise from varying water temperatures, pressure settings, or even the quality of the detergent used. For businesses in sectors where cleanliness is paramount, like the food industry, this inconsistency can lead to regulatory compliance problems, decreased customer satisfaction, and increased operational costs.

The Solution: To mitigate these challenges, B2B buyers should invest in models that offer adjustable temperature and pressure settings. When sourcing a hot water pressure washer, look for products that allow precise control over heat and pressure to match the specific cleaning task. Furthermore, choosing a pressure washer compatible with a wide range of detergents can enhance cleaning efficacy. Regular maintenance of the machine is crucial; ensure that the heating elements and nozzles are cleaned and serviced according to the manufacturer’s recommendations to maintain optimal performance.

Scenario 2: High Operating Costs and Energy Consumption

The Problem: Another common pain point for businesses in regions like Europe and the Middle East is the high operating costs associated with hot water pressure washers. The energy consumption for heating water can significantly increase utility bills, especially for companies that rely on these machines for daily operations. This financial burden can be particularly challenging for small to mid-sized enterprises looking to optimize their budgets.

The Solution: To address these high operating costs, consider investing in energy-efficient hot water pressure washers that utilize advanced technology to minimize energy use while maintaining cleaning effectiveness. Look for machines with features such as adjustable temperature controls, which allow operators to use only as much heat as needed for a specific task. Additionally, consider scheduling cleaning tasks during off-peak hours to take advantage of lower energy rates. Implementing a routine maintenance program can also enhance the efficiency of the pressure washer, ensuring it operates at peak performance without unnecessary energy waste.

Scenario 3: Equipment Mobility and Accessibility Issues

The Problem: For businesses operating in large facilities or outdoor environments, mobility can be a significant pain point. Heavy and cumbersome hot water pressure washers can hinder productivity as workers struggle to transport them to various cleaning sites. This issue is particularly prevalent in industries like construction and agriculture, where equipment needs to be moved frequently across job sites.

The Solution: To improve mobility and accessibility, B2B buyers should prioritize purchasing hot water pressure washers with features designed for easy transport. Look for models that are lightweight, equipped with durable wheels, and have a compact design. Additionally, consider investing in modular systems that allow for easy disassembly and transportation. For businesses operating in remote areas, battery-operated or fuel-powered pressure washers might also be advantageous, providing the necessary flexibility without being tethered to a power source. Training staff on efficient handling and movement techniques can further enhance operational efficiency.

By addressing these common pain points with targeted strategies, B2B buyers can enhance their cleaning operations and ensure they are getting the most out of their hot water pressure washer investments.

Strategic Material Selection Guide for hot water pressure washer

When selecting materials for hot water pressure washers, it is crucial to consider their performance characteristics, durability, and compatibility with various cleaning applications. Below, we analyze four common materials used in the construction of hot water pressure washers, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Stainless Steel in Hot Water Pressure Washers?

Stainless steel is widely recognized for its exceptional corrosion resistance and high-temperature tolerance. Typically rated for temperatures up to 300°C (572°F) and pressures exceeding 3000 PSI, stainless steel is ideal for demanding cleaning tasks. Its inherent strength ensures durability, making it suitable for both commercial and industrial applications.

Pros & Cons:

– Pros: High durability, excellent corrosion resistance, and aesthetic appeal.

– Cons: Higher initial cost and potential for thermal conductivity issues, which may require additional insulation.

Impact on Application:

Stainless steel is compatible with a variety of cleaning media, including detergents and solvents, making it versatile for different applications, from food processing to heavy machinery cleaning.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 for stainless steel. Additionally, local regulations regarding material sourcing and environmental impact may influence purchasing decisions.

How Does Aluminum Compare as a Material for Hot Water Pressure Washers?

Aluminum is another popular choice due to its lightweight nature and good thermal conductivity. It can withstand temperatures up to 150°C (302°F) and pressures around 2000 PSI, making it suitable for less demanding applications.

Pros & Cons:

– Pros: Lightweight, cost-effective, and good thermal efficiency.

– Cons: Lower strength compared to stainless steel and may require protective coatings to prevent corrosion.

Impact on Application:

Aluminum is often used in portable hot water pressure washers, where weight is a critical factor. However, it may not be suitable for harsh chemical environments without proper treatment.

