Discover the Best Type C Electrical Plug Solutions (2025)

Introduction: Navigating the Global Market for type c electrical plug

Navigating the complexities of the global market for type C electrical plugs can be a daunting task for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The challenge often lies in sourcing reliable suppliers while ensuring compliance with varying electrical standards and safety regulations. This guide serves as a comprehensive resource for understanding type C plugs, which are widely utilized across many countries, particularly in Europe.

In this guide, we will delve into the specifics of type C electrical plugs, including their design, applications, and compatibility with various sockets. Additionally, we will explore the nuances of supplier vetting, pricing considerations, and the implications of local regulations on purchasing decisions. By equipping B2B buyers with in-depth knowledge and practical insights, this guide empowers them to make informed choices that optimize their procurement strategies.

Whether you are based in Saudi Arabia seeking to expand your electrical product offerings, or in Poland looking to streamline your supply chain, understanding the type C electrical plug market is crucial. With actionable insights and clear recommendations, this guide aims to simplify your sourcing process, ensuring that you can confidently navigate the global landscape of electrical components.

Understanding type c electrical plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C (Europlug) | Two round pins (4 mm), rated 2.5 A | Low energy appliances like chargers | Pros: Widely compatible; Cons: Limited to low power applications. |

| Type C (CEE 7/17) | Two larger round pins (4.8 mm), rated 10/16 A | High energy devices like hair dryers | Pros: Suitable for high power; Cons: Incompatible with type N sockets. |

| Type E | Type C compatible, with a grounding pin | Appliances requiring grounding | Pros: Enhanced safety; Cons: Requires compatible sockets. |

| Type F | Similar to Type E but with thicker pins | Heavy-duty appliances and industrial tools | Pros: High current capacity; Cons: Bulkier design may limit use in compact spaces. |

| Type N | Hexagonally shaped, designed for 16 A | Used in Brazil and South Africa | Pros: High power capacity; Cons: Incompatible with traditional Type C plugs. |

What are the Key Characteristics of Type C (Europlug)?

The Type C plug, commonly referred to as the Europlug, features two round pins with a diameter of 4 mm and is rated for a maximum current of 2.5 A. It is widely used across Europe and is compatible with various sockets, making it a go-to choice for low-energy applications such as phone chargers and small appliances. B2B buyers should consider the Europlug for devices that do not require grounding, ensuring compatibility with the majority of European sockets.

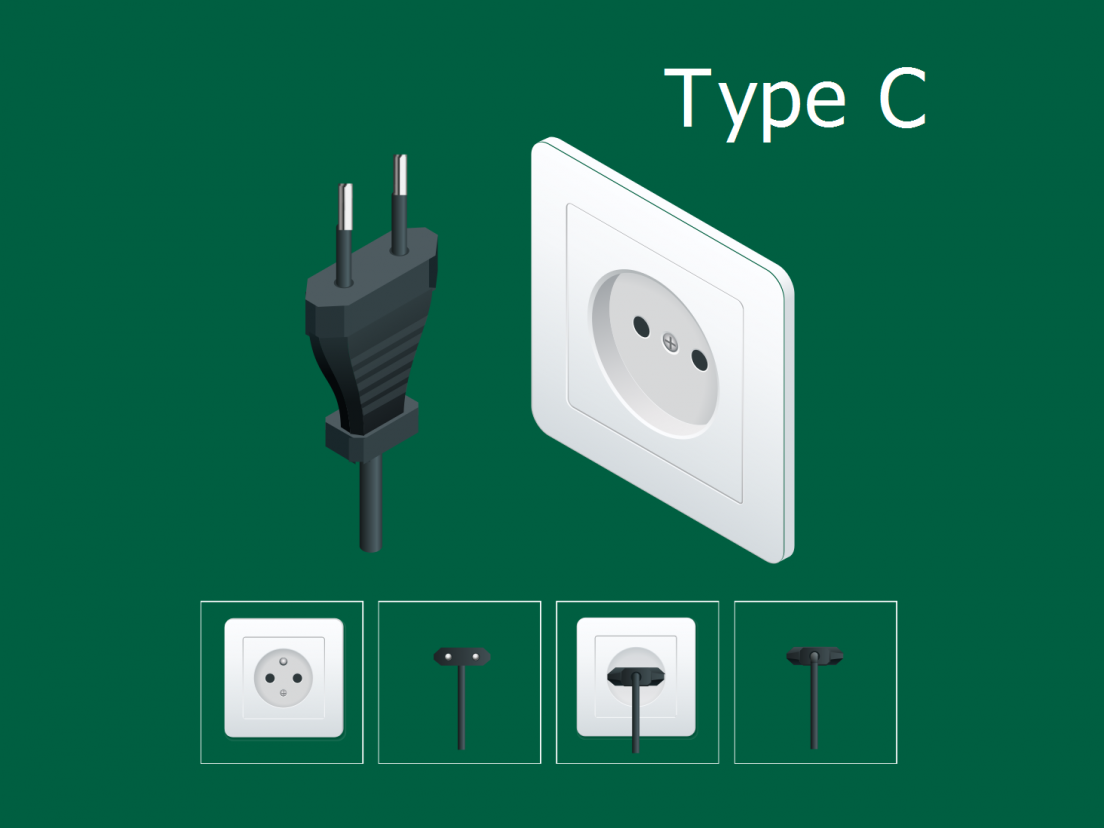

A stock image related to type c electrical plug.

