Discover the Best: Different Types of Electrical Outlets (2025)

Introduction: Navigating the Global Market for different types of electrical outlets

In today’s global marketplace, sourcing the right electrical outlets can be a daunting challenge for B2B buyers, especially when considering the diverse types available across different regions. Understanding the nuances of electrical outlet types—ranging from standard 15-amp duplex receptacles to advanced weather-resistant and smart outlets—can significantly influence operational efficiency and safety in various applications. This comprehensive guide serves as a valuable resource, delving into the specifications, applications, and regional variations of electrical outlets, while also addressing key factors like supplier vetting and cost considerations.

International buyers from Africa, South America, the Middle East, and Europe, including countries like Italy and Indonesia, will find actionable insights tailored to their unique market needs. The guide not only outlines the various outlet types and their respective uses but also emphasizes the importance of compliance with local electrical codes and standards. By equipping buyers with essential knowledge and best practices, this guide empowers informed purchasing decisions that can enhance project outcomes and reduce risks associated with electrical installations.

With a focus on practical applications and strategic sourcing, this resource aims to bridge the gap between diverse electrical requirements and reliable supplier partnerships, ensuring that businesses can confidently meet their electrical needs in an increasingly interconnected world.

Understanding different types of electrical outlets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 15-Amp Duplex Outlet | Standard two-slot design with a grounding hole | General office equipment, lamps | Pros: Widely compatible; Cons: Limited to lower power devices. |

| GFCI Outlet | Monitors electrical flow and shuts off if imbalance detected | Kitchens, bathrooms, outdoor areas | Pros: Enhances safety; Cons: May require professional installation. |

| AFCI Outlet | Detects dangerous arcing conditions to prevent fires | Residential and commercial living spaces | Pros: Fire prevention; Cons: More expensive than standard outlets. |

| Tamper-Resistant Outlet | Built-in shutters to prevent accidental insertion | Childcare facilities, schools | Pros: Increased safety; Cons: Slightly higher cost. |

| Weather-Resistant Outlet | Designed for outdoor use, resistant to moisture and UV rays | Patios, outdoor events, construction sites | Pros: Durable in harsh conditions; Cons: Limited to outdoor applications. |

What Are the Key Characteristics of 15-Amp Duplex Outlets?

The 15-amp duplex outlet is the most common type found in residential and commercial settings. It features a standard two-slot design with a U-shaped grounding hole, making it suitable for a wide range of devices, including lamps and small appliances. When purchasing, B2B buyers should consider the outlet’s compatibility with existing wiring and ensure that their electrical systems can handle the cumulative load of connected devices.

How Do GFCI Outlets Enhance Safety in B2B Environments?

Ground Fault Circuit Interrupter (GFCI) outlets are essential for areas prone to moisture, such as kitchens and bathrooms. These outlets continuously monitor electrical flow and shut off power when an imbalance is detected, significantly reducing the risk of electric shock. B2B buyers should prioritize GFCI outlets in environments where water exposure is likely, ensuring compliance with safety regulations and enhancing overall workplace safety.

What Makes AFCI Outlets a Smart Investment for Businesses?

Arc Fault Circuit Interrupter (AFCI) outlets are designed to detect dangerous arcing conditions that can lead to electrical fires. They are particularly recommended for residential and commercial living spaces. While they may come at a higher initial cost, the investment pays off by significantly reducing fire risks. B2B buyers should evaluate their electrical systems and consider AFCI outlets in areas with a high concentration of electrical devices.

Why Choose Tamper-Resistant Outlets for Child Safety?

Tamper-resistant outlets are equipped with built-in shutters that prevent accidental insertion of foreign objects. This feature makes them ideal for childcare facilities and educational institutions. While the cost may be slightly higher than standard outlets, the added safety benefits justify the investment, particularly in environments where children are present. B2B buyers should consider these outlets for any facility that prioritizes safety and compliance.

What Are the Benefits of Using Weather-Resistant Outlets in Outdoor Applications?

Weather-resistant outlets are specifically designed to withstand outdoor conditions, featuring protective covers that guard against moisture and UV damage. These outlets are perfect for patios, outdoor events, and construction sites. B2B buyers should assess their outdoor electrical needs and opt for weather-resistant outlets to ensure durability and reliability in harsh environments, ultimately reducing maintenance costs over time.

Key Industrial Applications of different types of electrical outlets

| Industry/Sector | Specific Application of different types of electrical outlets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of 20-amp outlets for heavy machinery and equipment | Ensures reliable power supply for continuous operation and minimizes downtime | Compliance with local electrical codes and standards, durability under industrial conditions |

| Healthcare | GFCI outlets in wet areas like bathrooms and kitchens | Enhances safety by preventing electrical shocks in high-risk environments | Certification for safety standards, ease of installation, and maintenance requirements |

| Hospitality | Combination outlets for lighting and charging stations | Provides convenience for guests and improves customer satisfaction | Aesthetic design, compatibility with various devices, and energy efficiency |

| Construction | Weather-resistant outlets on job sites | Protects electrical systems from environmental damage, ensuring safety and functionality | Resistance to weather conditions, compliance with safety regulations, and robust build quality |

| Retail | Smart outlets for inventory management and customer service | Enables energy management and enhances customer experience through charging solutions | Integration with smart systems, reliability, and scalability for future upgrades |

How Are Different Types of Electrical Outlets Used in Manufacturing?

