Discover Top Benefits of Linear Motion Mechanical Device (2025)

Introduction: Navigating the Global Market for linear motion mechanical device

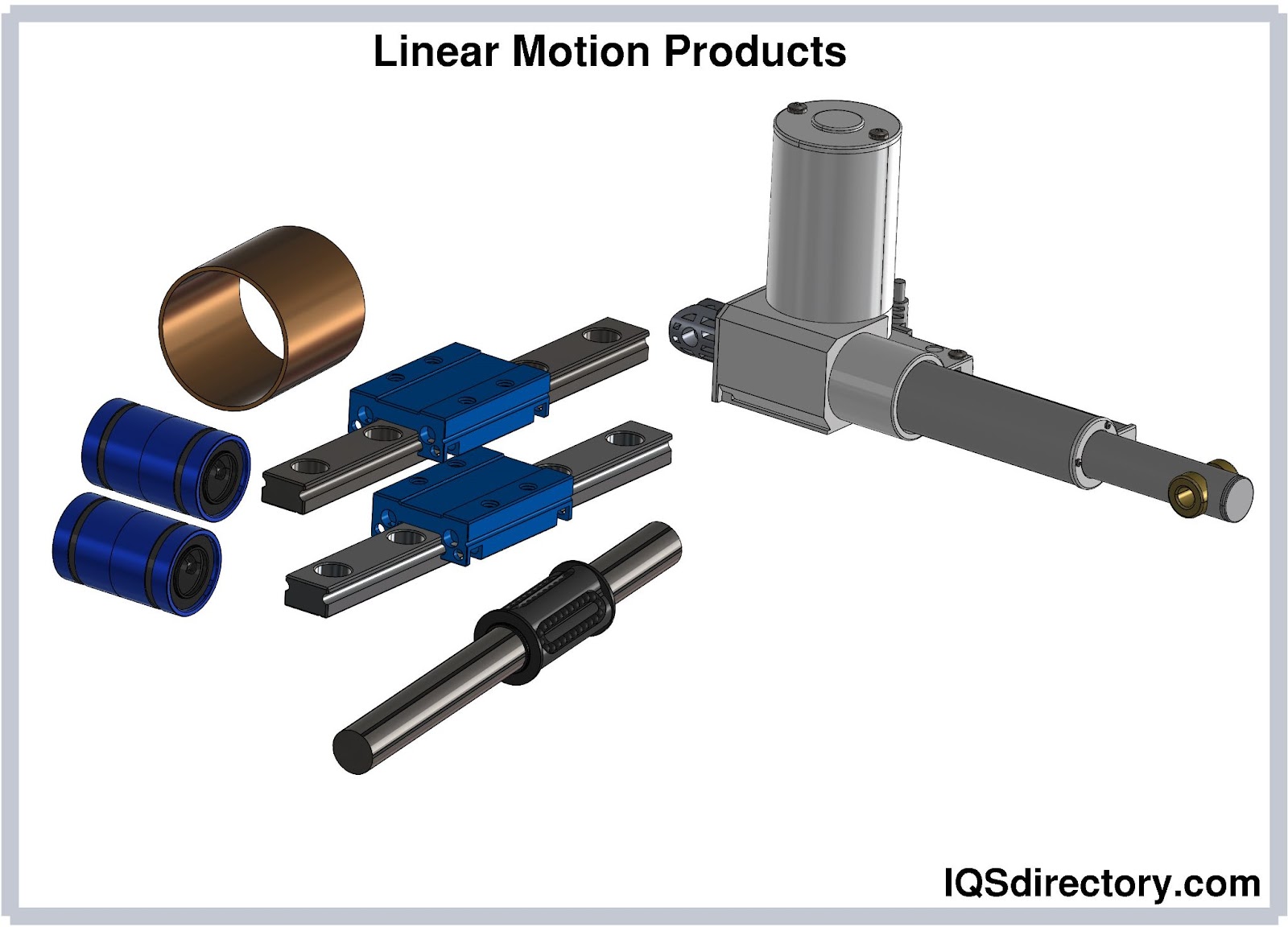

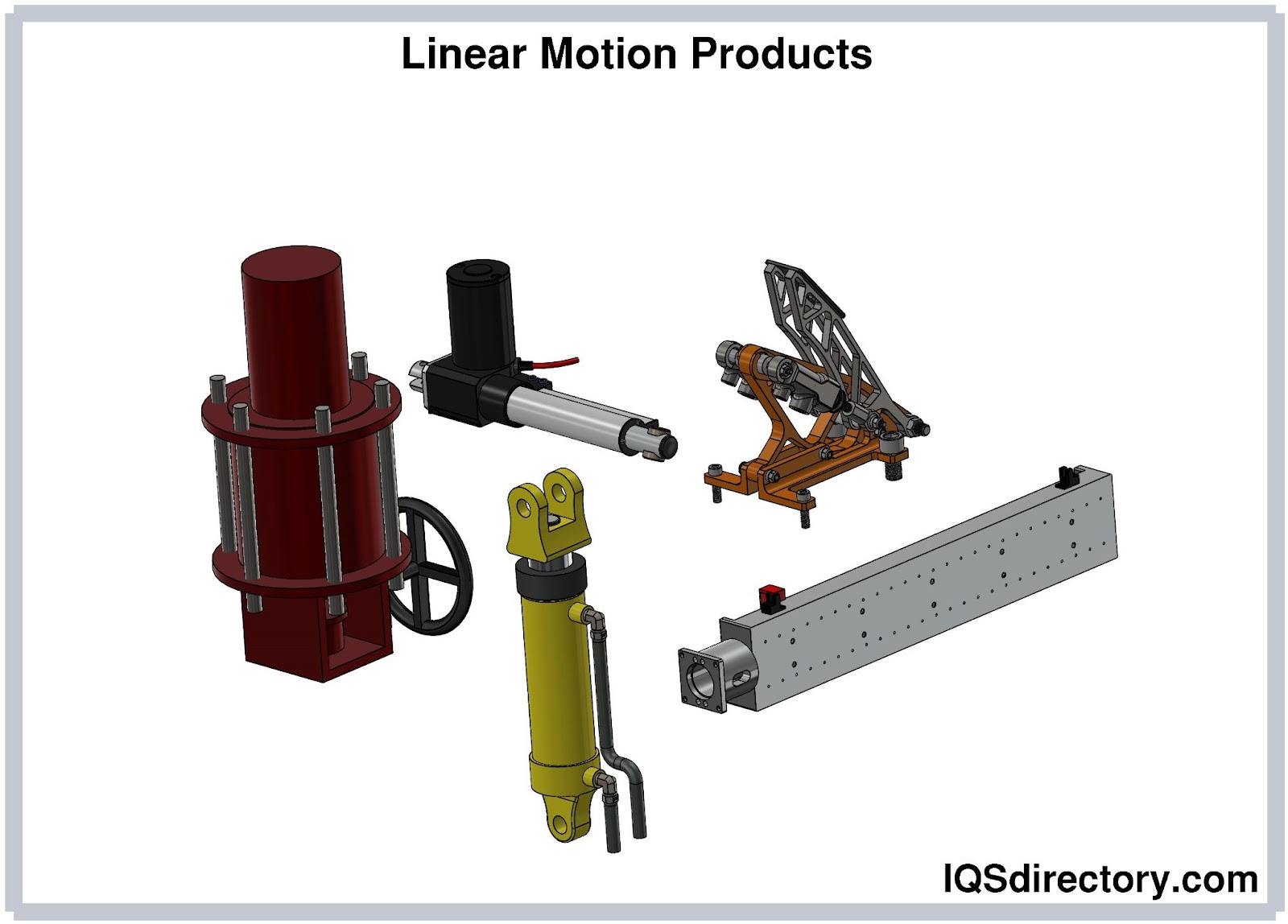

In the rapidly evolving global market for linear motion mechanical devices, international B2B buyers face a significant challenge: sourcing reliable and efficient solutions that meet specific operational needs. Linear motion devices, including electric actuators, ball screws, and linear bearings, play a critical role in various industries—from manufacturing to automation. This guide offers a comprehensive examination of the different types of linear motion products, their applications, and key considerations for selecting the right solutions for your business.

Understanding the diverse range of linear actuators, including hydraulic and pneumatic options, is essential for making informed purchasing decisions. Each type comes with unique advantages tailored to various applications, whether in robotics, industrial automation, or medical devices. Moreover, the guide delves into vital topics such as supplier vetting, cost analysis, and best practices for integration into existing systems.

For B2B buyers from Africa, South America, the Middle East, and Europe, this guide serves as an invaluable resource. It empowers you to navigate supplier landscapes, compare products, and ultimately enhance operational efficiency through informed choices. By leveraging the insights provided, businesses can streamline procurement processes and ensure they invest in the most suitable linear motion mechanical devices tailored to their specific requirements.

