Discover the Key Types of Electrical Outlets for Your Needs (2025)

Introduction: Navigating the Global Market for types of electrical outlets

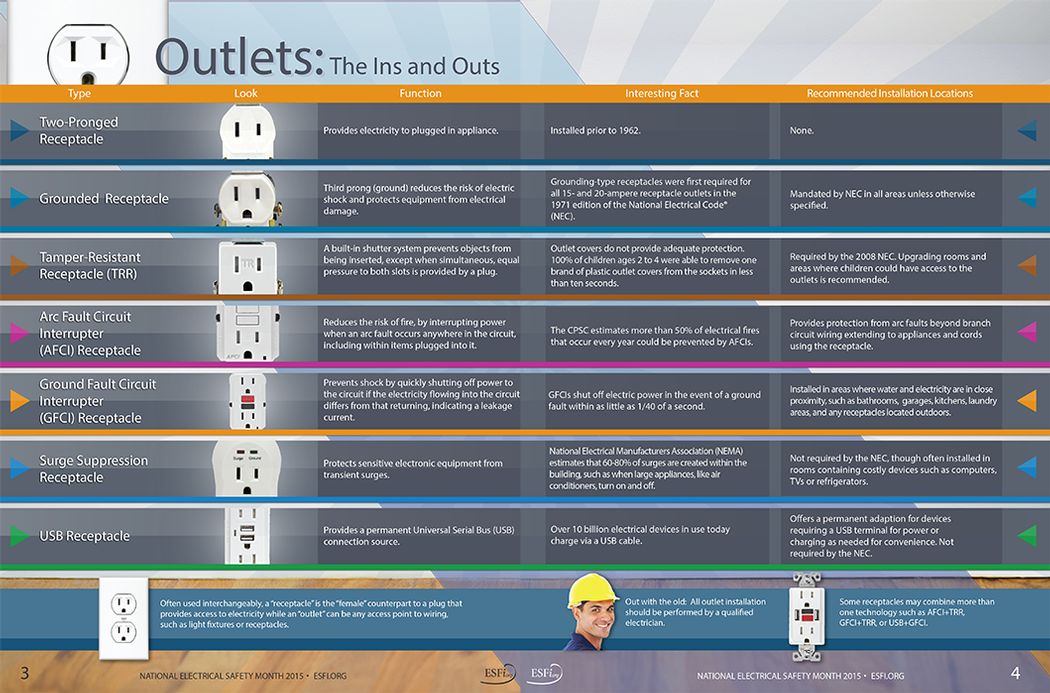

In the global marketplace, sourcing the right types of electrical outlets can present a significant challenge for international B2B buyers. With a myriad of options available, understanding the differences in specifications, safety standards, and compatibility is crucial to ensuring operational efficiency and safety. This comprehensive guide delves into the various types of electrical outlets, including 15-amp duplex receptacles, GFCI, AFCI, and specialty outlets, providing clarity on their applications and installation requirements.

Moreover, the guide offers actionable insights into supplier vetting processes, cost considerations, and compliance with local regulations—essential factors for businesses operating in diverse markets across Africa, South America, the Middle East, and Europe, including countries like Poland and Nigeria. By equipping buyers with the knowledge to make informed purchasing decisions, this resource not only enhances procurement strategies but also mitigates risks associated with electrical installations.

As you navigate the complexities of sourcing electrical outlets, this guide stands as a vital tool, empowering you to choose the right products that align with your operational needs and safety standards. Whether you’re upgrading existing infrastructure or launching new projects, understanding the nuances of electrical outlets is key to successful and compliant operations in your market.

Understanding types of electrical outlets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

