Discover Top Door Latch Types: A Complete Buying Guide (2025)

Introduction: Navigating the Global Market for door latch types

In today’s dynamic global market, sourcing the right door latch types can pose a significant challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The multitude of options available—ranging from mortice latches to panic latches—can be overwhelming, especially when each type offers unique features suited to specific applications. This comprehensive guide aims to demystify the various door latch types, providing insights into their functionalities, applications, and the critical factors to consider when making purchasing decisions.

Throughout this guide, we will explore the different categories of door latches, including their installation processes and material compositions. In addition to detailing the specifications and benefits of each latch type, we will delve into essential considerations for supplier vetting, ensuring that international buyers can identify reliable manufacturers and distributors. Cost analysis will also be covered, helping you to balance quality with budget constraints.

By equipping B2B buyers with in-depth knowledge and actionable insights, this guide empowers you to make informed decisions that enhance security and functionality in your facilities. Whether you are in the market for high-security latches in Europe or cost-effective solutions in Africa, understanding the nuances of door latch types will streamline your procurement process and ultimately contribute to your operational success.

Understanding door latch types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mortice Latches | Recessed installation, various sizes, suitable for heavy-duty use | Commercial buildings, residential doors | Pros: Secure, versatile, aesthetic options. Cons: Installation can be complex. |

| Rim Latches | Surface-mounted, easy installation, commonly used in older settings | Traditional homes, interior doors | Pros: Simple to install, good for retrofits. Cons: Lower security than mortice latches. |

| Nightlatches | Automatically locks when closed, often combined with deadlocks | Residential properties, high-security areas | Pros: Enhanced security, convenient. Cons: May require additional keys for access. |

| Roller Bolt Latches | Uses a rolling mechanism, quiet operation, adjustable settings | Light-duty applications, cupboards | Pros: Easy to install, ideal for internal use. Cons: Limited security for external doors. |

| Magnetic Latches | Utilizes magnets for closure, sleek design, suitable for modern interiors | Office spaces, modern residential doors | Pros: Aesthetically pleasing, easy to use. Cons: Less secure than traditional latches. |

What Are the Key Characteristics of Mortice Latches?

Mortice latches are designed to be recessed into the door, providing a clean and secure installation. They come in various sizes, making them suitable for both light and heavy-duty applications. B2B buyers should consider the specific needs of their commercial or residential properties, as these latches offer versatility and aesthetic appeal. However, the installation process can be complex, requiring skilled labor, which may add to overall costs.

How Do Rim Latches Differ from Other Latch Types?

Rim latches are mounted on the surface of the door, making them easy to install without the need for cutting into the door. They are commonly found in older homes and traditional settings, providing a nostalgic aesthetic. For B2B buyers, rim latches are ideal for retrofitting existing doors, but they may not offer the same level of security as mortice latches, which is a critical consideration for businesses requiring higher security measures.

Why Choose Nightlatches for Enhanced Security?

Nightlatches automatically lock the door when it is closed, providing an added layer of security for residential properties. They can be combined with deadlocks for enhanced protection in high-security areas. B2B buyers should evaluate their security needs, as nightlatches offer convenience and peace of mind, although they may require additional keys for access control, which could complicate management for larger facilities.

What Are the Advantages of Roller Bolt Latches?

Roller bolt latches operate using a rolling mechanism that allows for quiet and smooth operation. They are best suited for light-duty applications, such as internal doors and cupboards. For businesses, roller bolt latches are easy to install and adjust, making them a practical choice for environments that prioritize ease of use. However, their limited security features may not be suitable for external doors, which should be carefully considered when making purchasing decisions.

How Do Magnetic Latches Fit into Modern Interior Design?

Magnetic latches utilize magnets to hold doors closed, offering a sleek and contemporary design. They are particularly suited for modern office spaces and residential interiors that prioritize aesthetics. B2B buyers should note that while magnetic latches are user-friendly and visually appealing, they typically provide less security compared to traditional latch types. This trade-off should be evaluated based on the specific security requirements of the facility or space in question.

Key Industrial Applications of door latch types

| Industry/Sector | Specific Application of Door Latch Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Secure guest room doors with mortice latches | Enhances guest security and privacy | Durability, ease of installation, compliance with local regulations |

| Construction | Use of panic latches in emergency exits | Ensures safety and compliance with safety standards | Testing certifications, ease of use in emergencies, maintenance requirements |

| Manufacturing | Roller bolt latches for machinery access doors | Increases operational efficiency and safety | Load capacity, environmental resistance, compatibility with existing systems |

| Retail | Rim latches for storage rooms and display cases | Protects inventory and enhances security | Aesthetic appeal, ease of access, lock compatibility |

| Residential | Magnetic latches for interior doors | Provides a modern, seamless look | Style options, ease of installation, functionality in high-traffic areas |

How Are Door Latch Types Used in the Hospitality Sector?

