Discover Top Benefits of Truck Typer for B2B Buyers (2025)

Introduction: Navigating the Global Market for truck typer

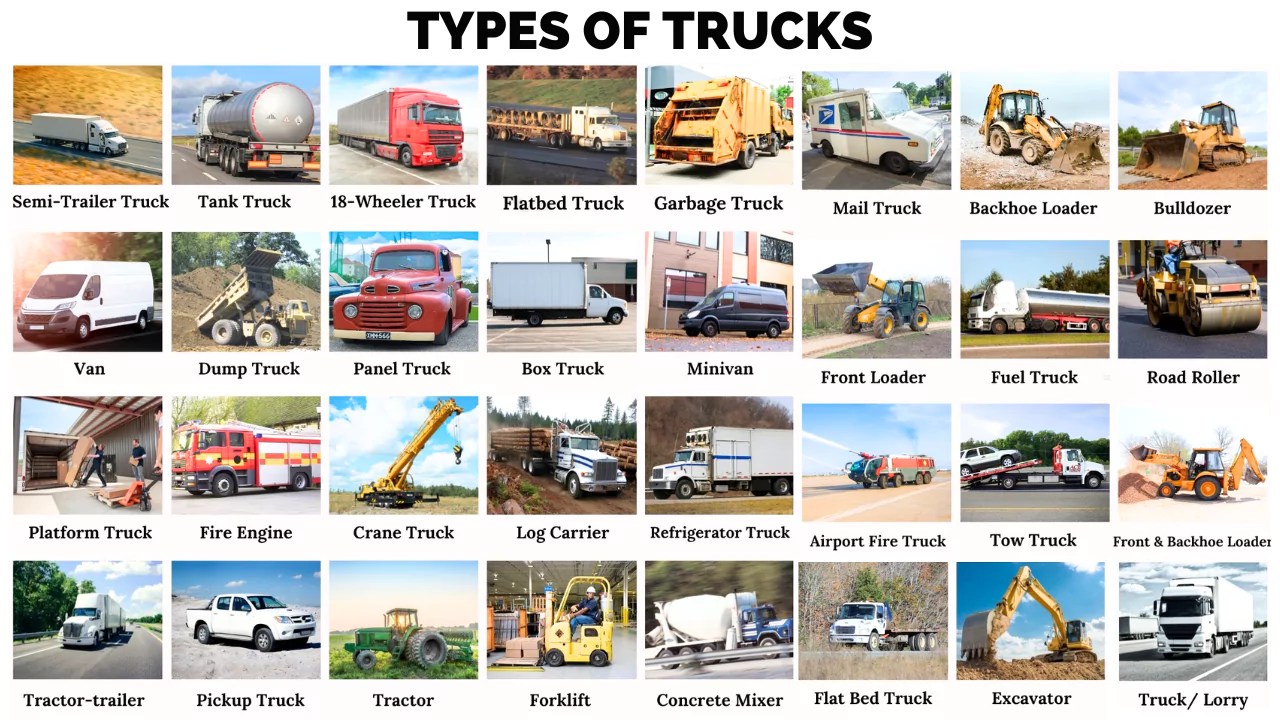

In today’s rapidly evolving logistics landscape, sourcing the right truck type for transporting goods can be a significant challenge for international B2B buyers. Understanding the various classifications of trucks—such as flatbed, refrigerated, and dry van—is essential for ensuring that your shipments meet specific cargo requirements while optimizing costs and efficiency. This guide aims to demystify the complexities of truck types, offering insights into their applications, the nuances of supplier vetting, and the potential costs involved.

As businesses from Africa, South America, the Middle East, and Europe (including countries like Nigeria and Saudi Arabia) navigate the global market, making informed purchasing decisions is crucial. This comprehensive resource empowers B2B buyers by providing actionable insights and best practices tailored to your unique regional challenges. By understanding the strengths and limitations of different truck types, you can enhance your supply chain strategy, reduce risks associated with cargo damage, and improve customer satisfaction.

In the sections that follow, we will explore the key factors to consider when selecting a truck type, effective methods for evaluating suppliers, and cost-saving strategies that can elevate your logistics operations. Equip yourself with the knowledge needed to make strategic decisions that align with your business goals and drive operational excellence in the competitive global marketplace.

Understanding truck typer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flatbed Trucks | Open design, no sides or roof, versatile load options | Construction, oversized cargo transport | Pros: Easy loading/unloading; Cons: Less protection from elements. |

| Refrigerated Trucks | Insulated body with temperature control capabilities | Food distribution, pharmaceuticals | Pros: Maintains temperature-sensitive goods; Cons: Higher operational costs. |

| Dry Van Trucks | Enclosed trailer with a solid structure | General freight transport | Pros: Protects cargo from weather; Cons: Limited loading flexibility. |

