Discover the Best Type of Electric Plugs for Your Needs (2025)

Introduction: Navigating the Global Market for type of electric plugs

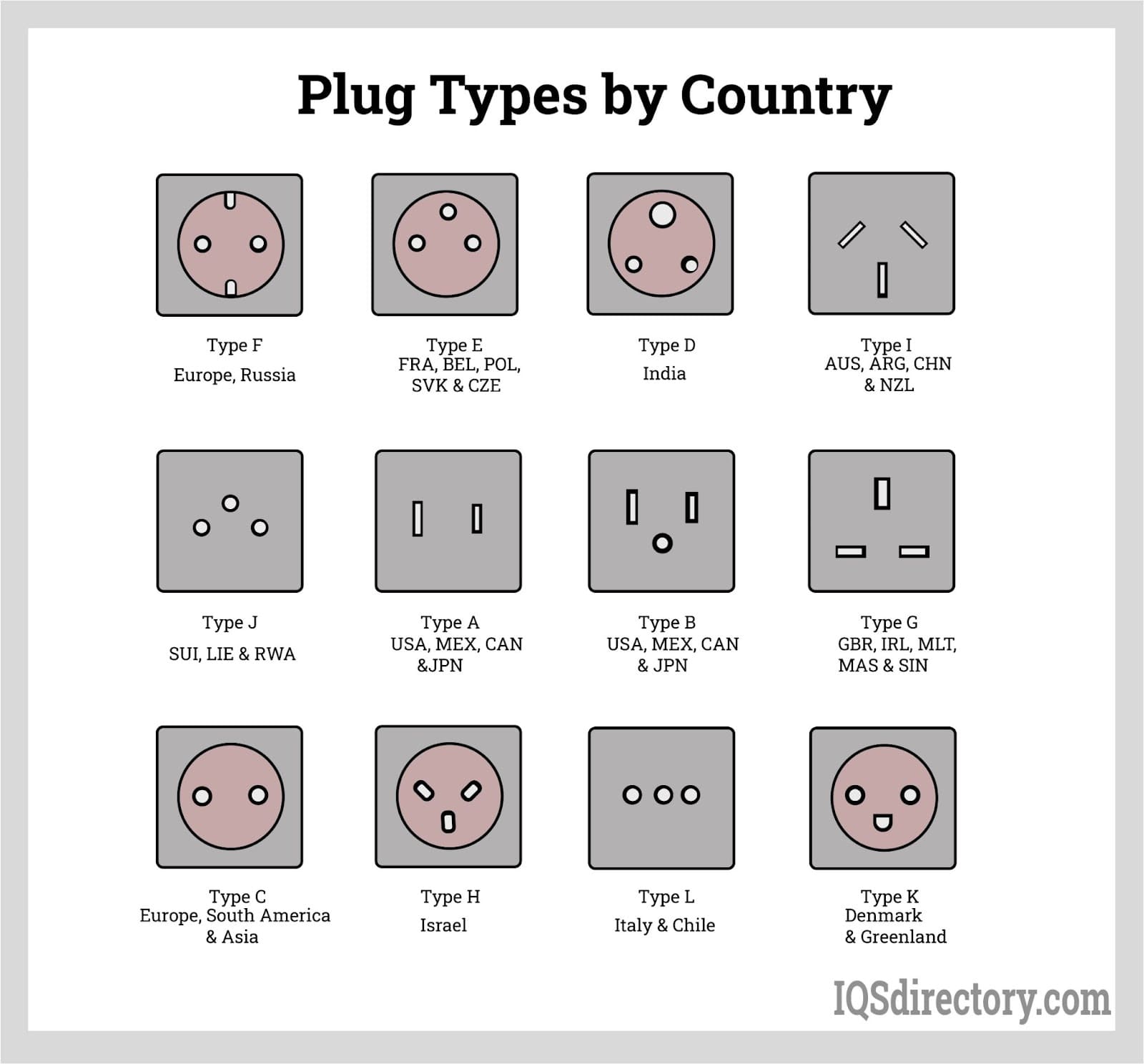

In today’s global marketplace, sourcing the right type of electric plugs can pose a significant challenge for international B2B buyers. With a diverse range of plug types and standards across regions, navigating these complexities is essential for ensuring compatibility and safety in electrical installations. This comprehensive guide aims to demystify the various types of electric plugs, providing valuable insights into their applications, geographical distributions, and specific requirements for sourcing.

The guide covers a wide spectrum of topics including the 15 distinct plug types recognized worldwide, their respective voltage and frequency specifications, and practical considerations for selecting the appropriate plug for your business needs. Furthermore, it delves into the critical aspects of supplier vetting and cost analysis, equipping buyers from Africa, South America, the Middle East, and Europe—such as those in Kenya and Colombia—with the knowledge to make informed purchasing decisions.

By understanding the intricacies of electric plugs and sockets, B2B buyers can mitigate risks associated with electrical compatibility and ensure seamless operations in their projects. This guide serves as a vital resource for those looking to enhance their procurement strategies, ultimately leading to more efficient and effective sourcing practices in an interconnected global market.

