Discover the Best Types of Plug Sockets for Your Needs (2025)

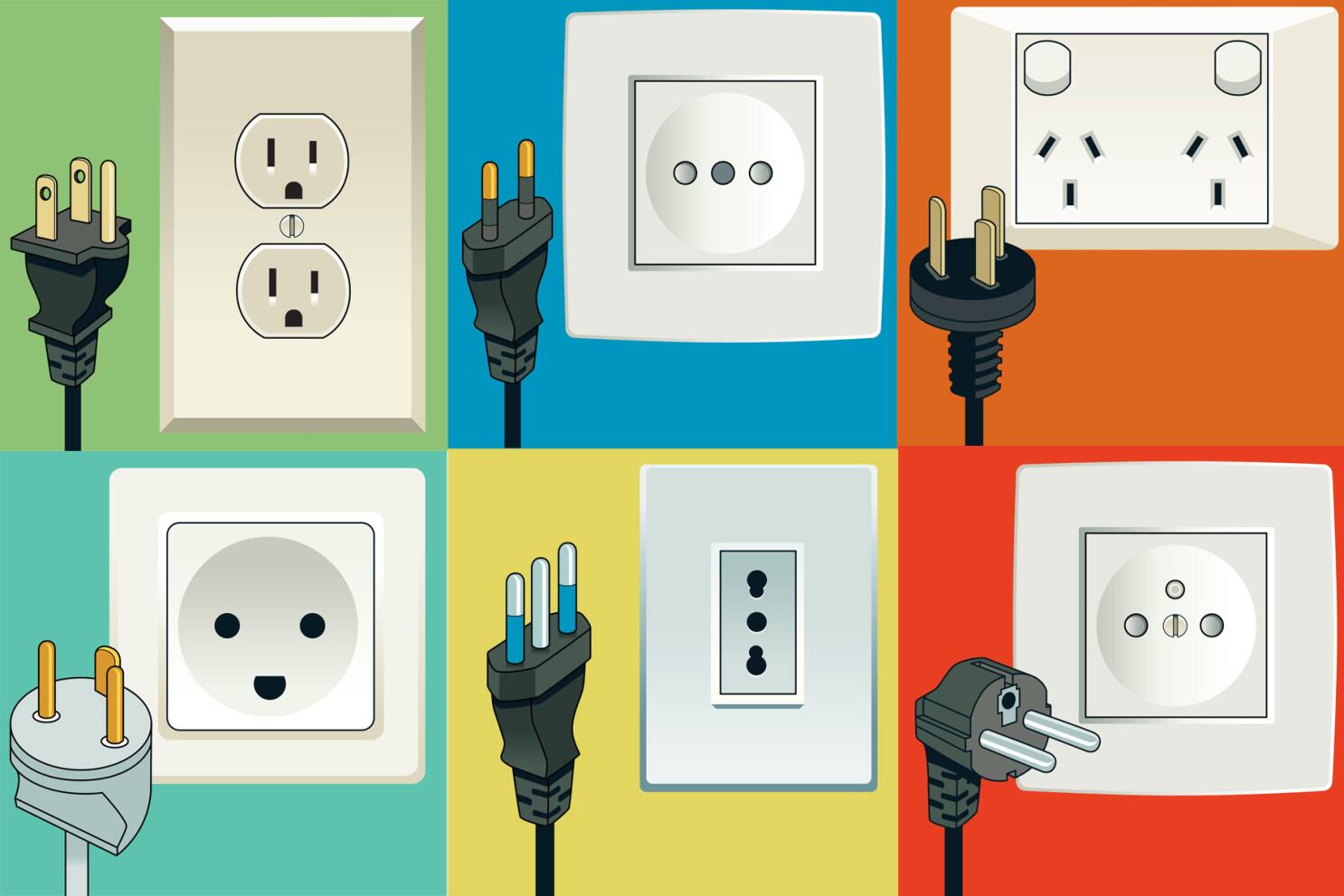

Introduction: Navigating the Global Market for types of plug sockets

In today’s interconnected world, sourcing the right types of plug sockets can be a daunting challenge for international B2B buyers. With over 15 distinct plug types used globally, navigating the complexities of electrical compatibility is crucial for ensuring operational efficiency and safety. This comprehensive guide delves into the various types of plug sockets, their applications, and the nuances of voltage and frequency differences across regions.

Buyers from Africa, South America, the Middle East, and Europe—countries such as Thailand and Mexico—must be equipped with the knowledge to make informed purchasing decisions. Understanding the specifications of different socket types not only aids in compliance with local regulations but also minimizes the risk of equipment damage and operational downtime.

This guide empowers you by providing actionable insights on supplier vetting, cost considerations, and best practices for integrating plug sockets into your business operations. By addressing these critical factors, we aim to streamline your sourcing process and enhance your competitive edge in the global market. Whether you’re expanding into new territories or seeking to optimize existing operations, this resource will serve as your authoritative reference for making smart, informed choices in the world of electrical components.

