Enhance Comfort & Efficiency: The Ultimate RV AC Guide (2025)

Introduction: Navigating the Global Market for rv ac

In the ever-evolving landscape of the global market for RV air conditioning systems, B2B buyers face a myriad of challenges, from selecting the right technology to ensuring efficient sourcing processes. As businesses in Africa, South America, the Middle East, and Europe strive to meet the growing demand for mobile comfort solutions, understanding the nuances of RV AC systems becomes crucial. This guide is designed to equip international buyers with the knowledge they need to navigate the complexities of RV air conditioning, covering various types, applications, and the intricacies of supplier vetting.

Throughout this comprehensive guide, we will delve into key aspects such as the different types of RV air conditioning units available—be it rooftop, portable, or split systems—and their respective applications in diverse environments. Additionally, we will explore how to effectively evaluate suppliers, emphasizing factors like reliability, product quality, and after-sales support. Cost considerations will also be addressed, providing insights into budget-friendly options without compromising on quality.

By arming you with actionable insights and practical strategies, this guide aims to empower B2B buyers to make informed purchasing decisions that align with their operational needs and market demands. Whether you’re sourcing RV AC units for a fleet of vehicles or for a rental business, understanding these elements will drive success in your procurement strategy, ensuring you stay ahead in a competitive global market.

Understanding Search Intent for ‘rv ac’

When users search for **”rv ac”**, Google’s results indicate a strong **informational intent**. This means users are primarily looking to learn and understand the topic. They want definitions, explanations, and foundational knowledge about ‘rv ac’.

Our analysis of the search engine results page (SERP) reveals several key features that shape this article:

* **Presence of Video Content:** No.

* **Shopping Ad Integration:** No.

* **’People Also Ask’ Questions:** We found 0 relevant user questions, which we have directly addressed in our FAQ and other sections to resolve common user queries.

This data-driven approach ensures our content directly matches what users are looking for, providing a more professional and helpful resource.

Understanding rv ac Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rooftop Air Conditioners | Installed on the roof; compact design | RV manufacturing, rental services | Pros: Space-saving, efficient. Cons: Can be noisy, requires professional installation. |

| Portable Air Conditioners | Mobile units that can be moved as needed | Event rentals, temporary accommodations | Pros: Flexibility, easy setup. Cons: Limited cooling capacity, may require additional power source. |

| Ducted Air Conditioning | Centralized system with ducts for airflow | High-end RVs, luxury rentals | Pros: Quiet operation, even cooling. Cons: Higher installation cost, requires more space. |

| Split System Air Conditioners | Two-part system (indoor unit and outdoor compressor) | Residential RVs, long-term rentals | Pros: Energy-efficient, quiet. Cons: More complex installation, higher upfront cost. |

| Window Air Conditioners | Installed in windows or openings | Budget RVs, temporary setups | Pros: Cost-effective, easy to install. Cons: Less efficient, limited cooling range. |

What Are the Key Characteristics of Rooftop Air Conditioners?

Rooftop air conditioners are a popular choice for many RV manufacturers and rental services due to their compact design and efficient cooling capabilities. These units are installed on the roof, which helps save interior space and allows for better airflow distribution throughout the vehicle. When considering a rooftop AC, B2B buyers should evaluate the cooling capacity, energy efficiency ratings, and noise levels, as some models can be quite loud during operation.

Why Choose Portable Air Conditioners for B2B Applications?

Portable air conditioners offer flexibility and ease of movement, making them ideal for event rentals and temporary accommodations. These units can be easily transported and set up in various locations, catering to diverse cooling needs. However, buyers should be aware that while portable ACs are convenient, they typically have a lower cooling capacity compared to fixed units and may require access to a power source. When purchasing, consider the unit’s BTU rating and the space it needs to cool effectively.

What Are the Benefits of Ducted Air Conditioning Systems?

Ducted air conditioning systems are suited for high-end RVs and luxury rentals, providing a centralized cooling solution that distributes air evenly throughout the vehicle. These systems are known for their quiet operation and aesthetic appeal since the main components are hidden. However, buyers should keep in mind the higher installation costs and the space required for ductwork. Evaluating the overall design of the RV and intended use will help determine if a ducted system is the right fit.