In the manufacturing sector, 20-amp outlets are vital for powering heavy machinery and equipment. These outlets support the operational needs of tools that require higher amperage, ensuring a reliable power supply that minimizes downtime. International B2B buyers must consider compliance with local electrical codes, the durability of the outlets under industrial conditions, and the availability of technical support for installation and maintenance.

What Role Do Electrical Outlets Play in Healthcare Settings?

In healthcare environments, GFCI outlets are crucial in wet areas such as bathrooms and kitchens to prevent electrical shocks. These outlets continuously monitor electrical currents and cut off power when imbalances are detected, enhancing safety for both patients and staff. Buyers in this sector should prioritize outlets that meet stringent safety certifications, are easy to install, and require minimal maintenance to ensure uninterrupted healthcare services.

A stock image related to different types of electrical outlets.

How Do Combination Outlets Benefit the Hospitality Industry?

Combination outlets that integrate switches and standard power sockets are increasingly used in the hospitality sector. They allow hotels to provide lighting control alongside charging stations for electronic devices, enhancing guest convenience and satisfaction. When sourcing these outlets, businesses should focus on aesthetic design, compatibility with various devices, and energy efficiency to align with sustainability goals.

Why Are Weather-Resistant Outlets Important for Construction Sites?

Weather-resistant outlets are essential on construction sites to protect electrical systems from environmental damage, such as moisture and dust. These outlets ensure that power remains accessible and functional, thereby maintaining safety standards on-site. Buyers should seek products that resist adverse weather conditions, comply with safety regulations, and boast robust build quality to withstand rigorous use.

How Do Smart Outlets Enhance Retail Operations?

In the retail sector, smart outlets facilitate energy management and improve customer service by enabling charging solutions for devices. They can be programmed to control power use based on store hours, enhancing energy efficiency. Retailers should consider the ease of integration with existing smart systems, the reliability of the outlets, and the potential for future scalability when sourcing these advanced solutions.

