Discover the Key Benefits of 55 Gallon Drum Size (2025)

Introduction: Navigating the Global Market for 55 gallon drum size

Navigating the complexities of sourcing the right 55-gallon drum size can pose significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the various types of drums—steel, plastic, and fiber—as well as their unique applications and specifications is crucial for ensuring product integrity and compliance with international shipping standards. This guide offers a comprehensive overview that addresses key considerations such as drum dimensions, material compatibility, and the implications of open versus closed-head designs.

By delving into the specifics of each drum type, this resource empowers buyers to make informed purchasing decisions that align with their operational needs. It also covers essential topics such as supplier vetting processes, pricing strategies, and best practices for cost-effective procurement. Whether you are based in Egypt, Thailand, or Brazil, understanding the nuances of 55-gallon drums will facilitate smoother logistics, optimize storage solutions, and enhance overall supply chain efficiency. This guide serves as your essential toolkit, equipping you with actionable insights to navigate the global market with confidence.

Understanding 55 gallon drum size Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Drum | Durable, often UN-rated, tight or open head options | Chemicals, oils, food products | Pros: Strong, reusable, versatile. Cons: Heavier, may require special handling. |

| Plastic Drum | Lightweight, typically HDPE, available in various colors | Chemicals, pharmaceuticals, food | Pros: Corrosion-resistant, lighter weight. Cons: Less durable than steel, potential for permeation. |

| Fiber Drum | Made of layered kraft paper, lightweight | Powders, dry goods | Pros: Eco-friendly, lightweight. Cons: Not suitable for liquids, less durable. |

| Open-Head Drum | Removable lid, easier access to contents | Thick liquids, semi-solids | Pros: Convenient for filling and dispensing. Cons: Less secure than tight-head options. |

| Tight-Head Drum | Permanently attached top, filled through bungs | Low-viscosity liquids, hazardous materials | Pros: Secure, ideal for hazardous materials. Cons: Limited access for refilling. |

What Are the Characteristics of Steel Drums?

Steel drums are the most robust option available, often constructed from cold-rolled steel and designed for durability. They typically feature a capacity of 55 gallons and are available in both open-head and tight-head configurations. Steel drums are suitable for a wide range of applications, particularly in industries dealing with chemicals, oils, and food products. When purchasing, consider the drum’s UN rating, which indicates its suitability for transporting hazardous materials, as well as its weight, which may necessitate special handling equipment.