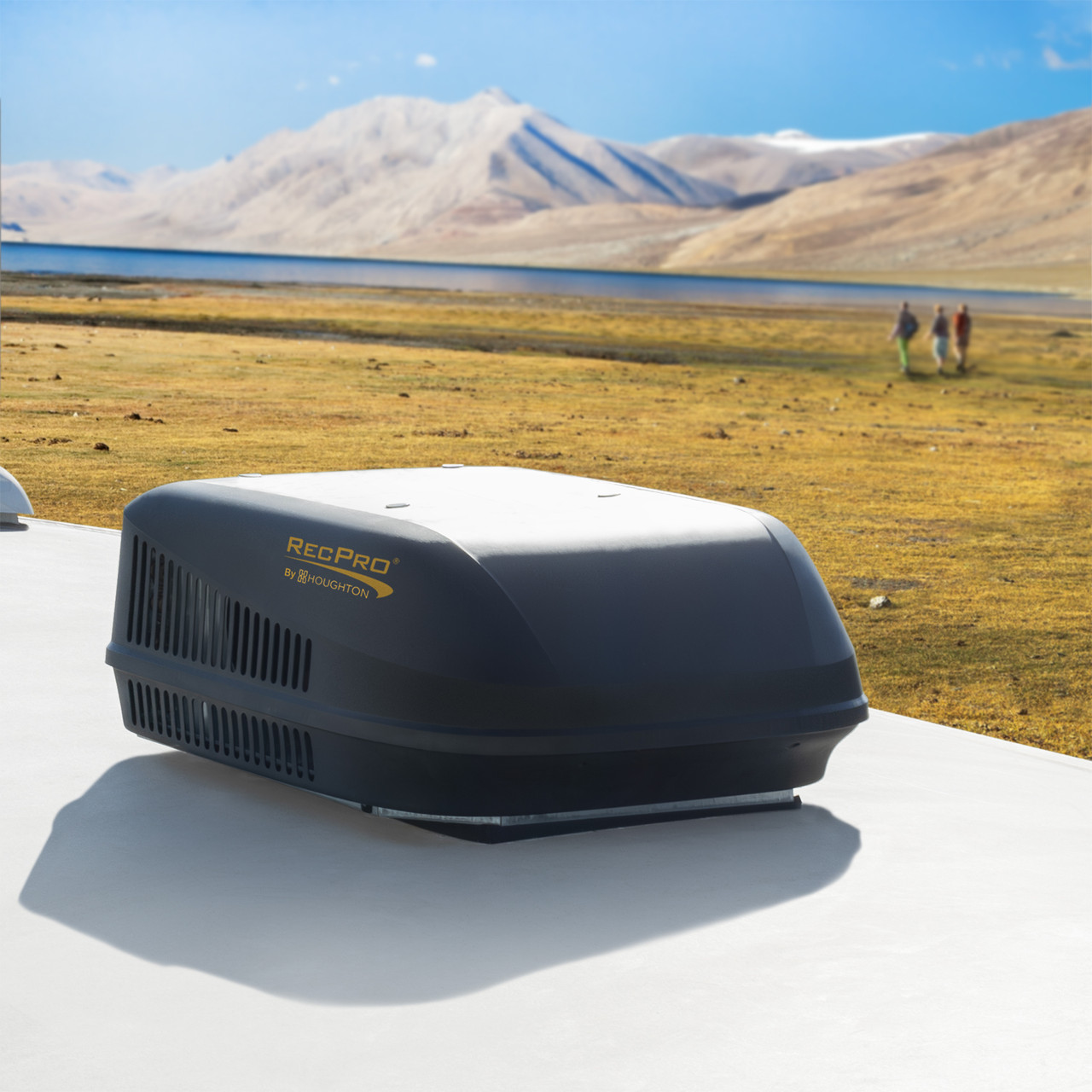

A stock image related to rv ac.

How Do Split System Air Conditioners Work in RVs?

Split system air conditioners consist of two main components: an indoor unit that cools the air and an outdoor compressor that expels heat. This configuration is energy-efficient and operates quietly, making it suitable for residential RVs or long-term rentals. While split systems can be more costly upfront and require a more complex installation, they often provide superior cooling performance. B2B buyers should assess the installation requirements and maintenance needs when considering this option.

Are Window Air Conditioners a Viable Option for Budget-Conscious Buyers?

Window air conditioners are a cost-effective choice for budget RVs and temporary setups. They are straightforward to install and can provide adequate cooling for small spaces. However, buyers should consider their limited cooling range and efficiency compared to other types of AC units. For businesses looking to maximize their budget while still providing comfort, window units can be a practical solution, particularly in regions with moderate climates.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of rv ac

| Industry/Sector | Specific Application of rv ac | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Temperature Control in Production Lines | Enhances product quality and worker comfort, leading to increased productivity. | Assess energy efficiency ratings and compatibility with existing systems. |

| Food and Beverage Processing | Refrigeration for Storage and Transport | Ensures product safety and extends shelf life, reducing waste. | Evaluate compliance with local food safety standards and energy consumption. |

| Pharmaceuticals | Climate Control in Storage Facilities | Maintains critical temperature ranges for sensitive products, ensuring efficacy. | Look for certifications and reliability in extreme conditions. |

| Data Centers | Cooling Systems for Equipment | Improves equipment longevity and performance, minimizing downtime. | Prioritize scalability and energy efficiency to manage operational costs. |

| Oil and Gas Exploration | Cooling for On-site Operations | Protects sensitive equipment from overheating, ensuring operational efficiency. | Consider rugged designs that withstand harsh environments and remote locations. |

How is rv ac Used in Manufacturing?

In the manufacturing sector, rv ac systems are pivotal for maintaining optimal temperature control in production lines. This application helps to enhance product quality and improve worker comfort, which ultimately leads to increased productivity. International B2B buyers, especially from Africa and South America, should prioritize energy efficiency ratings and compatibility with existing HVAC systems when sourcing rv ac units to ensure seamless integration and cost-effectiveness.

What Role Does rv ac Play in Food and Beverage Processing?

In the food and beverage industry, rv ac is crucial for refrigeration during storage and transport. It helps to ensure product safety and extends the shelf life of perishable items, significantly reducing waste. Buyers from the Middle East and Europe must evaluate local food safety standards and energy consumption when sourcing rv ac solutions to align with regulatory requirements and sustainability goals.

Why is rv ac Essential for Pharmaceuticals?