3 Common User Pain Points for ‘different types of electrical outlets’ & Their Solutions

Scenario 1: Incompatible Outlets for Diverse Equipment Needs

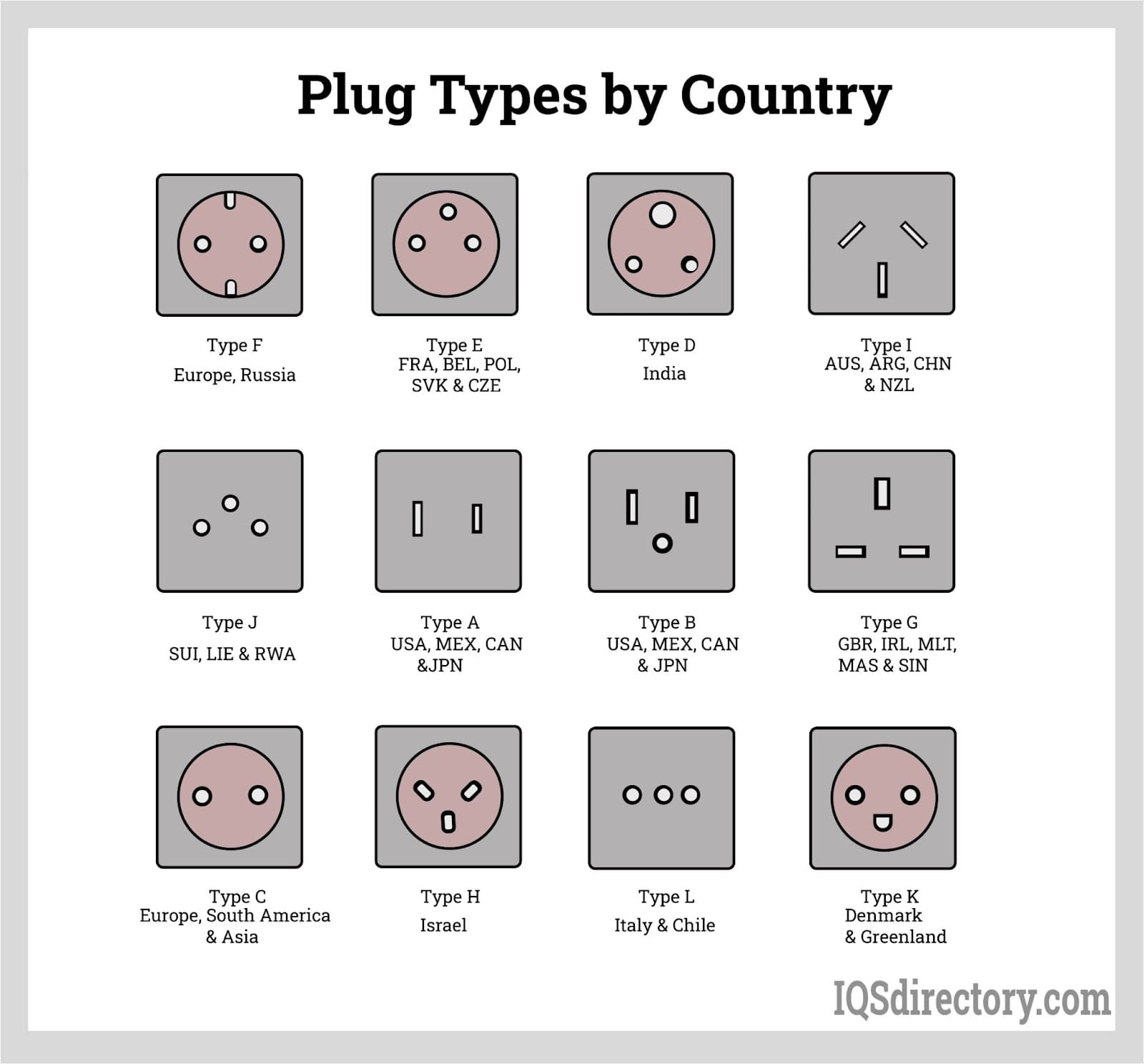

The Problem: International B2B buyers often face the challenge of sourcing electrical outlets that are compatible with a variety of equipment. For instance, a construction firm operating in multiple regions may find that the tools and machinery they purchase come with different plug types, which are incompatible with local electrical outlets. This not only leads to operational inefficiencies but can also result in increased costs due to the need for adapters or additional equipment.

The Solution: To effectively address this issue, it’s crucial to conduct thorough market research on the prevalent electrical outlet types in the regions of operation. For example, buyers should familiarize themselves with the international standards such as Type A, B, C, and others, which differ in pin configuration and voltage. When purchasing equipment, negotiate with suppliers to include compatible plugs or request equipment that comes with interchangeable plug options. Additionally, investing in multi-purpose power strips or universal adapters can provide a flexible solution that accommodates various plug types without compromising safety or efficiency.

Scenario 2: Safety Compliance in Electrical Installations

The Problem: Ensuring safety compliance with electrical installations can be a daunting task for B2B buyers, particularly in industries that deal with high power consumption or operate in damp environments. A manufacturing company in the Middle East, for example, may need to install outlets that meet local electrical codes, such as GFCI or AFCI outlets, to prevent electrical hazards. Failing to comply can lead to severe consequences, including workplace accidents and legal ramifications.

The Solution: To navigate these compliance challenges, it is essential to engage with local electrical standards and regulations before sourcing electrical outlets. Buyers should collaborate with certified electricians to ensure that installations not only meet safety codes but also suit the specific operational needs of the business. Prioritizing the procurement of GFCI outlets for wet areas and AFCI outlets for high-risk zones can significantly reduce the risk of electrical fires and shocks. Furthermore, establishing a routine inspection and maintenance schedule for all electrical installations will help ensure ongoing compliance and safety.

Scenario 3: Limited Access to Specialized Outlets

The Problem: B2B buyers often encounter difficulties in accessing specialized electrical outlets necessary for specific applications, such as USB outlets for charging devices in office spaces or tamper-resistant outlets for child safety in educational institutions. This limitation can hinder operational efficiency and user experience, especially in environments where multiple devices need to be powered simultaneously.

The Solution: To overcome this limitation, buyers should build relationships with multiple suppliers to widen their access to specialized electrical outlets. It’s advisable to source products from manufacturers known for a diverse product range, including smart outlets that can be controlled remotely or weather-resistant outlets for outdoor use. Additionally, buyers should consider bulk purchasing options to reduce costs and ensure that they have a steady supply of the necessary outlets. When planning electrical installations, involve electrical engineers to design layouts that effectively utilize these specialized outlets, thereby enhancing functionality and user convenience.

Strategic Material Selection Guide for different types of electrical outlets

What Are the Key Materials Used in Electrical Outlets?

When selecting electrical outlets for various applications, understanding the materials used in their construction is crucial. The choice of material affects performance, durability, compliance with international standards, and overall suitability for specific environments. Here, we analyze four common materials used in electrical outlets: thermoplastics, metals, ceramics, and composite materials.

How Do Thermoplastics Perform in Electrical Outlet Applications?

A stock image related to different types of electrical outlets.

Thermoplastics, such as polyvinyl chloride (PVC) and nylon, are widely used in electrical outlets due to their excellent insulating properties and resistance to chemicals. These materials can typically withstand temperatures ranging from -40°C to 85°C, making them suitable for various environments.

Pros: Thermoplastics are lightweight, cost-effective, and easy to mold into complex shapes, which simplifies manufacturing. Their insulating properties enhance safety, reducing the risk of electrical shock.

Cons: While thermoplastics offer good durability, they may not withstand extreme temperatures or mechanical stress as well as metals. Additionally, they can degrade under prolonged exposure to UV light unless treated.

For international B2B buyers, thermoplastics comply with standards such as ASTM D638 for tensile strength and UL 94 for flammability. However, buyers should ensure that the specific thermoplastic used meets local electrical safety standards.

What Role Do Metals Play in Electrical Outlet Construction?

Metals, particularly copper and aluminum, are often used for electrical contacts within outlets due to their excellent conductivity. Copper, with its high electrical conductivity and resistance to corrosion, is the preferred choice for most applications.