Understanding types of plug sockets Types and Variations

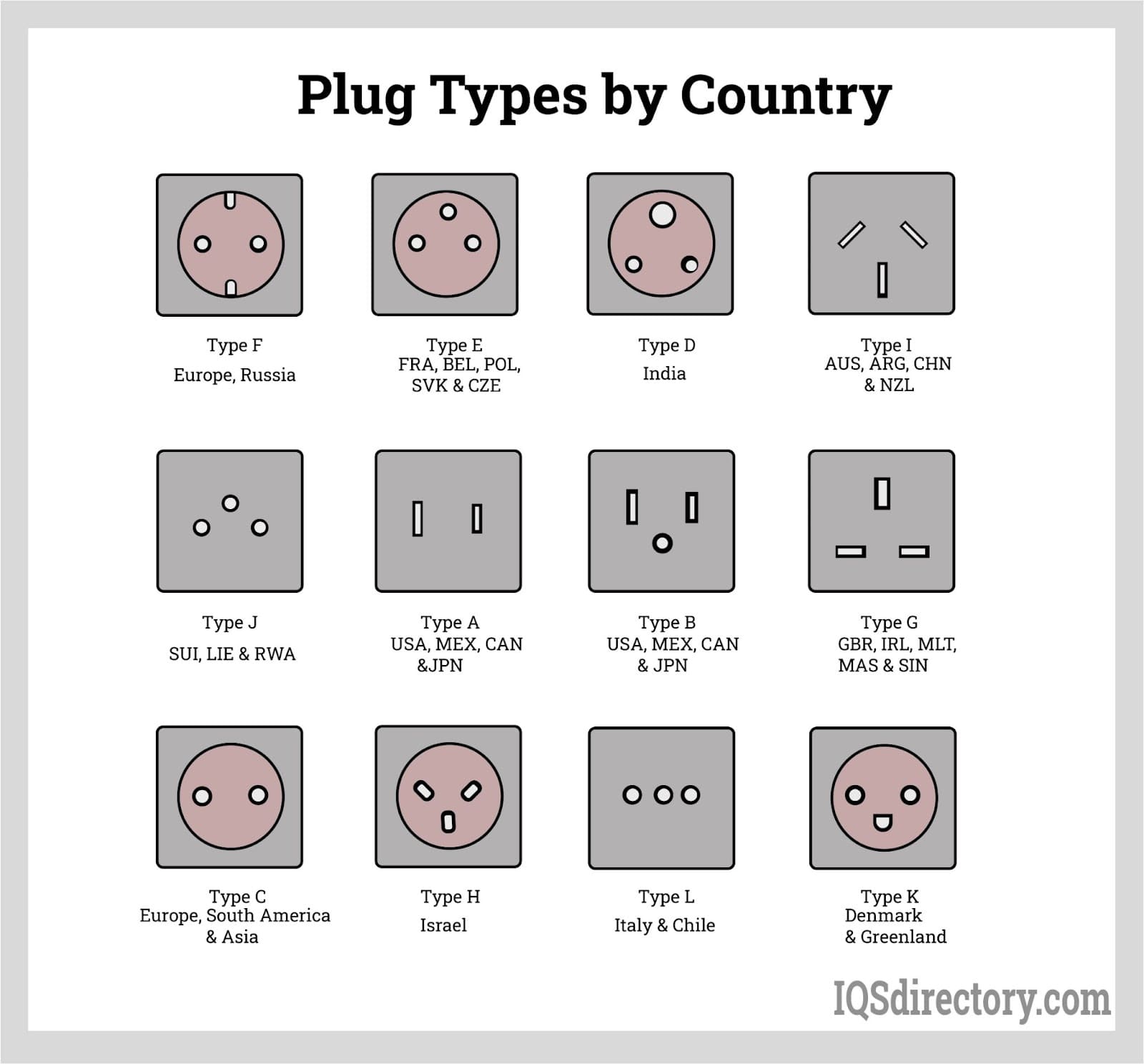

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | Two round pins, not grounded, rated for 2.5 A, 10 A, and 16 A | Common in appliances, lighting, and consumer electronics across Europe, Africa, and South America | Pros: Widely used, versatile; Cons: Not grounded, limited to lower power applications. |

| Type G | Three rectangular pins, grounded, rated for 13 A | Used in heavy-duty applications like commercial equipment and appliances in the UK and Ireland | Pros: Grounded for safety, suitable for high-powered devices; Cons: Bulkier design may not fit all sockets. |

| Type E/F | Two round pins with a grounding pin, rated for 16 A | Commonly used in Europe for household appliances and office equipment | Pros: Grounded for safety, compatible with multiple plug types; Cons: Limited to specific voltage ranges. |

| Type I | Two or three flat pins, rated for 10 A and 15 A | Utilized in Australia, New Zealand, and parts of Asia for general-purpose devices | Pros: Versatile, compatible with various devices; Cons: Different configurations can cause compatibility issues. |

| Type N | Three round pins, grounded, rated for 10 A, 16 A, and 20 A | Primarily used in Brazil and South Africa for industrial and commercial applications | Pros: High power ratings, versatile; Cons: Less common globally, limiting international compatibility. |

What are the Characteristics of Type C Plug Sockets?

Type C sockets, characterized by their two round pins, are prevalent in Europe, Africa, and South America. These plugs are typically rated for 2.5 A, 10 A, and 16 A, making them suitable for low to moderate power applications such as lighting and small appliances. B2B buyers should consider the safety implications, as Type C sockets are not grounded, potentially posing a risk in high-load situations. However, their widespread use offers compatibility advantages across various regions, making them an economical choice for importers and distributors.

How Does Type G Plug Socket Benefit Heavy-Duty Applications?

Type G sockets feature three rectangular pins and are grounded, rated for 13 A, making them ideal for heavy-duty applications like commercial appliances and machinery in the UK and Ireland. The grounding feature enhances safety, especially in environments where electrical faults may occur. B2B buyers should factor in the robust design that accommodates higher power loads. However, the bulkier size may limit compatibility with some devices, necessitating careful planning for installations.

Why Choose Type E/F Plug Sockets for European Markets?

Type E/F sockets are distinguished by their two round pins and grounding pin, rated for 16 A, making them a staple in European households and offices. Their compatibility with multiple plug types enhances flexibility, allowing for a variety of devices to be powered efficiently. For B2B buyers, the grounding feature offers enhanced safety, while the standardization across many countries simplifies logistics and inventory management. However, buyers should be aware of the voltage limitations to ensure compliance with local regulations.

What Are the Advantages of Type I Plug Sockets?