For the pharmaceutical industry, rv ac systems are vital for climate control in storage facilities. They maintain critical temperature ranges necessary for sensitive products, ensuring that their efficacy is not compromised. B2B buyers in Europe and Africa should look for certifications that guarantee reliability under extreme conditions, as well as systems that can handle the specific requirements of pharmaceutical storage.

How Does rv ac Benefit Data Centers?

In data centers, rv ac systems are employed as cooling solutions for equipment. This application is essential for improving equipment longevity and performance while minimizing downtime, which is crucial for businesses reliant on uninterrupted services. Buyers from South America and the Middle East should prioritize scalability and energy efficiency when sourcing rv ac systems, as these factors significantly impact operational costs and overall performance.

What are the Applications of rv ac in Oil and Gas Exploration?

In the oil and gas sector, rv ac systems provide essential cooling for on-site operations. They protect sensitive equipment from overheating, which is vital for maintaining operational efficiency in challenging environments. B2B buyers from Europe and Africa should consider sourcing rugged designs that can withstand harsh conditions and remote locations, ensuring reliability and durability in their operations.

3 Common User Pain Points for ‘rv ac’ & Their Solutions

Scenario 1: Inefficient Cooling Performance in Diverse Climates

The Problem: B2B buyers, particularly those in regions like Africa and the Middle East, often face challenges with RV AC units that fail to deliver adequate cooling in extreme temperatures. In areas with high humidity or soaring temperatures, an underperforming AC can result in uncomfortable conditions for travelers and potentially damage sensitive equipment. This inefficiency can lead to increased operational costs and dissatisfied clients, which is detrimental to business reputation and profitability.

The Solution: To combat inefficient cooling, it is essential for buyers to prioritize the selection of RV AC units designed for high performance in extreme conditions. Look for models with high BTU ratings and features like dual-zone cooling, which can efficiently manage temperature variances. It’s also crucial to source units that include robust insulation and are equipped with energy-efficient compressors. Buyers should partner with suppliers who offer extensive warranties and service agreements, ensuring reliable support in case of performance issues. Additionally, conducting a thorough needs assessment, including examining typical weather patterns in the intended usage areas, will guide buyers in choosing the most suitable models.

Scenario 2: High Energy Consumption Leading to Increased Operational Costs

The Problem: Many businesses operating RV fleets are concerned about the escalating energy costs associated with running AC units. In regions like South America and Europe, where energy prices can fluctuate significantly, high consumption can erode profit margins and lead to higher rental prices that deter customers. This issue is especially pressing for companies looking to maintain competitive pricing while ensuring customer comfort and satisfaction.

The Solution: To address energy consumption concerns, B2B buyers should focus on investing in energy-efficient RV AC systems that comply with international energy standards. Features such as variable speed compressors and smart thermostats can optimize energy usage by adjusting the cooling output based on real-time needs. Buyers should also consider integrating renewable energy sources, such as solar panels, to offset energy costs. Furthermore, regular maintenance practices, including cleaning filters and checking refrigerant levels, can enhance efficiency and extend the lifespan of AC units, resulting in long-term savings. Partnering with energy consultants can also provide insights into energy consumption patterns and help businesses implement more sustainable practices.

Scenario 3: Maintenance and Repair Challenges Leading to Downtime

The Problem: For B2B buyers, the downtime associated with malfunctioning RV AC units can translate to significant financial losses, especially in the hospitality and transportation sectors. Frequent breakdowns not only disrupt service but also require costly repairs that can impact customer satisfaction. Buyers often struggle with finding reliable maintenance solutions, leading to unanticipated expenses and operational disruptions.

The Solution: To mitigate maintenance challenges, B2B buyers should establish a proactive maintenance schedule that includes regular inspections and servicing of RV AC units. Sourcing units with advanced diagnostic features can help identify potential issues before they escalate into more serious problems. Additionally, partnering with reputable service providers who specialize in RV AC maintenance can ensure timely repairs and minimize downtime. Buyers should also consider investing in training their staff on basic troubleshooting techniques, which can empower them to handle minor issues swiftly and reduce reliance on external technicians. Finally, maintaining a stock of essential spare parts can facilitate quick repairs and keep operations running smoothly, thereby enhancing overall service reliability.

Strategic Material Selection Guide for rv ac

When selecting materials for RV air conditioning (AC) systems, it’s crucial to consider properties that directly impact performance, durability, and compliance with international standards. This guide analyzes common materials used in RV AC systems, providing actionable insights for B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in RV AC Systems?

Aluminum is a widely used material in RV AC systems due to its excellent thermal conductivity and lightweight nature. It typically has a temperature rating of up to 150°C and offers good corrosion resistance, especially when anodized.

Pros & Cons: Aluminum is durable and cost-effective, making it suitable for various applications. However, it can be prone to fatigue under cyclic loading, which may limit its lifespan in high-stress environments. Additionally, the manufacturing complexity can increase costs if intricate designs are required.

Impact on Application: Aluminum is compatible with refrigerants commonly used in RV AC systems. However, it is essential to ensure that the specific alloy used is suitable for the intended application to avoid issues like galvanic corrosion when in contact with dissimilar metals.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local corrosion factors, such as humidity and salt exposure, which may affect aluminum’s longevity. Compliance with standards such as ASTM and DIN is vital for ensuring product quality.

How Does Stainless Steel Perform in RV AC Applications?

