Discover the Titanium Boiling Point: Essential Insights (2025)

Introduction: Navigating the Global Market for titanium boiling point

In today’s competitive landscape, international B2B buyers face significant challenges when sourcing titanium, especially when considering its boiling point of 3,287 °C (5,949 °F) and its implications for various applications. Understanding titanium’s properties, including its thermal characteristics, is crucial for industries ranging from aerospace to medical devices. This guide will delve into the intricacies of titanium, focusing on its boiling point, its relevance in high-temperature applications, and the vital role it plays in structural integrity and performance.

Throughout this comprehensive resource, we will explore various aspects of titanium, including its types, applications, and supplier vetting processes. We will also provide insights into cost factors and market trends that can significantly impact procurement decisions. For international buyers, particularly from Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Argentina, having a thorough understanding of these elements is essential for making informed purchasing decisions.

By leveraging the insights offered in this guide, B2B buyers will be better equipped to navigate the complexities of the global titanium market. From sourcing strategies to evaluating supplier reliability, our actionable insights aim to empower your procurement process, ensuring you select the right titanium products for your business needs.

Understanding titanium boiling point Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercially Pure Titanium | High purity with minimal impurities; boiling point 3,287 °C | Aerospace, automotive, medical devices | Pros: Excellent corrosion resistance; Cons: Higher cost due to purity. |

| Titanium Alloys | Combines titanium with other metals; boiling point varies | Military, marine, industrial equipment | Pros: Enhanced strength and ductility; Cons: Alloy composition can complicate sourcing. |

| Titanium Dioxide (TiO2) | Non-metallic form; boiling point varies based on application | Pigments, coatings, pharmaceuticals | Pros: Versatile applications; Cons: Not suitable for structural applications. |

| Titanium Carbide (TiC) | Hard ceramic compound; high boiling point; used in cutting tools | Manufacturing, mining, construction | Pros: Exceptional hardness; Cons: Limited to specific applications due to brittleness. |

| Superalloys (Titanium-Based) | High-performance alloys; optimized for extreme conditions | Aerospace, energy production | Pros: Superior performance under high stress; Cons: Expensive and complex to manufacture. |

What are the Characteristics of Commercially Pure Titanium?

Commercially pure titanium is known for its high purity levels, with a boiling point of 3,287 °C. This form is particularly valued in industries requiring materials that can withstand extreme temperatures without compromising structural integrity. B2B buyers in aerospace and medical sectors should consider its excellent corrosion resistance and biocompatibility, making it ideal for surgical implants and high-performance aircraft components. However, the higher cost associated with its purity may be a consideration for budget-sensitive projects.

How Do Titanium Alloys Differ and What are Their Applications?

Titanium alloys are created by combining titanium with other metals, such as aluminum or vanadium, resulting in variations in boiling points and properties. These alloys are crucial in military, marine, and industrial applications due to their enhanced strength and ductility. Buyers should evaluate the specific alloy compositions to ensure they meet the mechanical and thermal demands of their applications. However, sourcing can be complicated due to the diverse compositions and potential variability in supply.

What is the Role of Titanium Dioxide in B2B Markets?

Titanium dioxide (TiO2) is a non-metallic form of titanium that serves various applications, particularly as a pigment in paints, coatings, and plastics. Its boiling point can vary based on the specific use case. B2B buyers in the coatings or pharmaceutical industries will find TiO2 valuable due to its opacity and UV resistance. Nonetheless, it is important to note that TiO2 is not suitable for structural applications, limiting its use in certain sectors.

What are the Benefits of Titanium Carbide for Manufacturing?

Titanium carbide (TiC) is a hard ceramic compound with a high boiling point, commonly used in cutting tools and wear-resistant applications. Its exceptional hardness makes it suitable for harsh manufacturing environments, particularly in mining and construction. B2B buyers should consider TiC for applications requiring durability and wear resistance. However, its brittleness may limit its use in applications subject to impact or shock loading.

How Do Superalloys Enhance Performance in Extreme Conditions?

Titanium-based superalloys are engineered for high-performance applications, particularly in aerospace and energy production. These alloys are designed to perform under extreme temperatures and stress, making them indispensable in critical applications. B2B buyers should assess the specific performance characteristics required for their applications, keeping in mind the higher costs and complexities associated with the manufacturing of these advanced materials.

Key Industrial Applications of titanium boiling point

| Industry/Sector | Specific Application of titanium boiling point | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | High-temperature components in jet engines | Enhanced performance and reliability under extreme conditions | Ensure suppliers meet aerospace-grade specifications and certifications. |

| Chemical Processing | Heat exchangers and reactors | Resistance to corrosion and high temperatures, leading to longer equipment life | Verify material purity and compliance with industry standards. |

| Medical Devices | Surgical instruments and implants | Biocompatibility and strength, reducing the risk of failure | Source from certified manufacturers with a track record in medical applications. |

| Oil and Gas | Subsea equipment and pipelines | Durability and resistance to harsh environments, minimizing downtime | Assess supplier capabilities in producing titanium components for extreme conditions. |

| Automotive | Performance parts in high-performance vehicles | Lightweight properties improving fuel efficiency and performance | Look for suppliers with expertise in titanium alloy production and processing. |

How Is Titanium Boiling Point Applied in Aerospace Components?