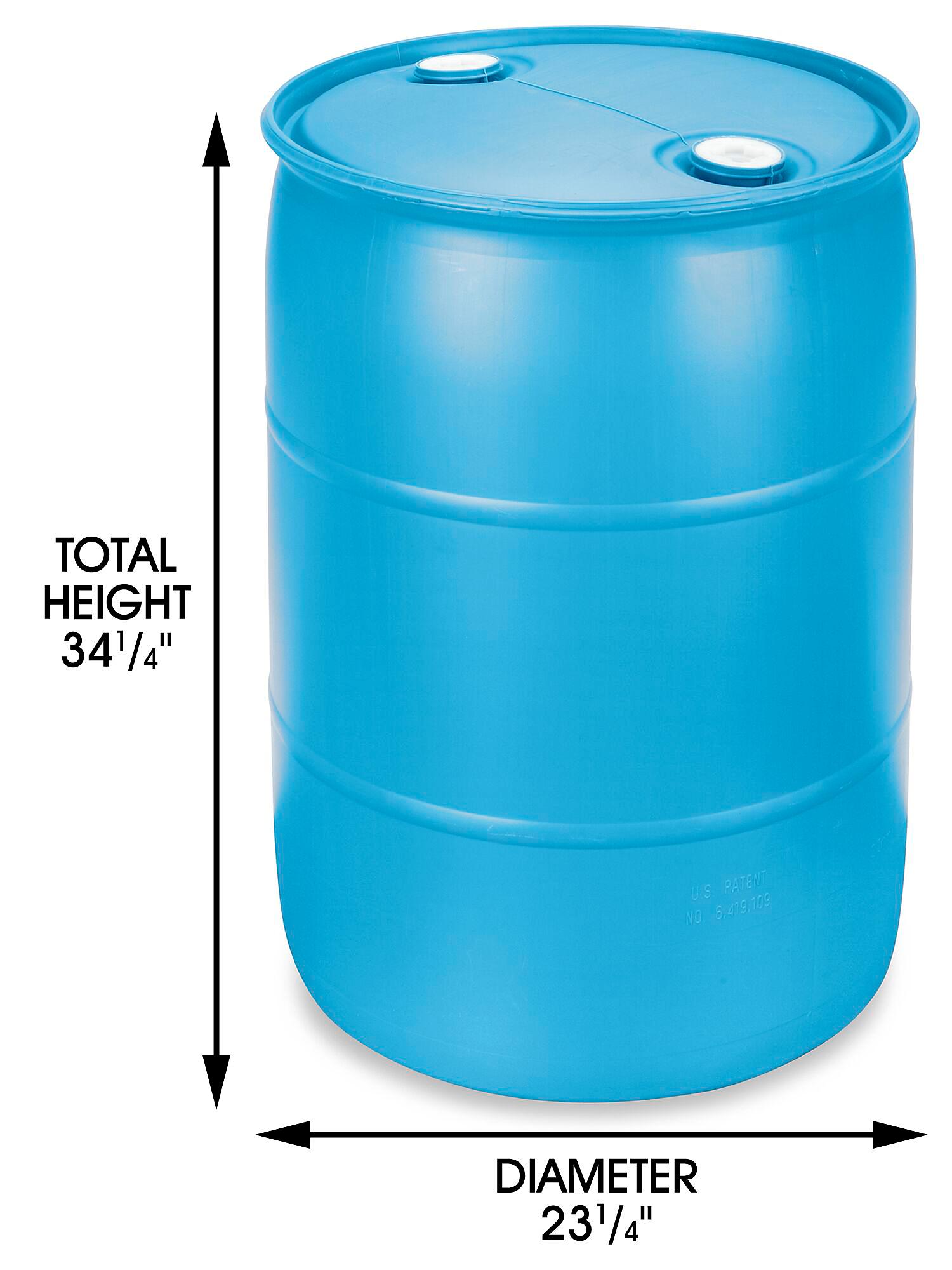

A stock image related to 55 gallon drum size.

Why Choose Plastic Drums for Your Business Needs?

Plastic drums, commonly made from high-density polyethylene (HDPE), are lightweight and resistant to corrosion, making them ideal for storing chemicals and pharmaceuticals. They come in various colors, which can indicate their compliance with food safety regulations. While they are less durable than steel drums, their lighter weight can reduce shipping costs. International buyers should ensure that the specific type of plastic drum meets their local regulatory requirements, especially for food storage.

What Are the Benefits of Fiber Drums?

Fiber drums are constructed from multiple layers of kraft paper, making them an eco-friendly alternative for packaging dry goods and powders. Their lightweight nature makes them easy to handle, and they are often used in industries such as food packaging and pharmaceuticals. However, buyers should note that fiber drums are not suitable for liquids, and their durability is lower compared to steel and plastic options. When purchasing, consider the drum’s weight capacity and whether it meets your specific storage needs.

How Do Open-Head Drums Differ from Tight-Head Drums?

Open-head drums feature a removable lid that allows for easy access to the contents, making them suitable for thick liquids and semi-solids. This design is particularly advantageous for applications that require frequent filling or dispensing. However, they may not provide the same level of security as tight-head drums, which have a permanently attached top and are filled through bungs. Buyers should assess their specific needs for accessibility versus security when deciding between these two options.

What Should You Consider When Choosing Tight-Head Drums?

Tight-head drums are designed with a permanently attached top, making them ideal for low-viscosity liquids and hazardous materials. Their design minimizes the risk of spillage and contamination, which is critical for industries handling dangerous goods. However, the limited access for refilling can be a drawback for some applications. When selecting a tight-head drum, it’s essential to consider the drum’s material compatibility with the intended contents, as well as its UN rating for safety in transportation.

Key Industrial Applications of 55 gallon drum size

| Industry/Sector | Specific Application of 55 Gallon Drum Size | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Storage and transportation of bulk chemicals | Ensures safe handling and compliance with hazardous material regulations | UN-rated drums for hazardous materials; material compatibility |

| Food and Beverage | Packaging for liquid food products and ingredients | Maintains product integrity and extends shelf life | FDA-approved materials; consideration for food safety standards |

| Oil and Gas | Transport of petroleum products and lubricants | Efficient bulk transport and storage solutions | Material durability; resistance to corrosion and temperature variations |

| Pharmaceuticals | Storage of active pharmaceutical ingredients (APIs) | Ensures product purity and compliance with health regulations | Stainless steel options; tamper-evident seals |

| Agriculture | Transport of fertilizers and pesticides | Facilitates bulk application and minimizes waste | Compatibility with chemical properties; safe handling features |

How is the 55 Gallon Drum Size Used in Chemical Manufacturing?

In the chemical manufacturing sector, 55-gallon drums are essential for the storage and transportation of bulk chemicals. These drums provide a robust and secure method for handling hazardous materials, ensuring compliance with international safety regulations. Buyers must ensure that the drums are UN-rated to meet the necessary performance standards for dangerous goods. Additionally, compatibility with the specific chemicals being stored is crucial to prevent contamination or degradation of the drum material.

What Role Do 55 Gallon Drums Play in the Food and Beverage Industry?

Within the food and beverage industry, 55-gallon drums are commonly used for packaging liquid food products, such as oils, sauces, and beverages. These drums help maintain product integrity and extend shelf life by providing a sealed environment. B2B buyers in this sector should prioritize FDA-approved materials to ensure compliance with food safety standards. Proper labeling and traceability are also important considerations for international trade, particularly in regions like Africa and South America where regulations may vary.

How Are 55 Gallon Drums Utilized in the Oil and Gas Industry?

The oil and gas industry relies heavily on 55-gallon drums for the transport of petroleum products, lubricants, and other essential fluids. These drums offer an efficient solution for bulk transport, minimizing the risk of spills and environmental hazards. Businesses must consider the durability of the drum material, as well as its resistance to corrosion and temperature variations, to ensure safe long-term storage. Sourcing from reputable manufacturers who provide detailed specifications is key to maintaining operational integrity.

What Are the Advantages of Using 55 Gallon Drums in Pharmaceuticals?