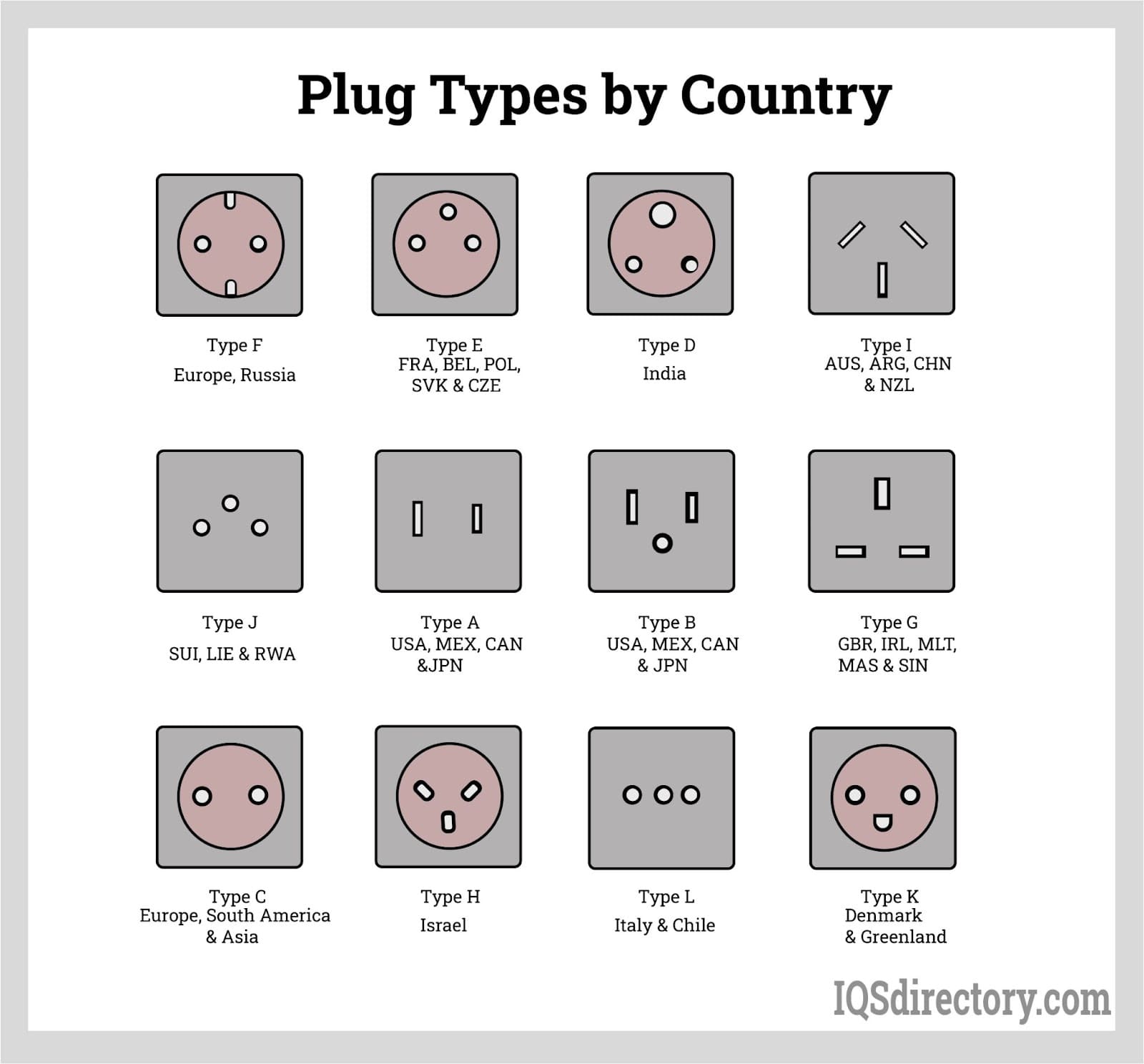

| 15-Amp Duplex Receptacle Outlet | Standard design with two outlets, accepts standard plugs, rated for 15 amps. | Small appliances, lamps, and electronics in offices. | Pros: Widely available and compatible with most devices. Cons: Limited to lower power appliances. |

| GFCI Outlets | Ground Fault Circuit Interrupter that shuts off power when it detects imbalance. | Bathrooms, kitchens, and outdoor areas in commercial spaces. | Pros: Enhances safety in wet areas. Cons: May require periodic testing and resetting. |

| AFCI Outlets | Arc Fault Circuit Interrupter designed to prevent electrical fires by detecting arcing. | Residential and commercial spaces, especially in living areas. | Pros: Provides fire prevention. Cons: More expensive than standard outlets. |

| Weather-Resistant Outlets | Designed for outdoor use, protects against moisture and UV rays. | Patios, outdoor installations, and construction sites. | Pros: Durable and safe for external use. Cons: Installation may require additional weatherproofing. |

| Smart Outlets | Can be controlled via mobile devices, allowing for remote management and scheduling. | Modern office buildings and smart homes. | Pros: Offers convenience and energy management. Cons: Higher initial investment and requires Wi-Fi. |

What Are the Characteristics and Suitability of 15-Amp Duplex Receptacle Outlets?

The 15-amp duplex receptacle outlet is the most common type of outlet found in residential and commercial settings. It is designed to accommodate standard plugs, making it suitable for powering small appliances, lamps, and electronics commonly used in offices. When purchasing, buyers should consider the overall electrical load in their facility, ensuring that the total amperage does not exceed the outlet’s capacity. Its widespread availability and compatibility with numerous devices make it an ideal choice for general use.

How Do GFCI Outlets Enhance Safety in B2B Environments?

GFCI outlets are vital for preventing electrical shocks in areas where moisture is present, such as bathrooms, kitchens, and outdoor spaces. These outlets continuously monitor the flow of electricity and automatically cut off power if they detect an imbalance, thus enhancing safety in commercial environments. When selecting GFCI outlets, businesses should evaluate the specific locations where they will be installed, ensuring compliance with local electrical codes. Regular testing and maintenance are essential to ensure continued functionality.

Why Are AFCI Outlets Important for Fire Prevention?

Arc Fault Circuit Interrupter (AFCI) outlets are specifically designed to detect potentially dangerous arcing conditions that could lead to electrical fires. This makes them particularly important in residential and commercial spaces, including living rooms and bedrooms. B2B buyers should consider the installation of AFCI outlets in high-risk areas to enhance fire safety. While they are more expensive than standard outlets, the investment can significantly reduce the risk of fire hazards, making them a prudent choice for responsible businesses.

What Are the Benefits of Using Weather-Resistant Outlets?

Weather-resistant outlets are engineered to withstand outdoor conditions, protecting against moisture and UV damage. These outlets are ideal for patios, construction sites, and any area exposed to the elements. When purchasing weather-resistant outlets, businesses should ensure they meet national safety standards for outdoor use. While these outlets may require additional installation considerations, their durability and safety features make them essential for outdoor electrical applications.

How Do Smart Outlets Contribute to Energy Management in B2B Settings?

Smart outlets provide advanced features that allow users to control them remotely via mobile devices. This capability enables businesses to manage energy usage effectively, scheduling devices to turn on or off as needed. Smart outlets are becoming increasingly popular in modern office buildings and smart homes. B2B buyers should consider the initial investment and ensure reliable Wi-Fi connectivity for optimal performance. The long-term energy savings and convenience often outweigh the upfront costs, making smart outlets a valuable addition to any facility.

Key Industrial Applications of types of electrical outlets

| Industry/Sector | Specific Application of types of electrical outlets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial machinery power supply | Ensures reliable operation of machinery | Voltage ratings, weather resistance, and durability |

| Hospitality | Guest room electrical systems | Enhances guest comfort and convenience | Compatibility with multiple plug types and safety features |

| Healthcare | Medical equipment connectivity | Supports critical care and patient safety | GFCI and AFCI outlets for safety, compliance with regulations |

| Construction & Real Estate | Temporary power solutions for sites | Facilitates construction work efficiency | Robustness, ease of installation, and weather resistance |

| Retail & Commercial | Point-of-sale systems and charging stations | Improves customer experience and service | USB outlets for convenience, high amperage ratings for devices |

How Are Types of Electrical Outlets Used in Manufacturing?