In the aerospace industry, titanium’s high boiling point (3,287 °C) is crucial for manufacturing high-temperature components in jet engines. These parts must withstand extreme thermal and mechanical stresses during flight. By using titanium, manufacturers enhance engine performance and reliability, significantly reducing the risk of failure. International buyers should ensure that suppliers adhere to strict aerospace standards and certifications, as the quality of titanium components directly impacts safety and operational efficiency.

What Role Does Titanium Boiling Point Play in Chemical Processing Equipment?

In chemical processing, titanium’s boiling point makes it an ideal choice for constructing heat exchangers and reactors that operate at elevated temperatures. Its exceptional resistance to corrosion extends the lifespan of equipment, ultimately leading to reduced maintenance costs and downtime. Buyers in this sector must verify the material’s purity and compliance with industry-specific standards, ensuring that the titanium used can withstand the harsh chemicals and conditions typical in processing environments.

How Is Titanium Boiling Point Beneficial in Medical Devices?

The medical industry utilizes titanium for surgical instruments and implants due to its high boiling point, which contributes to its strength and biocompatibility. This ensures that devices remain stable and effective in the human body, reducing the risk of rejection or failure. B2B buyers in the medical field should source titanium from certified manufacturers with proven expertise in producing medical-grade components, ensuring compliance with health regulations and standards.

A stock image related to titanium boiling point.

How Does Titanium Boiling Point Enhance Oil and Gas Equipment?

In the oil and gas sector, titanium’s high boiling point is a key factor in the production of subsea equipment and pipelines that must endure extreme environmental conditions. Its durability and resistance to corrosion help minimize downtime and maintenance costs, which are critical in this industry. International buyers should assess supplier capabilities in producing titanium components that meet the rigorous demands of offshore operations, ensuring reliability and safety.

Why Is Titanium Boiling Point Important for Automotive Performance Parts?

The automotive industry leverages titanium’s lightweight properties and high boiling point to create performance parts for high-performance vehicles. This results in improved fuel efficiency and overall vehicle performance. B2B buyers should seek suppliers with expertise in titanium alloy production and processing to ensure that the materials meet the specific performance requirements of high-end automotive applications.

3 Common User Pain Points for ‘titanium boiling point’ & Their Solutions

Scenario 1: Understanding Titanium Boiling Point for High-Temperature Applications

The Problem:

International B2B buyers often face challenges when sourcing titanium for high-temperature applications, such as aerospace and industrial machinery. The boiling point of titanium, approximately 3,287 °C (5,949 °F), can lead to misunderstandings regarding its thermal stability in high-stress environments. Buyers may struggle to ensure that the titanium they procure is suited for extreme conditions, leading to potential product failures or costly downtimes.

The Solution:

To mitigate these risks, it is essential to collaborate closely with suppliers who specialize in high-temperature titanium alloys. Buyers should inquire about the specific grades of titanium being offered and their thermal properties, including their boiling point and melting point. Conducting thorough material testing, such as thermal cycling tests, can help verify that the titanium maintains its integrity under operational temperatures. Furthermore, when specifying titanium for high-temperature applications, consider integrating additional elements into the alloy to enhance performance, such as aluminum or vanadium, which can improve strength and thermal stability.

Scenario 2: Sourcing Titanium with Accurate Thermal Properties

The Problem:

B2B buyers from various industries, particularly those in manufacturing and construction, frequently encounter discrepancies in the thermal properties of titanium provided by different suppliers. The boiling point of titanium is a critical factor that can affect manufacturing processes, especially in applications requiring precision, such as medical devices or automotive components. Misunderstanding these properties can lead to selection of unsuitable materials, causing production delays or quality issues.

The Solution:

To ensure accurate sourcing, buyers should demand comprehensive technical data sheets (TDS) that include verified boiling point information and other relevant thermal properties. It is advisable to engage suppliers who can provide certification for their titanium materials, confirming that they meet industry standards. Additionally, establishing a robust quality assurance process—including third-party testing for thermal properties—can help validate the specifications. This proactive approach enables buyers to select the right titanium products tailored to their specific applications, ensuring compliance with safety and performance standards.

Scenario 3: Utilizing Titanium’s Boiling Point in Product Design

The Problem:

In product development, particularly in sectors like aerospace and automotive, the boiling point of titanium can significantly influence design parameters. Designers may overlook the implications of titanium’s boiling point, leading to potential failures in thermal management systems or components subjected to extreme heat. This oversight can result in costly redesigns and extended time-to-market.

The Solution:

To integrate the boiling point of titanium effectively into product design, engineers should conduct a thorough thermal analysis during the design phase. This includes simulations that account for operational temperatures and potential thermal stresses. Collaborating with metallurgical experts can provide insights into how titanium behaves at high temperatures and inform design choices, such as the incorporation of heat shields or thermal barriers. Moreover, leveraging advanced manufacturing techniques, such as additive manufacturing, can allow for the creation of complex geometries that optimize thermal performance while adhering to the constraints imposed by titanium’s boiling point. By embedding thermal considerations into the design process, companies can enhance product reliability and performance.