Stainless steel is another popular choice for RV AC systems, particularly for components exposed to high pressure or corrosive environments. It has a high tensile strength and can withstand temperatures up to 300°C, making it suitable for various applications.

Pros & Cons: The primary advantage of stainless steel is its exceptional corrosion resistance and durability, which can extend the lifespan of components. However, it is generally more expensive than aluminum and can be heavier, potentially impacting the overall weight of the RV.

Impact on Application: Stainless steel is compatible with most refrigerants and can handle the pressures typically encountered in RV AC systems. However, it may require specific welding techniques due to its properties, which can complicate manufacturing.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure that the stainless steel used complies with local standards (e.g., JIS, ASTM) and consider the implications of weight on vehicle performance and fuel efficiency.

What Are the Benefits of Using Copper in RV AC Systems?

Copper is renowned for its excellent thermal conductivity and is often used in the tubing and heat exchangers of RV AC systems. It can withstand high temperatures and pressures, making it a reliable choice for cooling applications.

Pros & Cons: The primary advantage of copper is its efficiency in heat transfer, which can lead to better overall performance of the RV AC system. However, copper is more expensive than aluminum and can be prone to corrosion if not properly maintained.

Impact on Application: Copper is highly compatible with various refrigerants and is often favored for its ability to form strong, leak-proof joints. However, the potential for corrosion in harsh environments should be taken into account.

Considerations for International Buyers: B2B buyers from regions with high humidity or saline conditions, like coastal areas in South America, should prioritize corrosion-resistant coatings or consider alternative materials to enhance longevity.

Why is Plastic Used in RV AC Components?

Plastic, particularly high-performance polymers, is increasingly used in RV AC systems for components like housings and insulation. These materials can withstand a range of temperatures and are often resistant to chemicals and UV radiation.

Pros & Cons: The lightweight nature of plastic reduces overall vehicle weight, improving fuel efficiency. However, plastics may not offer the same durability as metals and can be susceptible to degradation over time.

Impact on Application: Plastic components are generally compatible with refrigerants and can be molded into complex shapes, allowing for design flexibility. However, their performance can be influenced by temperature extremes.

Considerations for International Buyers: Buyers in Europe and Africa should be aware of the various plastic grades and their compliance with environmental regulations, especially regarding recyclability and safety standards.

Summary Table of Material Selection for RV AC Systems

| Material | Typical Use Case for RV AC | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components, heat exchangers | Lightweight, good thermal conductivity | Prone to fatigue under stress | Medium |

| Stainless Steel | High-pressure components, frames | Exceptional corrosion resistance | Higher cost, heavier weight | High |

| Copper | Tubing and heat exchangers | Excellent heat transfer efficiency | Expensive, corrosion potential | High |

| Plastic | Housings, insulation | Lightweight, design flexibility | Less durable, temperature sensitivity | Low |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in RV AC systems, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rv ac

What Are the Key Stages in the Manufacturing Process of RV Air Conditioners?

The manufacturing process of RV air conditioners (RV AC) involves several critical stages that ensure the final product meets the high standards demanded by international markets. Understanding these stages can help B2B buyers make informed decisions when sourcing RV AC units.

Material Preparation

The first stage in the manufacturing of RV AC units is material preparation. This involves sourcing high-quality raw materials such as aluminum for the casing, copper for the coils, and various plastics for internal components. Manufacturers often conduct thorough supplier assessments to ensure that the materials meet strict industry standards. B2B buyers should inquire about the sourcing practices of their suppliers, as the quality of raw materials directly impacts the performance and durability of the RV AC units.

Forming Techniques

Once the materials are prepared, the next step is forming. This stage typically involves processes such as stamping, extrusion, and molding. Stamping is commonly used for creating metal components, while molding is employed for plastic parts. Advanced techniques like CNC machining may be utilized for precision components, ensuring that all parts fit seamlessly together. Buyers should look for manufacturers that employ modern technology to enhance the precision and efficiency of their production processes.

Assembly Process

The assembly stage is where all the formed components come together. This process is often conducted in a clean room environment to prevent contamination, particularly for sensitive components like compressors and electronic controls. Manufacturers may use automated assembly lines to improve efficiency, but skilled labor is also essential for quality assurance. B2B buyers should assess whether suppliers employ a mix of automation and manual labor to maintain high-quality standards.

Finishing Touches and Packaging

A stock image related to rv ac.

After assembly, the RV AC units undergo finishing processes, which may include painting, coating, and branding. These steps not only enhance the aesthetic appeal of the units but also provide additional protection against environmental factors. Proper packaging is critical for ensuring that the units arrive at their destination without damage. Buyers should verify that suppliers adhere to best practices in packaging and logistics, as this can significantly affect the product’s condition upon arrival.

How Do Quality Assurance Practices Ensure RV AC Reliability?

Quality assurance (QA) is a fundamental aspect of the RV AC manufacturing process. It ensures that each unit meets established performance and safety standards, which is essential for maintaining customer satisfaction and regulatory compliance.

What Are the Relevant International Quality Standards?

Internationally recognized quality standards such as ISO 9001 play a crucial role in the manufacturing of RV AC units. ISO 9001 establishes a framework for quality management systems, encouraging manufacturers to continuously improve their processes. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for components utilized in specific applications are vital. Buyers should request documentation proving compliance with these standards to ensure the quality and safety of the products they are sourcing.