In the hospitality industry, mortice latches are commonly employed to secure guest room doors. These latches provide a robust locking mechanism that enhances guest security and privacy, essential for maintaining a trustworthy environment. International buyers must consider factors such as durability and ease of installation when sourcing these latches, as they often face high foot traffic and require maintenance to ensure long-term functionality.

What Role Do Panic Latches Play in Construction?

Panic latches are crucial in construction, especially for emergency exits in commercial buildings. They provide a quick and easy exit route in emergencies, ensuring compliance with safety regulations and enhancing overall building safety. When sourcing panic latches, buyers should prioritize products with testing certifications to ensure reliability, along with ease of use during emergencies to facilitate rapid evacuation.

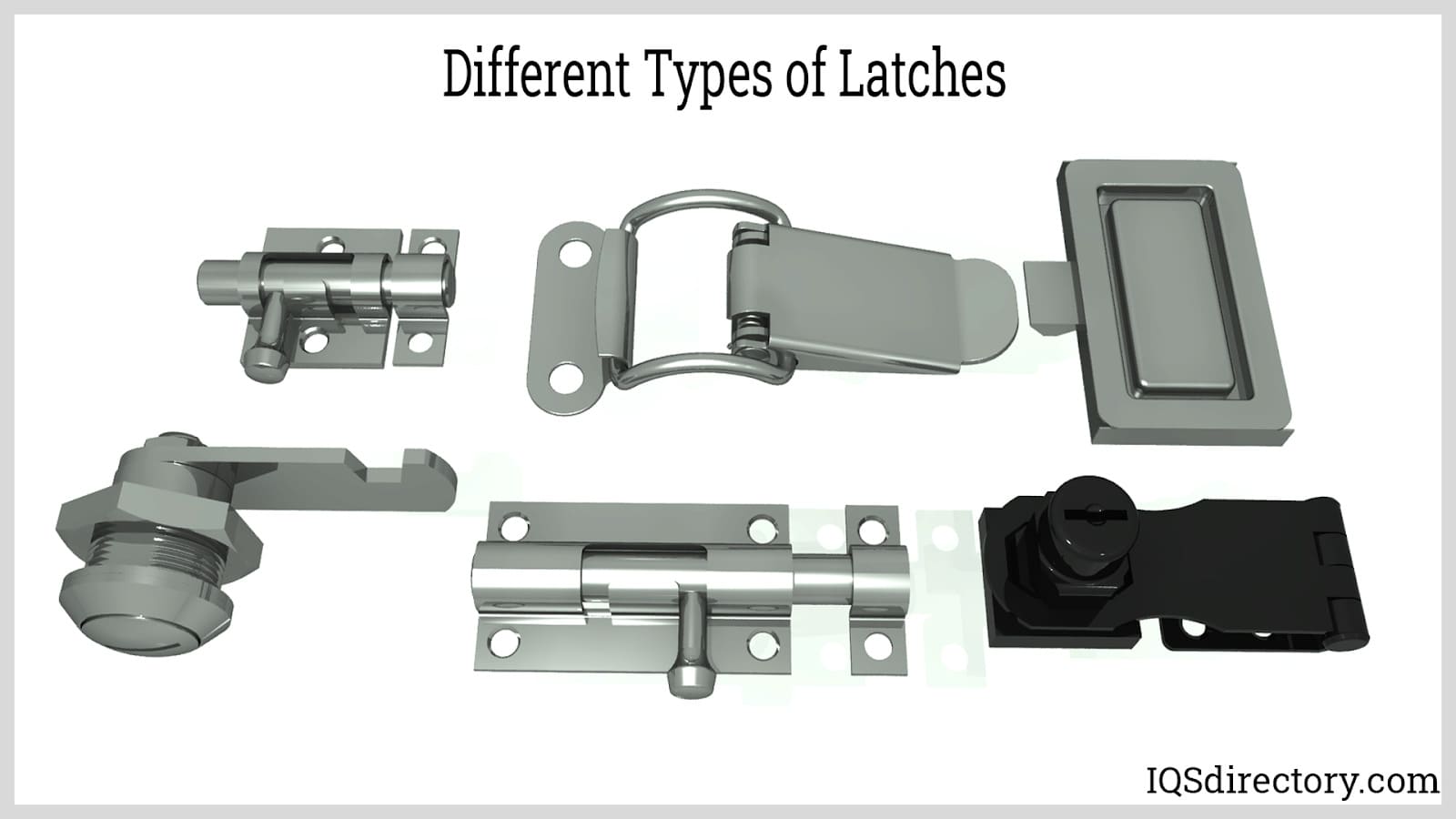

A stock image related to door latch types.

How Are Roller Bolt Latches Beneficial in Manufacturing?

In manufacturing environments, roller bolt latches are often used for securing machinery access doors. These latches enhance operational efficiency by providing a reliable locking mechanism that can withstand heavy use. Buyers in this sector should focus on the load capacity and environmental resistance of the latches, ensuring they can handle the specific conditions of their facilities while maintaining safety standards.

Why Are Rim Latches Important in Retail?