Considerations for International Buyers:

In regions like South America and Africa, where environmental conditions can vary, buyers should consider the need for protective coatings to enhance durability. Compliance with local standards, such as JIS for Japanese markets, may also be necessary.

What Role Does Polypropylene Play in Hot Water Pressure Washers?

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight properties. It can handle temperatures up to 90°C (194°F) and is often used in components like hoses and fittings.

Pros & Cons:

– Pros: Excellent chemical resistance, lightweight, and cost-effective.

– Cons: Limited temperature and pressure tolerance compared to metals, which may restrict its use in high-performance applications.

Impact on Application:

Polypropylene is ideal for applications involving acidic or alkaline cleaning agents, making it suitable for industries like agriculture and automotive.

Considerations for International Buyers:

Buyers should verify that polypropylene components meet relevant standards, such as DIN for European markets. Understanding the chemical compatibility of cleaning agents with polypropylene is also essential to avoid premature failure.

How Does Brass Enhance the Performance of Hot Water Pressure Washers?

Brass is an alloy of copper and zinc, valued for its strength and resistance to corrosion. It can withstand temperatures up to 120°C (248°F) and pressures around 2500 PSI, making it suitable for various fittings and connectors.

Pros & Cons:

– Pros: Good corrosion resistance, excellent machinability, and aesthetic appeal.

– Cons: Higher cost compared to plastic alternatives and potential for dezincification in certain environments.

Impact on Application:

Brass components are commonly used in pressure washer fittings, ensuring reliable connections and durability in various cleaning tasks.

Considerations for International Buyers:

For buyers in Europe and the Middle East, compliance with standards like ASTM B36 is crucial. Additionally, understanding local regulations regarding copper alloys can impact sourcing decisions.

Summary Table of Material Selection for Hot Water Pressure Washers

| Material | Typical Use Case for hot water pressure washer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and commercial cleaning applications | High durability and corrosion resistance | Higher initial cost | High |

| Aluminum | Portable hot water pressure washers | Lightweight and cost-effective | Lower strength and corrosion potential | Medium |

| Polypropylene | Chemical resistance applications | Excellent chemical resistance | Limited temperature and pressure tolerance | Low |

| Brass | Fittings and connectors | Good corrosion resistance | Higher cost and potential dezincification | Medium |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hot water pressure washer

What Are the Main Stages of Manufacturing Hot Water Pressure Washers?

The manufacturing of hot water pressure washers involves several critical stages designed to ensure product quality, performance, and durability. Understanding these stages can help international B2B buyers make informed decisions when selecting suppliers.

Material Preparation

The first step in the manufacturing process is material preparation. This phase involves sourcing high-quality raw materials, such as stainless steel, aluminum, and durable plastics. These materials are chosen for their resistance to corrosion and ability to withstand high temperatures and pressure. B2B buyers should inquire about the sourcing practices of suppliers to ensure they are using materials that meet industry standards.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. Common methods include:

- Laser Cutting: Precision cutting of metal components to exact specifications.

- Bending: Shaping metal parts into required angles and forms.

- Welding: Joining metal pieces to create robust structures.

Buyers should look for manufacturers that utilize advanced forming technologies to ensure high precision and consistency in their products.

Assembly Process

The assembly process is where individual components come together to create the final pressure washer. This phase typically involves:

- Component Integration: Installing key components such as pumps, heating elements, and hoses.

- Quality Checks: Implementing in-process inspections during assembly to catch any defects early.

B2B buyers should consider suppliers that have a structured assembly process with well-defined roles and responsibilities to enhance quality assurance.

Finishing Techniques

The finishing stage involves applying protective coatings and surface treatments to enhance durability and aesthetics. Techniques may include:

- Powder Coating: Providing a protective layer that is resistant to scratches and corrosion.

- Passivation: A chemical treatment that enhances the corrosion resistance of stainless steel components.

Understanding the finishing techniques employed by manufacturers can give buyers insight into the longevity and performance of the pressure washers.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is crucial in the manufacturing of hot water pressure washers. International buyers must be aware of relevant standards and quality control checkpoints to ensure they receive high-quality products.

International Standards (ISO 9001)

ISO 9001 is a globally recognized standard for quality management systems. Manufacturers who adhere to this standard demonstrate their commitment to quality and customer satisfaction. B2B buyers should prioritize suppliers with ISO 9001 certification, as this indicates a systematic approach to quality management.

