Discover the Best Types of Cabinet Hinges for Your Business (2025)

Introduction: Navigating the Global Market for types of cabinet hinges

Navigating the global market for types of cabinet hinges can be a daunting task for international B2B buyers, especially when considering the myriad of options available across different regions, including Africa, South America, the Middle East, and Europe. As businesses strive to enhance their furniture designs and improve functionality, the challenge lies in sourcing hinges that not only meet specific design requirements but also ensure durability and ease of use. This comprehensive guide addresses this challenge by detailing various types of cabinet hinges, their applications, and factors to consider when making purchasing decisions.

In this guide, you will explore the full spectrum of cabinet hinge options, from concealed and semi-concealed hinges to specialized designs like self-closing and soft-close varieties. Each section will provide insights into the unique features and benefits of these hinges, helping you determine which type aligns best with your projects. Additionally, we will discuss supplier vetting processes, cost considerations, and regional market trends to equip you with the knowledge needed to make informed purchasing decisions.

By the end of this guide, international B2B buyers will have a clearer understanding of how to effectively source cabinet hinges that not only enhance their products but also align with their operational and aesthetic goals, ultimately driving business success in a competitive marketplace.

Understanding types of cabinet hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| European Concealed Hinges | Fully hidden when door is closed; adjustable; soft-close option | Modern kitchens and bathrooms; furniture | Pros: Aesthetic appeal; easy installation; adjustable. Cons: Higher cost; requires precise installation. |

| Semi-Concealed Hinges | Partially visible; combines features of concealed and surface mount | Versatile cabinetry; commercial settings | Pros: Durable; flexible design; cost-effective. Cons: Less aesthetic than fully concealed options. |

| Full Overlay Hinges | Door fully covers the cabinet frame; minimal gaps | Contemporary cabinetry; retail displays | Pros: Sleek appearance; maximizes space; easy to use. Cons: Limited to specific cabinet designs. |

| Inset Hinges | Flush with cabinet frame; either concealed or exposed | High-end cabinetry; custom furniture | Pros: Elegant look; ideal for traditional designs. Cons: More complex installation; may require custom doors. |

| Self-Closing Hinges | Automatically closes the door; spring-loaded mechanism | Kitchen and bathroom cabinets | Pros: Convenience; enhances safety; reduces wear. Cons: May require more maintenance; limited design options. |

What Are European Concealed Hinges and Their Applications?

European concealed hinges, often referred to as cup hinges, are designed to be completely hidden when the cabinet door is closed. Their key features include adjustability and a soft-close option, making them ideal for modern kitchen and bathroom cabinetry. For B2B buyers, these hinges offer a sleek aesthetic that enhances the overall design of contemporary spaces. However, they come at a higher cost and require precise installation, which could be a consideration for projects with tight budgets.

How Do Semi-Concealed Hinges Work in Various Settings?

Semi-concealed hinges present a versatile solution by allowing a portion of the hinge mechanism to remain visible while still providing a sleek look. They are commonly used in versatile cabinetry and commercial settings, where durability and reliability are paramount. Buyers appreciate their cost-effectiveness and robust construction. However, they may not offer the same aesthetic appeal as fully concealed hinges, which could influence purchasing decisions based on project requirements.

Why Choose Full Overlay Hinges for Contemporary Cabinetry?

Full overlay hinges are characterized by their ability to allow cabinet doors to completely cover the frame, resulting in minimal gaps. This design is particularly popular in contemporary cabinetry and retail displays, where a sleek appearance is essential. Buyers benefit from the maximized space and ease of use these hinges provide. On the downside, their application is limited to specific cabinet designs, which may restrict options for some projects.

What Are the Benefits of Inset Hinges in High-End Cabinetry?

Inset hinges are installed flush with the cabinet frame, either concealed or exposed, and are often used in high-end cabinetry and custom furniture. Their elegant look makes them suitable for traditional designs, appealing to buyers seeking a classic aesthetic. However, they can be more complex to install and may require custom doors, which could increase project timelines and costs.

How Do Self-Closing Hinges Enhance Cabinet Functionality?

Self-closing hinges feature a spring-loaded mechanism that automatically closes the door, making them popular for kitchen and bathroom cabinets. These hinges add convenience and enhance safety by reducing the risk of doors being left open. Additionally, they help prolong the lifespan of cabinet doors by minimizing wear. However, buyers should consider that they may require more maintenance over time and might have limited design options compared to other hinge types.

Key Industrial Applications of types of cabinet hinges

| Industry/Sector | Specific Application of Types of Cabinet Hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Use of concealed hinges in modern cabinetry | Enhances aesthetic appeal and functionality of furniture | Quality of materials, adjustability, and soft-close features are essential. |

| Retail Fixtures | Semi-concealed hinges for display cabinets | Improves customer experience with easy access and sleek design | Durability and cost-effectiveness are critical for high-traffic areas. |

| Hospitality Industry | Self-closing hinges in hotel cabinetry | Ensures safety and convenience for guests and staff | Compliance with safety standards and ease of maintenance are vital. |

| Kitchen Remodeling | Full overlay hinges for contemporary kitchens | Maximizes space and provides a modern look | Compatibility with existing cabinetry and ease of installation are important. |

| Healthcare Facilities | Heavy-duty continuous hinges in medical cabinets | Ensures durability and safety for medical equipment storage | Must withstand frequent use and meet hygiene standards. |

How Are Types of Cabinet Hinges Utilized in Furniture Manufacturing?

