Discover the Best Plug Styles: Your Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for plug styles

In today’s interconnected global market, sourcing the right plug styles is a critical challenge for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With over 15 different plug types recognized worldwide, understanding the compatibility of electrical systems is essential for ensuring seamless operations. This guide aims to provide an in-depth exploration of various plug styles, their applications, and the key factors to consider when making informed purchasing decisions.

Navigating the complexities of electrical plugs extends beyond mere selection; it encompasses understanding voltage requirements, safety standards, and regional specifications that can significantly impact your business operations. Whether you are sourcing plug styles for manufacturing, construction, or consumer electronics, this guide will arm you with actionable insights. We will cover essential topics, including how to vet suppliers effectively, cost considerations, and the implications of choosing the wrong plug type for your equipment.

By leveraging this comprehensive resource, B2B buyers from regions like South Africa and Brazil will gain a nuanced understanding of the electrical landscape, allowing them to streamline their procurement processes and minimize risks. Empower your purchasing strategy with knowledge that fosters confidence and clarity in the global marketplace for plug styles.

Understanding plug styles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | 2 pins, not grounded, 220-240 V | Common in Europe, Africa, South America | Pros: Widely used, compatible with various devices. Cons: Not grounded, limited safety for high-power devices. |

| Type G | 3 pins, grounded, 220-250 V | Predominantly in the UK and Middle East | Pros: Grounded for safety, robust design. Cons: Less compatibility with other types, may require adapters. |

| Type N | 3 pins, grounded, 100-240 V | Used in Brazil and South Africa | Pros: Versatile voltage range, stable connection. Cons: Limited availability outside specified regions. |

| Type F | 2 pins, grounded, 220-240 V | Common across Europe and Russia | Pros: Grounded for safety, high compatibility. Cons: Requires specific sockets, less known in non-European markets. |

| Type I | 2 or 3 pins, grounded, 220-240 V | Mainly in Australia, New Zealand, and Argentina | Pros: Versatile pin configuration, stable connection. Cons: Limited compatibility outside specified regions. |

What Are the Characteristics of Type C Plugs?

Type C plugs are characterized by their two round pins and lack of grounding. Operating at 220-240 V, they are commonly used in various appliances across Europe, Africa, and South America. This type is especially suitable for low to moderate power devices such as chargers and small appliances. For B2B buyers, understanding that Type C plugs are widely accepted can facilitate easier procurement of compatible devices. However, the absence of grounding may pose safety risks for high-power applications, making it essential to evaluate the specific electrical requirements of devices.

Why Choose Type G Plugs for Your Business?

Type G plugs, with their three rectangular pins, are primarily used in the UK and the Middle East. The grounded design enhances safety, making them ideal for heavy-duty appliances and industrial equipment. B2B buyers should consider Type G plugs for applications that require robust and secure connections. Although they offer increased safety, the limited compatibility with other plug types may necessitate additional adapters, which could complicate logistics and increase costs.

What Makes Type N Plugs Ideal for South American Markets?

Type N plugs feature three round pins and operate within a voltage range of 100-240 V, making them particularly versatile for use in Brazil and South Africa. Their grounding capability provides additional safety, which is crucial for high-demand appliances. For international B2B buyers, sourcing Type N-compatible products can streamline operations within these regions. However, availability may be limited outside these markets, necessitating careful planning when considering expansion or international shipping.

How Does Type F Compare in European Applications?

Type F plugs, also known as “Schuko,” are widely used in Europe and Russia, featuring two round pins and grounding. They are designed for high compatibility with various devices, making them a preferred choice for businesses operating in these regions. B2B buyers should be aware of the specific socket requirements when purchasing Type F plugs, as they may not be universally compatible with all electrical systems. The grounded design enhances safety, but buyers should consider the need for specific outlets in their procurement strategy.

What Are the Advantages of Type I Plugs?

Type I plugs are characterized by their versatile pin configuration, which can be either two or three pins, and operate at 220-240 V. Predominantly used in Australia, New Zealand, and Argentina, they provide a stable connection suitable for various appliances. B2B buyers should leverage the adaptability of Type I plugs when sourcing products for these markets. However, their limited compatibility outside these regions may require additional considerations for international trade, making it crucial to assess the global reach of your product offerings.

Key Industrial Applications of plug styles

| Industry/Sector | Specific Application of plug styles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment | Ensures continuous operations and minimizes downtime | Compatibility with local voltage standards and plug types |

| Construction | Electrical tools and temporary power setups | Enhances efficiency in construction projects with reliable power | Durability and weather resistance of plugs and sockets |

| Telecommunications | Network equipment and data centers | Supports high-speed data transfer and reliable connectivity | Availability of specific plug styles for different regions |

| Hospitality | Guest room appliances and facilities management | Improves guest experience with accessible power options | Compliance with local electrical standards and safety ratings |

| Agriculture | Equipment for irrigation and processing | Increases productivity and reduces operational costs | Adaptability to diverse environmental conditions |

How Are Plug Styles Used in the Manufacturing Sector?

