Explore Different Types of Electrical Sockets: A Complete Guide (2025)

Introduction: Navigating the Global Market for different types of electrical sockets

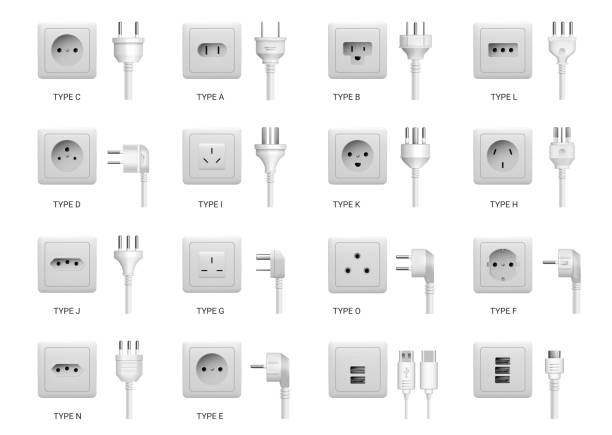

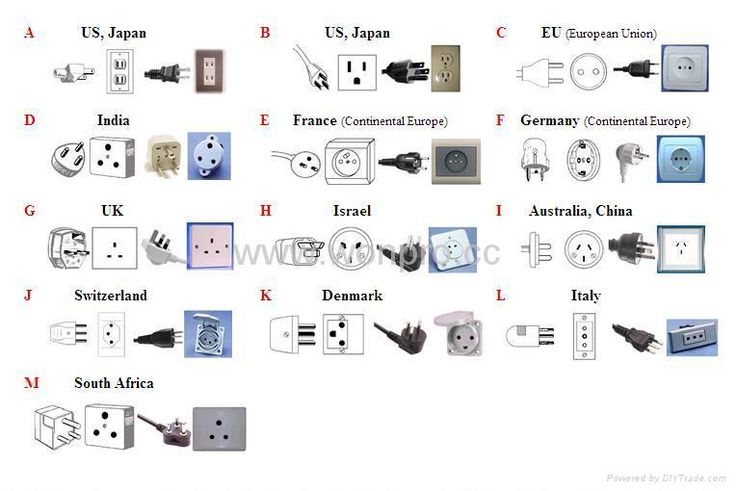

In the rapidly evolving global marketplace, sourcing the right electrical sockets can present significant challenges for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With a multitude of socket types available, including those designed for specific appliances and safety standards, understanding the nuances of each type is crucial for ensuring compatibility and safety. This comprehensive guide delves into the various types of electrical sockets—covering their applications, regional variations, and technical specifications—empowering businesses to make informed purchasing decisions.

Buyers will gain insights into the most commonly used socket types, such as Type C, which is prevalent in many African and South American countries, or Type G, widely used in the UK and parts of the Middle East. Additionally, the guide provides essential information on supplier vetting processes, cost considerations, and best practices for ensuring compliance with local regulations.

By equipping B2B buyers with knowledge about different socket specifications and safety features, this guide aims to simplify the procurement process and enhance operational efficiency. Whether you’re sourcing for a new construction project or upgrading existing infrastructure, understanding the global landscape of electrical sockets will help you mitigate risks and optimize your supply chain strategies.

Understanding different types of electrical sockets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | 2 pins, non-grounded, typically 220-240V | General electronics in Europe, Africa, Asia | Pros: Commonly used, versatile; Cons: Not grounded, limited to lower current ratings. |

| Type G | 3 pins, grounded, 13A, mainly 220-250V | UK and Middle East appliances | Pros: Enhanced safety with grounding; Cons: Bulkier design may limit space. |

| Type N | 3 pins, grounded, 10A, 16A, 20A, 100-240V | Brazil and South African devices | Pros: Supports multiple amperages; Cons: Limited to specific regions, compatibility issues. |

| Type E | 2 pins with a grounding hole, 16A, 220-240V | European appliances, lighting | Pros: Grounding enhances safety; Cons: Compatibility limited to specific plug types. |

| Type M | 3 pins, grounded, 16A, 220-240V | South African tools and appliances | Pros: High current capacity; Cons: Less common globally, may require adapters. |

What Are the Characteristics of Type C Sockets?

Type C sockets are characterized by their two-pin design, typically operating at 220-240V. They are prevalent in Europe, Africa, and parts of Asia, making them ideal for general electronic applications. B2B buyers should consider the widespread use of Type C sockets for appliances, chargers, and lighting solutions. However, the absence of grounding may limit their use for high-power devices or in environments where electrical safety is paramount.

How Do Type G Sockets Enhance Safety?

Type G sockets feature three pins, providing a grounding mechanism that enhances electrical safety. They are primarily used in the UK and parts of the Middle East, making them suitable for various appliances and industrial equipment. B2B buyers appreciate the robust design and safety features of Type G sockets, although their bulkiness may pose installation challenges in tight spaces. Compatibility with other plug types is also limited.

Why Are Type N Sockets Important for South America?