Understanding linear motion mechanical device Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Linear Actuator | Uses electric motors for precise control; versatile design options | Robotics, industrial automation, medical devices | Pros: High precision, low maintenance. Cons: Limited by power supply. |

| Hydraulic Actuator | Utilizes pressurized fluid for high force applications | Heavy machinery, construction, aerospace | Pros: High force output, suitable for heavy loads. Cons: Requires hydraulic systems and maintenance. |

| Pneumatic Actuator | Operates using compressed air for quick movements | Automation systems, assembly lines, robotics | Pros: Fast operation, low initial cost. Cons: Limited force and requires air supply. |

| Ball Screw | Converts rotational motion to linear with minimal friction | CNC machines, robotics, manufacturing processes | Pros: High efficiency and precision. Cons: More expensive than lead screws. |

| Linear Rail | Provides a low-friction guide for smooth linear motion | Material handling, packaging, assembly lines | Pros: High accuracy, easy to install. Cons: Requires proper alignment and maintenance. |

What Are Electric Linear Actuators and Their B2B Suitability?

Electric linear actuators are highly versatile devices that utilize electric motors to convert electrical energy into linear motion. They are particularly suited for applications requiring precision and control, such as robotics, industrial automation, and medical devices. When considering purchasing electric linear actuators, B2B buyers should evaluate the required force, speed, and the environmental conditions in which the actuators will operate. Additionally, understanding the power supply availability is crucial, as these devices depend on a stable electrical source.