How Does Type C (CEE 7/17) Differ from the Standard Type C?

The Type C (CEE 7/17) plug has the same pin length as the standard Europlug but features larger pins (4.8 mm) and can handle higher currents of up to 16 A. This plug is ideal for high-energy appliances such as hair dryers and vacuum cleaners. B2B buyers must ensure that their equipment is compatible with this plug type, especially in regions where Type N sockets are prevalent, as they are incompatible with the larger pins.

What are the Advantages of Using Type E Plugs?

Type E plugs are similar to Type C but include a grounding pin for safety, making them suitable for appliances that require earthing. This plug type is widely used in commercial and residential settings across Europe. For B2B buyers, investing in Type E plugs can enhance safety and compliance with local electrical regulations, particularly for devices with metal casings or those used in wet environments.

What Makes Type F Plugs Suitable for Heavy-Duty Applications?

Type F plugs, also known as Schuko plugs, are similar to Type E but have thicker pins and a higher current capacity, making them suitable for heavy-duty appliances and industrial applications. This plug type is designed to handle high power loads, making it an excellent choice for equipment like industrial machinery and large kitchen appliances. Buyers should consider the space and installation requirements due to the bulkier design.

Why Should Buyers Consider Type N Plugs?

Type N plugs, with their hexagonal shape, are designed for 16 A and are primarily used in Brazil and South Africa. They are not compatible with traditional Type C plugs, which can limit their use in international markets. B2B buyers should be aware of the regional specifications when sourcing equipment, as compatibility with local sockets is essential for seamless operations.

Key Industrial Applications of type c electrical plug

| Industry/Sector | Specific Application of type C Electrical Plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Charging small devices (e.g., smartphones, tablets) | Standardized charging solutions reduce costs | Ensure compatibility with local voltage and amperage standards. |

| Hospitality | Power supply for low-energy appliances (e.g., lamps) | Enhances guest experience with universal charging | Consider the need for multiple plug types to accommodate guests. |

| Retail | Point of sale (POS) systems | Streamlined operations with reliable power supply | Evaluate durability and compliance with local electrical codes. |

| Education | Classroom equipment (e.g., projectors, laptops) | Facilitates modern learning environments | Look for bulk purchasing options and warranty provisions. |

| Healthcare | Medical devices (e.g., monitors, portable equipment) | Ensures consistent operation of critical devices | Verify compliance with healthcare regulations and safety standards. |

How is the Type C Electrical Plug Used in Consumer Electronics?

In the consumer electronics sector, the Type C electrical plug is predominantly used for charging small devices such as smartphones and tablets. This plug’s design allows it to fit into various sockets across different regions, making it a universal solution for manufacturers targeting international markets. By standardizing charging solutions, businesses can significantly reduce costs associated with producing multiple plug types. International buyers should ensure that the plugs comply with local voltage and amperage standards to avoid compatibility issues.

What Role Does the Type C Plug Play in Hospitality?

In the hospitality industry, Type C plugs are commonly used to power low-energy appliances, such as bedside lamps and charging stations. This application enhances the guest experience by providing convenient and accessible charging options. Hotels and resorts can benefit from the universal nature of the Type C plug, which allows for easy integration into existing infrastructure. When sourcing these plugs, businesses should consider the need for multiple plug types to accommodate guests from various regions.

How is the Type C Plug Essential for Retail Operations?

Retail businesses utilize Type C plugs for powering point of sale (POS) systems, which are critical for streamlined operations. The reliability of Type C plugs ensures that transactions can be processed without interruption, which is vital for customer satisfaction. Retailers should evaluate the durability of the plugs and ensure compliance with local electrical codes when sourcing, as this will help minimize downtime and maintenance costs.

Why is the Type C Plug Important in Educational Settings?

In educational institutions, Type C plugs are used to power classroom equipment, including projectors and laptops. This facilitates modern learning environments where technology plays a crucial role in teaching and engagement. Schools and universities looking to enhance their technological capabilities should consider bulk purchasing options for Type C plugs, ensuring they meet local electrical standards and come with warranty provisions to protect their investment.

How Does the Type C Plug Benefit Healthcare Facilities?

A stock image related to type c electrical plug.

In the healthcare sector, Type C plugs are vital for powering medical devices such as monitors and portable equipment. Ensuring a consistent power supply is crucial for the operation of critical devices, which can directly impact patient care. Healthcare providers must verify that the plugs comply with industry regulations and safety standards when sourcing, as this will ensure both reliability and compliance in a highly regulated environment.

3 Common User Pain Points for ‘type c electrical plug’ & Their Solutions

Scenario 1: Compatibility Issues with Type C Plugs in Global Markets

The Problem:

B2B buyers often face compatibility challenges when sourcing Type C electrical plugs for their businesses, especially when they operate across multiple countries. For instance, a company based in South America may import appliances that use Type C plugs, only to find that local sockets are of a different type, such as Type N in Brazil. This can lead to costly delays, increased operational expenses, and customer dissatisfaction if products cannot be used as intended.

