Discover the Best Outlet Types US: Your Essential Guide (2025)

Introduction: Navigating the Global Market for outlet types us

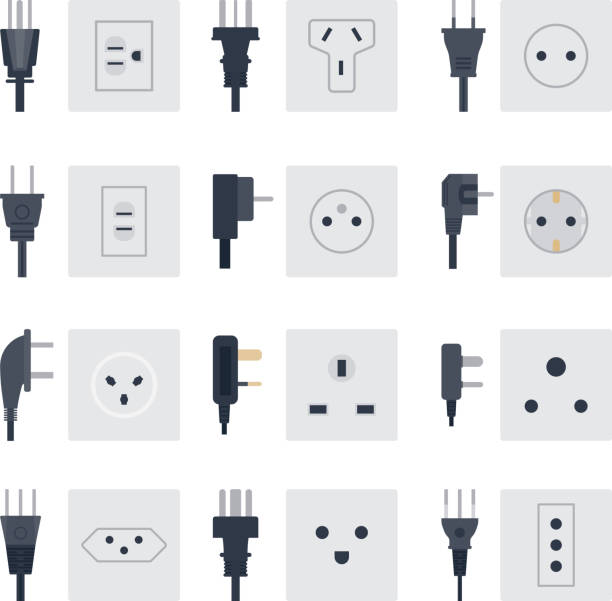

In an increasingly interconnected world, international B2B buyers face the significant challenge of sourcing the right electrical outlet types for their specific needs. Understanding the diverse range of outlet configurations, such as Type A and Type B, is essential for ensuring compatibility with various appliances and devices. This comprehensive guide delves into the different types of electrical outlets available in the U.S., their applications, and vital considerations for sourcing. From safety features to voltage requirements, we aim to equip you with the knowledge necessary to make informed purchasing decisions.

As a B2B buyer from regions such as Africa, South America, the Middle East, and Europe—like Brazil or the UAE—navigating the nuances of outlet types is crucial for avoiding costly errors and ensuring operational efficiency. This guide not only outlines the key characteristics and uses of each outlet type but also provides insights into supplier vetting processes, cost implications, and regulatory compliance. By understanding the landscape of electrical outlets, you can streamline your procurement processes and select the most suitable products for your market.

Armed with actionable insights and expert recommendations, you will be empowered to tackle the complexities of global sourcing. Whether you are upgrading existing systems or outfitting new facilities, this guide serves as your roadmap to successful electrical outlet procurement in the U.S. market.

Understanding outlet types us Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel prongs, no grounding pin | Small appliances, chargers | Pros: Widely used in North America; affordable. Cons: Limited power capacity; lacks grounding. |

| Type B | Two flat prongs plus a grounding pin | Heavy-duty appliances, office equipment | Pros: Enhanced safety with grounding; versatile. Cons: Requires compatible devices. |

| GFCI (Ground Fault Circuit Interrupter) | Integrated safety mechanism that monitors electrical flow | Bathrooms, kitchens, outdoor equipment | Pros: Protects against electrical shocks; required in specific areas. Cons: More expensive than standard outlets. |

| AFCI (Arc Fault Circuit Interrupter) | Prevents electrical fires by detecting arc faults | Residential, commercial buildings | Pros: Increases safety; recommended for living areas. Cons: Installation can be costly. |

| Weather-Resistant | Designed to withstand moisture and outdoor conditions | Outdoor installations, construction sites | Pros: Durable and safe for external use; protects against weather. Cons: Higher upfront cost; specific installation requirements. |

What Are the Characteristics of Type A Outlets?

Type A outlets feature two flat parallel prongs, ideal for devices with lower power requirements, such as lamps and chargers. They are predominantly used in North America and parts of South America and Asia. While they are cost-effective and easy to find, B2B buyers should be aware of their limited power capacity and lack of grounding, which can pose safety risks when connecting sensitive equipment.

How Do Type B Outlets Enhance Safety for Businesses?

Type B outlets have the same two flat prongs as Type A outlets but include a grounding pin for enhanced safety. This makes them suitable for powering heavy-duty appliances and office equipment that require a stable and safe electrical supply. While they provide a reliable power source, businesses must ensure that their equipment is compatible with this outlet type to avoid potential operational disruptions.

Why Are GFCI Outlets Essential for Specific Applications?

Ground Fault Circuit Interrupter (GFCI) outlets are crucial for environments with higher electrical shock risks, such as bathrooms and kitchens. They monitor electrical flow and cut off power when a fault is detected, making them indispensable for safety in commercial settings. While they are more expensive than standard outlets, their installation is often required by electrical codes, making them a necessary investment for compliance and safety.

What Are the Benefits of Using AFCI Outlets in Commercial Spaces?

Arc Fault Circuit Interrupter (AFCI) outlets are designed to prevent electrical fires by detecting arc faults. They are recommended for residential and commercial buildings, particularly in living areas. Although the installation costs can be higher, the enhanced safety they provide justifies the expense, especially for businesses looking to minimize fire risks and ensure compliance with safety regulations.