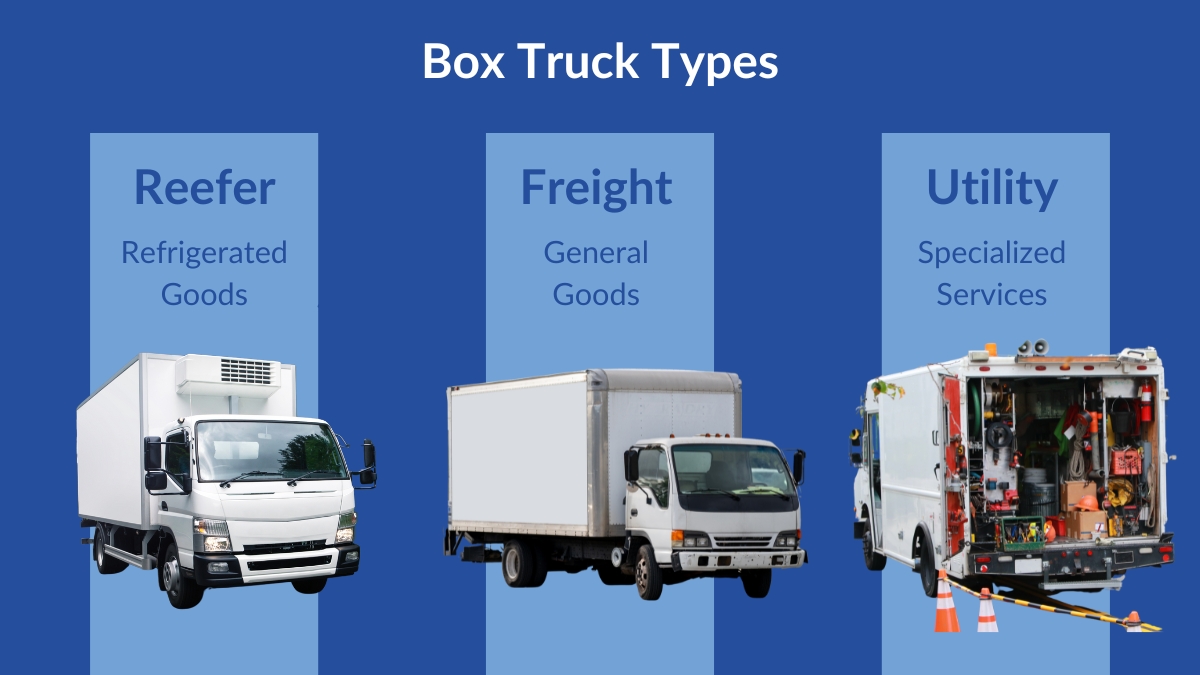

| Box Trucks | Cargo area is enclosed with a separate cabin | Urban deliveries, furniture transport | Pros: Versatile for various goods; Cons: Limited cargo capacity compared to larger trucks. |

| Tanker Trucks | Cylindrical tanks for liquid transport | Fuel distribution, chemicals, food products | Pros: Efficient for liquid transport; Cons: Requires specialized handling and permits. |

What are the Key Characteristics of Flatbed Trucks for B2B Buyers?

Flatbed trucks are characterized by their open design, which allows for easy loading and unloading of oversized or irregularly shaped cargo. This type of truck is ideal for industries such as construction and manufacturing, where heavy machinery and building materials are frequently transported. B2B buyers should consider the flatbed’s versatility and ease of access when selecting this type of truck, though they should also be aware of the lack of protection from weather elements, which can lead to potential damage to cargo.

Why Choose Refrigerated Trucks for Transporting Sensitive Goods?

Refrigerated trucks are equipped with temperature control systems that make them essential for transporting perishable goods such as food and pharmaceuticals. These trucks ensure that products remain within a specific temperature range, thereby preventing spoilage and ensuring compliance with health regulations. When purchasing refrigerated trucks, B2B buyers must assess the operational costs, as these vehicles typically require more maintenance and fuel compared to standard trucks. However, the benefits of preserving sensitive cargo often outweigh these costs.

How Do Dry Van Trucks Meet General Freight Needs?

Dry van trucks feature an enclosed trailer that protects cargo from external conditions, making them suitable for general freight transport across various industries. They are particularly advantageous for goods that require protection from weather and theft. B2B buyers should consider the advantages of security and weather protection when opting for dry van trucks, although they may find limited loading flexibility as a drawback, especially for oversized items.

What are the Advantages of Using Box Trucks for Urban Deliveries?

Box trucks are designed with an enclosed cargo area and a separate cabin, making them well-suited for urban deliveries and smaller loads. They are versatile and can accommodate a variety of goods, from furniture to appliances. For B2B buyers, the compact size of box trucks allows for easier navigation in crowded urban environments. However, they come with a limited cargo capacity compared to larger trucks, which may affect logistics planning for larger shipments.

Why are Tanker Trucks Necessary for Liquid Transport?

Tanker trucks are specifically designed to transport liquids, featuring cylindrical tanks that can carry a range of products from fuel to food-grade liquids. Their design ensures efficient transport while maintaining the integrity of the liquid. B2B buyers in industries such as fuel distribution or chemical transport must consider the need for specialized handling and permits associated with tanker trucks. While they offer efficient transport solutions, the complexity of regulations and safety requirements can be a significant consideration for potential buyers.

Key Industrial Applications of truck typer

| Industry/Sector | Specific Application of Truck Typer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transportation of perishable goods using refrigerated trucks | Ensures product freshness and compliance with health standards | Temperature control capabilities, reliability, and maintenance support |

| Construction | Delivery of heavy machinery and materials using flatbed trucks | Reduces downtime and improves project timelines | Load capacity, vehicle durability, and compliance with local regulations |

| Retail | Distribution of consumer goods with dry van trucks | Enhances inventory turnover and customer satisfaction | Fleet size, route optimization software, and delivery tracking systems |

| Pharmaceuticals | Transporting temperature-sensitive medications | Maintains efficacy of drugs and ensures regulatory compliance | Advanced temperature monitoring, secure handling, and traceability |

| Automotive | Shipping of auto parts and vehicles using specialized trucks | Streamlines supply chain and minimizes delays | Customization options, load security features, and international shipping capabilities |

How is Truck Typer Used in the Food and Beverage Industry?

