Discover the Benefits of Using Bearing GIFs in 2025

Introduction: Navigating the Global Market for bearing gif

Navigating the global market for bearing GIFs can be a complex endeavor for international B2B buyers, especially when sourcing high-quality materials that meet specific industrial needs. Whether you’re looking to enhance your product catalog with engaging visuals or seeking effective communication tools for training and marketing, understanding the nuances of bearing GIFs is crucial. This guide delves into various types of bearing GIFs, their applications across different industries, and essential supplier vetting strategies to ensure quality and reliability.

For B2B buyers from Africa, South America, the Middle East, and Europe—countries like Germany and Colombia—making informed purchasing decisions is paramount. This comprehensive resource empowers you with actionable insights, including cost considerations, the technological requirements for implementation, and how to leverage GIFs for maximum impact in your operations. By understanding the market landscape and the factors influencing pricing and availability, you can streamline your procurement process and enhance your competitive edge.

Ultimately, this guide aims to equip you with the knowledge necessary to navigate the intricacies of sourcing bearing GIFs, ensuring that you make choices that align with your business objectives while maximizing your return on investment. Embrace the potential of bearing GIFs to drive engagement and efficiency in your operations, all while making informed and strategic purchasing decisions.

Understanding bearing gif Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ball Bearing GIF | Shows spherical rolling elements in motion | Automotive, manufacturing, machinery | Pros: Versatile, widely applicable. Cons: Can wear out quickly under heavy loads. |

| Roller Bearing GIF | Illustrates cylindrical rolling elements | Heavy machinery, conveyor systems | Pros: High load capacity. Cons: Greater friction than ball bearings. |

| Thrust Bearing GIF | Demonstrates axial load support | Aerospace, automotive, industrial equipment | Pros: Excellent axial load handling. Cons: Limited radial load capacity. |

| Magnetic Bearing GIF | Displays non-contact magnetic levitation | High-speed applications, turbines | Pros: Minimal friction, high speed. Cons: Complex installation and maintenance. |

| Composite Bearing GIF | Combines multiple bearing types in one visual | Robotics, precision instruments | Pros: Tailored solutions for specific applications. Cons: Potentially higher costs. |

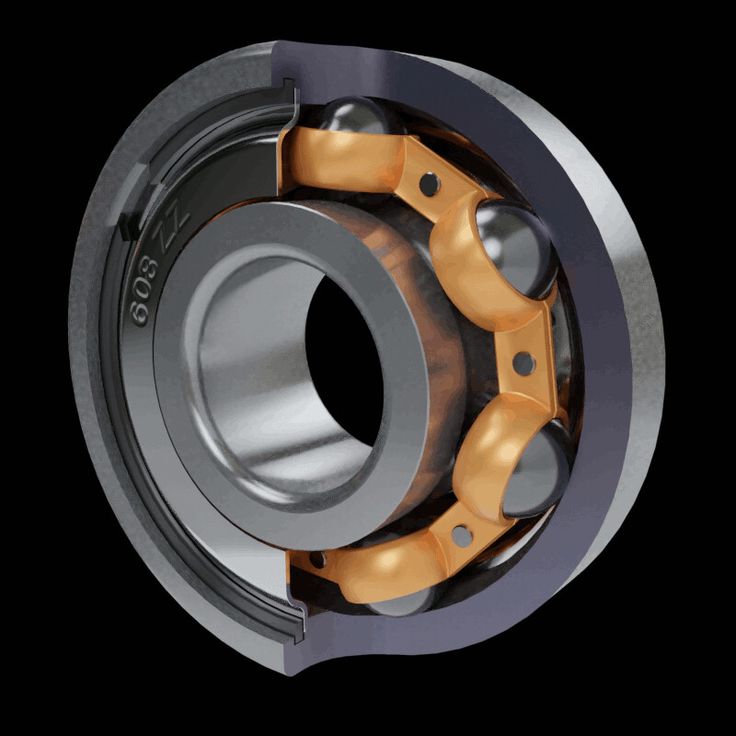

What Are the Key Characteristics of Ball Bearing GIFs?

Ball bearing GIFs visually represent the motion of spherical rolling elements, which are crucial in reducing friction in various applications. These GIFs are particularly relevant in industries like automotive and manufacturing, where ball bearings are commonly used. When purchasing, buyers should consider the load capacity and potential wear over time, as ball bearings may require frequent replacement in high-stress environments.

How Do Roller Bearing GIFs Differ from Other Types?

Roller bearing GIFs depict cylindrical rolling elements that provide enhanced load-bearing capacity compared to ball bearings. They are primarily used in heavy machinery and conveyor systems where high radial loads are present. Buyers should assess the friction levels and the specific load requirements of their operations, as roller bearings can generate more friction than their ball counterparts, which may impact efficiency.

Why Are Thrust Bearing GIFs Important for Specific Applications?