Strategic Material Selection Guide for titanium boiling point

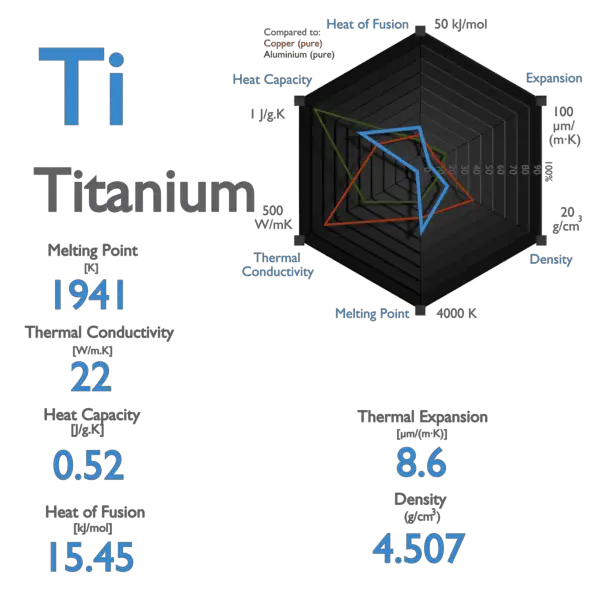

What Are the Key Properties of Titanium Relevant to Boiling Point Applications?

Titanium is renowned for its impressive boiling point of 3,287 °C (5,949 °F), making it an ideal material for high-temperature applications. Its low density and high strength-to-weight ratio further enhance its appeal in various sectors, including aerospace, automotive, and chemical processing. Additionally, titanium exhibits excellent corrosion resistance, particularly in aggressive environments, which is crucial for maintaining performance over time.

How Do Different Materials Compare for High-Temperature Applications?

1. Titanium Alloys

Key Properties:

Titanium alloys maintain the high boiling point of pure titanium while enhancing mechanical properties through alloying elements like aluminum and vanadium. They can withstand high temperatures and pressures, making them suitable for aerospace and industrial applications.

Pros & Cons:

The primary advantage of titanium alloys is their superior strength and weight characteristics, allowing for lightweight designs without compromising structural integrity. However, they can be more expensive than other metals, and their manufacturing processes can be complex, requiring specialized techniques.

Impact on Application:

Titanium alloys are compatible with various media, including seawater and acidic environments, making them ideal for marine and chemical processing applications.

Considerations for International Buyers:

Buyers in regions like the Middle East and Europe must consider compliance with local standards such as ASTM and DIN, especially for aerospace applications where safety regulations are stringent.

2. Inconel

Key Properties:

Inconel is a high-performance nickel-chromium alloy known for its excellent oxidation and corrosion resistance at elevated temperatures, with a boiling point exceeding that of titanium.

Pros & Cons:

Inconel’s durability and resistance to extreme conditions make it suitable for high-stress applications. However, its cost is considerably higher than titanium, and it is more challenging to machine, which can increase manufacturing complexity.

Impact on Application:

Inconel is often used in gas turbines and chemical processing equipment due to its ability to withstand harsh environments, making it a reliable choice for critical applications.

Considerations for International Buyers:

Buyers should ensure that Inconel meets the necessary certifications for their specific applications, especially in regulated industries.

3. Stainless Steel

Key Properties:

Stainless steel has a boiling point around 2,800 °C (5,072 °F) and is known for its corrosion resistance and strength. It is widely used in various industries due to its versatility.

Pros & Cons:

The main advantage of stainless steel is its cost-effectiveness and ease of fabrication. However, it does not perform as well as titanium at high temperatures, particularly in corrosive environments.

Impact on Application:

Stainless steel is suitable for a wide range of applications, including food processing and construction, but may not be ideal for high-temperature or highly corrosive settings.

Considerations for International Buyers:

International buyers should be aware of the different grades of stainless steel and their respective properties to ensure compatibility with their specific applications.

4. Carbon Steel

Key Properties:

Carbon steel has a boiling point similar to stainless steel but lacks the corrosion resistance of titanium and stainless steel. It is often used in structural applications.

Pros & Cons:

Carbon steel is relatively inexpensive and easy to work with. However, its susceptibility to rust and corrosion limits its use in harsh environments.

Impact on Application:

While suitable for construction and manufacturing, carbon steel may not be appropriate for applications involving high temperatures or corrosive substances.

Considerations for International Buyers:

Buyers should consider local environmental conditions and potential corrosion issues when selecting carbon steel for their projects.