In the food and beverage sector, truck typers are critical for transporting perishable goods, particularly with refrigerated trucks. These vehicles ensure that products remain at safe temperatures throughout transit, thus preserving freshness and preventing spoilage. For international buyers in regions such as Africa and the Middle East, sourcing trucks with reliable cooling systems and robust maintenance support is essential to meet health regulations and consumer expectations.

What are the Applications of Truck Typer in Construction?

Construction companies often rely on flatbed trucks for transporting heavy machinery and materials to job sites. These trucks facilitate timely deliveries, which is crucial for maintaining project schedules. Buyers from South America and Europe should consider the load capacity and durability of these trucks to ensure they can handle the rigors of construction environments while complying with local transportation laws.

How Does Truck Typer Enhance Retail Distribution?

In the retail sector, dry van trucks are employed for the distribution of consumer goods. These vehicles allow for efficient inventory management and timely delivery, enhancing customer satisfaction. B2B buyers in Europe and Africa should focus on sourcing trucks equipped with route optimization software and real-time tracking capabilities to improve logistics efficiency and reduce operational costs.

Why is Truck Typer Important for Pharmaceuticals?

The pharmaceutical industry often requires specialized transportation for temperature-sensitive medications. Truck typers with advanced temperature monitoring systems are essential to ensure that products maintain their efficacy during transit. Buyers from regions with stringent regulatory frameworks, such as Europe and the Middle East, must prioritize secure handling and traceability features when sourcing these vehicles to ensure compliance and protect public health.

How is Truck Typer Utilized in the Automotive Sector?

In the automotive industry, truck typers are crucial for shipping auto parts and vehicles. Specialized trucks streamline the supply chain, reducing delays and ensuring timely delivery to manufacturers and dealerships. International buyers, particularly from Africa and South America, should look for trucks with customization options and load security features to cater to specific shipping needs and enhance operational efficiency.

3 Common User Pain Points for ‘truck typer’ & Their Solutions

Scenario 1: Navigating Complex Truck Type Specifications

The Problem:

B2B buyers often face challenges in understanding the different types of trucks available for their logistics needs. With various classifications such as flatbed, refrigerated, and dry van trucks, selecting the right truck type can be overwhelming. This complexity is particularly pronounced in international markets like Africa and South America, where local regulations and cargo requirements can further complicate decisions. Buyers may struggle to determine which truck type will best meet their transportation needs, leading to delays, increased costs, and potential damage to goods.

The Solution:

To overcome this challenge, B2B buyers should invest in comprehensive training and resources that clarify truck types and their specific applications. Engaging with logistics experts or consulting firms can provide valuable insights into the unique requirements of various markets. Additionally, creating a checklist based on cargo type, weight, and delivery timelines can help streamline the selection process. Buyers should prioritize suppliers who offer detailed specifications and educational resources regarding their truck types. Utilizing software that matches cargo needs with appropriate truck types can also enhance decision-making efficiency.

Scenario 2: Ensuring Compliance with Local Regulations

The Problem:

Another significant pain point for B2B buyers is ensuring compliance with local transportation regulations, which can vary dramatically across regions. For instance, in the Middle East and Europe, regulations may dictate specific requirements for vehicle emissions, weight limits, and even truck types permitted on certain roads. Failure to comply can result in fines, shipment delays, and damage to business reputation, especially for international shipments that cross multiple borders.

The Solution:

To address regulatory compliance issues, buyers should conduct thorough research into the local laws governing transportation in their target regions. Establishing partnerships with local logistics providers who understand the regulatory landscape is crucial. These partners can provide real-time updates on changes in regulations and assist in navigating compliance requirements. Additionally, buyers should consider utilizing compliance management software that tracks regulations by region, ensuring they remain informed and can adjust their logistics strategies accordingly.

Scenario 3: Managing Operational Costs Effectively

The Problem:

Operational costs in logistics can escalate quickly, especially if B2B buyers do not choose the right truck type for their shipments. For example, using an oversized truck for a small load can result in unnecessary fuel costs and higher maintenance expenses. In regions like Africa and South America, where logistics infrastructure may not be as developed, the impact of operational inefficiencies can be even more pronounced, affecting overall profitability.

The Solution:

To manage operational costs effectively, buyers should analyze their shipping needs meticulously before selecting a truck type. Conducting a cost-benefit analysis that compares the operational costs of different truck types against their cargo needs can provide clarity. Additionally, leveraging technology such as route optimization software can help reduce fuel consumption and improve delivery efficiency. Buyers should also consider employing a mix of truck types based on seasonal demand fluctuations, which can help optimize fleet usage and minimize idle time. Regularly reviewing and adjusting the logistics strategy based on performance metrics will also help in maintaining cost-effectiveness.

By addressing these common pain points through informed decision-making, strategic partnerships, and technology utilization, B2B buyers can enhance their logistics operations and ultimately drive business success.

Strategic Material Selection Guide for truck typer

What Are the Common Materials Used in Truck Typer Construction?

When selecting materials for truck typers, it is essential to consider the specific requirements of the application, including durability, cost, and performance under various conditions. Below are analyses of four common materials used in truck typers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform as a Material for Truck Typers?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures, which is crucial for truck typers that may encounter challenging operational environments.

Pros & Cons: The primary advantage of steel is its strength and resistance to deformation. However, it is prone to corrosion if not properly treated, which can lead to increased maintenance costs. Additionally, steel can be more expensive to manufacture and transport, particularly in regions with limited access to steel production facilities.

Impact on Application: Steel’s robustness makes it ideal for truck typers that are expected to handle heavy loads or operate in harsh environments. However, buyers must consider the need for protective coatings to prevent rust, especially in humid climates.

Specific Considerations for International Buyers: Compliance with international standards such as ASTM for steel grades is critical. Buyers from regions like Nigeria and Saudi Arabia should ensure that suppliers can meet these standards to avoid issues with quality and safety.