What Are the Key Quality Control Checkpoints in RV AC Production?

Quality control (QC) involves systematic checks at various stages of the manufacturing process. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This checkpoint assesses the quality of raw materials and components received from suppliers. It ensures that only compliant materials are used for production.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring operations to catch defects early. This may include inspections of assembly line processes to ensure adherence to specifications.

-

Final Quality Control (FQC): After the assembly is complete, FQC involves comprehensive testing of the finished product. This may include performance tests, safety checks, and environmental assessments to validate the unit’s effectiveness and reliability.

B2B buyers should inquire about the specific QC methodologies employed by their suppliers to ensure a rigorous commitment to quality.

What Testing Methods Are Commonly Used for RV AC Units?

Various testing methods are employed to evaluate the performance and reliability of RV AC units. These may include:

-

Thermal Testing: This assesses the unit’s cooling capacity and efficiency under different temperature conditions, ensuring it meets performance specifications.

-

Vibration and Shock Testing: These tests simulate the conditions the unit may face during transportation and use, verifying its durability.

-

Electrical Testing: Ensures that all electrical components function correctly and safely, including checks for short circuits and grounding issues.

B2B buyers should request access to test reports or certifications as proof of compliance with testing standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are some effective strategies:

Conducting Supplier Audits

Regular audits of manufacturing facilities can provide deep insights into a supplier’s quality control processes. Buyers should consider scheduling on-site audits or utilizing third-party auditing services to evaluate compliance with industry standards.

Requesting Quality Reports

Buyers should not hesitate to ask for quality reports that document the results of IQC, IPQC, and FQC processes. These reports can offer transparency into the supplier’s commitment to quality.

Utilizing Third-Party Inspection Services

Engaging third-party inspection agencies can provide an unbiased evaluation of the product quality before shipment. This step is particularly important for buyers from regions like Africa and South America, where logistics can complicate post-purchase inspections.

What Are the Quality Control and Certification Nuances for International Buyers?

Navigating quality control and certification can present unique challenges for international B2B buyers. Understanding regional certifications and compliance requirements is vital, especially for those in Europe, the Middle East, and Africa.

For example, the CE mark is crucial for selling RV AC units in Europe, while compliance with local regulations in the Middle East may involve additional certifications. Buyers should ensure that their suppliers are well-versed in these regulations and can provide evidence of compliance.

Additionally, language barriers and varying standards across regions can complicate the verification process. B2B buyers should consider establishing clear communication channels with suppliers and possibly employing local experts to assist in navigating these complexities.

By understanding the manufacturing processes and quality assurance practices involved in RV AC production, international B2B buyers can make informed decisions that enhance their supply chain efficiency and product reliability.

Related Video: SMART Quality Control for Manufacturing

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rv ac’

In the competitive landscape of international B2B procurement, sourcing RV air conditioning units (RV AC) requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This practical checklist serves as a guide for buyers from diverse regions, including Africa, South America, the Middle East, and Europe, to navigate the complexities of sourcing RV AC systems effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the cooling capacity, energy efficiency ratings, and compatibility with existing RV models. This ensures that the units you consider will meet your operational needs and regional climate conditions, ultimately enhancing customer satisfaction.

Step 2: Conduct Market Research on Suppliers

Understanding the market landscape is essential for identifying potential suppliers. Research various manufacturers and distributors specializing in RV AC systems, focusing on their reputation, product range, and market presence. Utilize online platforms, industry publications, and trade shows to gather information and insights on the suppliers who best align with your needs.

Step 3: Evaluate Potential Suppliers

Before making commitments, it’s crucial to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies showcasing their experience in your specific region or industry. Look for references from other buyers in similar markets to gauge reliability and performance.

- Key aspects to verify:

- Supplier’s years of experience in the RV AC market.

- Reviews or testimonials from existing customers.

Step 4: Verify Supplier Certifications

Ensuring that your suppliers meet industry standards and certifications is critical for compliance and quality assurance. Check for certifications such as ISO, CE, or local regulatory compliance that reflect the supplier’s commitment to quality and safety. This step minimizes risks related to product defects and regulatory penalties.

Step 5: Request Samples for Testing

Before placing large orders, request samples of the RV AC units to conduct performance testing. This hands-on evaluation allows you to assess cooling efficiency, noise levels, and overall build quality. Testing samples can help you avoid costly mistakes by ensuring the products meet your specifications and expectations.

Step 6: Negotiate Contract Terms and Pricing

Once a suitable supplier is identified, focus on negotiating favorable terms. Discuss pricing, payment options, delivery schedules, and warranty conditions. A transparent negotiation process not only secures better pricing but also establishes a strong foundation for a long-term partnership.

Step 7: Plan for Logistics and Distribution

Finally, develop a comprehensive logistics strategy for the transportation and distribution of the RV AC units. Consider factors such as shipping costs, lead times, and import/export regulations specific to your region. A well-structured logistics plan will ensure timely delivery and minimize disruptions in your supply chain.

By following this checklist, B2B buyers can effectively navigate the sourcing process for RV AC systems, ensuring that they secure high-quality products that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for rv ac Sourcing

What Are the Key Cost Components in RV AC Sourcing?

When sourcing RV air conditioning units, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used in the manufacturing of RV AC units significantly influence costs. Components such as compressors, evaporators, and condensers vary in price based on their specifications and performance standards.