Industry-Specific Certifications (CE, API)

In addition to ISO 9001, various industry-specific certifications may apply depending on the region and application. For instance:

- CE Marking: Required in Europe, this certification indicates compliance with health, safety, and environmental protection standards.

- API Certification: Relevant for manufacturers in the oil and gas industry, this certification ensures that products meet specific performance and safety criteria.

Buyers should verify that their suppliers hold the necessary certifications for their target markets.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is an integral part of the manufacturing process, ensuring that hot water pressure washers meet specified standards before they reach the market. Key QC checkpoints include:

Incoming Quality Control (IQC)

IQC involves inspecting raw materials and components as they arrive at the manufacturing facility. This process ensures that only materials meeting quality standards are used in production. Buyers should request information on IQC procedures to ensure that suppliers maintain high standards from the outset.

In-Process Quality Control (IPQC)

During the assembly process, IPQC checks are performed to identify defects or deviations from specifications. This stage is essential for catching issues early and reducing waste. B2B buyers should inquire about the frequency and methods of IPQC in the manufacturing process.

Final Quality Control (FQC)

FQC is the last checkpoint before products are shipped. It typically involves comprehensive testing of finished products, including:

- Performance Testing: Evaluating the pressure washer’s operational efficiency.

- Safety Testing: Ensuring compliance with safety standards.

Buyers should ensure that their suppliers conduct thorough FQC to guarantee product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is essential for mitigating risks associated with product quality. Here are actionable steps B2B buyers can take:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should establish a clear audit protocol, focusing on compliance with international standards and internal quality practices.

Reviewing Quality Control Reports

Requesting and reviewing quality control reports can give buyers a comprehensive understanding of a supplier’s QC measures. These reports should detail inspection results, defect rates, and corrective actions taken.

Engaging Third-Party Inspection Services

B2B buyers can benefit from engaging third-party inspection services to conduct independent assessments of suppliers. These services provide unbiased evaluations of manufacturing practices and product quality, adding an additional layer of assurance.

What QC and Certification Nuances Should International Buyers Keep in Mind?

When sourcing hot water pressure washers from international suppliers, B2B buyers must navigate various QC and certification nuances. Here are several considerations:

- Regional Compliance: Different regions have specific regulations and standards that manufacturers must comply with. Buyers should ensure their suppliers are familiar with local requirements in Africa, South America, the Middle East, and Europe.

- Documentation: Proper documentation of certifications and quality control processes is essential for international trade. Buyers should request copies of relevant certificates and quality assurance documentation.

- Cultural Considerations: Different cultures may have varying approaches to quality management and transparency. Establishing clear communication channels can help bridge any gaps in understanding.

By being proactive in understanding manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions and build successful partnerships in the hot water pressure washer market.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot water pressure washer’

In today’s competitive market, sourcing a hot water pressure washer requires careful consideration and strategic planning. This checklist is designed to guide international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, through the essential steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Before initiating the purchasing process, clearly outline your technical requirements. Consider factors such as pressure ratings, temperature capabilities, and flow rate. Understanding these specifications will help you identify models that suit your operational needs and avoid overspending on unnecessary features.

- Pressure Ratings: Determine the PSI (pounds per square inch) required for your cleaning tasks.

- Temperature Range: Assess the required water temperature to enhance cleaning efficiency.

Step 2: Research Market Trends and Demand

Conduct thorough market research to understand current trends and demand for hot water pressure washers in your region. This insight will not only help in selecting the right product but also in negotiating better prices with suppliers.

- Industry Reports: Look for reports that highlight growth areas and technological advancements in pressure washers.

- Competitor Analysis: Observe what similar businesses are using to optimize their cleaning processes.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. A well-established supplier with a solid track record can significantly impact your operational success.

- Supplier Background: Check how long they’ve been in business and their market reputation.

- Client Testimonials: Look for reviews or case studies relevant to your industry.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering meet international quality and safety standards. Certifications indicate that the products comply with necessary regulations and can assure you of their reliability.

- ISO Certifications: Look for suppliers with ISO 9001 or similar certifications that reflect quality management.

- Safety Standards: Check for compliance with local and international safety regulations.

Step 5: Request Sample Units

Before finalizing any purchase, request samples of the hot water pressure washers you are considering. Testing a unit in your operational environment allows you to assess its performance, ease of use, and maintenance needs.