Type I sockets, featuring two or three flat pins, are commonly used in Australia, New Zealand, and parts of Asia. Rated for 10 A and 15 A, they are versatile enough for general-purpose devices, from consumer electronics to appliances. B2B buyers should consider the varying configurations of Type I plugs, as they can lead to compatibility challenges. However, their widespread use in multiple regions makes them a practical choice for manufacturers looking to penetrate these markets.

How Does Type N Plug Socket Meet Industrial Needs?

Type N sockets, with three round pins and a grounding feature, are rated for 10 A, 16 A, and 20 A, making them suitable for industrial and commercial applications primarily in Brazil and South Africa. Their higher power ratings enable the use of heavy machinery and equipment, appealing to B2B buyers in sectors requiring reliable electrical solutions. However, given their limited global presence, companies must consider the potential challenges in sourcing and compatibility when operating in international markets.

Key Industrial Applications of types of plug sockets

| Industry/Sector | Specific Application of types of plug sockets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial machinery and equipment connections | Ensures reliable power supply for operational efficiency | Compatibility with local voltage and socket types, durability |

| Construction | Temporary power setups at construction sites | Provides safe and flexible power solutions during project phases | Compliance with safety standards, weather resistance |

| Hospitality | Electrical systems in hotels and restaurants | Enhances guest experience with reliable power for appliances | Variety of plug types to accommodate international guests |

| Healthcare | Medical equipment power supply | Ensures safety and reliability of critical medical devices | Certification for medical use, compatibility with local standards |

| Telecommunications | Powering communication equipment | Supports uninterrupted service and connectivity | Robustness for outdoor installations, voltage compatibility |

How Are Types of Plug Sockets Used in Manufacturing?

In the manufacturing sector, plug sockets are critical for connecting industrial machinery and equipment. Reliable power supply is essential for maximizing operational efficiency, minimizing downtime, and ensuring safety. International B2B buyers must consider the compatibility of plug types with local voltage standards, as well as the durability of sockets to withstand harsh industrial environments. Additionally, sourcing plug sockets that meet international safety certifications can mitigate risks associated with electrical hazards.

A stock image related to types of plug sockets.

What Role Do Plug Sockets Play in Construction?

Construction sites often require temporary power setups to support various tools and machinery. Types of plug sockets facilitate flexible and safe power solutions during different phases of a project. For B2B buyers in the construction industry, it is vital to ensure that the selected sockets comply with local safety standards and can withstand outdoor conditions. Weather-resistant sockets can protect against moisture and dust, which is crucial for maintaining operational integrity on-site.

How Are Plug Sockets Utilized in the Hospitality Sector?

In the hospitality industry, plug sockets are integral to the electrical systems found in hotels and restaurants. They ensure that guests have access to power for personal devices and that essential appliances function reliably. B2B buyers must consider a variety of plug types to accommodate the diverse needs of international guests, including those from different regions with varying plug standards. Additionally, investing in high-quality sockets can enhance the overall guest experience and reduce maintenance costs.

Why Are Plug Sockets Important in Healthcare?

In healthcare settings, the power supply for medical equipment is non-negotiable. Plug sockets must ensure the safety and reliability of critical medical devices, which can directly impact patient care. Buyers in this sector should prioritize sourcing plug sockets that are certified for medical use and compatible with local electrical standards. The reliability of these sockets is paramount, as any failure could lead to severe consequences for patient safety.

What Significance Do Plug Sockets Have in Telecommunications?

Telecommunications rely heavily on a stable power supply for communication equipment. Types of plug sockets are essential for powering devices that support uninterrupted service and connectivity. For international B2B buyers in this sector, sourcing robust sockets that can withstand outdoor installations and are compatible with local voltage requirements is crucial. Ensuring that the sockets are designed for high-performance applications can significantly enhance the reliability of telecommunications infrastructure.

3 Common User Pain Points for ‘types of plug sockets’ & Their Solutions

Scenario 1: Navigating Multiple Plug Standards in International Trade

The Problem:

B2B buyers engaged in international trade often encounter the challenge of differing plug socket types across regions. For instance, a company in South Africa sourcing electronics from Europe may find that their devices are incompatible with local power infrastructure. This discrepancy can lead to operational delays, increased costs for adapters or converters, and potential safety hazards due to improper usage of electrical equipment. This scenario is particularly challenging for businesses looking to scale their operations across borders while ensuring compliance with local electrical standards.

The Solution:

To mitigate these issues, B2B buyers should conduct thorough research on the plug socket types and voltage specifications of their target markets. Utilizing resources like the International Electrotechnical Commission (IEC) standards can provide clarity on compatibility. Additionally, consider engaging with local suppliers or manufacturers who can supply compatible products or offer advice on necessary adaptations. Creating a standardized checklist that includes plug type, voltage, and frequency for each region can streamline the procurement process and reduce the risk of incompatibility. Furthermore, investing in universal adapters or multi-socket power strips designed for various plug types can enhance operational flexibility and minimize downtime during transitions.

Scenario 2: Ensuring Safety Compliance for Electrical Installations

The Problem:

Safety compliance is a critical concern for B2B buyers, especially when installing plug sockets in commercial or industrial settings. For example, a company in the Middle East may overlook the importance of using GFCI (Ground Fault Circuit Interrupter) outlets in wet areas, leading to potential electrical hazards. Non-compliance with local electrical codes not only poses safety risks but can also result in hefty fines and liability issues if accidents occur.

The Solution:

To ensure safety compliance, B2B buyers should familiarize themselves with local electrical codes and regulations regarding plug sockets and their installation. Conducting regular training for installation teams on the importance of using appropriate outlets—like GFCI in bathrooms and kitchens or weather-resistant sockets outdoors—can significantly enhance workplace safety. Partnering with certified electricians who understand local regulations can also prevent costly compliance oversights. Additionally, implementing a routine inspection program to evaluate the condition and compliance of existing installations will help maintain safety standards and reduce the risk of electrical accidents.