How Do Weather-Resistant Outlets Benefit Outdoor Installations?

Weather-resistant outlets are specifically designed to endure outdoor conditions, making them ideal for construction sites and outdoor installations. They protect against moisture, reducing the risk of electrical shock and damage. While they may come with a higher upfront cost, the long-term benefits of safety and durability make them a smart choice for B2B buyers in industries that require reliable outdoor electrical solutions.

Key Industrial Applications of outlet types us

| Industry/Sector | Specific Application of outlet types us | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Installation of GFCI and AFCI outlets | Enhanced safety in residential and commercial buildings, reducing liability risks. | Compliance with local electrical codes; sourcing from certified manufacturers. |

| Hospitality | Use of combination outlets in guest rooms | Maximizes convenience for guests by allowing multiple devices to charge simultaneously. | Durability and aesthetic design; must meet international safety standards. |

| Manufacturing | Heavy-duty outlets for machinery | Ensures reliable power supply for high-capacity machines, preventing downtime. | Voltage compatibility and load ratings; consider regional electrical standards. |

| Healthcare | Installation of weather-resistant outlets | Protects medical equipment from moisture, ensuring operational reliability in varied environments. | Sourcing from suppliers with proven track records in healthcare compliance. |

| Retail | Deployment of tamper-resistant outlets | Increases safety in public areas, particularly where children are present, enhancing customer experience. | Availability of various outlet types; focus on compliance with safety regulations. |

How Are GFCI and AFCI Outlets Used in Construction?

In the construction industry, GFCI (Ground Fault Circuit Interrupter) and AFCI (Arc Fault Circuit Interrupter) outlets are crucial for ensuring electrical safety in both residential and commercial buildings. These outlets minimize the risk of electrical shocks and fires, which can lead to significant liability issues. For international B2B buyers, it’s essential to ensure that these outlets comply with local electrical codes and standards. Sourcing from certified manufacturers guarantees that the products meet safety regulations, thereby protecting both workers and investments.

What Are the Benefits of Combination Outlets in Hospitality?

Combination outlets in the hospitality sector provide an efficient solution for guest rooms, allowing multiple devices to charge at once without the need for additional adapters. This convenience enhances the overall guest experience, which is vital for maintaining competitive advantage in the hospitality market. International buyers should prioritize sourcing durable and aesthetically pleasing combination outlets that meet international safety standards, ensuring both functionality and guest satisfaction.

How Do Heavy-Duty Outlets Support Manufacturing Operations?

In manufacturing, heavy-duty outlets are essential for powering large machinery and equipment. These outlets ensure a reliable power supply, which is critical for maintaining operational efficiency and minimizing downtime. International B2B buyers should consider voltage compatibility and load ratings when sourcing these outlets, as different regions may have varying electrical standards. Partnering with reputable suppliers who understand local requirements can help mitigate risks associated with equipment failure.

Why Are Weather-Resistant Outlets Important in Healthcare?

Weather-resistant outlets play a vital role in healthcare settings, particularly in areas where moisture is a concern. These outlets protect sensitive medical equipment from potential water damage, thereby ensuring consistent operational reliability. For international buyers in the healthcare sector, sourcing from suppliers with a strong track record in compliance with healthcare regulations is paramount. This ensures that the outlets not only meet safety standards but also support the critical functions of medical facilities.

How Do Tamper-Resistant Outlets Enhance Safety in Retail?

In the retail industry, tamper-resistant outlets are crucial for enhancing safety, especially in environments frequented by children. These outlets prevent accidental shocks and provide peace of mind to both customers and staff. When sourcing these outlets, international buyers should focus on compliance with local safety regulations and the availability of various outlet types to accommodate different retail environments. This attention to detail can significantly enhance customer experience and safety in retail spaces.

3 Common User Pain Points for ‘outlet types us’ & Their Solutions

Scenario 1: Navigating Voltage Compatibility Issues Across Regions

The Problem:

International B2B buyers often encounter significant challenges when dealing with electrical outlets, particularly concerning voltage compatibility. For instance, a buyer in Brazil may source machinery designed for North American outlets (Type A or B), but upon delivery, they discover the voltage and plug configuration do not match local standards (which may be Type N). This mismatch can lead to equipment damage or operational delays, causing frustration and financial loss.

The Solution:

To effectively navigate voltage compatibility, buyers should conduct thorough research before purchasing equipment. It’s crucial to verify the voltage requirements and outlet types specific to each target market. Buyers can invest in universal power adapters or voltage converters that accommodate various outlet types and voltages. Additionally, when specifying equipment, work with suppliers who understand international electrical standards, ensuring they provide products that either meet local specifications or include necessary adapters. Building relationships with local electrical contractors can also facilitate smoother installations and compliance with local codes.