Type N sockets, used predominantly in Brazil and South Africa, accommodate three pins and are rated for multiple amperages (10A, 16A, 20A). This versatility makes them suitable for a range of electrical devices, from light fixtures to heavy machinery. For B2B buyers, understanding the amperage requirements of their equipment is crucial, as using the wrong type can lead to performance issues or safety hazards. However, the limited geographic usage of Type N may necessitate careful planning for international operations.

What Makes Type E Sockets Suitable for European Markets?

Type E sockets have two pins with an additional grounding hole, rated at 16A and typically operating at 220-240V. They are widely used across Europe, making them ideal for B2B applications in the region. Their grounding feature enhances safety, particularly for high-power devices. However, buyers must be aware of compatibility issues with other plug types, which may require additional adapters or converters for seamless operation.

How Do Type M Sockets Support High Current Applications?

Type M sockets, featuring three grounded pins and rated for 16A at 220-240V, are mainly found in South Africa. They are suitable for high-current applications, making them ideal for industrial tools and heavy appliances. B2B buyers should consider the capacity of Type M sockets when selecting electrical solutions for their operations. However, their limited global presence might pose challenges for international buyers, necessitating the use of adapters or converters in other regions.

Key Industrial Applications of different types of electrical sockets

| Industry/Sector | Specific Application of different types of electrical sockets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial machinery requiring Type C and Type D sockets | Ensures compatibility with heavy machinery, enhancing operational efficiency | Voltage ratings, durability under stress, and compatibility with local standards |

| Hospitality | GFCI outlets in kitchens and bathrooms | Enhances safety and compliance with local regulations, reducing liability risks | Certification standards, moisture resistance, and ease of installation |

| Healthcare | Tamper-resistant outlets in patient care areas | Protects vulnerable populations from electrical hazards, ensuring patient safety | Compliance with health regulations, ease of maintenance, and reliability |

| Construction | Weather-resistant sockets for outdoor sites | Provides reliable power supply in adverse weather conditions, minimizing downtime | IP ratings, ease of installation, and resistance to environmental factors |

| Retail | Combination outlets for point-of-sale systems | Increases efficiency by allowing multiple devices to operate simultaneously | Compatibility with various device types, electrical load capacity, and safety certifications |

How Are Different Types of Electrical Sockets Used in Manufacturing?

In the manufacturing sector, Type C and Type D sockets are commonly utilized to accommodate heavy machinery and equipment that operate on higher voltages (220-240V). These sockets ensure that the electrical supply is consistent and reliable, which is critical for maintaining operational efficiency. International B2B buyers must consider the voltage ratings and durability of these sockets, ensuring they can withstand the stresses of industrial environments and comply with local electrical standards.

What Role Do GFCI Outlets Play in Hospitality Settings?

In the hospitality industry, GFCI (Ground Fault Circuit Interrupter) outlets are essential in kitchens and bathrooms where moisture is prevalent. These sockets protect against electrical shocks, aligning with safety regulations and reducing liability risks for businesses. Buyers should prioritize sourcing GFCI outlets that meet local certification standards and are moisture-resistant, ensuring they can withstand the unique challenges of hospitality environments.

Why Are Tamper-Resistant Outlets Important in Healthcare?

Healthcare facilities require tamper-resistant outlets to safeguard patients, especially in vulnerable areas such as pediatric wards. These outlets prevent accidental electrical shocks, thereby enhancing patient safety. B2B buyers in the healthcare sector should focus on outlets that comply with health regulations, are easy to maintain, and provide reliable performance to ensure a safe environment for both patients and staff.

How Do Weather-Resistant Sockets Benefit Construction Projects?

Weather-resistant sockets are critical in the construction industry, particularly for outdoor sites where exposure to the elements is a concern. These sockets maintain a reliable power supply even in adverse weather conditions, reducing downtime and enhancing productivity. Buyers should consider the Ingress Protection (IP) ratings of these sockets, ensuring they are suitable for the environmental conditions they will face on-site.

What Advantages Do Combination Outlets Offer in Retail?

In retail environments, combination outlets are increasingly used at point-of-sale systems to allow multiple devices—such as cash registers, card readers, and printers—to operate simultaneously. This enhances operational efficiency and customer service. International B2B buyers should look for combination outlets that are compatible with various device types, have adequate electrical load capacity, and meet safety certifications to ensure smooth operations.

3 Common User Pain Points for ‘different types of electrical sockets’ & Their Solutions

Scenario 1: Compatibility Issues with Diverse Electrical Sockets

The Problem:

B2B buyers frequently encounter compatibility issues when sourcing electrical sockets for their projects, especially when dealing with international clients or suppliers. For instance, a company based in Nigeria may need to import equipment that uses Type C sockets, while the local infrastructure primarily uses Type D. This mismatch can lead to operational delays, increased costs due to adapter purchases, and even safety hazards if incompatible products are used. The challenge is not only about the type of socket but also understanding the voltage and current ratings, which can vary significantly between regions.