Summary Table of Material Comparisons

| Material | Typical Use Case for Titanium Boiling Point | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium Alloys | Aerospace components | High strength-to-weight ratio | Higher cost and complex manufacturing | High |

| Inconel | Gas turbines, chemical processing | Excellent oxidation resistance | Very high cost and difficult to machine | High |

| Stainless Steel | Food processing, construction | Cost-effective and easy to fabricate | Limited high-temperature performance | Medium |

| Carbon Steel | Structural applications | Inexpensive and easy to work with | Susceptible to rust and corrosion | Low |

This analysis provides a comprehensive overview of materials relevant to titanium’s boiling point, helping international B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium boiling point

What Are the Main Stages of Titanium Manufacturing Processes?

The manufacturing of titanium, particularly focusing on its boiling point and related applications, encompasses several critical stages: material preparation, forming, assembly, and finishing. Understanding these processes is vital for B2B buyers who are looking for reliable suppliers capable of delivering high-quality titanium products.

Material Preparation: What Are the Initial Steps?

The first stage involves the extraction and purification of titanium from its ores, primarily ilmenite and rutile. The Kroll process is the most common method used to obtain titanium, where titanium tetrachloride (TiCl4) is produced and subsequently reduced using magnesium. This results in a spongy form of titanium that requires further processing.

Key techniques during this stage include:

– Chemical Reduction: Ensuring the purity of the titanium by controlling the environment to minimize contamination.

– Quality Control of Raw Materials: Verifying the source and quality of ores to ensure they meet industry standards before processing.

Forming: How Is Titanium Shaped?

Once the titanium sponge is produced, it undergoes various forming processes to create the desired shapes and sizes. Common techniques include:

– Forging: This process involves heating the titanium and then shaping it under pressure. It enhances the mechanical properties of titanium, making it suitable for high-stress applications.

– Casting: This method allows for the production of complex shapes but requires careful control of the melting process to avoid contamination and defects.

During forming, it is essential to monitor temperature and pressure closely to maintain the integrity of the titanium structure, particularly as titanium has a high melting point (approximately 1,660 °C).

Assembly: What Are the Key Considerations?

In the assembly stage, titanium components are often joined using welding techniques specific to titanium, such as gas tungsten arc welding (GTAW). This process requires a controlled atmosphere to prevent oxidation, which could compromise the quality of the weld.

Key considerations include:

– Welding Procedures: Establishing and following standard operating procedures (SOPs) to ensure consistent quality.

– Post-Weld Treatments: Implementing processes such as annealing to relieve stresses and improve material properties.

What Quality Assurance Standards Are Relevant for Titanium Manufacturing?

Quality assurance is a crucial aspect of titanium manufacturing, particularly for B2B buyers who need assurance of product reliability and compliance with international standards.

Which International Standards Should Buyers Be Aware Of?

Several international standards are relevant for titanium manufacturing:

– ISO 9001: This standard specifies requirements for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

– ISO 13485: For manufacturers producing titanium medical devices, this standard focuses on quality management systems specific to the medical industry.

– CE Marking: Essential for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

– API Standards: For titanium used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is critical for safety and performance.

What Are the Key Quality Control Checkpoints in Titanium Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that titanium products meet required specifications throughout the manufacturing process.

How Are QC Checkpoints Structured?

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Key factors include chemical composition, physical properties, and absence of defects.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify issues early. Techniques such as visual inspections, dimensional checks, and non-destructive testing (NDT) are commonly used.

-

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to verify that they meet all specifications. Common tests include:

– Mechanical Testing: Assessing tensile strength, ductility, and hardness.

– Chemical Analysis: Ensuring the titanium meets specified alloy compositions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, ensuring the reliability of titanium suppliers is paramount. Here are actionable insights:

What Should Buyers Look For in Supplier Audits?

-

Supplier Audits: Conducting regular audits of suppliers’ manufacturing processes and quality control systems is essential. This can include reviewing their ISO certifications and compliance with specific industry standards.

-

Documentation and Reporting: Requesting detailed quality reports, including inspection and testing results, provides transparency and builds trust.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. This is particularly important for critical applications in aerospace and medical industries.

What Are the Common Testing Methods for Titanium Quality Assurance?

Testing methods play a crucial role in verifying the quality of titanium products.

Which Testing Methods Are Most Effective?

- X-ray Diffraction (XRD): Used to determine the crystal structure and phase identification of titanium.

- Scanning Electron Microscopy (SEM): Provides high-resolution images to assess surface morphology and detect defects.

- Energy Dispersive X-ray Spectroscopy (EDS): This method identifies the elemental composition of titanium alloys, ensuring they meet specified requirements.

A stock image related to titanium boiling point.

By understanding the manufacturing processes, quality assurance standards, and verification methods, international B2B buyers can make informed decisions when selecting titanium suppliers. This ensures they receive high-quality products that meet their specific industry needs, ultimately supporting their business objectives and enhancing their competitive edge in the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium boiling point’

In the pursuit of sourcing titanium, particularly focusing on its boiling point, international B2B buyers must navigate various technical specifications and supplier evaluations. This guide provides a step-by-step checklist designed to streamline the procurement process and ensure that buyers make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing titanium. Consider factors such as the desired purity level, mechanical properties, and specific applications of the titanium you need. Understanding these requirements will help you communicate effectively with suppliers and ensure they can meet your needs.