The Solution:

To mitigate compatibility issues, international B2B buyers should conduct thorough market research to identify the electrical standards of the target countries. It is crucial to source Type C plugs that are not only compliant with local regulations but also compatible with the prevalent socket types in those markets. When placing orders, buyers should specify the required plug types for their appliances and seek suppliers who can provide adaptable solutions, such as plug adapters or multi-type plugs that can fit various socket configurations. Furthermore, consider investing in a comprehensive compatibility chart for your team, which outlines the plug and socket types used in the countries where you operate. This proactive approach ensures that your products are usable upon arrival, minimizing downtime and enhancing customer satisfaction.

Scenario 2: Limited Power Rating of Type C Plugs Affecting Appliance Performance

The Problem:

Another common pain point for B2B buyers is the limited power rating of Type C plugs, which are generally rated for a maximum of 2.5 amps. This limitation can hinder the performance of high-energy appliances, such as hair dryers or vacuum cleaners, particularly in regions where higher wattage devices are common. For businesses that rely on these appliances, the inability to use them effectively can lead to operational inefficiencies and increased costs due to the need for replacements or modifications.

The Solution:

To address the limitations of Type C plugs, buyers should carefully evaluate the power requirements of their appliances before making a purchase. Consider sourcing appliances that are designed for lower energy consumption or opt for the less common Type C (CEE 7/17) plug, which accommodates higher amperage (up to 16 amps). Additionally, work closely with suppliers to ensure that the appliances can operate efficiently within the local electrical standards. For businesses that require higher power usage, investing in a combination of Type C plugs and appropriate adapters can provide flexibility and ensure that all devices can operate effectively without damaging the appliances or compromising safety.

Scenario 3: Safety Concerns with Ungrounded Type C Plugs

The Problem:

Safety is a major concern for B2B buyers using Type C plugs, as they are ungrounded and may pose risks when used with appliances that require grounding for safe operation. This is particularly relevant in regions where electrical standards have shifted towards grounded systems, creating potential hazards for users and damaging equipment. Buyers often find themselves in a dilemma: how to balance the widespread use of Type C plugs with the need for safer, grounded solutions.

The Solution:

To enhance safety while utilizing Type C plugs, buyers should prioritize sourcing appliances that are specifically designed for Class II applications, which do not require grounding. When procuring equipment, confirm that the devices are compliant with the latest safety regulations. Additionally, consider working with manufacturers that provide Type E or F plugs, which are grounded and compatible with Type C sockets, allowing for safer operation without compromising the usability of Type C appliances. Educating your staff on electrical safety standards and the implications of using ungrounded plugs can further mitigate risks. Investing in safety training and regular equipment inspections can ensure compliance and enhance the overall safety of your operations.

Strategic Material Selection Guide for type c electrical plug

What Materials are Commonly Used for Type C Electrical Plugs?

When selecting materials for type C electrical plugs, it’s essential to consider properties that affect performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of type C plugs: thermoplastics, thermosetting plastics, copper, and nickel plating.

How Do Thermoplastics Perform in Type C Electrical Plugs?

Key Properties: Thermoplastics, such as polycarbonate (PC) and polyamide (PA), are known for their excellent electrical insulation properties and temperature resistance, typically rated up to 85°C. They also offer good impact resistance, making them suitable for various applications.

Pros & Cons: The primary advantage of thermoplastics is their lightweight nature and ease of processing, which reduces manufacturing complexity and costs. However, they can be less durable compared to thermosetting plastics, especially under high-temperature conditions, leading to potential deformation.

Impact on Application: Thermoplastics are compatible with a wide range of electrical applications, including household appliances and consumer electronics. Their insulation properties help prevent electrical leakage, crucial for safety.

Considerations for International Buyers: Compliance with standards such as IEC 60884-1 is critical. Buyers in regions like Europe and the Middle East should ensure that the selected thermoplastic meets local regulations regarding fire safety and electrical insulation.

What Role Does Thermosetting Plastic Play in Type C Plugs?

Key Properties: Thermosetting plastics, such as phenolic resin, exhibit superior thermal stability and chemical resistance, making them ideal for high-temperature applications. They can withstand temperatures exceeding 150°C.

Pros & Cons: The durability of thermosetting plastics is a significant advantage, as they maintain structural integrity under stress. However, they are more expensive and complex to manufacture than thermoplastics, which may deter cost-sensitive buyers.

Impact on Application: These materials are particularly suited for heavy-duty appliances, such as hair dryers and industrial equipment, where heat resistance is paramount.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for thermosetting plastics, especially in regions with stringent electrical safety regulations, such as Europe.

Why is Copper Preferred for Conductors in Type C Plugs?

Key Properties: Copper is an excellent conductor of electricity, with low resistance and high thermal conductivity. It can handle significant electrical loads, making it suitable for various applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances the efficiency of electrical devices. However, copper is prone to corrosion, which can affect longevity unless adequately treated or coated.