- Performance Testing: Evaluate the unit’s cleaning efficiency and durability during trial runs.

- Maintenance Assessment: Consider how easy it is to maintain and repair the equipment.

Step 6: Negotiate Terms and Conditions

Once you have chosen a supplier, engage in negotiations regarding pricing, delivery times, warranties, and after-sales support. Establishing clear terms upfront can prevent misunderstandings and enhance your purchasing experience.

- Pricing Structure: Discuss volume discounts or long-term purchasing agreements.

- After-Sales Support: Ensure you understand the level of support provided post-purchase.

Step 7: Finalize the Purchase Agreement

Review all contractual details before signing. Ensure that all agreed terms are documented, including delivery schedules, payment terms, and warranty details.

- Legal Review: Consider having a legal expert review the contract to safeguard your interests.

- Payment Terms: Clarify whether payments will be made upfront, on delivery, or through financing options.

By following this checklist, international B2B buyers can navigate the complexities of procuring a hot water pressure washer, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for hot water pressure washer Sourcing

What Are the Key Cost Components of Hot Water Pressure Washers?

When sourcing hot water pressure washers, understanding the cost structure is crucial for making informed purchasing decisions. The primary components that influence the cost include:

-

Materials: The quality of materials used in manufacturing hot water pressure washers significantly affects the price. High-grade stainless steel, durable plastics, and efficient heating elements contribute to a higher initial cost but may result in lower maintenance and replacement costs over time.

-

Labor: Labor costs vary by region and can impact the final price. In countries with higher labor costs, such as those in Europe, the manufacturing cost per unit will increase. Consider the labor conditions in the supplier’s country when evaluating quotes.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Understanding how these overheads are calculated can provide insight into the supplier’s pricing strategy.

-

Tooling: The cost of tooling can be substantial, especially for customized designs or specifications. If you require modifications to standard models, be prepared for potential tooling fees that could impact overall pricing.

-

Quality Control (QC): Robust QC processes ensure product reliability and performance, but they can also add to the overall cost. Suppliers with stringent QC measures may charge higher prices, but this often translates into better long-term reliability.

-

Logistics: Shipping and handling costs can vary widely depending on the location of the supplier and the destination. International buyers should consider freight costs, customs duties, and any potential delays that could impact delivery.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary based on competition, demand, and market conditions. Understanding the market dynamics in your region can help in negotiations.

How Do Price Influencers Affect Hot Water Pressure Washer Costs?

Several factors influence the pricing of hot water pressure washers, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have MOQs that can affect pricing, so understanding these thresholds can help manage costs.

-

Specifications and Customization: Customized units tailored to specific needs often come at a premium. Be clear about your requirements to avoid unexpected costs.

-

Material Quality and Certifications: Products that meet international standards or come with certifications (e.g., CE, ISO) may carry higher costs. However, the assurance of quality can justify the price, especially for safety-critical applications.

-

Supplier Factors: The reputation and reliability of the supplier can significantly influence pricing. Established suppliers with a proven track record may charge more but offer better service and warranty conditions.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. Terms such as FOB (Free on Board) or CIF (Cost Insurance and Freight) dictate who bears shipping costs and risks, affecting the total cost of ownership.

What Tips Can Help International Buyers Negotiate Better Prices?

For buyers from Africa, South America, the Middle East, and Europe, negotiating the best price involves strategic considerations:

-

Research and Compare: Conduct thorough market research to understand prevailing prices and options available in your region. Compare multiple suppliers to identify competitive pricing.

-

Negotiate Terms: Don’t hesitate to negotiate not only the price but also payment terms, delivery schedules, and warranty conditions. Flexibility on both sides can lead to a better deal.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the pressure washer, including maintenance, energy consumption, and parts replacement. A lower upfront cost may not always be the best value if TCO is high.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Consider long-term partnerships for ongoing needs, which may also yield discounts.

-

Stay Informed on Market Trends: Keep abreast of market trends and fluctuations in material costs or global supply chain issues. This knowledge can provide leverage during negotiations.

Disclaimer on Pricing

Prices for hot water pressure washers can vary widely based on specifications, supplier locations, and market conditions. The insights provided here are indicative and should be used as a guideline. Always conduct direct inquiries with suppliers for accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing hot water pressure washer With Other Solutions

When considering the purchase of a hot water pressure washer, it’s essential to evaluate alternative solutions that may also meet your cleaning needs. Understanding the comparative advantages and limitations of each option can help international B2B buyers make informed decisions tailored to their specific industry requirements.