In the manufacturing sector, types of electrical outlets are crucial for powering industrial machinery. Reliable outlets such as 20-amp receptacles are necessary to handle the high electrical demands of heavy equipment. International B2B buyers must consider voltage ratings and the durability of outlets, especially in regions with fluctuating power supply. Weather-resistant outlets are essential for outdoor machinery, minimizing downtime due to electrical issues.

What Role Do Electrical Outlets Play in Hospitality?

In the hospitality industry, electrical outlets enhance guest comfort by providing access to power for personal devices. Hotels typically use a combination of standard 15-amp duplex outlets and USB charging ports in guest rooms to accommodate various electronics. B2B buyers must ensure compatibility with international plug types and consider tamper-resistant options for safety, especially in family-friendly accommodations. This attention to detail can significantly enhance the guest experience.

Why Are Electrical Outlets Critical in Healthcare Settings?

In healthcare facilities, the reliability of electrical outlets is paramount for medical equipment connectivity. GFCI and AFCI outlets are commonly used to protect sensitive devices and ensure patient safety in areas where water exposure is possible, such as operating rooms and patient rooms. B2B buyers in this sector should prioritize compliance with healthcare regulations and seek outlets that can withstand frequent use while maintaining safety standards.

How Are Electrical Outlets Utilized in Construction and Real Estate?

Temporary power solutions using electrical outlets are vital in construction and real estate development. Sites often require multiple outlets for tools and equipment, and the use of robust, weather-resistant outlets can ensure consistent power supply in various environmental conditions. Buyers should focus on the ease of installation and durability, as outlets must withstand the rigors of a construction site while remaining functional for various applications.

What Benefits Do Electrical Outlets Provide in Retail and Commercial Spaces?

In retail and commercial environments, electrical outlets are essential for point-of-sale systems and charging stations. The integration of USB outlets allows customers to charge devices while shopping, enhancing their overall experience. B2B buyers should look for outlets with high amperage ratings to support multiple devices simultaneously, ensuring that the retail environment remains efficient and customer-friendly.

3 Common User Pain Points for ‘types of electrical outlets’ & Their Solutions

Scenario 1: Compatibility Issues with Local Electrical Standards

The Problem: Many international B2B buyers encounter challenges when sourcing electrical outlets compatible with local standards. For instance, a construction firm in Nigeria may import appliances designed for European specifications, only to find that the electrical outlets in their facilities do not accommodate these plugs. This results in delays, increased costs, and potentially unsafe practices as teams attempt to create makeshift solutions.

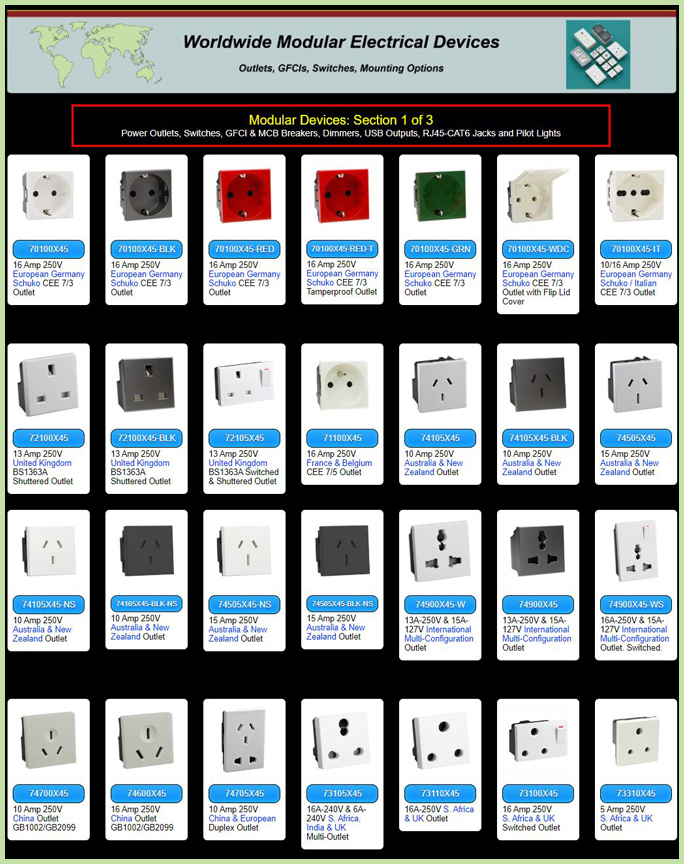

The Solution: To mitigate compatibility issues, B2B buyers should conduct thorough research on the electrical standards of the countries where they operate. This includes understanding the types of plugs and sockets prevalent in those regions, such as Type D in India or Type C in much of Europe. Buyers can collaborate with local electrical supply distributors to source the correct outlet types that comply with local regulations. Additionally, consider investing in universal or combination outlets that can accommodate multiple plug types, thereby reducing the need for adapters and enhancing safety and efficiency on-site.

Scenario 2: Safety Concerns with Electrical Installations

The Problem: Safety is a paramount concern for B2B buyers, particularly in industries like construction and manufacturing. A company in South America might face challenges with the installation of standard outlets, leading to electrical hazards such as short circuits or fires, especially in environments where equipment is frequently used. If the selected outlets do not meet safety codes, it can lead to significant liability issues.