In the retail sector, rim latches are frequently used to secure storage rooms and display cases. They protect valuable inventory from theft while allowing easy access for staff. When sourcing rim latches, businesses should consider aesthetic appeal and ease of access, as these factors can impact the overall shopping experience and operational efficiency.

What Advantages Do Magnetic Latches Offer in Residential Applications?

Magnetic latches are increasingly popular in modern residential applications, particularly for interior doors. They offer a sleek, seamless appearance while providing reliable closure without the noise of traditional latches. For international buyers, it’s important to evaluate style options and ease of installation, particularly in high-traffic areas where functionality and visual appeal are both critical.

3 Common User Pain Points for ‘door latch types’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Door Latch for Security Needs

The Problem: International B2B buyers often grapple with selecting the appropriate door latch type that provides optimal security for their facilities. With various options available, including mortice latches, nightlatches, and panic latches, the challenge lies in understanding which latch type meets specific security requirements. For example, a buyer in South America may need to secure a warehouse but might be unsure whether to opt for a heavy-duty mortice latch or a panic latch for emergency exits. This indecision can lead to inadequate security measures that expose the facility to risks.

The Solution: To address this challenge, B2B buyers should conduct a thorough security assessment of their premises. This includes evaluating the level of foot traffic, the types of doors being secured, and potential vulnerabilities. Once these factors are analyzed, buyers can refer to detailed specifications of each latch type. For instance, using mortice latches for high-traffic areas provides robust security, while panic latches are ideal for emergency exits, ensuring compliance with safety regulations. Buyers should consult with trusted suppliers who can provide expert recommendations based on local regulations and security needs. Furthermore, investing in latches that offer features like keyless entry or master keying can enhance security and accessibility.

Scenario 2: Installation Challenges with Different Door Latch Types

The Problem: Another common pain point for B2B buyers is the installation complexity associated with various door latch types. Buyers in the Middle East may encounter doors that require specific latch installations, such as rim latches on older structures where retrofitting is necessary. The challenge often stems from the need for specialized tools and skills, which may not be readily available, resulting in delays and increased labor costs.

The Solution: To mitigate installation issues, buyers should prioritize door latches that offer straightforward installation methods. For instance, rim latches are surface-mounted and do not require extensive modifications to the door, making them a practical choice for older buildings. Buyers should also consider suppliers that provide comprehensive installation guides and customer support. Additionally, engaging local contractors who specialize in door hardware can streamline the installation process and ensure that the latches are fitted correctly. By doing so, buyers can save time and costs associated with improper installation, while ensuring optimal functionality and security.

Scenario 3: Maintenance and Durability Concerns Over Time

The Problem: As door latches are subjected to frequent use, durability and maintenance become critical issues for B2B buyers. Buyers from Europe, particularly those managing commercial properties, often find that standard latches wear out quickly under heavy usage, leading to malfunctioning doors and increased repair costs. This can be particularly problematic in high-traffic environments, where maintaining security and accessibility is crucial.

The Solution: To combat durability issues, buyers should invest in high-quality door latches specifically designed for heavy-duty applications. For example, selecting latches made from corrosion-resistant materials, such as stainless steel, can significantly enhance longevity. Additionally, buyers should establish a regular maintenance schedule that includes lubricating moving parts and checking for wear and tear. Partnering with suppliers who offer warranties or service agreements can also provide peace of mind and facilitate easier replacements when necessary. By prioritizing durable latch options and proactive maintenance, buyers can reduce long-term costs and ensure the reliability of their door security systems.

Strategic Material Selection Guide for door latch types

When selecting door latches for various applications, the choice of material plays a critical role in determining performance, durability, and overall suitability. Here, we analyze four common materials used in door latch manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel for Door Latches?

Steel is one of the most commonly used materials for door latches due to its exceptional strength and durability. It typically offers high tensile strength, making it suitable for heavy-duty applications. Steel latches can withstand significant temperature variations and pressure, which is crucial in environments with fluctuating conditions. Additionally, steel can be treated with various coatings to enhance its corrosion resistance, making it suitable for both indoor and outdoor applications.

Pros and Cons of Steel:

– Pros: High durability, excellent strength, and good temperature resistance. Steel latches can be cost-effective in bulk manufacturing.

– Cons: Prone to corrosion if not properly coated, which can limit its lifespan in humid or coastal environments. The manufacturing complexity can increase with the need for additional protective coatings.

How Does Brass Compare as a Material for Door Latches?

Brass is another popular choice for door latches, especially in residential and decorative applications. Known for its aesthetic appeal, brass offers good corrosion resistance, particularly in indoor settings. It has a moderate strength level, making it suitable for light to medium-duty applications. Brass latches also have natural antimicrobial properties, which can be beneficial in healthcare or food service environments.

Pros and Cons of Brass:

– Pros: Attractive appearance, good corrosion resistance, and inherent antimicrobial properties.

– Cons: Lower strength compared to steel, which may not be suitable for heavy-duty applications. Brass can also be more expensive due to its material cost.

What Are the Benefits of Plastic in Door Latch Manufacturing?