Thrust bearing GIFs illustrate components designed to support axial loads, making them essential in aerospace, automotive, and industrial equipment applications. Their ability to handle significant axial forces while maintaining stability makes them invaluable for systems with high directional loads. Buyers must evaluate the radial load limitations, as thrust bearings typically cannot manage radial forces well, which could lead to operational failures if misapplied.

What Are the Advantages of Magnetic Bearing GIFs?

Magnetic bearing GIFs showcase a unique technology that utilizes magnetic fields to support rotating shafts without physical contact. This non-contact design allows for minimal friction and enables high-speed applications, such as in turbines and high-performance motors. However, buyers should be aware of the complexity involved in installation and maintenance, as well as the higher initial costs, which may impact budget considerations.

How Do Composite Bearing GIFs Cater to Diverse Needs?

Composite bearing GIFs combine different bearing types into a single visual representation, highlighting their versatility in applications like robotics and precision instruments. These GIFs are instrumental for buyers looking for customized solutions tailored to specific operational needs. However, while they offer unique advantages, composite bearings may also come at a higher price point, requiring careful cost-benefit analysis during procurement.

Key Industrial Applications of bearing gif

| Industry/Sector | Specific Application of Bearing GIF | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Training and Education | Enhances understanding of bearing functions and applications. | Quality of educational content, compatibility with training programs. |

| Automotive | Product Demonstration | Visual representation aids in showcasing product features. | Resolution and clarity of GIFs, relevance to target audience. |

| Mining and Construction | Equipment Maintenance | Illustrates maintenance procedures, reducing downtime. | Durability of materials, ease of understanding maintenance steps. |

| Aerospace | Design Validation | Visual aids facilitate design reviews and approvals. | Accuracy in representation, compliance with industry standards. |

| Robotics | Simulation and Testing | Provides dynamic insights into bearing performance in robotic applications. | Precision in simulations, integration with testing software. |

How is Bearing GIF Used in Manufacturing Training and Education?

In the manufacturing sector, bearing GIFs are valuable tools for training and education. They provide dynamic visual representations of how bearings function and their various applications in machinery. This enhances learners’ understanding and retention of complex concepts, which is crucial for new employees in African, South American, Middle Eastern, and European industries. Buyers should consider the quality and clarity of the GIFs to ensure they align with their training programs and meet the educational needs of their workforce.

A stock image related to bearing gif.

What Role Does Bearing GIF Play in Automotive Product Demonstration?

In the automotive industry, bearing GIFs serve as effective product demonstration tools. They allow manufacturers to showcase the features and benefits of their bearing products in an engaging format. This is particularly beneficial for international buyers who may not have the opportunity to physically inspect products. When sourcing bearing GIFs for marketing, businesses should prioritize resolution and clarity to ensure that the visuals accurately represent the product’s specifications and appeal to the target audience.

How Do Bearing GIFs Facilitate Equipment Maintenance in Mining and Construction?

In the mining and construction sectors, bearing GIFs play a critical role in illustrating equipment maintenance procedures. By visually demonstrating maintenance steps, these GIFs help reduce equipment downtime and improve operational efficiency. For international buyers in regions like Africa and the Middle East, understanding the maintenance requirements of heavy machinery is essential for ensuring long-term performance. Key sourcing considerations include the durability of materials used in the GIFs and their ability to effectively communicate complex maintenance procedures.

How are Bearing GIFs Used for Design Validation in Aerospace?

In aerospace, bearing GIFs are instrumental in the design validation process. They provide visual aids that facilitate design reviews and approvals, helping engineers and stakeholders understand the intricacies of bearing integration within aircraft systems. International buyers, particularly from Europe, must ensure that the GIFs accurately represent the bearing designs and comply with stringent industry standards. This accuracy is critical in preventing costly design errors and ensuring safety in aerospace applications.

What Benefits Do Bearing GIFs Provide in Robotics Simulation and Testing?

In robotics, bearing GIFs are utilized for simulation and testing purposes, offering dynamic insights into bearing performance in various robotic applications. They enable engineers to visualize how bearings will behave under different operational conditions, which is vital for optimizing robotic designs. Buyers in South America and Africa should look for precision in these simulations, as this can significantly impact the effectiveness of their robotic systems. Integration with testing software and the accuracy of the representations are key factors to consider when sourcing these GIFs.

3 Common User Pain Points for ‘bearing gif’ & Their Solutions

Scenario 1: Difficulty in Visualizing Complex Mechanisms with Bearing GIFs

The Problem: In industries such as manufacturing and automotive, B2B buyers often face challenges when trying to visualize the functionality and operation of bearings in complex machinery. Static images or text descriptions may not provide the clarity needed for decision-makers to fully understand how a bearing operates within a system. This can lead to miscommunication, incorrect specifications, or even costly errors in procurement.