What Role Does Aluminum Play in Truck Typer Manufacturing?

Key Properties: Aluminum is lightweight and offers excellent corrosion resistance, making it an attractive option for truck typers that require mobility and efficiency. It also has a good strength-to-weight ratio, which can enhance fuel efficiency.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can lead to lower shipping costs and improved fuel efficiency. However, aluminum is generally less durable than steel and may not be suitable for extremely heavy loads.

Impact on Application: Aluminum is particularly effective in applications where weight savings are crucial, such as in fuel-efficient transport solutions. However, it may not be the best choice for heavy-duty applications where maximum strength is required.

Specific Considerations for International Buyers: Buyers should be aware of the varying standards for aluminum alloys across regions. For instance, compliance with DIN standards in Europe or JIS in Japan is essential for ensuring material quality.

How Does Composite Material Compare in Truck Typer Applications?

Key Properties: Composite materials, often made from a combination of plastic and fiberglass, are known for their lightweight and high strength. They also offer excellent resistance to corrosion and chemicals.

Pros & Cons: The primary advantage of composites is their resistance to environmental factors, which can significantly extend the lifespan of truck typers. However, they can be more expensive to manufacture and may require specialized handling during production.

Impact on Application: Composites are suitable for applications that require a high degree of resistance to chemicals and moisture, making them ideal for transporting sensitive materials. However, their cost may be a barrier for some buyers.

Specific Considerations for International Buyers: Buyers should ensure that the composites used meet local regulatory standards, particularly in regions with strict environmental regulations. Understanding the certification process for composites in different countries is vital.

What Is the Importance of Rubber in Truck Typer Design?

Key Properties: Rubber is flexible and offers excellent shock absorption, making it ideal for components that experience significant vibration and movement. It also has good resistance to wear and tear.

Pros & Cons: The main advantage of rubber is its ability to absorb shocks and vibrations, which can enhance the performance and lifespan of truck typers. However, rubber can degrade over time when exposed to UV light and extreme temperatures.

Impact on Application: Rubber is essential for components like seals and gaskets, where flexibility and durability are crucial. However, buyers must consider the environmental conditions the rubber will be exposed to, as this can affect its longevity.

Specific Considerations for International Buyers: Buyers should look for rubber materials that comply with international standards, such as ASTM D2000. Additionally, understanding the local climate conditions is important for selecting the right type of rubber.

Summary Table of Material Selection for Truck Typers

| Material | Typical Use Case for Truck Typer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High strength and durability | Prone to corrosion | High |

| Aluminum | Lightweight transport solutions | Excellent corrosion resistance | Less durable than steel | Medium |

| Composite | Chemical and moisture-sensitive cargo | High resistance to environmental factors | Higher manufacturing costs | High |

| Rubber | Seals and gaskets | Excellent shock absorption | Degrades under UV and extreme temps | Medium |

This guide provides a comprehensive overview of material selection for truck typers, enabling international B2B buyers to make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for truck typer

What Are the Key Stages in the Manufacturing Process of Truck Types?

The manufacturing process for truck types is a meticulous and structured operation that ensures the creation of vehicles capable of meeting diverse transportation needs. This process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

1. Material Preparation

In the initial stage, raw materials are sourced based on the specifications of the truck type being produced. Common materials include high-strength steel for the chassis, aluminum for lightweight components, and composite materials for certain body parts. Quality checks are performed to ensure that these materials meet industry standards. This step may involve selecting suppliers who comply with international standards such as ISO 9001, which guarantees quality management systems.

2. Forming

The forming stage involves shaping the raw materials into the necessary components of the truck. Techniques such as stamping, welding, and machining are commonly employed. For example, chassis components are often stamped from steel sheets and then welded together to form a robust frame. Advanced computer numerical control (CNC) machines may be used to ensure precision in cutting and shaping parts, which is critical for the overall performance and safety of the truck.

3. Assembly

During the assembly stage, the formed components are brought together. This process often involves multiple sub-assemblies, such as the drivetrain, electrical systems, and bodywork. Quality Control (QC) checkpoints are essential here to verify that each component is correctly installed and functioning as intended. This includes in-process quality checks (IPQC) where technicians inspect assemblies at various stages of completion to catch any potential issues early.

4. Finishing

The final stage is finishing, where the truck is painted, and any additional features are added. This may involve applying protective coatings to enhance durability and aesthetics. After finishing, final quality checks (FQC) are conducted to ensure that the truck meets all specifications and is ready for delivery. This stage is critical for ensuring that the truck can withstand the operational environments it will face, especially in diverse regions like Africa and South America.

What International Standards Should B2B Buyers Consider in Quality Assurance?

Quality assurance in truck manufacturing is vital for ensuring safety, reliability, and compliance with industry regulations. B2B buyers must be aware of the relevant international and industry-specific standards that govern manufacturing processes.

ISO 9001 Certification

ISO 9001 is a globally recognized standard for quality management systems. Manufacturers with this certification demonstrate a commitment to consistent quality and customer satisfaction. Buyers should look for suppliers who hold ISO 9001 certification as it indicates rigorous internal processes and continuous improvement practices.

CE Marking

For buyers in Europe, CE marking is crucial. It signifies that the product meets EU safety, health, and environmental protection standards. Trucks must comply with these regulations to be sold in the European market, providing assurance to buyers regarding the safety and compliance of the vehicles.