Pros: Metal components provide superior performance in terms of conductivity and durability. They can handle higher currents and are less prone to overheating, which enhances the safety and longevity of the outlet.

Cons: The primary drawback of metals is their susceptibility to corrosion, especially in humid or saline environments. This can lead to increased maintenance costs and potential failures over time.

International buyers should consider compliance with standards such as IEC 61238 for compression connections and ensure that the metals used are suitable for the specific environmental conditions of their region.

How Do Ceramics Enhance Electrical Outlet Performance?

Ceramics are often used in high-voltage applications due to their excellent thermal stability and electrical insulation properties. They can withstand high temperatures and are resistant to wear and tear.

Pros: Ceramics are highly durable and can operate effectively in extreme conditions, making them suitable for industrial applications. Their insulating properties prevent electrical leakage, enhancing safety.

Cons: The main limitation of ceramics is their brittleness, which can lead to breakage during installation or use. Additionally, they are generally more expensive than thermoplastics and metals.

For B2B buyers, compliance with international standards such as ASTM C20 for ceramic materials is essential, especially when considering applications in regions with extreme weather conditions.

What Are the Benefits of Composite Materials in Electrical Outlets?

Composite materials, which combine various substances to enhance performance, are increasingly used in electrical outlets. These materials often blend thermoplastics with reinforcing fibers to improve strength and thermal resistance.

Pros: Composites offer a good balance of lightweight properties, strength, and resistance to environmental factors. They can be tailored for specific applications, providing versatility.

Cons: The manufacturing process for composites can be more complex and costly compared to traditional materials. Additionally, the long-term durability of composites may vary based on the specific formulation used.

For international B2B buyers, it is crucial to verify that composite materials meet relevant standards, such as ISO 527 for tensile properties, to ensure reliability in various applications.

Summary Table of Material Properties for Electrical Outlets

| Material | Typical Use Case for different types of electrical outlets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and commercial outlets | Lightweight and cost-effective | Limited temperature and mechanical stress limits | Low |

| Metals | Electrical contacts in outlets | Superior conductivity and durability | Susceptible to corrosion | Medium |

| Ceramics | High-voltage and industrial outlets | Excellent thermal stability and insulation | Brittle and prone to breakage | High |

| Composite Materials | Specialty applications requiring tailored properties | Good balance of strength and lightweight | Complex manufacturing process | Medium |

This strategic material selection guide provides B2B buyers with a comprehensive understanding of the materials used in electrical outlets, enabling informed decisions that align with local standards and specific application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for different types of electrical outlets

What Are the Key Stages in the Manufacturing Process of Electrical Outlets?

Manufacturing electrical outlets involves several critical stages, each designed to ensure that the final product meets safety and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality raw materials, primarily plastics for the outer casing and metals like copper for the internal connections. Suppliers must ensure that materials comply with relevant international standards to guarantee safety and durability. For instance, the plastic used in outlets should be flame-retardant and resistant to impacts.

-

Forming: During this stage, the prepared materials are shaped into the desired outlet components. Injection molding is the most common technique used for plastic parts, allowing for precise dimensions and complex designs. For metal components, stamping or die-casting is often employed to achieve the necessary shapes and sizes quickly.

-

Assembly: Once the individual components are formed, they are assembled into complete electrical outlets. This process may include manual or automated methods, depending on the scale of production. Automated assembly lines enhance efficiency and reduce human error, ensuring consistency across batches.

-

Finishing: After assembly, the outlets undergo finishing processes, which may involve painting, coating, or applying labels. This not only improves aesthetics but also adds protective layers that enhance durability against environmental factors. In some cases, outlets may also receive additional treatments to improve their resistance to moisture or UV exposure.

How Is Quality Assurance Implemented in Electrical Outlet Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of electrical outlets to ensure safety and compliance with international standards. Key QA components include adherence to international standards, defined QC checkpoints, and comprehensive testing methods.

-

International Standards and Certifications: Manufacturers must comply with various international standards, such as ISO 9001 for quality management systems, and specific electrical safety standards like CE in Europe or UL in the United States. These certifications provide assurance that the products meet established safety and performance criteria, which is crucial for international buyers.

-

Quality Control Checkpoints: The QA process typically involves several checkpoints:

– Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to verify that production is adhering to quality standards. This might include checking dimensions, material properties, and assembly integrity.

– Final Quality Control (FQC): After the manufacturing process, the completed outlets undergo thorough testing to ensure they function correctly and safely. This includes electrical testing to check for proper insulation, grounding, and functionality under load. -

Common Testing Methods for Electrical Outlets: Various testing methods are employed to verify the quality of electrical outlets. These may include:

– Dielectric Strength Testing: Ensures that the insulation can withstand high voltages without breakdown.

– Temperature Rise Testing: Measures how much the outlet heats up under load to prevent overheating.

– Durability Testing: Simulates repeated use to assess the outlet’s lifespan and reliability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in international markets like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps to consider:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should request access to audit reports and certifications to assess compliance with international standards.

-

Review Quality Reports: Suppliers should provide documentation detailing their quality control processes and results from various tests conducted. This includes IQC, IPQC, and FQC reports that highlight the effectiveness of their QA measures.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can conduct independent assessments of the supplier’s manufacturing practices and product quality, providing unbiased reports that can inform purchasing decisions.