Scenario 2: Ensuring Safety with Ground Fault Circuit Interrupters (GFCI)

The Problem:

Safety is a paramount concern for businesses that rely on heavy-duty electrical equipment. Many outlets in regions like the Middle East and Africa may lack the necessary safety features, such as GFCI protection, which is critical for preventing electrical shocks. A construction company using power tools in a damp environment faces the risk of severe accidents due to inadequate protection, which can result in injuries and costly legal liabilities.

The Solution:

B2B buyers must prioritize the selection of GFCI outlets for environments where moisture is present. When sourcing outlets, ensure that GFCI features are explicitly included in the specifications. It is also advisable to conduct regular safety audits of electrical installations to confirm compliance with local safety regulations. Collaborating with certified electrical engineers can help design a comprehensive electrical safety plan that includes the installation of GFCI outlets in critical areas. Training staff on the importance of using GFCI outlets and recognizing potential hazards can further enhance workplace safety.

Scenario 3: Overcoming Limited Plug Options in Multi-Device Environments

The Problem:

In offices or manufacturing plants where multiple devices require power, the lack of sufficient outlet types can create significant operational inefficiencies. A buyer in Europe might find that standard outlets do not accommodate the variety of plugs used by their imported equipment, leading to the need for multiple adapters or power strips. This situation not only clutters workspaces but also increases the risk of overload and equipment damage.

The Solution:

To address this issue, buyers should consider investing in combination outlets that provide multiple plug options in one unit. These outlets can support various plug types and voltages, streamlining the powering of devices. When planning electrical installations, work with suppliers to design a customized outlet configuration that meets specific power needs and minimizes the use of adapters. Additionally, implementing smart power management systems can help track power usage and prevent overloads, ensuring a safe and efficient electrical environment. Regular assessments of outlet usage can further inform future purchases and installations, allowing for more efficient operations.

Strategic Material Selection Guide for outlet types us

What Are the Key Materials Used in Electrical Outlets?

When selecting electrical outlets for various applications, the choice of materials is critical. Different materials offer unique properties that can significantly impact the performance, safety, and durability of the outlets. Below, we analyze four common materials used in the manufacturing of electrical outlets, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Thermoplastics Perform in Electrical Outlet Applications?

Key Properties: Thermoplastics, such as polycarbonate and nylon, are widely used in electrical outlets due to their excellent electrical insulation properties and resistance to impact and chemicals. They can withstand temperatures ranging from -40°C to 85°C, making them suitable for various environments.

Pros & Cons: The primary advantage of thermoplastics is their lightweight nature and ease of manufacturing, which allows for cost-effective production. However, they may not offer the same level of durability as metals in high-stress applications, and their performance can degrade under prolonged exposure to UV light.

Impact on Application: Thermoplastics are ideal for residential and light commercial applications, where high mechanical strength is not a primary concern. They are compatible with standard electrical media and can be designed to meet various international safety standards.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the thermoplastic materials comply with local electrical safety regulations, such as IEC standards. In the UAE and Europe, adherence to DIN and EN standards is crucial.

What Role Do Metals Play in Electrical Outlet Manufacturing?

Key Properties: Metals such as copper and aluminum are often used for the conductive components of electrical outlets. Copper has excellent conductivity and corrosion resistance, while aluminum is lightweight and cost-effective.

Pros & Cons: The key advantage of using metals is their superior electrical conductivity, which ensures efficient power transfer. However, metals can be prone to corrosion, especially in humid environments, and may require protective coatings, which can increase manufacturing complexity and cost.

Impact on Application: Metal components are essential in heavy-duty outlets designed for industrial applications, where high power loads are common. They are compatible with a wide range of electrical media and can support higher voltage ratings.

Considerations for International Buyers: Buyers should consider the local climate when selecting metal components. For instance, in humid regions like parts of Africa and the Middle East, corrosion-resistant coatings may be necessary. Compliance with ASTM and JIS standards is also important for ensuring safety and reliability.

How Do Composites Enhance Electrical Outlet Performance?

Key Properties: Composite materials, which combine plastics and metals, offer a balance of strength, durability, and insulation. They can withstand high temperatures and provide excellent resistance to environmental factors.

Pros & Cons: Composites are highly durable and can be tailored for specific applications, making them suitable for both residential and industrial outlets. However, they can be more expensive to produce compared to standard thermoplastics or metals.

Impact on Application: Composites are particularly beneficial in applications where both mechanical strength and electrical insulation are critical, such as in outdoor or industrial settings. They can handle various media and are designed to meet stringent safety requirements.

Considerations for International Buyers: For buyers in Europe and the Middle East, it is essential to verify that composite materials meet local regulatory standards. The complexity of composite manufacturing may also require suppliers to provide detailed certifications.

What Are the Advantages of Using Rubber in Electrical Outlets?

Key Properties: Rubber is often used in weather-resistant electrical outlets due to its excellent flexibility and resistance to moisture and extreme temperatures.

Pros & Cons: The main advantage of rubber is its ability to prevent electrical shock and protect against environmental factors. However, it may not be suitable for high-temperature applications, and its durability can vary based on the type of rubber used.