- Boiling Point Importance: Titanium has a boiling point of 3,287 °C (5,949 °F), which is vital for applications in high-temperature environments. Ensure that the titanium sourced meets or exceeds this specification for your specific use case.

Step 2: Identify Reputable Suppliers

Start your sourcing journey by compiling a list of potential suppliers. Research companies that specialize in titanium production and have a solid reputation in the market.

- Sources of Information: Utilize industry directories, trade shows, and online platforms to identify suppliers. Look for those with certifications that comply with international standards, which indicate reliability and quality.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, thorough vetting is essential. Request detailed company profiles, including their manufacturing processes, quality control measures, and case studies.

- Reference Checks: Ask for references from other businesses within your industry or region. This will provide insights into the supplier’s reliability and the quality of their titanium products.

Step 4: Assess Compliance with Standards

Ensure that your selected suppliers adhere to relevant industry standards and regulations. Compliance with ISO certifications, ASTM specifications, and other international standards is non-negotiable for high-quality titanium sourcing.

- Documentation Verification: Request documentation that verifies compliance. This includes test results, material safety data sheets (MSDS), and certificates of analysis (CoA) for the titanium being supplied.

Step 5: Request Sample Testing

Before finalizing any purchase, request samples of the titanium. Conduct independent testing to verify its boiling point and other critical properties.

- Testing Methods: Use recognized testing methods to assess properties such as melting and boiling points, as well as mechanical strength. This step is essential for ensuring that the titanium meets your application requirements.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier and verified their products, negotiate the terms of your purchase. Discuss pricing, lead times, and payment terms to ensure transparency.

- Long-term Partnerships: Consider the potential for long-term partnerships and bulk purchasing agreements. This can lead to better pricing and priority service in the future.

Step 7: Plan for Logistics and Delivery

Finally, plan your logistics carefully. Discuss shipping options, lead times, and delivery methods with your supplier to ensure timely receipt of the titanium.

- Customs and Regulations: Be aware of any customs regulations or import duties that may apply in your country. Planning ahead will help avoid delays and additional costs.

By following this checklist, B2B buyers can ensure a systematic and efficient approach to sourcing titanium, particularly focusing on its boiling point and other critical specifications.

Comprehensive Cost and Pricing Analysis for titanium boiling point Sourcing

What are the Key Cost Components in Sourcing Titanium Boiling Point?

When sourcing titanium, particularly in the context of its boiling point applications, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The base material cost of titanium is influenced by market demand, extraction methods, and the purity of the titanium being sourced. Higher purity grades, often required for aerospace or medical applications, command a premium.

-

Labor: The labor costs involved in processing titanium can vary significantly based on the region. Skilled labor for handling titanium, especially in refining and machining processes, can be a considerable expense.

-

Manufacturing Overhead: This includes costs associated with facilities, equipment maintenance, and utilities. The overhead can be higher in regions with stricter regulations on environmental impact and worker safety.

-

Tooling: Specialized tooling is often required to work with titanium due to its unique properties. The cost of such tools should be factored into the overall pricing.

-

Quality Control (QC): Ensuring that titanium meets specific quality standards involves rigorous testing and certification processes, which add to the cost. This is particularly relevant for industries that require high safety standards.

-

Logistics: Transportation costs can vary widely based on the distance from the supplier to the buyer, as well as the mode of transport. For international buyers, understanding Incoterms is essential to grasp responsibilities and costs associated with shipping.

-

Margin: Suppliers will typically include a margin in their pricing, which can fluctuate based on market conditions and competition.

How Do Price Influencers Affect Titanium Boiling Point Sourcing?

Several factors can influence the pricing of titanium:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower unit prices due to economies of scale. Buyers should negotiate MOQs that suit their needs without incurring unnecessary costs.

-

Specifications and Customization: Custom requirements, such as specific alloy compositions or dimensions, can significantly increase costs. Clearly defining specifications upfront can help mitigate unexpected expenses.

-

Quality and Certifications: Certifications from recognized bodies (e.g., ISO, ASTM) can impact pricing. Buyers may need to pay extra for materials that meet stringent quality requirements.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can affect pricing. Established suppliers may command higher prices due to their proven track records.

-

Incoterms: Different Incoterms can influence the total cost of ownership. For instance, a supplier offering DDP (Delivered Duty Paid) might seem more expensive upfront but could save buyers on logistics and customs handling.

What Are the Best Practices for Negotiating Titanium Prices?

-

Conduct Market Research: Understanding current market conditions and pricing trends can empower buyers during negotiations. This includes being aware of fluctuations in titanium prices driven by global demand and geopolitical factors.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield favorable conditions.

-

Consider Total Cost of Ownership: Rather than focusing solely on the upfront price, consider the total cost of ownership, including logistics, quality assurance, and potential rework costs. This holistic view can reveal better value propositions.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and help buyers make informed decisions.

-

Understand Payment Terms: Payment terms can significantly impact cash flow. Negotiating favorable terms can help manage expenses more effectively.

What Should International B2B Buyers Consider When Sourcing Titanium?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Import Duties and Tariffs: Understanding local regulations regarding import duties can affect the final cost. Buyers should ensure they are informed about any tariffs that may apply to titanium imports.