Impact on Application: Copper is ideal for applications requiring reliable electrical connections, such as in household appliances. Its performance can significantly impact energy efficiency.

Considerations for International Buyers: Buyers must consider the quality of copper used, as low-grade copper can lead to overheating and safety hazards. Compliance with standards like ASTM B170 is crucial for ensuring quality.

How Does Nickel Plating Enhance Type C Electrical Plugs?

Key Properties: Nickel plating provides a protective layer over copper, enhancing corrosion resistance and reducing wear. This plating typically withstands temperatures up to 200°C.

Pros & Cons: The key advantage of nickel plating is its ability to extend the life of electrical connections by preventing oxidation. However, the plating process adds to manufacturing costs and complexity.

Impact on Application: Nickel-plated connectors are particularly beneficial in humid or corrosive environments, ensuring reliable performance over time.

Considerations for International Buyers: Buyers should ensure that the nickel plating process complies with international standards, such as ISO 4520, to guarantee quality and durability.

Summary Table of Material Selection for Type C Electrical Plugs

| Material | Typical Use Case for type C electrical plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Household appliances, consumer electronics | Lightweight, easy to process | Less durable under high temperatures | Medium |

| Thermosetting Plastics | Heavy-duty appliances, industrial equipment | Superior thermal stability | Higher cost, complex manufacturing | High |

| Copper | Electrical connections in appliances | Excellent conductivity | Prone to corrosion | Medium |

| Nickel Plating | Connectors in humid/corrosive environments | Enhanced corrosion resistance | Adds to cost and manufacturing complexity | Medium |

This guide aims to provide actionable insights for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, ensuring informed decisions when selecting materials for type C electrical plugs.

In-depth Look: Manufacturing Processes and Quality Assurance for type c electrical plug

What Are the Main Stages of Manufacturing Type C Electrical Plugs?

Manufacturing Type C electrical plugs involves several key stages, each critical to ensuring the final product meets safety and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Type C Electrical Plugs?

The first step in the manufacturing process is material preparation. Manufacturers typically use high-quality thermoplastic or thermosetting materials for the plug casing and copper alloys for the pins. These materials are selected for their electrical conductivity, durability, and resistance to wear and heat.

To prepare the materials, manufacturers follow these steps:

– Sourcing: Materials are sourced from certified suppliers to ensure compliance with international standards.

– Quality Inspection: Incoming materials undergo rigorous quality checks (IQC – Incoming Quality Control) to verify their specifications and performance characteristics.

– Pre-processing: The materials may be treated or processed to enhance their properties, such as applying surface treatments to improve corrosion resistance.

What Techniques Are Used in Forming Type C Electrical Plugs?

Once the materials are prepared, the next stage is forming. This involves shaping the components of the plug through various techniques, including:

- Injection Molding: This method is commonly used to create the plastic casing of the plug. Molten plastic is injected into molds, which are designed to the exact specifications of the Type C plug.

- Stamping: Metal parts, such as the pins, are often produced using stamping processes. This involves cutting and shaping metal sheets into the desired forms.

- Machining: For precision components, machining techniques may be employed to achieve the exact dimensions required for the plug’s functionality.

These processes require advanced machinery and skilled operators to ensure accuracy and consistency in production.

How Are Type C Electrical Plugs Assembled?

The assembly of Type C plugs is a critical stage that involves the integration of all individual components. This typically includes:

- Pin Insertion: The metal pins are inserted into the plastic casing. This step requires precise alignment to ensure proper electrical contact.

- Soldering: Connections may be soldered to ensure a secure and reliable electrical connection between the pins and internal wiring.

- Final Assembly: The casing is closed, and any additional components, such as strain relief features, are added to enhance durability.

Each step in the assembly process is closely monitored to maintain quality and safety standards.

What Finishing Processes Are Applied to Type C Electrical Plugs?

After assembly, the plugs undergo finishing processes to enhance their appearance and functionality. This may include:

- Surface Treatment: Coatings may be applied to improve aesthetics and resistance to environmental factors.

- Testing and Inspection: Each plug is subjected to rigorous testing, including electrical continuity tests, insulation resistance tests, and mechanical stress tests.

- Packaging: The final products are carefully packaged to prevent damage during transportation.

What International Standards and Quality Assurance Practices Are Relevant for Type C Electrical Plugs?

Quality assurance is paramount in the manufacturing of Type C electrical plugs. Several international standards and industry-specific certifications govern the quality and safety of electrical components.

Which International Standards Should B2B Buyers Consider?

B2B buyers should be familiar with the following international standards:

- ISO 9001: This is the global standard for quality management systems. Compliance indicates that the manufacturer has robust quality management practices in place.

- CE Marking: Required for products sold in the European Economic Area, CE marking signifies conformity with health, safety, and environmental protection standards.

- IEC Standards: The International Electrotechnical Commission (IEC) sets standards for electrical and electronic products, ensuring they are safe and reliable.

How Is Quality Control Implemented in Manufacturing?

Quality control (QC) in the manufacturing of Type C plugs typically involves multiple checkpoints:

- Incoming Quality Control (IQC): Inspections are conducted on raw materials before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures that processes remain within specified limits.