Plastic latches are increasingly used in various applications due to their lightweight nature and resistance to corrosion. They are often employed in environments where moisture is prevalent, such as bathrooms or kitchens. Plastic latches are typically manufactured using injection molding, which allows for complex shapes and designs while keeping costs low.

Pros and Cons of Plastic:

– Pros: Lightweight, corrosion-resistant, and cost-effective for high-volume production.

– Cons: Generally less durable than metal options, with limited temperature resistance. Plastic may not be suitable for high-security applications due to its lower strength.

Why Is Stainless Steel a Preferred Material for High-Performance Latches?

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it ideal for high-performance door latches. It is particularly advantageous in harsh environments, including coastal areas or industrial settings, where exposure to moisture and chemicals is common. Stainless steel latches can withstand high temperatures and are often used in applications requiring compliance with strict hygiene standards.

Pros and Cons of Stainless Steel:

– Pros: High strength, excellent corrosion resistance, and suitability for a wide range of applications.

– Cons: Higher manufacturing costs compared to standard steel and brass, which may impact budget-sensitive projects.

Summary Table of Material Selection for Door Latch Types

| Material | Typical Use Case for door latch types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty commercial doors | High strength and durability | Prone to corrosion without coating | Medium |

| Brass | Residential decorative doors | Attractive appearance and antimicrobial | Lower strength than steel | High |

| Plastic | Moisture-prone environments | Lightweight and corrosion-resistant | Less durable and lower temperature resistance | Low |

| Stainless Steel | High-performance and industrial doors | Excellent corrosion resistance | Higher cost compared to other metals | High |

In conclusion, the selection of materials for door latches should align with the specific application requirements, environmental conditions, and budget constraints. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider local standards and preferences when making their material choices to ensure compliance and optimal performance.

In-depth Look: Manufacturing Processes and Quality Assurance for door latch types

What Are the Main Stages of Manufacturing Door Latch Types?

The manufacturing process of door latches involves several critical stages that ensure the final product meets both functional and quality standards. Understanding these stages is essential for B2B buyers aiming to source reliable and durable door latches.

Material Preparation: Which Materials Are Commonly Used?

The first step in the manufacturing process is material preparation. Door latches are typically made from metals such as steel, brass, or aluminum due to their strength and durability. In some cases, plastic components may also be utilized, especially in lighter-duty applications. The materials must be sourced from reputable suppliers to ensure compliance with quality standards.

Before production begins, the raw materials undergo a thorough inspection to check for any defects or inconsistencies. This is crucial, as the quality of the raw materials directly impacts the performance and longevity of the door latches.

What Techniques Are Used in the Forming Stage?

Once the materials are prepared, the next stage is forming. Various techniques can be used depending on the type of door latch being manufactured:

-

Stamping: This is a common technique used for creating flat components such as latch plates and strike plates. A stamping press shapes the metal into the desired form, ensuring precision and uniformity.

-

Casting: For more complex designs, casting may be employed. This involves pouring molten metal into a mold to create intricate shapes that would be difficult to achieve through stamping.

-

Machining: Many latches require additional machining processes, such as drilling or milling, to achieve the necessary tolerances for moving parts. This step ensures that components fit together seamlessly, which is critical for the functionality of the latch.

-

Extrusion: For certain types of latches, such as tubular latches, extrusion is used to create long, continuous shapes that can be cut to length as needed.

How is Assembly Conducted for Door Latch Types?

After the components are formed, the next stage is assembly. This process may involve the following:

-

Manual Assembly: Skilled workers assemble the components by hand, ensuring that each part is correctly aligned and secured. This is particularly important for intricate latches where precision is key.

-

Automated Assembly: In larger manufacturing facilities, automated assembly lines may be employed. Robotics and machinery can speed up the process and enhance consistency across batches.

-

Quality Checks During Assembly: Throughout the assembly process, operators perform checks to ensure that components meet quality standards. This may include verifying the fit of moving parts and checking for any visible defects.

What Finishing Techniques Are Commonly Used for Door Latches?

The finishing stage is crucial for both aesthetics and functionality. Common finishing techniques include:

-

Plating: Many door latches undergo plating (e.g., nickel or chrome plating) to enhance corrosion resistance and improve appearance.

-

Powder Coating: For a more durable finish, powder coating is applied. This process involves applying a dry powder that is then cured under heat to create a hard finish.

-

Painting: Some manufacturers may opt for traditional paint finishes, especially for decorative latches.

-

Packaging: Finally, finished products are packaged to prevent damage during transportation. Proper packaging also ensures that the latches reach the buyer in pristine condition.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is a vital aspect of the manufacturing process, ensuring that door latches perform as expected and meet safety regulations.

Which International Standards Are Relevant?

B2B buyers should be aware of several international standards that relate to the manufacturing and quality assurance of door latches:

-

ISO 9001: This standard specifies requirements for a quality management system (QMS). Manufacturers certified under ISO 9001 are committed to consistently providing products that meet customer and regulatory requirements.