In furniture manufacturing, concealed hinges are widely employed in modern cabinetry designs. These hinges provide a seamless appearance, allowing cabinet doors to close flush against the frame, which is particularly important for aesthetic-focused furniture pieces. Buyers in this sector should prioritize high-quality materials for durability and features such as adjustability and soft-close mechanisms to enhance user experience. For international buyers, understanding local preferences for design and functionality is crucial, especially in regions like Europe, where minimalism is highly valued.

What Role Do Cabinet Hinges Play in Retail Fixtures?

In retail environments, semi-concealed hinges are commonly used in display cabinets to create a clean and appealing look that enhances the customer experience. These hinges allow for easy access to merchandise while maintaining a visually appealing facade. When sourcing hinges for retail fixtures, businesses should consider durability due to high foot traffic and the need for cost-effective solutions. International buyers should also be aware of local trends in retail design, which may influence hinge selection and application.

How Do Self-Closing Hinges Benefit the Hospitality Industry?

Self-closing hinges are essential in hotel cabinetry, ensuring that cabinet doors close automatically. This feature not only enhances convenience for guests but also promotes safety by preventing doors from remaining ajar. When sourcing for the hospitality sector, it is crucial to ensure that the hinges comply with safety standards and are easy to maintain. International buyers, particularly from the Middle East and Africa, should also consider the climate and environmental factors that may affect hinge performance.

Why Are Full Overlay Hinges Important in Kitchen Remodeling?

Full overlay hinges are ideal for contemporary kitchen designs, as they allow cabinet doors to fully cover the frame, maximizing space and providing a sleek aesthetic. Buyers in the kitchen remodeling sector should ensure that the hinges are compatible with existing cabinetry and are easy to install. In regions like South America and Europe, where modern kitchen designs are prevalent, understanding the specific requirements for these hinges can lead to better project outcomes.

How Are Heavy-Duty Continuous Hinges Used in Healthcare Facilities?

Heavy-duty continuous hinges are critical in healthcare facilities for medical cabinets that require frequent use. These hinges provide the necessary strength and durability to withstand the demands of a medical environment while ensuring safety for stored equipment. When sourcing for healthcare applications, buyers must consider hinges that meet hygiene standards and are easy to clean. International buyers should also be aware of regulatory requirements specific to their regions, ensuring compliance in their sourcing decisions.

3 Common User Pain Points for ‘types of cabinet hinges’ & Their Solutions

Scenario 1: Choosing the Right Hinge for Cabinet Types

The Problem:

B2B buyers often struggle with selecting the appropriate hinge type for their specific cabinet designs. This challenge is compounded by the various cabinet styles available in the market, such as frameless and framed cabinets. For instance, a supplier may purchase a bulk order of hinges, only to find that they do not fit the existing cabinet structures, leading to costly returns and delays in project timelines. Additionally, the lack of clear specifications and compatibility guidelines can create confusion, resulting in poor inventory management and increased operational costs.

The Solution:

To effectively address this issue, it is crucial to establish a systematic approach for selecting cabinet hinges based on the specific cabinet type. Buyers should begin by categorizing their cabinets as either framed or frameless. For framed cabinets, semi-concealed or face frame hinges are typically the best choices, while concealed hinges work well for frameless designs.

Before placing orders, buyers should consult with manufacturers or suppliers who provide detailed product specifications, including overlay measurements and hinge types compatible with specific cabinet designs. Utilizing a standardized measurement guide to assess the dimensions and overlay requirements will ensure the correct hinges are sourced, thus minimizing the risk of compatibility issues. Additionally, employing a tracking system for hinge types and their applications can streamline inventory management, reducing waste and enhancing project efficiency.