In the manufacturing industry, plug styles are crucial for powering various machinery and equipment. Different regions, such as Africa and South America, have varying electrical standards, making it essential for international buyers to select plugs compatible with local voltage and frequency requirements. Ensuring that machinery can connect to local power sources minimizes downtime and enhances productivity, making it vital for businesses to source equipment with appropriate plug styles.

What Are the Applications of Plug Styles in Construction?

Construction sites often require temporary power setups for tools and equipment. Plug styles play a significant role in ensuring that electrical tools can be powered safely and efficiently. Buyers in this sector should prioritize plugs that are durable and weather-resistant, as construction environments can be challenging. Additionally, understanding local electrical standards is essential to avoid compatibility issues that could delay project timelines.

How Do Plug Styles Impact Telecommunications?

In the telecommunications sector, plug styles are integral to powering network equipment and data centers. High-speed data transfer relies on reliable electrical connections, making the choice of plug style critical. For international B2B buyers, it is important to source plugs that meet local standards while also ensuring they support the necessary voltage and amperage for advanced telecommunications equipment. This attention to detail helps maintain uninterrupted service and connectivity.

Why Are Plug Styles Important in Hospitality?

In the hospitality industry, plug styles are vital for powering guest room appliances and managing facilities. Providing accessible power options enhances the guest experience, allowing for the use of personal devices and equipment. For international buyers, compliance with local electrical standards is key to ensuring safety and reliability. This includes sourcing plugs that are compatible with the specific electrical systems of the region, which can vary significantly between Europe, the Middle East, and Africa.

How Are Plug Styles Used in Agriculture?

Agricultural operations often rely on specialized equipment for irrigation and processing, which necessitates the use of appropriate plug styles. Ensuring that power connections are compatible with local standards can significantly boost productivity and reduce operational costs. Buyers in this sector should consider the adaptability of plug styles to diverse environmental conditions, ensuring that equipment can function effectively in various climates and terrains.

3 Common User Pain Points for ‘plug styles’ & Their Solutions

Scenario 1: Compatibility Issues Across Regions

The Problem:

International B2B buyers often face significant challenges when dealing with different plug styles across regions. For instance, a company based in South Africa may need to source equipment from a supplier in Europe, where Type C and Type M plugs are common. The lack of compatibility can lead to delays in project timelines, increased costs due to the need for adapters, and potential safety hazards if equipment is improperly connected. This situation not only affects logistics but can also disrupt the overall workflow and productivity of businesses.

The Solution:

To mitigate compatibility issues, B2B buyers should invest time in understanding the plug and socket types prevalent in their target markets. Creating a comprehensive chart of plug styles, voltages, and current ratings for regions of interest—such as Africa, South America, the Middle East, and Europe—can serve as a quick reference guide during procurement. Additionally, buyers should specify universal or multi-type plugs in their procurement contracts when sourcing equipment. This proactive approach minimizes the risk of electrical mismatches and allows for seamless integration of equipment regardless of the plug style used in different regions.

Scenario 2: Safety Concerns with Plug Styles

The Problem:

Safety is a critical concern when dealing with different plug styles. Many buyers may not be aware that specific plug types, such as the Type G plug used in the UK, have grounding pins designed to prevent electrical shocks. A buyer sourcing equipment without considering the safety standards of their region might inadvertently expose their workforce to dangerous electrical faults. This oversight can lead to costly accidents, equipment damage, and legal liabilities.

The Solution:

B2B buyers should prioritize safety by ensuring that all electrical equipment meets the local electrical codes and standards. Before making a purchase, it is essential to consult with local electrical engineers or safety consultants to assess the compatibility of equipment with the existing infrastructure. Additionally, investing in safety training for employees on the proper use of equipment and plug types can significantly reduce the risk of accidents. Buyers should also consider sourcing equipment that incorporates built-in safety features, such as surge protectors and circuit breakers, tailored to the local plug style.

Scenario 3: Limited Availability of Specific Plug Styles

The Problem:

International B2B buyers often encounter limited availability of specific plug styles, which can hinder their operations. For instance, a company in Brazil may find it challenging to source machinery that uses Type N plugs, particularly if they are relying on suppliers that predominantly stock Type C or other incompatible styles. This scarcity can lead to extended lead times for equipment delivery, resulting in missed opportunities and frustrated clients.