Scenario 3: Managing Power Supply for Diverse Equipment Needs

The Problem:

Many businesses face the challenge of managing power supply for a range of equipment that requires different plug types and power specifications. A manufacturing plant in Brazil, for instance, may utilize machinery that requires Type N plugs while also needing to operate standard office equipment that uses Type C plugs. This mismatch can lead to power inefficiencies, increased operational costs, and complications in equipment management.

The Solution:

To address this pain point, B2B buyers should consider installing a mix of outlet types tailored to their specific equipment needs. Conducting a comprehensive audit of all equipment and their power requirements will provide insight into the necessary plug types. Implementing a power distribution system that includes both standard and specialized outlets will allow for more efficient energy use. Moreover, investing in smart power management systems that monitor usage and adapt to the needs of different devices can lead to significant energy savings. It’s also advisable to consult with electrical engineers to design a customized solution that accommodates diverse equipment while ensuring optimal performance and safety.

Strategic Material Selection Guide for types of plug sockets

What are the Key Materials Used in Plug Socket Manufacturing?

When selecting plug sockets, understanding the materials used in their construction is crucial for ensuring product performance, safety, and compliance with international standards. Below, we analyze four common materials used in plug socket manufacturing: thermoplastics, metals, ceramics, and rubber.

How Do Thermoplastics Perform in Plug Socket Applications?

Thermoplastics, such as polycarbonate and nylon, are widely used in plug socket production due to their excellent electrical insulation properties and durability. These materials can withstand high temperatures (up to 120°C) and have good chemical resistance, making them suitable for various environments.

Pros: Thermoplastics are lightweight, cost-effective, and easy to mold, which simplifies manufacturing processes. They also provide good impact resistance and can be produced in various colors, enhancing aesthetic appeal.

Cons: While thermoplastics are durable, they can be susceptible to UV degradation over time if not treated properly. Additionally, they may not perform well under extreme temperatures beyond their rated limits.

Impact on Application: Thermoplastics are ideal for residential and light commercial applications where safety and aesthetics are important. However, they may not be suitable for high-load industrial environments.

Considerations for International Buyers: Buyers should ensure compliance with standards such as IEC 60884-1 and UL 498, which govern the safety and performance of electrical accessories. Countries in Africa, South America, and the Middle East may have specific regulations that require certification for thermoplastic materials.

What Role Do Metals Play in Plug Socket Design?

Metals, particularly copper and brass, are often used for the conductive components of plug sockets. These materials are chosen for their excellent electrical conductivity and mechanical strength.

Pros: Metal components ensure reliable electrical connections and can handle high current loads. They are also resistant to corrosion, especially when plated with nickel or tin, enhancing their lifespan.

Cons: Metals can be heavier and more expensive than thermoplastics, increasing overall production costs. Additionally, they may require more complex manufacturing processes, such as machining or stamping.

Impact on Application: Metal components are essential in high-load applications, such as industrial plug sockets, where durability and conductivity are paramount.

Considerations for International Buyers: Buyers should be aware of corrosion resistance standards, particularly in humid or coastal environments. Compliance with ASTM B117 for salt spray testing is crucial for ensuring longevity in such conditions.

How Do Ceramics Enhance Plug Socket Performance?

Ceramics are used in high-temperature and high-voltage applications due to their excellent thermal and electrical insulation properties. They can withstand extreme temperatures (up to 200°C) and are inherently non-combustible.

Pros: Ceramics provide superior dielectric strength and are resistant to wear and tear. They also have a high resistance to chemical corrosion, making them suitable for harsh environments.

Cons: The brittleness of ceramics can be a drawback, as they may crack or break under mechanical stress. Additionally, ceramics are generally more expensive to produce than thermoplastics.

Impact on Application: Ceramics are ideal for specialized applications, such as industrial or outdoor plug sockets, where high performance is required under demanding conditions.

Considerations for International Buyers: Buyers should check for compliance with international standards such as IEC 60695-2-10 for fire safety. Different regions may have varying requirements for the use of ceramic materials in electrical applications.

Why is Rubber Important for Plug Socket Safety?

Rubber is often used in the insulation and protective covers of plug sockets. It is valued for its flexibility and excellent electrical insulating properties.

Pros: Rubber is highly resistant to abrasion and can withstand a wide range of temperatures. It also provides a good grip, making it easier to plug and unplug devices.

Cons: Rubber can degrade over time when exposed to UV light and certain chemicals, which may limit its lifespan. Additionally, it can be more challenging to mold compared to thermoplastics.

Impact on Application: Rubber is particularly useful in outdoor or industrial settings where moisture and dust are concerns. Its flexibility allows for better sealing against environmental factors.

Considerations for International Buyers: Buyers should ensure that rubber materials meet relevant safety standards, such as IEC 60529 for ingress protection, especially in regions with high humidity or dust levels.

Summary Table of Material Properties for Plug Sockets

| Material | Typical Use Case for types of plug sockets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and light commercial sockets | Lightweight and cost-effective | UV degradation potential | Low |

| Metals | High-load industrial sockets | Excellent conductivity and strength | Heavier and more expensive | High |

| Ceramics | High-temperature and high-voltage sockets | Superior thermal and electrical insulation | Brittle and expensive | High |

| Rubber | Outdoor and industrial sockets | Flexible and abrasion-resistant | Degradation from UV exposure | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for types of plug sockets

What Are the Key Stages in Manufacturing Plug Sockets?

The manufacturing process for plug sockets involves several critical stages, ensuring that the final products meet both safety and functionality standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing plug sockets.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. Plug sockets are typically made from high-quality thermoplastics and metal components. The thermoplastics provide insulation, while metals such as copper and brass are used for electrical conductivity. Sourcing these materials from reliable suppliers is crucial; buyers should ensure that the materials comply with international standards like ISO 9001.