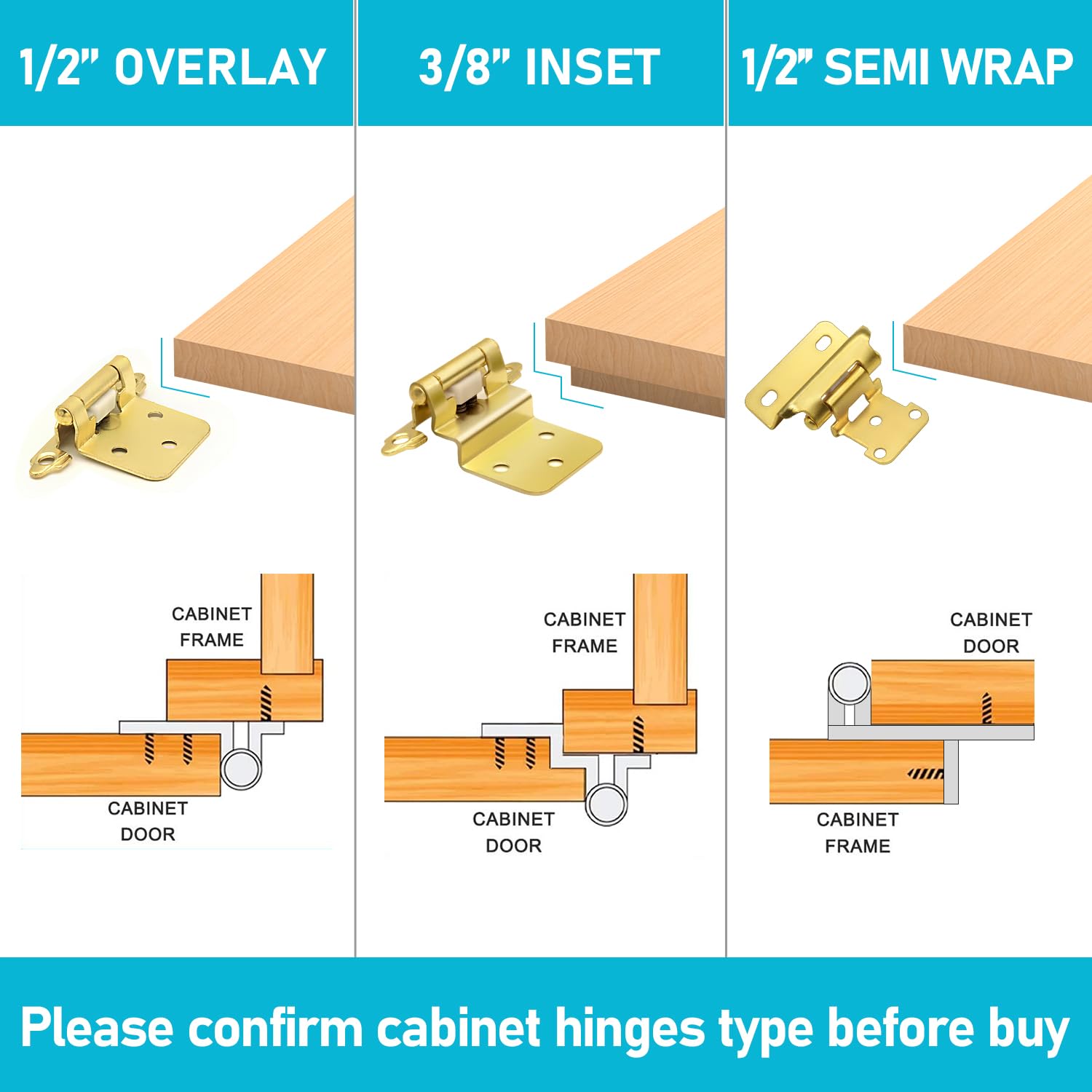

A stock image related to types of cabinet hinges.

Scenario 2: Dealing with Noise and Wear in Cabinet Operations

The Problem:

Another common issue faced by B2B buyers is the noise and wear associated with cabinet doors that do not close smoothly. This can be particularly problematic in environments such as hotels, restaurants, or office spaces, where a quieter ambiance is essential. The use of standard hinges can lead to doors slamming shut, causing not only an unpleasant sound but also potential damage to the cabinet structure over time. This concern can result in frequent replacements and repairs, ultimately affecting the bottom line.

The Solution:

To mitigate noise and wear on cabinet doors, buyers should invest in soft-close or self-closing cabinet hinges. These hinges are designed to slow down the closing motion of the door, preventing slamming and allowing for a quieter operation. When sourcing these hinges, it’s important to consider the weight and size of the cabinet doors, as heavier doors may require specialized hinges capable of bearing additional weight.

Buyers should also ensure that the installation process is performed correctly, as improper alignment can negate the benefits of soft-close mechanisms. Providing training or detailed installation guides for staff can enhance the functionality of these hinges and extend the life of the cabinets. Finally, regular maintenance checks can help identify wear on hinges early, allowing for timely replacements and preventing further damage.

Scenario 3: Understanding the Long-Term Cost Implications of Hinge Choices

The Problem:

B2B buyers often overlook the long-term cost implications associated with different types of cabinet hinges. While it may be tempting to choose the cheapest options available, inferior quality hinges can lead to increased maintenance costs, frequent replacements, and ultimately a lower return on investment (ROI). This is especially true for businesses operating in high-use environments where durability is key. Buyers may find themselves in a cycle of replacing low-quality hinges, which can drain budgets and resources over time.

The Solution:

To make more informed purchasing decisions, buyers should conduct a thorough analysis of the total cost of ownership (TCO) for different hinge options. This analysis should include the initial purchase price, expected lifespan, maintenance costs, and the frequency of required replacements. Investing in high-quality hinges, such as those made from durable materials like stainless steel or brass, can offer better longevity and performance.

Buyers can also seek out manufacturers that offer warranties or guarantees on their products, as this can provide additional assurance of quality. Furthermore, establishing long-term relationships with trusted suppliers can lead to bulk purchasing discounts and improved pricing negotiations, thereby optimizing costs over time. By prioritizing quality and longevity in their hinge selections, buyers can significantly enhance their overall cost efficiency and operational effectiveness.

Strategic Material Selection Guide for types of cabinet hinges

What are the Key Properties of Common Materials Used in Cabinet Hinges?

When selecting cabinet hinges, the material plays a crucial role in determining the hinge’s performance, durability, and suitability for specific applications. Here, we analyze four common materials used in cabinet hinges: steel, stainless steel, brass, and plastic. Each material has unique properties that impact its performance and application in various environments.

How Does Steel Perform in Cabinet Hinge Applications?

Key Properties: Steel is known for its high strength and durability, making it suitable for heavy-duty applications. It has good temperature resistance but can be prone to corrosion if not properly treated.

Pros & Cons: Steel hinges are generally cost-effective and can withstand significant wear and tear. However, they may require additional coatings or treatments to prevent rust, especially in humid environments. This can complicate manufacturing and increase costs.

Impact on Application: Steel hinges are ideal for cabinets that experience frequent use, such as in kitchens or workshops. They are compatible with a variety of cabinet styles but may not be suitable for environments with high moisture levels without proper treatment.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the steel used complies with local standards for corrosion resistance. In Europe, adherence to ASTM or DIN standards is essential for quality assurance.