Understanding type of electric plugs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | Two round pins, no ground | General appliances, electronics | Pros: Widely used, compatible with many devices. Cons: Not grounded; may pose safety risks with high-power equipment. |

| Type G | Three rectangular pins, grounded | UK and Middle East appliances | Pros: Grounded for safety, suitable for high-power devices. Cons: Less common outside the UK; may require adapters for international use. |

| Type E | Two round pins, one hole for grounding | European electronics and appliances | Pros: Grounding enhances safety, common in Europe. Cons: Limited compatibility with non-European plugs. |

| Type I | Two flat pins, one vertical pin for grounding | Australia, New Zealand, and China appliances | Pros: Grounded design, versatile for many devices. Cons: May need adapters for non-compatible plugs. |

| Type N | Three pins, grounded, compatible with Type C | Brazil and South Africa appliances | Pros: High compatibility, suitable for various devices. Cons: Less common globally; may require adapters. |

What Are the Key Characteristics of Type C Plugs?

Type C plugs are characterized by their two round pins and lack of grounding, making them a prevalent choice across Europe, Africa, and South America. They are typically used for low to medium power applications, such as small appliances and electronics. B2B buyers should consider their compatibility with devices, especially in regions where Type C is standard. While they offer convenience, the absence of grounding can pose safety risks for high-power equipment, necessitating careful consideration in purchasing decisions.

Why Choose Type G Plugs for B2B Applications?

Type G plugs feature three rectangular pins and are grounded, making them a popular choice in the UK, Ireland, and parts of the Middle East. Their robust design allows them to handle higher power loads, making them suitable for commercial and industrial applications. B2B buyers should prioritize Type G for equipment requiring grounding, ensuring safety and reliability. However, their limited use outside the UK can necessitate the purchase of adapters, which may complicate international operations.

How Does Type E Plug Suitability Impact Purchasing Decisions?

Type E plugs, with two round pins and an additional hole for grounding, are primarily used in France and several other European countries. Their design enhances safety for devices that require grounding, making them ideal for high-power applications. B2B buyers should consider regional compatibility when sourcing equipment, as Type E plugs may not work with devices designed for other plug types. While they are common in Europe, buyers may face challenges when integrating equipment from non-European regions.

What Are the Advantages of Using Type I Plugs?

Type I plugs are identifiable by their two flat pins and a grounding pin, commonly used in Australia, New Zealand, and parts of China. Their grounded design provides an added layer of safety for various devices, making them suitable for both residential and commercial applications. B2B buyers should evaluate their supply chains to ensure compatibility with Type I plugs, particularly when importing equipment. However, the need for adapters in non-compatible regions may add complexity to international transactions.

Why Is Type N a Viable Option for B2B Buyers?

Type N plugs are distinguished by their three pins and compatibility with Type C sockets, commonly found in Brazil and South Africa. Their design accommodates a range of power levels, making them suitable for diverse applications. B2B buyers should consider Type N for operations in these regions, ensuring they meet local electrical standards. While Type N offers high compatibility, its lesser-known status globally may require additional investment in adapters for international use, impacting procurement strategies.

Key Industrial Applications of type of electric plugs

| Industry/Sector | Specific Application of type of electric plugs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment | Ensures operational efficiency and minimizes downtime | Compatibility with local voltage and frequency standards |

| Telecommunications | Charging and powering network equipment | Supports reliable communication networks | Compliance with international standards and certifications |

| Construction | Temporary power supply for tools and equipment | Enhances productivity on construction sites | Durability and weather resistance of plugs and sockets |

| Hospitality | Guest room electrical appliances | Improves guest satisfaction and comfort | Variety of plug types to accommodate international guests |

| Healthcare | Medical equipment power supply | Ensures critical equipment operates without interruption | Adherence to safety standards and regulations |

How is ‘Type of Electric Plugs’ Used in Manufacturing?

In the manufacturing sector, type of electric plugs are essential for powering various machinery and equipment. These plugs ensure that machines operate efficiently, which is critical in high-output environments. For B2B buyers, it is vital to consider compatibility with local voltage and frequency standards, as mismatches can lead to equipment damage or operational downtime. Additionally, sourcing plugs that can withstand the industrial environment, such as those resistant to dust and moisture, is crucial for maintaining productivity.

What Role Do Electric Plugs Play in Telecommunications?

Telecommunications companies rely heavily on electric plugs for charging and powering network equipment, such as routers and switches. A stable power supply is critical for maintaining reliable communication networks, which are essential for business operations. For international B2B buyers, compliance with international standards and certifications is a key consideration, as it ensures the safety and reliability of the equipment. Furthermore, understanding the specific plug types used in different regions can aid in seamless equipment integration.

How are Electric Plugs Utilized in Construction?