How Are Plug Sockets Formed?

Once materials are prepared, the next stage is forming. This involves molding the plastic casing of the plug sockets using techniques such as injection molding. In this process, heated plastic is injected into molds to create the desired shape. Metal parts, like pins and connectors, are usually stamped or machined. This stage requires precision machinery to ensure that each component fits perfectly and meets the specifications for electrical safety.

What Is Involved in the Assembly Process?

After forming, the individual components are assembled. This process may include inserting metal pins into the plastic casing, wiring, and adding safety features such as shutters or grounding mechanisms. Automation plays a significant role in assembly, enhancing consistency and reducing labor costs. However, manual checks are often performed to ensure that critical components are correctly positioned.

What Finishing Techniques Are Used?

The final stage of manufacturing involves finishing processes that enhance both aesthetics and functionality. This may include surface treatments like painting, labeling, or applying anti-corrosion coatings to metal parts. Quality assurance checks are performed at this stage to confirm that the plug sockets are ready for distribution.

How Is Quality Assurance Implemented in Plug Socket Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of plug sockets, as these products must meet strict safety and performance standards. International B2B buyers should be aware of various QA processes and standards applicable in this industry.

What International Standards Should B2B Buyers Look For?

The most relevant international standard for quality management is ISO 9001, which emphasizes a systematic approach to managing business processes. In addition, buyers should ensure that plug sockets comply with specific industry standards such as CE marking in Europe, which signifies that a product meets EU safety, health, and environmental protection requirements.

What Are the Key Quality Control Checkpoints?

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components before they enter the production line. Buyers should verify that suppliers have robust IQC processes in place.

-

In-Process Quality Control (IPQC): During assembly, IPQC ensures that the manufacturing process is adhering to quality standards. This involves monitoring critical parameters such as dimensions, electrical resistance, and safety features.

-

Final Quality Control (FQC): Once the plug sockets are fully assembled, FQC checks the final product against specifications, focusing on appearance, functionality, and safety. Common tests include electrical continuity tests, insulation resistance tests, and thermal tests.

What Testing Methods Are Commonly Used for Plug Sockets?

To ensure that plug sockets meet safety and performance standards, various testing methods are employed:

-

Electrical Testing: This includes measuring voltage, current capacity, and continuity. Buyers should confirm that suppliers perform thorough electrical testing to minimize risks.

-

Mechanical Testing: This assesses the physical durability of the sockets, including resistance to wear and impact. Testing for heat resistance is also critical, especially in high-temperature environments.

-

Environmental Testing: Plug sockets may undergo tests to evaluate their performance under different environmental conditions, such as humidity and temperature variations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should take several steps to verify the quality control practices of suppliers:

What Are the Best Practices for Supplier Audits?

Conducting thorough supplier audits is essential. Buyers should assess the manufacturing facility’s adherence to ISO standards, the availability of quality documentation, and the results of previous quality control checks. Audits can be performed in-person or through third-party inspection services, which can provide an unbiased evaluation of the supplier’s practices.

How Can Buyers Request Quality Reports?

Buyers should request detailed quality reports from suppliers, including IQC, IPQC, and FQC results. This documentation provides insights into the supplier’s commitment to quality and can help buyers identify any potential issues before placing large orders.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services is a valuable strategy for buyers looking to mitigate risks. These services can conduct independent assessments of the manufacturing process, materials, and finished products, ensuring compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the regional regulations and compliance requirements is critical for international B2B buyers. Different regions may have specific certification requirements, such as UL certification in the United States or SANS certification in South Africa. Buyers should stay informed about these nuances to ensure that the products they source meet local regulations.

In conclusion, by understanding the manufacturing processes and quality assurance protocols associated with plug sockets, international B2B buyers can make informed decisions that enhance product safety and reliability while ensuring compliance with regional standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of plug sockets’

To assist international B2B buyers in navigating the complexities of sourcing plug sockets, this practical sourcing guide outlines essential steps to ensure that your procurement process is efficient, compliant, and tailored to your specific requirements.

Step 1: Identify Your Market Requirements

Understanding the specific plug socket types used in your target markets is crucial. Different regions use various socket types, voltages, and frequencies, which can impact compatibility with local appliances and infrastructure. For example, Type C is prevalent in Europe and Africa, while Type G is primarily used in the UK and Middle East.

- Research Local Standards: Consult local regulations and standards to ensure compliance.

- Assess Voltage Compatibility: Ensure that the sockets match the voltage requirements of the devices you plan to use.

Step 2: Define Your Technical Specifications

Before reaching out to suppliers, clearly define the technical specifications of the plug sockets you need. This includes the type of plug, amperage, grounding requirements, and material specifications.

- Consider Application: Different applications may require different types of sockets, such as GFCI outlets for wet environments or tamper-resistant options for safety.

- Quality Standards: Specify any international quality certifications required, such as ISO or IEC standards.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. This step is critical to mitigate risks associated with quality and reliability.

- Request Documentation: Ask for company profiles, certifications, and references from other clients in similar industries.

- Assess Production Capabilities: Ensure they can meet your volume and timeline requirements without compromising quality.

Step 4: Request Samples for Testing

Before finalizing a supplier, request samples of the plug sockets to assess their quality and compatibility with your equipment.

- Conduct Compatibility Tests: Ensure that the sockets work seamlessly with your devices.

- Inspect Build Quality: Look for durability and safety features that meet your specifications.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, initiate negotiations on pricing and terms of service. This step is vital to ensure you receive the best value for your investment.

- Discuss Bulk Pricing: Inquire about discounts for larger orders or long-term contracts.

- Clarify Delivery Terms: Ensure that shipping times, responsibilities, and costs are clearly outlined.