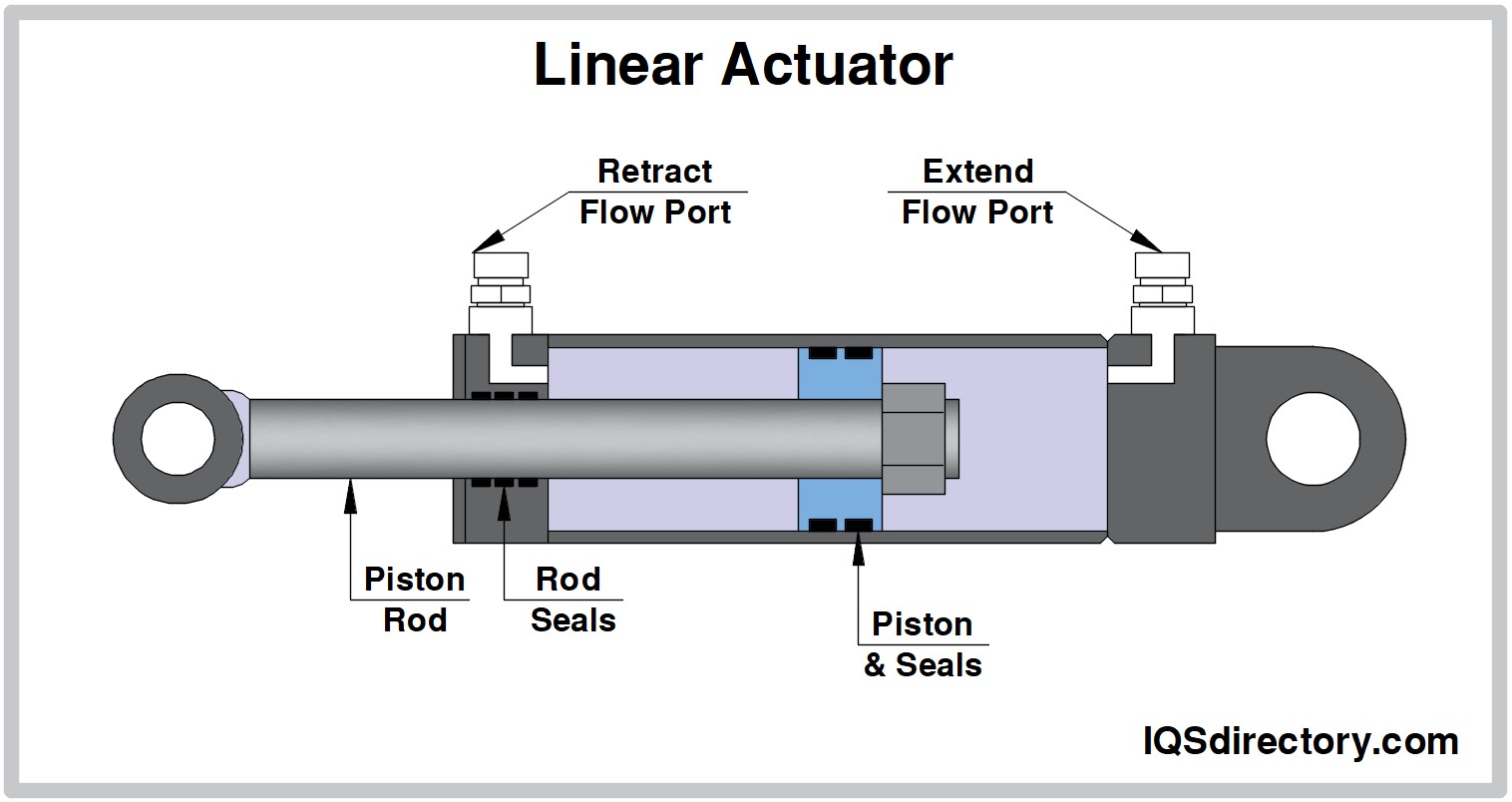

How Do Hydraulic Actuators Function in Heavy-Duty Applications?

Hydraulic actuators are designed for applications that necessitate high force output, making them ideal for heavy machinery, construction equipment, and aerospace systems. They operate using pressurized fluid, which allows them to handle substantial loads effectively. Buyers should consider the operational environment and the availability of hydraulic systems when selecting hydraulic actuators. While they provide excellent force capabilities, they also require regular maintenance and a robust hydraulic setup, which can add to overall operational costs.

What Advantages Do Pneumatic Actuators Offer for Automation Systems?

Pneumatic actuators are known for their rapid and repetitive motion capabilities, making them suitable for automation systems, assembly lines, and robotics. Utilizing compressed air, these actuators are often more cost-effective and simpler to integrate than their electric or hydraulic counterparts. B2B buyers should assess the speed and force requirements of their applications when considering pneumatic actuators. However, they must also factor in the need for a compressed air supply, which can impact operational efficiency.

Why Choose Ball Screws for Precision Applications?

Ball screws are mechanical devices that convert rotational motion into linear motion with minimal friction, making them highly efficient for applications like CNC machines and robotics. Their design involves a screw shaft and a nut with balls rolling between, which enhances precision and reduces wear. B2B buyers should consider the specific application requirements, including load capacity and speed, when opting for ball screws. While they tend to be more expensive than lead screws, their efficiency and longevity often justify the investment.

How Do Linear Rails Enhance Material Handling Processes?

Linear rails are integral components in systems requiring smooth and precise linear movement, such as material handling, packaging, and assembly lines. They provide a low-friction guide for carriages, allowing for efficient transport of goods. Buyers should evaluate the installation space and alignment requirements when selecting linear rails, as proper setup is essential for optimal performance. Although they may require ongoing maintenance to ensure alignment and functionality, their high accuracy and ease of installation make them a popular choice in various industrial applications.

Key Industrial Applications of linear motion mechanical device

| Industry/Sector | Specific Application of Linear Motion Mechanical Device | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated Assembly Lines | Increases efficiency and reduces labor costs | Look for precision, load capacity, and compatibility |

| Agriculture | Precision Farming Equipment | Enhances crop yield through accurate positioning | Consider environmental resistance and maintenance needs |

| Healthcare | Medical Equipment (e.g., hospital beds, lifts) | Improves patient care and operational efficiency | Focus on safety standards and reliability |

| Aerospace | Flight Control Systems | Ensures high precision and safety in operations | Evaluate material quality and compliance with regulations |

| Robotics | Robotic Arm Movement | Increases automation capabilities and flexibility | Assess actuator speed, size, and integration capabilities |

How Are Linear Motion Mechanical Devices Used in Manufacturing?

In the manufacturing sector, linear motion mechanical devices are integral to automated assembly lines. These devices facilitate the precise movement of components, ensuring that parts are assembled correctly and efficiently. By automating these processes, businesses can significantly enhance production rates while reducing labor costs. International buyers should prioritize sourcing devices that offer high precision, adequate load capacity, and compatibility with existing systems to maximize their investment.

What Role Do Linear Motion Devices Play in Agriculture?

In agriculture, linear motion mechanical devices are vital for precision farming equipment. These devices enable accurate positioning of machinery, such as planters and harvesters, which can lead to improved crop yields. By using technology that minimizes human error, farmers can optimize their operations. Buyers from regions like Africa and South America should consider environmental resistance and ease of maintenance when selecting these devices, ensuring they can withstand diverse agricultural conditions.

How Are Linear Motion Devices Enhancing Healthcare Solutions?

In the healthcare industry, linear motion mechanical devices are essential for various medical equipment, such as hospital beds and patient lifts. These devices contribute to improved patient care by allowing for smooth and precise adjustments that enhance comfort and accessibility. International B2B buyers must focus on sourcing products that meet stringent safety standards and demonstrate reliability, as these factors directly impact patient outcomes and operational efficiency.