In the construction industry, type of electric plugs are commonly used to provide temporary power supply for tools and equipment on job sites. This application enhances productivity, allowing workers to use power tools without interruption. Buyers must consider the durability and weather resistance of plugs and sockets, as construction sites often expose equipment to harsh conditions. Additionally, ensuring that plugs can handle high power loads is essential for safety and efficiency.

Why are Electric Plugs Important in the Hospitality Sector?

In the hospitality industry, electric plugs are crucial for powering guest room electrical appliances, such as lamps, chargers, and entertainment systems. Providing a variety of plug types accommodates international guests, enhancing their overall experience and satisfaction. B2B buyers in this sector should focus on sourcing plugs that meet safety standards while also being aesthetically pleasing to fit the hotel’s decor. Moreover, ensuring that plugs can handle diverse voltage requirements is essential for customer satisfaction.

How Do Electric Plugs Support Healthcare Operations?

Electric plugs play a vital role in healthcare facilities by supplying power to critical medical equipment, such as monitors, imaging devices, and life-support systems. Reliable power supply is essential to ensure that these devices operate without interruption, directly impacting patient care. For international B2B buyers, adherence to safety standards and regulations is paramount, as healthcare settings require the highest level of reliability. Additionally, understanding the specific plug types required for different medical equipment can streamline the procurement process.

3 Common User Pain Points for ‘type of electric plugs’ & Their Solutions

Scenario 1: Navigating Plug Compatibility Across Regions

The Problem: International B2B buyers often face significant challenges when sourcing electrical equipment that requires specific plug types. For example, a company based in Kenya may import machinery from Europe, only to discover that the plug types are incompatible. This discrepancy can lead to delays in operations, increased shipping costs for adapters, and potential damage to expensive equipment if incorrect plugs are used. Moreover, the varying voltage and frequency requirements across regions add another layer of complexity, increasing the risk of equipment malfunction.

The Solution: To mitigate these issues, B2B buyers should conduct thorough research on the plug types and electrical standards of both the exporting and importing countries. Utilizing resources like the IEC and WorldStandards to create a comprehensive compatibility chart is essential. When sourcing equipment, specify the required plug type and voltage to the supplier upfront. Additionally, consider investing in universal power adapters or multi-plug power strips that can accommodate various plug types. Implementing a standard operating procedure for checking compatibility before equipment purchase can save time and costs in the long run.

Scenario 2: Ensuring Safety and Compliance in Electrical Installations

The Problem: Safety is a paramount concern when dealing with electrical installations, especially for B2B buyers in sectors like manufacturing or construction. Buyers may encounter plug types that lack proper grounding or fail to meet local safety standards, leading to potential hazards like electrical shocks or fires. For instance, a company in Brazil using Type N plugs might find that their imported equipment, which uses Type C plugs, does not comply with local safety regulations.

The Solution: Buyers should prioritize compliance by familiarizing themselves with local electrical codes and standards. Before purchasing electrical equipment, they should verify that the plug types and configurations comply with local regulations. Partnering with reliable suppliers who provide documentation on safety compliance can also mitigate risks. Furthermore, conducting regular safety audits and training for employees on the correct use of electrical equipment can enhance workplace safety. Consider hiring local electrical engineers who can provide insights into safe installation practices and compliance requirements.

Scenario 3: Managing Supply Chain Disruptions Due to Plug Variability

The Problem: Supply chain disruptions can severely impact B2B operations, particularly when dealing with various plug types. For example, a company in Colombia might face delays when their supplier in Europe sends equipment with Type E plugs instead of the expected Type A plugs. Such disruptions can halt production lines, leading to financial losses and dissatisfaction among clients.

The Solution: To alleviate the impact of supply chain variability, B2B buyers should establish strong relationships with multiple suppliers across different regions. This diversification not only reduces dependency on a single source but also allows for quicker problem resolution when discrepancies arise. Implementing a robust inventory management system that tracks plug types and their respective compatibility can help businesses anticipate issues before they escalate. Additionally, creating a strategic plan that includes contingency measures, such as pre-ordering a stock of essential adapters and converters, can ensure continuity in operations despite potential disruptions. Regular communication with suppliers about potential changes in plug types or standards can also enhance preparedness for any supply chain challenges.

Strategic Material Selection Guide for type of electric plugs

When selecting materials for electric plugs, international B2B buyers must consider various factors that affect product performance and compliance with regional standards. Below, we analyze four common materials used in the manufacturing of electric plugs, focusing on their key properties, advantages and disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polycarbonate in Electric Plugs?

Polycarbonate is a widely used thermoplastic known for its excellent impact resistance and high-temperature tolerance. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environments. Additionally, polycarbonate exhibits good electrical insulation properties, which is essential for safety in electric plugs.

A stock image related to type of electric plugs.

Pros & Cons: Polycarbonate is durable and lightweight, which contributes to the overall longevity of electric plugs. However, it can be more expensive than other plastics, and its manufacturing process may be complex, requiring specialized equipment.

Impact on Application: Polycarbonate’s high temperature and pressure ratings make it ideal for plugs used in industrial settings where heavy machinery is involved.