-

CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Standards: The American Petroleum Institute (API) sets standards for manufacturing equipment used in oil and gas applications, which may also include door latches for industrial settings.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): Before production starts, raw materials are inspected for defects and compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators perform regular inspections to catch any issues early on. This may include measuring tolerances and checking for proper assembly.

-

Final Quality Control (FQC): After assembly and finishing, the final products undergo comprehensive testing. This may include functional tests, durability tests, and visual inspections to ensure that they meet all specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensure that they are sourcing high-quality door latches.

What Methods Can Be Used for Verification?

-

Audits: Conducting supplier audits is one of the most effective ways to verify quality control processes. This can include on-site visits to assess manufacturing practices and quality management systems.

-

Quality Reports: Requesting quality control reports from suppliers can provide insights into their QC processes and performance metrics. This should include data on defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can take place at various stages of the manufacturing process.

-

Certifications: Verify that suppliers hold relevant certifications (such as ISO 9001 or CE) that demonstrate their commitment to quality.

What Are the QC Nuances for International B2B Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider specific nuances in quality control:

-

Regional Standards: Different regions may have unique standards and regulations that manufacturers must comply with. Understanding these can help buyers select suppliers that meet their local market requirements.

-

Cultural Differences: Communication styles and business practices can vary significantly across regions. Building strong relationships with suppliers and understanding their operational culture can enhance quality assurance efforts.

-

Supply Chain Transparency: International buyers should seek suppliers who are transparent about their sourcing and manufacturing processes. This can help mitigate risks associated with quality and compliance.

By understanding the manufacturing processes and quality assurance protocols for door latches, B2B buyers can make informed decisions and select suppliers that align with their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door latch types’

In today’s global marketplace, sourcing the right door latch type is essential for ensuring security and functionality in various applications, from commercial buildings to residential properties. This guide will assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed decisions when procuring door latches.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it is crucial to outline the specific technical requirements for the door latches you need. Consider factors such as the type of door (interior or exterior), the level of security required, and any environmental conditions (e.g., weather resistance for outdoor latches).

- Key Considerations:

- Load-bearing capacity

- Size and design compatibility with existing doors

- Compliance with local building codes

Step 2: Research Different Door Latch Types

Familiarize yourself with the various types of door latches available in the market. Understanding the differences between mortice latches, rim latches, and panic latches, among others, will help you select the most suitable option for your application.

- Common Types:

- Mortice Latches: Ideal for heavy-duty applications.

- Rim Latches: Great for traditional or rustic settings.

- Panic Latches: Essential for emergency exits.

Step 3: Evaluate Potential Suppliers

Conduct thorough research to identify reliable suppliers who specialize in door hardware. Look for companies with a strong reputation and experience in your specific region to ensure they understand local market demands and regulations.

- What to Check:

- Supplier certifications and compliance with international standards

- Customer reviews and testimonials

- Case studies relevant to your industry

Step 4: Request Samples and Product Specifications

Once you have shortlisted potential suppliers, request samples of the door latches you are considering. Evaluating samples allows you to assess the quality and functionality firsthand, ensuring they meet your specifications.

- Details to Request:

- Material composition and durability

- Installation instructions

- Maintenance requirements

Step 5: Verify Lead Times and Availability

Understanding the lead times and availability of the door latches is essential for planning your project timeline. Ensure that the suppliers can meet your deadlines and can handle any fluctuations in demand.

- Important Aspects:

- Production capacity to meet bulk orders

- Shipping options and associated costs

- Flexibility in order quantities

Step 6: Negotiate Pricing and Payment Terms

Once you are satisfied with the product quality and availability, engage in negotiations regarding pricing and payment terms. Establishing clear and fair terms will help maintain a healthy supplier relationship while ensuring budget compliance.

- Points to Discuss:

- Volume discounts for bulk orders

- Payment methods (e.g., letters of credit, upfront payments)

- Warranty and return policies

Step 7: Finalize the Order and Confirm Delivery

After negotiations, finalize your order and confirm all details in writing. Ensure that both parties have a clear understanding of the order specifics, including delivery timelines and installation support, if necessary.

- Key Confirmation Points:

- Order confirmation with specifications

- Delivery schedule and tracking information

- Contact points for any post-order support

By following this practical sourcing checklist, B2B buyers can streamline their procurement process, ensuring that they select the most appropriate door latch types for their needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for door latch types Sourcing

What Are the Key Cost Components in Sourcing Door Latch Types?

When sourcing door latches, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include stainless steel, brass, and plastic. Higher-quality materials usually lead to increased durability and security but also raise the overall price.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Custom tooling for specific latch designs can lead to significant upfront costs. Buyers should consider whether the tooling costs are justifiable based on anticipated order volumes.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the products meet safety and performance standards. While this adds to the cost, it protects the buyer from future liabilities.

-

Logistics: Shipping costs, which can be influenced by distance, mode of transport, and the size of the order, must be factored into the total cost. For international shipments, customs duties and taxes may also apply.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the industry standard margins can assist buyers in negotiating better prices.