Impact on Application: Rubber is ideal for outdoor outlets or applications where moisture is a concern. It is compatible with various electrical media and can enhance the safety profile of the outlet.

Considerations for International Buyers: Buyers should ensure that rubber materials meet local safety standards, especially in regions with extreme weather conditions, such as Africa and South America. Compliance with IEC standards is also recommended.

Summary Table of Material Selection for Electrical Outlets

| Material | Typical Use Case for outlet types us | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and light commercial | Lightweight, cost-effective | Less durable under UV exposure | Low |

| Metals | Heavy-duty industrial applications | Superior electrical conductivity | Prone to corrosion, requires coatings | Medium |

| Composites | Outdoor and industrial applications | High strength and excellent insulation | Higher production cost | High |

| Rubber | Weather-resistant outdoor outlets | Prevents electrical shock, moisture-proof | Not suitable for high temperatures | Medium |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for outlet types us

What Are the Main Stages of Manufacturing Electrical Outlets?

Manufacturing electrical outlets involves a series of well-defined processes to ensure that the final product meets industry standards and performs reliably. The stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Outlet Manufacturing?

The primary materials used in the production of electrical outlets include thermoplastics, metals (such as copper and brass), and various insulating materials. Thermoplastics like polycarbonate and nylon are common for the outer casing due to their durability and resistance to heat. Metals are used for the conductive components, while insulators prevent accidental electrical contact. Suppliers must ensure that all materials comply with international safety and environmental standards, such as RoHS (Restriction of Hazardous Substances).

How Are Electrical Outlets Formed During Manufacturing?

The forming stage involves shaping the prepared materials into the desired outlet components. This is typically achieved through various manufacturing techniques such as injection molding for plastic parts and stamping for metal components. Injection molding allows for high precision and rapid production of the outlet casings, while stamping ensures the metal parts are correctly shaped for optimal electrical performance. Automation is frequently employed to enhance efficiency and maintain consistency throughout the manufacturing process.

What Does the Assembly Process Involve for Electrical Outlets?

Once the individual components are formed, they are brought together in the assembly stage. This can be a manual or automated process, depending on the manufacturer’s capabilities. The assembly typically involves:

- Inserting Conductive Components: The metal prongs and internal wiring are inserted into the plastic housing.

- Wiring Connections: Electrical connections are made to ensure that the outlet operates correctly.

- Quality Checks: Initial checks (such as visual inspections) are performed to identify any immediate defects.

Robust assembly procedures are critical to ensuring that the outlets function safely and efficiently.

What Finishing Techniques Are Used in Outlet Manufacturing?

The finishing stage focuses on enhancing the outlet’s appearance and functionality. Common finishing processes include:

- Surface Treatment: Components may undergo treatments to improve resistance to corrosion and wear. This includes electroplating for metal parts to enhance conductivity and durability.

- Labeling and Branding: Final products are labeled with necessary safety information, certification marks, and branding.

- Packaging: Outlets are packaged securely to prevent damage during transport.

How Is Quality Assurance Implemented in Electrical Outlet Manufacturing?

Quality assurance (QA) is a crucial aspect of manufacturing electrical outlets, ensuring that products meet specified standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Additionally, regional certifications like CE (European Conformity) for the European market and UL (Underwriters Laboratories) for North America are essential for compliance and safety. Buyers from Africa, South America, the Middle East, and Europe should ensure that suppliers have appropriate certifications based on their target markets.

Which Quality Control Checkpoints Are Commonly Used?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to identify defects early.

- Final Quality Control (FQC): The finished products undergo rigorous testing, including electrical safety tests, insulation resistance checks, and functional tests to ensure they operate as intended.

What Testing Methods Are Commonly Used for Electrical Outlets?

B2B buyers should be aware of several common testing methods used to assess the quality and safety of electrical outlets:

- Dielectric Strength Testing: Ensures that the insulation can withstand high voltage without breaking down.

- Mechanical Stress Testing: Assesses the durability of outlets under mechanical stress to ensure they can withstand everyday use.

- Temperature Rise Testing: Evaluates how much the outlet heats up during operation, crucial for preventing overheating and potential fires.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following verification methods:

- Supplier Audits: Conduct on-site audits of manufacturing facilities to assess compliance with quality standards and practices.

- Quality Reports: Request detailed quality reports that outline testing results and any corrective actions taken for defects.

- Third-Party Inspections: Engage independent inspection agencies to conduct unbiased evaluations of the supplier’s products and processes.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate various certification requirements and quality control nuances that can differ by region. For instance, while CE certification is crucial for products sold in Europe, different standards may apply in Africa or South America. Understanding local regulations and ensuring that suppliers are compliant can help mitigate risks associated with product safety and market access.

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions when sourcing electrical outlets, ensuring they receive products that meet their operational needs and comply with necessary standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘outlet types us’

Introduction

Sourcing the right electrical outlets is critical for ensuring compatibility, safety, and efficiency in your operations. This guide provides a step-by-step checklist for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By following these actionable steps, you can make informed decisions and streamline the procurement process for outlet types commonly used in the U.S.