The Solution: To effectively utilize bearing GIFs for better visualization, B2B buyers should seek out high-quality animated GIFs that demonstrate the operation of specific bearing types in real-world applications. Platforms like Giphy or Tenor can be useful for sourcing these GIFs. When selecting GIFs, ensure they depict various angles and operational scenarios of the bearings in question. Additionally, embedding these GIFs in presentations or technical documentation can enhance understanding among team members and stakeholders. Consider using GIFs that illustrate common bearing failures and their solutions, which can be invaluable during training sessions or discussions about maintenance best practices.

Scenario 2: Inadequate Information for Marketing and Training Purposes

The Problem: For companies involved in the distribution or manufacturing of bearings, effectively marketing their products and training employees can be a significant hurdle. Traditional marketing materials often lack the engaging content that modern audiences prefer. As a result, potential clients may not fully grasp the benefits of specific bearings, and employees may struggle to retain essential training information.

The Solution: Incorporating bearing GIFs into marketing campaigns and training modules can significantly enhance engagement. B2B buyers should focus on creating educational content that includes GIFs demonstrating the unique selling points of their bearings, such as durability, efficiency, and application versatility. For training purposes, GIFs showing installation procedures or maintenance tips can serve as effective visual aids. Consider using platforms like Pixabay or Wikimedia Commons to source royalty-free GIFs, or collaborate with graphic designers to produce customized animations tailored to your product line. This approach not only makes your content more appealing but also aids in better retention of information.

Scenario 3: Difficulty in Communicating Technical Specifications

The Problem: When dealing with international suppliers or clients, B2B buyers often encounter issues with technical specifications, particularly when these specifications are conveyed through text alone. Language barriers and differences in technical terminology can lead to misunderstandings, resulting in incorrect orders or mismatched expectations.

The Solution: To bridge communication gaps, B2B buyers should leverage bearing GIFs that visually represent technical specifications and functionalities. For instance, instead of merely stating the load capacity of a bearing, a GIF can show how the bearing performs under various loads, providing a clearer understanding of its capabilities. It is advisable to create a library of GIFs that corresponds to different specifications, including dimensions, materials used, and application scenarios. Additionally, consider pairing these visuals with multilingual captions to cater to diverse markets in Africa, South America, the Middle East, and Europe. This practice not only enhances clarity but also builds trust with international partners by demonstrating a commitment to effective communication and understanding.

Strategic Material Selection Guide for bearing gif

When selecting materials for bearing GIFs, international B2B buyers must consider various properties and applications to ensure optimal performance and longevity. Below, we analyze four common materials used in the manufacturing of bearing GIFs, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Steel for Bearing GIFs?

Steel is one of the most commonly used materials for bearings due to its excellent mechanical properties. It typically exhibits high strength, good wear resistance, and the ability to withstand high temperatures and pressures. For instance, stainless steel variants can offer enhanced corrosion resistance, making them suitable for applications in humid or corrosive environments.

Pros: Steel bearings are durable and can handle heavy loads, making them ideal for industrial applications. They are also relatively cost-effective compared to other materials.

Cons: The main drawback is that steel can corrode if not properly treated or if exposed to harsh environments. Additionally, the manufacturing process can be complex, impacting lead times.

Impact on Application: Steel bearings are compatible with a wide range of media, including oils and greases, which are often used in machinery.

Considerations for Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN, especially in regions like Germany where such standards are strictly adhered to.

How Does Plastic Compare as a Material for Bearing GIFs?

Plastic bearings, often made from materials like nylon or PTFE (Teflon), are gaining popularity due to their lightweight nature and resistance to corrosion. These materials are particularly advantageous in applications where weight reduction is crucial.

Pros: Plastic bearings are resistant to chemicals and do not require lubrication, which can reduce maintenance costs. They also operate quietly, making them suitable for applications in consumer products.

Cons: They generally have lower load-bearing capacities compared to steel and can be susceptible to wear under high-stress conditions.

Impact on Application: Plastic bearings are ideal for applications in corrosive environments, such as in food processing or chemical manufacturing.

Considerations for Buyers: International buyers should look for certifications that ensure the plastic meets safety and environmental standards, particularly in Europe where regulations can be stringent.

What are the Benefits of Ceramic Materials in Bearing GIFs?

Ceramic materials, such as silicon nitride, are increasingly used in high-performance bearing applications due to their unique properties. They are lightweight, non-corrosive, and have excellent wear resistance.

Pros: Ceramic bearings can operate at higher temperatures than metal bearings and are less likely to deform under stress. They also exhibit superior electrical insulation properties.

Cons: The primary limitation is their cost; ceramic bearings are significantly more expensive than their metal or plastic counterparts. Additionally, they can be brittle, which may lead to failure under shock loads.

Impact on Application: Ceramic bearings are well-suited for high-speed applications in aerospace and automotive industries, where performance is critical.

Considerations for Buyers: Buyers should ensure that ceramic bearings meet relevant international standards, especially in high-tech industries prevalent in Europe and North America.

How Does Bronze Serve as a Material for Bearing GIFs?

Bronze, an alloy of copper and tin, is another traditional material used in bearing applications. It offers good wear resistance and is often used in applications requiring low friction.