What Advantages Does Stainless Steel Offer for Cabinet Hinges?

Key Properties: Stainless steel is highly resistant to corrosion and staining, making it suitable for both indoor and outdoor applications. It can withstand high temperatures and is often used in environments that require hygiene, such as kitchens and medical facilities.

Pros & Cons: The primary advantage of stainless steel hinges is their longevity and low maintenance requirements. However, they tend to be more expensive than regular steel hinges, which may be a consideration for budget-conscious buyers.

Impact on Application: Stainless steel hinges are perfect for cabinets in coastal areas or humid climates, where rust and corrosion are significant concerns. They are also compatible with modern design aesthetics, making them popular in contemporary cabinetry.

Considerations for International Buyers: Buyers in the Middle East and Europe should verify that the stainless steel meets relevant standards, such as JIS or ASTM, to ensure quality and durability.

Why Choose Brass for Cabinet Hinges?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and aesthetic appeal. It has good strength and can be easily machined into intricate designs.

Pros & Cons: The primary advantage of brass hinges is their attractive appearance, which can enhance the overall look of cabinetry. However, they can be more expensive than steel options and may not be as strong under heavy loads.

Impact on Application: Brass hinges are often used in decorative cabinets and furniture where aesthetics are a priority. They are suitable for low to medium-use applications but may not be ideal for heavy-duty environments.

Considerations for International Buyers: Buyers from Europe and South America should look for brass hinges that comply with local quality standards to ensure they meet aesthetic and functional requirements.

What Role Does Plastic Play in Cabinet Hinge Selection?

Key Properties: Plastic hinges are lightweight and resistant to corrosion, making them suitable for various applications. They can withstand moderate temperatures but may not perform well under extreme conditions.

Pros & Cons: The main advantage of plastic hinges is their low cost and ease of installation. However, they may lack the strength and durability of metal hinges, making them less suitable for heavy-duty applications.

Impact on Application: Plastic hinges are often used in lightweight cabinets or temporary installations. They are ideal for environments where moisture is a concern, such as bathrooms or outdoor settings.

Considerations for International Buyers: Buyers should ensure that plastic hinges meet relevant safety and quality standards, especially in regions like Africa and the Middle East, where product durability may be a concern.

Summary Table of Material Selection for Cabinet Hinges

| Material | Typical Use Case for types of cabinet hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications in kitchens | High strength and durability | Prone to corrosion without treatment | Medium |

| Stainless Steel | Coastal and humid environments | Corrosion-resistant and low maintenance | Higher cost compared to steel | High |

| Brass | Decorative cabinets and furniture | Attractive appearance | Less strong under heavy loads | Medium to High |

| Plastic | Lightweight and moisture-sensitive cabinets | Low cost and lightweight | Less durable than metal options | Low |

This analysis provides a comprehensive overview of the materials commonly used in cabinet hinges, offering actionable insights for international B2B buyers to make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of cabinet hinges

What Are the Key Stages in the Manufacturing Process of Cabinet Hinges?

A stock image related to types of cabinet hinges.

The manufacturing process of cabinet hinges involves several critical stages, each essential to producing high-quality, durable products. Understanding these stages can help B2B buyers assess potential suppliers and ensure they meet their specific requirements.

1. Material Preparation: How Are Raw Materials Selected and Processed?

The first step in hinge manufacturing is the careful selection and preparation of raw materials. Common materials used include steel, brass, and stainless steel. Each material has unique properties that affect the hinge’s strength, corrosion resistance, and aesthetic appeal.

- Material Inspection: Suppliers typically conduct initial inspections to ensure the raw materials meet industry standards and specifications. This might include checking for defects, measuring thickness, and verifying alloy composition.

- Cutting and Shaping: The raw materials are then cut into required shapes and sizes using techniques like laser cutting or stamping. Precision is crucial here, as inaccuracies can lead to poor fitting hinges.

2. Forming: What Techniques Are Used to Shape Cabinet Hinges?

Once the materials are prepared, the next stage is forming. This involves shaping the metal into the desired hinge configuration.

- Stamping: Many manufacturers use stamping machines to create the basic hinge shape quickly and efficiently. This method is well-suited for high-volume production.

- Machining: Some hinges may require additional machining to create precise holes for screws or to develop complex designs. CNC (Computer Numerical Control) machining is often employed for its accuracy.

- Bending: After stamping, hinges may undergo bending processes to achieve the necessary angles and configurations. This is particularly important for hinges that need to fit specific cabinet designs.

3. Assembly: How Are Cabinet Hinges Assembled for Durability?

The assembly stage involves bringing together all the components of the hinge. This is where quality control becomes crucial.

- Component Assembly: Depending on the hinge type, this may include attaching the hinge leaves, springs (for self-closing hinges), and any decorative elements.

- Welding or Riveting: In some designs, components are welded or riveted together to enhance strength. This is particularly relevant for heavy-duty hinges that must support significant weight.

What Quality Assurance Measures Are Essential for Cabinet Hinges?

Quality assurance (QA) is critical throughout the manufacturing process to ensure that cabinet hinges meet international standards and customer expectations. For B2B buyers, understanding these QA measures is vital for selecting reliable suppliers.

1. What International Standards Should B2B Buyers Be Aware Of?

Several international standards govern the quality of cabinet hinges. Familiarity with these standards can help buyers assess potential suppliers effectively.

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality. Suppliers certified under ISO 9001 demonstrate a commitment to maintaining high standards throughout their manufacturing processes.