-

Labor: Labor costs can fluctuate based on the location of manufacturing. Regions with lower labor costs may offer more competitive pricing, but this can impact quality and consistency. Buyers should evaluate the labor practices of suppliers to ensure they meet ethical standards.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and salaries of non-production staff. Understanding these costs can provide insights into the overall pricing structure of potential suppliers.

-

Tooling: Depending on the customization required, tooling costs can be significant. Custom molds and production tools can add to the initial investment but are often necessary for tailored solutions.

-

Quality Control (QC): Rigorous quality control processes ensure that the final product meets international standards, which can add to the cost. However, investing in quality control can reduce long-term costs associated with returns and warranty claims.

-

Logistics: Shipping and handling costs should not be overlooked. International buyers must consider freight, customs duties, and insurance, which can vary significantly based on the shipping method and distance.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding their business model and margin expectations can aid in negotiation.

How Do Price Influencers Affect RV AC Sourcing?

Several factors influence pricing in the RV AC market, especially for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing due to economies of scale. Buyers should assess their purchasing strategy to maximize savings.

-

Specifications and Customization: Customized units may incur higher costs. Buyers should clarify their needs upfront to avoid unexpected charges.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or CE) can enhance the price but are crucial for compliance and reliability.

-

Supplier Factors: Relationships with suppliers, their reputation, and their production capabilities can influence pricing. Building long-term partnerships can lead to more favorable terms.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. They define responsibilities for shipping, insurance, and tariffs, impacting the total cost.

What Buyer Tips Can Enhance Cost Efficiency in RV AC Sourcing?

-

Negotiate Strategically: Use your understanding of cost components to negotiate better terms. Presenting a clear understanding of your needs and the market landscape can strengthen your position.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, assess the TCO, including maintenance, operation, and end-of-life disposal costs. This approach can lead to more informed purchasing decisions.

-

Stay Informed on Pricing Nuances: Be aware of pricing trends in different regions, as economic factors can fluctuate. For example, currency exchange rates or local market demand in Africa, South America, the Middle East, and Europe can impact costs.

-

Research Supplier Backgrounds: Conduct thorough due diligence on suppliers. Look for reviews, certifications, and previous client experiences to ensure reliability and quality.

-

Consider Alternative Suppliers: Don’t limit your options to a single region. Exploring suppliers from various geographical areas can open up competitive pricing opportunities.

Disclaimer on Indicative Prices

Prices for RV AC units can vary widely based on the factors discussed above. It is essential for buyers to gather quotes from multiple suppliers and consider all cost components to make informed purchasing decisions. Regularly reviewing market conditions and supplier capabilities will also help maintain cost efficiency across sourcing operations.

Alternatives Analysis: Comparing rv ac With Other Solutions

Understanding Alternatives for RV AC Solutions

When evaluating cooling solutions for recreational vehicles (RV), it’s essential to explore alternatives that meet specific operational and budgetary requirements. By comparing RV AC with other viable solutions, B2B buyers can make informed decisions that align with their business goals and environmental conditions. Below, we delve into two prominent alternatives: Evaporative Coolers and Portable Air Conditioners.

Comparison Table of RV AC and Alternatives

| Comparison Aspect | RV AC | Evaporative Cooler | Portable Air Conditioner |

|---|---|---|---|

| Performance | High cooling capacity | Moderate cooling; effective in dry climates | Variable; can cool small spaces |

| Cost | Higher initial investment | Lower initial cost; less efficient in humid areas | Moderate cost; energy-efficient options available |

| Ease of Implementation | Requires installation | Easy to set up; minimal installation | Portable; plug-and-play |

| Maintenance | Regular service needed | Low maintenance; occasional filter cleaning | Moderate; filter cleaning and drainage needed |

| Best Use Case | Optimal for diverse climates | Best for arid regions | Ideal for temporary or small spaces |

What Are the Pros and Cons of Evaporative Coolers?

Evaporative coolers, also known as swamp coolers, utilize water evaporation to cool the air, making them an eco-friendly option. Their primary advantage is cost-effectiveness; they consume less electricity and have lower initial costs compared to RV AC units. However, their performance diminishes in high humidity, limiting their effectiveness in certain climates. Businesses operating in arid regions, like parts of Africa and the Middle East, may find these coolers particularly beneficial, as they provide adequate cooling at a fraction of the cost.

How Do Portable Air Conditioners Compare?

Portable air conditioners offer flexibility and convenience, making them suitable for temporary installations or smaller spaces. They are easy to transport and require minimal setup, appealing to businesses that need a quick cooling solution. However, their cooling capacity is typically lower than that of RV AC units, making them less suitable for larger vehicles or extreme temperatures. Additionally, while they may be energy-efficient, ongoing operational costs can add up, making them less favorable for long-term use in permanent setups.

Choosing the Right Solution for Your Needs

When selecting a cooling solution, B2B buyers should assess their specific requirements, including climate conditions, budget constraints, and operational needs. RV AC units provide robust performance across various environments but require a higher initial investment and ongoing maintenance. In contrast, evaporative coolers and portable air conditioners offer more affordable and flexible options, but their effectiveness can vary based on environmental factors.

Ultimately, evaluating the trade-offs among these solutions will help international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, make a decision that aligns with their operational strategies and financial considerations.