Considerations for Buyers: Buyers in regions like Kenya and Colombia should ensure that polycarbonate plugs comply with local safety standards, such as ASTM or IEC, to avoid regulatory issues.

How Does PVC Compare as a Material for Electric Plugs?

Polyvinyl chloride (PVC) is another common material used in electric plug manufacturing. It is known for its flexibility and resistance to environmental stressors, including moisture and chemicals. PVC can operate effectively in a temperature range of -15°C to 60°C.

Pros & Cons: The primary advantage of PVC is its cost-effectiveness and ease of manufacturing. However, it has lower durability compared to polycarbonate and can become brittle over time, especially in extreme temperatures.

Impact on Application: PVC is suitable for residential and light commercial applications where flexibility and moisture resistance are crucial.

Considerations for Buyers: Buyers from the Middle East, where high temperatures are prevalent, should consider the long-term performance of PVC plugs and ensure they meet local standards.

What Are the Benefits of Using Metal Components in Electric Plugs?

Metal components, such as brass or copper, are often used in the contacts of electric plugs due to their excellent electrical conductivity and corrosion resistance. These materials can handle high current loads and are typically rated for temperatures up to 200°C.

Pros & Cons: The main advantage of metal components is their superior conductivity and durability. However, they can be prone to corrosion if not properly coated, and their manufacturing process can be more complex and costly.

Impact on Application: Metal contacts are essential in heavy-duty plugs used in industrial applications, where high current and durability are paramount.

Considerations for Buyers: Buyers in Europe should focus on the corrosion resistance of metal components to ensure compliance with local regulations, particularly in coastal areas where salt exposure is a concern.

How Does Thermoplastic Elastomer (TPE) Enhance Electric Plug Performance?

Thermoplastic elastomer (TPE) is a versatile material that combines the properties of rubber and plastic. It offers excellent flexibility, durability, and resistance to extreme temperatures, ranging from -40°C to 100°C.

Pros & Cons: TPE is highly resilient and can withstand repeated bending without cracking. However, it may be more expensive than traditional plastics and can have a more complex manufacturing process.

Impact on Application: TPE is ideal for plugs that require flexibility, such as those used in portable devices.

Considerations for Buyers: Buyers in South America should evaluate the performance of TPE plugs in varying climates and ensure they meet local electrical standards.

Summary Table of Material Selection for Electric Plugs

| Material | Typical Use Case for type of electric plugs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Industrial plugs | High impact resistance and temperature tolerance | Higher cost and complex manufacturing | High |

| PVC | Residential and light commercial plugs | Cost-effective and easy to manufacture | Lower durability, can become brittle | Low |

| Metal (Brass/Copper) | Heavy-duty industrial plugs | Superior conductivity and durability | Prone to corrosion if not properly coated | Medium |

| Thermoplastic Elastomer | Flexible portable device plugs | Excellent flexibility and durability | Higher cost and complex manufacturing | Medium |

This guide provides actionable insights for international B2B buyers to make informed decisions when selecting materials for electric plugs, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for type of electric plugs

What Are the Main Stages of Manufacturing Electric Plugs?

The manufacturing of electric plugs involves several critical stages that ensure the final product meets safety and performance standards. Here’s a breakdown of the main stages:

-

Material Preparation

The first step involves selecting high-quality materials such as thermoplastics for the plug casing and copper or brass for the pins. These materials are tested for electrical conductivity, durability, and thermal resistance. Suppliers often need to provide certifications indicating that their materials meet international standards like ISO 9001. -

Forming

During this stage, the prepared materials are shaped into the desired forms. For thermoplastics, processes like injection molding are commonly employed to create the outer casing of the plugs. Meanwhile, metal pins are produced through stamping or extrusion methods. The precision of this process is crucial to ensure compatibility with sockets. -

Assembly

Once the components are formed, the next step is assembly. This often involves automated machines that insert the metal pins into the plastic casing. Ensuring proper alignment and fit is essential to prevent electrical malfunctions. Skilled workers may also conduct manual assembly for more complex plug designs, especially those requiring grounding features. -

Finishing

The final stage includes quality checks and finishing processes such as surface treatment to enhance durability and aesthetic appeal. This may involve applying coatings to prevent corrosion or improve grip. The plugs are then subjected to various tests to ensure they meet safety and performance standards.

How Is Quality Assurance Implemented in Electric Plug Manufacturing?

A stock image related to type of electric plugs.

Quality assurance (QA) is integral to the manufacturing process of electric plugs. It ensures that products are reliable and safe for end-users. Here are some key components of a robust QA system:

-

What Are the International Standards for Electric Plugs?

Compliance with international standards is crucial for manufacturers targeting global markets. Common standards include:

– ISO 9001: This standard outlines the criteria for a quality management system and emphasizes continuous improvement.

– CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

– UL Certification: Important for products sold in North America, ensuring they meet safety standards. -

What QC Checkpoints Should Be Established?

Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection checks raw materials against specifications before production begins. It prevents defective materials from entering the production line.

– In-Process Quality Control (IPQC): Ongoing checks during manufacturing ensure that processes remain within defined parameters, thus maintaining product integrity.

– Final Quality Control (FQC): This final inspection occurs before shipping. It includes functional tests, visual inspections, and safety checks to ensure that the plugs meet all regulatory standards. -

What Testing Methods Are Commonly Used?

Various testing methods are employed to assess the quality of electric plugs:

– Electrical Testing: Measures insulation resistance and continuity to ensure safe operation.

– Mechanical Testing: Evaluates the durability of the plug under stress, including pull tests on the pins.

– Temperature Testing: Assesses how the plugs perform under extreme temperatures to ensure they do not overheat during use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are actionable strategies:

-

Conducting Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request access to their quality management documentation and results from internal audits to assess compliance with international standards. -

Requesting Quality Reports

Suppliers should provide quality control reports that document testing results, including any non-conformities and corrective actions taken. Buyers can analyze these reports to gauge the reliability of the supplier’s products. -

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can add an extra layer of verification. These independent entities can conduct pre-shipment inspections to ensure that products meet specified standards before they leave the factory.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with international suppliers, B2B buyers should be aware of several nuances that can affect quality control:

-

Cultural Differences in Quality Standards

Different regions may have varying expectations regarding quality. Understanding local standards and practices can help buyers communicate their requirements more effectively. -

Regulatory Compliance

Compliance with local regulations and international standards is essential, especially for electrical products. Buyers should ensure that suppliers can demonstrate adherence to all relevant laws in both the supplier’s and buyer’s countries. -

Logistics and Supply Chain Considerations

The logistics involved in shipping electric plugs can introduce risks. Buyers should consider how transportation conditions may affect product quality and whether suppliers have measures in place to mitigate these risks.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for electric plugs is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as implementing robust quality control measures, suppliers can deliver reliable products. Buyers from diverse regions must navigate international standards and local regulations, ensuring they partner with manufacturers committed to quality and compliance. By employing thorough verification strategies, businesses can safeguard their investments and ensure product safety and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type of electric plugs’

In the global marketplace, sourcing the right type of electric plugs is critical for ensuring compatibility and safety in your electrical installations. This practical checklist will guide international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, through the essential steps to effectively procure electric plugs suited to their needs.

Step 1: Identify Required Plug Types for Your Region

Understanding the specific plug types used in your target market is the first step. Each region has its own electrical standards, including plug types A through O, which vary in design and voltage requirements.

– Research local standards: Use resources like the IEC or WorldStandards to verify which plugs are compatible in your country or region.

– Consider voltage and frequency: Ensure that the plugs meet the voltage (e.g., 220-240V in most of Europe) and frequency (e.g., 50Hz) specifications.

Step 2: Define Your Technical Specifications

Clearly outline the technical requirements for the plugs you need to source. This includes the number of pins, grounding options, and current ratings.

– Assess your equipment requirements: Identify the power needs of the devices that will use these plugs.

– Include safety standards: Ensure compliance with local safety regulations to prevent electrical hazards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform due diligence. Vetting suppliers is crucial to ensure reliability and product quality.

– Request documentation: Ask for certifications, product samples, and case studies to evaluate their credibility.

– Check references: Look for testimonials or references from other businesses in your industry to gauge satisfaction levels.

Step 4: Analyze Pricing and Payment Terms

Pricing can vary significantly among suppliers. It’s essential to compare costs while considering payment terms.

– Request quotes: Gather detailed quotes from multiple suppliers, noting any additional costs such as shipping or taxes.

– Negotiate terms: Discuss payment options that suit your cash flow, including discounts for bulk purchases.

Step 5: Assess Lead Times and Delivery Options

Understanding the lead times for production and delivery is vital for planning your projects effectively.

– Confirm timelines: Inquire about the average production time and shipping duration to avoid delays.

– Consider logistics: Evaluate the supplier’s shipping options to ensure they can meet your delivery requirements.

Step 6: Verify Compliance with International Standards

Ensure that the plugs you are sourcing comply with relevant international safety and quality standards.

– Look for certifications: Check for certifications such as CE, UL, or ISO that indicate adherence to safety regulations.

– Consider market entry requirements: Some regions may have specific standards that products must meet before being sold.

Step 7: Establish a Quality Control Process

Before finalizing your order, set up a quality control process to minimize the risk of defects.

– Define inspection criteria: Outline what quality checks will be performed upon receipt of the goods.

– Plan for returns: Establish a clear return policy in case the products do not meet your specifications or quality expectations.

By following this checklist, international B2B buyers can navigate the complexities of sourcing electric plugs effectively, ensuring that they meet their operational needs while adhering to local regulations and standards.

Comprehensive Cost and Pricing Analysis for type of electric plugs Sourcing

What Are the Key Cost Components in Electric Plug Sourcing?