- CE Marking: For products sold in the European Union, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for buyers in Europe.

- API Standards: Although more common in oil and gas, some hinge manufacturers may adhere to API standards for specific industrial applications.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical for maintaining product integrity and performance. B2B buyers should inquire about the following checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to identify any defects or deviations from quality standards.

- Final Quality Control (FQC): Once hinges are assembled, a final inspection is performed to ensure they function correctly and meet all design specifications.

3. Which Testing Methods Are Commonly Used for Cabinet Hinges?

Manufacturers often employ various testing methods to ensure the durability and functionality of hinges. Some common testing methods include:

- Load Testing: This evaluates how much weight the hinge can support without failure, ensuring it can withstand the intended use.

- Corrosion Resistance Testing: This assesses how well the hinge can resist environmental factors, particularly important for buyers in humid or coastal areas.

- Cycle Testing: This simulates the opening and closing of the cabinet door to ensure the hinge operates smoothly over an extended period.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for international buyers to ensure they receive reliable products.

1. What Should Buyers Look for in Supplier Audits and Reports?

When evaluating suppliers, buyers should request detailed audit reports that outline the supplier’s quality management practices. Key aspects to review include:

- Certification Documentation: Ensure that the supplier holds relevant certifications such as ISO 9001 or CE marking.

- Quality Control Reports: Look for comprehensive reports detailing the results of IQC, IPQC, and FQC processes.

A stock image related to types of cabinet hinges.

2. How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing capabilities. This is particularly beneficial for buyers in regions like Africa and South America, where local standards may vary. Third-party inspectors can:

- Conduct On-Site Audits: They can evaluate the manufacturing facilities and processes to ensure compliance with international standards.

- Perform Random Sampling: Inspectors can randomly sample products to verify quality before shipment.

What Are the Quality Control Nuances for International Buyers?

Understanding the nuances of quality control in different regions is essential for B2B buyers, particularly those sourcing from Africa, South America, the Middle East, and Europe.

- Cultural Differences: Be aware that quality perceptions may vary across regions. It’s essential to communicate specific quality requirements clearly.

- Regulatory Compliance: Each region may have unique compliance requirements. Buyers should familiarize themselves with local regulations to avoid issues during importation.

- Supplier Relationships: Building strong relationships with suppliers can facilitate better quality assurance practices, as open communication leads to improved understanding and adherence to quality standards.

By comprehensively understanding the manufacturing processes and quality assurance measures for cabinet hinges, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of cabinet hinges’

To assist international B2B buyers in sourcing cabinet hinges effectively, this checklist provides a structured approach to ensure you select the right type for your needs. Follow these steps to streamline your procurement process and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your project is crucial. Consider the type of cabinets you are working with—framed or frameless—and the overlay style (full, half, or partial). This will determine the hinge type needed, ensuring compatibility with your existing systems and aesthetic preferences.

- Framed vs. Frameless: Identify whether your cabinets have a face frame or not, as this impacts hinge selection.

- Overlay Measurement: Measure the overlay to find the correct hinge that aligns with your design.

Step 2: Research Different Types of Cabinet Hinges

Familiarize yourself with the various types of cabinet hinges available in the market. Common types include concealed, semi-concealed, and self-closing hinges. Understanding their functionality and best use cases will aid in making the right choice for your application.

- Concealed Hinges: Ideal for modern designs; they provide a sleek look.

- Self-Closing Hinges: Important for ensuring doors close securely without manual assistance.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and case studies to understand their capabilities and reliability. Look for suppliers who have experience in your specific region to mitigate logistical challenges.

- Supplier Reputation: Check for reviews and testimonials from other businesses, particularly in your industry.

- Quality Assurance: Ensure suppliers adhere to international quality standards and certifications relevant to your region.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the hinges you are considering. This will allow you to assess quality, functionality, and compatibility with your cabinets before placing a bulk order.

- Material Inspection: Examine the materials used; durability is key in cabinet hardware.

- Functionality Testing: Ensure the hinges operate smoothly and meet your design specifications.

Step 5: Negotiate Terms and Pricing

Discuss pricing, payment terms, and lead times with your selected supplier. Effective negotiation can lead to better pricing and more favorable payment conditions, which is essential for maintaining cash flow in your business.

- Bulk Order Discounts: Inquire about discounts for larger orders to maximize your budget.

- Delivery Schedules: Confirm lead times to align with your project timelines.

Step 6: Finalize Your Order and Confirm Details

After agreeing on terms, finalize your order by confirming quantities, specifications, and delivery schedules. It’s vital to document all agreements in writing to avoid misunderstandings.

- Order Confirmation: Ensure that the order reflects all agreed-upon details to prevent discrepancies.

- Communication Channels: Establish clear lines of communication for any questions or concerns during the order process.

Step 7: Plan for Quality Control Upon Arrival

Upon receiving your hinges, conduct a quality control check to ensure they meet the agreed specifications. This step is crucial to avoid costly returns or project delays.

- Visual Inspection: Check for any physical damage or defects.

- Functionality Test: Ensure that all hinges operate as intended before installation.

By following this checklist, B2B buyers can navigate the complexities of sourcing cabinet hinges effectively, ensuring they select the right products for their specific needs while optimizing their procurement processes.

Comprehensive Cost and Pricing Analysis for types of cabinet hinges Sourcing

What Are the Key Cost Components in Sourcing Cabinet Hinges?