Pros: Bronze bearings are durable and can withstand heavy loads, making them suitable for industrial machinery. They also have good corrosion resistance, particularly in marine environments.

Cons: The main drawback is the higher cost compared to steel. Additionally, bronze bearings may require lubrication to prevent wear.

Impact on Application: Bronze bearings are compatible with various lubricants and are often used in applications involving water or marine environments.

Considerations for Buyers: Buyers should be aware of the specific grades of bronze that comply with industry standards, particularly in regions like South America where material quality can vary.

Summary Table of Material Selection for Bearing GIFs

| Material | Typical Use Case for bearing gif | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy industrial machinery | High strength and durability | Susceptible to corrosion | Medium |

| Plastic | Consumer products, food processing | Lightweight and corrosion-resistant | Lower load capacity | Low |

| Ceramic | Aerospace, automotive | High temperature resistance | Brittle and expensive | High |

| Bronze | Marine applications, industrial machinery | Good wear resistance | Higher cost and lubrication needed | Medium |

This strategic material selection guide provides international B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in bearing GIFs. By understanding these factors, buyers can make informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bearing gif

What Are the Main Stages of Manufacturing for Bearings?

The manufacturing of bearings involves a series of well-defined stages that ensure the final product meets the required performance and quality standards. Understanding these stages is crucial for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe.

Material Preparation: What Materials Are Used in Bearing Manufacturing?

The initial stage of bearing manufacturing involves selecting and preparing materials. Common materials include high-carbon steel, stainless steel, and ceramics, chosen for their strength and wear resistance. The materials undergo processes such as heat treatment to enhance their hardness and durability.

For buyers, it’s essential to inquire about the specific materials used by suppliers. Ensure they comply with international standards and regulations, as the choice of material significantly impacts the bearing’s longevity and performance.

Forming Process: How Are Bearings Shaped?

Once the materials are prepared, the forming process begins. This typically involves methods like forging, machining, and stamping.

- Forging: This method is used to create the outer and inner rings of the bearing, providing superior strength.

- Machining: Precision machining is employed to achieve the required dimensions and tolerances for the rolling elements and raceways.

- Stamping: This is used for producing simpler components and is often employed in the production of cages.

Buyers should assess the forming techniques used by suppliers, as advanced technology can lead to higher precision and better performance.

Assembly: What Steps Are Involved in Bearing Assembly?

The assembly stage involves putting together the various components of the bearing, including the inner and outer rings, rolling elements (balls or rollers), and cages.

This process can be highly automated or performed manually, depending on the complexity and type of bearing. Automated assembly lines often ensure higher consistency and lower defect rates. Buyers should verify the assembly methods used by potential suppliers, as these can affect the product’s reliability.

Finishing: How Is the Final Product Prepared for Sale?

The finishing process includes surface treatments and inspections to ensure the bearings meet specifications. Common finishing techniques include:

- Grinding: This is used to achieve the final dimensions and surface finish.

- Coating: Bearings may be coated to enhance corrosion resistance or reduce friction.

- Cleaning: Thorough cleaning is essential to remove any contaminants that could affect performance.

Buyers should request information on the finishing processes and any post-production testing performed to ensure quality.

What Quality Assurance Measures Are Essential for Bearings?

Quality assurance (QA) is critical in bearing manufacturing to ensure that products meet both international and industry-specific standards.

Which International Standards Should Buyers Be Aware Of?

For B2B buyers, understanding relevant quality standards is essential. ISO 9001 is the most recognized international standard for quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition, depending on the application, other standards may apply, such as:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Certification: Relevant for bearings used in the oil and gas industry.

Buyers should verify that suppliers possess the appropriate certifications and that these are current.

What Are the Key Quality Control Checkpoints in Bearing Manufacturing?

Quality control (QC) checkpoints play a vital role throughout the manufacturing process. Here are the main checkpoints to consider:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help detect defects early and prevent non-conforming products from progressing to later stages.

- Final Quality Control (FQC): This final inspection checks the finished products against specifications to ensure they are free from defects and ready for shipment.

Buyers can request detailed QC reports from suppliers, which should outline the results of these inspections.

How Can Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers adhere to high-quality standards, international buyers can take several steps:

What Should Buyers Look for in Supplier Audits and Reports?

- Supplier Audits: Conducting regular audits of suppliers can reveal their adherence to quality management practices. Buyers should look for audits performed by reputable third-party organizations.

- Quality Reports: Request comprehensive quality reports that detail the results of IQC, IPQC, and FQC. These reports should provide insights into the defect rates and any corrective actions taken.

How Important Are Third-Party Inspections for Quality Assurance?

Third-party inspections can offer an unbiased assessment of a supplier’s quality control processes. Engaging a third-party inspection service can help ensure that the bearings meet specified quality standards before shipment, reducing the risk of receiving non-compliant products.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations regarding bearing manufacturing. For instance, European buyers may prioritize CE marking, while buyers from the Middle East might focus on compliance with local industry standards. Buyers should familiarize themselves with these regional differences to ensure compliance and avoid potential issues.