API Standards

In specific contexts, particularly when dealing with specialized trucks (like those used in oil and gas), API (American Petroleum Institute) standards may apply. These standards are critical for ensuring that the trucks can safely transport hazardous materials.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for international B2B buyers, especially when sourcing from diverse regions. Here are key methods to ensure that suppliers maintain high-quality standards:

Conducting Audits

Regular audits of suppliers can provide insights into their quality control processes. Buyers should consider performing both scheduled and random audits to assess compliance with industry standards and internal quality protocols. These audits can help identify areas for improvement and ensure that the supplier adheres to best practices.

Reviewing Quality Control Reports

Suppliers should provide comprehensive QC reports detailing their quality assurance processes, including results from inspections and tests. Buyers should request these documents to understand the supplier’s commitment to quality and any actions taken in response to identified issues.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can enhance the reliability of quality assessments. Independent inspectors can evaluate the manufacturing processes and final products against industry standards. This adds an additional layer of assurance for buyers, ensuring that the trucks meet the required specifications before shipment.

What Common Testing Methods Are Employed in Truck Manufacturing?

Quality assurance in truck manufacturing involves various testing methods to ensure that each vehicle meets safety and performance standards. Common testing methods include:

Performance Testing

This includes dynamic testing of the truck’s components, such as brakes and engines, to ensure they perform under expected conditions. Performance tests can simulate real-world scenarios to evaluate how well the truck can handle loads and navigate different terrains.

Load Testing

Load testing is crucial for verifying that the truck can support its intended cargo weight without compromising structural integrity. This is especially important for trucks designed for heavy-duty use, where overloads can lead to failures.

Environmental Testing

Environmental tests assess how trucks perform under extreme conditions, such as high temperatures, humidity, and corrosive environments. This is particularly relevant for international buyers in regions with diverse climates, ensuring the vehicle’s reliability in varying conditions.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in the truck manufacturing process is essential. Here are key considerations:

Regional Compliance Requirements

Different regions have specific compliance requirements that manufacturers must meet. Buyers should familiarize themselves with local regulations that may affect the design and safety standards of trucks in their respective markets.

Cultural and Operational Differences

Cultural factors can influence quality management practices. Buyers should consider how local practices may affect supplier reliability and quality assurance. Engaging with suppliers who understand these nuances can lead to better outcomes.

Establishing Strong Relationships

Building strong relationships with suppliers can enhance communication regarding quality control. Regular dialogue about expectations and performance can foster a collaborative approach to maintaining high standards.

In conclusion, B2B buyers must be diligent in understanding the manufacturing processes and quality assurance practices associated with truck types. By considering these factors, they can make informed decisions that align with their operational needs and ensure compliance with international standards.

A stock image related to truck typer.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘truck typer’

Introduction

In today’s global marketplace, selecting the right type of truck for your logistics needs is essential for efficient transportation and cost management. This practical sourcing guide provides a step-by-step checklist for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, looking to procure various truck types. By following these steps, you will ensure that you make informed decisions that align with your operational requirements and budget constraints.

Step 1: Define Your Cargo Requirements

Understanding the specifics of your cargo is the first step in selecting the appropriate truck type. Different trucks are designed for various cargo needs—refrigerated trucks for perishable goods, flatbeds for oversized items, and dry vans for general freight. Clearly defining your cargo requirements will help streamline the sourcing process and ensure that the selected truck type can handle your goods without risk of damage.

Step 2: Identify Your Budget Constraints

Before beginning the procurement process, establish a clear budget that encompasses both the purchase or lease cost and the ongoing operational expenses. Consider factors such as fuel efficiency, maintenance costs, and insurance premiums. A well-defined budget helps prevent overspending and ensures that you can afford the total cost of ownership for the truck type you choose.

Step 3: Research Potential Suppliers

A stock image related to truck typer.

Conduct thorough research to identify potential suppliers who specialize in the truck types you need. Look for suppliers with a proven track record in your region, as they will be familiar with local regulations and logistical challenges. Request company profiles, case studies, and references from other buyers to gauge their reliability and performance.

- Tip: Utilize online reviews and industry forums to gather insights about supplier reputation.

Step 4: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers hold relevant certifications and comply with industry regulations. Certifications can indicate quality standards, safety practices, and environmental compliance. Verify that the supplier meets the necessary legal requirements for the specific truck types you are interested in, as this will mitigate risks associated with non-compliance.

Step 5: Request Detailed Proposals

Once you have narrowed down potential suppliers, request detailed proposals that outline the specifications, pricing, and service offerings for the truck types you are considering. Pay attention to the terms of service, warranty options, and after-sales support. A comprehensive proposal will give you a clearer picture of the value each supplier brings to the table.

- Consider: Comparing multiple proposals side-by-side to identify the best fit for your needs.

Step 6: Arrange for Test Drives or Demonstrations

If possible, arrange for test drives or demonstrations of the truck types you are considering. This hands-on experience allows you to assess the vehicle’s performance, comfort, and suitability for your operations. Pay attention to handling, cargo space, and ease of loading and unloading.

Step 7: Finalize Terms and Conditions

After selecting a supplier and truck type, ensure that you carefully review and finalize all terms and conditions before making a purchase or lease agreement. This includes payment terms, delivery schedules, and any service level agreements. Clear communication at this stage helps prevent misunderstandings and establishes a solid foundation for your business relationship.

By following this checklist, international B2B buyers can make informed decisions that enhance their logistics operations and ensure they select the right truck type to meet their specific needs.

Comprehensive Cost and Pricing Analysis for truck typer Sourcing

What Are the Key Cost Components in Truck Type Sourcing?

When sourcing truck types, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The type of materials used directly affects the cost. For example, a flatbed truck may require high-strength steel, while a refrigerated truck needs insulation materials and cooling systems. The choice of materials can significantly influence both the price and the longevity of the vehicle.