Comparison Table of Hot Water Pressure Washer and Alternatives

| Comparison Aspect | Hot Water Pressure Washer | Steam Cleaner | Chemical Cleaning System |

|---|---|---|---|

| Performance | High cleaning efficiency, effective for grease and oil removal | Effective for sanitization, less effective on heavy dirt | Good for specific stains, may require more time |

| Cost | Moderate to high initial investment, operational costs depend on fuel/electricity | Lower initial investment, ongoing costs for water and electricity | Varies widely; low initial but potential high chemical costs |

| Ease of Implementation | Requires training for optimal use and safety | User-friendly, minimal training required | Requires knowledge of chemical handling and safety protocols |

| Maintenance | Regular maintenance needed for pump and heating elements | Minimal maintenance, mainly descaling | Maintenance of equipment and storage of chemicals |

| Best Use Case | Ideal for industrial applications, automotive, and construction | Ideal for food service, healthcare, and residential cleaning | Ideal for specialized cleaning tasks in sensitive environments |

What are the Pros and Cons of Using a Steam Cleaner?

Steam cleaners use high-temperature steam to sanitize surfaces, making them a popular alternative for specific cleaning tasks.

Pros:

– Effective Sanitization: Steam cleaning is excellent for killing bacteria and viruses, making it suitable for industries like healthcare and food service.

– Eco-Friendly: This method typically requires no chemicals, reducing environmental impact.

Cons:

– Limited Heavy-Duty Cleaning: While effective for sanitization, steam cleaners may struggle with heavy grease and grime, which is often found in industrial settings.

– Longer Cleaning Times: The need for thorough steaming can increase the time taken to clean large areas compared to hot water pressure washers.

How Does a Chemical Cleaning System Compare?

Chemical cleaning systems involve the use of various cleaning agents to tackle stains and dirt. These systems are often deployed in settings where specific stains or contaminants are an issue.

Pros:

– Targeted Cleaning: Chemical systems can be tailored to specific types of stains, making them very effective in certain contexts.

– Cost-Effective for Small Jobs: Lower equipment costs may be appealing for businesses with limited cleaning needs.

Cons:

– Potential Hazards: The need for chemical handling can pose safety risks, requiring trained personnel.

– Environmental Concerns: Chemical runoff can lead to environmental challenges, especially in sensitive ecosystems.

How to Choose the Right Solution for Your Needs?

When selecting between a hot water pressure washer and its alternatives, it is crucial to consider the specific cleaning requirements of your industry. For heavy-duty applications, such as in automotive and construction sectors, a hot water pressure washer may be the best choice due to its superior cleaning power. Conversely, if your focus is on sanitization in food service or healthcare, a steam cleaner might be more suitable. Chemical cleaning systems can be effective for specialized applications but require careful handling and consideration of environmental impacts.

Ultimately, your decision should align with your business goals, budget constraints, and safety regulations. Engaging with suppliers and conducting pilot tests can also provide insights into which solution will deliver the best return on investment for your operations.

Essential Technical Properties and Trade Terminology for hot water pressure washer

What Are the Key Technical Properties of Hot Water Pressure Washers?

Understanding the technical properties of hot water pressure washers is crucial for B2B buyers, especially when making informed purchasing decisions. Here are some essential specifications:

1. Pressure Rating (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the force at which water is expelled from the machine. A higher PSI usually means better cleaning efficiency, allowing for the removal of tough stains and grime. For commercial applications in industries like construction or agriculture, choosing a washer with an appropriate PSI rating ensures that cleaning tasks are completed quickly and effectively.

2. Flow Rate (GPM)

Flow rate, measured in gallons per minute (GPM), refers to the amount of water the washer can deliver. A higher GPM means that more water is used, which can enhance cleaning efficiency for large areas or heavy-duty tasks. B2B buyers should consider their specific cleaning needs and choose a pressure washer that balances both PSI and GPM effectively to optimize performance.

3. Temperature Range

The temperature range indicates the maximum temperature of the water used for cleaning. Hot water pressure washers can typically reach temperatures between 140°F and 200°F (60°C to 93°C). The ability to use hot water is essential for breaking down grease and oil, making it a preferred choice for industries like automotive and food processing. Buyers should assess the temperature requirements based on the specific cleaning applications.