The Solution:

To overcome the challenge of limited availability, B2B buyers should diversify their supplier base and consider sourcing from manufacturers that specialize in international compliance. Establishing relationships with multiple suppliers across different regions can provide access to a wider range of plug styles and reduce dependency on a single source. Additionally, buyers should explore the option of customizing equipment with the required plug types during the manufacturing process, ensuring that the final product meets local requirements. Implementing a robust inventory management system can also help track the availability of different plug styles, allowing buyers to make informed purchasing decisions and avoid delays in their operations.

Strategic Material Selection Guide for plug styles

What Are the Key Properties of Common Materials Used in Plug Styles?

When selecting materials for plug styles, several factors come into play, including electrical conductivity, thermal stability, and resistance to environmental factors. Below, we analyze four common materials used in plug manufacturing.

How Does Polyvinyl Chloride (PVC) Perform in Plug Styles?

Key Properties: PVC is known for its excellent electrical insulation properties and resistance to moisture and chemicals. It can withstand temperatures up to 70°C (158°F) and has a good dielectric strength.

Pros & Cons: PVC is cost-effective and relatively easy to mold, making it a popular choice for mass production. However, it can become brittle over time, especially when exposed to UV light, leading to potential failures in outdoor applications.

Impact on Application: PVC is suitable for low to medium voltage applications, making it ideal for household plugs. However, it is not recommended for high-temperature environments or applications requiring high durability.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as IEC 60884 for safety and performance. In regions like South Africa and Brazil, where humidity can be high, selecting UV-stabilized PVC can enhance longevity.

What Advantages Does Thermoplastic Elastomer (TPE) Offer?

Key Properties: TPE combines the properties of rubber and plastic, offering flexibility and resilience. It operates effectively in a temperature range from -40°C to 100°C (-40°F to 212°F).

Pros & Cons: TPE is highly durable and resistant to wear, making it suitable for heavy-duty applications. However, it is generally more expensive than PVC and may require specialized molding techniques.

Impact on Application: TPE is ideal for plugs that need to withstand mechanical stress and harsh environmental conditions, such as outdoor power tools. Its flexibility allows for easy connection and disconnection, enhancing user experience.

Considerations for International Buyers: Compliance with ASTM D624 for tensile strength is crucial. Buyers in Europe and the Middle East may prefer TPE for its robust performance in extreme climates.

Why Is Nylon a Preferred Material for Plug Styles?

Key Properties: Nylon is known for its high strength-to-weight ratio, excellent abrasion resistance, and thermal stability, withstanding temperatures up to 120°C (248°F).

Pros & Cons: Its durability makes nylon plugs suitable for industrial applications. However, it can be more expensive than other materials and may require additional treatments to improve UV resistance.

Impact on Application: Nylon is particularly effective in applications requiring mechanical strength and resistance to chemicals, making it suitable for industrial and commercial plugs.

Considerations for International Buyers: Buyers should ensure that nylon components meet DIN EN 60335 standards for household appliances. In regions like Africa, where electrical infrastructure may vary, nylon’s robustness can provide a reliable solution.

How Does Metal Contribute to Plug Performance?

Key Properties: Metals such as copper and brass are commonly used for contacts in plugs due to their excellent electrical conductivity and thermal properties.

Pros & Cons: Metal contacts ensure low resistance and high durability. However, they can be susceptible to corrosion if not properly coated or treated, which can affect performance over time.

Impact on Application: Metal is essential for high-current applications, ensuring efficient power transfer. It is often used in industrial plugs where reliability is critical.

Considerations for International Buyers: Buyers should look for corrosion-resistant coatings, especially in humid environments like those found in parts of South America and the Middle East. Compliance with JIS standards for electrical connectors can also be a factor.

Summary Table of Material Selection for Plug Styles

| Material | Typical Use Case for Plug Styles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Household plugs | Cost-effective and easy to mold | Can become brittle over time | Low |

| Thermoplastic Elastomer (TPE) | Outdoor power tools and heavy-duty plugs | Highly durable and flexible | More expensive, requires specialized molding | Med |

| Nylon | Industrial and commercial plugs | High strength-to-weight ratio | More expensive, UV treatment needed | High |

| Metal | High-current industrial applications | Excellent electrical conductivity | Susceptible to corrosion without treatment | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them choose the right plug styles based on specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for plug styles

What Are the Main Stages of Manufacturing Plug Styles?

Manufacturing plug styles involves a systematic approach to ensure quality and functionality. The typical stages include material preparation, forming, assembly, and finishing.

Material Preparation for Plug Manufacturing

The process begins with sourcing high-quality raw materials, which can include thermoplastics, metals, and insulation materials. The choice of materials is critical as it affects durability, conductivity, and safety. B2B buyers should prioritize suppliers that utilize materials compliant with international safety standards, such as UL or IEC standards. This ensures that the plugs can withstand the electrical loads and environmental conditions they will face in their end applications.

How Are Plugs Formed?