-

Labor: Labor costs encompass wages for skilled workers involved in manufacturing and assembly. Countries with a lower labor cost may offer competitive pricing; however, this can sometimes correlate with quality. Always consider the balance between cost and craftsmanship.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, maintenance, and factory rent. Efficient manufacturing processes can help reduce these overhead costs, impacting the final pricing.

-

Tooling: Customization often requires specialized tooling, which can add to the initial investment. Understanding the tooling costs associated with specific truck types is essential for accurate budgeting.

-

Quality Control (QC): Ensuring that each truck meets safety and performance standards involves QC processes. Investing in rigorous QC can lead to higher upfront costs but may save money in the long run by reducing warranty claims and enhancing customer satisfaction.

-

Logistics: Shipping costs vary based on the distance and mode of transportation. International buyers should be aware of the implications of shipping costs, which can fluctuate due to fuel prices and geopolitical factors.

-

Margin: Suppliers often include a profit margin in their pricing. Understanding industry norms for margins can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Truck Type Pricing?

Several factors can influence the pricing of truck types:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often leads to discounts. B2B buyers should negotiate for lower prices based on larger order volumes, which can significantly reduce the overall cost per unit.

-

Specifications and Customization: Customized trucks with specific features will generally command higher prices. Buyers should clearly define their specifications to avoid unnecessary costs.

-

Materials and Quality Certifications: Trucks built with high-quality materials or those that meet specific industry certifications (like ISO or ASME) will typically be priced higher. Understanding the implications of these certifications can help in making informed purchasing decisions.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their products but often provide better after-sales support and warranty services.

-

Incoterms: The shipping terms defined by Incoterms can affect the final cost. Buyers should understand the implications of terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight), as these can shift cost responsibilities and risks.

What Are Effective Buyer Tips for Cost-Efficiency in Truck Type Sourcing?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, consider the following tips for effective sourcing:

-

Negotiate Terms: Always negotiate with suppliers to find mutually beneficial terms. Leverage bulk orders or long-term contracts to secure better pricing.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operation, and resale value when determining the overall cost. A cheaper truck may have higher operating costs that negate initial savings.

-

Research Pricing Nuances: Understand the local market dynamics in your region. Prices can vary significantly based on local demand, import tariffs, and currency fluctuations.

-

Consider Local Suppliers: Engaging with local manufacturers can reduce logistics costs and tariffs, making sourcing more cost-effective.

-

Stay Informed: Regularly review market trends and pricing changes within the truck industry to ensure you are making informed purchasing decisions.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on numerous factors including market conditions, specific supplier agreements, and geographical location. Always conduct thorough research and obtain multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing truck typer With Other Solutions

Introduction to Alternatives in Truck Typing Solutions

When considering the optimal solution for truck typing, it’s crucial to evaluate various alternatives that can meet the specific needs of B2B logistics. Selecting the right method or technology can significantly impact operational efficiency, cost management, and overall performance. In this analysis, we will compare ‘Truck Typer’ against two viable alternatives: Typing Simulation Software and Manual Typing Training Programs. Each option presents unique advantages and challenges that can cater to diverse business requirements.

Comparison Table of Truck Typing Solutions

| Comparison Aspect | ‘Truck Typer’ | Typing Simulation Software | Manual Typing Training Programs |

|---|---|---|---|

| Performance | High accuracy and speed enhancement | Offers realistic typing scenarios | Varies based on instructor quality |

| Cost | Subscription-based pricing | One-time purchase or subscription | Varies by course length and provider |

| Ease of Implementation | User-friendly interface | Moderate; requires setup | High; requires scheduling and attendance |

| Maintenance | Minimal; updates provided | Regular updates needed | No ongoing maintenance; self-paced |

| Best Use Case | Ideal for competitive training | Great for individual skill development | Suitable for group learning environments |

Detailed Breakdown of Each Alternative

1. Typing Simulation Software

Typing Simulation Software provides an interactive environment that mimics real-world typing scenarios. It often incorporates gamified elements to engage users and enhance retention. This type of software is particularly effective for individuals seeking to improve their typing speed and accuracy through realistic practice sessions.

Pros:

– Engaging interface that keeps users motivated.

– Ability to track progress over time, allowing for targeted skill improvement.

– Can be used independently, making it suitable for remote learning.

Cons:

– May require initial setup time and a learning curve for users unfamiliar with technology.

– Costs can add up if multiple licenses are needed for a team.

2. Manual Typing Training Programs

Manual Typing Training Programs involve traditional classroom or online settings where an instructor leads the course. This method can be beneficial for organizations looking to provide structured learning environments, particularly for larger groups.

Pros:

– Direct feedback from instructors can facilitate faster learning.

– Group settings encourage peer learning and collaboration.

– Structured curriculum ensures comprehensive coverage of skills.

Cons:

– Less flexibility in scheduling compared to software solutions.

– Quality and effectiveness can vary significantly based on the instructor.

– Potentially higher costs associated with hiring qualified trainers.

Conclusion: Choosing the Right Solution for Your Needs

When deciding on the most suitable solution for truck typing, B2B buyers should consider their specific operational requirements, budget constraints, and training goals. ‘Truck Typer’ excels in performance and ease of use, making it ideal for companies focused on enhancing individual typing skills quickly. In contrast, Typing Simulation Software offers a more immersive experience, while Manual Typing Training Programs provide structured learning but with less flexibility. Ultimately, aligning the choice with organizational objectives and employee learning preferences will lead to the most effective outcomes.

Essential Technical Properties and Trade Terminology for truck typer

What Are the Essential Technical Properties of Truck Types?