In the pharmaceutical sector, 55-gallon drums are utilized for storing active pharmaceutical ingredients (APIs) and other sensitive materials. These drums help maintain product purity and are often constructed from stainless steel to prevent contamination. International buyers must ensure that the drums include tamper-evident seals and comply with stringent health regulations. The ability to clean and reuse these drums also adds value, especially in regions where sustainability is a growing concern.

How Do 55 Gallon Drums Support Agricultural Applications?

In agriculture, 55-gallon drums are used to transport fertilizers and pesticides efficiently. They facilitate bulk application, reducing waste and ensuring that farmers have the necessary materials readily available. Buyers should consider the compatibility of the drum material with the chemicals being stored, as well as the safe handling features to protect workers. Additionally, sourcing from local suppliers in regions like the Middle East and Africa can help reduce transportation costs and improve supply chain efficiency.

3 Common User Pain Points for ’55 gallon drum size’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Type of 55-Gallon Drum

The Problem: International B2B buyers often struggle with choosing the appropriate type of 55-gallon drum for their specific applications. For instance, a company in Egypt may need to store a corrosive chemical but is unsure whether to opt for a steel, plastic, or fiber drum. The consequences of making the wrong choice can lead to hazardous spills, product contamination, and significant financial losses.

The Solution: To effectively select the right drum, buyers should start by conducting a compatibility assessment based on the material of the drum and the chemical properties of the substance to be stored. For corrosive materials, a UN-rated plastic drum made from high-density polyethylene (HDPE) is typically recommended due to its resistance to chemical degradation. Buyers should also consider the drum’s head type; closed-head drums are ideal for low-viscosity liquids while open-head drums are better for thicker substances. Consulting with suppliers who provide detailed product specifications and safety data sheets can further assist in making informed decisions. Additionally, consider sourcing from manufacturers that offer customization options, allowing for tailored solutions that meet specific regulatory and safety standards.

Scenario 2: Managing Storage and Space Constraints for 55-Gallon Drums

The Problem: In regions with limited warehouse space, such as in urban areas of South America, B2B buyers face challenges in storing 55-gallon drums efficiently. Overcrowded storage can lead to accessibility issues, increased risk of accidents, and potential damage to products.

The Solution: To optimize storage, buyers should implement a vertical storage system that utilizes shelving capable of holding multiple drums securely. Using pallets that can stack drums safely can also maximize vertical space. Moreover, buyers should consider the drum design; for instance, lightweight fiber drums can be stacked more easily than steel drums. It’s also advisable to maintain clear labeling and organization of the stored drums to ensure quick access and compliance with safety regulations. Regular inventory checks can help manage stock levels and ensure that older drums are used first, reducing the risk of product expiration.

Scenario 3: Ensuring Compliance with International Shipping Regulations for 55-Gallon Drums

The Problem: B2B buyers dealing with international shipping of 55-gallon drums often encounter confusion regarding compliance with various international regulations. For example, a company in the Middle East may face difficulties ensuring that their hazardous materials meet UN packaging standards, risking delays and potential fines.

The Solution: To navigate compliance challenges, buyers should familiarize themselves with the International Maritime Organization (IMO) and United Nations (UN) regulations pertaining to hazardous materials. Utilizing UN-rated drums is essential; these drums are designed and tested to withstand specific conditions during transport. Buyers should work closely with suppliers who have experience in international shipping and can provide guidance on the proper labeling, documentation, and packaging required for specific products. Engaging a logistics partner who specializes in hazardous materials can also streamline the shipping process and ensure compliance with local and international laws. Regular training for staff on compliance issues can further mitigate risks associated with shipping hazardous goods.

By addressing these common pain points with practical solutions, international B2B buyers can enhance their operations, reduce risks, and ensure seamless processes in handling 55-gallon drums.

Strategic Material Selection Guide for 55 gallon drum size

What Are the Key Properties of Steel 55 Gallon Drums?

Steel drums, often made from low-carbon steel or stainless steel, are renowned for their strength and durability. They typically have a temperature rating that can withstand both high and low extremes, making them suitable for a variety of applications, including hazardous materials. Their corrosion resistance varies depending on the type of steel; stainless steel drums offer superior protection against corrosive substances.

Pros and Cons of Steel Drums

Steel drums are highly durable, making them ideal for long-term storage and transport of liquids and solids. They are also recyclable, which is a significant advantage for environmentally conscious buyers. However, their higher initial cost and weight can be limiting factors, particularly for international shipping where weight can impact freight costs. Additionally, they require proper handling to avoid rusting if not maintained correctly.

Impact on Application

Steel drums are compatible with a wide range of media, including chemicals, oils, and food products when properly lined. However, they are not suitable for highly corrosive substances without a protective lining. International buyers must ensure compliance with local regulations regarding the transport of hazardous materials.

How Do Plastic 55 Gallon Drums Compare in Performance?

Plastic drums, typically made from high-density polyethylene (HDPE), are lightweight and resistant to many chemicals. They have a lower temperature rating than steel drums but are suitable for a range of applications, particularly in the food and beverage industries. Their resistance to UV light makes them ideal for outdoor storage.

Pros and Cons of Plastic Drums

The primary advantage of plastic drums is their cost-effectiveness and lightweight nature, making them easy to handle and transport. They are also resistant to corrosion and do not rust. However, they are less durable than steel drums and can be vulnerable to punctures or impacts. Additionally, their compatibility with certain chemicals must be carefully considered, as some solvents can degrade the plastic.