What Is the Impact of Linear Motion Devices in Aerospace?

Linear motion mechanical devices are critical in aerospace applications, particularly in flight control systems. These devices ensure precise movements that are crucial for the safety and efficiency of aircraft operations. For international buyers in the aerospace sector, evaluating the material quality and ensuring compliance with industry regulations are paramount. This scrutiny helps mitigate risks associated with safety and performance in aviation.

How Do Linear Motion Devices Contribute to Robotics?

In the robotics field, linear motion mechanical devices facilitate the movement of robotic arms, enabling complex tasks such as assembly, welding, and material handling. This capability enhances automation and flexibility in manufacturing processes. B2B buyers should assess actuator speed, size, and integration capabilities to ensure that the devices can meet the specific demands of their robotic applications, particularly in competitive markets across Europe and the Middle East.

3 Common User Pain Points for ‘linear motion mechanical device’ & Their Solutions

Scenario 1: Ensuring Precision in Automated Systems

The Problem:

Many B2B buyers, particularly those in industries such as manufacturing and robotics, struggle with achieving the required precision in automated systems. Linear motion mechanical devices, like electric actuators, must perform with high accuracy to ensure that processes such as assembly or material handling operate smoothly. When these devices fail to deliver the necessary precision, it can lead to costly downtimes, wasted materials, and a drop in overall productivity. Buyers often find it challenging to select the right actuator type or configuration that meets their specific application requirements, especially in environments with varying loads and speeds.

The Solution:

To address precision challenges, it is crucial to conduct a thorough needs assessment before purchasing linear motion devices. Begin by identifying the specific performance criteria, including load capacity, speed, and stroke length. Electric linear actuators are often preferred for their high precision, but selecting the right subtype—screw-driven, belt-driven, or gear-driven—depends on the application. For example, screw-driven actuators are excellent for high-load, low-speed operations, while belt-driven types are more suitable for high-speed applications. Collaborating with suppliers who offer customization options can also help meet unique specifications. Regularly calibrating and maintaining the actuators will ensure sustained performance, thereby minimizing operational disruptions.

Scenario 2: Overcoming Environmental Challenges

The Problem:

International B2B buyers operating in sectors like agriculture or construction frequently encounter harsh environmental conditions that can affect the performance of linear motion mechanical devices. Factors such as extreme temperatures, humidity, or exposure to dust and corrosive substances can lead to equipment failures. For instance, a hydraulic actuator used in an outdoor agricultural setting may fail due to moisture ingress or temperature extremes, leading to increased maintenance costs and operational delays.

The Solution:

To mitigate environmental risks, it is essential to choose linear motion devices that are specifically designed for the intended operating conditions. For harsh environments, consider opting for actuators with weather-resistant casings or IP-rated enclosures that protect against moisture and dust. Additionally, using hydraulic actuators with corrosion-resistant materials can enhance durability in outdoor settings. Implementing regular maintenance schedules is also vital; this includes cleaning, inspection, and lubrication to prevent wear and ensure long service life. Buyers should work closely with manufacturers to understand the environmental ratings of their products and to select options that align with their specific conditions.

Scenario 3: Managing Integration with Existing Systems

The Problem:

Many B2B buyers face integration challenges when introducing new linear motion mechanical devices into existing systems. Compatibility issues can arise with older machinery or software, leading to operational inefficiencies and increased costs. For example, a new electric actuator may not interface properly with legacy control systems, resulting in suboptimal performance or even complete system failures.

The Solution:

Before acquiring new linear motion devices, conduct a comprehensive compatibility assessment of the existing systems. This involves analyzing the current control interfaces, power requirements, and communication protocols. To facilitate smoother integration, opt for linear motion devices that offer standardized interfaces, such as those compliant with widely accepted industrial protocols (e.g., CANopen, EtherCAT). Engaging with suppliers who provide technical support and integration services can also streamline the process. Furthermore, consider investing in modular systems that allow for easier upgrades and adaptations in the future, ensuring longevity and scalability in your operational setup. Regular training for staff on new systems can also enhance the overall integration experience, minimizing resistance to change and maximizing productivity.

Strategic Material Selection Guide for linear motion mechanical device

What Are the Key Materials for Linear Motion Mechanical Devices?

Selecting the right material for linear motion mechanical devices is critical for ensuring optimal performance, durability, and cost-effectiveness. Below, we analyze four common materials used in these applications, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Aluminum Alloys Perform in Linear Motion Applications?

Aluminum alloys are widely used in linear motion devices due to their lightweight and excellent corrosion resistance. They typically have a temperature rating up to 150°C and can withstand moderate pressure.

Pros: Aluminum alloys are durable, easy to machine, and provide a good strength-to-weight ratio. They are also relatively cost-effective and can be anodized for enhanced surface protection.

Cons: While aluminum alloys are resistant to corrosion, they can be less durable than steel under heavy loads. Additionally, they may not perform well in high-temperature environments beyond their rated limits.

Impact on Application: Aluminum is compatible with various media, making it suitable for applications in industries such as food processing and pharmaceuticals. However, it may not be ideal for environments with extreme temperatures or heavy mechanical stresses.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards (e.g., ASTM) and consider the availability of aluminum alloys in their market.

What Are the Benefits of Using Stainless Steel in Linear Motion Devices?

Stainless steel is a popular choice for linear motion devices due to its exceptional strength and corrosion resistance. It can handle high temperatures (up to 300°C) and pressures, making it suitable for demanding applications.

Pros: Stainless steel offers high durability, making it ideal for heavy-duty applications. It is also resistant to rust and corrosion, which is crucial in harsh environments.

Cons: The primary drawback is the cost, as stainless steel is generally more expensive than aluminum. Additionally, its weight can be a disadvantage in applications where weight savings are critical.

Impact on Application: Stainless steel is compatible with various media, including corrosive substances, making it suitable for industries such as oil and gas, pharmaceuticals, and food processing.

Considerations for International Buyers: Buyers should look for compliance with international standards (e.g., DIN, JIS) and verify that the stainless steel grades meet their specific application needs.