The Solution:

To mitigate compatibility issues, B2B buyers should conduct thorough research on the electrical standards of the target market. This includes understanding the types of plugs and sockets used in specific countries, as well as their voltage and frequency requirements. Engaging with local electrical engineers or consultants can provide insights into regional practices and ensure compliance with local regulations. Buyers should prioritize sourcing sockets that are versatile or have universal compatibility features. Additionally, consider investing in multi-standard sockets that accommodate various plug types, which can streamline operations and reduce the need for multiple adapters.

Scenario 2: Safety Concerns with Electrical Outlets

The Problem:

Safety is paramount in electrical installations, yet many B2B buyers overlook the safety ratings of electrical sockets. For example, in regions prone to electrical surges, using standard sockets without built-in safety features can result in equipment damage, fire hazards, or even electrical shocks. This concern is particularly pressing for businesses in the Middle East, where environmental factors like dust and humidity can compromise socket integrity. Buyers often find themselves navigating a complex landscape of safety standards, which can be overwhelming.

The Solution:

To enhance safety in electrical installations, B2B buyers should prioritize sourcing GFCI (Ground Fault Circuit Interrupter) and AFCI (Arc Fault Circuit Interrupter) sockets, especially for high-risk areas such as kitchens and bathrooms. These sockets automatically shut off power when they detect faults, significantly reducing the risk of electrical accidents. Buyers should also ensure that all sockets comply with international safety standards, such as IEC 60884-1. Conducting regular training sessions for installation teams on best practices for socket installation and maintenance can further enhance safety. Consider collaborating with reputable manufacturers known for their commitment to safety to ensure the highest quality products.

Scenario 3: Sourcing Quality Electrical Sockets in Bulk

The Problem:

B2B buyers often face challenges in sourcing quality electrical sockets in bulk, particularly when working with new suppliers. Inconsistent product quality can lead to increased returns, project delays, and damaged reputations. For instance, a construction firm in South America may struggle to find a reliable supplier for Type N sockets, leading to variations in product specifications that can compromise the entire project. This inconsistency can also drive up costs and reduce operational efficiency.

The Solution:

To ensure consistent quality when sourcing electrical sockets, B2B buyers should establish strong relationships with certified suppliers who adhere to recognized quality standards. Conducting a thorough vetting process, including requesting samples and reviewing certifications, can help mitigate risks associated with poor-quality products. Buyers should also consider participating in industry trade shows or forums to connect with reputable manufacturers and distributors. Implementing a quality assurance program that includes regular inspections and testing of received products can further safeguard against inconsistencies. Additionally, maintaining an open line of communication with suppliers regarding quality expectations can foster a collaborative environment focused on delivering reliable products.

Strategic Material Selection Guide for different types of electrical sockets

When selecting materials for electrical sockets, international B2B buyers must consider several factors that influence performance, durability, and compliance with local standards. This guide analyzes four common materials used in electrical socket manufacturing, focusing on their properties, advantages, disadvantages, and implications for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Thermoplastic Materials in Electrical Sockets?

Thermoplastics, such as polyvinyl chloride (PVC) and nylon, are widely used in electrical sockets due to their excellent insulation properties and resistance to moisture. They can typically withstand temperatures ranging from -40°C to 85°C, making them suitable for various environments. Additionally, thermoplastics exhibit good chemical resistance, which is crucial for sockets exposed to different media.

Pros and Cons:

Thermoplastics are lightweight and cost-effective, making them an attractive choice for manufacturers. However, they may not be as durable as other materials, particularly in high-temperature applications. Their lower mechanical strength can limit their use in heavy-duty sockets.

Impact on Application:

Thermoplastics are ideal for residential and light commercial applications but may not be suitable for industrial settings where high durability is required.

Considerations for International Buyers:

Buyers should ensure that thermoplastic sockets comply with local standards, such as IEC (International Electrotechnical Commission) or ASTM (American Society for Testing and Materials), particularly in regions where electrical safety is critical.

How Do Metal Materials Enhance Electrical Socket Performance?

Metals like brass and copper are often used in the conductive components of electrical sockets due to their excellent electrical conductivity and durability. Brass, for example, can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros and Cons:

The primary advantage of metal materials is their longevity and reliability in high-load environments. However, they can be more expensive and may require additional coatings to prevent corrosion, especially in humid or coastal regions.

Impact on Application:

Metal components are essential for sockets used in industrial settings or for heavy appliances, where consistent electrical flow and durability are paramount.

Considerations for International Buyers:

Buyers should be aware of the corrosion resistance ratings and ensure compliance with local electrical codes, particularly in regions with high humidity or saline conditions.

What Role Do Ceramic Materials Play in Electrical Socket Manufacturing?

Ceramic materials are often used in high-voltage sockets due to their excellent insulation properties and resistance to heat. They can withstand temperatures up to 1000°C, making them suitable for applications where overheating is a concern.

Pros and Cons:

Ceramics are highly durable and resistant to environmental factors, but they are also more brittle than other materials, which can lead to breakage during installation or use. Additionally, they tend to be more expensive to manufacture.