What Challenges Do International Buyers Face in Quality Control?

International buyers may encounter challenges related to language barriers, varying quality expectations, and different regulatory environments. Establishing clear communication with suppliers and understanding their quality assurance practices is crucial for overcoming these challenges.

By taking these steps, international B2B buyers can ensure they source high-quality bearings that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bearing gif’

To effectively procure bearing GIFs for your business needs, it is essential to follow a structured approach. This checklist will guide you through the critical steps necessary for successful sourcing, ensuring you acquire high-quality digital assets that meet your operational requirements.

Step 1: Define Your Use Case for Bearing GIFs

Understanding your specific use case is foundational for sourcing the right bearing GIFs. Are you using them for marketing, educational purposes, or technical documentation? Identifying the context will help you determine the style, format, and resolution needed.

- Marketing Needs: Consider GIFs that are engaging and visually appealing.

- Technical Documentation: Opt for clear and detailed animations that accurately depict functionality.

Step 2: Research Reputable Sources for Bearing GIFs

Before making any purchases or downloads, research reliable platforms that provide high-quality bearing GIFs. Websites like GIPHY, Tenor, and Pixabay are popular choices.

- Quality Assurance: Look for platforms that offer user-generated content with ratings or reviews.

- Licensing Information: Ensure that the GIFs are royalty-free or come with appropriate licensing for commercial use.

Step 3: Evaluate File Formats and Compatibility

Different applications may require specific file formats. Check whether the GIFs are compatible with your intended use, whether it’s for web integration, presentations, or social media.

- Common Formats: Ensure that the files are in widely supported formats like GIF, PNG, or MP4.

- Resolution Requirements: Consider the resolution needed for the quality of display you aim to achieve.

Step 4: Verify Licensing and Usage Rights

It is critical to confirm the licensing agreements attached to the GIFs you intend to use. Misuse of copyrighted material can lead to legal issues.

- Commercial Use: Look for GIFs labeled for commercial use, especially if you plan to use them in promotional material.

- Attribution Requirements: Note if the GIFs require attribution, and be prepared to provide credit where necessary.

Step 5: Assess Customization Options

If the available GIFs do not meet your exact needs, consider sourcing options that allow for customization. Some platforms offer services to create bespoke GIFs tailored to your specifications.

- Tailored Solutions: Engage designers or use GIF creation tools to develop animations that represent your brand accurately.

- Feedback Loop: Be sure to have a review process to refine the final product based on your team’s input.

Step 6: Check Supplier Reputation and Reviews

When engaging with a supplier or platform, it’s essential to assess their reputation. Look for reviews from other B2B buyers to gauge their reliability.

- Customer Testimonials: Seek feedback from businesses in similar industries or regions.

- Case Studies: Request examples of previous work to evaluate the quality and relevance of their offerings.

Step 7: Finalize the Procurement Process

Once you have identified suitable GIFs and verified all necessary details, proceed with the procurement process. Ensure that payment methods are secure and that you receive all necessary documentation.

- Secure Transactions: Use trusted payment gateways to protect your financial information.

- Documentation: Keep records of your purchases and licensing agreements for future reference.

Following this comprehensive checklist will streamline your sourcing process for bearing GIFs, ensuring you select assets that align with your business objectives while mitigating potential risks.

Comprehensive Cost and Pricing Analysis for bearing gif Sourcing

What Are the Key Cost Components in Bearing GIF Sourcing?

When sourcing bearing GIFs, understanding the cost structure is crucial for international B2B buyers. Key components of the cost include:

-

Materials: The cost of raw materials used in creating GIFs, such as software licenses and design resources, can vary significantly. High-quality images or animations may require more advanced software and skilled designers, impacting overall costs.

-

Labor: Skilled labor is essential for creating professional-grade GIFs. The cost of designers and animators can vary based on their expertise and geographical location, with rates being generally higher in Europe compared to Africa or South America.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. For digital products like GIFs, overhead might be lower compared to physical goods, but still significant if considering long-term software subscriptions and server costs.

-

Tooling: While not typically a major factor in digital GIF production, any specialized tools or software licenses necessary for creating high-quality GIFs could contribute to the overall cost.

-

Quality Control (QC): Ensuring the quality of the final product involves additional labor and potential software tools, especially if the GIFs need to meet specific industry standards or client specifications.

-

Logistics: Although GIFs are digital products, logistics costs can arise from the distribution of large files or the need for a robust digital infrastructure to host and deliver these assets.

-

Margin: Suppliers will always include a markup to ensure profitability. Understanding the typical margins in your region can help in negotiating better prices.

What Influences Pricing for Bearing GIFs?

Several factors can influence the pricing of bearing GIFs, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit prices. Buyers should negotiate MOQs that align with their needs to achieve cost savings.