4. Fuel Type

Hot water pressure washers may operate on various fuel types, including electricity, diesel, or propane. The choice of fuel affects operational costs and maintenance requirements. For instance, electric models may be more suitable for indoor use, while diesel units offer mobility and power for outdoor tasks. Understanding the fuel options can guide buyers in selecting a machine that aligns with their operational environment and budget.

5. Durability and Build Material

The durability of a pressure washer is often determined by the materials used in its construction, such as stainless steel or heavy-duty plastic. Machines built with higher-grade materials tend to withstand wear and tear better, providing a longer service life and reducing replacement costs. B2B buyers should consider the operating conditions and select washers that can endure harsh environments.

Which Trade Terms Should B2B Buyers Understand?

Familiarity with industry jargon can significantly streamline the purchasing process. Here are some common terms related to hot water pressure washers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are marketed under another brand’s name. When purchasing hot water pressure washers, it’s essential to understand whether the equipment is sourced from an OEM, as this can affect product reliability and warranty terms.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is critical for B2B buyers, particularly those looking to minimize inventory costs or test a new product line without committing to large quantities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information on specific products. B2B buyers should use RFQs to obtain competitive pricing and terms from multiple suppliers, ensuring they make informed decisions based on budget and quality.

4. Incoterms (International Commercial Terms)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers during international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and payment responsibilities, which is particularly important for international B2B buyers in regions like Africa and South America.

5. Warranty

Warranty refers to the manufacturer’s promise regarding the lifespan and performance of the product. Knowing the warranty terms on hot water pressure washers can protect B2B buyers from unexpected repair costs and ensure they receive value for their investment.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing hot water pressure washers, thereby maximizing their operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the hot water pressure washer Sector

What Are the Current Market Dynamics Influencing the Hot Water Pressure Washer Sector?

The global market for hot water pressure washers is experiencing robust growth, driven by increasing demand across various sectors such as construction, agriculture, and industrial cleaning. Key drivers include the rising emphasis on hygiene and cleanliness, particularly post-pandemic, and the growing awareness of environmental sustainability. Notably, regions like Africa and South America are witnessing a surge in construction projects, thereby escalating the need for efficient cleaning solutions.

Emerging trends in B2B technology, such as automation and IoT integration, are reshaping sourcing strategies. Companies are increasingly seeking pressure washers that not only deliver high performance but also offer connectivity features for real-time monitoring and maintenance. This trend is particularly relevant for international buyers from Europe and the Middle East, where operational efficiency and data-driven decisions are paramount. Furthermore, with the rise of e-commerce platforms, buyers can now access a wider range of suppliers, making it crucial to analyze supplier credibility and product quality.