When sourcing electric plugs, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. For instance, plugs made from high-quality plastics and metals may be pricier but offer better durability and safety. Sourcing local materials can also reduce transportation costs.

-

Labor: Labor costs vary by region. Countries with lower wage rates may offer more competitive pricing, but it’s essential to consider the skill level of the workforce, which can affect the quality of the final product.

-

Manufacturing Overhead: This includes costs associated with factory operation, utilities, and equipment maintenance. Efficient manufacturing processes can help keep these costs down.

-

Tooling: Initial setup costs for molds and other tools can be significant, especially for custom designs. Buyers should factor in these costs when negotiating pricing.

-

Quality Control (QC): Ensuring that plugs meet international safety standards requires a robust QC process, which adds to the overall costs. Certifications such as CE, UL, or IEC can influence pricing.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on the origin and destination. Incoterms also play a vital role in determining who bears these costs.

-

Margin: Suppliers typically add a margin to cover their expenses and profit. This can vary significantly depending on the supplier’s reputation and market position.

How Do Price Influencers Affect Electric Plug Costs?

Several factors can influence the pricing of electric plugs:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate favorable MOQs to optimize their costs.

-

Specifications and Customization: Custom designs or specific specifications can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications can raise the price. However, investing in quality can reduce long-term costs associated with failures or safety issues.

-

Supplier Factors: The supplier’s experience, reputation, and location can affect pricing. Established suppliers may charge more but offer better reliability and support.

-

Incoterms: Understanding Incoterms is essential as they dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Choosing the right Incoterm can lead to cost savings.

What Buyer Tips Can Enhance Cost Efficiency in Electric Plug Sourcing?

International B2B buyers can adopt several strategies to enhance cost efficiency:

-

Negotiate Firmly: Always negotiate pricing, especially when placing large orders. Suppliers may have more flexibility than initially apparent.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, potential tariffs, and the long-term reliability of the plugs. A cheaper option may lead to higher costs down the line.

-

Understand Pricing Nuances: Prices can fluctuate based on market conditions, material costs, and geopolitical factors. Staying informed about these dynamics can help buyers make better purchasing decisions.

-

Leverage Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local manufacturers can reduce shipping costs and lead times.

-

Focus on Quality: Investing in high-quality plugs can prevent issues related to safety and compliance, ultimately saving costs associated with recalls or replacements.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Buyers should conduct thorough due diligence to obtain the most accurate and relevant pricing information tailored to their needs.

Alternatives Analysis: Comparing type of electric plugs With Other Solutions

Exploring Alternative Solutions to Electric Plugs

In the global market, the need for efficient power solutions has led to the exploration of alternatives to traditional electric plugs. While plugs are widely used for connecting devices to power sources, there are emerging technologies that can offer similar benefits. This analysis will compare electric plugs with two viable alternatives: wireless power transfer and universal power adapters.

Comparison Table of Electric Plugs and Alternative Solutions

| Comparison Aspect | Type Of Electric Plugs | Wireless Power Transfer | Universal Power Adapters |

|---|---|---|---|

| Performance | Reliable for fixed installations, supports various voltages | Effective for charging compatible devices, limited range | Compatible with multiple plug types, but may have reduced power efficiency |

| Cost | Low to moderate initial investment | Higher initial setup cost, ongoing R&D expenses | Moderate cost per unit; savings on travel and multi-region use |

| Ease of Implementation | Simple installation, requires specific sockets | Requires specialized equipment, limited by device compatibility | Easy to use, simply plug and play |

| Maintenance | Low maintenance, durable | Higher maintenance due to technology changes | Minimal maintenance, but may need replacement over time |

| Best Use Case | Home and office use, consistent energy needs | Ideal for mobile devices, public charging stations | Travel and international use where multiple plug types are needed |

In-Depth Analysis of Alternatives

How Does Wireless Power Transfer Compare to Electric Plugs?

Wireless power transfer (WPT) technology allows devices to be charged without physical connections. This method is particularly beneficial for mobile devices and electric vehicles, offering convenience and reducing wear on connectors. However, WPT has limitations, including a shorter effective range and potential inefficiencies in energy transfer. For B2B buyers, investing in WPT may be advantageous in sectors focused on innovation and user experience, but the higher initial costs and technology maintenance should be weighed against the reliability of traditional plugs.

What Are the Benefits of Using Universal Power Adapters Instead of Electric Plugs?

Universal power adapters provide flexibility for users traveling across different regions with varying plug types. They allow for a single adapter to be used with multiple devices, reducing the need for multiple plug types. While they are user-friendly and cost-effective for frequent travelers, their efficiency may not match that of dedicated electric plugs, especially in high-power applications. B2B buyers in sectors like tourism and international trade may find universal adapters particularly useful, as they simplify logistics and reduce equipment costs.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between traditional electric plugs and alternative solutions, B2B buyers must consider their specific operational needs, budget constraints, and the technical environment of their business. Electric plugs remain a reliable choice for fixed installations, while wireless power transfer offers cutting-edge convenience for mobile applications. Universal power adapters serve as a practical solution for businesses with international operations. Ultimately, the decision should align with the company’s operational model and long-term energy strategy.