The Solution: B2B buyers should prioritize the selection of outlets that enhance safety features, such as Ground Fault Circuit Interrupter (GFCI) and Arc Fault Circuit Interrupter (AFCI) outlets. These types are specifically designed to prevent electrical shocks and reduce fire risks. Buyers should ensure that their electrical installations are performed by certified electricians who are familiar with local safety codes. Furthermore, conducting regular safety audits and training sessions for staff on the proper use and maintenance of electrical outlets can significantly reduce the risk of accidents.

Scenario 3: Insufficient Power Supply for High-Demand Equipment

The Problem: As businesses scale, their power requirements often exceed the capabilities of standard 15-amp outlets. For example, a manufacturing facility in Poland may experience frequent outages or tripped breakers when using standard outlets to power heavy machinery. This not only disrupts operations but can also lead to costly downtime and equipment damage.

The Solution: To address insufficient power supply, B2B buyers should evaluate their equipment’s power requirements and invest in appropriate outlets, such as 20-amp receptacles or dedicated circuits. It is crucial to work with electrical engineers to design a tailored electrical system that can handle the load without risk of overload. Buyers should also consider installing rotating or smart outlets that can accommodate multiple plugs and devices efficiently, allowing for flexibility in power usage. Investing in surge protectors for sensitive equipment can further protect against power spikes, ensuring the longevity and reliability of machinery.

Strategic Material Selection Guide for types of electrical outlets

What Are the Key Materials Used in Electrical Outlets?

When selecting electrical outlets for various applications, the choice of material is crucial for ensuring performance, safety, and compliance with local regulations. Here, we analyze four common materials used in the manufacturing of electrical outlets: thermoplastic, metal, ceramic, and rubber. Each material has its own unique properties, advantages, and limitations that can significantly impact the end product’s suitability for specific applications.

A stock image related to types of electrical outlets.

How Does Thermoplastic Perform in Electrical Outlet Applications?

Thermoplastic is a widely used material in electrical outlet production, known for its excellent insulation properties and durability. It typically has a high-temperature rating, often exceeding 100°C, making it suitable for a variety of environments.

Pros: Thermoplastic is lightweight, cost-effective, and easy to mold, allowing for intricate designs and features like tamper-resistance. Its corrosion resistance makes it ideal for residential and light commercial applications.

Cons: While thermoplastic is durable, it may not withstand extreme temperatures as well as other materials, which can limit its use in high-heat environments.

Impact on Application: Thermoplastic outlets are generally compatible with standard electrical systems and are often used in residential settings.

Considerations for International Buyers: Compliance with international standards such as IEC and ASTM is essential. Buyers in regions like Africa and South America should ensure that the materials used meet local electrical codes.

What Are the Advantages of Metal in Electrical Outlets?

Metal, particularly steel or aluminum, is often utilized for its strength and durability. Metal outlets typically have a high-temperature rating and excellent conductivity.

Pros: Metal outlets are robust and can withstand harsh environmental conditions. They are also less prone to damage from impacts compared to plastic alternatives.

Cons: The cost of metal outlets is generally higher, and they may require additional insulation to prevent electrical shocks. Manufacturing complexity is also greater due to the need for metalworking processes.

Impact on Application: Metal outlets are often used in industrial or commercial settings where durability is paramount. They are suitable for high-load applications but need to be properly insulated.

Considerations for International Buyers: Buyers should be aware of corrosion resistance standards, especially in humid regions like the Middle East. Compliance with local standards, such as DIN for European buyers, is crucial.

Why Choose Ceramic for Electrical Outlets?

Ceramic materials are less common but are valued for their excellent heat resistance and insulating properties. They can typically withstand temperatures above 200°C.

Pros: Ceramic outlets are highly resistant to heat and fire, making them ideal for high-temperature applications. They also provide excellent electrical insulation.

Cons: The brittleness of ceramic can lead to breakage during installation or use. Additionally, they are heavier and more expensive than other materials.

Impact on Application: Ceramic outlets are often used in specialized applications, such as laboratories or industrial settings, where heat resistance is critical.

Considerations for International Buyers: Buyers in Europe and Africa should ensure that ceramic outlets meet stringent safety standards, as the material may not be as widely accepted in all regions.

How Does Rubber Enhance Electrical Outlet Functionality?

Rubber is primarily used in weather-resistant electrical outlets, especially for outdoor applications. It has excellent insulation properties and can withstand moisture and UV exposure.

Pros: Rubber outlets are highly resistant to moisture and can prevent electrical shock in wet conditions. They are also flexible and durable.

Cons: Rubber can degrade over time when exposed to extreme temperatures or UV light, which may limit its lifespan.

Impact on Application: Rubber outlets are ideal for outdoor use and in environments where moisture is a concern, such as patios or near swimming pools.

Considerations for International Buyers: Compliance with international weather-resistance standards is vital for buyers in regions with extreme weather conditions, such as parts of Africa and South America.

Summary Table of Material Selection for Electrical Outlets

| Material | Typical Use Case for types of electrical outlets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Residential and light commercial applications | Lightweight and cost-effective | Limited high-temperature resistance | Low |

| Metal | Industrial and commercial settings | High durability and strength | Higher cost and complex manufacturing | High |

| Ceramic | Specialized applications (labs, industrial) | Excellent heat resistance | Brittle and heavy | Medium |

| Rubber | Outdoor and weather-resistant applications | Moisture and UV resistance | Degrades over time | Medium |

This guide provides valuable insights for international B2B buyers to make informed decisions when selecting electrical outlets based on material properties, application suitability, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of electrical outlets

What Are the Key Stages in the Manufacturing Process of Electrical Outlets?

The manufacturing of electrical outlets involves several key stages that ensure the final product meets safety standards and functional requirements. Understanding these stages can help B2B buyers make informed decisions about their suppliers.