-

Currency Fluctuations: Exchange rates can impact pricing, especially in cross-border transactions. Buyers should consider hedging strategies to mitigate currency risk.

-

Cultural Considerations: Different regions may have varying expectations regarding negotiation styles and business practices. Adapting to these cultural nuances can facilitate smoother negotiations.

Disclaimer on Indicative Prices

Prices for titanium are subject to market fluctuations and can vary based on numerous factors, including the specifics of the order and supplier capabilities. It is recommended that buyers conduct due diligence and obtain updated quotes to ensure accurate budgeting.

Alternatives Analysis: Comparing titanium boiling point With Other Solutions

Understanding Alternatives to Titanium Boiling Point

When evaluating materials for high-temperature applications, the boiling point of titanium (3,287 °C or 5,949 °F) is a critical factor. However, there are several alternative materials and methods that may offer comparable or superior performance depending on the specific requirements of a project. This section compares titanium with two viable alternatives: Nickel-based Alloys and Tantalum.

Comparison Table of Titanium Boiling Point Against Alternatives

| Comparison Aspect | Titanium Boiling Point | Nickel-based Alloys | Tantalum |

|---|---|---|---|

| Performance | Excellent high-temp stability; light weight | High strength and corrosion resistance at elevated temperatures | Superior corrosion resistance; high melting point (5,469 °F) |

| Cost | Moderate; generally higher than steel | Higher than titanium; costs vary significantly with alloying elements | Very high; limited availability increases cost |

| Ease of Implementation | Requires specialized processing techniques | Requires careful welding and machining | Machinability can be challenging; specialized tools needed |

| Maintenance | Low maintenance; resistant to corrosion | Moderate; susceptible to environmental factors | Low maintenance; excellent long-term stability |

| Best Use Case | Aerospace, marine applications, biomedical implants | Aerospace, chemical processing, and high-temperature environments | Chemical processing, electronics, and nuclear applications |

Detailed Breakdown of Alternatives

What Are Nickel-based Alloys and Their Advantages?

Nickel-based alloys are engineered materials that provide excellent mechanical properties and resistance to oxidation and corrosion at high temperatures. They are particularly effective in aerospace and chemical processing industries, where extreme conditions are common. The main advantage of nickel alloys is their ability to maintain strength and integrity at temperatures where titanium might not perform as well. However, the cost can be significantly higher, and the complexity of welding and machining these alloys can pose challenges.

How Does Tantalum Compare to Titanium?

Tantalum is known for its remarkable corrosion resistance and high melting point, making it an ideal choice for applications in harsh environments, such as chemical processing and electronics. Its ability to withstand high temperatures and reactiveness with other materials is impressive. However, tantalum is much more expensive and less available than titanium, which can be a significant drawback for B2B buyers. Additionally, the machining and processing of tantalum require specialized tools and techniques, which can increase operational costs.

How to Choose the Right Solution for Your Needs

Selecting the appropriate material depends on various factors, including performance requirements, budget constraints, and application specifics. For high-temperature applications where weight is a concern, titanium remains a strong contender due to its balance of performance and cost. However, if the application demands superior corrosion resistance or operates in extreme conditions, considering nickel-based alloys or tantalum may be worthwhile despite the higher costs. Ultimately, B2B buyers should evaluate their specific needs, including the operational environment and long-term maintenance expectations, to make an informed decision on which solution aligns best with their objectives.

Essential Technical Properties and Trade Terminology for titanium boiling point

What Are the Key Technical Properties of Titanium Boiling Point?

When considering the boiling point of titanium, several technical properties are critical for B2B buyers, especially those in sectors such as aerospace, automotive, and manufacturing. Understanding these properties ensures that businesses can select the right titanium products for their specific applications.

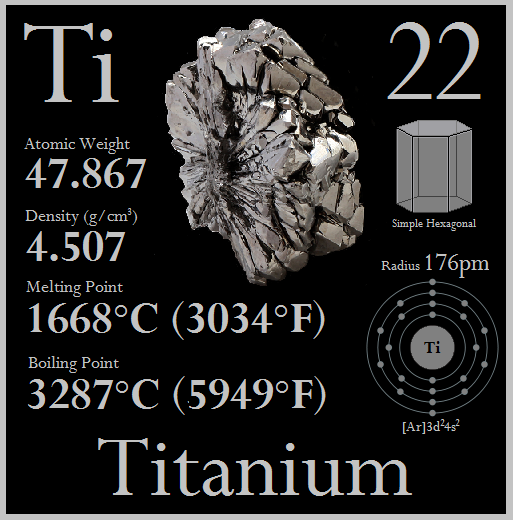

1. Boiling Point

The boiling point of titanium is approximately 3,287 °C (5,949 °F). This high boiling point makes titanium suitable for high-temperature applications, such as aerospace components and industrial machinery, where materials are subject to extreme conditions.