Step 6: Verify Compliance with Safety Standards

Ensure that the plug sockets comply with relevant safety standards in your target market. This is essential not only for legal compliance but also for the safety of end-users.

- Check Certification Marks: Look for certification from recognized bodies such as UL, CE, or other local compliance organizations.

- Request Test Reports: Ask for documentation verifying that the products have passed safety tests.

Step 7: Plan for After-Sales Support

After securing your supplier, consider the after-sales support they provide. This can be crucial for maintaining quality and addressing any issues that arise.

- Establish Communication Channels: Ensure you have a direct line of communication for support and inquiries.

- Understand Warranty Policies: Familiarize yourself with warranty terms and conditions for the products.

By following these steps, international B2B buyers can effectively source plug sockets that meet their specific needs while ensuring compliance and quality.

Comprehensive Cost and Pricing Analysis for types of plug sockets Sourcing

What Are the Key Cost Components in Plug Socket Manufacturing?

Understanding the cost structure of plug sockets is essential for B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials include high-quality plastics and metals, which ensure durability and safety. For instance, the use of copper for conductors may be more expensive but ensures better conductivity.

-

Labor: Labor costs vary based on the manufacturing location. Countries with lower labor costs, such as those in parts of Asia, may offer competitive pricing, while regions like Europe may see higher labor costs due to stringent labor laws and wage standards.

-

Manufacturing Overhead: This includes costs associated with utilities, factory maintenance, and administrative expenses. Efficient production processes can help minimize overhead, affecting overall pricing.

-

Tooling: Initial tooling costs can be high, especially for custom designs. These costs are amortized over production runs, making larger orders more cost-effective.

-

Quality Control (QC): Rigorous QC processes are essential, particularly for electrical components. This can add to costs but is crucial for ensuring compliance with safety standards.

-

Logistics: Shipping and handling costs vary greatly depending on the distance, mode of transport, and Incoterms. For international shipments, customs duties and tariffs can also impact overall costs.

-

Margin: Suppliers typically build in a profit margin that varies based on market conditions, competition, and perceived value of their products.

How Do Price Influencers Impact Plug Socket Costs?

Several factors influence the pricing of plug sockets, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts. Suppliers may set MOQs, which can affect pricing flexibility.

-

Specifications and Customization: Custom designs or specific standards (like certifications for safety or voltage compatibility) can increase costs. Buyers should consider whether customization is essential for their needs.

-

Material Quality and Certifications: Higher quality materials and certifications (like CE or UL) can drive up costs but may be necessary for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record and quality assurance.

-

Incoterms: Understanding shipping terms is critical. FOB (Free on Board) might offer different pricing structures than CIF (Cost, Insurance, and Freight), impacting the total landed cost.

What Are the Buyer Tips for Negotiating Plug Socket Prices?

B2B buyers can employ several strategies to enhance cost-efficiency when sourcing plug sockets:

-

Negotiate Bulk Discounts: Leverage order volume to negotiate better pricing. Suppliers are often willing to reduce prices for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and operational costs. Opting for higher-quality sockets may reduce long-term costs related to failures or replacements.

-

Research Market Prices: Conduct thorough market research to understand the average pricing for different types of plug sockets. This knowledge empowers buyers during negotiations.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can provide leverage in negotiations and ensure competitive pricing.

-

Stay Informed on International Pricing Nuances: Pricing can vary widely based on region. Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and trade agreements that may affect costs.

Disclaimer for Indicative Prices

Prices for plug sockets can vary significantly based on numerous factors, including location, order size, and specific requirements. It is essential for buyers to request quotes from multiple suppliers and consider the full scope of costs involved in sourcing these electrical components.

Alternatives Analysis: Comparing types of plug sockets With Other Solutions

Understanding Alternatives to Types of Plug Sockets

In the world of electrical infrastructure, various solutions exist to meet the diverse needs of international B2B buyers. While traditional plug sockets remain widely used, alternative solutions have emerged, each offering unique advantages and disadvantages. This analysis compares types of plug sockets with two viable alternatives: Universal Charging Stations and Wireless Power Transfer Systems. By examining these options, businesses can make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Types Of Plug Sockets | Universal Charging Stations | Wireless Power Transfer Systems |

|---|---|---|---|

| Performance | Reliable for various devices; limited by plug type compatibility. | Versatile; supports multiple device types with varying power requirements. | Limited range; effective only in close proximity. |

| Cost | Generally low initial cost; installation may vary based on infrastructure. | Moderate cost; initial investment can be high but may save on future adaptations. | High upfront costs for technology and installation; ongoing maintenance needed. |

| Ease of Implementation | Simple installation; widely understood and accepted. | Requires specific infrastructure; may need training for staff. | Complex installation; requires specialized equipment and training. |

| Maintenance | Low maintenance; durable and long-lasting. | Moderate maintenance; may need updates or replacements as technology evolves. | High maintenance; sensitive to environmental factors and wear. |

| Best Use Case | Ideal for fixed installations in homes and offices with standard appliances. | Best for public spaces and businesses needing to charge multiple devices simultaneously. | Suitable for environments requiring flexible power solutions without physical connections, like hospitals or labs. |

What Are the Advantages and Disadvantages of Universal Charging Stations?

Universal charging stations provide an effective solution for businesses that require a versatile charging option for various devices. These stations often support multiple charging standards, making them suitable for offices, cafes, and public areas where users have different types of devices. However, the initial investment can be considerable, and they may require specialized infrastructure. Additionally, ongoing maintenance and updates to accommodate new technology can add to the long-term costs.

How Do Wireless Power Transfer Systems Compare?

Wireless power transfer systems offer a unique approach to powering devices without physical connections. This technology is particularly advantageous in environments where traditional plug sockets may be impractical, such as in hospitals or clean rooms where minimizing physical contact is essential. However, the technology comes with high upfront costs and requires ongoing maintenance. Its limited range means that it may not be suitable for all applications, making it a more specialized solution.