When it comes to selecting the right truck for your logistics needs, understanding key technical properties is crucial. Here are some critical specifications to consider:

1. Load Capacity

Load capacity refers to the maximum weight a truck can carry safely. This specification is vital for B2B buyers because exceeding the load capacity can lead to legal penalties, increased wear and tear on the vehicle, and potential damage to goods. For instance, a flatbed truck with a high load capacity is ideal for transporting heavy machinery, while smaller trucks may suffice for lighter loads.

2. Dimensions and Tolerance

Truck dimensions, including length, width, and height, dictate the type of cargo that can be transported. Tolerance levels indicate the acceptable variance in these dimensions. This is particularly important for international shipping where compliance with local regulations is necessary. Ensuring that your cargo fits within these dimensions not only prevents delays but also optimizes loading efficiency.

3. Fuel Efficiency

Fuel efficiency is a measure of how much fuel a truck consumes relative to the distance traveled. This property impacts operational costs significantly. For international B2B buyers, selecting fuel-efficient trucks can result in substantial savings, especially in regions where fuel prices are high. Additionally, this consideration aligns with sustainability goals, as lower fuel consumption leads to reduced emissions.

4. Cargo Type Compatibility

Understanding the compatibility of various truck types with specific cargo is essential. For example, refrigerated trucks are designed for temperature-sensitive goods, while dry vans are suitable for general freight. This knowledge allows B2B buyers to choose the right truck type, reducing the risk of product spoilage and ensuring compliance with safety regulations.

5. Vehicle Durability and Maintenance Requirements

The durability of a truck affects its lifespan and the frequency of maintenance needed. Trucks that are built with high-quality materials and components may require less frequent repairs, which can lower overall costs. Buyers should consider the long-term maintenance implications when evaluating different truck types, especially in regions where service availability may be limited.

6. Payload Distribution

Payload distribution refers to how weight is distributed across the truck’s axles. Proper distribution is critical for maintaining vehicle stability and avoiding overloading any single axle. For B2B buyers, ensuring appropriate payload distribution is vital for safety, legal compliance, and optimizing transport efficiency.

What Are Common Trade Terms Used in Truck Typing?

Understanding industry jargon is essential for effective communication and negotiations in the logistics sector. Here are some common trade terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In truck typing, knowing the OEM helps buyers ensure they are sourcing quality parts that meet the specifications of the truck type they are using.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budget planning and inventory management, especially when dealing with specialized trucks or parts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on specific products or services. For international buyers, issuing an RFQ can streamline the procurement process, enabling you to compare prices and terms from multiple vendors efficiently.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and insurance responsibilities, ensuring smooth international transactions.

5. Tare Weight

Tare weight is the weight of the truck when empty. Understanding tare weight is essential for calculating the net weight of the cargo being transported, which is crucial for compliance with load limits and regulations.

6. Freight Forwarder

A freight forwarder is a third-party company that arranges the logistics of shipping goods on behalf of shippers. Engaging with a freight forwarder can simplify the shipping process for B2B buyers, providing expertise in navigating customs and optimizing routes.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, optimize their logistics operations, and enhance their supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the truck typer Sector

What Are the Key Market Dynamics and Trends Affecting the Truck Typer Sector?

The truck typer sector is undergoing significant transformations driven by globalization, technological advancements, and evolving consumer demands. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the following key trends shaping the market.

1. Increasing Demand for Diverse Truck Types

As logistics needs become more complex, the demand for various truck types, such as refrigerated and flatbed trucks, is on the rise. Companies are increasingly focused on selecting the right truck type to optimize their supply chains and minimize costs. For instance, refrigerated trucks are essential for transporting perishable goods, while flatbeds cater to oversized equipment. This trend necessitates that buyers engage with suppliers who can offer a range of specialized vehicles.

2. Technology Integration in Logistics

The adoption of digital solutions, such as fleet management software and IoT devices, is enhancing operational efficiency. These technologies enable real-time tracking of shipments, predictive maintenance of vehicles, and improved route optimization. Buyers in the truck typer sector should prioritize suppliers who integrate these technologies into their offerings to gain a competitive advantage.

3. Shift Towards Localized Sourcing

In response to global disruptions, many companies are shifting towards localized sourcing strategies. This trend is particularly relevant for buyers in Africa and South America, where local suppliers can offer quicker turnaround times and reduced shipping costs. Understanding the local market dynamics and establishing relationships with regional suppliers can significantly enhance supply chain resilience.

How Can Sustainability and Ethical Sourcing Impact the Truck Typer Sector?

As the world increasingly prioritizes sustainability, the truck typer sector must also adapt to these environmental concerns. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to ethical sourcing and sustainability practices.

1. Environmental Impact of Trucking

The trucking industry contributes significantly to carbon emissions. Consequently, buyers should seek suppliers who utilize eco-friendly trucks, such as those powered by alternative fuels or electric vehicles. This not only helps reduce the carbon footprint but also meets the growing consumer demand for sustainable practices.

2. Importance of Ethical Supply Chains

Ethical sourcing is becoming a critical factor in supplier selection. Buyers should ensure that their suppliers adhere to fair labor practices and environmental regulations. This includes verifying that the materials used in truck manufacturing, such as metals and plastics, are sourced responsibly.

3. Green Certifications and Materials

Investing in suppliers with green certifications (like ISO 14001) can enhance a company’s reputation and appeal to environmentally conscious consumers. Moreover, utilizing sustainable materials in truck production can lead to reduced waste and lower lifecycle costs. Buyers should actively inquire about the sustainability practices of potential suppliers to ensure alignment with their corporate responsibility goals.