- Final Quality Control (FQC): After production, finished products undergo thorough testing to verify they meet all required specifications.

Common testing methods include:

– Electrical Testing: Checking for proper voltage and current ratings.

– Mechanical Testing: Assessing durability under stress and strain.

– Environmental Testing: Evaluating performance under various temperature and humidity conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are actionable steps to ensure compliance and quality:

- Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control measures, including testing results and certifications.

- Utilize Third-Party Inspection Services: Engaging third-party inspectors can offer an impartial assessment of the manufacturing processes and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions have varying regulations regarding electrical products. Understanding local compliance is essential for market entry.

- Cultural Differences: Approaches to quality assurance may differ based on cultural practices. Establishing clear communication and expectations can mitigate misunderstandings.

- Logistics Considerations: International shipping introduces risks of damage. Ensuring robust packaging and handling processes can protect product integrity during transit.

By understanding the manufacturing processes and quality assurance practices for Type C electrical plugs, international B2B buyers can make informed purchasing decisions, ensuring they acquire reliable and compliant products for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type c electrical plug’

In the dynamic world of international business, sourcing the right products, such as type C electrical plugs, requires a structured approach to ensure quality and compliance. This guide serves as a practical checklist for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, to streamline their procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the type C electrical plugs you procure meet your operational needs. Consider factors such as amperage ratings (typically 2.5 A for standard plugs), dimensions of the pins (4 mm diameter), and any specific standards required for your industry. This clarity will help you communicate effectively with suppliers and avoid costly mistakes.

Step 2: Research Market Trends and Regulations

Understanding the market landscape and relevant regulations is vital for successful sourcing. Familiarize yourself with the electrical standards in your target regions, particularly in Europe and other areas where type C plugs are prevalent. Compliance with local regulations not only ensures safety but also facilitates smoother customs processes.

- Key Considerations:

- Verify if the plugs comply with the IEC standards.

- Stay updated on any changes in regulations, particularly regarding safety and environmental impacts.

Step 3: Evaluate Potential Suppliers

Before finalizing any procurement decisions, it is essential to conduct a thorough evaluation of potential suppliers. Look for manufacturers with a proven track record in producing type C plugs. Request detailed company profiles, certifications, and case studies to gauge their reliability.

- What to Look For:

- Supplier certifications (e.g., ISO, CE) that indicate quality management.

- References from other businesses in your industry or region.

Step 4: Request Product Samples

Once you have shortlisted suppliers, requesting product samples is a critical step. This allows you to assess the quality and functionality of the type C plugs firsthand. Pay attention to the materials used, durability, and overall design to ensure they meet your specifications.

- Testing Criteria:

- Perform electrical and mechanical tests to check the plugs’ performance.

- Evaluate the ease of use and compatibility with different sockets.

Step 5: Negotiate Pricing and Terms

Engaging in negotiations is a key part of the sourcing process. Make sure to discuss pricing, payment terms, and delivery schedules upfront. Understanding the total cost of ownership, including shipping and tariffs, will help you make informed decisions.

- Negotiation Tips:

- Be clear about your budget and expected order volumes.

- Consider long-term partnerships for better pricing and service.

Step 6: Ensure After-Sales Support and Warranty

After securing a deal, confirm the availability of after-sales support and warranty terms. Reliable customer service can significantly impact your operations, especially if issues arise with the plugs.

- Support Aspects:

- Inquire about return policies and warranty durations.

- Assess the responsiveness of the supplier’s customer support team.

Step 7: Monitor Quality and Compliance Post-Purchase

After procurement, it is essential to continuously monitor the quality and compliance of the plugs. Regular audits and inspections can prevent issues that may affect your operations.

- Quality Control Measures:

- Set up a schedule for quality assessments and compliance checks.

- Maintain open communication with your supplier for ongoing improvements.

By following these steps, B2B buyers can streamline their sourcing process for type C electrical plugs, ensuring that they procure high-quality products that meet their specific needs while adhering to regional standards.

Comprehensive Cost and Pricing Analysis for type c electrical plug Sourcing

What Are the Key Cost Components for Sourcing Type C Electrical Plugs?

When sourcing Type C electrical plugs, understanding the cost structure is critical for B2B buyers to ensure effective budgeting and negotiation. The primary cost components include:

-

Materials: The raw materials for Type C plugs typically include high-quality plastics for the casing and copper for the conductive pins. The cost of these materials can fluctuate based on market demand and supply chain conditions.

-

Labor: Labor costs can vary significantly by region. In countries with lower labor costs, such as those in parts of Africa and South America, manufacturers can offer competitive pricing. However, labor regulations and skill levels may impact the overall quality of the product.

-

Manufacturing Overhead: This encompasses costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, contributing to lower pricing for the buyer.

-

Tooling: Tooling costs are significant, especially for custom designs or high-volume orders. Buyers should consider whether they are sourcing standard or customized plugs, as custom tooling can significantly increase upfront costs.

-

Quality Control (QC): Ensuring that plugs meet international standards (e.g., IEC, UL) involves quality assurance processes that can add to the overall cost. Buyers should factor in the potential costs of inspection and testing to ensure compliance.