How Do Plastic Composites Enhance Linear Motion Devices?

Plastic composites, such as polyoxymethylene (POM) and nylon, are increasingly used in linear motion devices due to their lightweight and low-friction properties. They typically have a temperature rating up to 80°C and are resistant to many chemicals.

Pros: These materials are cost-effective, lightweight, and provide excellent wear resistance. They also minimize noise and vibration, making them suitable for applications requiring smooth operation.

Cons: Plastic composites may not withstand high loads or extreme temperatures as effectively as metals. They can also degrade over time when exposed to UV light or certain chemicals.

Impact on Application: Plastic composites are ideal for applications in robotics, automation, and consumer products where weight and noise reduction are priorities.

Considerations for International Buyers: Buyers should ensure that the selected plastic materials comply with relevant standards and are available in their local markets.

What Role Does Bronze Play in Linear Motion Systems?

Bronze is a traditional material used in linear motion devices, particularly for bushings and bearings. It has good wear resistance and can operate at temperatures up to 200°C.

Pros: Bronze offers excellent durability and low friction, making it suitable for heavy-load applications. It is also resistant to corrosion and has good thermal conductivity.

Cons: The main disadvantages are its higher cost compared to plastics and aluminum, and it may require lubrication to maintain optimal performance.

Impact on Application: Bronze is often used in applications involving heavy machinery, automotive components, and marine environments due to its robustness.

Considerations for International Buyers: Buyers should verify compliance with industry standards and consider the availability of bronze components in their specific regions.

Summary Table of Material Selection for Linear Motion Devices

| Material | Typical Use Case for Linear Motion Mechanical Device | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Robotics, food processing, light machinery | Lightweight and corrosion-resistant | Less durable under heavy loads | Medium |

| Stainless Steel | Oil and gas, pharmaceuticals, heavy machinery | High durability and corrosion-resistant | Higher cost and weight | High |

| Plastic Composites | Robotics, automation, consumer products | Low friction and lightweight | Limited load capacity and temperature | Low |

| Bronze | Heavy machinery, automotive components, marine use | Excellent wear resistance | Higher cost and lubrication needed | Medium |

This comprehensive analysis provides international B2B buyers with actionable insights into selecting the right materials for linear motion mechanical devices, considering their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for linear motion mechanical device

What Are the Typical Manufacturing Processes for Linear Motion Mechanical Devices?

Manufacturing linear motion mechanical devices involves several key stages that ensure the final product meets performance and quality standards. Understanding these processes is essential for international B2B buyers who seek reliable suppliers.

Material Preparation: What Materials Are Used in Manufacturing Linear Motion Devices?

The first step in the manufacturing process is material preparation. Common materials for linear motion devices include:

- Steel and Aluminum: These metals are preferred for their strength-to-weight ratio and durability. They are often used in components like rails and actuators.

- Plastics: Used in applications where weight reduction is crucial, plastics can also offer corrosion resistance.

- Composite Materials: These materials combine the benefits of both metals and plastics, providing enhanced performance in specific applications.

Materials must be sourced from reputable suppliers, and their quality can significantly affect the final product’s performance. International buyers should ensure that their suppliers adhere to relevant material standards.

How Are Linear Motion Devices Formed and Assembled?

Once the materials are prepared, they undergo forming, which may include machining, molding, or extrusion. Key techniques in this stage include:

- Machining: This involves cutting, grinding, or drilling the materials to precise dimensions. CNC (Computer Numerical Control) machines are commonly used for their accuracy.

- Injection Molding: For components made from plastic, injection molding allows for the creation of complex shapes with minimal waste.

- Welding and Joining: This process is essential for assembling different components. Techniques such as TIG (Tungsten Inert Gas) welding are often employed for high-strength joints.

After forming, the assembly process brings together various components, such as actuators, rails, and bearings. Precision is critical in this stage to ensure smooth linear motion and operational reliability.

What Finishing Processes Are Applied to Linear Motion Devices?

Finishing processes enhance the aesthetic and functional properties of linear motion devices. Common techniques include:

- Surface Treatment: Processes like anodizing or powder coating improve corrosion resistance and wear properties.

- Polishing: This technique is used to achieve a smooth surface finish, reducing friction and improving performance.

- Quality Testing and Inspection: Before final packaging, devices undergo rigorous testing to ensure they meet specified tolerances and functional requirements.

How Is Quality Assurance Managed in Linear Motion Device Manufacturing?

Quality assurance (QA) is a critical component of manufacturing linear motion devices, ensuring that products are reliable and meet international standards.

What Are the Relevant International Standards for Quality Assurance?

For linear motion mechanical devices, several international and industry-specific standards are applicable:

- ISO 9001: This standard outlines the requirements for a quality management system. Compliance ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For devices used in the oil and gas industry, compliance with API (American Petroleum Institute) standards is crucial for safety and reliability.

Understanding these standards helps B2B buyers assess supplier credibility and product quality.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves various checkpoints throughout the manufacturing process. Key QC stages include:

- Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials before they enter the production line. Materials that do not meet standards are rejected.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks ensure that processes are being followed correctly and that products are within specified tolerances.

- Final Quality Control (FQC): At the end of the production line, final inspections and tests verify that the finished products meet all quality and performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify a supplier’s quality control processes to ensure they receive high-quality products.

What Audit Methods Can Be Used to Assess Supplier Quality?

- Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes evaluating their compliance with ISO 9001 and other relevant standards.

- Reviewing Quality Reports: Requesting access to quality control reports can help buyers understand the effectiveness of a supplier’s QC processes.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control and compliance with international standards.

What Are the Quality Control Nuances for International Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following nuances:

- Cultural Differences: Understanding local business practices and regulatory environments can aid in smoother negotiations and compliance checks.

- Logistical Challenges: Ensure that suppliers can meet delivery timelines and maintain quality throughout the shipping process.

- Language Barriers: Clear communication is vital. Consider using interpreters or bilingual representatives to facilitate discussions about quality requirements.

Conclusion: How Can International B2B Buyers Ensure Quality in Linear Motion Devices?