-

Material Preparation: The first step in manufacturing electrical outlets is the preparation of raw materials. Common materials include thermoplastics for the housing, copper for the conductors, and various metals for contacts. Suppliers typically source these materials from certified vendors, and it is critical for buyers to verify the quality and origin of these materials. Quality raw materials play a significant role in the durability and safety of the outlets.

-

Forming and Molding: After material preparation, the next stage is forming and molding. Thermoplastic materials are heated and injected into molds to create the outlet’s housing. This process often employs techniques such as injection molding, which allows for precision and efficiency. The choice of molding technique can affect the outlet’s structural integrity and overall performance.

-

Assembly: Once the individual components are formed, they are assembled. This involves fitting the electrical contacts, wiring, and safety features like GFCI mechanisms into the molded housings. Automated assembly lines are commonly used to enhance speed and reduce human error. For B2B buyers, understanding the assembly process can provide insights into the efficiency and scalability of a supplier’s operations.

-

Finishing: The final manufacturing stage is finishing, which includes the application of protective coatings and final inspections. This stage ensures that the outlets can withstand environmental factors such as moisture and UV exposure, particularly for outdoor or weather-resistant models. It is essential for buyers to inquire about the finishing processes used by suppliers, as these can significantly impact product longevity.

How Is Quality Assurance Implemented During Electrical Outlet Manufacturing?

Quality assurance (QA) is critical in the manufacturing of electrical outlets to ensure safety and compliance with international standards. Understanding the QA process can help B2B buyers assess potential suppliers effectively.

-

Relevant International Standards: Compliance with international standards such as ISO 9001 is essential for manufacturers of electrical outlets. ISO 9001 outlines requirements for a quality management system, helping organizations ensure consistent quality in their products. Additionally, certifications like CE (Conformité Européenne) and UL (Underwriters Laboratories) indicate that products meet specific safety and performance standards required in various markets.

-

Quality Control Checkpoints: The QA process typically involves several checkpoints:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components for defects before they enter the production line.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are conducted to monitor for defects and ensure adherence to specifications.

– Final Quality Control (FQC): After assembly, finished products undergo rigorous testing to confirm they meet safety and performance standards before they are shipped. -

Common Testing Methods: Various testing methods are employed to ensure the reliability and safety of electrical outlets. These may include:

– Electrical Tests: Verifying insulation resistance, continuity, and dielectric strength to prevent electrical hazards.

– Mechanical Tests: Assessing the durability and structural integrity of the outlets under stress.

– Environmental Tests: Evaluating the performance of outlets in extreme conditions, such as high humidity or temperature fluctuations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

A stock image related to types of electrical outlets.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is paramount. Here are actionable steps to ensure supplier reliability:

-

Conduct Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. B2B buyers should consider both scheduled and surprise audits to get a comprehensive view of supplier operations.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports that outline their QA processes, including results from IQC, IPQC, and FQC. These reports should also highlight compliance with relevant international standards.

-

Utilize Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These organizations can conduct independent assessments of manufacturing facilities and products to ensure compliance with industry standards.

-

Understand QC/Cert Nuances for Different Markets: Different regions may have specific certification requirements. For example, European markets may require CE marking, while other regions may adhere to different standards. B2B buyers must familiarize themselves with these nuances to ensure compliance and market acceptance.

What Are the Common Challenges in Quality Assurance for Electrical Outlets?

While manufacturers strive for quality, several challenges can arise in the QA process. Understanding these challenges can help B2B buyers anticipate potential issues:

-

Material Variability: Sourcing raw materials from different suppliers can lead to variability in quality. Manufacturers must maintain stringent checks to ensure consistency.

-

Technological Advancements: As electrical technology evolves, manufacturers must keep pace with new safety features and standards. This requires ongoing training and investment in new equipment.

-

Regulatory Changes: Compliance with changing regulations can be challenging. Manufacturers must stay informed about new laws and standards affecting electrical outlets in different markets.

Conclusion

Understanding the manufacturing processes and quality assurance measures for electrical outlets is essential for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming, assembly, and finishing stages, as well as rigorous QA practices, buyers can make informed decisions that enhance their product offerings and ensure compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of electrical outlets’

Introduction

Navigating the procurement of electrical outlets for your business can be complex, especially given the diversity of types and specifications required for different applications. This guide provides a practical checklist to help international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—make informed decisions when sourcing electrical outlets. By following these steps, you can ensure that you select the right products that meet safety standards and operational needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to determine the specific types of electrical outlets required for your operations. Consider the voltage, amperage, and design that aligns with your equipment and infrastructure.

- Voltage Requirements: Ensure the outlets match the voltage used in your region (e.g., 230V in Europe vs. 120V in the U.S.).

- Amperage Ratings: Identify whether you need standard 15-amp outlets or higher-rated 20-amp options for heavy machinery.

Step 2: Research Compliance and Safety Standards

Understanding local and international safety standards is crucial for electrical products. Electrical outlets must comply with specific regulations to ensure safety and reliability.

- Certification Verification: Look for outlets that have certifications from recognized bodies (e.g., CE in Europe, UL in the U.S.) to guarantee they meet safety standards.

- Regulatory Requirements: Familiarize yourself with local electrical codes that may dictate outlet types and installation practices.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, conduct a thorough evaluation. This step is vital to ensure reliability and quality in your procurement process.

- Request Documentation: Ask for company profiles, case studies, and references from buyers in similar industries or regions.

- Supplier Experience: Look for suppliers with a proven track record in your target market, particularly in providing the specific types of outlets you need.

Step 4: Assess Product Variety and Availability

Different projects may require various types of electrical outlets, including GFCI, AFCI, and USB outlets. Ensure your supplier can provide a comprehensive range.

- Product Range: Check if the supplier offers multiple outlet types and configurations to meet your diverse needs.

- Stock Levels: Verify the supplier’s inventory to ensure they can fulfill orders promptly, reducing potential delays in your projects.