When sourcing cabinet hinges, it’s essential to understand the various cost components involved in the pricing structure. The primary cost elements include:

-

Materials: The choice of materials significantly influences the overall cost. Common materials for cabinet hinges include stainless steel, brass, and plastic. Each material offers varying durability, aesthetics, and price points.

-

Labor: Labor costs can vary depending on the region of production. In regions with lower labor costs, such as parts of South America and Africa, you may find more competitive pricing.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities and maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs for custom hinge designs can be substantial. These costs are often amortized over larger production runs, making them less impactful per unit when sourcing in high volumes.

-

Quality Control (QC): Rigorous QC processes ensure that the hinges meet specific standards. This may involve additional costs for testing and certification, which are particularly important for international buyers seeking compliance with local regulations.

-

Logistics: Shipping costs can vary significantly based on the distance and method of transportation. Incoterms also play a critical role in determining who bears the shipping costs and risks.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on market conditions and competition.

How Do Price Influencers Impact Cabinet Hinges Sourcing?

Several factors influence the pricing of cabinet hinges, and understanding these can aid in effective sourcing:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually yield better pricing due to economies of scale. Negotiating MOQs can lead to more favorable terms.

-

Specifications and Customization: Custom designs or specific features can increase costs. It is essential to balance customization needs with budget constraints to avoid overspending.

-

Material Choices: As mentioned, materials directly affect pricing. Opting for more cost-effective materials can help manage budgets, but it’s crucial to consider the impact on quality.

-

Quality and Certifications: Hinges that comply with international quality standards may come at a premium. However, they can also reduce long-term costs associated with replacements or failures.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer higher quality but at a higher price point.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the overall cost structure.

What Are the Best Negotiation Tips for International B2B Buyers?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Research Market Prices: Understand the average pricing for different types of cabinet hinges in your target market to negotiate effectively.

-

Leverage Volume Discounts: Use your purchasing power to negotiate better terms. Suppliers are often willing to lower prices for larger orders.

-

Be Open to Alternative Suppliers: Explore multiple suppliers to find the best pricing and terms. This can also give you leverage in negotiations.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs associated with installation, maintenance, and potential replacements. This broader view can justify a higher upfront cost if it leads to greater savings in the long run.

-

Clarify Terms: Ensure that all terms, including delivery timelines and payment conditions, are clear before finalizing any agreements. Misunderstandings can lead to unexpected costs.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

International buyers must be aware of several pricing nuances that can affect their sourcing strategies:

-

Currency Fluctuations: Exchange rates can impact the final cost of imported hinges. It’s advisable to lock in rates when possible or negotiate prices in a stable currency.

-

Tariffs and Duties: Import tariffs can significantly affect the total cost. Understanding the applicable tariffs for your region can help in budgeting effectively.

-

Local Regulations: Compliance with local regulations may require additional costs for certifications or adjustments to products. Factor these into your overall cost assessment.

Disclaimer on Indicative Prices

Prices for cabinet hinges can vary widely based on the factors mentioned above. The figures provided in this analysis are indicative and should not be considered fixed. Always seek updated quotes from suppliers to ensure accurate budgeting for your specific needs.

Alternatives Analysis: Comparing types of cabinet hinges With Other Solutions

Understanding Alternatives to Cabinet Hinges

When evaluating cabinet hinge solutions, it’s essential to consider alternatives that may offer different functionalities or advantages. While traditional cabinet hinges are widely used, alternative solutions such as sliding door systems and pivot hinges can cater to specific design needs and performance requirements. This analysis aims to provide a clear comparison of these options, helping B2B buyers make informed decisions based on their specific applications and environments.

Comparison Table: Types of Cabinet Hinges vs. Alternatives

| Comparison Aspect | Types of Cabinet Hinges | Sliding Door Systems | Pivot Hinges |

|---|---|---|---|

| Performance | Reliable for standard use; offers various styles for different applications | Smooth operation over long spans; ideal for larger openings | Allows full door rotation; space-saving design |

| Cost | Generally affordable, varies by type and material | Higher initial investment due to track systems | Moderate cost; installation complexity can increase expenses |

| Ease of Implementation | Simple installation for most types; requires precise measurements | Requires track installation; may need professional help | Can be complex to install; requires accurate alignment |

| Maintenance | Low maintenance; occasional lubrication needed | Moderate; tracks may require cleaning and adjustments | Low; durable designs often need minimal upkeep |

| Best Use Case | Kitchen and bathroom cabinetry; furniture applications | Large cabinets or room dividers; modern spaces | Spaces with limited swing room; unique architectural designs |

Detailed Breakdown of Alternatives

Sliding Door Systems

Sliding door systems utilize tracks to allow doors to glide open and closed, making them an excellent choice for spaces where traditional hinged doors may not fit. They provide a sleek, modern aesthetic and are ideal for larger openings, such as room dividers or closet doors. However, the initial investment can be higher, and installation may require professional assistance, particularly if the track needs to be mounted in a non-standard way. Maintenance can be moderate, as the tracks may need periodic cleaning to ensure smooth operation.

Pivot Hinges

Pivot hinges offer a unique solution, allowing doors to rotate around a pivot point rather than swinging on a traditional hinge. This design is particularly beneficial in spaces with limited swing room, as it requires less clearance. Pivot hinges can accommodate heavier doors and are often used in commercial settings or for high-end residential designs. However, they can be more complex to install, and precise alignment is crucial to ensure proper function. While the cost is moderate, the need for skilled installation can add to overall expenses.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate cabinet hinge or alternative solution largely depends on the specific requirements of your project. For traditional cabinetry, a variety of cabinet hinges can provide reliable performance and ease of installation. If your design calls for modern aesthetics or space-saving features, sliding door systems or pivot hinges may be more suitable. By carefully considering factors such as performance, cost, ease of implementation, and maintenance, international B2B buyers can make informed decisions that align with their project goals and operational needs.