What Is the Evolution of the Truck Typer Sector for B2B Buyers?

A stock image related to truck typer.

The truck typer sector has evolved significantly over the decades, adapting to technological innovations and changing market demands. Initially, trucks were primarily designed for utility, focusing on basic transportation needs. However, as logistics became more sophisticated, the variety of truck types expanded to include specialized vehicles capable of handling specific cargo requirements.

The introduction of technologies such as GPS tracking and automated fleet management systems has revolutionized the industry, allowing for increased efficiency and reliability in logistics operations. Furthermore, the rise of e-commerce has accelerated demand for rapid delivery services, prompting the development of agile supply chains and diverse truck options.

Today, B2B buyers must navigate a complex landscape where understanding truck types, sourcing trends, and sustainability practices is crucial for making informed purchasing decisions. By staying abreast of these trends, international buyers can optimize their logistics strategies and ensure competitive positioning in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of truck typer

-

How do I choose the right truck type for my specific cargo needs?

Selecting the appropriate truck type is crucial for ensuring the safe and efficient transportation of your goods. Start by assessing the nature of your cargo—does it require temperature control, special handling, or is it oversized? For instance, refrigerated trucks are ideal for perishable items, while flatbed trucks suit bulky or heavy equipment. Collaborate with logistics providers who can guide you in determining the best truck type based on your shipment’s dimensions, weight, and any regulatory requirements. -

What are the most common truck types used in international logistics?

International logistics frequently employs various truck types, including flatbed, dry van, refrigerated, and tanker trucks. Flatbed trucks are versatile for oversized loads, while dry vans provide enclosed transportation for general cargo. Refrigerated trucks are essential for temperature-sensitive shipments like food and pharmaceuticals, and tankers are used for liquids. Understanding these classifications helps you select the right vehicle to meet your logistics needs and ensures compliance with international shipping regulations. -

What factors should I consider when vetting suppliers for truck types?

When vetting suppliers, evaluate their industry experience, customer reviews, and the range of truck types they offer. Consider their fleet’s condition and compliance with safety standards. It’s also essential to check their reliability in meeting delivery timelines and their ability to handle customs and import/export regulations specific to your region. Engage in discussions about their logistics capabilities, including tracking and communication systems, to ensure they align with your operational needs. -

How can I customize my truck type for specific transport requirements?

Customization options for truck types can include temperature control systems for refrigerated trucks, specialized loading equipment for flatbeds, or adjustable shelving for dry vans. Discuss your specific needs with the supplier, as many offer modifications to enhance functionality. Ensure that any customization complies with local regulations and international shipping standards. This tailored approach not only improves efficiency but also ensures the safe transport of your unique cargo. -

What are the minimum order quantities (MOQ) for purchasing truck types?

Minimum order quantities can vary significantly based on the supplier and the truck type. For instance, manufacturers might have higher MOQs for specialized trucks compared to standard models. It’s advisable to inquire about MOQs during your supplier discussions, particularly if you are a new business or looking to test the market. Some suppliers may offer flexibility for first-time buyers, allowing for smaller orders to assess the quality and performance of their trucks. -

What payment terms should I expect when sourcing truck types internationally?

Payment terms for international truck purchases typically include options like letters of credit, advance payments, and net terms. It’s essential to negotiate terms that align with your cash flow and risk management strategies. Common terms include 30% upfront and the remaining 70% upon delivery or a certain number of days post-delivery. Always ensure that the payment terms are documented in the purchase agreement to avoid misunderstandings and facilitate smoother transactions. -

How do I ensure quality assurance for my truck purchases?

To ensure quality assurance when purchasing trucks, request detailed product specifications and certifications from suppliers. Conducting a factory audit or visiting the supplier’s premises can provide insight into their manufacturing processes. Additionally, consider third-party inspections before shipment to verify that the trucks meet your standards. Establishing a clear return policy in case of defects can also protect your investment and maintain quality standards. -

What logistics considerations should I keep in mind when sourcing truck types from different regions?

When sourcing trucks internationally, consider logistics factors such as shipping methods, customs clearance, and local regulations. Understand the impact of transport costs on your budget, including duties and taxes. It’s also vital to evaluate the supplier’s ability to handle logistics, including their experience with cross-border shipments and delivery timelines. Collaborating with a logistics partner familiar with the regions involved can streamline the process and mitigate potential delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for truck typer

Why is Strategic Sourcing Essential for Selecting Truck Types?

In today’s competitive landscape, understanding the nuances of truck types is crucial for international B2B buyers aiming to streamline logistics operations. By strategically sourcing the appropriate truck type—be it refrigerated, flatbed, or dry van—businesses can significantly enhance their supply chain efficiency. This not only minimizes risks of damage but also ensures timely deliveries, ultimately leading to improved customer satisfaction.

How Can International Buyers Benefit from Tailored Truck Solutions?

For buyers in Africa, South America, the Middle East, and Europe, leveraging tailored truck solutions can yield substantial cost benefits. Selecting the right vehicle based on specific cargo requirements allows businesses to optimize transportation costs while complying with local regulations. This strategic approach to sourcing not only meets immediate logistical needs but also fosters long-term partnerships with reliable 3PL providers.

What’s Next for B2B Buyers in Truck Logistics?

As the global logistics landscape continues to evolve, staying informed about advancements in truck technology and sourcing strategies will be pivotal. International B2B buyers should actively seek opportunities to collaborate with logistics experts who can provide insights tailored to their unique markets. Embrace this opportunity to innovate your supply chain and position your business for future growth. Engage with reputable suppliers today to ensure that you are equipped to meet the demands of tomorrow’s marketplace.