Conclusion: How to Choose the Right Power Solution for Your Business

When selecting the right electrical solution, B2B buyers should consider their specific needs and operational environments. Types of plug sockets remain a dependable choice for standard residential and office applications, providing ease of use and low maintenance. In contrast, universal charging stations and wireless power transfer systems offer innovative alternatives that can enhance flexibility and convenience in high-demand scenarios. Evaluating factors such as performance, cost, and ease of implementation will help businesses make informed decisions that align with their operational goals and customer requirements.

Essential Technical Properties and Trade Terminology for types of plug sockets

What Are the Essential Technical Properties of Plug Sockets?

A stock image related to types of plug sockets.

Understanding the critical specifications of plug sockets is vital for B2B buyers involved in electrical equipment procurement. Here are some essential technical properties that should be considered:

1. Material Grade

The material used in plug sockets directly affects their durability and safety. Common materials include thermoplastics for the casing and copper for the pins. High-quality materials can withstand heat and resist corrosion, ensuring longevity in various environmental conditions. For B2B buyers, selecting sockets made from superior materials can lead to reduced replacement costs and increased reliability in operational settings.

2. Current Rating (Amperage)

The current rating, usually expressed in amps (A), indicates the maximum electrical current a socket can safely handle. Common ratings include 10A, 15A, and 16A. Choosing the correct amperage is crucial for preventing overheating and potential fire hazards. B2B buyers must assess their equipment requirements to ensure compatibility, reducing the risk of equipment failure and enhancing safety.

3. Voltage Rating

Plug sockets come with specific voltage ratings, typically ranging from 100V to 250V. For instance, sockets in Europe often operate at 220-240V, while those in North America usually function at 100-127V. Understanding voltage ratings is essential for ensuring that devices operate efficiently without risk of damage. For international buyers, this knowledge is critical for compliance with local electrical standards and regulations.

4. Pin Configuration and Grounding

The design and arrangement of the pins, including whether they are grounded or not, are crucial for compatibility with various plugs. Different regions utilize distinct pin configurations (e.g., Type C in Europe vs. Type G in the UK). Grounding enhances safety by preventing electrical shocks. Buyers should pay attention to these configurations to avoid mismatches that can lead to equipment damage or safety issues.

5. Tolerance Levels

Tolerance refers to the permissible limit of variation in the dimensions and electrical characteristics of the sockets. High tolerance levels ensure consistent performance and safety standards. For B2B transactions, it’s essential to verify that suppliers meet industry standards, which helps in maintaining quality assurance across electrical installations.

What Are Common Trade Terms Related to Plug Sockets?

Familiarity with industry jargon can facilitate smoother transactions and negotiations in the B2B space. Here are several common trade terms relevant to plug sockets:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing plug sockets, understanding OEM relationships can help buyers identify reputable suppliers who maintain high manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs to align with their purchasing needs without incurring unnecessary costs.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. This process is vital for comparing offers and ensuring competitive pricing. B2B buyers should prepare clear RFQs to facilitate accurate and timely responses from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery terms. Familiarity with these terms helps buyers understand their obligations, shipping costs, and risk levels associated with the transportation of plug sockets across borders.

5. Certification Standards

Certification standards, such as CE (Conformité Européenne) and UL (Underwriters Laboratories), indicate that products meet specific safety and quality criteria. For B2B buyers, ensuring that plug sockets have the necessary certifications is essential for compliance with local regulations and for maintaining safety in electrical installations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right plug sockets for their specific needs while maintaining safety and compliance in their operations.

Navigating Market Dynamics and Sourcing Trends in the types of plug sockets Sector

What Are the Current Market Dynamics and Key Trends in the Plug Socket Sector?

The global market for electrical plug sockets is influenced by various factors, including technological advancements, regulatory changes, and regional electricity standards. A significant driver is the increasing globalization of trade, which demands compatibility across different plug types. As businesses expand their operations internationally, the need for standardized or adaptable plug sockets has become more pronounced.

Emerging trends in the B2B sector include the rise of smart technology integration in electrical sockets, such as smart plugs that enable remote control and energy monitoring. Additionally, there is a growing preference for multifunctional outlets that combine different types of connections, enhancing convenience for users. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide products that meet local electrical standards while also offering universal compatibility.

Another notable trend is the shift towards higher safety standards and certifications, driven by increasing awareness of electrical hazards. This includes the adoption of Ground Fault Circuit Interrupter (GFCI) and Arc Fault Circuit Interrupter (AFCI) technologies, which are becoming more common in residential and commercial applications. Buyers in emerging markets should prioritize suppliers who comply with international safety regulations to ensure product reliability and consumer trust.

How Is Sustainability and Ethical Sourcing Impacting the Plug Socket Sector?

Sustainability is becoming a crucial factor in the sourcing of electrical products, including plug sockets. The environmental impact of manufacturing processes and materials used in these products is under scrutiny. Buyers are increasingly looking for suppliers who adopt sustainable practices, such as using recyclable materials and reducing waste throughout their production lines.

Moreover, ethical sourcing is essential in maintaining a responsible supply chain. This includes ensuring fair labor practices and minimizing the carbon footprint associated with transportation. Certifications like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) are becoming essential credentials for suppliers, as they indicate compliance with environmental standards.

In addition to certifications, buyers are encouraged to seek products that incorporate eco-friendly materials, such as bioplastics or sustainably sourced metals. These products not only reduce environmental impact but also cater to an increasingly eco-conscious consumer base, enhancing brand reputation and marketability.