Step 1: Define Your Technical Specifications

Before diving into the sourcing process, it’s essential to establish clear technical specifications for the outlets you need. This includes voltage ratings, amperage, and outlet types (e.g., Type A or Type B). Understanding these requirements ensures that the outlets you procure will be compatible with your equipment and meet local safety standards.

- Voltage Requirements: Ensure that the voltage matches your electrical systems, typically 120V for U.S. outlets.

- Amperage Needs: Decide if you need 15-amp or 20-amp outlets based on the devices you plan to power.

Step 2: Research Regulatory Standards

Familiarize yourself with the relevant electrical codes and standards in both the U.S. and your home country. Compliance with these regulations is crucial to avoid legal issues and ensure safety.

- Local Codes: Check for any local electrical codes that might dictate outlet types or installation practices.

- International Standards: Be aware of international standards such as IEC (International Electrotechnical Commission) that may affect your procurement.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure they can meet your technical and regulatory requirements. This includes looking into their reputation, reliability, and product quality.

- Supplier Profiles: Request detailed company profiles that outline their experience, certifications, and product offerings.

- References: Ask for case studies or references from other businesses that have sourced similar products.

Step 4: Verify Product Certifications

Ensure that the electrical outlets you intend to purchase have the necessary safety and performance certifications. This step is vital for guaranteeing the quality and reliability of the products.

- Certification Bodies: Look for certifications from recognized bodies such as UL (Underwriters Laboratories) or CE (Conformité Européenne).

- Documentation: Request copies of certification documents to verify compliance with relevant safety standards.

Step 5: Assess Pricing and Terms

Analyze pricing structures from various suppliers while considering the total cost of ownership, including shipping, taxes, and potential import duties. Understanding the financial implications will help you stay within budget.

- Bulk Discounts: Inquire about discounts for bulk purchases, which can significantly reduce costs.

- Payment Terms: Clarify payment terms and conditions to avoid unexpected financial burdens.

Step 6: Conduct Quality Checks Upon Arrival

Once the products are delivered, conduct thorough quality checks to ensure they meet your specifications. This is a critical step to prevent issues during installation or use.

- Visual Inspection: Check for any physical damage or defects in the outlets.

- Testing: If feasible, test a sample of the outlets to confirm they function as expected.

Step 7: Establish a Reliable Supply Chain

Building a strong relationship with your suppliers can enhance your sourcing process. Establish communication channels for ongoing support and future orders.

- Regular Updates: Keep suppliers informed about your future needs and any changes in specifications.

- Feedback Mechanism: Create a feedback loop to discuss product performance and areas for improvement.

By following this checklist, B2B buyers can effectively navigate the sourcing process for electrical outlets, ensuring they make informed and strategic decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for outlet types us Sourcing

What Are the Key Cost Components for Sourcing Electrical Outlets?

When analyzing the cost structure for sourcing electrical outlets, several key components need to be considered:

-

Materials: The primary materials used in manufacturing electrical outlets include high-quality plastics, metal components for the prongs, and insulating materials. The choice of materials significantly affects both the durability and safety of the outlets, which can influence overall costs.

-

Labor: Labor costs vary based on the region of manufacturing. In countries with higher labor costs, such as many in Europe, the price of outlets may be higher compared to those produced in regions with lower labor costs, like parts of Africa and South America.

-

Manufacturing Overhead: This includes costs associated with the facility, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead, but these practices may require an initial investment in technology and training.

-

Tooling: The cost of tooling can be significant, especially for custom outlet designs. This includes the initial setup costs for molds and dies used in the manufacturing process.

-

Quality Control (QC): Ensuring that outlets meet safety and performance standards is critical. Companies may incur additional costs related to testing and certification, particularly if they are targeting markets with stringent regulations.

-

Logistics: Transportation costs can vary widely based on the origin of the product and the destination. International shipping, customs duties, and local distribution expenses should all be factored into the total cost.

-

Margin: Manufacturers and suppliers typically add a profit margin to cover their expenses and provide returns to stakeholders. This margin can vary based on market demand and competition.

How Do Price Influencers Impact the Sourcing of Electrical Outlets?

Understanding the various price influencers is essential for international B2B buyers looking to source electrical outlets effectively:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to lower per-unit costs. Buyers should negotiate MOQs to align with their demand forecasts to optimize costs.

-

Specifications and Customization: Customized outlets that meet specific needs (e.g., tamper-resistant or weather-resistant) can lead to higher costs. Buyers should assess whether the additional features justify the price increase.

-

Materials Quality and Certifications: Higher-quality materials and certifications, such as UL or CE, will raise the cost but can enhance safety and performance. Buyers should evaluate the importance of these certifications based on their target market.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but can offer better assurance of product performance.