Essential Technical Properties and Trade Terminology for type of electric plugs

What Are the Key Technical Properties of Electric Plugs?

When evaluating electric plugs for international trade, several technical properties are essential for ensuring compatibility, safety, and performance. Here are critical specifications to consider:

-

Material Grade

– Electric plugs are commonly made from thermoplastics or thermosetting plastics, which provide durability and insulation. Metal components, such as pins, are typically made from copper or brass for excellent conductivity. Understanding the material grade is vital for assessing the plug’s lifespan and resistance to environmental factors. -

Voltage Rating

– Each plug type has a specific voltage rating, usually ranging from 100V to 250V. It’s crucial to match the voltage rating of the plug with the electrical system of the destination country. Failing to do so can result in equipment failure or safety hazards, making this a critical specification for B2B buyers. -

Current Rating (Amperage)

– The current rating indicates the maximum amount of electrical current the plug can handle. Common ratings include 10A, 16A, and 20A. Selecting a plug with an appropriate current rating ensures that it can support the electrical load of the devices being used, which is essential for operational efficiency and safety. -

Pin Configuration

– The design and arrangement of pins differ by plug type. For instance, Type C plugs have two round pins, while Type G plugs feature three rectangular pins. Understanding the pin configuration is vital for ensuring compatibility with sockets in different regions and preventing electrical accidents. -

Insulation Resistance

– Insulation resistance measures the effectiveness of the insulating materials in preventing electric shocks. High insulation resistance is crucial for safety, particularly in environments with moisture or dust. B2B buyers should prioritize plugs with high insulation ratings to ensure compliance with safety standards. -

Temperature Range

– Plugs are rated for specific temperature ranges, indicating the environments in which they can safely operate. This specification is particularly important for buyers in regions with extreme climates, ensuring that the plugs will function reliably under local conditions.

What Are Common Trade Terms Related to Electric Plugs?

In the world of international trade, understanding industry jargon is crucial for effective communication and negotiation. Here are some common terms related to electric plugs:

-

OEM (Original Equipment Manufacturer)

– An OEM produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, working with an OEM can ensure that the plugs meet specific quality and compatibility standards, reducing risks associated with sourcing components. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to avoid overcommitting to inventory that may not sell quickly, particularly when dealing with plugs that vary by region. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price offers from suppliers. For international buyers, submitting an RFQ for electric plugs helps clarify specifications and pricing, enabling better budget management and supplier selection. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to navigate shipping, insurance, and delivery responsibilities effectively. -

Certification Standards

– These are regulatory benchmarks that products must meet to be sold in specific markets. Examples include CE marking in Europe and UL certification in the USA. Familiarity with certification standards is crucial for ensuring compliance and market access for electric plugs. -

Trade Tariffs

– Trade tariffs are taxes imposed on imported goods. Awareness of applicable tariffs on electric plugs can significantly affect the total cost of procurement and pricing strategies in different markets.

By understanding these technical properties and trade terminology, international B2B buyers can make informed decisions, ensuring they procure the right electric plugs for their needs.

Navigating Market Dynamics and Sourcing Trends in the type of electric plugs Sector

A stock image related to type of electric plugs.

What Are the Key Market Dynamics Driving the Electric Plugs Sector?

The electric plugs market is witnessing significant growth, driven by globalization, increased consumer electronics usage, and the rising demand for standardized electrical systems. With over 15 distinct plug types in use worldwide, international B2B buyers must navigate varying regulations and standards. Countries in Africa, South America, the Middle East, and Europe are experiencing a surge in electrical infrastructure development, particularly in urban areas. This creates opportunities for sourcing high-quality plugs that comply with local standards, such as Type C and Type G plugs, which are commonly used in these regions.

Emerging trends in the sector include the adoption of smart technology in electric plugs, enabling features like energy monitoring and remote control. This innovation is particularly appealing to businesses aiming to enhance energy efficiency and reduce operational costs. Additionally, the demand for universal plug systems is on the rise, driven by increased international travel and the globalization of supply chains. Buyers should remain vigilant about these trends and consider the long-term implications of investing in advanced plug technologies.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Electric Plugs?

Sustainability is becoming a crucial consideration for B2B buyers in the electric plugs sector. The environmental impact of manufacturing processes, including the extraction of raw materials and energy consumption, necessitates a focus on ethical sourcing practices. Buyers should prioritize suppliers who adhere to environmental regulations and demonstrate a commitment to sustainability through certifications such as ISO 14001.

Moreover, the use of eco-friendly materials in electric plug production is gaining traction. For instance, manufacturers are increasingly utilizing recycled plastics and sustainable metals, which not only reduce environmental harm but also appeal to environmentally conscious consumers. B2B buyers should engage with suppliers who can provide transparency regarding their supply chains and the sustainability of their products, ensuring that they align with their corporate social responsibility goals.