Impact on Application

Plastic drums are well-suited for storing liquids, chemicals, and food products, but they are not recommended for high-temperature applications. International buyers should check for compliance with food safety standards, especially in regions like Europe and South America.

What Are the Benefits of Fiber 55 Gallon Drums?

Fiber drums, constructed from layers of kraft paper and adhesive, offer a lightweight alternative for dry goods. They are typically used for non-hazardous materials and have a lower temperature rating than metal drums.

Pros and Cons of Fiber Drums

Fiber drums are cost-effective and environmentally friendly, as they are made from renewable resources and are recyclable. They are lightweight, which can reduce shipping costs. However, they are not suitable for liquids or hazardous materials and can be less durable than metal options, particularly in humid environments.

Impact on Application

These drums are ideal for storing powders, granules, and other dry products. International buyers should be aware of local regulations regarding packaging materials and ensure that fiber drums meet specific standards for their intended use.

Summary of Considerations for International B2B Buyers

When selecting the appropriate drum material, international buyers must consider factors such as compliance with local and international standards (e.g., ASTM, DIN, JIS), the nature of the products being stored or transported, and the specific environmental conditions of their regions. Understanding these aspects will help ensure that the selected drum material meets both operational and regulatory requirements.

| Material | Typical Use Case for 55 gallon drum size | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Transporting hazardous liquids and chemicals | High durability and strength | Heavier and more expensive | High |

| Plastic | Storing food products and chemicals | Lightweight and cost-effective | Less durable and temperature-sensitive | Medium |

| Fiber | Packaging dry goods like powders and granules | Environmentally friendly and lightweight | Not suitable for liquids or hazardous materials | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon drum size

What Are the Main Stages of Manufacturing 55 Gallon Drums?

Manufacturing 55-gallon drums involves several key stages, each critical to ensuring the final product meets the durability and safety standards required for international shipping and storage. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for 55 Gallon Drum Production?

The first step in the manufacturing process is material preparation. For steel drums, this involves sourcing high-quality cold-rolled or stainless steel sheets. These sheets are inspected for defects and then cut to precise dimensions based on the specific drum design. For plastic drums, high-density polyethylene (HDPE) is the material of choice, which is also subjected to quality checks before being processed. Fiber drums, made from layered kraft paper, undergo a similar inspection and preparation phase to ensure consistency and strength.

What Forming Techniques Are Used in 55 Gallon Drum Production?

Once the materials are prepared, the forming process begins. Steel sheets are formed into cylindrical shapes through a process called roll forming, where they are passed through rollers that gradually shape them into a drum. The ends are then welded on, creating a seamless structure. In the case of plastic drums, blow molding is employed, where molten plastic is expanded within a mold to create the desired shape. Fiber drums are constructed by rolling layers of paper into a cylinder and securing the ends with adhesives or mechanical fasteners.

What Assembly Processes Are Involved in Creating 55 Gallon Drums?

The assembly stage involves attaching various components to the formed drum. For open-head drums, a removable lid is affixed with a locking ring, while closed-head drums have fixed tops with bungs for filling and dispensing. During this stage, quality checks are crucial to ensure that all components fit securely and function correctly. Any defects can lead to leaks or product contamination, which could pose significant risks in international trade.

How Does Finishing Enhance the Quality of 55 Gallon Drums?

The finishing stage includes painting and lining the drums, which not only improves aesthetics but also protects the drum from corrosion and chemical damage. Steel drums may receive a protective coating, while plastic drums are often molded in specific colors for identification and safety purposes. For drums intended for hazardous materials, additional linings or coatings may be applied to ensure compatibility with the contained substances.

What International Standards Are Relevant for Quality Assurance in Drum Manufacturing?

Quality assurance in the manufacturing of 55-gallon drums is governed by various international standards, with ISO 9001 being one of the most recognized. This standard outlines the requirements for a quality management system, ensuring that manufacturers maintain consistent quality in their processes and products. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications further validate the quality and safety of the drums.

What Are the Key Quality Control Checkpoints During Drum Manufacturing?

Quality control (QC) is integral to the manufacturing process, typically divided into three main checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to ensure that each stage meets quality standards. This may include checking weld integrity, dimensions, and assembly correctness.

-

Final Quality Control (FQC): Once the drums are fully assembled and finished, a final inspection is performed. This includes testing for leaks, structural integrity, and compliance with relevant standards before the drums are packaged for shipping.

What Testing Methods Are Commonly Used to Ensure Drum Quality?

Various testing methods are employed to validate the quality of 55-gallon drums. These include:

- Hydrostatic Testing: Drums are filled with water to a specific pressure to check for leaks and structural integrity.

- Drop Testing: This assesses the drum’s ability to withstand impacts and ensures it can protect its contents during transport.

- Chemical Compatibility Testing: Especially important for drums intended for hazardous materials, this ensures that the drum material does not react adversely with the contents.

How Can B2B Buyers Verify Supplier Quality Control Processes?

International B2B buyers should conduct thorough due diligence when selecting drum suppliers. Here are some actionable steps to verify supplier quality control processes:

-

Request Certification Documents: Ensure the manufacturer has relevant certifications (e.g., ISO 9001, CE, API) and ask for copies of these documents.