Impact on Application:

Ceramic sockets are ideal for specialized applications, such as industrial machinery or outdoor settings where high durability is required.

Considerations for International Buyers:

Buyers must ensure that ceramic sockets meet relevant international standards, such as IEC 60947 for low-voltage switchgear and control gear.

How Do Composite Materials Compare in Electrical Socket Applications?

Composite materials, which combine plastic and metal properties, are increasingly being used in electrical sockets. These materials offer a balance between strength and weight, making them versatile for various applications.

Pros and Cons:

The primary advantage of composite materials is their ability to resist environmental stressors while remaining lightweight. However, they can be more complex to manufacture and may not be as widely accepted in all markets.

Impact on Application:

Composite sockets are suitable for both residential and commercial applications, providing a good balance of performance and cost.

Considerations for International Buyers:

Buyers should verify the material certifications and compliance with local standards, especially in regions with stringent electrical safety regulations.

Summary Table of Material Selection for Electrical Sockets

| Material | Typical Use Case for different types of electrical sockets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Residential and light commercial applications | Lightweight and cost-effective | Lower durability in high temps | Low |

| Metal | Heavy-duty and industrial applications | High durability and conductivity | Higher cost and corrosion risk | High |

| Ceramic | High-voltage and specialized applications | Excellent heat and insulation | Brittle and expensive | High |

| Composite | Versatile for residential and commercial applications | Balanced strength and weight | Complex manufacturing | Medium |

This guide provides actionable insights for international B2B buyers, ensuring they can make informed decisions regarding the materials used in electrical sockets, tailored to their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for different types of electrical sockets

What Are the Key Stages in the Manufacturing Process of Electrical Sockets?

The manufacturing process for electrical sockets involves several critical stages, each contributing to the final product’s quality and functionality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used for Electrical Sockets?

The first step in the manufacturing process is material preparation. Electrical sockets are typically made from a combination of plastic, metal, and rubber. The plastic is often thermoplastic, such as polycarbonate or nylon, which provides durability and insulation. Metal components, such as copper or brass, are used for the contacts and terminals to ensure good electrical conductivity.

Before production, these materials are sourced from reliable suppliers who meet international quality standards. B2B buyers should inquire about the origin and specifications of these materials to ensure compliance with safety and quality requirements.

How Are Electrical Sockets Formed During Manufacturing?

The forming stage involves shaping the prepared materials into the various components of the socket. This can include injection molding for the plastic parts and stamping or machining for the metal components.

Injection molding is a prevalent technique for producing the socket casing, allowing for complex shapes and high-volume production. Metal components may undergo processes such as die-casting or CNC machining to achieve precise dimensions.

A stock image related to different types of electrical sockets.

B2B buyers should look for manufacturers that utilize advanced forming technologies to ensure high-quality and consistent products.

What Does the Assembly Process Entail for Electrical Sockets?

Once the individual components are formed, they are assembled into the final product. This stage typically involves the following steps:

- Component Inspection: Each part is inspected for defects before assembly.

- Joining: Components are joined using various methods, such as soldering for electrical connections and screws or clips for mechanical assembly.

- Final Assembly: The complete unit is assembled, ensuring that all parts fit properly and function as intended.

Effective assembly processes are critical for ensuring the reliability and safety of electrical sockets. B2B buyers should verify that potential suppliers have well-documented assembly procedures and skilled labor.

What Finishing Techniques Are Used for Electrical Sockets?

The finishing stage enhances the appearance and functionality of electrical sockets. This may include surface treatments, such as painting, coating, or plating, to improve corrosion resistance and aesthetic appeal.

Quality control at this stage is vital, as finishing defects can lead to customer dissatisfaction and product failures. B2B buyers should consider suppliers who invest in modern finishing technologies to ensure high-quality outcomes.

What Are the Quality Assurance Standards Relevant to Electrical Socket Manufacturing?

Quality assurance (QA) is essential in the manufacturing of electrical sockets to ensure safety and compliance with international standards. B2B buyers should be familiar with the following key quality standards:

Which International Standards Should Electrical Socket Manufacturers Comply With?

-

ISO 9001: This standard focuses on quality management systems and is widely recognized globally. Compliance indicates that the manufacturer has effective processes in place to ensure product quality.

-

CE Marking: In Europe, electrical products, including sockets, must meet safety and environmental standards. The CE mark signifies compliance with relevant EU directives.

-

UL Certification: For North American markets, UL (Underwriters Laboratories) certification is crucial, indicating that the product has been tested for safety.

B2B buyers should request documentation proving compliance with these standards to ensure the supplier’s commitment to quality.

What Are the Quality Control Checkpoints During Electrical Socket Production?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components before they enter the production line to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to detect any deviations from established processes. This can include inspections at various stages of assembly.

-

Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing to ensure it meets all quality and safety standards. This may involve electrical testing, mechanical testing, and visual inspections.

B2B buyers should inquire about the QC procedures of potential suppliers, including the frequency and types of inspections conducted.