-

Understand Certification Nuances: International buyers must be aware that certifications may vary by region. For instance, a product certified in Europe may not meet the specific requirements in the Middle East or Africa. Buyers should ensure that suppliers have the necessary certifications relevant to their target markets.

What Are the Challenges in Ensuring Quality Control for International B2B Buyers?

International B2B buyers face unique challenges when it comes to ensuring quality control in electrical outlets. Understanding these challenges can help buyers make informed decisions.

-

Regulatory Differences: Different countries have varying regulations regarding electrical safety and quality standards. Buyers must navigate these complexities to ensure compliance, which may require additional research and verification of supplier certifications.

-

Supply Chain Variability: Global supply chains can introduce variability in material quality and manufacturing practices. Buyers should establish strong relationships with suppliers and maintain open communication to mitigate risks associated with supply chain disruptions.

-

Cultural and Language Barriers: Engaging with suppliers from different regions may present cultural and language challenges that can affect negotiations and quality assurance processes. Buyers should consider working with local representatives or experts who understand the nuances of the region.

-

Technological Advancements: As technology evolves, so do the standards and expectations for electrical outlets. Buyers must stay informed about industry trends and advancements to ensure they are sourcing the latest and safest products.

By understanding the manufacturing processes, quality assurance measures, and challenges associated with sourcing electrical outlets, international B2B buyers can make informed purchasing decisions that prioritize safety and compliance while meeting their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different types of electrical outlets’

To ensure successful procurement of various types of electrical outlets, it is essential for international B2B buyers to follow a structured approach. This guide provides a step-by-step checklist to help you make informed decisions and secure the right products for your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the electrical outlets you need. Consider factors such as voltage, amperage, and compatibility with local standards. This step is crucial because different regions have varying electrical systems, and understanding these specifications helps avoid costly mistakes.

- Voltage Requirements: Identify whether you need 120V or 240V outlets.

- Amperage Needs: Determine if standard 15-amp or 20-amp outlets are sufficient for your applications.

Step 2: Research Local Compliance Standards

Familiarize yourself with local electrical codes and compliance standards that apply to electrical outlets in your target market. This knowledge is vital to ensure safety and legality in your installations.

- Regulatory Bodies: Identify local regulatory authorities that govern electrical installations.

- Documentation Requirements: Ensure that suppliers provide necessary certifications and compliance documentation.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers thoroughly. Request comprehensive company profiles, case studies, and references from clients within your industry or region.

- Supplier Reputation: Look for suppliers with positive reviews and a proven track record.

- Quality Assurance Processes: Inquire about their quality control measures to ensure the reliability of their products.

Step 4: Assess Product Variety and Specifications

Evaluate the range of electrical outlets offered by suppliers to ensure they meet your diverse needs. Different types, such as GFCI, AFCI, and tamper-resistant outlets, may be necessary based on the application.

- Specialty Outlets: Check if suppliers provide outlets suited for specific environments, such as weather-resistant options for outdoor use.

- Custom Solutions: Determine if the supplier can accommodate custom specifications if needed.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications and quality assurances. This step is crucial for ensuring that the products meet international safety and performance standards.

- ISO Certifications: Look for suppliers with ISO certifications, indicating adherence to international quality management standards.

- Local Certifications: Check for certifications specific to your region, such as CE marking in Europe or SANS in South Africa.

Step 6: Request Samples for Testing

Before finalizing your order, request samples of the electrical outlets you intend to purchase. Testing samples allows you to verify their quality and compatibility with your systems.

- Performance Testing: Evaluate the functionality and durability of the samples under typical operating conditions.

- Installation Considerations: Assess how easily the outlets can be integrated into your existing systems.

Step 7: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate favorable terms and conditions. This step is essential for securing the best price and ensuring reliable supply.

- Payment Terms: Discuss payment options that align with your cash flow needs.

- Delivery Timelines: Establish clear timelines for delivery and any penalties for delays to ensure that your project schedules remain on track.

By following this checklist, international B2B buyers can streamline their sourcing process for electrical outlets, ensuring they make informed decisions that align with their operational needs and compliance requirements.

Comprehensive Cost and Pricing Analysis for different types of electrical outlets Sourcing

What Are the Key Cost Components in Sourcing Electrical Outlets?

When sourcing electrical outlets, international B2B buyers need to understand the various cost components that contribute to the overall pricing. The primary components include:

-

Materials: The cost of raw materials such as plastics, metals, and electronic components significantly impacts the pricing. Higher quality materials tend to increase costs but also enhance durability and safety.

-

Labor: Labor costs can vary significantly depending on the region and the skill level required for assembly. In countries with higher labor rates, such as parts of Europe, costs will be elevated compared to regions in Africa or South America where labor may be less expensive.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these costs, impacting the final price.

-

Tooling: The initial setup cost for molds and specialized equipment can be substantial, particularly for custom outlet designs. Buyers should consider whether they need standard or custom outlets, as this will influence tooling costs.

-

Quality Control (QC): Implementing rigorous quality control measures ensures that the products meet international safety standards, which can add to the cost but is essential for compliance and customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on the destination, shipping method, and Incoterms. Import duties and taxes can also significantly affect overall expenses.