-

Logistics: Shipping costs vary based on the origin of the product, chosen Incoterms, and delivery timelines. Buyers should consider both direct shipping costs and potential tariffs when calculating total expenses.

-

Margin: Suppliers will typically add a profit margin to cover their costs and risks. Understanding market conditions and competitor pricing can aid in negotiating better terms.

How Do Pricing Influencers Impact the Cost of Type C Electrical Plugs?

Several factors can influence the pricing of Type C plugs, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower unit costs. Understanding the supplier’s MOQ can help buyers negotiate better pricing based on their needs.

-

Specifications and Customization: Custom designs or specifications may incur additional costs. Buyers should assess whether standard models meet their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications can lead to increased costs. Buyers should evaluate the importance of certifications such as CE or RoHS in their target markets.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can impact pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The chosen Incoterm affects shipping costs and responsibilities. Buyers should be clear on who bears the costs for shipping, insurance, and customs duties to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in Type C Plug Sourcing?

To maximize cost-efficiency when sourcing Type C electrical plugs, international buyers should consider the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules. Building a strong relationship with suppliers can also lead to better terms over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider the long-term implications of sourcing decisions. This includes quality, warranty, and potential replacement costs.

-

Research Market Prices: Conduct market research to understand average pricing in your region. This knowledge can empower you during negotiations and help identify competitive suppliers.

-

Consider Regional Suppliers: For buyers in Africa or South America, sourcing from local suppliers may reduce shipping costs and lead times, improving overall efficiency.

-

Assess Quality vs. Cost: While low-cost options may be tempting, they can lead to higher TCO due to failures and replacements. Always balance cost with quality to ensure long-term satisfaction.

A stock image related to type c electrical plug.

What Should Buyers Keep in Mind Regarding Indicative Prices?

Buyers should note that prices for Type C electrical plugs can vary widely based on the factors discussed. It is essential to obtain multiple quotes and assess the conditions surrounding each offer. Prices can be indicative and subject to change based on market dynamics, currency fluctuations, and geopolitical factors. Always confirm current pricing before finalizing any orders to ensure budget alignment and minimize unexpected costs.

Alternatives Analysis: Comparing type c electrical plug With Other Solutions

When considering the Type C electrical plug for international B2B transactions, it’s essential to evaluate alternative solutions that can cater to the diverse electrical needs across different regions, especially in Africa, South America, the Middle East, and Europe. Understanding these alternatives can aid B2B buyers in making informed decisions based on specific requirements, such as compatibility, safety, and cost-effectiveness.

| Comparison Aspect | Type C Electrical Plug | Alternative 1: Type E Plug | Alternative 2: Type F Plug |

|---|---|---|---|

| Performance | Rated at 2.5A, suitable for low energy devices. | Rated at 16A, allows for higher power devices. | Similar to Type E, supports up to 16A with grounding. |

| Cost | Generally low-cost and widely available. | Slightly higher due to grounding features. | Comparable to Type E, depending on market supply. |

| Ease of Implementation | Simple design, easily compatible with many sockets. | Requires specific sockets, may need installation adjustments. | Compatible with Type E sockets, easier integration. |

| Maintenance | Minimal, no grounding concerns. | Requires periodic checks for grounding integrity. | Similar to Type E, needs occasional maintenance. |

| Best Use Case | Ideal for low-power appliances like chargers and lamps. | Best for high-power devices like heaters and kitchen appliances. | Suitable for high-power devices, especially in regions with Type E sockets. |

What Are the Advantages and Disadvantages of Using Type E Plugs?

The Type E plug is a viable alternative, especially in many European countries. It supports higher power consumption, rated at 16A, which makes it suitable for appliances that require more energy. The main advantage of the Type E plug is its grounding feature, which enhances safety by preventing electric shocks. However, this plug requires compatible sockets, which may necessitate additional installation in regions primarily using Type C plugs. This can lead to higher upfront costs and potential compatibility issues for businesses transitioning their electrical systems.

How Does the Type F Plug Compare as an Alternative?

The Type F plug, also known as the “Schuko” plug, is another robust alternative that supports up to 16A. Its design includes grounding, making it safer for high-energy appliances such as air conditioners and industrial equipment. Like the Type E, it offers good compatibility with various sockets in Europe but may require additional infrastructure changes for regions primarily using Type C. The Type F plug is often preferred in professional settings where safety and performance are paramount, but it can be more expensive than the Type C option.

Conclusion: How to Choose the Right Electrical Plug Solution for Your Business Needs

When selecting the appropriate electrical plug solution, B2B buyers should assess their specific operational requirements. For businesses primarily using low-energy devices in regions where Type C is prevalent, the Type C plug remains a cost-effective and simple choice. However, for those requiring higher power solutions, the Type E or Type F plugs offer enhanced safety and performance. Ultimately, understanding the local infrastructure, appliance requirements, and long-term operational goals will guide buyers in making the most informed decision that aligns with their business strategy.

Essential Technical Properties and Trade Terminology for type c electrical plug

What are the Essential Technical Properties of the Type C Electrical Plug?