By understanding the manufacturing processes and quality assurance measures involved in producing linear motion mechanical devices, international B2B buyers can make informed decisions. Focusing on suppliers who adhere to international standards, engage in thorough quality control, and are transparent about their processes will help ensure the procurement of high-quality products tailored to specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘linear motion mechanical device’

Introduction

When sourcing linear motion mechanical devices, international B2B buyers must navigate a complex landscape of specifications, suppliers, and applications. This guide provides a practical checklist to help you make informed decisions, ensuring you acquire the right equipment that meets your operational needs and standards.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the sourcing process. Consider factors such as load capacity, speed, and precision.

– What to include:

– Type of actuator (electric, hydraulic, pneumatic).

– Required stroke length and speed of movement.

– Environmental conditions (e.g., humidity, temperature) that might affect performance.

Step 2: Conduct Market Research on Suppliers

Thorough market research is essential for identifying potential suppliers. Utilize online directories, industry publications, and trade shows to gather a list of candidates.

– Key actions:

– Investigate suppliers’ reputations and their experience in your specific industry.

– Check for reviews or testimonials from previous clients, especially those from your region (Africa, South America, the Middle East, Europe).

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– What to look for:

– Certifications and compliance with international standards (ISO, CE).

– Product warranty and post-purchase support, which are critical for ensuring long-term reliability.

Step 4: Request Samples and Perform Testing

Sampling is a vital step in the procurement process. Request samples of the linear motion devices to assess their performance and compatibility with your systems.

– Testing considerations:

– Evaluate the ease of installation and integration into your existing machinery.

– Test under conditions that mimic your operational environment to ensure performance standards are met.

Step 5: Negotiate Terms and Conditions

Once you’ve shortlisted suppliers, engage in negotiations to finalize terms and conditions. This includes pricing, delivery timelines, and payment terms.

– Important aspects:

– Ensure clarity on lead times and logistics, particularly if sourcing from international suppliers.

– Discuss return policies and support in case of defects or issues post-purchase.

Step 6: Review After-Sales Support and Maintenance Options

Assessing after-sales support is crucial for the longevity of your investment. Reliable support can significantly reduce downtime and maintenance costs.

– Key questions to ask:

– What type of training is provided for your staff?

– Are spare parts readily available, and what is the supplier’s response time for servicing?

Step 7: Finalize the Purchase and Monitor Performance

After concluding negotiations and placing your order, maintain ongoing communication with your supplier.

– Follow-up actions:

– Monitor the performance of the devices upon installation and provide feedback to the supplier.

– Establish a schedule for regular maintenance checks to prolong the life of your linear motion systems.

By following this checklist, international B2B buyers can ensure a systematic approach to sourcing linear motion mechanical devices, leading to more successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for linear motion mechanical device Sourcing

What Are the Key Cost Components in Sourcing Linear Motion Mechanical Devices?

When evaluating the cost structure for linear motion mechanical devices, international B2B buyers should consider several critical components:

-

Materials: The choice of materials significantly affects the overall cost. Common materials include aluminum, steel, and plastics, each offering different durability and performance characteristics. For instance, high-quality steel may increase the initial investment but could enhance longevity and reduce replacement costs.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing but could also face challenges related to skill levels and workforce reliability.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and other operational expenses. Understanding the overhead rates of potential suppliers can provide insight into their pricing models.

-

Tooling: Custom tooling for specific applications can lead to higher initial costs. However, efficient tooling can improve production rates and reduce per-unit costs in the long run.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability but can add to costs. Buyers should assess whether the supplier’s QC measures align with their quality requirements.

-

Logistics: Shipping costs are a crucial factor, especially for international transactions. Buyers should consider the distance, shipping method, and potential tariffs or import duties when calculating total costs.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Linear Motion Device Sourcing?

Several factors influence the pricing of linear motion mechanical devices:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers should assess their needs carefully to avoid over-purchasing while still taking advantage of volume pricing.

-

Specifications and Customization: Customized solutions typically incur higher costs due to the need for specialized manufacturing processes. Buyers should balance their requirements with budget constraints.

-

Materials: As previously mentioned, the choice of materials can substantially impact pricing. Higher-grade materials often justify their costs through enhanced performance.

-

Quality and Certifications: Devices that meet international quality standards or certifications (e.g., ISO, CE) may have a premium price but can ensure compliance and reliability.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can influence pricing. Established suppliers may charge more but often provide better quality assurance and service.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) is vital, as they define the responsibilities of buyers and sellers regarding shipping costs and risks.

What Tips Can Help Buyers Negotiate Better Prices for Linear Motion Devices?

To optimize sourcing costs, international B2B buyers should consider the following strategies:

-

Negotiate Terms: Always engage in negotiations, focusing on price, payment terms, and delivery schedules. Building a good relationship with suppliers can lead to better terms over time.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes purchase price, installation, maintenance, and disposal costs. A lower initial price may not always result in long-term savings.

-

Understand Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing trends and how local market conditions affect costs. For example, currency fluctuations can significantly impact pricing in international transactions.

-

Request Samples: Before placing a large order, request samples to assess quality. This can help avoid costly mistakes and ensure that the final product meets expectations.

Disclaimer on Indicative Prices

Prices for linear motion mechanical devices can vary widely based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive a competitive price that reflects their specific needs and circumstances.

Alternatives Analysis: Comparing linear motion mechanical device With Other Solutions

When evaluating linear motion mechanical devices, it is essential to consider viable alternatives that may offer similar functionalities or benefits. This analysis aims to compare linear motion devices against other solutions, such as pneumatic actuators and hydraulic actuators, to help B2B buyers make informed decisions.

| Comparison Aspect | Linear Motion Mechanical Device | Pneumatic Actuator | Hydraulic Actuator |

|---|---|---|---|

| Performance | High precision and control | Fast response, less precise | High force, precise control |

| Cost | Moderate initial investment | Lower upfront cost | Higher upfront and maintenance costs |

| Ease of Implementation | Requires specific setup | Generally easy to install | Complex installation required |

| Maintenance | Low maintenance needs | Moderate maintenance | High maintenance due to fluid leaks |

| Best Use Case | Industrial automation, robotics | Assembly lines, packaging | Heavy machinery, construction |

What Are the Advantages and Disadvantages of Pneumatic Actuators?