Step 5: Consider Pricing and Payment Terms

Pricing can significantly impact your budget, so it’s essential to compare costs across different suppliers while also considering the total value offered.

- Transparent Pricing: Request detailed quotes that outline unit prices, shipping costs, and any additional fees.

- Flexible Payment Terms: Look for suppliers that offer favorable payment terms, which can help manage cash flow effectively.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, negotiation is key to securing the best deal. This can include pricing, delivery schedules, and warranty terms.

- Delivery Schedules: Discuss lead times to ensure that the supplier can meet your project deadlines.

- Warranty and Returns: Clarify warranty conditions and return policies in case the products do not meet your specifications.

Step 7: Plan for Post-Purchase Support

Finally, ensure that your supplier provides ongoing support after the purchase. This is essential for addressing any issues that may arise during installation or use.

- Technical Assistance: Confirm that the supplier offers technical support for installation and troubleshooting.

- Training Resources: Inquire if they provide training materials or sessions for your team to ensure proper usage and maintenance of the outlets.

By following these steps, you can streamline your sourcing process and make informed decisions that will benefit your business in the long run.

Comprehensive Cost and Pricing Analysis for types of electrical outlets Sourcing

What Are the Key Cost Components in Electrical Outlet Manufacturing?

Understanding the cost structure of electrical outlets is essential for B2B buyers, especially when sourcing from international suppliers. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include plastics for housings, copper for wiring, and various metals for contacts. High-quality materials that meet international safety standards can raise costs but are crucial for reliability and longevity.

-

Labor: Labor costs vary by region, with countries in Africa and South America often experiencing lower labor costs compared to Europe. However, skilled labor for quality assurance and technical assembly may command higher wages, influencing overall pricing.

-

Manufacturing Overhead: This includes costs associated with the factory operation, such as utilities, equipment maintenance, and depreciation. Efficient manufacturing processes can help minimize these costs, benefiting buyers.

-

Tooling: The initial investment in tooling for specific outlet designs or customizations can be substantial. Depending on the complexity, these costs can be amortized over larger production runs, making bulk orders more economical.

-

Quality Control (QC): Ensuring compliance with safety regulations and quality standards is non-negotiable. The costs associated with testing and certification can vary significantly based on the outlet type and market requirements.

-

Logistics: Shipping costs, including freight, tariffs, and insurance, are critical, especially for international buyers. These costs can be mitigated by choosing suppliers closer to the destination market or negotiating favorable shipping terms.

-

Margin: Suppliers will include a profit margin, which can vary widely based on market conditions, competition, and negotiation skills.

How Do Price Influencers Affect the Cost of Electrical Outlets?

When sourcing electrical outlets, several price influencers come into play:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. However, buyers must balance stock levels with demand to avoid excess inventory.

-

Specifications and Customization: Custom designs, such as smart outlets or tamper-resistant options, will increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Outlets that comply with international safety standards (e.g., CE, UL) will generally cost more but provide peace of mind regarding quality and safety.

-

Supplier Factors: Established suppliers with a good reputation may charge higher prices due to perceived reliability. Conducting thorough supplier assessments can help identify the best balance between cost and quality.

-

Incoterms: Understanding the terms of shipping and delivery can significantly influence overall costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, which can affect pricing negotiations.

What Tips Can International Buyers Use for Cost Efficiency?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for cost-effective sourcing:

-

Negotiate Wisely: Leverage volume purchases to negotiate better pricing. Establishing long-term relationships with suppliers can also lead to favorable terms and discounts.

-

Evaluate Total Cost of Ownership (TCO): When assessing pricing, consider not just the initial purchase price but also installation, maintenance, and potential downtime costs. Higher upfront costs for quality outlets can lead to savings over time.

-

Understand Pricing Nuances: Be aware of seasonal pricing trends and market fluctuations that could impact costs. For example, sourcing during off-peak seasons may yield better pricing due to reduced demand.

-

Conduct Market Research: Familiarize yourself with local market conditions and competitor pricing. This knowledge can strengthen your negotiating position and help you identify the best suppliers.

-

Consider Local Suppliers: Sourcing from local manufacturers may reduce logistics costs and lead times. Additionally, local suppliers may better understand regional compliance standards.

Disclaimer

Prices for electrical outlets can fluctuate based on market conditions, supplier negotiations, and other factors. It’s advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing types of electrical outlets With Other Solutions

A stock image related to types of electrical outlets.

Understanding Alternative Solutions to Electrical Outlets

In the realm of electrical power distribution, traditional electrical outlets are commonly used to connect appliances and devices. However, there are various alternative solutions that can provide similar functionality, each with its own set of advantages and disadvantages. This analysis aims to compare different types of electrical outlets with other viable solutions, helping B2B buyers make informed decisions based on their specific needs.

Comparison Table of Electrical Outlets and Alternatives

| Comparison Aspect | Types Of Electrical Outlets | Wireless Charging Solutions | Smart Power Strips |

|---|---|---|---|

| Performance | Reliable for consistent power supply; suitable for high-demand appliances | Limited by device compatibility; slower charging for larger devices | Allows multiple devices to be powered and controlled; can manage power consumption |

| Cost | Generally low-cost; installation may vary based on wiring | Higher initial investment for compatible devices | Moderate cost; may require additional investment for smart features |

| Ease of Implementation | Requires electrical installation and compliance with local codes | Minimal installation; plug-and-play for compatible devices | Easy to set up; requires Wi-Fi for smart features |

| Maintenance | Low maintenance; infrequent replacement | Low maintenance; depends on device longevity | Moderate; software updates may be needed for smart features |

| Best Use Case | Best for permanent installations in homes and commercial spaces | Ideal for mobile devices in casual settings | Suitable for homes and offices needing flexible power management |

Exploring Alternative Solutions in Detail

What Are the Advantages and Disadvantages of Wireless Charging Solutions?