What Common Testing Methods Are Used for Quality Assurance in Electrical Sockets?

Testing methods are crucial for verifying the safety and performance of electrical sockets. Common testing methods include:

- Electrical Testing: This checks for proper conductivity, insulation resistance, and short-circuit protection.

- Mechanical Testing: Assessing the physical durability of the socket, including impact resistance and stress tests.

- Environmental Testing: Ensuring that sockets can withstand various environmental conditions, such as moisture, temperature extremes, and UV exposure.

B2B buyers should seek suppliers who conduct comprehensive testing and provide certificates of conformity for their products.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that potential suppliers adhere to rigorous quality control practices, B2B buyers can take several steps:

-

Supplier Audits: Conduct on-site audits to evaluate the supplier’s manufacturing processes, quality systems, and compliance with international standards.

-

Request Quality Reports: Ask for detailed QC reports that outline testing results and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Consider hiring third-party inspection agencies to evaluate the supplier’s quality control processes and product compliance.

-

Certification Verification: Verify the authenticity of certifications claimed by suppliers to ensure they meet industry standards.

By taking these steps, B2B buyers can mitigate risks and ensure they partner with manufacturers committed to quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regional Compliance: Different regions may have varying standards and regulations. It’s essential to ensure that products comply with local regulations in the target market.

-

Cultural Differences: Understanding cultural attitudes towards quality and safety can influence how manufacturers approach quality assurance.

-

Supply Chain Transparency: International buyers should prioritize suppliers that provide transparency in their supply chains, as this can affect product quality and compliance.

By considering these factors, international B2B buyers can make more informed decisions when sourcing electrical sockets, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different types of electrical sockets’

When it comes to procuring different types of electrical sockets, an organized approach can streamline the process and ensure that you meet your operational needs effectively. This checklist provides a practical guide for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. Consider factors such as voltage, amperage, and compatibility with local electrical standards. Understanding these specifications helps in selecting sockets that meet safety regulations and operational efficiency.

- Identify the socket types needed based on your market (e.g., Type C for Europe or Type M for South Africa).

- Consider the application of the sockets—residential, commercial, or industrial use.

Step 2: Research Local Standards and Regulations

Each region has specific electrical standards that sockets must comply with. Familiarize yourself with local regulations to avoid legal complications.

- Consult local electrical codes to ensure the products meet safety and installation requirements.

- Stay informed about any changes in regulations that may affect your sourcing decisions.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your needs reliably. Look for established companies with a good track record.

- Request documentation such as certifications and compliance with international standards (e.g., IEC).

- Seek references from other businesses in your industry to gauge supplier reliability and product quality.

Step 4: Analyze Product Quality and Features

Assess the quality of the sockets you intend to procure. Focus on durability, safety features, and overall design.

- Check for safety certifications such as CE, UL, or other relevant approvals.

- Evaluate features like weather resistance for outdoor applications or tamper resistance for child safety.

Step 5: Negotiate Pricing and Payment Terms

Once you identify suitable suppliers, engage in negotiations to secure favorable pricing and payment terms.

- Request bulk pricing discounts if your order volume is significant.

- Clarify payment terms such as upfront deposits or credit options to manage cash flow effectively.

Step 6: Request Samples for Testing

Before finalizing your order, request samples to assess the product quality firsthand. Testing samples can reveal issues that may not be evident in product descriptions.

- Conduct compatibility tests to ensure the sockets work with your existing equipment.

- Evaluate durability through stress testing to ascertain long-term performance.

Step 7: Plan for Logistics and Delivery

Coordinate logistics to ensure timely delivery of your electrical sockets.

- Discuss shipping options with suppliers to find the best balance between cost and speed.

- Consider local customs regulations that may affect importation timelines or additional costs.

By following this structured checklist, B2B buyers can enhance their sourcing process for electrical sockets, ensuring they make informed decisions that align with their business needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for different types of electrical sockets Sourcing

When sourcing electrical sockets, international B2B buyers must navigate a complex landscape of costs and pricing structures. Understanding the various cost components and pricing influencers is crucial for making informed purchasing decisions.

What Are the Key Cost Components of Electrical Sockets?

-

Materials: The primary materials used in electrical sockets include plastic for the housing and metal for the connectors. The choice of materials can significantly impact the durability and safety standards of the sockets. For example, sockets made from high-grade thermoplastic are more resistant to heat and impact, which could justify a higher price point.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs, such as those in Southeast Asia, can offer significant savings, while manufacturers in Europe may incur higher labor expenses. Understanding the labor market in the supplier’s region can help buyers anticipate costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and equipment maintenance. Efficient manufacturing processes can help minimize these costs, but buyers should be aware of how they can influence the final price.

-

Tooling: Custom tooling for specific socket designs can be a substantial upfront investment. Buyers should inquire about tooling costs when considering custom socket designs, as these can significantly affect the overall pricing.

-

Quality Control (QC): Ensuring that electrical sockets meet international safety and quality standards is essential, particularly for buyers in regions with stringent regulations. Investing in robust QC processes can add to the cost but ultimately ensures product reliability and compliance.