Once the materials are prepared, they undergo various forming techniques. For thermoplastic components, injection molding is a common method, allowing for precision in shaping complex designs. For metal parts, stamping or machining may be utilized, ensuring that connectors fit snugly within sockets. Buyers should inquire about the specific forming techniques used by suppliers, as these directly impact the integrity and performance of the final product.

What Does the Assembly Process Involve?

The assembly stage involves combining the formed components into a complete plug. This can include soldering electrical contacts, attaching insulation, and ensuring that all parts fit together securely. Automated assembly lines are often employed to enhance efficiency and reduce human error. B2B buyers should request information about the assembly process to understand how quality is maintained at this stage, including any automated inspection systems that might be in place.

How Is Finishing Achieved in Plug Manufacturing?

Finishing processes, such as surface treatment and labeling, are crucial for both aesthetic and functional purposes. Surface treatments may involve applying coatings to enhance corrosion resistance or improve grip. Labeling not only provides essential information but also helps in compliance with safety regulations. Buyers should look for suppliers that adhere to strict finishing standards to ensure the longevity and safety of the plugs.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance (QA) is a vital component of plug manufacturing, ensuring that products meet specified requirements and safety standards. International standards like ISO 9001 are commonly adopted, focusing on quality management systems.

Which International Standards Are Relevant for Plug Manufacturing?

In addition to ISO 9001, industry-specific standards such as CE marking in Europe, UL certification in the U.S., and IEC standards globally are significant. These certifications indicate compliance with safety and performance benchmarks. B2B buyers should ensure that their suppliers possess these certifications, as they not only reflect product quality but also influence market acceptance.

What Are the Key QC Checkpoints in Plug Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, commonly categorized into Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: This stage verifies the quality of incoming materials against specified standards, ensuring only compliant materials enter production.

- IPQC: During production, random sampling and testing are conducted to identify defects early. This may include dimensional checks and electrical testing.

- FQC: Final inspections occur before products are packaged, focusing on aesthetic and functional attributes.

B2B buyers should seek suppliers that implement rigorous QC checkpoints to mitigate risks associated with defective products.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of supplier quality control is critical for international buyers to ensure product reliability and compliance.

What Are Effective Methods for Supplier Audits?

One effective way to verify quality control practices is through supplier audits. These can be conducted by the buyer or third-party inspectors to assess the manufacturing process, QC systems, and compliance with international standards. Buyers should request audit reports, which provide insights into the supplier’s operational capabilities and adherence to quality protocols.

How Can B2B Buyers Use Test Reports to Ensure Quality?

Requesting test reports is another method to verify quality. These reports should detail the results of various tests conducted during the manufacturing process, such as electrical safety tests, thermal endurance tests, and insulation resistance tests. Having access to these documents allows buyers to evaluate the supplier’s commitment to quality assurance.

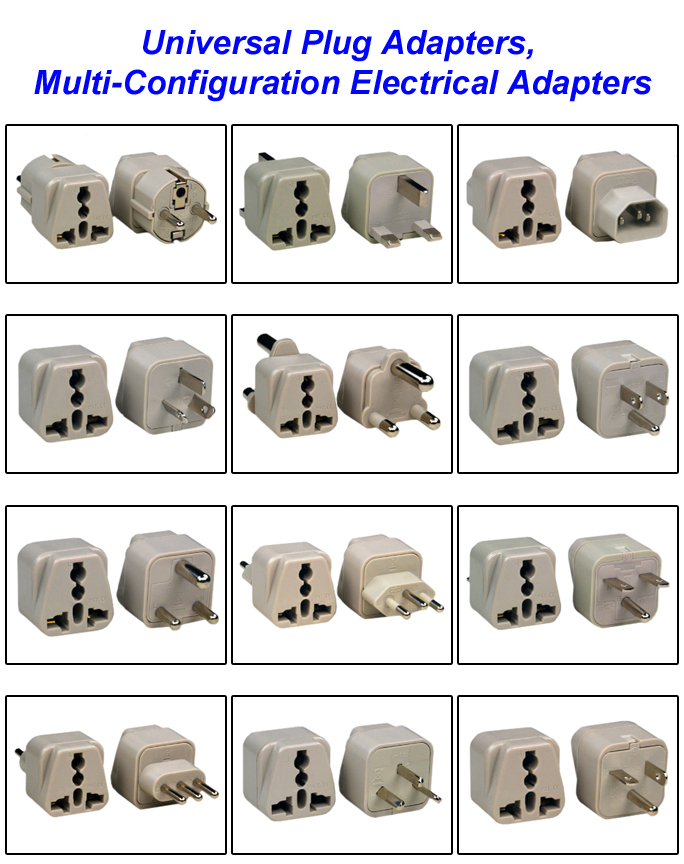

A stock image related to plug styles.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various quality assurance and certification nuances that can impact purchasing decisions.

