Improve Accuracy: The Ultimate RTD Temperature Sensor Guide (2025)

Introduction: Navigating the Global Market for rtd temperature sensor

Navigating the complex landscape of sourcing RTD temperature sensors presents a significant challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the intricacies of these sensors, which operate on the principle of resistance change with temperature variations, is crucial for ensuring accurate and reliable temperature measurements in various industrial applications. This comprehensive guide delves into the various types of RTD sensors, their specifications, and the critical applications across diverse sectors, including manufacturing, food processing, and energy.

International buyers will benefit from insights into the supplier vetting process, ensuring that they partner with reputable manufacturers who adhere to global quality standards. The guide also addresses the cost factors associated with RTD sensors, helping businesses budget effectively while maximizing performance. Additionally, it highlights the importance of understanding local regulations and compliance standards that may affect purchasing decisions.

By equipping B2B buyers with the knowledge needed to make informed choices, this guide empowers them to navigate the global market with confidence, ultimately leading to improved operational efficiency and cost-effectiveness in their temperature measurement processes. Whether you’re based in Nigeria, Spain, or elsewhere, this resource serves as a critical tool for enhancing your procurement strategy in the realm of RTD temperature sensors.

Understanding rtd temperature sensor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Platinum RTD | Most common type, 100 Ohm at 0°C, high accuracy | Industrial automation, HVAC | Pros: High stability and accuracy. Cons: Higher cost compared to other types. |

| Nickel RTD | 120 Ohm at 0°C, faster response time | Food processing, pharmaceuticals | Pros: Cost-effective, good for moderate accuracy. Cons: Less stable than platinum. |

| Copper RTD | Low resistance (10 Ohm at 25°C), limited range | Electrical applications, low-temp | Pros: Inexpensive, good for low-temperature applications. Cons: Not suitable for high-accuracy needs. |

| Thin-Film RTD | Miniaturized design, faster response time | Aerospace, medical devices | Pros: Compact size, quick response. Cons: More fragile, limited to specific applications. |

| Wire-Wound RTD | Robust construction, high accuracy | Heavy industry, energy production | Pros: High durability, excellent accuracy. Cons: Bulkier, may require more installation space. |

What Are the Characteristics of Platinum RTD Sensors?

Platinum RTDs are the industry standard for temperature measurement, characterized by a nominal resistance of 100 Ohms at 0°C and a temperature coefficient of 0.00385 Ohm/Ohm/°C. Their stability and accuracy make them ideal for applications in industrial automation and HVAC systems. When purchasing, buyers should consider their need for precision and the operating environment, as platinum RTDs excel in stable conditions.

How Do Nickel RTD Sensors Compare in Speed and Cost?

Nickel RTDs, with a nominal resistance of 120 Ohms at 0°C, offer a faster response time compared to their platinum counterparts, making them suitable for industries like food processing and pharmaceuticals. They are generally more affordable, which is appealing for companies looking to balance cost and performance. However, buyers should note that they may not provide the same level of long-term stability as platinum sensors.

What Are the Benefits and Limitations of Copper RTD Sensors?

Copper RTDs operate at a low resistance of 10 Ohms at 25°C, making them suitable for electrical applications and low-temperature environments. Their cost-effectiveness is a significant advantage, particularly for businesses operating on tight budgets. However, their limited temperature range and lower accuracy compared to platinum and nickel sensors may restrict their application in high-precision environments.

Why Choose Thin-Film RTD Sensors for Specific Applications?

Thin-film RTDs are designed for compact applications, offering a quick response time and miniaturized design, making them ideal for aerospace and medical devices. While they provide excellent accuracy, their fragility means they are less suitable for harsh environments. B2B buyers should assess whether the compact size and speed justify their use in specialized applications.

What Makes Wire-Wound RTD Sensors a Durable Option?

Wire-wound RTDs are known for their robust construction and high accuracy, making them a preferred choice for heavy industries and energy production. Their durability ensures reliable performance under demanding conditions. However, their bulkier size may pose installation challenges, and buyers should consider the available space and mounting options when selecting these sensors for their applications.

Key Industrial Applications of rtd temperature sensor

| Industry/Sector | Specific Application of RTD Temperature Sensor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Monitoring temperature in pasteurization processes | Ensures food safety and quality, reducing spoilage risk | Compliance with food safety standards and certifications |

| Oil and Gas | Temperature measurement in refining processes | Enhances operational efficiency and safety | Robustness in harsh environments and resistance to corrosion |

| Pharmaceutical | Monitoring temperature in drug manufacturing | Guarantees product stability and efficacy | High accuracy and reliability to meet regulatory requirements |

| HVAC Systems | Temperature control in heating and cooling systems | Improves energy efficiency and occupant comfort | Compatibility with existing control systems and ease of installation |

| Chemical Processing | Temperature monitoring in reaction vessels | Optimizes reaction conditions, improving yield | Resistance to aggressive chemicals and high-temperature environments |

How are RTD Temperature Sensors Used in the Food and Beverage Industry?

In the food and beverage sector, RTD temperature sensors are crucial for monitoring temperatures during pasteurization, cooking, and storage. By ensuring that food products reach the required temperatures, these sensors help maintain safety standards and prevent spoilage. For B2B buyers, sourcing RTDs that comply with local food safety regulations is essential. Additionally, the sensors must be durable and easy to clean to meet hygiene requirements.