-

Logistics: Shipping costs, including freight and handling, can fluctuate based on the destination and chosen Incoterms. Buyers should consider logistics as a key component of the total cost of ownership.

-

Margin: Supplier margins will vary based on market competition, perceived value, and the supplier’s brand reputation. Understanding the competitive landscape can help buyers gauge whether they are getting a fair price.

How Do Price Influencers Affect Electrical Socket Costs?

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often leads to better pricing. Suppliers may offer volume discounts, which can lower the per-unit cost significantly.

-

Specifications and Customization: Custom designs or specific features (such as GFCI or tamper-resistant sockets) can increase costs due to additional manufacturing requirements. Buyers should assess whether these features are necessary for their applications.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like CE, UL, or IEC) often come at a premium. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, which can significantly affect the total cost.

What Are Some Buyer Tips for Cost-Efficiency in Sourcing Electrical Sockets?

-

Negotiate: Don’t hesitate to negotiate terms and prices with suppliers. Many manufacturers are open to discussions, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and energy efficiency.

-

Research Local Regulations: Different regions have varying standards for electrical products. Understanding these can prevent costly compliance issues later.

-

Assess Supplier Reliability: Conduct due diligence on suppliers to ensure they have a good reputation for quality and service. This can mitigate risks associated with defective products.

-

Stay Informed on Market Trends: Keep an eye on market trends and economic factors that might influence pricing. For instance, fluctuations in raw material costs can directly impact socket prices.

In conclusion, international B2B buyers must consider a myriad of factors when sourcing electrical sockets to ensure they achieve cost efficiency while meeting quality and compliance standards. By understanding the cost structure and price influencers, buyers can make informed decisions that align with their business needs.

Alternatives Analysis: Comparing different types of electrical sockets With Other Solutions

Understanding Alternatives to Different Types of Electrical Sockets

In the ever-evolving landscape of electrical infrastructure, international B2B buyers must consider various solutions beyond traditional electrical sockets. While different types of electrical sockets are essential for connecting devices to power sources, there are alternative technologies and methods that can achieve similar goals. This analysis compares electrical sockets with two viable alternatives: Wireless Power Transfer (WPT) and Smart Power Strips.

Comparison Table

| Comparison Aspect | Different Types Of Electrical Sockets | Wireless Power Transfer (WPT) | Smart Power Strips |

|---|---|---|---|

| Performance | Reliable, consistent power delivery | Limited range, efficiency varies | Flexible, surge protection |

| Cost | Moderate installation and maintenance | High initial investment | Low cost, easy to implement |

| Ease of Implementation | Requires electrical wiring and outlets | Requires compatible devices | Plug-and-play configuration |

| Maintenance | Regular inspections needed | Minimal maintenance | Requires monitoring for overload |

| Best Use Case | Residential and commercial applications | Ideal for mobile devices, public spaces | Suitable for home and office use |

What Are the Advantages and Disadvantages of Wireless Power Transfer (WPT)?

Wireless Power Transfer (WPT) technology eliminates the need for physical connectors by transferring energy through electromagnetic fields. This innovation is particularly advantageous for mobile devices or environments where traditional wiring is cumbersome, such as in public spaces or healthcare facilities. However, the performance of WPT can be inconsistent, especially over longer distances, and it may require specific alignment between devices. Moreover, the initial investment in WPT infrastructure can be significantly higher compared to traditional sockets.

How Do Smart Power Strips Compare to Traditional Electrical Sockets?

Smart Power Strips offer a modern alternative to conventional electrical sockets by providing surge protection and energy management features. They allow users to control connected devices remotely, schedule power usage, and monitor energy consumption, making them highly efficient for both residential and commercial settings. The ease of implementation is a strong point, as they simply plug into existing outlets. However, they may not provide the same robust power delivery as fixed electrical sockets and require monitoring to prevent overloads, which can be a drawback in high-demand applications.

Conclusion: How Should B2B Buyers Choose the Right Electrical Solution?

When selecting an electrical solution, B2B buyers should assess their specific needs based on performance, cost, ease of implementation, and maintenance requirements. Different types of electrical sockets remain the standard for reliable power delivery in many applications. However, alternative solutions like Wireless Power Transfer and Smart Power Strips can offer unique benefits in specific scenarios. Buyers must evaluate their operational context, potential growth, and technological compatibility to determine the most effective and sustainable solution for their business needs. Making an informed choice can enhance efficiency, safety, and scalability in electrical infrastructure.

Essential Technical Properties and Trade Terminology for different types of electrical sockets

What Are the Essential Technical Properties of Electrical Sockets?

When selecting electrical sockets for international markets, understanding the technical specifications is crucial for ensuring compatibility, safety, and functionality. Here are some key properties to consider:

1. Material Grade

The materials used in electrical sockets, such as thermoplastic or polycarbonate, directly affect durability and heat resistance. High-grade materials can withstand extreme temperatures and resist wear and tear, making them suitable for high-demand environments. For B2B buyers, selecting sockets with superior material grades can lead to lower failure rates and longer product lifespans, ultimately saving costs in replacements and maintenance.