-

Margin: Suppliers typically build in a profit margin based on their costs and market conditions. Understanding supplier margins can aid in negotiating better pricing.

How Do Price Influencers Affect Electrical Outlet Costs?

Several factors can influence the pricing of electrical outlets, especially for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders generally reduce per-unit costs. Buyers should negotiate for lower prices based on higher order volumes, as suppliers are often willing to offer discounts.

-

Specifications and Customization: Custom outlets designed for specific applications or unique specifications may incur higher costs due to the need for specialized materials or tooling.

-

Materials: The choice of materials can lead to cost variations. For example, outlets designed for outdoor use may require weather-resistant materials, which can be more expensive than standard options.

-

Quality and Certifications: Outlets that meet international safety certifications (e.g., CE, UL) often come at a premium. Buyers should assess whether these certifications are necessary for their target markets, as they can significantly affect pricing.

-

Supplier Factors: The reliability, reputation, and location of the supplier can impact costs. Suppliers with a proven track record may charge more for their products due to perceived quality and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they dictate who bears the costs and risks during shipping. Selecting favorable terms can lead to cost savings.

What Tips Can Help B2B Buyers Optimize Costs for Electrical Outlets?

To maximize cost-efficiency when sourcing electrical outlets, consider the following strategies:

-

Negotiation: Don’t hesitate to negotiate pricing and terms with suppliers. Leverage your purchasing volume and commitment to foster better deals.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the purchase price. Consider factors such as durability, maintenance costs, and energy efficiency to make informed decisions.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local regulations that could impact pricing. Establishing relationships with local suppliers can also help mitigate these costs.

-

Market Research: Conduct thorough market research to understand competitive pricing in your region. This knowledge can empower buyers during negotiations and help identify the best suppliers.

Disclaimer on Indicative Prices

Prices for electrical outlets can vary widely based on the aforementioned factors. It is essential for buyers to obtain quotes directly from suppliers to understand current market rates and avoid assumptions based on outdated or generalized pricing information.

Alternatives Analysis: Comparing different types of electrical outlets With Other Solutions

Exploring Alternatives to Different Types of Electrical Outlets

When selecting electrical solutions for commercial or industrial applications, it’s essential to consider various alternatives to standard electrical outlets. The right choice can influence not only the efficiency and safety of operations but also long-term maintenance costs and adaptability to changing technologies. Below, we compare traditional electrical outlets with alternative solutions that can meet similar needs.

Comparison Table of Electrical Solutions

| Comparison Aspect | Different Types of Electrical Outlets | Smart Power Strips | Wireless Charging Stations |

|---|---|---|---|

| Performance | Reliable for high power needs; various types for different applications | Good for multiple devices; limited by plug capacity | Convenient for small devices; limited range and speed |

| Cost | Moderate initial investment; installation costs vary | Generally lower initial cost; some may lack durability | Higher upfront cost for quality units; ongoing tech updates |

| Ease of Implementation | Standard installation; requires electrical knowledge | Simple plug-and-play setup; no wiring needed | Requires compatible devices; may need specific installation |

| Maintenance | Low maintenance; periodic inspections recommended | Minimal maintenance; replace if malfunctioning | Low maintenance; may require updates for compatibility |

| Best Use Case | Ideal for heavy machinery, appliances, and permanent installations | Suitable for office environments with multiple devices | Best for mobile devices in casual or shared spaces |

In-Depth Look at Alternatives

A stock image related to different types of electrical outlets.

Smart Power Strips: Are They a Viable Replacement?

Smart power strips offer a modern solution for powering multiple devices simultaneously. These strips often include features such as surge protection, energy monitoring, and remote control via smartphone apps. They are particularly beneficial in environments where devices are frequently plugged and unplugged, such as offices or conference rooms. However, they may not be suitable for high-demand applications, as their performance can be limited by the total amperage they can handle. For B2B buyers, the decision to use smart power strips should consider the specific power needs of their devices and potential safety requirements.

Wireless Charging Stations: A Convenient Solution for Small Devices

Wireless charging stations are an innovative alternative for powering smartphones, tablets, and other small devices without the clutter of cables. They enhance convenience in settings like conference rooms or communal workspaces, where users can easily charge devices by simply placing them on the pad. However, these stations are limited to devices that support wireless charging technology and typically charge slower than traditional outlets. B2B buyers should evaluate whether their workforce primarily uses compatible devices and if the slower charging speed aligns with their operational needs.

Conclusion: Choosing the Right Electrical Solution

When determining the best electrical solution for your business, it’s crucial to weigh the advantages and disadvantages of each option against your specific operational requirements. While traditional electrical outlets provide reliability and high performance for heavy-duty applications, alternatives like smart power strips and wireless charging stations can offer convenience and flexibility for modern office environments. Consider factors such as cost, ease of implementation, and maintenance needs to make an informed decision that enhances productivity and safety in your business operations.

Essential Technical Properties and Trade Terminology for different types of electrical outlets

What Are the Key Technical Properties of Electrical Outlets?