-

Incoterms: Understanding the Incoterms agreed upon in the purchase agreement is crucial, as they define who is responsible for shipping, insurance, and duties, which can impact overall costs.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing Electrical Outlets?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips to enhance cost-efficiency in sourcing electrical outlets:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery timelines with suppliers. Establishing a good relationship can lead to better terms and discounts on future orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the lifetime costs associated with installation, maintenance, and potential failures. High-quality outlets may have a higher upfront cost but can save money over time.

-

Research Regional Variations: Prices can vary significantly based on local market conditions. Buyers should research and compare prices from multiple suppliers across different regions to identify the best deals.

-

Stay Informed on Regulatory Changes: Regulations regarding electrical safety can change. Keeping abreast of these changes can help buyers make informed sourcing decisions and avoid costly compliance issues.

-

Consider Local Suppliers: Whenever feasible, consider sourcing from local suppliers to reduce shipping costs and lead times. This can also foster local economic development and improve supply chain resilience.

Disclaimer on Indicative Prices

Prices for electrical outlets can fluctuate based on numerous factors, including market demand, raw material costs, and geopolitical influences. It is essential for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure they are receiving competitive pricing.

Alternatives Analysis: Comparing outlet types us With Other Solutions

Exploring Alternatives to ‘Outlet Types Us’: A Comparative Analysis

In the realm of electrical solutions, the variety of outlet types available can cater to specific needs and applications. However, businesses may find themselves considering alternative technologies or methods that serve similar purposes. This section presents a comparative analysis of ‘Outlet Types Us’ against two viable alternatives: Smart Power Strips and Wireless Charging Solutions. Understanding these options is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Outlet Types Us | Smart Power Strips | Wireless Charging Solutions |

|---|---|---|---|

| Performance | Reliable for standard appliances with specific voltage ratings | Offers surge protection and multiple outlets; can manage load | Convenient for compatible devices; limited by device design |

| Cost | Varies by type; typically low to moderate | Moderate; slightly higher due to technology | Higher initial investment; cost-effective in the long run |

| Ease of Implementation | Straightforward installation for standard wiring | Easy to set up; plug-and-play functionality | Requires compatible devices; may need installation for specific setups |

| Maintenance | Minimal; replace faulty outlets as needed | Minimal; replace if damaged, no complex maintenance | Low; just ensure devices are compatible and clean charging pads |

| Best Use Case | Ideal for fixed installations in residential and commercial settings | Best for managing multiple devices in one location | Suitable for modern devices lacking traditional charging ports |

In-Depth Look at Alternatives

What are Smart Power Strips and Their Advantages?

Smart power strips serve as advanced versions of traditional power strips, often featuring surge protection, USB ports, and the ability to control connected devices remotely via apps. They are particularly useful in environments where multiple devices need to be powered simultaneously, such as in offices or conference rooms. The ability to monitor energy usage can also lead to cost savings and improved energy efficiency.

Pros:

– Surge protection increases safety for sensitive electronics.

– Remote control features enhance convenience and energy management.

– Multiple outlets reduce clutter and enhance accessibility.

Cons:

– Slightly more expensive than standard outlets or power strips.

– Compatibility issues may arise with older devices.

How Do Wireless Charging Solutions Compare?

Wireless charging solutions eliminate the need for physical connectors, allowing users to charge devices simply by placing them on a charging pad. This technology is increasingly popular in modern workplaces and public spaces. The convenience of wireless charging can enhance user experience, especially for mobile devices.

Pros:

– Reduces wear and tear on charging ports, extending device lifespan.

– Streamlined design improves aesthetics and minimizes cable clutter.

– Increasingly compatible with a wide range of devices.

Cons:

– Limited to devices that support wireless charging, which may exclude older models.

– Slower charging speeds compared to traditional wired solutions.

How to Choose the Right Solution for Your Needs

For B2B buyers, the decision on which electrical solution to adopt hinges on specific operational needs, budget constraints, and existing infrastructure. If the goal is to support a range of standard appliances and devices, ‘Outlet Types Us’ remains a solid choice. However, for environments where multiple devices need to be charged simultaneously or where energy management is a priority, smart power strips may offer the best value. On the other hand, for businesses focusing on modern mobile devices, investing in wireless charging solutions can enhance user convenience and satisfaction.

Ultimately, evaluating the unique requirements of your business will guide you in selecting the most effective electrical outlet solution.

Essential Technical Properties and Trade Terminology for outlet types us

What Are the Essential Technical Properties of Electrical Outlets?

Understanding the technical specifications of electrical outlets is crucial for international B2B buyers, especially when sourcing products for diverse applications. Here are key properties that should be considered:

1. Material Grade

The material used in electrical outlets significantly affects their durability and performance. Common materials include thermoplastic for the housing, which offers good insulation and resistance to heat, and copper or brass for the prongs, providing excellent conductivity. Selecting outlets with high-grade materials can ensure longevity and reliability, reducing the likelihood of failures that could disrupt operations.