Spotlight on Potential rv ac Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘rv ac’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for rv ac

What Are the Essential Technical Properties of RV AC Units?

Understanding the technical properties of RV air conditioning (AC) units is crucial for international B2B buyers, particularly when sourcing products from diverse regions such as Africa, South America, the Middle East, and Europe. Here are some key specifications to consider:

-

Cooling Capacity (BTU/h)

– The cooling capacity is measured in British Thermal Units per hour (BTU/h) and indicates how much heat the unit can remove from a space. A higher BTU rating corresponds to a greater cooling capacity. It is essential for buyers to match the cooling capacity with the size of the RV to ensure efficient performance. Oversized units can lead to increased energy costs, while undersized units may struggle to cool the space adequately. -

Energy Efficiency Ratio (EER)

– The EER measures the efficiency of an AC unit by comparing its cooling output to the energy consumed. A higher EER indicates a more energy-efficient unit, which is particularly important for B2B buyers looking to minimize operational costs and meet sustainability goals. Energy-efficient units not only reduce electricity bills but also comply with various environmental regulations. -

Operating Voltage

– RV AC units typically operate on either 120V or 240V power supply. Understanding the required voltage is crucial for ensuring compatibility with the RV’s electrical system. Buyers must verify voltage specifications to avoid potential damage to the unit or the RV’s electrical system, which could lead to costly repairs and downtime. -

Weight and Dimensions

– The weight and dimensions of the RV AC unit are critical for compatibility with the RV design. Buyers should consider the structural integrity of the vehicle and ensure that the AC unit can be installed without compromising the RV’s stability. Additionally, knowing the weight can aid in logistics planning, particularly when transporting units across borders. -

Noise Level (dBA)

– The noise level of an RV AC unit, measured in decibels (dBA), affects the comfort of the occupants. Lower noise levels are preferable, especially for residential or recreational use. B2B buyers should inquire about the dBA rating to select units that provide a comfortable environment, particularly for long-term stays.

What Trade Terminology Should B2B Buyers Know for RV AC?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the RV AC context, understanding OEM relationships can help buyers ensure they are sourcing high-quality parts and components, which can directly affect the performance and reliability of the AC unit. -

MOQ (Minimum Order Quantity)

– MOQ refers to the minimum number of units a supplier is willing to sell in a single order. B2B buyers must consider MOQs when planning their inventory and budget. Understanding these requirements can aid in negotiating terms that align with the buyer’s operational needs and cash flow. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer submits to solicit price quotes from suppliers. Including specific requirements such as technical specifications and quantities ensures that suppliers provide accurate and competitive pricing. Crafting a clear RFQ can streamline the procurement process and lead to better purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms recognized internationally, which define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk allocation, and delivery obligations. This knowledge is vital for successful negotiations and ensuring smooth logistics. -

Warranty Period

– The warranty period is the duration during which the manufacturer guarantees the performance of the RV AC unit against defects. Buyers should carefully review warranty terms, as they can vary significantly among manufacturers. Understanding warranty coverage helps mitigate risks associated with product failures and ensures accountability from suppliers.

These technical properties and trade terms are critical for international B2B buyers in the RV AC market. By equipping themselves with this knowledge, they can make informed purchasing decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the rv ac Sector

What are the Key Market Dynamics Influencing the RV AC Sector?

The RV AC sector is witnessing significant transformations driven by several global factors. As the demand for recreational vehicles (RVs) continues to rise, international B2B buyers must be aware of the market dynamics that influence sourcing decisions. In regions like Africa, South America, the Middle East, and Europe, the growth of domestic tourism and outdoor activities has spurred the need for efficient and reliable RV air conditioning systems. Additionally, advancements in technology, such as smart cooling solutions and energy-efficient designs, are reshaping consumer expectations and influencing purchasing decisions.

Emerging trends in B2B technology also play a crucial role in sourcing strategies. The integration of IoT (Internet of Things) in RV AC units allows for remote monitoring and control, making systems more user-friendly and appealing to modern consumers. Furthermore, digital platforms that facilitate direct sourcing from manufacturers are becoming increasingly popular, enabling buyers to access a wider selection of products and negotiate better prices. The emphasis on quality assurance and compliance with international standards is also paramount, as buyers seek to mitigate risks associated with subpar products from less regulated markets.

How Important is Sustainability and Ethical Sourcing in the RV AC Sector?

Sustainability is no longer a buzzword but a critical factor in the decision-making process for B2B buyers in the RV AC sector. The environmental impact of manufacturing and disposing of air conditioning units is substantial, prompting a shift towards greener alternatives. International buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using eco-friendly refrigerants and energy-efficient components.

Moreover, ethical sourcing is gaining traction among businesses that aim to enhance their brand reputation. Buyers should assess their supply chains to ensure compliance with labor laws and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ENERGY STAR not only validate a manufacturer’s commitment to sustainability but also provide assurance to buyers regarding the quality and efficiency of the products. In an era where consumers are more conscious of their environmental footprint, aligning with sustainable suppliers can significantly enhance marketability and customer loyalty.

What is the Evolution of the RV AC Sector and Its Implications for B2B Buyers?