Pneumatic actuators utilize compressed air to generate linear motion, making them suitable for applications requiring speed and repetitive motion. One of their significant advantages is the lower upfront cost compared to linear motion devices. They can be easily integrated into existing systems due to their simpler installation requirements. However, pneumatic actuators may lack the precision of linear motion devices, making them less suitable for applications where exact positioning is critical.

How Do Hydraulic Actuators Compare?

Hydraulic actuators operate using pressurized fluid to produce linear motion, offering high force capabilities essential for heavy-duty applications. They are ideal for environments where substantial load handling is necessary, such as in construction equipment. Despite their strong performance, hydraulic systems come with higher initial costs and maintenance challenges, including the risk of fluid leaks. Their complexity in installation can also be a barrier for some businesses, particularly those with limited technical expertise.

Conclusion: How to Choose the Right Solution for Your Needs?

Selecting the appropriate solution for linear motion applications depends on various factors, including performance requirements, budget constraints, and installation capabilities. Businesses in Africa, South America, the Middle East, and Europe should assess their specific needs, considering factors such as the required precision, load handling capabilities, and ongoing maintenance. Understanding the strengths and weaknesses of linear motion devices in comparison to pneumatic and hydraulic actuators will empower B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for linear motion mechanical device

What Are the Essential Technical Properties of Linear Motion Mechanical Devices?

When selecting linear motion mechanical devices, international B2B buyers must understand several critical specifications. These properties directly affect the performance, reliability, and suitability of the devices for specific applications.

1. Material Grade: Why Does It Matter?

The material used in the construction of linear motion devices, such as aluminum, steel, or specialized polymers, significantly impacts durability and performance. Higher-grade materials can withstand greater loads and resist wear and corrosion, making them ideal for heavy-duty applications. For buyers in regions like Africa and South America, where environmental factors can vary widely, selecting the right material can ensure longevity and reduce maintenance costs.

2. Load Capacity: How Much Can It Handle?

Load capacity refers to the maximum weight a linear actuator or similar device can support during operation. It is crucial for B2B buyers to assess the load requirements of their specific applications. Choosing a device with an inadequate load capacity can lead to failure, downtime, and increased costs. Understanding the precise load limits helps in selecting the right device for machinery, automation, or robotics.

3. Tolerance: What Precision Do You Need?

Tolerance measures the permissible limit of variation in the dimensions of the device. In linear motion applications, precise tolerances are vital for ensuring smooth operation and reducing friction. Buyers in industries such as aerospace or medical devices, where precision is paramount, should prioritize devices with tight tolerances to ensure optimal functionality and safety.

4. Speed: How Fast Does It Need to Move?

The speed of a linear motion device indicates how quickly it can complete its operation. Depending on the application, such as in assembly lines or robotics, different speed ratings are required. Buyers must evaluate their operational needs to ensure that the selected devices can perform efficiently without compromising on quality.

5. Stroke Length: How Far Will It Travel?

Stroke length defines the maximum distance a linear actuator can move. It is essential for applications that require significant movement, such as lifting or sliding mechanisms. Understanding the required stroke length helps buyers ensure that the actuator can meet their operational demands without limitations.

What Are the Common Trade Terms in the Linear Motion Industry?

Familiarity with industry jargon can streamline communication and negotiation processes for B2B buyers. Here are some common terms that are essential in the linear motion sector.

1. OEM (Original Equipment Manufacturer): Who Are They?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the linear motion industry, partnering with OEMs can offer buyers access to high-quality components tailored to their specifications. Understanding OEM relationships can help buyers ensure they receive reliable products.

2. MOQ (Minimum Order Quantity): What Does It Mean?

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it directly impacts inventory management and cash flow. Knowing the MOQ helps in planning purchases and negotiating better terms, especially for companies in emerging markets where capital may be limited.

3. RFQ (Request for Quotation): How to Use It?

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is vital for securing competitive pricing and understanding market rates. Buyers should be prepared to provide detailed specifications to receive accurate quotes from suppliers.

4. Incoterms: What Are They?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms can help international buyers navigate logistics and ensure compliance with trade regulations, minimizing risks associated with international transactions.

5. Lead Time: How Long Until You Get It?

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for effective project management and scheduling. Buyers need to consider lead times when planning their operations, particularly in industries with tight deadlines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring linear motion mechanical devices, ensuring they select the right solutions for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the linear motion mechanical device Sector

What Are the Current Market Dynamics and Key Trends in the Linear Motion Mechanical Device Sector?

The linear motion mechanical device sector is experiencing robust growth driven by several global factors. Increasing automation across industries such as manufacturing, automotive, and aerospace is a significant driver, as companies seek to enhance efficiency and reduce operational costs. Moreover, the rise of smart technologies, including IoT and Industry 4.0, is transforming how linear motion devices are integrated into production systems. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed purchasing decisions.

A stock image related to linear motion mechanical device.

A stock image related to linear motion mechanical device.

One of the most notable trends is the shift towards electric linear actuators, which are favored for their precision, energy efficiency, and lower maintenance requirements compared to traditional hydraulic and pneumatic systems. Additionally, the demand for compact and lightweight designs is increasing, especially in sectors like automotive and aerospace, where space and weight are critical. Emerging markets are also witnessing a surge in demand for customized solutions, prompting suppliers to innovate and offer tailored linear motion devices to meet specific application needs.

As B2B buyers evaluate suppliers, they should consider the technological capabilities and product diversity offered by manufacturers. Factors such as lead time, support services, and the ability to provide integrated solutions will play a pivotal role in supplier selection. Understanding regional dynamics, including local regulations and market entry barriers, will also be essential for successful sourcing.

How Can Sustainability and Ethical Sourcing Impact Your Supply Chain for Linear Motion Mechanical Devices?