How Do Price Influencers Affect Door Latch Sourcing?

Several factors can influence the pricing of door latches, including:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize their pricing.

-

Specifications and Customization: Custom latches tailored to specific needs can increase costs. Buyers should clarify their requirements upfront to receive accurate quotes.

-

Material Quality and Certifications: Premium materials and certifications (e.g., ISO, CE) typically command higher prices. Buyers should weigh the benefits of certified products against their budgets.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge a premium but often provide better quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can affect total costs.

What Are Effective Buyer Tips for Cost-Efficiency in Door Latch Procurement?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, consider the following strategies to enhance cost-efficiency:

-

Negotiation: Always negotiate pricing with suppliers. Leverage competitive quotes from multiple suppliers to secure the best deals.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the purchase price. This includes installation, maintenance, and potential replacement costs over the product’s lifecycle.

-

Understand Pricing Nuances for International Buyers: Be aware of the currency exchange rates and their fluctuations. Consider locking in prices in your local currency to mitigate risks.

-

Local Regulations: Familiarize yourself with local regulations and standards that might affect product selection and costs. Compliance can lead to additional expenses if not considered early in the sourcing process.

-

Supplier Relationships: Cultivating strong relationships with suppliers can lead to better pricing, priority service, and favorable terms in the long run.

Conclusion

While the costs associated with sourcing door latches can vary widely based on numerous factors, a thorough understanding of these components and influencers can empower international B2B buyers to make informed purchasing decisions. Be proactive in negotiations and consider the total cost of ownership to maximize value. Always seek indicative prices and be prepared for fluctuations based on market conditions and supplier dynamics.

Alternatives Analysis: Comparing door latch types With Other Solutions

Understanding Alternatives to Door Latch Types

When it comes to securing doors, selecting the right mechanism is crucial for functionality, safety, and ease of use. While door latch types are a popular choice, there are alternative solutions available that may suit specific needs or circumstances. This analysis will compare door latch types with two viable alternatives: Electronic Lock Systems and Smart Lock Technology.

Comparison Table: Door Latch Types vs. Alternatives

| Comparison Aspect | Door Latch Types | Electronic Lock Systems | Smart Lock Technology |

|---|---|---|---|

| Performance | Reliable for basic security | High security with access control | High security with remote access |

| Cost | Generally low cost | Moderate to high cost | Moderate to high cost |

| Ease of Implementation | Straightforward installation | Requires wiring or battery setup | Usually easy installation, may require app setup |

| Maintenance | Low maintenance | Moderate maintenance due to battery replacement | Moderate maintenance, requires app updates |

| Best Use Case | Residential and commercial doors | High-security areas, commercial applications | Smart homes, tech-savvy users |

Detailed Breakdown of Alternatives

What Are Electronic Lock Systems and Their Benefits?

Electronic lock systems offer enhanced security features, allowing for access control through keypads, cards, or biometrics. They are ideal for businesses requiring stringent security measures as they can track entry and exit, providing a log of who accessed the premises. However, they can be more expensive than traditional door latches and may require professional installation. Additionally, the need for regular battery replacements can add to maintenance costs.

Pros:

– High security and access control

– Entry logs for monitoring

– Flexibility in access methods (keypad, card, biometrics)

Cons:

– Higher initial investment

– Potential technical issues

– Regular maintenance required for batteries

How Does Smart Lock Technology Compare?

Smart lock technology represents a growing trend in door security, particularly popular in residential settings. These locks can be controlled remotely via smartphones, allowing users to lock or unlock doors from anywhere. They often integrate with home automation systems, providing seamless access and monitoring. While smart locks offer convenience and advanced features, they can be susceptible to hacking and may require a stable Wi-Fi connection for optimal functionality.

Pros:

– Remote access and control

– Integration with home automation systems

– User-friendly and convenient

Cons:

– Vulnerability to cyber threats

– Dependency on Wi-Fi and app functionality

– May require additional investment in smart home infrastructure

Conclusion: How to Choose the Right Solution for Your Needs

A stock image related to door latch types.

When considering door latch types versus alternatives like electronic lock systems or smart lock technology, B2B buyers must evaluate their specific security needs, budget, and the intended use case. For traditional environments where reliability and low cost are priorities, door latches remain a solid choice. Conversely, for high-security commercial applications, electronic locks offer advanced features, while smart locks cater to tech-savvy users seeking convenience. Ultimately, understanding the distinct advantages and limitations of each option will guide buyers in making an informed decision that best aligns with their operational requirements.

Essential Technical Properties and Trade Terminology for door latch types

What Are the Key Technical Properties of Door Latch Types?

When sourcing door latches for your business needs, understanding the critical specifications is essential for ensuring product quality and suitability. Here are some key technical properties that should be considered:

1. Material Grade: Why is it Important?

The material grade of a door latch determines its durability, corrosion resistance, and overall performance. Common materials include stainless steel, brass, and zinc alloys. For instance, stainless steel latches are ideal for environments exposed to moisture, making them suitable for coastal regions or areas with high humidity. In contrast, brass latches offer aesthetic appeal and moderate corrosion resistance, often used in residential applications. Choosing the right material is vital for longevity and maintenance, impacting your total cost of ownership.