How Do Regional Standards Affect Quality Assurance?

Different regions may have unique standards and certifications that influence product acceptance. For instance, while CE marking is essential in Europe, UL certification holds more weight in North America. Buyers from Africa, South America, the Middle East, and Europe should be aware of these differences to ensure compliance and facilitate market entry.

What Should Buyers Know About Compliance with Local Regulations?

In addition to international standards, local regulations may impose additional requirements. For instance, some countries may require specific labeling or safety certifications beyond what is mandated internationally. Buyers should conduct thorough research on local regulations and ensure their suppliers can meet these requirements to avoid potential import issues.

Conclusion: Ensuring Quality in Plug Manufacturing

By understanding the manufacturing processes and quality assurance mechanisms in plug manufacturing, B2B buyers can make informed decisions when selecting suppliers. Prioritizing suppliers who adhere to international standards, implement rigorous QC processes, and demonstrate transparency in their operations will ultimately lead to better product reliability and market success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plug styles’

In the rapidly evolving landscape of global commerce, international B2B buyers must navigate the complexities of sourcing electrical plugs. This step-by-step checklist is designed to guide you through the process, ensuring you make informed decisions that align with your operational needs and regional standards.

Step 1: Identify Your Plug Type Requirements

Understanding the specific plug types used in your target markets is crucial. Different regions utilize various plug styles, such as Type C in Europe and Type M in South Africa. Research the electrical standards of the countries you are sourcing for to ensure compatibility with local infrastructure.

- Key Considerations:

- Voltage and current ratings (e.g., 220-240V for Europe).

- Grounding requirements based on local safety regulations.

Step 2: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the design, size, and material specifications of the plugs you need. Defining these parameters upfront helps streamline communication with suppliers.

- Specific Details to Include:

- Number of pins and their arrangement (e.g., 2-pin vs. 3-pin).

- Materials used in manufacturing (e.g., thermoplastic or metal).

Step 3: Conduct Market Research on Potential Suppliers

It’s essential to identify and evaluate potential suppliers. Look for manufacturers with a proven track record in producing the plug styles you require. Utilize industry reports and trade shows to gather insights about reliable suppliers.

- What to Look For:

- Supplier certifications (ISO, CE, etc.) that ensure compliance with international standards.

- Reviews and testimonials from other B2B buyers, particularly those in your region.

Step 4: Request Product Samples

Once you have shortlisted suppliers, request samples of the plugs you intend to procure. Evaluating physical samples is vital to assess quality, durability, and compliance with your specifications.

- Sample Evaluation Criteria:

- Check for physical defects or inconsistencies in design.

- Test compatibility with existing equipment and sockets.

Step 5: Verify Supplier Certifications

Before finalizing your order, ensure that your chosen supplier has the necessary certifications. This step is crucial to mitigate risks associated with product safety and compliance.

- Important Certifications to Consider:

- CE marking for compliance with European standards.

- UL listing for safety in North America.

Step 6: Negotiate Terms and Conditions

Engage in discussions regarding pricing, lead times, and payment terms. Clear communication at this stage can prevent misunderstandings later on.

- Key Negotiation Points:

- Minimum order quantities and bulk discounts.

- Warranty and return policies to protect your investment.

Step 7: Establish a Logistics Plan for Shipping

Finally, develop a logistics plan to ensure timely delivery of your plugs. Consider factors like shipping methods, customs regulations, and local distribution channels.

- Logistics Considerations:

- Choose reliable freight forwarders experienced in international shipping.

- Understand local import regulations to avoid delays or additional costs.

By following this checklist, you can ensure a streamlined and effective sourcing process for electrical plugs that meets your business needs and adheres to regional standards.

Comprehensive Cost and Pricing Analysis for plug styles Sourcing

What Are the Key Cost Components in Plug Styles Sourcing?

Understanding the cost structure of plug styles is essential for B2B buyers looking to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. For instance, plugs made from high-quality plastics and metals, which meet international safety standards, typically command higher prices. Buyers should evaluate the trade-off between durability and cost.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer cheaper products, but this could affect quality. It’s crucial to assess the skill level of the workforce in the supplier’s region.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Suppliers with efficient operations may offer competitive pricing.

-

Tooling: Custom tooling for specific plug styles can entail significant upfront costs. Buyers should consider these costs when negotiating pricing, especially for customized orders.

-

Quality Control: Rigorous QC processes can add to the overall cost but are essential for ensuring product safety and compliance. Buyers should seek suppliers who prioritize quality assurance to mitigate risks.

-

Logistics: Shipping and handling costs can vary widely based on the destination, volume, and shipping method. Incoterms can influence these costs significantly, so it’s important for buyers to understand the implications of the chosen terms.

-

Margin: Suppliers will include their profit margins in the final price. Understanding the average market margin can help buyers negotiate better.