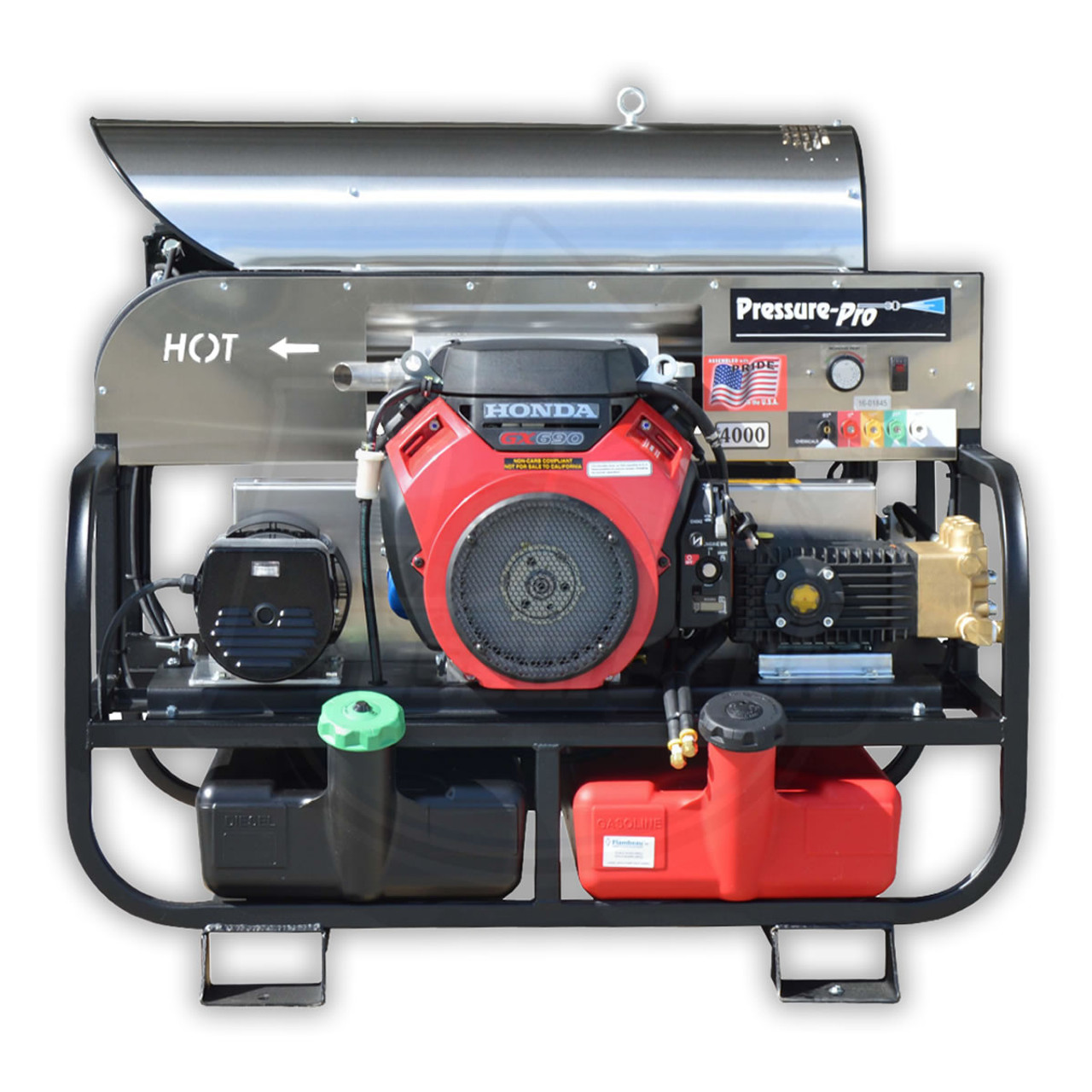

A stock image related to hot water pressure washer.

How Can Sustainability and Ethical Sourcing Impact My Purchase Decisions?

The importance of sustainability in the hot water pressure washer sector cannot be overstated. Environmental concerns are prompting businesses to seek equipment that minimizes water and energy consumption. Hot water pressure washers designed with energy-efficient technologies help reduce operational costs while meeting stringent regulatory standards.

Ethical sourcing has become a critical factor for B2B buyers. Companies are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials and adhering to fair labor practices. Certifications like Energy Star and EcoLabel serve as indicators of a product’s environmental impact and can significantly influence buyer decisions. Buyers in regions such as the UAE and Spain should look for these certifications when sourcing equipment, as they not only enhance brand reputation but also align with global sustainability goals.

How Has the Hot Water Pressure Washer Market Evolved Over Time?

The evolution of the hot water pressure washer market can be traced back to the early industrial era when steam-powered machines were first utilized for cleaning. Over the decades, advancements in technology have led to the development of more efficient and user-friendly models. The introduction of electric and gas-powered options has broadened the applicability of hot water pressure washers across various industries.

Today, the focus has shifted from merely functionality to incorporating smart technologies and eco-friendly practices. As markets in Africa, South America, the Middle East, and Europe expand, international buyers must stay informed about the latest innovations and sustainability practices in the sector. Understanding this historical context aids in making informed purchasing decisions that align with modern business needs.

A stock image related to hot water pressure washer.

In summary, navigating the market dynamics and sourcing trends within the hot water pressure washer sector requires a keen understanding of global drivers, emerging technologies, and sustainability standards. By prioritizing these aspects, international B2B buyers can ensure they make strategic and responsible procurement choices.

Related Video: Trade and tariffs | APⓇ Microeconomics | Khan Academy

Frequently Asked Questions (FAQs) for B2B Buyers of hot water pressure washer

-

How do I choose the right hot water pressure washer for my business needs?