2. Current Rating (Amperage)

Each type of socket has a specified amperage rating, which indicates the maximum amount of current it can handle safely. Common ratings include 10A, 15A, and 20A. Understanding these ratings is essential for ensuring that the socket can safely power the intended appliances. Buyers must match the current rating of sockets to the requirements of their equipment to prevent electrical failures or hazards.

3. Voltage Compatibility

Electrical sockets are designed to operate at specific voltage levels, commonly ranging from 100-240V depending on the region. For international buyers, it’s critical to select sockets that align with the voltage standards of their target markets. This ensures compliance with local regulations and safety standards, preventing potential damage to appliances and reducing the risk of electrical hazards.

4. Grounding Mechanism

The grounding mechanism in sockets is vital for electrical safety, as it protects against electric shocks. Sockets may have different grounding configurations, such as 2-pin (ungrounded) or 3-pin (grounded). B2B buyers must consider the grounding type to ensure compatibility with local electrical codes and to guarantee the safety of end-users.

5. Tamper Resistance

For sockets used in residential or child-friendly environments, tamper-resistant designs are essential. These sockets prevent unauthorized access to the electrical contacts, significantly reducing the risk of electrical shocks. When sourcing products, consider the inclusion of tamper-resistant features as a selling point in markets with stringent safety regulations.

What Are Common Trade Terms in the Electrical Socket Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s product. In the electrical socket market, B2B buyers often source sockets from OEMs who can provide customized solutions tailored to specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is important for B2B buyers to understand, as it can affect inventory management and cash flow. Knowing the MOQ helps in planning purchases and ensuring that the order aligns with demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other relevant information for specific products. For B2B buyers, issuing an RFQ is an effective way to compare offers from multiple suppliers and negotiate better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly regarding shipping and logistics. For example, terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) clarify who bears the risk and cost at various points in the shipping process, which is crucial for B2B buyers to understand when importing electrical sockets.

5. Compliance Certification

Compliance certification indicates that products meet specific regulatory standards, such as safety and quality. For electrical sockets, certifications like CE (European Conformity) or UL (Underwriters Laboratories) are essential for ensuring that the products can be legally sold and used in various markets. B2B buyers should prioritize suppliers who can provide the necessary certifications to mitigate legal risks.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing electrical sockets, ensuring they meet both market demands and regulatory standards.

Navigating Market Dynamics and Sourcing Trends in the different types of electrical sockets Sector

What Are the Global Drivers Influencing the Electrical Socket Market?

The global market for electrical sockets is experiencing significant transformation driven by several factors. Firstly, the increasing demand for consumer electronics and smart home technologies is reshaping the landscape. As more households and businesses integrate smart devices, the need for versatile and safe electrical outlets, such as GFCI and AFCI sockets, is on the rise. Additionally, the push for renewable energy solutions is fostering innovations in power distribution, leading to increased interest in specialty sockets designed for solar applications.

A stock image related to different types of electrical sockets.

Emerging markets in Africa and South America are presenting unique opportunities for international B2B buyers. The expansion of infrastructure projects in these regions is prompting a shift towards modern electrical systems. Countries like Nigeria and Brazil are focusing on enhancing their electrical grids, which necessitates the procurement of diverse socket types that comply with local standards and requirements. In the Middle East, ongoing construction and development projects are driving demand for high-quality, durable electrical sockets that can withstand extreme environmental conditions.

Furthermore, the trend towards standardization and the adoption of universal socket designs are gaining traction in Europe and beyond. This trend simplifies sourcing for international buyers by reducing compatibility issues and inventory complexity. As businesses strive for efficiency and cost-effectiveness, understanding these market dynamics becomes crucial for making informed purchasing decisions.

How Is Sustainability Influencing the Sourcing of Electrical Sockets?

Sustainability is now a cornerstone of supply chain strategies across industries, including the electrical socket sector. International B2B buyers are increasingly prioritizing suppliers that demonstrate environmental responsibility and ethical practices. This shift is not only driven by regulatory pressures but also by consumer demand for sustainable products.

The environmental impact of manufacturing electrical sockets, from resource extraction to production processes, is significant. Buyers must consider sourcing from manufacturers that utilize recycled materials and sustainable manufacturing techniques. Certifications such as Energy Star and RoHS (Restriction of Hazardous Substances) are essential indicators of a product’s environmental friendliness and compliance with international standards.

Additionally, ethical sourcing practices are becoming more critical. Ensuring that suppliers uphold fair labor practices and contribute positively to local communities can enhance a company’s reputation and foster long-term partnerships. As B2B buyers navigate the complexities of global sourcing, integrating sustainability into their procurement processes is not just a trend; it’s a strategic imperative that can lead to competitive advantages in the marketplace.

What Is the Evolution of Electrical Sockets and Its Relevance to B2B Buyers?