-

Specifications and Customization: Custom GIFs tailored to specific requirements or branding will generally cost more than standard offerings. Clear specifications can help suppliers provide more accurate quotes.

-

Materials and Quality Certifications: The quality of the GIFs, including resolution and design complexity, will significantly impact pricing. Suppliers may charge a premium for higher-quality images or animations that meet specific certification standards.

-

Supplier Factors: The supplier’s reputation, location, and production capacity can also affect pricing. Established suppliers may offer better quality but at a higher price point.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, all of which can affect overall costs.

What Are the Best Negotiation Tips for International B2B Buyers?

For buyers from regions like Africa, South America, the Middle East, and Europe, strategic negotiation can lead to better pricing and terms:

-

Research and Understand Local Markets: Familiarize yourself with local pricing norms and supplier costs in your region. This knowledge can strengthen your negotiation position.

-

Leverage Total Cost of Ownership (TCO): Evaluate not just the initial costs but also the long-term benefits and expenses associated with the GIFs, such as potential updates or maintenance costs.

-

Build Relationships with Suppliers: Establishing a good relationship with suppliers can lead to more favorable terms and pricing. Long-term partnerships often yield better prices.

-

Be Prepared to Walk Away: Knowing your budget limits and being willing to walk away can empower you in negotiations, making suppliers more inclined to offer better terms.

-

Request Sample Work: Before committing to larger orders, request sample GIFs to assess quality. This can also serve as a negotiation tool if the quality does not meet your expectations.

Disclaimer on Pricing

Prices for bearing GIFs can vary widely based on the factors mentioned above. The figures provided in any quotes should be viewed as indicative and subject to change based on market conditions, supplier capabilities, and negotiation outcomes. Always ensure to clarify all terms and conditions before finalizing any agreements.

Alternatives Analysis: Comparing bearing gif With Other Solutions

When considering solutions for enhancing mechanical performance and visual communication in engineering contexts, it’s essential to explore various alternatives to the ‘bearing gif’. These alternatives may offer distinct advantages depending on the specific needs of your organization. Below, we will compare ‘bearing gif’ with two viable alternatives: 3D Animation Software and Static Diagrams.

Comparison Table

| Comparison Aspect | Bearing Gif | 3D Animation Software | Static Diagrams |

|---|---|---|---|

| Performance | High visual engagement; effectively demonstrates motion | Very high; allows for detailed simulations and interactions | Moderate; provides a clear, but static view |

| Cost | Low to moderate | High; requires software and skilled personnel | Low; minimal resources needed |

| Ease of Implementation | Easy; requires minimal setup | Complex; requires training and software installation | Very easy; can be created with basic tools |

| Maintenance | Low; infrequent updates needed | High; needs regular updates and software maintenance | Low; rarely needs updates |

| Best Use Case | Quick visual reference and marketing | Detailed engineering presentations and simulations | Basic educational or instructional use |

What are the Advantages and Disadvantages of 3D Animation Software?

3D Animation Software excels in creating detailed and interactive representations of mechanical components, allowing for a comprehensive understanding of how parts work together. This method is particularly beneficial for complex assemblies where motion and interaction are crucial. However, the costs associated with purchasing software licenses and the need for skilled personnel to create animations can be significant. Additionally, the implementation process can be complex, requiring time and training.

Why Use Static Diagrams Over Bearing Gifs?

Static Diagrams serve as an excellent alternative when simplicity is key. They provide clear and concise visual representations of components without the need for complex software or animations. This makes them highly cost-effective and easy to produce, often using basic graphic design tools. However, static diagrams lack the dynamic elements that bearing gifs and 3D animations offer, which can lead to a less engaging experience and potentially miss communicating intricate functions.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right visual representation tool for bearings or other mechanical components, B2B buyers should consider their specific requirements. If quick, engaging visuals are needed for marketing or presentations, bearing gifs may be the best option. For detailed engineering discussions or simulations, investing in 3D animation software could yield better results despite the higher costs. Conversely, if budget constraints are a priority and the information can be effectively conveyed with simplicity, static diagrams may be the most practical choice.

Ultimately, the choice between these alternatives will depend on factors such as budget, the complexity of the information to be conveyed, and the intended audience. By carefully evaluating these aspects, international B2B buyers can select the most appropriate solution to meet their operational needs.

Essential Technical Properties and Trade Terminology for bearing gif

What Are the Essential Technical Properties of Bearing GIFs?

A stock image related to bearing gif.

When considering the purchase or use of bearing GIFs in a B2B context, understanding their technical properties is crucial for making informed decisions. Here are some key specifications to keep in mind:

1. Material Grade

The material used in bearings significantly affects their performance and durability. Common materials include stainless steel, chrome steel, and plastic composites. Each material has different wear resistance, load capacity, and corrosion resistance. For international buyers, selecting the right material is essential for ensuring longevity and reliability in various applications, from automotive to industrial machinery.