Wireless charging solutions eliminate the need for physical plugs, allowing devices to charge simply by being placed on a charging pad. This technology is particularly advantageous for mobile devices, promoting convenience and reducing wear on charging ports. However, it may not be suitable for larger appliances, as the charging speed is generally slower compared to traditional outlets. Additionally, compatibility is a concern, as not all devices support wireless charging.

How Do Smart Power Strips Enhance Power Management?

Smart power strips provide a modern twist on traditional outlets by allowing users to control multiple devices through a single unit. They often come with features like surge protection, timers, and energy monitoring, making them ideal for both home and office environments. While they offer significant flexibility and energy savings, smart power strips may require a higher upfront investment and depend on a stable Wi-Fi connection for full functionality.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between types of electrical outlets and alternative solutions like wireless charging or smart power strips, B2B buyers should consider their specific use cases, budget constraints, and the types of devices they intend to power. Traditional electrical outlets are reliable for high-demand applications, while alternatives may offer flexibility and convenience in different scenarios. By evaluating the performance, cost, ease of implementation, and maintenance of each option, buyers can make informed decisions that best suit their operational needs and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for types of electrical outlets

What Are the Key Technical Properties of Electrical Outlets?

Understanding the technical properties of electrical outlets is essential for B2B buyers, particularly when sourcing products for diverse markets like Africa, South America, the Middle East, and Europe. Here are some critical specifications to consider:

1. Amperage Rating

The amperage rating indicates the maximum electrical current an outlet can handle without overheating. Common ratings include 15-amp and 20-amp outlets. For B2B buyers, choosing the correct amperage is vital to ensure safety and compliance with local electrical codes. Misjudging the amperage can lead to equipment failure or fire hazards, particularly in regions with different electrical standards.

2. Voltage Compatibility

Electrical outlets are designed for specific voltage levels, commonly 120V or 230V, depending on the region. Understanding voltage compatibility is crucial for international buyers to ensure that appliances and tools operate efficiently without damage. This knowledge can prevent costly mistakes and enhance customer satisfaction by ensuring products meet local requirements.

3. Material Composition

The materials used in the manufacturing of electrical outlets, such as thermoplastics or metals, affect durability and safety. High-quality materials can withstand environmental factors like moisture or UV exposure, which is particularly important in outdoor applications. B2B buyers should prioritize suppliers that adhere to international standards to guarantee product longevity and reliability.

4. Grounding Mechanism

Proper grounding is critical for preventing electrical shocks and ensuring the safety of electrical installations. Outlets can feature different grounding methods, such as a grounding hole or integrated ground wires. Buyers must understand the grounding requirements specific to their market to ensure compliance and safety standards are met.

5. Tamper Resistance

Tamper-resistant outlets are designed with safety features to prevent accidental electrical shocks, particularly in environments with children. These outlets include built-in shutters that only open when a plug is inserted. For B2B buyers, offering tamper-resistant options can be a significant selling point, especially in residential and commercial sectors focused on safety.

6. Weather Resistance

Weather-resistant outlets are constructed to withstand outdoor conditions, such as rain or humidity. They often feature protective covers and corrosion-resistant materials. For B2B buyers operating in regions with extreme weather, investing in weather-resistant outlets can reduce warranty claims and enhance customer trust in the product’s durability.

What Are Common Trade Terms in the Electrical Outlet Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better prices for bulk purchases.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it affects budgeting and inventory management. Knowing the MOQ helps in planning purchases to avoid excess stock or missed opportunities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process is vital for buyers to compare costs and ensure they are getting the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms helps B2B buyers manage shipping costs, delivery timelines, and risk during transit, which is especially important when dealing with international suppliers.

5. Certification Standards

Certification standards refer to the compliance of electrical products with safety and performance regulations. Familiarity with relevant standards (like IEC, UL, or CE) ensures that buyers source safe and reliable products that meet regional compliance.

By understanding these technical properties and industry terms, international B2B buyers can make informed purchasing decisions that enhance safety, compliance, and customer satisfaction in their respective markets.

Navigating Market Dynamics and Sourcing Trends in the types of electrical outlets Sector

What Are the Current Market Dynamics and Key Trends in the Electrical Outlet Sector?

The global electrical outlet market is evolving rapidly, driven by increasing urbanization, technological advancements, and a growing emphasis on safety and efficiency. In regions like Africa, South America, the Middle East, and Europe, B2B buyers are witnessing a surge in demand for diverse electrical outlet types, including Ground Fault Circuit Interrupter (GFCI) and Arc Fault Circuit Interrupter (AFCI) outlets, due to heightened safety regulations. Emerging markets are also increasingly adopting smart technology, with smart outlets that can be controlled remotely becoming a sought-after feature.

Sourcing trends indicate a growing preference for products that integrate sustainability and energy efficiency. For instance, weather-resistant outlets are gaining traction in outdoor applications in humid climates, while tamper-resistant outlets are essential for child safety in residential projects. Additionally, the proliferation of USB outlets reflects the shift towards accommodating modern electronic devices, which further enhances their appeal in both residential and commercial settings.

Furthermore, the rise of e-commerce platforms is reshaping the way international buyers procure electrical outlets. This trend facilitates easier access to various suppliers and manufacturers, enabling B2B buyers to compare products and prices effectively. As competition intensifies, suppliers are increasingly focusing on innovative designs and features that cater to the specific needs of different markets, making it essential for international buyers to stay informed about the latest developments in the sector.

How Is Sustainability and Ethical Sourcing Impacting the Electrical Outlet Market?