The evolution of electrical sockets has been shaped by technological advancements and changing consumer needs. The early 20th century saw the introduction of standardized plug types, which aimed to improve safety and compatibility. As electrical appliances became more prevalent, the demand for various socket types grew, leading to the establishment of multiple international standards.

In recent decades, the rise of electronics and the smart home movement has accelerated innovations in socket design, such as the development of USB-integrated outlets and smart sockets that allow for remote control and energy monitoring. This evolution is particularly relevant for B2B buyers who must stay abreast of the latest trends to ensure their offerings meet market demands.

Understanding the historical context of electrical sockets can also inform sourcing decisions. As countries continue to modernize their electrical infrastructure, buyers must be aware of the specific socket types and standards required in different regions. This knowledge can facilitate smoother transactions and reduce the risk of non-compliance with local regulations, ultimately benefiting B2B operations in a global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of different types of electrical sockets

-

How do I solve compatibility issues with different electrical socket types?

To address compatibility issues, first, identify the socket type used in your target market, as different regions utilize various standards (e.g., Type C in Europe and Type G in the UK). When sourcing sockets, ensure they are compatible with local plugs and voltage specifications. Consider offering universal adapters or multi-type sockets to accommodate a range of plug types. Additionally, conduct market research to understand the most prevalent types in your region, which can guide your purchasing decisions. -

What is the best electrical socket type for my business needs?

The best electrical socket type depends on your specific business requirements, such as the voltage and amperage of your equipment. For instance, if you operate in Europe or Africa, Type C or Type F sockets may be suitable due to their widespread use and 16A rating. For specialized industrial applications, consider heavy-duty sockets like Type M or N. Analyze your equipment’s power needs and select sockets that ensure safety and efficiency in your operations. -

How can I vet suppliers for electrical sockets?

To effectively vet suppliers, start by checking their certifications and compliance with international standards, such as IEC or ISO. Request samples to assess product quality, and inquire about their manufacturing processes. Additionally, review customer feedback and seek references from other businesses in your network. Establish communication to gauge responsiveness and customer service, which are critical for long-term partnerships. It’s also beneficial to visit the supplier’s facility if possible, to ensure they meet your quality expectations. -

What are the minimum order quantities (MOQ) for electrical sockets?

Minimum order quantities can vary significantly based on the supplier and socket type. Typically, MOQs range from 100 to 1,000 units for standard types. For customized or specialty sockets, MOQs may be higher due to the additional production costs. Discuss your needs with potential suppliers to negotiate favorable terms, especially if you’re a smaller buyer. Some suppliers may offer flexibility on MOQs for first-time orders to build a relationship. -

What payment terms should I expect when sourcing electrical sockets?

Payment terms can vary widely among suppliers. Common practices include a 30% deposit upfront with the balance due before shipping, or net 30 days after receipt of goods. Discuss payment methods such as letters of credit, PayPal, or bank transfers. Ensure that the terms are clearly outlined in your purchase agreement to avoid misunderstandings. Be aware of any additional fees for international transactions, such as currency conversion or transaction fees. -

How do I ensure quality assurance for my electrical socket orders?

To ensure quality assurance, establish clear specifications and standards that the products must meet. Request certifications and test reports from the supplier to verify compliance with relevant safety standards. Implement a quality control process, including pre-shipment inspections and random sampling upon arrival. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and issues. -

What logistics considerations should I take into account when importing electrical sockets?

Logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with importing electrical products to help navigate these complexities. Be sure to understand the import duties and taxes applicable to your country. Additionally, plan for lead times, which can vary depending on the supplier’s location and shipping method. Properly labeling and packaging your goods can also prevent delays at customs. -

Can I customize electrical sockets for my specific applications?

Yes, many manufacturers offer customization options for electrical sockets. This can include modifications to size, color, or additional features like surge protection or tamper resistance. When discussing customization, provide detailed specifications and requirements to the supplier. Be prepared for potential increases in MOQs and lead times, as custom orders may require additional setup and manufacturing processes. Customizing sockets can enhance your product offering and cater to specific market needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

A stock image related to different types of electrical sockets.

Strategic Sourcing Conclusion and Outlook for different types of electrical sockets

Strategic sourcing in the realm of electrical sockets is essential for B2B buyers navigating the diverse global landscape. Understanding the various socket types, such as Type C and Type G, and their specific voltage and amperage ratings is crucial for ensuring compatibility with appliances and equipment. By prioritizing sockets that meet regional standards, buyers can enhance safety and operational efficiency, while minimizing installation issues.

Moreover, leveraging strategic sourcing practices enables businesses to identify reliable suppliers who adhere to international quality standards. This not only assures the longevity of electrical installations but also supports compliance with local regulations. As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for specific socket types will grow, making informed purchasing decisions even more critical.

Looking forward, international B2B buyers should consider investing in innovative socket solutions that accommodate evolving technology, such as smart home systems. Engage with suppliers who can offer a diverse range of options tailored to your market needs. By doing so, you position your business to thrive in a competitive landscape, ensuring you are equipped to meet future electrical demands.