2. Tolerance Levels

Tolerance refers to the allowable deviation from a specified dimension in bearing manufacturing. Precise tolerances are critical for ensuring the correct fit and function of bearings within machinery. High-tolerance bearings reduce friction and wear, enhancing efficiency. Buyers should specify their tolerance requirements to avoid compatibility issues, especially when sourcing from different global suppliers.

3. Load Capacity

Load capacity indicates the maximum load a bearing can handle before failure. It is usually expressed in radial and axial loads. Understanding load capacity is vital for buyers to ensure that the bearings can withstand the operational demands of their applications. Insufficient load capacity can lead to premature failure, resulting in costly downtimes.

4. Speed Rating

The speed rating defines the maximum rotational speed a bearing can sustain without failure. This specification is crucial in applications like motors and turbines, where high speeds are common. Buyers should assess their operational speeds to select bearings with an adequate speed rating, ensuring optimal performance.

5. Lubrication Type

Bearings can be lubricated in various ways, including grease, oil, or self-lubricating materials. The choice of lubrication affects the bearing’s operational temperature, friction levels, and service life. Buyers need to understand the lubrication requirements for their specific application to maintain bearing efficiency and longevity.

6. Sealing Mechanism

The sealing mechanism protects bearings from contaminants such as dust and moisture. Different sealing options, such as rubber seals or metal shields, offer varying levels of protection. Choosing the right sealing type is essential for extending the life of the bearings, particularly in harsh environments.

What Are Common Trade Terms in the Bearing Industry?

Understanding industry jargon is equally important for B2B buyers, as it facilitates smoother transactions and clearer communications. Here are several common trade terms relevant to bearing purchases:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. In the bearing industry, buyers often seek OEM products for quality assurance and compatibility with existing machinery. Understanding OEM specifications helps buyers maintain consistency in their operations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand as it can impact inventory management and cost-efficiency. Smaller businesses, in particular, should negotiate MOQs that align with their operational needs to avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. It typically includes detailed specifications and quantities. Submitting an RFQ helps buyers compare prices and services from different suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for buyers to avoid unexpected costs and ensure smooth logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the bearing industry, lead times can vary based on production capacity and shipping logistics. Buyers should account for lead time in their planning to avoid disruptions in their supply chain.

By familiarizing themselves with these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions that enhance their purchasing strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the bearing gif Sector

What Are the Current Market Dynamics and Key Trends in the Bearing GIF Sector?

The global bearing GIF market is influenced by several key drivers, including technological advancements, rising demand from various industries, and the increasing focus on digital marketing strategies. As industries such as automotive, aerospace, and manufacturing continue to expand, the need for high-quality bearings and corresponding visual content, such as GIFs, becomes crucial. B2B buyers from regions like Africa, South America, the Middle East, and Europe, particularly Germany and Colombia, should be aware of the digital transformation that is reshaping how companies present their products.

Emerging trends include the integration of Augmented Reality (AR) and Virtual Reality (VR) technologies in product showcases, which can enhance the customer experience and engagement. Additionally, the use of social media platforms for sharing GIFs related to bearings is on the rise, allowing for more dynamic marketing strategies. The shift towards e-commerce and online marketplaces is also significant, as it offers buyers the convenience of sourcing products while accessing visual content that aids in decision-making.

Moreover, as companies strive to differentiate themselves in a competitive marketplace, they are increasingly investing in customized and branded GIFs that resonate with their target audiences. Buyers should consider suppliers who leverage these trends to enhance their product offerings and improve brand visibility.

How Is Sustainability and Ethical Sourcing Important in the Bearing GIF Sector?

Sustainability and ethical sourcing have become pivotal considerations for B2B buyers in the bearing GIF sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, has prompted a shift towards more sustainable practices. Buyers are increasingly seeking suppliers who prioritize eco-friendly materials and production methods. This is particularly relevant in industries where bearings are utilized, as a commitment to sustainability can enhance brand reputation and appeal to environmentally-conscious customers.

Incorporating ‘green’ certifications and sustainable materials into the supply chain is essential for companies looking to attract international buyers. Certifications such as ISO 14001 for environmental management systems can serve as valuable indicators of a supplier’s commitment to sustainability. Furthermore, using recycled materials in manufacturing bearings and related products can significantly reduce the environmental footprint.

For buyers in Africa, South America, the Middle East, and Europe, understanding the importance of ethical supply chains is crucial. This includes ensuring fair labor practices and transparency throughout the sourcing process. By aligning with suppliers who prioritize ethical considerations, buyers can contribute to a more sustainable and responsible industry.

What Is the Brief Evolution and History of the Bearing GIF Sector?

The evolution of the bearing GIF sector can be traced back to the increasing digitalization of marketing strategies in the early 2000s. As businesses began to recognize the value of visual content in engaging customers, GIFs emerged as a popular medium for showcasing products due to their ability to convey complex information quickly and effectively.