2. Load Capacity: How Much Weight Can It Handle?

Load capacity refers to the maximum weight a latch can securely hold without failure. This specification is particularly crucial for commercial applications where heavy doors or frequent use is expected. For example, a latch designed for heavy-duty use may support up to 150 kg, while standard latches might only handle 50 kg. Understanding the load capacity ensures that the latch will perform adequately in its intended environment, preventing operational failures.

3. Tolerance Levels: What Are They and Why Do They Matter?

Tolerance levels indicate the allowable deviation from specified dimensions during manufacturing. For door latches, this might include the thickness of the latch plate or the diameter of the bolt. High-tolerance manufacturing processes ensure that latches fit properly and operate smoothly, which is crucial for security applications. Poor tolerances can lead to misalignment, making the latch ineffective. This specification is vital for maintaining quality control in large orders.

A stock image related to door latch types.

4. Finish Types: How Do They Affect Performance?

The finish of a door latch not only influences its appearance but also its performance in various environments. Common finishes include polished chrome, powder coating, and satin nickel. Each finish has different properties regarding corrosion resistance, wear, and aesthetic appeal. For example, powder-coated latches are excellent for outdoor applications due to their durability and resistance to rust. Selecting the right finish can enhance the product’s lifespan and reduce maintenance costs.

5. Security Rating: What Does It Mean?

Security ratings, such as those provided by organizations like ANSI (American National Standards Institute) or BHMA (Builders Hardware Manufacturers Association), classify door latches based on their resistance to forced entry. A higher security rating indicates better resistance, which is particularly important for commercial applications or secure residential environments. Understanding these ratings helps buyers select products that meet their security needs.

What Are Common Trade Terms in Door Latch Procurement?

Navigating the B2B procurement landscape requires familiarity with specific trade terminology. Here are some essential terms that international buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of door latches, understanding whether you’re dealing with an OEM or a reseller can impact pricing and warranty options. OEM products often provide a more direct supply chain and potentially lower costs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell per order. This is particularly relevant for B2B buyers, as it can affect inventory management and cash flow. Understanding the MOQ can help you negotiate better terms or plan your purchasing strategy more effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. When seeking door latches, submitting an RFQ can help you gather competitive quotes and facilitate better negotiations. It’s an essential step in the procurement process, especially for bulk orders.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risks, and costs associated with the delivery of door latches. For instance, terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) clarify when ownership and risk transfer from seller to buyer.

5. Lead Time: What Should You Expect?

Lead time refers to the time taken from placing an order until it is delivered. In the door latch industry, lead times can vary significantly based on the manufacturer, product customization, and shipping logistics. Understanding lead times is crucial for planning projects and ensuring timely delivery.

By familiarizing yourself with these essential technical properties and trade terms, you can make more informed decisions when sourcing door latches for your business needs.

Navigating Market Dynamics and Sourcing Trends in the door latch types Sector

What Are the Key Market Dynamics and Trends in the Door Latch Types Sector?

The door latch types market is experiencing significant growth driven by various global factors. The increasing focus on security and safety in both residential and commercial properties is a primary catalyst. In regions like Africa and South America, rapid urbanization and a growing middle class are leading to a surge in construction activities, thereby amplifying the demand for reliable door latch systems. Simultaneously, in Europe and the Middle East, stringent building regulations and the need for advanced locking mechanisms are prompting businesses to invest in high-quality door hardware.

Emerging technologies, such as smart locks and automated door latches, are reshaping the landscape. B2B buyers are increasingly leaning towards suppliers that offer digital solutions, allowing for remote access and enhanced security features. The rise of e-commerce platforms is also influencing sourcing trends, enabling international buyers to access a broader range of products and suppliers, often at competitive prices. Additionally, the trend towards customization is notable, with many manufacturers now providing tailored solutions to meet specific buyer requirements.

How Can Sustainability and Ethical Sourcing Impact Door Latch Types?

Sustainability is becoming a crucial aspect of the door latch types sector. The environmental impact of manufacturing processes, from resource extraction to production waste, is under scrutiny. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing energy consumption during production.

Ethical sourcing is equally important, as businesses look to ensure that their supply chains are free from human rights abuses and that they support fair labor practices. Certifications like FSC (Forest Stewardship Council) for wood products and ISO 14001 for environmental management are becoming vital for suppliers aiming to attract conscientious buyers.

Furthermore, the demand for “green” materials, such as biodegradable plastics and sustainably sourced metals, is on the rise. By aligning with suppliers who prioritize sustainability, international B2B buyers can not only enhance their corporate social responsibility profiles but also meet the increasing consumer demand for eco-friendly products.

What Is the Historical Evolution of Door Latch Types?

The evolution of door latch types reflects advancements in technology and changes in societal needs. Historically, door latches date back thousands of years, primarily serving as simple mechanisms to secure entry points. Early latches were made from wood and metal, designed to be easily operable yet secure enough to deter unauthorized access.