The RV AC sector has evolved significantly over the past few decades, transitioning from basic cooling solutions to sophisticated systems that prioritize comfort and efficiency. Initially, RV air conditioning units were bulky and inefficient, often leading to high energy consumption and maintenance costs. However, advancements in technology have led to the development of compact, lightweight, and energy-efficient models that better meet the needs of modern RV owners.

For international B2B buyers, understanding this evolution is crucial. The shift towards higher efficiency ratings and the introduction of smart technology in RV AC units mean that buyers must stay informed about the latest innovations and trends. This knowledge enables them to make informed purchasing decisions that not only meet current market demands but also position them favorably for future growth. As the RV market continues to expand globally, leveraging this historical context can lead to strategic sourcing and competitive advantages in various regions.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of rv ac

-

How do I solve the issue of high energy costs when using RV AC units?

To mitigate high energy costs associated with RV AC units, consider investing in energy-efficient models that have a high Seasonal Energy Efficiency Ratio (SEER). Additionally, using smart thermostats can optimize energy consumption by adjusting the temperature based on your usage patterns. Ensuring proper insulation in your RV will also help maintain cooler temperatures, reducing the reliance on AC. Lastly, explore solar-powered RV AC options, which can significantly cut down on energy expenses, especially in sunny regions like Africa and South America. -

What is the best RV AC unit for hot climates?

For hot climates, such as those found in parts of Africa and the Middle East, a rooftop RV air conditioner with a higher BTU (British Thermal Unit) rating is advisable, typically between 13,500 to 15,000 BTUs. Brands known for durability and efficiency in extreme temperatures include Dometic and Advent. Additionally, consider models with features like variable speed fans and energy-saving modes, which can provide comfort while minimizing energy usage. The choice of unit should also reflect the size of the RV to ensure optimal cooling. -

What are the most important factors to consider when sourcing RV AC units internationally?

When sourcing RV AC units internationally, prioritize factors such as supplier reliability, product quality, and compliance with local regulations. Assess the supplier’s manufacturing practices and certifications to ensure they meet international quality standards. Additionally, consider the total cost of ownership, including shipping, tariffs, and potential customs duties. Engaging with suppliers that offer warranties and after-sales support can also provide peace of mind in your purchasing decision. -

How can I ensure the quality of RV AC units from international suppliers?

To ensure the quality of RV AC units from international suppliers, conduct thorough due diligence before making a purchase. Request product samples and verify their performance through independent testing if possible. Look for suppliers that follow ISO standards or have relevant certifications like CE or UL. Engaging third-party inspection services before shipment can also guarantee that the products meet your specifications. Additionally, customer reviews and testimonials can provide insights into the supplier’s reliability and product quality. -

What are the minimum order quantities (MOQ) for RV AC units from suppliers?

Minimum order quantities for RV AC units can vary widely among suppliers, ranging from as low as 5 units to over 100 units depending on the manufacturer and your location. It’s essential to clarify MOQs during initial discussions with suppliers. If MOQ is a concern, consider discussing the possibility of a trial order or partnering with other businesses to meet the minimum requirement. Some suppliers may also offer flexibility for first-time buyers or bulk orders, so it’s worth negotiating. -

What payment terms should I expect when sourcing RV AC units internationally?

Payment terms can differ significantly based on the supplier’s policies and your negotiation skills. Commonly, suppliers may request a 30% deposit upfront and the remaining balance before shipment. However, for established relationships, payment terms can be extended to 60 or even 90 days. Always verify the security of payment methods, such as using letters of credit or escrow services, especially for high-value transactions. It’s prudent to discuss payment terms early in the negotiation process to avoid misunderstandings. -

How can I manage logistics and shipping for RV AC units from international suppliers?

Managing logistics for RV AC units involves selecting reliable shipping partners familiar with handling bulky items. Discuss with your supplier about their preferred logistics providers and shipping methods. Consider factors such as shipping times, costs, and insurance options to safeguard your investment. It’s advisable to choose Door-to-Door services, especially if you lack transport facilities. Additionally, stay informed about import regulations, tariffs, and potential customs delays to ensure a smooth delivery process. -

What are the best practices for maintaining RV AC units after purchase?

Regular maintenance is crucial for the longevity and efficiency of RV AC units. Start by cleaning or replacing filters every month to ensure optimal airflow. Check the condenser coils for dirt build-up and clean them as necessary. Schedule annual professional inspections to catch any potential issues early and ensure that the unit operates efficiently. Additionally, keep the area around the AC unit clear of debris to promote airflow. Document maintenance activities to track performance and identify any recurring issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rv ac

In navigating the competitive landscape of RV air conditioning (AC) systems, strategic sourcing emerges as a critical component for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. By prioritizing quality and supplier reliability, businesses can significantly reduce costs while enhancing their product offerings. Understanding local market dynamics and regulations is essential for sourcing components that not only meet operational standards but also resonate with consumer preferences.

What are the long-term benefits of strategic sourcing in the RV AC industry? Leveraging strong supplier relationships can lead to improved negotiation power, access to innovative technologies, and resilience against supply chain disruptions. Moreover, adopting sustainable sourcing practices aligns with global environmental initiatives, further amplifying brand reputation and customer loyalty.

As the RV industry continues to evolve, international buyers are encouraged to stay proactive. Engaging with suppliers who prioritize innovation and sustainability will position businesses at the forefront of market trends. Now is the time to reassess sourcing strategies, embrace collaboration, and invest in partnerships that will drive future growth in the RV AC sector.