Essential Technical Properties and Trade Terminology for types of cabinet hinges

What Are the Essential Technical Properties of Cabinet Hinges?

Understanding the technical specifications of cabinet hinges is crucial for international B2B buyers, particularly when sourcing from diverse markets across Africa, South America, the Middle East, and Europe. Here are key properties to consider:

1. Material Grade

The material of cabinet hinges significantly affects their durability and performance. Common materials include stainless steel, brass, and plastic. Stainless steel is known for its corrosion resistance and strength, making it ideal for humid environments, while brass offers aesthetic appeal and good corrosion resistance. Buyers should assess the material grade to ensure it meets their application requirements and local environmental conditions.

2. Load Capacity

Load capacity refers to the maximum weight a hinge can support without compromising its function. It is critical to evaluate this specification based on the cabinet’s intended use—whether for kitchen, bathroom, or commercial applications. A hinge with insufficient load capacity can lead to premature failure, resulting in costly repairs and replacements.

3. Tolerance

Tolerance indicates the allowable deviation in measurements during the manufacturing process. This specification is essential for ensuring that hinges fit correctly and function smoothly within the cabinet design. Poor tolerance can lead to misalignment and operational issues, emphasizing the need for precise manufacturing standards.

4. Pivot Point Location

The pivot point is where the hinge rotates, affecting how the cabinet door opens and closes. Different types of hinges have varying pivot point locations, which can influence the door’s swing radius and overall functionality. Understanding the pivot point is critical for buyers aiming to optimize space and accessibility in their designs.

5. Finish and Coating

The finish of a hinge not only impacts its appearance but also its resistance to wear and corrosion. Common finishes include polished, brushed, and powder-coated options. Buyers should consider the aesthetic requirements of their projects, as well as the environmental factors that may affect the hinge’s longevity.

What Trade Terminology Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication. Here are essential terms that international B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end products. Understanding OEM relationships can help buyers identify reliable suppliers and ensure that they are sourcing quality hinges that meet their specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects budgeting and inventory management. Buyers should negotiate MOQs that align with their purchasing needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This process helps in comparing offers and ensuring competitive pricing. Crafting a clear RFQ can significantly streamline the procurement process.

4. Incoterms

Incoterms, or International Commercial Terms, are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for managing shipping costs, risks, and delivery obligations. Familiarity with Incoterms can prevent misunderstandings and ensure compliance with international trade regulations.

5. Lead Time

Lead time is the period between placing an order and receiving the product. It is critical for project planning and inventory management. Buyers should inquire about lead times to ensure that their supply chain remains efficient and that projects stay on schedule.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when selecting cabinet hinges that meet their specific needs and enhance their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the types of cabinet hinges Sector

What Are the Key Market Trends Impacting the Types of Cabinet Hinges Sector?

The global cabinet hinges market is driven by several factors, including the rising demand for modular and customizable furniture, particularly in urban areas across Africa, South America, the Middle East, and Europe. The shift towards modern interior design, which favors sleek aesthetics and functionality, is propelling the popularity of concealed and soft-close hinges. Emerging technologies in manufacturing, such as automation and precision engineering, are enhancing the quality and durability of cabinet hinges, enabling B2B buyers to source products that offer both reliability and aesthetic appeal.

Moreover, the increasing emphasis on e-commerce platforms has transformed the sourcing landscape. International buyers can now access a wider range of products from various suppliers with just a few clicks. This trend is particularly significant in regions like South America and Africa, where traditional supply chains are evolving. B2B buyers are encouraged to leverage these platforms to compare prices, evaluate quality, and read customer reviews, ensuring they make informed purchasing decisions.

Additionally, sustainability is becoming a critical factor in the purchasing process. Buyers are increasingly looking for suppliers who prioritize sustainable practices, such as using eco-friendly materials and reducing waste in production. This shift towards sustainability is not only beneficial for the environment but also aligns with the growing consumer demand for responsible products.

How Is Sustainability Shaping Sourcing Decisions for Cabinet Hinges?

Sustainability and ethical sourcing have become paramount in the cabinet hinges sector, impacting how international B2B buyers approach their purchasing decisions. The environmental impact of manufacturing processes is under scrutiny, pushing manufacturers to adopt greener practices. Buyers are now seeking suppliers who utilize sustainable materials, such as recycled metals and eco-friendly coatings, to reduce their carbon footprint.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly focused on ensuring that their suppliers adhere to fair labor practices and environmentally responsible sourcing. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems are becoming critical considerations in supplier evaluations.

Additionally, consumers in regions like Europe and North America are demanding transparency in sourcing, which is trickling down to the B2B market. Suppliers who can demonstrate their commitment to sustainability through certifications and responsible practices not only attract more customers but also build stronger brand loyalty. Thus, B2B buyers should prioritize partnerships with manufacturers that align with these values, fostering a more sustainable future for the industry.

How Have Cabinet Hinges Evolved Over Time?

The evolution of cabinet hinges reflects broader trends in design and functionality. Traditionally, hinges were simple mechanical devices made from heavy metals, often visible and bulky. Over time, innovations led to the development of concealed hinges, which provide a cleaner look by hiding the hinge mechanism when the cabinet door is closed. This design change has been particularly significant in modern European cabinetry, where aesthetics are paramount.