2. Material Grade

Titanium is available in various grades, each with unique properties. Common grades include Grade 1 (commercially pure titanium) and Grade 5 (Ti-6Al-4V). Selecting the appropriate grade is vital, as it affects the material’s strength, ductility, and corrosion resistance. For example, Grade 5 is often preferred in aerospace due to its excellent strength-to-weight ratio.

3. Tolerance

Tolerance refers to the allowable variation in dimensions and properties of titanium products. High precision is crucial in applications where materials must fit seamlessly into assemblies. Tighter tolerances ensure better performance and safety, particularly in critical applications like aircraft components.

4. Density

Titanium has a density of approximately 4.5 g/cm³, making it lighter than many other metals while maintaining high strength. This characteristic is particularly important in industries such as automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance.

5. Thermal Conductivity

Titanium’s thermal conductivity is about 22 W/(m·K). This property influences how heat is distributed through the material, which is critical in high-temperature applications. Understanding thermal conductivity helps buyers determine how titanium will perform in thermal management applications.

6. Heat of Vaporization

The heat of vaporization for titanium is approximately 425 kJ/mol. This metric indicates the energy required to transform titanium from a liquid to a gas state. In B2B contexts, this property is essential for processes involving high-temperature machining or casting.

What Are Common Trade Terms Related to Titanium Boiling Point?

Navigating the titanium market involves understanding specific trade terminology that can impact purchasing decisions. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the titanium industry, knowing whether a supplier is an OEM can help buyers assess the quality and compatibility of titanium products for their applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For titanium products, understanding MOQ helps buyers plan their procurement strategies and manage inventory costs effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products or services. In the titanium sector, submitting an RFQ can help buyers compare prices and terms from various suppliers, ensuring they get the best deal.

4. Incoterms

Incoterms (International Commercial Terms) are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for international B2B buyers, as they clarify shipping responsibilities, insurance, and risk management.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. In titanium procurement, lead times can vary significantly based on material availability, processing times, and shipping. Buyers should consider lead times when planning projects to avoid delays.

6. Certification Standards

Certification standards, such as ASTM or ISO, ensure that titanium products meet specific quality and performance criteria. Familiarity with these standards helps buyers ensure compliance and reliability in their applications.

By understanding these technical properties and trade terminology, international B2B buyers can make informed decisions when sourcing titanium, optimizing their supply chain and ensuring product reliability in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the titanium boiling point Sector

What Are the Key Trends and Market Dynamics in the Titanium Boiling Point Sector?

A stock image related to titanium boiling point.

The titanium sector is experiencing robust growth, driven by increasing demand across various industries, including aerospace, automotive, and medical devices. The boiling point of titanium, recorded at 3,287 °C (5,949 °F), plays a crucial role in applications requiring high-temperature resistance and stability. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate market dynamics influenced by technological advancements and geopolitical factors.

Emerging trends include the rise of additive manufacturing and advanced alloy formulations, enabling the production of titanium components with complex geometries. This has reduced material waste and improved efficiency, making titanium more accessible for smaller manufacturers. Additionally, the global push towards electrification in transportation is driving demand for lightweight, high-strength materials, with titanium leading the way due to its superior properties.

Another significant trend is the increasing collaboration between manufacturers and suppliers to streamline sourcing processes. Buyers are now leveraging digital platforms for procurement, enabling real-time data access and enhanced decision-making. The focus on supply chain transparency and agility is paramount, especially in the face of fluctuating global market conditions and sourcing risks.

How Does Sustainability and Ethical Sourcing Impact the Titanium Boiling Point Sector?

Sustainability and ethical sourcing are becoming non-negotiable factors in the titanium supply chain. The extraction and processing of titanium can have significant environmental impacts, including habitat disruption and carbon emissions. As such, B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices and demonstrate environmental stewardship.

The importance of ethical supply chains is underscored by growing consumer awareness and regulatory pressures. Buyers are encouraged to seek suppliers that have acquired ‘green’ certifications, which indicate compliance with environmental standards and practices. Certifications such as ISO 14001 (Environmental Management) and responsible sourcing labels can provide assurance that the titanium is sourced from environmentally responsible operations.

Moreover, innovations in recycling titanium scrap are gaining traction, as they not only reduce waste but also lower the carbon footprint associated with titanium production. Engaging with suppliers who prioritize recycled materials can offer buyers a competitive edge in meeting sustainability goals and appealing to eco-conscious markets.

What Is the Historical Context of Titanium in B2B Markets?

Titanium was first discovered in the late 18th century, but it wasn’t until the mid-20th century that it gained prominence in industrial applications. Initially utilized in military and aerospace sectors due to its high strength-to-weight ratio and corrosion resistance, titanium’s versatility has led to its adoption across various industries, including medical implants and consumer electronics.

The development of the Kroll process in the 1950s revolutionized titanium production, allowing for more efficient extraction and refining. As technology advanced, the alloying of titanium with other metals further enhanced its properties, making it an essential material for high-performance applications. This historical evolution has shaped the current B2B landscape, where titanium is recognized not only for its mechanical properties but also for its potential in sustainable manufacturing practices.