Initially used in sectors like entertainment and social media, the application of GIFs in B2B marketing gained momentum as companies sought innovative ways to present their offerings. The introduction of high-speed internet and advanced graphic design tools facilitated the creation and sharing of GIFs, making them an integral part of digital marketing strategies.

Today, bearing GIFs are utilized not only for promotional purposes but also for educational content, demonstrating product features and functionalities. This evolution highlights the importance of adapting to technological advancements and consumer preferences, enabling B2B buyers to make informed purchasing decisions based on engaging and informative visual content.

Frequently Asked Questions (FAQs) for B2B Buyers of bearing gif

-

How do I find reliable suppliers for bearing GIFs?

Finding reliable suppliers for bearing GIFs involves several steps. Start by researching online platforms that specialize in industrial graphics and animations, such as Giphy or Tenor. Look for suppliers with a strong portfolio and positive reviews. Additionally, consider reaching out to industry forums and LinkedIn groups dedicated to mechanical engineering or industrial design. Always verify supplier credentials and ask for samples to assess the quality of their GIFs before proceeding. -

What is the best platform for sourcing bearing GIFs for my business?

The best platform for sourcing bearing GIFs largely depends on your specific needs. For a wide variety of animated graphics, Giphy and Tenor are excellent choices as they offer extensive libraries. If you require custom GIFs tailored to your brand or specific applications, consider hiring a freelance graphic designer through platforms like Fiverr or Upwork. Ensure that the platform you choose allows for commercial use of the GIFs to avoid legal issues. -

What customization options are available for bearing GIFs?

Customization options for bearing GIFs can include altering colors, adding company logos, or changing the animations to better suit your branding needs. Many graphic designers and animation studios offer these services, allowing you to create unique content that aligns with your marketing strategy. Be clear about your requirements when discussing projects with suppliers to ensure they can meet your expectations. -

What are the minimum order quantities (MOQ) for purchasing bearing GIFs?

Minimum order quantities for purchasing bearing GIFs can vary significantly by supplier. Some platforms allow you to download GIFs individually, while others may have MOQs for bulk purchases or custom designs. When negotiating with suppliers, clarify the MOQ to avoid any surprises and ensure it aligns with your budget and marketing needs. -

What payment terms should I expect when sourcing bearing GIFs internationally?

Payment terms for sourcing bearing GIFs internationally can vary based on the supplier’s policies and your relationship with them. Common options include upfront payment, 50% deposit with the remainder upon delivery, or payment after receipt of the goods. Always negotiate favorable terms that protect your interests, especially when dealing with overseas suppliers, and consider using secure payment methods like PayPal or escrow services. -

How can I ensure quality assurance for the bearing GIFs I purchase?

To ensure quality assurance for the bearing GIFs you purchase, request samples before making a bulk order. Evaluate the quality of the animations, resolution, and adherence to your specifications. Additionally, establish clear communication with the supplier about your quality expectations and ask about their quality control processes. It may also be beneficial to read reviews or request references from previous clients. -

What logistics considerations should I keep in mind when sourcing bearing GIFs from abroad?

When sourcing bearing GIFs from abroad, consider logistics such as file transfer methods, bandwidth requirements, and potential delays in receiving digital assets. Ensure that the supplier can provide the GIFs in the format you need, and clarify the delivery timeline. Additionally, familiarize yourself with any legal restrictions or copyright considerations that may apply to digital content in your region. -

How do I handle copyright issues when using bearing GIFs in my marketing?

Handling copyright issues when using bearing GIFs requires understanding the licensing agreements associated with each GIF. Always check if the GIFs are free to use commercially or if they require attribution. If you’re unsure, consider obtaining permission from the creator or purchasing licenses for exclusive use. This will help you avoid legal complications and ensure that your marketing efforts comply with copyright laws.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bearing gif

The landscape of strategic sourcing for bearing GIFs is evolving, driven by technological advancements and the increasing demand for innovative visual content in B2B marketing. As international buyers from Africa, South America, the Middle East, and Europe seek to enhance their digital communication strategies, leveraging bearing GIFs can be a powerful tool. These animations not only capture attention but also effectively convey complex information about products and services in an engaging manner.

How Can Strategic Sourcing Enhance Your Business?

Strategic sourcing allows businesses to identify and collaborate with suppliers who provide high-quality, relevant GIF content tailored to their specific needs. This not only ensures consistency in branding but also enhances the overall customer experience. By prioritizing strategic partnerships with suppliers who understand regional market dynamics—particularly in countries like Germany and Colombia—buyers can optimize their marketing strategies and drive engagement.

A stock image related to bearing gif.

What’s Next for International B2B Buyers?

Looking ahead, the integration of bearing GIFs into marketing efforts will continue to grow. As you navigate this dynamic environment, focus on building relationships with content creators and suppliers who can deliver unique, high-quality GIFs that resonate with your target audience. Embrace innovation and stay ahead of the competition by incorporating GIFs that not only inform but also entertain. Take action now to explore the potential of bearing GIFs in your business strategy and unlock new avenues for growth.