-

Conduct Supplier Audits: Arrange on-site audits to assess the manufacturing facility and quality control processes. This provides firsthand insight into their operational standards.

-

Review Quality Control Reports: Ask suppliers for their QC reports, which should detail testing results and any corrective actions taken in case of failures.

-

Engage Third-Party Inspectors: Consider hiring third-party inspection services to perform independent quality checks before shipment, ensuring the drums meet required specifications and standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing 55-gallon drums from manufacturers in different regions (e.g., Africa, South America, the Middle East, and Europe), B2B buyers should be aware of the following nuances:

-

Regulatory Variations: Different countries may have varying regulations regarding materials and safety standards. Ensure that the supplier complies with both local and international regulations.

-

Cultural Considerations: Understanding the local business culture can help in negotiating terms and establishing trust with suppliers.

-

Logistical Challenges: Consider the logistical aspects of importing drums, including customs regulations, shipping costs, and potential delays. It’s advisable to work with suppliers who have experience in exporting to your region.

A stock image related to 55 gallon drum size.

By understanding the manufacturing processes and quality assurance measures involved in producing 55-gallon drums, international B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality and safety standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gallon drum size’

To successfully procure 55-gallon drums, international B2B buyers must navigate various considerations, from selecting the right material to ensuring compliance with regulations. This step-by-step checklist serves as a practical guide to streamline your sourcing process, ensuring that you make informed decisions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the appropriate 55-gallon drum. Consider the material—steel, plastic, or fiber—and whether you need an open-head or closed-head design. Each type has unique applications; for instance, steel drums are ideal for hazardous materials, while plastic drums are suitable for chemicals.

- Material Compatibility: Ensure the drum material is compatible with the contents you plan to store or transport.

- Head Type: Determine if you need easy access (open-head) or sealed storage (closed-head) based on your product’s viscosity.

Step 2: Understand Regulatory Compliance

Familiarize yourself with the regulations governing the transportation and storage of your products, especially if they are classified as hazardous. Compliance with local and international standards, such as UN ratings, is non-negotiable.

- UN Ratings: Check if the drum is UN-rated for hazardous materials, which indicates that it meets strict safety standards.

- Regional Regulations: Be aware of specific regulations in your target markets (e.g., Africa, South America, Middle East, Europe) that may affect drum specifications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is essential to conduct thorough evaluations. Request company profiles, certifications, and references from other buyers in similar industries or regions to assess their reliability.

- Supplier Reputation: Look for suppliers with a proven track record in delivering quality products.

- Customer Feedback: Investigate online reviews or seek testimonials from previous customers to gauge satisfaction levels.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples will help you verify the drum’s quality and suitability for your specific requirements.

- Quality Checks: Assess the drum’s integrity, such as its ability to withstand pressure and environmental conditions.

- Compatibility Testing: Ensure the drum can safely store or transport your intended products without leakage or degradation.

Step 5: Negotiate Pricing and Terms

Once you have narrowed down your supplier options, engage in negotiations to secure favorable pricing and terms. Discuss bulk discounts, shipping costs, and payment terms.

- Cost Analysis: Compare quotes from multiple suppliers to ensure competitive pricing.

- Terms of Sale: Clarify return policies and warranty conditions to protect your investment.

Step 6: Plan for Logistics and Storage

Consider the logistics involved in transporting and storing your drums. Planning ahead can save costs and mitigate risks associated with delays or damages.

- Transportation Requirements: Evaluate the transportation methods available and their costs based on your location and target market.

- Storage Solutions: Ensure you have adequate storage space that complies with safety regulations, especially for hazardous materials.

Step 7: Monitor and Evaluate Performance

After procurement, continuously monitor the performance of the drums in use. Collect feedback from your team and assess if the drums meet your operational needs.

- Performance Metrics: Track the durability and reliability of the drums under various conditions.

- Supplier Performance: Evaluate your supplier’s responsiveness and service quality for future procurement decisions.

By following this checklist, B2B buyers can ensure a systematic approach to sourcing 55-gallon drums that meet their specific needs while adhering to regulatory requirements and maintaining high quality.

Comprehensive Cost and Pricing Analysis for 55 gallon drum size Sourcing

What Are the Key Cost Components for Sourcing 55 Gallon Drums?

When sourcing 55-gallon drums, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of material—steel, plastic, or fiber—directly impacts the cost. Steel drums tend to be more expensive due to the raw material costs and the process of cold-rolled steel manufacturing. Plastic drums may be cheaper but can vary based on the type of plastic used (HDPE, PVC).

-

Labor: Labor costs encompass the workforce required for manufacturing, quality control, and packaging. Regions with higher labor costs, such as parts of Europe, may see increased prices compared to those in Africa or South America.

-

Manufacturing Overhead: This includes utilities, rent, and depreciation of equipment. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer competitive pricing.

-

Tooling: The initial costs for molds and machines used in drum production can be significant. For custom or specialized drums, these costs can be amortized over larger production runs, impacting the pricing for lower volume orders.

-

Quality Control (QC): Ensuring that drums meet international standards (like UN ratings for hazardous materials) can add to costs. Quality certifications may also be a requirement for certain buyers, influencing the overall price.