How Do Price Influencers Affect Plug Styles Costs?

Several factors influence pricing for plug styles, making it vital for buyers to be aware of them:

-

Volume and Minimum Order Quantity (MOQ): Generally, larger orders lead to lower per-unit costs. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Customized plugs tailored to specific requirements often come at a premium. Buyers must weigh the benefits of customization against the added costs.

-

Material Quality and Certifications: Higher quality materials and certifications, such as UL or CE, ensure safety and reliability but also increase costs. Buyers should assess whether the extra expense aligns with their operational needs.

-

Supplier Factors: The reliability, reputation, and location of suppliers can greatly influence pricing. Established suppliers may charge more due to their proven track record, but they often provide better assurance of quality and service.

-

Incoterms: The choice of Incoterms affects the distribution of shipping costs and responsibilities. Understanding these terms can help buyers predict total costs more accurately.

What Are the Best Tips for Negotiating Plug Styles Pricing?

When negotiating prices for plug styles, B2B buyers should consider the following tips:

-

Research and Compare: Gather market intelligence on pricing and quality from multiple suppliers. This data can serve as leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with quality, maintenance, and logistics. Emphasizing TCO can shift the conversation from price alone to value.

-

Be Clear About Requirements: Clearly define specifications and expectations to avoid misunderstandings that can lead to increased costs later in the process.

-

Explore Long-Term Relationships: Building long-term relationships with suppliers can yield better pricing and terms over time. Consider discussing future orders to negotiate bulk pricing.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and pricing fluctuations can empower buyers to make timely decisions and negotiate effectively.

Are There Pricing Nuances for International B2B Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, face unique pricing nuances:

-

Currency Fluctuations: Variability in exchange rates can significantly impact pricing. Buyers should consider hedging strategies to mitigate risks.

-

Import Duties and Taxes: Understanding the local import duties and taxes is crucial. These can add substantial costs that must be factored into the total price.

-

Cultural Factors: Different regions may have varying expectations regarding negotiation styles and pricing transparency. Being culturally aware can enhance negotiation outcomes.

Disclaimer on Indicative Prices

Prices for plug styles can vary widely based on the aforementioned factors. Buyers are encouraged to obtain specific quotes from suppliers to ensure accuracy and relevance to their unique needs.

Alternatives Analysis: Comparing plug styles With Other Solutions

When evaluating different solutions for electrical connectivity, it’s essential to consider alternatives to traditional plug styles. These alternatives can provide varying levels of efficiency, cost-effectiveness, and adaptability depending on the specific needs of your operations. Below, we compare plug styles against two viable alternatives: wireless power transmission and universal power supply systems.

| Comparison Aspect | Plug Styles | Wireless Power Transmission | Universal Power Supply Systems |

|---|---|---|---|

| Performance | Reliable for fixed installations | Limited range, efficiency varies | High compatibility across devices |

| Cost | Moderate initial cost | Higher due to technology | Varies, often higher upfront |

| Ease of Implementation | Simple installation process | Requires specialized equipment | Generally easy but may need adapters |

| Maintenance | Low maintenance | Moderate, requires periodic checks | Low, minimal upkeep required |

| Best Use Case | Residential and commercial use | Charging of mobile devices, tools | Industrial applications, multiple devices |

What Are the Advantages and Disadvantages of Wireless Power Transmission?

Wireless power transmission utilizes electromagnetic fields to transfer energy between a transmitter and a receiver. One significant advantage is the elimination of physical connectors, which can be beneficial in environments where moisture or physical wear could be problematic. However, the technology is still developing, and the efficiency can vary based on distance and interference from other electronic devices. This method is ideal for charging portable devices, but may not yet be suitable for heavy-duty industrial applications.

How Do Universal Power Supply Systems Compare?

Universal power supply systems are designed to accommodate various plug types and voltages, providing a versatile solution for businesses that operate in multiple regions. This adaptability allows companies to use a single power supply across different devices, simplifying logistics and reducing the need for multiple types of plugs. However, the initial investment can be higher, and organizations may need to purchase adapters for specific plug types, which can complicate setup. This solution is particularly effective for international businesses that require consistent power across diverse equipment.

Conclusion: How Can B2B Buyers Choose the Right Solution?

A stock image related to plug styles.

Selecting the right electrical connectivity solution depends on several factors, including the specific applications, budget constraints, and operational environments. Plug styles are reliable for traditional setups, especially in fixed installations. In contrast, wireless power transmission offers innovative solutions for portable devices, while universal power supply systems provide flexibility for businesses operating internationally. B2B buyers should evaluate their specific needs, considering performance, cost, and ease of implementation to make the most informed decision. By aligning the choice with operational requirements, businesses can enhance efficiency and reduce overhead costs.