When considering Type C electrical plugs for international trade, understanding their technical specifications is crucial for ensuring compatibility, safety, and efficiency. Here are some key properties that B2B buyers should take into account:

1. Material Grade

The Type C plug is typically made from high-grade thermoplastics and copper. The thermoplastic casing provides durability and heat resistance, while copper ensures excellent conductivity. Buyers should prioritize plugs that meet international standards such as IEC 60884-1, which ensures safety and reliability in performance.

2. Current Rating

Type C plugs are rated for a maximum current of 2.5 amperes for low-energy appliances and up to 16 amperes for higher-energy models. This specification is critical when selecting plugs for specific applications, as using a plug rated for lower current with a high-energy device can lead to overheating and potential hazards.

3. Pin Dimensions and Configuration

The Type C plug features two round pins, each measuring 4 mm in diameter and spaced 19 mm apart. Understanding these dimensions is essential for compatibility with various sockets. This flexibility allows Type C plugs to fit into Type E, F, and other compatible sockets, making them a versatile choice for international buyers.

4. Insulation and Safety Features

Insulated sleeves on the pins are designed to prevent accidental contact, enhancing user safety. Buyers should ensure that plugs have adequate insulation to comply with safety regulations in their respective markets, especially in regions where grounding is increasingly required.

5. Temperature Tolerance

The Type C plug should be able to operate within a temperature range of -10°C to +40°C. This tolerance is crucial for applications in varying climates, particularly in regions like Africa and South America, where extreme temperatures can be common.

6. Compliance with Standards

B2B buyers should confirm that the Type C plugs comply with regional and international electrical standards, including CE marking in Europe and relevant certifications in Africa and South America. Compliance ensures that the products meet safety and performance criteria, reducing liability and enhancing brand reputation.

What Trade Terminology Should B2B Buyers Understand for Type C Electrical Plugs?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms relevant to purchasing Type C electrical plugs:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships can help buyers ensure that they are sourcing high-quality components that meet specific design and performance criteria.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is important for budgeting and inventory management, particularly for businesses looking to minimize costs while ensuring sufficient stock levels.

3. RFQ (Request for Quotation)

An RFQ is a document that potential buyers send to suppliers to request pricing and terms for products. In the context of Type C plugs, an RFQ should include specific requirements like material specifications, compliance standards, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding the total cost and logistics of importing Type C plugs.

5. Lead Time

Lead time refers to the time it takes from placing an order until the goods are delivered. This is a critical factor for businesses that rely on timely deliveries to maintain production schedules or meet customer demands.

6. Certification

Certification indicates that a product has been tested and meets specific safety and performance standards. For Type C plugs, certifications such as UL (Underwriters Laboratories) or CE marking are vital for ensuring compliance in different markets, which can affect market entry and sales.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing Type C electrical plugs, ensuring they meet both operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the type c electrical plug Sector

What Are the Key Market Dynamics and Trends Influencing Type C Electrical Plug Sourcing?

The global market for type C electrical plugs is witnessing significant growth, driven by increasing demand for standardized electrical components across various regions. This plug type is predominantly used in Europe and many developing countries in Africa and South America, making it a critical component for international trade and commerce. The rise of electronic devices requiring efficient power sources has led to a surge in demand for type C plugs, particularly in sectors such as consumer electronics, automotive, and renewable energy.

Emerging trends in sourcing include a shift towards integrating smart technology into electrical components. This includes the incorporation of smart plugs that offer energy monitoring and control features, catering to eco-conscious consumers and businesses alike. Additionally, the demand for customizable and modular plug designs is on the rise, allowing manufacturers to adapt to specific market needs while optimizing production efficiency.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focusing on sourcing strategies that prioritize supplier reliability and compliance with international standards. This trend is essential as businesses seek to mitigate risks associated with supply chain disruptions and ensure the quality of their electrical components.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Type C Electrical Plug Procurement?

The environmental impact of electrical component manufacturing is a growing concern for B2B buyers in the type C electrical plug sector. As sustainability becomes a focal point for businesses, it is essential to adopt sourcing practices that minimize ecological footprints. This includes selecting suppliers who utilize eco-friendly materials and processes in their production.

Ethical supply chains are paramount, especially in regions with varying labor standards. Buyers should prioritize manufacturers that adhere to fair labor practices and demonstrate transparency in their sourcing. Certifications such as ISO 14001 for environmental management and Fair Trade certification can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of recyclable materials in type C plug production is becoming increasingly important. Manufacturers that embrace innovative materials, such as biodegradable plastics or recycled metals, not only reduce waste but also appeal to the growing market of environmentally conscious consumers. B2B buyers should actively seek partnerships with suppliers who prioritize these sustainable practices, thus enhancing their brand reputation while contributing to a healthier planet.

What Is the Historical Context Behind the Type C Electrical Plug’s Popularity?

The type C electrical plug, also known as the Europlug, has its origins in the early 20th century, designed to provide a universal solution for low-energy appliances across Europe. Its straightforward design features two round pins and is compatible with a variety of sockets, making it versatile for international use. Over the decades, as electrical standards evolved, the type C plug became the preferred choice in many countries, especially in Europe, due to its simplicity and efficiency.