Understanding the technical specifications of electrical outlets is crucial for B2B buyers looking to make informed purchasing decisions. Here are several essential properties to consider:

-

Amperage Rating

Amperage, measured in amps, indicates the maximum current that an outlet can safely handle. Common ratings include 15 amps and 20 amps. Selecting the appropriate amperage is vital for ensuring that the outlet can support the electrical load of appliances without overheating or causing circuit failures. -

Voltage Rating

The voltage rating, typically 120V or 240V, specifies the electrical potential difference that the outlet is designed to accommodate. Understanding voltage requirements is essential for compatibility with appliances and devices. Incorrect voltage ratings can lead to equipment damage or electrical hazards. -

Material Composition

The materials used in the construction of electrical outlets (e.g., thermoplastic, metal) affect durability and safety. High-quality materials can provide better insulation and resistance to environmental factors, which is especially important for outdoor or industrial applications. B2B buyers should prioritize outlets made from robust materials to ensure long-term reliability. -

Grounding Mechanism

Outlets can be either grounded or ungrounded. Grounded outlets provide an additional safety feature that helps prevent electric shock by redirecting excess current to the ground. Understanding grounding mechanisms is essential for compliance with safety regulations and for ensuring the safety of users. -

Tamper Resistance

Tamper-resistant outlets feature built-in mechanisms that prevent unauthorized access, making them ideal for residential and commercial environments where child safety is a concern. This property is particularly relevant for B2B buyers in sectors such as education or childcare, where safety regulations may be stringent. -

Weather Resistance

Weather-resistant outlets are designed to withstand harsh environmental conditions, making them suitable for outdoor use. They typically feature protective covers and corrosion-resistant components. For businesses operating in regions with extreme weather, investing in weather-resistant outlets is essential to maintain operational continuity.

What Are Common Trade Terms Related to Electrical Outlets?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are some key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. Understanding OEM relationships can help B2B buyers identify reliable suppliers and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is essential for budgeting and inventory management, as it can impact the overall cost-effectiveness of a purchase. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of products. B2B buyers should use RFQs to obtain competitive pricing and ensure they are making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that clarify the responsibilities of buyers and sellers in shipping transactions. Understanding these terms is vital for managing logistics and ensuring compliance with international trade regulations. -

UL Listing (Underwriters Laboratories)

A UL listing indicates that a product has been tested for safety and compliance with established standards. For B2B buyers, verifying UL listings can prevent costly recalls and enhance product safety. -

Surge Protection

Surge protection refers to the ability of an outlet or device to protect against voltage spikes. This feature is particularly important for businesses that rely on sensitive electronics, as it can prevent damage from electrical surges.

Understanding these technical properties and trade terms can empower international B2B buyers from Africa, South America, the Middle East, and Europe to make informed decisions regarding electrical outlet procurement. By prioritizing quality and safety, businesses can protect their investments and ensure operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the different types of electrical outlets Sector

What Are the Current Market Dynamics and Key Trends in the Electrical Outlets Sector?

The electrical outlets market is experiencing significant growth driven by technological advancements and increasing demand for energy-efficient solutions. International B2B buyers, especially in Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the sector. The rise of smart home technology is one of the most notable trends, with smart outlets enabling remote access and energy management through mobile applications. This trend is particularly appealing to businesses looking to enhance their energy efficiency and reduce operational costs.

Additionally, the growing emphasis on safety and compliance is prompting a shift towards GFCI and AFCI outlets, which protect against electrical shocks and fires. As regulations tighten globally, ensuring compliance with local electrical codes becomes essential for businesses involved in construction and renovation projects. Furthermore, the increasing awareness of sustainability is steering buyers towards tamper-resistant and weather-resistant outlets, which not only enhance safety but also extend product lifespan in diverse environments.

Emerging markets are also witnessing a surge in demand for specialty outlets tailored for specific appliances, contributing to the diversification of product offerings. B2B buyers should leverage this trend by sourcing versatile electrical solutions that can cater to various applications, ensuring a competitive edge in their respective markets.

How Can Sustainability and Ethical Sourcing Impact Electrical Outlet Procurement?

Sustainability has become a pivotal consideration in the procurement of electrical outlets. B2B buyers must evaluate the environmental impact of their sourcing decisions, focusing on manufacturers that prioritize eco-friendly practices. The production of electrical outlets often involves materials that can contribute to environmental degradation if not sourced responsibly. Therefore, opting for suppliers that utilize recycled materials or sustainable sourcing methods is crucial.

Moreover, ethical supply chains are integral to building a reputable brand. Businesses should seek manufacturers who adhere to fair labor practices and demonstrate a commitment to social responsibility. Certifications such as ISO 14001 for environmental management and Fair Trade standards can serve as indicators of a supplier’s commitment to ethical practices.

Incorporating ‘green’ certifications into the procurement process not only aligns with corporate social responsibility goals but also meets the increasing consumer demand for sustainable products. B2B buyers should actively engage with suppliers who offer eco-friendly options, such as energy-efficient outlets or those made from sustainable materials, ensuring that their purchasing decisions contribute positively to the environment.

How Has the Electrical Outlet Market Evolved Over Time?

The evolution of electrical outlets has been marked by significant technological advancements and changing consumer needs. Initially designed for basic functionality, electrical outlets have transformed into sophisticated devices that prioritize safety and energy efficiency. The introduction of GFCI outlets in the 1970s was a response to the increasing awareness of electrical safety, while AFCI outlets emerged in the 2000s to combat electrical fires caused by arcing faults.