Sustainability and ethical sourcing are now critical considerations for B2B buyers in the electrical outlet sector. The environmental impact of manufacturing processes has prompted companies to seek suppliers that prioritize eco-friendly materials and sustainable practices. This includes sourcing materials that are recyclable or made from recycled components, which not only reduces waste but also appeals to environmentally conscious consumers.

Certification schemes, such as ENERGY STAR and other green certifications, are gaining importance among buyers looking to ensure that the products they source meet specific environmental standards. These certifications can help businesses demonstrate their commitment to sustainability, which is increasingly becoming a competitive differentiator in the market.

Moreover, the focus on ethical supply chains is essential to mitigate risks associated with labor practices and environmental degradation. B2B buyers are encouraged to partner with manufacturers that adhere to strict labor laws and environmental regulations. This not only enhances brand reputation but also fosters customer loyalty in a market where consumers are increasingly aware of the social and environmental implications of their purchases.

What Is the Brief History and Evolution of Electrical Outlets?

The history of electrical outlets dates back to the late 19th century when the first electrical systems were developed. Initially, electrical connections were rudimentary and often unsafe, leading to the need for standardized outlet designs. The introduction of the first two-prong plug in the early 20th century marked a significant advancement in electrical safety.

As electrical appliances became more prevalent, the design and functionality of outlets evolved. The 15-amp and 20-amp outlets commonly used today were established to meet the growing demand for safe and efficient power supply. Over the decades, innovations such as GFCI and AFCI outlets were introduced to enhance safety, especially in areas prone to moisture and fire hazards.

In recent years, the rise of smart technology has further transformed the electrical outlet landscape. Smart outlets, which allow for remote control and monitoring, reflect the increasing integration of technology into everyday life. This evolution underscores the ongoing need for B2B buyers to remain vigilant about industry trends and advancements as they source electrical outlets for their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of types of electrical outlets

-

1. How do I choose the right electrical outlet for my specific application?

Choosing the right electrical outlet depends on the amperage and voltage requirements of your devices. For standard appliances, a 15-amp duplex outlet is commonly used, while larger appliances may require a 20-amp outlet. Ensure that the outlet type matches the circuit specifications and is suitable for the environment, such as using GFCI outlets in wet areas or weather-resistant outlets for outdoor use. Always consult local electrical codes and standards to ensure compliance and safety. -

2. What are the most common types of electrical outlets available in international markets?

International markets feature various outlet types, including Type A, B, C, D, E, F, and G, each designed for specific voltage and plug configurations. For example, Type C is widely used in Europe and parts of Asia, while Type N is common in Brazil. B2B buyers should identify the specific requirements for their target markets to ensure compatibility with local electrical systems and avoid supply chain disruptions. -

3. How can I ensure the quality of electrical outlets before purchasing?

To ensure quality, prioritize suppliers with established reputations and certifications, such as ISO or IEC standards. Request product samples and technical specifications to evaluate materials and performance. Additionally, consider third-party quality assurance inspections and product testing reports to verify compliance with international safety standards. Building relationships with reliable manufacturers can further enhance confidence in product quality. -

4. What are the typical minimum order quantities (MOQs) for electrical outlets?

Minimum order quantities can vary significantly depending on the supplier and the type of outlet. Generally, MOQs range from 500 to 5,000 units for standard products. For customized or specialty outlets, MOQs may be higher due to production costs. It’s essential to communicate with suppliers to negotiate terms that align with your purchasing strategy and market demands. -

5. What payment terms should I expect when sourcing electrical outlets internationally?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, letters of credit, or 30-60 day payment terms post-delivery. It is advisable to negotiate terms that minimize risk, especially for large orders. Consider using escrow services or trade financing options to protect your investment, particularly when dealing with new suppliers or high-value transactions. -

6. How do I handle logistics for importing electrical outlets from overseas?

When importing electrical outlets, collaborate with a reliable logistics partner to manage shipping and customs clearance. Understand the specific regulations and tariffs applicable in your country, as they can affect overall costs. Ensure that your shipping documentation is complete and accurate to avoid delays. Additionally, consider the lead time for production and shipping to align with your inventory needs. -

7. What certifications should electrical outlets have for international trade?

For international trade, electrical outlets should possess certifications relevant to safety and performance, such as CE marking in Europe, UL listing in the United States, and IEC standards for global compliance. These certifications assure buyers that the products meet specific safety and quality requirements. Always verify the validity of certifications with the supplier before making a purchase. -

8. Can I customize electrical outlets to meet my specific requirements?

Yes, many manufacturers offer customization options for electrical outlets, including design, color, and functionality. Customization may involve additional costs and longer lead times, so it’s essential to discuss your requirements upfront. Providing detailed specifications and understanding the manufacturer’s capabilities will help ensure that the final product aligns with your business needs and market preferences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of electrical outlets

What are the Key B2B Takeaways for Sourcing Electrical Outlets?

In the dynamic landscape of electrical outlets, strategic sourcing is essential for international B2B buyers. Understanding the diverse types of outlets—such as GFCI, AFCI, tamper-resistant, and weather-resistant—enables buyers to align product choices with safety standards and operational needs. Each outlet type serves a specific purpose, whether it’s ensuring safety in wet environments or accommodating modern technology like USB charging.

How Can Strategic Sourcing Impact Your Business?

By prioritizing strategic sourcing, businesses can enhance their supply chain efficiency, reduce costs, and ensure compliance with local regulations. This approach not only fosters better supplier relationships but also ensures access to high-quality products that meet diverse market demands across regions, including Africa, South America, the Middle East, and Europe.

What’s Next for International B2B Buyers?

As the market continues to evolve, international buyers must stay informed about emerging trends in electrical outlets and smart technologies. Engage with suppliers who demonstrate innovation and flexibility to meet the unique demands of your local market. Now is the time to leverage these insights and invest in strategic sourcing initiatives that will position your business for success in the global marketplace.