Essential Technical Properties and Trade Terminology for plug styles

What Are the Key Technical Properties of Plug Styles?

Understanding the essential technical properties of plug styles is crucial for international B2B buyers, particularly those engaged in electrical engineering, manufacturing, or appliance design. Here are some key specifications:

-

Material Grade

– The material used in the construction of plugs significantly influences their durability and conductivity. Common materials include copper for conductors and thermoplastic for the casing. High-quality materials ensure that plugs can withstand wear and tear, which is vital for long-term reliability in industrial applications. -

Current Rating (Amperage)

– This specification indicates the maximum current the plug can safely carry. Common ratings include 10A, 16A, and 20A. Understanding the current rating is essential for ensuring compatibility with the electrical systems in various regions. This knowledge helps buyers avoid potential hazards like overheating or electrical fires. -

Voltage Rating

– Plugs are designed to operate at specific voltage levels, typically ranging from 100V to 250V. For instance, European plugs generally operate at 220-240V. Buyers must ensure that the plugs they procure match the voltage specifications of their target markets to prevent equipment malfunction or damage. -

Pin Configuration and Size

– The shape, size, and arrangement of the pins differ among plug types, affecting compatibility with sockets. For example, Type C plugs have two round pins, while Type G features three rectangular pins. Buyers need to consider the local standards of their operating regions to ensure proper fit and functionality. -

Temperature Rating

– This property indicates the range of temperatures the plug can endure without degrading. For industrial applications, plugs may need to function in extreme conditions. Selecting plugs with appropriate temperature ratings ensures operational safety and longevity. -

Safety Certifications

– Plugs must meet various international safety standards, such as IEC or UL certifications. These certifications validate that the plugs have undergone rigorous testing for safety and performance. Buyers should prioritize certified products to ensure compliance with local regulations and to minimize liability risks.

What Are Common Trade Terms Related to Plug Styles?

Understanding the terminology associated with plug styles can streamline the purchasing process for international B2B buyers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can lead to better quality assurance and potential cost savings when sourcing plugs. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. This term is critical for buyers as it can impact inventory costs and purchasing strategies. Knowing the MOQ helps in planning orders to meet production needs without overcommitting resources. -

RFQ (Request for Quotation)

– An RFQ is a formal request from a buyer to suppliers to provide pricing for specific products. This process is vital for obtaining competitive pricing and understanding market rates for various plug styles. -

Incoterms (International Commercial Terms)

– These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and import duties. Familiarity with Incoterms helps buyers negotiate terms that minimize risk and ensure clarity in logistics. -

Lead Time

– This refers to the time it takes from placing an order to receiving the products. Understanding lead times is crucial for project planning, especially in industries where timely delivery is essential for maintaining operations. -

Certification Mark

– A certification mark indicates that a product meets specific safety and performance standards. Buyers should look for plugs with recognized certification marks to ensure compliance with local regulations and to guarantee product reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing plug styles, ensuring compatibility, safety, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the plug styles Sector

A stock image related to plug styles.

What Are the Key Market Dynamics and Trends Affecting Plug Styles for International B2B Buyers?

The global plug styles market is shaped by several key drivers, including technological advancements, globalization, and the increasing demand for standardized electrical solutions. In regions such as Africa, South America, the Middle East, and Europe, the diversity of plug types poses challenges for international B2B buyers. The proliferation of e-commerce and digital platforms has facilitated easier access to various plug styles, enabling buyers to source products from different manufacturers worldwide. Notably, the push for universal compatibility is gaining traction, as businesses seek to streamline their supply chains and reduce operational costs associated with managing multiple plug types.

Emerging trends indicate a shift towards smart and energy-efficient plug designs. With the rise of the Internet of Things (IoT), smart plugs are becoming increasingly popular, allowing users to control devices remotely and monitor energy consumption. This trend is particularly relevant for B2B buyers focused on enhancing operational efficiency and reducing energy costs. Additionally, the demand for durable and versatile plug types, such as Type C and Type G, is rising, as they cater to a wide range of appliances and are compatible across different regions.

How Is Sustainability Influencing Plug Styles and Sourcing Practices?

As environmental concerns become paramount in global commerce, sustainability is reshaping sourcing practices in the plug styles sector. International B2B buyers are increasingly prioritizing suppliers who adhere to ethical and sustainable practices. This includes sourcing materials that have minimal environmental impact and ensuring that production processes comply with international environmental standards.

The importance of ethical supply chains cannot be overstated, as consumers and businesses alike are demanding transparency regarding the origins of the products they purchase. Certifications such as Energy Star and RoHS (Restriction of Hazardous Substances) are becoming essential for manufacturers aiming to appeal to eco-conscious buyers. These certifications not only signal compliance with environmental regulations but also indicate a commitment to reducing waste and promoting sustainability in product design. B2B buyers should actively seek out suppliers who can provide evidence of sustainable practices, thereby enhancing their own brand reputation and meeting the growing demand for environmentally friendly products.