In summary, understanding the market dynamics, embracing sustainability, and recognizing the historical significance of titanium are critical for international B2B buyers looking to source high-quality titanium products effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of titanium boiling point

-

How does the boiling point of titanium affect its applications in different industries?

The boiling point of titanium, which is approximately 3,287 °C (5,949 °F), plays a crucial role in its applications, particularly in aerospace, automotive, and chemical processing industries. Its high boiling point ensures stability and performance under extreme temperatures, making it ideal for components in jet engines and spacecraft. Additionally, industries utilizing high-temperature processes benefit from titanium’s ability to maintain its properties without deformation or degradation, thus enhancing safety and efficiency in operations. -

What are the implications of titanium’s boiling point for international shipping and handling?

When sourcing titanium, the high boiling point indicates that the metal can withstand significant thermal stress. For international shipping, this means that suppliers must ensure proper handling and packaging to prevent damage during transport. Additionally, understanding the thermal properties can guide buyers in choosing appropriate storage conditions to maintain material integrity. Buyers from regions like Africa and South America should consider local climate conditions that might affect the storage and handling of titanium products. -

What should I consider when vetting suppliers for titanium based on boiling point characteristics?

When vetting suppliers, it’s essential to assess their expertise in handling high-temperature materials. Ensure that potential suppliers provide detailed specifications about the titanium they offer, including its boiling point and how it aligns with your application needs. Look for certifications and quality assurance processes that guarantee the material’s performance at high temperatures. Engage with suppliers who can demonstrate a history of supplying to industries with similar demands, particularly in regions like the Middle East and Europe. -

How can I customize titanium products based on boiling point requirements?

Customization of titanium products can be achieved through alloying and processing techniques. Buyers should communicate their specific requirements, including desired thermal properties related to boiling point, to potential suppliers. This may involve selecting particular titanium alloys that offer enhanced performance under high temperatures. Collaborating with suppliers who have experience in material science and engineering will ensure that the customized products meet rigorous industry standards and application needs. -

What are the minimum order quantities (MOQs) for titanium products, and how do they relate to boiling point specifications?

Minimum order quantities for titanium products can vary significantly based on the supplier and the specific product requirements. Buyers should inquire about MOQs that align with their project needs, particularly if high-performance titanium with precise boiling point characteristics is required. Some suppliers may offer flexibility for smaller orders, especially for custom specifications. Understanding the supplier’s production capabilities and lead times is crucial to ensuring timely delivery and meeting project deadlines. -

What payment terms should I negotiate when sourcing titanium internationally?

When sourcing titanium, particularly from international suppliers, it is critical to negotiate favorable payment terms that protect your investment. Common terms include advance payments, letters of credit, and payment upon delivery. Ensure that the terms reflect the value of the titanium being sourced, considering its high boiling point and associated processing costs. Buyers from regions like Saudi Arabia and Argentina should be aware of currency fluctuations and international banking fees, which can impact overall costs. -

How can I ensure quality assurance (QA) for titanium based on its boiling point?

To ensure quality assurance for titanium products, especially those that need to perform at high temperatures, implement a robust QA process. This should include requesting detailed material certifications and testing reports from suppliers that verify the boiling point and other critical properties. Engage third-party testing labs if necessary to validate the supplier’s claims. Establishing a relationship with suppliers who prioritize quality and compliance with international standards will also enhance confidence in the materials sourced. -

What logistics considerations should I keep in mind when sourcing titanium?

Logistics play a vital role in sourcing titanium, particularly due to its significant weight and value. Buyers should evaluate shipping methods that maintain the integrity of the titanium during transport, considering factors such as temperature control and protection from moisture. Additionally, understanding import/export regulations specific to titanium in your region is essential. Collaborating with logistics providers experienced in handling metals will ensure that your titanium arrives on time and in optimal condition.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for titanium boiling point

Why Is Understanding the Boiling Point of Titanium Crucial for B2B Buyers?

In conclusion, understanding the boiling point of titanium, which stands at an impressive 3,287 °C (5,949 °F), is vital for B2B buyers across various sectors, including aerospace, automotive, and medical industries. This characteristic not only underscores titanium’s suitability for high-temperature applications but also highlights the importance of selecting quality titanium products that can withstand extreme conditions. Buyers from Africa, South America, the Middle East, and Europe should prioritize strategic sourcing to ensure they are acquiring materials that meet rigorous standards and specifications.

How Can Strategic Sourcing Enhance Your Titanium Procurement?

Strategic sourcing enables companies to leverage supplier relationships, optimize procurement processes, and reduce costs while ensuring product quality. By forming partnerships with reliable suppliers, businesses can access advanced titanium alloys and products that enhance performance and durability.

What’s Next for International B2B Buyers?

As the demand for titanium continues to rise globally, now is the time for international B2B buyers to act. Engaging in proactive sourcing strategies and staying informed about market trends will empower businesses to secure competitive advantages. By prioritizing quality and sustainability in titanium procurement, companies can not only meet their operational needs but also contribute to a more responsible supply chain. Take the next step in your sourcing journey today—evaluate your suppliers, and consider how titanium can elevate your product offerings.