The introduction of soft-close technology further revolutionized the industry. This mechanism allows cabinet doors to close gently, preventing slamming and enhancing user experience. As consumer preferences shifted towards more functional and stylish furniture, manufacturers responded by integrating advanced technologies into hinge designs.

Today, the market offers a diverse range of hinges, including those that accommodate various cabinet styles and user needs. From self-closing mechanisms to adjustable concealed hinges, the options available cater to a global audience, including B2B buyers from Africa, South America, the Middle East, and Europe, ensuring they have access to innovative and high-quality solutions for their cabinetry needs.

Frequently Asked Questions (FAQs) for B2B Buyers of types of cabinet hinges

-

How do I choose the right cabinet hinge for my project?

Choosing the right cabinet hinge involves assessing your cabinet type (framed or frameless), overlay configuration (full or partial), and the desired aesthetic. For frameless cabinets, concealed or European hinges are ideal, while framed cabinets may benefit from semi-concealed or surface-mounted hinges. Consider the door’s weight and usage frequency, as heavy doors require robust hinges. Additionally, evaluate any special features like soft-close mechanisms to enhance user experience. Collaborating with suppliers who understand your market can provide tailored recommendations. -

What is the best hinge type for modern kitchen cabinets?

For modern kitchen cabinets, European or concealed hinges are often the best choice. These hinges provide a sleek, minimalistic look, allowing for seamless cabinetry design. Their adjustability ensures perfect alignment, while many models include soft-close features to prevent slamming. If you’re sourcing for high-end projects in Europe or the Middle East, investing in quality concealed hinges can elevate the overall aesthetic and functionality of kitchen installations, appealing to discerning clients. -

How can I ensure the quality of cabinet hinges from international suppliers?

To ensure quality when sourcing cabinet hinges internationally, conduct thorough supplier vetting. Request product samples to evaluate material quality and finish. Look for suppliers with certifications such as ISO 9001, which indicates adherence to quality management standards. Engage in direct communication to clarify specifications and compliance with international standards. Additionally, consider arranging third-party inspections before shipment to verify that products meet your requirements. -

What are the minimum order quantities (MOQ) for cabinet hinges?

Minimum order quantities for cabinet hinges can vary significantly among suppliers. Typically, MOQs range from 100 to 1,000 units depending on the type of hinge and the supplier’s production capabilities. When negotiating with suppliers, clarify the MOQ and explore options for smaller initial orders, especially if you are entering new markets. This flexibility can help you manage cash flow while testing demand for different hinge types in your region. -

What payment terms should I negotiate when buying cabinet hinges?

When negotiating payment terms for cabinet hinges, aim for terms that balance risk and cash flow. Common terms include a 30% deposit upon order confirmation, with the remaining 70% payable before shipment. For larger orders or ongoing relationships, consider negotiating net 30 or net 60 terms to allow for product testing and market response. Ensure that payment methods are secure and consider using letters of credit for added protection in international transactions. -

How can I customize cabinet hinges for my specific needs?

Many suppliers offer customization options for cabinet hinges, including finishes, sizes, and features. To initiate customization, provide detailed specifications, including dimensions, material preferences, and any unique design elements. Collaborate closely with your supplier to ensure that your requirements are feasible and within their manufacturing capabilities. Be prepared for potential minimum order requirements for custom products, and allow sufficient lead time for production and delivery. -

What logistics considerations should I keep in mind when sourcing cabinet hinges internationally?

When sourcing cabinet hinges internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose reliable shipping partners experienced in handling hardware products to ensure safe and timely delivery. Factor in potential delays due to customs clearance, especially when importing to regions with stringent regulations. Additionally, maintain clear communication with your supplier regarding shipping terms, including Incoterms, to avoid misunderstandings. -

How can I handle warranty claims for defective cabinet hinges?

To effectively manage warranty claims for defective cabinet hinges, establish clear terms with your supplier upfront. Document the warranty period and conditions under which claims can be made. In case of defects, gather evidence such as photographs and descriptions of the issue and communicate promptly with the supplier. Understand the return process and any associated costs. A proactive approach in addressing warranty claims can strengthen your business relationship and ensure customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of cabinet hinges

What Are the Key Takeaways for Strategic Sourcing of Cabinet Hinges?

In summary, understanding the diverse types of cabinet hinges is essential for making informed purchasing decisions. International B2B buyers should consider factors such as hinge type, application, and the specific requirements of their cabinet designs. The strategic sourcing of cabinet hinges not only enhances product quality but also optimizes supply chain efficiency. Buyers from Africa, South America, the Middle East, and Europe can leverage these insights to select hinges that meet their market demands while ensuring durability and aesthetic appeal.

How Can Buyers Prepare for Future Trends in Cabinet Hinges?

As the demand for modern and customizable cabinetry grows, the importance of sourcing high-quality hinges will continue to rise. Buyers should stay ahead by monitoring trends in design, technology, and materials, such as the increasing popularity of soft-close and concealed hinges. By fostering relationships with reliable suppliers, buyers can ensure they have access to the latest innovations in cabinet hardware.

What Should International Buyers Do Next?

Take actionable steps today by evaluating your current sourcing strategies and aligning them with the insights provided. Explore partnerships with manufacturers who prioritize quality and offer a range of hinge types suitable for your projects. By doing so, you will not only enhance your product offerings but also position your business for growth in an evolving market.