Choosing the right hot water pressure washer involves understanding your specific cleaning requirements, including the types of surfaces you’ll be cleaning, the level of dirt or grime, and the frequency of use. Consider the machine’s PSI (pounds per square inch) and GPM (gallons per minute) ratings, as higher numbers typically indicate more cleaning power. Additionally, assess the fuel type (electric vs. gas) based on your operational environment and logistical considerations. Lastly, check for compatibility with any cleaning detergents you plan to use. -

What are the benefits of using hot water pressure washers over cold water models?

Hot water pressure washers are particularly effective for removing grease, oil, and stubborn dirt, making them ideal for industries like automotive, food processing, and manufacturing. The heated water helps to break down contaminants more efficiently, which can save time and labor costs. Additionally, hot water can sanitize surfaces, making it a preferred choice in environments that require high hygiene standards. For businesses in regions with varying climate conditions, hot water models can also be effective in colder temperatures where cold water washers may not function optimally. -

What should I consider when sourcing hot water pressure washers from international suppliers?

When sourcing from international suppliers, consider their reputation, reliability, and compliance with international quality standards. Look for suppliers with a proven track record in the industry, verified certifications, and positive customer reviews. Evaluate their production capabilities and lead times to ensure they can meet your demands. Additionally, assess the terms of trade, including shipping logistics, customs regulations, and potential tariffs, especially when importing to regions like Africa and South America. -

What are the minimum order quantities (MOQ) for hot water pressure washers?

Minimum order quantities can vary significantly between suppliers. Typically, manufacturers may set MOQs to ensure cost-effectiveness in production and shipping. It’s essential to communicate your needs upfront and negotiate MOQs that align with your business model. For new ventures, consider sourcing from suppliers willing to provide sample units for evaluation before committing to larger orders. This approach can help mitigate risks while ensuring the product meets your quality expectations. -

What payment terms should I negotiate with hot water pressure washer suppliers?

When negotiating payment terms, consider options such as letters of credit, advance payments, or staggered payments based on shipment milestones. Aim for terms that protect your cash flow while establishing trust with the supplier. For larger orders, consider negotiating payment upon delivery or after product inspection. Always ensure that payment methods are secure and offer protection against fraud, particularly when dealing with international transactions. -

How do I ensure quality assurance when purchasing hot water pressure washers?

To ensure quality assurance, request detailed product specifications, certifications, and compliance with industry standards from suppliers. Conduct factory audits or third-party inspections, if feasible, to verify production processes. Ask for samples before making bulk purchases, and consider implementing a quality control protocol upon receipt of goods. Establish clear communication channels with suppliers regarding any quality issues and ensure they have a robust return policy. -

What logistics considerations should I keep in mind when importing hot water pressure washers?

Logistics considerations include shipping methods, routes, and potential delays due to customs clearance. Determine whether to opt for air freight for faster delivery or sea freight for cost savings, especially for bulk orders. Understand the import regulations specific to your region, including any required documentation and tariffs. Collaborating with a reputable freight forwarder can help streamline the process and ensure compliance with local laws, which is crucial for B2B operations. -

Can hot water pressure washers be customized for specific business needs?

Yes, many manufacturers offer customization options to meet specific business requirements. Customizations may include modifications to size, pressure settings, nozzle types, and additional features like trailers or integrated detergent tanks. When discussing customization, clearly outline your needs and expectations to the supplier. Be aware that custom orders may affect lead times and pricing, so factor this into your budgeting and planning processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hot water pressure washer

In today’s competitive landscape, strategic sourcing is pivotal for international B2B buyers seeking hot water pressure washers. By understanding local market dynamics in regions such as Africa, South America, the Middle East, and Europe, businesses can make informed decisions that align with their operational needs and budget constraints. Key takeaways include the importance of evaluating supplier reliability, negotiating favorable terms, and ensuring compliance with regional regulations.

Moreover, leveraging digital platforms for supplier discovery and assessment can enhance procurement efficiency. As sustainability becomes increasingly vital, sourcing energy-efficient models will not only reduce operational costs but also meet the growing demand for environmentally friendly solutions.

Looking ahead, the hot water pressure washer market is poised for growth, driven by advancements in technology and increased industrial applications. International B2B buyers should actively engage with suppliers to explore innovative features and adapt to evolving customer requirements. By prioritizing strategic sourcing, businesses can secure a competitive edge in their respective markets. Now is the time to take action—evaluate your sourcing strategies and invest in partnerships that will drive your business forward.