What Is the Evolution of Plug Styles and Its Relevance to Today’s Market?

The evolution of plug styles can be traced back to the late 19th century, when the first standardized plugs were developed in response to the need for safe and efficient electrical connections. Over the years, numerous plug types emerged globally, each designed to meet specific electrical requirements and safety standards. This historical context is crucial for understanding current market dynamics, as it highlights the challenges of harmonizing different plug types in a globalized economy.

Today, with over 15 distinct plug types in use worldwide, the need for compatibility and standardization is more pressing than ever. The lack of a universal standard has led to logistical complexities for international B2B buyers, who must navigate varying regulations and preferences across different regions. Understanding the historical developments in plug styles can provide valuable insights into current sourcing trends, enabling buyers to make informed decisions when selecting products that meet both their operational needs and the expectations of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of plug styles

-

How do I choose the right plug style for my equipment?

Selecting the appropriate plug style for your equipment involves understanding the specific electrical requirements of your devices, including voltage, amperage, and compatibility with local socket types. It’s crucial to consider the region where your equipment will be used; for example, Type C plugs are common in Europe and South America, while Type M is primarily used in South Africa. Ensure that the plug style matches the socket type in your target market to avoid compatibility issues. -

What is the best plug style for international trade?

The best plug style for international trade largely depends on your target markets. For example, Type C is widely accepted in many countries across Europe, Africa, and South America, making it a versatile choice. However, if you’re targeting specific regions like the UK or Middle Eastern countries, you might consider Type G or Type H respectively. Always research the local standards and regulations to ensure compliance and avoid shipping delays. -

How can I vet suppliers for plug styles effectively?

Vetting suppliers for plug styles can be done by checking their certifications, reviews, and compliance with international standards. Look for suppliers with ISO certifications, which indicate adherence to quality management systems. Additionally, request samples to evaluate product quality and assess their responsiveness to inquiries. Networking within industry forums or attending trade shows can also provide insights into reputable suppliers. -

What are the minimum order quantities (MOQs) for plug styles?

Minimum order quantities for plug styles can vary significantly depending on the supplier and the type of plug. Generally, MOQs can range from 100 to several thousand units. It’s advisable to negotiate terms based on your initial needs and future projections. Some suppliers may offer lower MOQs for first-time buyers or if you commit to larger future orders. -

What payment terms should I expect when sourcing plug styles internationally?

Payment terms for sourcing plug styles can differ based on the supplier’s policies and the relationship established. Common terms include a 30% deposit before production and the remaining balance before shipment. Some suppliers may offer letters of credit for larger transactions, providing additional security. Always clarify payment methods, such as wire transfers or PayPal, to avoid any misunderstandings. -

How do I ensure quality assurance (QA) for plug styles?

Ensuring quality assurance for plug styles involves implementing a multi-step process. First, require suppliers to provide product certifications that meet international safety standards, such as CE, UL, or IEC. Conduct regular audits of the manufacturing process and request third-party inspections before shipment. Establish a clear return policy to address any defects or non-compliance with specifications. -

What logistics considerations should I keep in mind when importing plug styles?

When importing plug styles, consider factors such as shipping methods, customs regulations, and import duties. Choose a reliable freight forwarder experienced in handling electrical goods to navigate these complexities. Additionally, familiarize yourself with the documentation required for customs clearance, including commercial invoices and packing lists. Proper planning can help minimize delays and unexpected costs. -

Can I customize plug styles to meet specific requirements?

Yes, many suppliers offer customization options for plug styles to meet specific requirements. This can include modifications in design, color, or even electrical specifications. Discuss your needs with potential suppliers early in the negotiation process to understand their capabilities and any associated costs. Customization can enhance your product’s appeal in your target market and provide a competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plug styles

In conclusion, the diversity of plug styles worldwide presents both challenges and opportunities for international B2B buyers. Understanding the specific requirements of different plug types—such as Type C prevalent in Europe and Africa, or Type N used in Brazil—enables buyers to make informed purchasing decisions that align with local standards and safety regulations. Strategic sourcing is essential; it not only ensures compliance but also optimizes supply chain efficiency and cost-effectiveness.

As businesses expand into new markets, the ability to adapt to various electrical standards can significantly enhance customer satisfaction and operational resilience. Buyers are encouraged to establish partnerships with reliable suppliers who understand the nuances of local markets, ensuring a seamless integration of products into their operations.

Looking ahead, the trend towards globalization and digitalization will likely drive demand for versatile and adaptable plug solutions. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, should proactively seek innovative solutions that meet evolving electrical needs. Embrace strategic sourcing to secure a competitive edge and position your business for future growth.