-

Logistics: Transportation costs vary significantly based on the origin and destination, especially for international shipping. Factors such as fuel prices, shipping methods, and Incoterms can affect logistics costs.

-

Margin: Suppliers will incorporate a profit margin into the pricing. Understanding the typical margins in different regions can help buyers negotiate better deals.

How Do Price Influencers Affect 55 Gallon Drum Sourcing?

Several factors can influence the pricing of 55-gallon drums:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often come with discounts. Buyers should evaluate their needs to optimize order sizes.

-

Specifications and Customization: Custom features (like specific coatings or fittings) can increase costs. Buyers should assess whether these enhancements are necessary for their applications.

-

Material Quality and Certifications: Drums that meet higher quality standards or have specific certifications (e.g., food-grade, UN-rated) will typically command higher prices.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can influence price. Established suppliers may charge more but offer better quality assurance and customer support.

-

Incoterms: Understanding the shipping terms can help buyers manage costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost.

What Are the Best Tips for Buyers to Optimize Costs?

-

Negotiation Strategies: Leverage volume purchases and long-term contracts to negotiate better pricing. Establishing strong relationships with suppliers can also lead to favorable terms.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also the operational costs associated with the drums, such as disposal, transportation, and potential reconditioning.

-

Understand Pricing Nuances for International Buyers: Factors like currency fluctuations, import tariffs, and local regulations can affect overall costs. Buyers should conduct thorough market research to understand these variables.

-

Explore Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local manufacturers can reduce shipping costs and lead times.

-

Evaluate Reusability Options: Consider investing in high-quality drums that can be reused multiple times. While the upfront cost may be higher, the long-term savings can be substantial.

Conclusion: What Should Buyers Keep in Mind?

When sourcing 55-gallon drums, international buyers must navigate a complex landscape of costs and pricing factors. Understanding the cost structure, being aware of pricing influencers, and employing strategic negotiation techniques can lead to more favorable outcomes. Prices can vary widely based on the aforementioned factors, so it is advisable to obtain multiple quotes and conduct thorough due diligence. Keep in mind that prices are indicative and can fluctuate based on market conditions, material costs, and supplier capabilities.

Alternatives Analysis: Comparing 55 gallon drum size With Other Solutions

Understanding Alternatives to 55 Gallon Drum Size for B2B Buyers

In the quest for efficient and effective storage and transport solutions, B2B buyers often seek alternatives to the traditional 55-gallon drum. While the 55-gallon drum remains a popular choice due to its durability and versatility, various other solutions exist that may better suit specific operational needs. This section compares the 55-gallon drum against two viable alternatives: Intermediate Bulk Containers (IBCs) and Bulk Bags (FIBC).

Comparison Table of Storage Solutions

| Comparison Aspect | 55 Gallon Drum Size | Intermediate Bulk Container (IBC) | Bulk Bag (FIBC) |

|---|---|---|---|

| Performance | Durable, versatile for liquids and solids | High capacity, suitable for various liquids | Lightweight, ideal for dry bulk materials |

| Cost | Moderate initial cost, reusable | Higher initial investment, reusable | Lower cost, disposable or reusable |

| Ease of Implementation | Simple to handle, requires minimal equipment | Requires forklift for handling | Easily handled, no special equipment needed |

| Maintenance | Low maintenance, easy to clean | Requires maintenance for seals and valves | Minimal maintenance, depends on contents |

| Best Use Case | Chemicals, oils, and other bulk liquids | Large volume liquid storage, hazardous materials | Granular materials, powders, and bulk solids |

Detailed Breakdown of Alternatives

What are Intermediate Bulk Containers (IBCs) and How Do They Compare?

Intermediate Bulk Containers (IBCs) typically hold between 275 to 330 gallons, making them larger than a standard 55-gallon drum. They are often made of plastic with a steel frame and are designed for bulk liquid transport. The main advantage of IBCs is their higher capacity, which reduces the number of trips needed for transport. However, they require forklifts for handling, which may not be feasible for all businesses, especially smaller operations. The initial investment is typically higher than that of a 55-gallon drum, but their reusable nature can offset costs over time.

Why Choose Bulk Bags (FIBC) for Your Operations?

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, are lightweight and designed for transporting dry bulk materials. They come in various sizes, often holding up to 2,000 pounds or more, and are easy to handle without special equipment. Bulk bags are typically less expensive than both 55-gallon drums and IBCs, making them a cost-effective option for many businesses. However, they are not suitable for liquids and may not provide the same level of protection against contamination as drums or IBCs. Their disposability can also be a disadvantage in terms of environmental impact.

How to Choose the Right Solution for Your Needs

When selecting the appropriate storage or transport solution, B2B buyers should consider several factors, including the type of materials to be stored, the required capacity, handling capabilities, and budget constraints. The 55-gallon drum is an excellent choice for businesses dealing with liquids and hazardous materials due to its durability and ease of use. However, if larger volumes are needed, IBCs may be more suitable despite their higher cost and handling requirements. Conversely, if the focus is on transporting dry bulk materials, bulk bags provide a lightweight and economical solution. Ultimately, understanding the specific needs and operational constraints will guide buyers in making the most effective choice for their storage and transport challenges.