The recent integration of smart technology into electrical outlets reflects the growing trend towards home automation and energy management. Modern outlets now feature built-in USB ports, allowing for convenient charging of devices without the need for adapters. This evolution is not only enhancing user convenience but also influencing procurement strategies, as businesses seek to offer innovative solutions that meet contemporary demands.

As the market continues to evolve, B2B buyers must stay informed about emerging technologies and trends, enabling them to make strategic sourcing decisions that align with industry advancements and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of different types of electrical outlets

-

How do I choose the right electrical outlet for my appliances?

Choosing the right electrical outlet involves understanding the amperage and voltage requirements of your appliances. For instance, standard 15-amp outlets are suitable for small appliances, while 20-amp outlets are necessary for high-demand devices like microwaves. Assess the specific needs of your equipment and ensure that the outlet matches the circuit capacity. Consider factors such as location (indoor vs. outdoor) and safety features like GFCI for wet areas. Collaborating with suppliers who understand local regulations and standards can further ensure compliance and safety. -

What types of electrical outlets are essential for international business operations?

For international business operations, consider using a variety of electrical outlets tailored to your needs. Essential types include standard 15-amp duplex outlets for everyday devices, GFCI outlets for safety in wet areas, and AFCI outlets for fire prevention. Additionally, USB outlets are increasingly popular for charging mobile devices without adapters. When sourcing, ensure the outlets comply with local standards in your target markets, such as CE certification in Europe or SABS in South Africa, to avoid regulatory issues. -

What are the best practices for vetting suppliers of electrical outlets?

When vetting suppliers, prioritize those with proven track records in quality and compliance. Check for certifications that meet international standards, such as ISO 9001 for quality management. Request samples to evaluate product quality and ensure they align with your specifications. Additionally, consider their logistics capabilities, including shipping times and costs, especially for international sourcing. Reviews and testimonials from other B2B buyers can provide insights into their reliability and customer service. -

How can I customize electrical outlets for my specific needs?

Customization options for electrical outlets may include changes in amperage ratings, color, or additional features like built-in USB ports. Discuss your specific requirements with suppliers, as many manufacturers offer tailored solutions. Ensure you communicate your needs clearly, including any regulatory standards that must be met in your region. Understand the minimum order quantities (MOQs) for customized products, as this may affect your budget and inventory planning. -

What are common minimum order quantities (MOQs) for electrical outlets?

MOQs for electrical outlets vary by supplier and product type. Typically, for standard outlets, MOQs may range from 500 to 1,000 units, while specialized or customized outlets might have higher MOQs due to production costs. When negotiating, consider your projected sales and inventory needs to avoid overstocking. Additionally, clarify whether the MOQ applies to a single product type or across multiple products to provide flexibility in your order. -

What payment terms should I expect when sourcing electrical outlets internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (usually 30-50%) with the balance due upon delivery or before shipping. Some suppliers may offer net terms, allowing payment within a specified period after receipt of goods. Always discuss and negotiate terms upfront to ensure they align with your cash flow capabilities. Additionally, consider using secure payment methods like letters of credit to protect your transactions in international trade. -

How can I ensure the quality of electrical outlets before finalizing my order?

To ensure quality, request third-party testing certifications from suppliers, such as UL or CE marks, which indicate compliance with safety standards. Conduct a factory audit if possible, or hire an inspection service to evaluate products before shipment. Ask for samples to assess product quality firsthand, and consider implementing a quality assurance process that includes regular checks on incoming shipments. Establishing clear specifications and expectations with your supplier can also help mitigate quality issues. -

What logistics considerations should I keep in mind when importing electrical outlets?

Logistics considerations include understanding shipping methods (air vs. sea), lead times, and customs regulations in your destination country. Ensure that your supplier can provide the necessary documentation for customs clearance, such as invoices and certificates of origin. Factor in costs for shipping, duties, and taxes when calculating total landed costs. Partnering with a freight forwarder experienced in electrical components can streamline the process and help you navigate any complexities in international shipping.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for different types of electrical outlets

In navigating the diverse landscape of electrical outlets, international B2B buyers must prioritize strategic sourcing to ensure compatibility, safety, and efficiency in their operations. Understanding the specific requirements of various outlet types—such as 15-amp, GFCI, and smart outlets—enables businesses to select solutions tailored to their unique environments, whether in Africa, South America, the Middle East, or Europe.

Why is Strategic Sourcing Essential for Electrical Outlets?

Strategic sourcing not only optimizes procurement costs but also enhances the reliability of electrical systems. By aligning product specifications with local electrical codes and consumer needs, businesses can mitigate risks associated with electrical failures and enhance overall operational safety.

What’s Next for B2B Buyers in the Electrical Outlet Market?

As technology advances, the demand for smart and weather-resistant outlets is expected to grow. Buyers should stay informed about emerging trends and innovations that can further enhance energy efficiency and user safety.

In conclusion, investing in the right electrical outlets is crucial for operational success. International buyers are encouraged to engage with reputable suppliers, leverage market insights, and prioritize quality to foster sustainable partnerships that meet future demands.