What Is the Historical Context of Electric Plugs and Their Evolution?

The evolution of electric plugs can be traced back to the late 19th century when various designs emerged to accommodate the increasing demand for electrical devices. Initially, plugs were designed without standardized specifications, leading to a patchwork of types across different regions. Over time, this lack of standardization became problematic, prompting international bodies to develop guidelines for plug designs, voltages, and safety standards.

Today, the market has settled into a more structured framework, with specific plug types being associated with particular regions—Type C being prevalent in Europe and Africa, while Type G dominates the UK and parts of the Middle East. This historical context is essential for B2B buyers as it underscores the importance of understanding local electrical standards when sourcing electric plugs, ensuring compatibility and safety in their applications.

Frequently Asked Questions (FAQs) for B2B Buyers of type of electric plugs

-

How do I determine the correct plug type for my market?

To identify the appropriate plug type for your target market, consult a comprehensive list of plug and socket types used globally. Websites like WorldStandards and IEC provide detailed maps and charts that specify plug types by country. Additionally, consider the voltage and frequency requirements, as these can affect compatibility. Engaging with local distributors or industry experts can also provide valuable insights into the most common plug types used in your specific region, ensuring your products meet local standards. -

What is the best type of electric plug for African markets?

In many African countries, Type C and Type G plugs are the most commonly used. Type C is prevalent in countries like Kenya and Nigeria, while Type G is used in countries like South Africa and Ghana. When sourcing plugs for these markets, ensure that they comply with local electrical standards and safety regulations. Additionally, consider the voltage range (typically 220-240V) and the frequency (50Hz), as these factors will influence the performance and safety of electrical devices. -

What should I consider when vetting suppliers for electric plugs?

When vetting suppliers, prioritize those with a proven track record in manufacturing compliant electric plugs. Request certifications that demonstrate adherence to international safety standards, such as IEC or ISO certifications. Conduct factory audits or request samples to evaluate product quality. Additionally, assess their capacity for customization, minimum order quantities (MOQ), and lead times to ensure they can meet your specific needs and timelines. -

How can I customize electric plugs for my specific needs?

Customization options for electric plugs often include alterations in design, color, or functionality (e.g., adding USB ports). When discussing customization with suppliers, be clear about your requirements and any regulatory standards that must be met. Some manufacturers may offer design services, while others may require you to provide detailed specifications. Be prepared for potential changes in MOQ and pricing based on the complexity of the customization. -

What are the typical payment terms for international B2B transactions?

Payment terms can vary significantly among suppliers, but common practices include a deposit (typically 30-50%) upon order confirmation, with the balance paid before shipment. Consider using secure payment methods like letters of credit or escrow services to mitigate risks. It’s also advisable to establish clear terms regarding payment timelines and penalties for late payments in your contracts to protect both parties. -

What are the quality assurance processes for electric plugs?

Quality assurance processes should involve multiple stages, including raw material inspection, in-process quality checks, and final product testing. Ensure your supplier conducts tests for safety standards compliance, such as insulation resistance and mechanical strength. Request documentation of quality control procedures and test results to verify that the products meet industry standards. Regular audits of the manufacturing process can further ensure consistent quality. -

How do logistics and shipping affect my sourcing strategy?

Logistics play a crucial role in your sourcing strategy, impacting delivery times and overall costs. When selecting suppliers, consider their location relative to your market to minimize shipping times and costs. Evaluate their shipping partners and track record for timely deliveries. Additionally, factor in customs regulations and potential tariffs that could affect the overall landed cost of your products. Building strong relationships with logistics providers can help streamline the shipping process. -

What are the common challenges faced when sourcing electric plugs internationally?

Common challenges include navigating varying regulations and standards across different countries, which can complicate compliance. Language barriers and cultural differences may also hinder communication with suppliers. Additionally, fluctuations in currency exchange rates can impact pricing. To mitigate these challenges, conduct thorough market research, establish clear lines of communication with suppliers, and consider working with local partners who understand the regional landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type of electric plugs

In the evolving landscape of global trade, strategic sourcing of electric plugs is crucial for B2B buyers looking to enhance operational efficiency and ensure compliance with diverse international standards. Understanding the various plug types—ranging from Type A to Type N—along with their voltage and compatibility characteristics, is essential for making informed purchasing decisions. This knowledge not only minimizes logistical challenges but also mitigates risks associated with electrical safety and equipment failure.

How Can B2B Buyers Leverage Strategic Sourcing for Electric Plugs?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must prioritize supplier relationships and quality assurance. Engaging with manufacturers who adhere to international safety and performance standards can streamline the procurement process and enhance product reliability. Furthermore, aligning sourcing strategies with local market needs will facilitate smoother operations and better customer satisfaction.

As we look ahead, the demand for standardized solutions is likely to grow. By adopting a proactive approach to sourcing, businesses can stay ahead of regulatory changes and market trends. Now is the time to reevaluate your sourcing strategies and invest in reliable suppliers that can support your growth in the global market.