Essential Technical Properties and Trade Terminology for 55 gallon drum size

What Are the Key Technical Properties of 55 Gallon Drums?

Understanding the technical specifications of 55-gallon drums is crucial for international B2B buyers, particularly when considering safety, compliance, and operational efficiency. Below are some critical specifications you should be aware of:

1. Material Grade

The most common materials for 55-gallon drums are steel, plastic (HDPE), and fiberboard. Steel drums are often made from low-carbon or stainless steel, providing superior strength and durability, essential for transporting hazardous materials. Plastic drums, typically made from high-density polyethylene (HDPE), are lighter and resistant to corrosion, making them ideal for chemicals. Choosing the right material is vital for ensuring the integrity of the contents and compliance with local regulations.

2. Dimensions and Tolerance

Standard dimensions for a 55-gallon steel drum generally include a height of 33 to 36.75 inches and a diameter of 22.375 to 24.5 inches. Understanding these tolerances is important for storage and shipping considerations. If drums are too large or too small, it can affect stacking efficiency and transportation costs. Accurate measurements also ensure compatibility with existing storage systems and equipment.

3. Weight Capacity

A filled 55-gallon drum can weigh approximately 500 pounds, depending on the density of the contents. Knowing the weight capacity is essential for logistical planning and transportation. Buyers should ensure that their handling equipment can accommodate the weight, especially in regions where manual handling is more common.

4. Closure Type

Drums can come in two primary closure types: open-head and tight-head. Open-head drums have removable lids, making them suitable for viscous materials, while tight-head drums are sealed and ideal for low-viscosity liquids. This distinction impacts how products are filled, stored, and accessed, which is crucial for operational efficiency.

5. UN Rating

UN ratings are crucial for buyers dealing with hazardous materials. These ratings indicate that the drum meets specific performance standards set by the United Nations for transporting dangerous goods. Ensuring compliance with UN regulations is not only a legal requirement but also enhances safety during transport and storage.

What Are Common Trade Terms Related to 55 Gallon Drums?

Familiarity with trade terminology can significantly streamline the purchasing process and enhance communication with suppliers. Here are some essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

In the context of 55-gallon drums, an OEM refers to the company that manufactures the drums based on specific designs or specifications. Understanding the OEM relationship can help buyers ensure they are receiving high-quality products that meet their standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For 55-gallon drums, MOQs can vary significantly between suppliers and can impact purchasing decisions, particularly for small to medium-sized businesses. Knowing the MOQ helps buyers plan their inventory and budget accordingly.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to potential suppliers to request pricing and terms for a specific quantity of goods. This is particularly useful when sourcing 55-gallon drums, as it allows buyers to compare prices and terms from different suppliers before making a decision.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is critical for international transactions involving 55-gallon drums, as they dictate who bears the cost and risk during transport.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For 55-gallon drums, lead times can vary based on the supplier’s location, manufacturing capabilities, and shipping methods. Knowing the lead time is essential for effective inventory management and planning.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and ensure compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the 55 gallon drum size Sector

What Are the Current Market Dynamics in the 55 Gallon Drum Sector?

A stock image related to 55 gallon drum size.

The market for 55-gallon drums is influenced by a variety of global drivers including the increasing demand for bulk storage solutions across industries such as chemicals, food and beverage, and pharmaceuticals. In regions like Africa, South America, the Middle East, and Europe, the rise in manufacturing activities and cross-border trade is propelling the need for robust and versatile packaging solutions. Emerging technologies in the B2B space, including automation in manufacturing and smart inventory management systems, are reshaping sourcing trends. Companies are increasingly seeking suppliers who can provide just-in-time delivery and customized solutions to enhance operational efficiency.

Furthermore, there is a noticeable shift towards the use of eco-friendly materials and designs, driven by regulatory pressures and consumer demand for sustainable practices. International B2B buyers are advised to monitor the evolving landscape of compliance standards, particularly those pertaining to hazardous materials and UN ratings, which ensure safe transportation and storage. The integration of digital platforms for procurement is also becoming commonplace, facilitating easier access to suppliers and enhancing transparency in the sourcing process.

How Is Sustainability Shaping Sourcing Trends in the 55 Gallon Drum Market?

Sustainability is increasingly becoming a cornerstone of sourcing strategies in the 55-gallon drum sector. The environmental impact of packaging materials is under scrutiny, and businesses are prioritizing ethical sourcing practices. Buyers from Africa, South America, the Middle East, and Europe should consider suppliers that offer environmentally friendly options, such as drums made from recycled materials or those that meet specific ‘green’ certifications.

The importance of ethical supply chains cannot be overstated. Companies that adopt sustainable practices not only comply with regulations but also enhance their brand reputation among environmentally conscious consumers. Additionally, utilizing reusable and recyclable drum options can significantly reduce waste and lower overall costs. Buyers should look for suppliers that provide detailed information on their sustainability practices and certifications, such as ISO 14001 for environmental management, to ensure that they are partnering with responsible manufacturers.

How Has the 55 Gallon Drum Evolved Over Time?

The 55-gallon drum, originally designed for transporting oil in the early 1900s, has undergone significant evolution to meet the changing needs of various industries. The introduction of steel drums marked a turning point, providing a durable and reusable alternative to wooden barrels. Over the decades, manufacturers have diversified drum materials to include plastic and fiber, catering to a wide range of applications from hazardous materials to food products.