With the Industrial Revolution, the mass production of metal latches began, leading to more standardized designs and improved functionality. The 20th century saw the introduction of new materials and locking mechanisms, including spring-loaded and electronic latches, catering to the growing demand for security in increasingly complex architectural designs. Today, the focus is on integrating technology with traditional security features, creating smart door latches that enhance both convenience and safety for users.

In conclusion, understanding the market dynamics, emphasizing sustainability, and recognizing the historical context of door latch types can empower international B2B buyers to make informed sourcing decisions. By aligning with current trends and values, businesses can ensure they remain competitive and responsible in their procurement processes.

Frequently Asked Questions (FAQs) for B2B Buyers of door latch types

-

How do I choose the right door latch type for my business needs?

Choosing the right door latch involves assessing the specific requirements of your application. Consider factors such as security needs, door type, and frequency of use. For high-security areas, mortice or deadbolt latches are ideal, while for interior doors, tubular or roller bolt latches may suffice. Additionally, assess the environment; for outdoor use, opt for weather-resistant materials. Collaborating with suppliers who understand your industry can provide tailored recommendations. -

What is the best door latch type for high-security applications?

For high-security applications, multipoint latch locks or deadbolt latches are recommended. These types provide enhanced security by locking at multiple points along the door frame, making forced entry significantly more difficult. Nightlatches can also be effective when combined with a solid deadlock. Always ensure that the latches comply with local security standards and regulations to safeguard your premises effectively. -

How can I ensure the quality of door latches when sourcing internationally?

To ensure quality, perform thorough supplier vetting. Request samples and verify certifications that align with international quality standards, such as ISO or ANSI. Conduct factory audits if feasible, and check references from previous clients. Additionally, utilizing platforms that provide supplier ratings can help identify reliable manufacturers. Quality assurance processes should be clearly outlined in your agreement to mitigate risks. -

What are the minimum order quantities (MOQs) for door latches from suppliers?

Minimum order quantities can vary significantly based on the supplier and the type of latch. Typically, MOQs for standard types range from 100 to 1,000 units, but custom designs may require larger orders. Always inquire about MOQs before finalizing agreements, as many suppliers may offer flexibility for larger contracts or long-term partnerships. Discussing your specific needs can lead to more favorable terms. -

What payment terms should I expect when sourcing door latches internationally?

Payment terms often vary by supplier and region. Common terms include a 30% deposit upon order confirmation and the balance due before shipment. Some suppliers may offer net payment terms, allowing payment within 30 to 90 days after delivery. It’s crucial to negotiate terms that suit your cash flow while ensuring the supplier’s confidence in fulfilling your order. Always review payment methods for security and fraud protection. -

How can I customize door latches to fit my brand requirements?

Customization options typically include material selection, finishes, and branding (such as logo engravings). Many suppliers offer bespoke designs to meet specific aesthetic or functional requirements. Discuss your vision with suppliers early in the negotiation process to understand their capabilities. Be prepared to provide detailed specifications and, if necessary, collaborate on prototypes to ensure the final product aligns with your expectations. -

What logistical considerations should I keep in mind when importing door latches?

Logistical considerations include shipping methods, lead times, and customs regulations. Assess whether you need air freight for speed or sea freight for cost-effectiveness. Familiarize yourself with the importing country’s customs duties and regulations, as these can impact overall costs and delivery timelines. Establishing a relationship with a reliable logistics provider can streamline the shipping process and mitigate potential delays. -

How do I handle warranty and after-sales support for door latches purchased internationally?

When sourcing internationally, clarify warranty terms and after-sales support before purchasing. Ensure that the supplier offers a warranty that covers defects and issues for a reasonable period. Understand the process for returns or repairs, especially if products need to be sent back internationally. Strong after-sales support can significantly enhance your buying experience and ensure that any issues are resolved promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for door latch types

In navigating the diverse landscape of door latch types, international B2B buyers must prioritize strategic sourcing to ensure they select the most suitable products for their specific needs. Each type of latch—from mortice to roller bolt—offers unique advantages tailored to various applications, whether for residential, commercial, or industrial environments. Understanding the functionality, security features, and installation requirements of these latches is crucial for making informed purchasing decisions.

How Can Strategic Sourcing Enhance Your Procurement Process?

Strategic sourcing not only streamlines procurement but also fosters relationships with reliable suppliers who can provide quality products that meet international standards. This is particularly important for buyers in Africa, South America, the Middle East, and Europe, where regional preferences and regulations may vary significantly.

What Should International Buyers Consider for Future Procurement?

As the demand for security and functionality continues to evolve, staying abreast of the latest innovations in door latch technology will be vital. Consider reaching out to manufacturers who offer customizable solutions to meet your specific requirements. Take the next step in your procurement strategy by evaluating your current door latch needs and exploring partnerships that can enhance your operational efficiency. Investing in the right door latch solutions today will pave the way for safer, more secure environments tomorrow.