2. Current Rating (Amperage)

Current rating, measured in amps (A), determines the maximum electrical load an outlet can handle. Common ratings include 15A and 20A for residential and light commercial use. For B2B buyers, choosing the correct amperage is critical to ensure that the outlet can safely support the electrical demands of connected devices, preventing overheating and potential hazards.

3. Voltage Rating

Electrical outlets are designed to operate at specific voltage levels, typically 120V in North America and 230V in Europe. Understanding voltage ratings is essential for international buyers to ensure compatibility with the electrical systems in their respective countries. Mismatched voltage can lead to equipment damage and safety risks.

4. Frequency

Frequency, measured in hertz (Hz), indicates the number of cycles per second in the electrical supply. Most outlets in North America operate at 60Hz, while in Europe, the standard is typically 50Hz. For B2B buyers, recognizing the frequency is vital when importing electrical equipment, as it can affect the performance and efficiency of devices.

5. Tamper Resistance

Tamper-resistant (TR) outlets are designed with built-in safety features to prevent accidental insertion of foreign objects, making them essential for environments with children. For businesses, investing in TR outlets can reduce liability and enhance safety, particularly in settings like schools and childcare facilities.

What Are Common Trade Terms Related to Electrical Outlets?

Familiarity with industry jargon is essential for navigating the procurement process effectively. Here are several key terms relevant to electrical outlets:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with reputable OEMs ensures high-quality products that meet specified standards, vital for maintaining brand integrity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses to manage inventory and cash flow effectively. B2B buyers should negotiate MOQs that align with their operational needs and purchasing capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. This process allows buyers to compare costs and terms from different manufacturers, facilitating informed purchasing decisions. B2B buyers should clearly outline their specifications in the RFQ to receive accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping, insurance, and delivery responsibilities, helping to avoid disputes and misunderstandings in cross-border trade.

5. Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product meets specific safety and performance criteria. For B2B buyers, sourcing outlets with recognized certifications can ensure compliance with local regulations and enhance product reliability.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring they select the right electrical outlets for their business needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the outlet types us Sector

What Are the Key Market Dynamics and Sourcing Trends in the Outlet Types US Sector?

The global electrical outlet market is influenced by several key drivers that shape the sourcing and purchasing decisions of international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. One significant trend is the increasing demand for advanced electrical outlets, such as GFCI and AFCI outlets, which provide enhanced safety features. This trend is particularly pronounced in markets that are prioritizing safety regulations in residential and commercial spaces.

Another emerging trend is the shift towards smart home technology. The integration of smart outlets that can be controlled remotely is gaining traction, driven by consumer interest in convenience and energy efficiency. B2B buyers in regions like the UAE and Brazil are increasingly looking for suppliers that can provide innovative solutions that meet these market demands.

A stock image related to outlet types us.

Furthermore, sustainability is becoming a crucial factor in the sourcing process. Buyers are not only seeking quality products but also environmentally friendly options. This shift is prompting manufacturers to adopt greener practices and offer products made from sustainable materials. As a result, international B2B buyers must stay informed about the evolving preferences and regulatory changes in their respective markets to make informed sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact the Outlet Types US Sector?

Sustainability and ethical sourcing are increasingly important considerations for B2B buyers in the electrical outlet sector. The environmental impact of manufacturing processes, including the use of hazardous materials and energy consumption, is under scrutiny. Buyers are looking for suppliers that prioritize sustainability, which includes the use of recyclable materials and the implementation of energy-efficient manufacturing practices.

A stock image related to outlet types us.

Ethical supply chains are also becoming a focal point. Buyers are more inclined to partner with manufacturers who demonstrate transparency in their sourcing practices and who are committed to fair labor standards. Certifications such as Energy Star, UL (Underwriters Laboratories) certification, and RoHS (Restriction of Hazardous Substances) compliance are becoming essential criteria for evaluating suppliers. These certifications not only reassure buyers about the quality and safety of products but also align with the growing consumer demand for environmentally responsible products.

By prioritizing sustainability and ethical sourcing, international buyers can enhance their brand reputation and appeal to eco-conscious consumers. In regions like Europe, where sustainability regulations are stringent, aligning with these practices can provide a competitive edge.

What Is the Evolution of Outlet Types in the US Market?

The evolution of electrical outlets in the US can be traced back to the early 20th century when standardization began to take shape. Initially, Type A and Type B outlets dominated, primarily designed for lower voltage applications. Over the decades, as technology advanced and the demand for more power-hungry appliances increased, the need for more specialized outlets emerged.

The introduction of GFCI outlets in the 1970s marked a significant turning point in safety standards, addressing the rising concerns about electrical shocks in wet areas. As the market continued to evolve, the incorporation of features like tamper resistance and weatherproofing became essential in residential and commercial applications.

Today, the focus is on integrating smart technology into outlet designs, reflecting the broader trend of digital transformation across industries. This evolution has not only improved safety and functionality but has also opened new avenues for international B2B buyers to explore innovative solutions that cater to modern electrical needs.