The design of the drum has also evolved, with innovations such as open-head and closed-head configurations allowing for more versatile use cases. Today, the 55-gallon drum remains a critical component in global supply chains, symbolizing efficiency and reliability in bulk storage and transportation. Understanding this evolution can help international B2B buyers make informed decisions when selecting the right drum type for their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon drum size

-

How do I determine the right type of 55-gallon drum for my product?

Selecting the appropriate 55-gallon drum type depends on the nature of your product. For liquids, choose between tight-head drums, which have a permanently attached lid and are ideal for low-viscosity substances, and open-head drums, suitable for thicker liquids or solids. Consider the drum material as well; steel drums are robust and suitable for hazardous materials, while plastic drums are lightweight and resistant to corrosion. Always verify compatibility with your product to ensure safety and compliance with international shipping regulations. -

What is the best material for a 55-gallon drum based on my shipping needs?

The best material for your 55-gallon drum depends on the contents being shipped. Steel drums offer durability and are suitable for hazardous materials, while plastic drums are ideal for corrosive substances. Fiber drums are lightweight and often used for dry goods. When choosing, consider factors like weight restrictions during shipping, the potential for corrosion, and whether the drum will be reused or recycled, as these aspects influence both cost and compliance with international regulations. -

What are the common dimensions of a 55-gallon drum?

A standard 55-gallon drum typically measures between 33 to 36.75 inches in height and 22.375 to 24.5 inches in diameter. Steel drums usually fall within the range of 33 to 34.75 inches in height. It’s crucial to confirm these dimensions with suppliers, especially for logistics and storage planning. Variations exist based on drum type (open or closed head) and material, so always ensure that the specific measurements meet your operational requirements. -

What should I consider when sourcing 55-gallon drums internationally?

When sourcing 55-gallon drums from international suppliers, consider factors such as compliance with local and international safety standards, shipping logistics, and customs regulations. Research the supplier’s reputation, production capabilities, and quality assurance processes. Additionally, evaluate their ability to provide documentation for hazardous materials if applicable. Establish clear communication regarding lead times, payment terms, and minimum order quantities (MOQs) to avoid potential delays or misunderstandings. -

What are the typical payment terms for purchasing 55-gallon drums?

Payment terms for purchasing 55-gallon drums can vary significantly between suppliers and regions. Common arrangements include payment in advance, net 30 or net 60 terms, or a letter of credit for larger orders. It’s essential to negotiate terms that align with your cash flow and risk management strategies. Always clarify the implications of each payment method, including potential discounts for early payment or penalties for late payments, to ensure a smooth transaction process. -

How can I verify the quality of 55-gallon drums from potential suppliers?

To verify the quality of 55-gallon drums, request samples for testing before placing a bulk order. Evaluate the drums for structural integrity, compatibility with your products, and compliance with UN ratings for hazardous materials. Additionally, ask for certifications and quality assurance documentation from the supplier. Conducting site visits or audits, if feasible, can also provide insights into their manufacturing processes and quality control measures, ensuring you are sourcing from a reliable supplier. -

What is the minimum order quantity (MOQ) for 55-gallon drums, and how does it affect my purchasing decision?

The minimum order quantity (MOQ) for 55-gallon drums typically ranges from 50 to 500 units, depending on the supplier and drum type. Understanding the MOQ is crucial as it impacts your initial investment and inventory management. If your needs are smaller, look for suppliers who offer flexible MOQs or consider collaborating with other businesses to meet the minimum requirement. Always factor in storage capabilities and potential demand fluctuations when making your decision. -

What logistics considerations should I keep in mind when shipping 55-gallon drums internationally?

When shipping 55-gallon drums internationally, consider factors such as packaging, weight distribution, and compliance with international shipping regulations. Ensure that drums are securely packaged to prevent leaks or damage during transit. Familiarize yourself with the import/export regulations in both the sending and receiving countries, particularly if shipping hazardous materials. Collaborate with logistics providers experienced in handling industrial products to streamline the shipping process and avoid unexpected delays or costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 55 gallon drum size

What Are the Key Takeaways for International B2B Buyers Regarding 55 Gallon Drums?

In summary, the strategic sourcing of 55-gallon drums offers several advantages for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. The versatility of these drums—available in steel, plastic, and fiber—accommodates a wide range of products, making them an ideal choice for various industries. Understanding the differences between open-head and closed-head configurations is crucial for selecting the right drum for your specific needs, whether for liquids, powders, or solids.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing not only streamlines procurement processes but also ensures compliance with international shipping standards. By investing in high-quality, UN-rated drums, businesses can protect their products and enhance safety in transport. Moreover, leveraging local suppliers can reduce shipping costs and lead times, creating a more resilient supply chain.

What Is the Future Outlook for 55 Gallon Drum Sourcing?

As global trade continues to evolve, the demand for 55-gallon drums is expected to grow, driven by industries such as chemicals, food and beverage, and pharmaceuticals. International B2B buyers should stay informed about market trends and innovations in drum materials and designs to remain competitive. Embrace the opportunity to optimize your sourcing strategies and ensure that you are equipped to meet the demands of the future. Engaging with reliable suppliers and considering sustainable options will not only contribute to operational efficiency but also align with global sustainability goals.