Historically, the plug has played a crucial role in the expansion of electrical infrastructure, facilitating the growth of consumer electronics and appliances. As global trade expanded, the type C plug emerged as a standard component, further solidifying its importance in the international market. This historical context not only highlights the plug’s adaptability but also underscores its relevance in today’s rapidly evolving technological landscape, making it a focal point for international B2B buyers looking to source reliable electrical components.

Frequently Asked Questions (FAQs) for B2B Buyers of type c electrical plug

-

How do I ensure the quality of Type C electrical plugs from international suppliers?

To ensure quality, establish a comprehensive vetting process for suppliers. Request samples and certifications that comply with international standards (e.g., IEC 60884-1). Consider third-party inspections and audits to verify manufacturing practices. Additionally, seek suppliers with a proven track record in your target markets, as this can indicate reliability and adherence to quality norms. Maintain clear communication regarding quality expectations and implement a robust quality assurance program post-purchase. -

What is the best sourcing strategy for Type C electrical plugs for my business?

The best sourcing strategy involves a multi-faceted approach. Begin by conducting market research to identify reputable suppliers in your target regions, such as Europe and Asia. Utilize platforms like Alibaba or Global Sources, and attend industry trade shows for direct engagement. Establish relationships with multiple suppliers to mitigate risks associated with supply chain disruptions. Consider local suppliers in regions like Africa and South America to reduce shipping costs and lead times, enhancing your competitiveness. -

What are the typical minimum order quantities (MOQs) for Type C electrical plugs?

MOQs for Type C electrical plugs can vary significantly based on the supplier and manufacturing capabilities. Generally, MOQs range from 500 to 10,000 units. However, some manufacturers may offer lower MOQs for custom orders or samples. Always discuss MOQs upfront and negotiate terms that fit your business needs, especially if you are just starting or testing a new market. Building a long-term relationship with a supplier may also allow for flexibility in MOQs. -

What payment terms should I expect when sourcing Type C electrical plugs internationally?

Payment terms can differ widely between suppliers and regions. Common options include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer favorable terms, such as net 30 or net 60 days, especially for established relationships. Always clarify payment methods (e.g., bank transfer, letter of credit) and ensure they are secure. It’s advisable to use trusted payment platforms that provide buyer protection, reducing the risk of fraud. -

How can I customize Type C electrical plugs for my brand?

Customization options for Type C electrical plugs typically include branding, color variations, and packaging design. Communicate your specific requirements to the supplier, ensuring they have the capabilities for customization. Be prepared to provide artwork and branding guidelines. Discuss lead times for custom orders, as they may extend the delivery schedule. Additionally, inquire about costs associated with customization, as these can impact your overall budget. -

What logistics considerations should I keep in mind when importing Type C electrical plugs?

When importing Type C electrical plugs, consider shipping methods (air vs. sea), which impact cost and delivery time. Ensure compliance with local regulations regarding electrical products, including safety certifications and customs documentation. Work with experienced freight forwarders to navigate logistics challenges, including tariffs and duties. Additionally, monitor shipping schedules closely to avoid delays, particularly in peak seasons, and maintain clear communication with suppliers regarding shipping updates. -

What are the common safety standards for Type C electrical plugs?

Type C electrical plugs should comply with international safety standards such as IEC 60884-1 and local regulations in target markets. Check for certifications like CE marking in Europe or UL certification in the United States. These standards ensure the plugs are designed to prevent electrical hazards. Always request documentation from suppliers proving compliance with these standards, as this can protect your brand from liability and ensure customer safety. -

How can I effectively manage supplier relationships for Type C electrical plugs?

To manage supplier relationships effectively, maintain open and consistent communication regarding expectations, orders, and feedback. Schedule regular check-ins to discuss performance and address any concerns promptly. Building rapport can lead to better pricing and priority during high-demand periods. Utilize performance metrics to evaluate suppliers, ensuring they meet quality, delivery, and service standards. Additionally, consider visiting suppliers periodically to strengthen partnerships and gain insights into their operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type c electrical plug

In conclusion, the strategic sourcing of Type C electrical plugs is a vital consideration for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The widespread adoption of this plug type across numerous markets underscores its significance in global commerce. By understanding the specifications, compatibility, and regional regulations associated with Type C plugs, businesses can enhance their procurement strategies, ensuring compliance while optimizing operational efficiency.

International buyers should prioritize sourcing from reputable manufacturers who adhere to quality standards, particularly as the demand for sustainable and energy-efficient solutions grows. Establishing strong supplier relationships can lead to better pricing, improved delivery timelines, and access to innovative products that meet evolving market needs.

Looking ahead, as global markets become increasingly interconnected, the importance of strategic sourcing will only intensify. Now is the time for B2B buyers to evaluate their sourcing strategies and align them with future trends in electrical components. Engage with trusted suppliers, leverage market intelligence, and ensure that your procurement processes are agile enough to adapt to changing demands. By doing so, you will position your business for success in the dynamic landscape of electrical plug sourcing.