In an era increasingly focused on sustainability, B2B buyers must consider the environmental impact of their sourcing decisions. The linear motion mechanical device sector is no exception, with rising awareness about the carbon footprint associated with manufacturing processes and materials used. Buyers are encouraged to seek suppliers that prioritize eco-friendly practices, such as using sustainable materials and minimizing waste during production.

A stock image related to linear motion mechanical device.

Ethical sourcing is becoming a crucial factor in supplier evaluation, particularly for companies looking to enhance their corporate social responsibility (CSR) profiles. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility can serve as benchmarks for assessing supplier practices. Furthermore, the use of “green” materials in the production of linear motion devices—such as recyclable metals or biodegradable components—can not only reduce environmental impact but also appeal to a growing segment of eco-conscious consumers.

Investing in suppliers that demonstrate a commitment to sustainability can lead to long-term benefits, including improved brand reputation and customer loyalty. For buyers in regions like Africa and South America, where sustainable development is a priority, aligning sourcing strategies with ethical and environmental considerations can significantly enhance market competitiveness.

How Has the Linear Motion Mechanical Device Sector Evolved Over Time?

The evolution of the linear motion mechanical device sector can be traced back to the early days of industrial automation. Initially, linear motion devices were primarily mechanical systems using gears and levers, which limited precision and efficiency. The introduction of electric and hydraulic actuators marked a significant advancement, allowing for greater control and adaptability in various applications.

As technology progressed, the development of computer-aided design (CAD) and simulation tools enabled manufacturers to create more sophisticated linear motion systems, including the integration of sensors and smart technologies. This evolution has led to the current landscape, characterized by high-performance, energy-efficient devices that cater to diverse industrial needs.

For international B2B buyers, understanding this historical context can provide insights into the rapid advancements in technology and the importance of selecting suppliers that are committed to innovation and quality. As the sector continues to evolve, staying abreast of the latest trends and technologies will be essential for maintaining a competitive edge in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of linear motion mechanical device

-

How do I select the right linear motion device for my application?

Choosing the right linear motion device involves assessing your specific application needs, such as load capacity, speed, and precision. For instance, electric actuators are ideal for applications requiring precise control, while hydraulic actuators suit heavy-duty tasks. Evaluate environmental conditions, such as temperature and exposure to dust or moisture, as these factors can influence actuator performance. Consulting with suppliers to discuss your requirements can lead to better customization options and enhanced operational efficiency. -

What is the best linear actuator type for industrial automation?

For industrial automation, electric linear actuators are often the best choice due to their precision, flexibility, and ease of control. They can be screw-driven, belt-driven, or gear-driven, allowing for tailored solutions based on speed and force requirements. Hydraulic actuators are also suitable for heavy-duty applications where high force is necessary. Ultimately, the selection should align with your specific operational demands and the nature of the materials being handled. -

What are the key factors to consider when sourcing linear motion devices internationally?

When sourcing linear motion devices globally, key factors include the reliability of the supplier, quality assurance processes, and compliance with international standards. Additionally, consider the supplier’s experience in your industry, their ability to provide customization, and their logistics capabilities. It’s also vital to understand local regulations, import duties, and tariffs that may affect your total costs. Establishing good communication with suppliers can help clarify these aspects and streamline the procurement process. -

What is the minimum order quantity (MOQ) for linear motion devices?

The minimum order quantity (MOQ) for linear motion devices varies by supplier and product type. Generally, manufacturers may set an MOQ to cover production costs efficiently. It’s advisable to inquire directly with suppliers about their MOQ policies, as some may offer flexibility based on your specific needs or if you are a first-time buyer. Understanding MOQs can help you manage inventory effectively and avoid overstocking or stockouts. -

How can I ensure the quality of linear motion devices before purchasing?

To ensure quality, request samples or prototypes before placing a bulk order. Review the supplier’s certifications, such as ISO 9001, to confirm adherence to international quality standards. Additionally, consider conducting audits of the manufacturing facilities or seeking third-party inspections. Establishing a clear quality assurance agreement, detailing performance metrics and testing procedures, can also help maintain high standards throughout the procurement process. -

What payment terms should I expect when buying linear motion devices from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include upfront deposits (usually 30-50%) and the balance upon delivery or after inspection. Letter of Credit (LC) is another option that offers security for both parties. It’s important to discuss and negotiate these terms before finalizing the purchase. Understanding the supplier’s payment preferences can facilitate smoother transactions and mitigate financial risks. -

What are the logistics considerations for importing linear motion devices?

Logistics considerations include shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder familiar with the import regulations of your country. Understand the costs associated with shipping, insurance, and duties, as these can significantly affect your overall budget. Additionally, ensure that the supplier provides all necessary documentation, such as invoices, packing lists, and certificates of origin, to facilitate smooth customs processing. -

How can I customize linear motion devices to fit my specific needs?

Many suppliers offer customization options for linear motion devices, allowing you to tailor specifications such as size, load capacity, speed, and control mechanisms. Engage with your supplier early in the design process to communicate your requirements. Providing detailed application scenarios and performance expectations will help them propose the best solutions. Additionally, inquire about the supplier’s capacity for rapid prototyping to expedite the development of customized solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for linear motion mechanical device

In conclusion, strategic sourcing of linear motion mechanical devices is vital for optimizing operational efficiency and enhancing product quality across various industries. By understanding the diverse types of linear actuators—such as electric, hydraulic, and pneumatic—international B2B buyers can make informed decisions that align with their specific operational needs. Additionally, sourcing from reliable manufacturers ensures not only product reliability but also compliance with international standards, which is crucial in regions like Africa, South America, the Middle East, and Europe.

What are the next steps for B2B buyers in the linear motion market? As you consider your sourcing strategies, prioritize suppliers that offer customization options and robust after-sales support. Engaging with manufacturers who understand local market dynamics can significantly enhance your supply chain resilience.

Looking ahead, the demand for precision motion control solutions will continue to grow, driven by advancements in automation and robotics. Seize this opportunity to innovate and stay competitive by integrating cutting-edge linear motion devices into your operations. Take action today to secure your supply chain and position your business for future success.