Frequently Asked Questions (FAQs) for B2B Buyers of outlet types us

-

How do I solve compatibility issues when sourcing electrical outlets for different regions?

To solve compatibility issues with electrical outlets, first identify the socket types and voltage standards of the regions you are targeting. For instance, Type A and B outlets are common in North America, while Type C and E are prevalent in Europe and parts of Africa. Consider sourcing multi-type outlets or adapters that can accommodate various plug configurations. Ensure to communicate with your suppliers about the specific requirements for each region, including voltage and frequency, to avoid product returns and customer dissatisfaction. -

What is the best type of electrical outlet for commercial applications?

For commercial applications, the best type of electrical outlet often depends on the specific equipment being used. Typically, 20-amp outlets are recommended for heavy-duty appliances, as they can handle a larger load compared to standard 15-amp outlets. GFCI outlets are crucial in wet areas to prevent electrical shocks, while AFCI outlets are recommended in living spaces to reduce fire risks. Always assess the power requirements of your devices and consult with suppliers to ensure compliance with local electrical codes. -

How can I verify the quality of electrical outlets from international suppliers?

To verify the quality of electrical outlets from international suppliers, request product samples and perform independent testing for safety and compliance with international standards (such as IEC or UL). Additionally, check for certifications and quality assurance processes employed by the manufacturer. Look for reviews or testimonials from other clients and consider conducting factory audits if feasible. Establishing a solid relationship with suppliers can also provide insights into their quality control measures. -

What are the minimum order quantities (MOQs) for electrical outlets?

Minimum order quantities (MOQs) for electrical outlets can vary significantly based on the supplier and the specific outlet type. Many manufacturers set MOQs ranging from 100 to 1,000 units for standard products, while custom designs may require higher MOQs. It’s essential to discuss your needs with potential suppliers upfront to find a partner that aligns with your purchasing capacity. Consider negotiating lower MOQs if you are testing a new market or product line. -

What payment terms should I negotiate when sourcing electrical outlets internationally?

When sourcing electrical outlets internationally, negotiate payment terms that protect your investment and align with your cash flow. Common options include a 30% deposit with the balance due upon shipment, or net 30/60 days after delivery. Consider using letters of credit for larger orders to ensure security for both parties. Always clarify the currency of payment, as fluctuations can impact the final costs. It’s advisable to conduct thorough research on the supplier’s financial stability before finalizing payment arrangements. -

How do I handle logistics and shipping for electrical outlets sourced from abroad?

Handling logistics for international shipments of electrical outlets involves selecting reliable freight forwarders experienced in handling electrical goods. Ensure compliance with import regulations and customs requirements in your destination country to avoid delays. Consider shipping options based on urgency and budget, such as air freight for faster delivery or ocean freight for cost savings. Always track shipments and maintain communication with your suppliers to address any issues promptly. -

What customization options are available for electrical outlets?

Customization options for electrical outlets can include variations in color, size, features (such as USB ports), and branding. Many manufacturers offer bespoke solutions to meet specific market needs. When discussing customization with suppliers, clearly outline your requirements and any relevant safety standards that must be met. Be prepared for longer lead times and potentially higher costs associated with custom orders, and ensure that prototypes are tested for quality before mass production. -

What are the key safety standards for electrical outlets I should be aware of?

Key safety standards for electrical outlets vary by region but often include IEC standards in Europe, UL standards in North America, and specific local regulations in Africa and South America. These standards cover aspects such as electrical safety, fire resistance, and environmental impact. When sourcing outlets, ensure that your suppliers comply with the relevant standards for your target markets. Request documentation to verify compliance and consider third-party testing for additional assurance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for outlet types us

What Are the Key Takeaways for B2B Buyers of Electrical Outlets?

In navigating the complex landscape of electrical outlets, international B2B buyers must prioritize strategic sourcing to ensure compliance with local standards and compatibility with regional appliances. Understanding the various types of outlets—such as Type A and Type B—enables businesses to select the appropriate solutions for their operational needs while mitigating risks associated with electrical safety and efficiency.

A stock image related to outlet types us.

How Can Strategic Sourcing Enhance Your Electrical Outlet Procurement?

Strategic sourcing not only streamlines procurement processes but also fosters relationships with reliable suppliers, ensuring access to high-quality products that meet the electrical requirements of different markets. This is especially crucial for buyers from regions like Africa, South America, the Middle East, and Europe, where specific outlet types may dominate. By aligning sourcing strategies with local standards, businesses can enhance operational efficiency and reduce downtime.

What Does the Future Hold for Electrical Outlet Sourcing?

Looking ahead, the demand for innovative outlet solutions—such as GFCI and weather-resistant options—will likely increase. B2B buyers should stay informed on emerging trends and technologies that enhance safety and performance in electrical systems. Embrace this opportunity to invest in strategic sourcing that not only meets current needs but also anticipates future market shifts. Collaborate with trusted suppliers to ensure your business remains competitive and compliant in an evolving landscape.