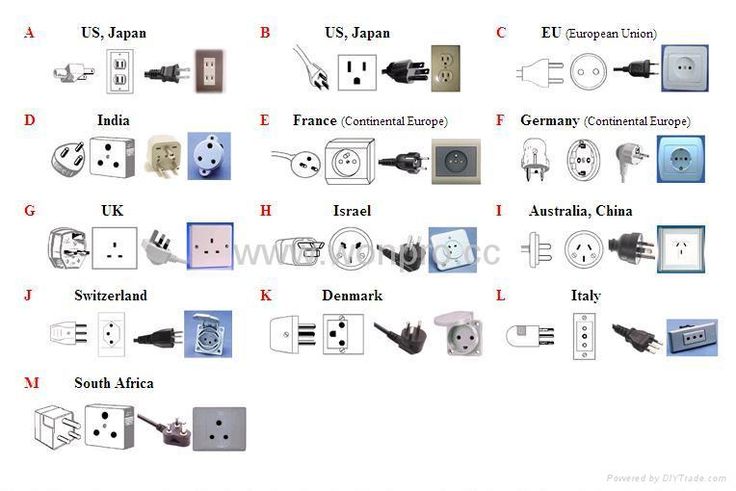

How Have Plug Socket Designs Evolved Over Time?

A stock image related to types of plug sockets.

The evolution of plug sockets reflects the advancement of electrical technology and the growing complexity of electrical systems. Initially, plug designs were simplistic, often featuring just two flat pins. However, as safety concerns increased, so did the complexity of designs. The introduction of grounding pins and the development of various socket types addressed the need for safety and compatibility with a broader range of devices.

Over the decades, the proliferation of electronic devices and international travel necessitated the standardization of plug types. This led to the creation of various socket types, each tailored to specific regional electrical standards. Today, the market offers a diverse range of options, from traditional two-pin designs to advanced smart sockets that integrate with home automation systems.

The ongoing innovation in socket design is expected to continue as the demand for energy-efficient and user-friendly solutions grows. As international B2B buyers navigate this landscape, understanding the historical context of plug socket development can provide valuable insights into current trends and future directions in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of types of plug sockets

-

How do I choose the right plug socket type for my region?

Choosing the right plug socket type depends on the specific electrical standards of your region. Each country has designated plug types, voltages, and frequencies. For international buyers, it’s crucial to refer to comprehensive guides that detail socket types by country, such as those provided by the International Electrotechnical Commission (IEC) or WorldStandards. Ensure that the products you source are compatible with local electrical systems to avoid safety hazards and equipment malfunctions. -

What is the best plug socket type for my electronic appliances?

The best plug socket type for your electronic appliances largely depends on the power requirements and the type of plugs used by your devices. For instance, if your appliances are primarily European, opt for Type C or Type F sockets, which are standard in many countries. For appliances that require grounding, consider sockets like Type E or Type G. Always check the voltage and amperage ratings to ensure compatibility and safety. -

How can I verify the reliability of a supplier for plug sockets?

To verify a supplier’s reliability for plug sockets, consider conducting thorough due diligence. Check for certifications that comply with international standards, such as ISO or CE marks. Request references from other clients and assess their delivery performance and quality assurance processes. Additionally, visiting the supplier’s facility or attending trade shows can provide firsthand insight into their operations and product quality. -

What are the minimum order quantities (MOQs) for plug sockets?

Minimum order quantities (MOQs) for plug sockets can vary significantly among suppliers based on production capabilities and inventory levels. Typically, MOQs may range from 100 to 1,000 units for standard types. It’s advisable to discuss your specific needs with potential suppliers, as they may offer flexible options for bulk orders or allow for smaller trial orders, especially for new clients. -

What payment terms should I expect when sourcing plug sockets internationally?

Payment terms for international sourcing of plug sockets usually involve upfront deposits, with the balance due upon shipment or delivery. Common terms include 30% deposit and 70% before shipment, but this can vary based on supplier policies and your negotiation strength. Using secure payment methods, such as letters of credit or escrow services, can help mitigate risks associated with international transactions. -

How can I ensure quality assurance for plug sockets sourced from abroad?

To ensure quality assurance for plug sockets sourced internationally, request detailed product specifications and certifications. Consider implementing a quality control plan that includes pre-shipment inspections conducted by a third-party agency. Establishing clear communication with your supplier regarding quality standards and conducting regular audits can also help maintain product integrity throughout the supply chain. -

What logistics considerations should I take into account when importing plug sockets?

When importing plug sockets, logistics considerations include shipping methods, customs regulations, and tariffs. Evaluate the cost and time implications of air versus sea freight based on your delivery timeline. Ensure compliance with local customs requirements and be aware of any import duties that may apply. Partnering with a reliable freight forwarder can streamline the process and mitigate potential delays. -

Can I customize plug sockets according to my specific requirements?

Many suppliers offer customization options for plug sockets, including design, color, and functionality to suit specific market needs. Discuss your requirements with potential manufacturers to explore customization possibilities. Keep in mind that custom orders may come with higher MOQs and longer lead times, so plan your sourcing strategy accordingly to align with your project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of plug sockets

As international B2B buyers navigate the diverse landscape of plug sockets, understanding the complexities of various types is crucial. Each region, from Africa to Europe and beyond, presents unique requirements influenced by local standards, voltage, and compatibility. Strategic sourcing of plug sockets not only ensures compliance with these regulations but also facilitates smoother operations and enhances customer satisfaction.

What are the key factors to consider for successful sourcing of plug sockets? Buyers should prioritize quality, durability, and safety features, such as GFCI and AFCI outlets, especially in regions prone to electrical issues. Moreover, recognizing the growing trend towards universal and multi-functional sockets can provide a competitive edge in diverse markets.

Looking ahead, the demand for reliable and innovative electrical solutions will continue to rise. By aligning sourcing strategies with emerging trends and regional needs, businesses can position themselves for success. Engage with reputable suppliers who understand the intricacies of your market and can offer tailored solutions. This proactive approach not only mitigates risks but also opens doors to new opportunities in a rapidly evolving global marketplace.