What Role Do RTD Temperature Sensors Play in the Oil and Gas Industry?

In the oil and gas industry, RTD temperature sensors are employed to monitor temperatures in refining processes, ensuring that operations run smoothly and safely. They provide critical data that helps operators optimize processes and prevent potential hazards related to overheating. Buyers in this sector should prioritize sensors that can withstand extreme temperatures and harsh environments, ensuring long-term reliability and minimal maintenance.

Why Are RTD Temperature Sensors Important in Pharmaceutical Manufacturing?

RTD temperature sensors are vital in pharmaceutical manufacturing, where precise temperature control is necessary for drug stability and efficacy. They are used in various processes, including storage and transportation of sensitive materials. International B2B buyers should look for sensors that offer high accuracy and reliability, as these attributes are essential to comply with stringent regulatory standards governing the pharmaceutical industry.

How Do RTD Temperature Sensors Enhance HVAC Systems?

In HVAC systems, RTD temperature sensors are used to monitor and control temperatures for heating and cooling. This ensures optimal performance and energy efficiency, directly impacting operational costs and occupant comfort. Buyers should consider sensors that are compatible with existing systems and easy to install, as well as those that provide accurate readings to facilitate effective climate control.

What Benefits Do RTD Temperature Sensors Provide in Chemical Processing?

In chemical processing, RTD temperature sensors are essential for monitoring temperatures within reaction vessels. They help maintain optimal conditions, which can significantly improve product yield and quality. Buyers in this industry must focus on sourcing sensors that can resist aggressive chemicals and operate effectively in high-temperature environments, ensuring safe and efficient processing.

3 Common User Pain Points for ‘rtd temperature sensor’ & Their Solutions

Scenario 1: Inaccurate Temperature Readings Leading to Process Failures

The Problem: Many B2B buyers face the challenge of inaccurate temperature readings from RTD sensors due to improper installation or suboptimal sensor selection. This can lead to critical process failures, especially in industries such as food and beverage, pharmaceuticals, and chemical manufacturing. For instance, a buyer in Nigeria may install a sensor designed for ambient temperature monitoring in a high-heat industrial environment, resulting in significant production downtime and product spoilage.

The Solution: To overcome this problem, buyers should conduct a thorough analysis of their operational environment before selecting an RTD temperature sensor. This includes understanding the temperature range, the specific application requirements, and the environmental conditions (like humidity and potential exposure to chemicals). Additionally, employing a three-wire RTD configuration can enhance accuracy by compensating for lead resistance. Buyers should also consider using sensors with a known tolerance class (such as DIN Class A) to ensure the highest level of accuracy for critical applications. Consulting with manufacturers or suppliers to verify that the chosen sensor is suitable for the intended environment can also prevent costly errors.

Scenario 2: Difficulty in Sensor Integration with Existing Systems

The Problem: Buyers often encounter difficulties when integrating new RTD sensors into their existing measurement systems, leading to compatibility issues and increased operational risks. For example, a company in Spain may invest in high-quality RTD sensors but find that their legacy data acquisition systems cannot effectively read the new sensors, resulting in wasted resources and project delays.

The Solution: To ensure seamless integration, buyers should prioritize compatibility during the selection process. This involves assessing the existing measurement systems and understanding the input requirements of the RTD sensors. Opting for standard RTD configurations, such as the widely-used 100 Ohm Platinum sensors, can enhance compatibility with most industrial controllers. Furthermore, buyers should consider investing in signal conditioning equipment or data acquisition systems that support the specific RTD type they are using. Engaging with technical support teams from sensor manufacturers can also provide valuable insights into the integration process, allowing buyers to mitigate risks associated with system compatibility.

Scenario 3: High Maintenance Costs Due to Sensor Wear and Tear

The Problem: Frequent maintenance and replacement of RTD sensors can lead to unexpected costs, especially in harsh environments where sensors are subjected to extreme temperatures or corrosive substances. A buyer in the Middle East, for instance, might find that their RTD sensors fail prematurely due to exposure to high ambient temperatures and dust, leading to increased operational costs and downtimes.

The Solution: To address the issue of high maintenance costs, it is crucial for buyers to select RTD sensors that are specifically designed for their operational conditions. This includes choosing sensors with robust protective housings and materials that can withstand environmental challenges. For example, using RTD sensors with stainless steel housings can enhance durability in corrosive environments. Additionally, implementing a proactive maintenance schedule that includes regular inspections and calibrations can help identify potential issues before they lead to sensor failure. Buyers should also explore options for extended warranties or service agreements with manufacturers to cover unexpected sensor replacements, thereby minimizing long-term costs.

Strategic Material Selection Guide for rtd temperature sensor

What Are the Key Materials Used in RTD Temperature Sensors?

When selecting RTD (Resistance Temperature Detector) temperature sensors, the choice of materials is critical to ensure optimal performance and reliability. Here, we analyze four common materials used in RTD sensors: Platinum, Nickel, Copper, and Stainless Steel. Each material has unique properties that affect sensor performance, durability, and suitability for specific applications.

How Does Platinum Perform in RTD Temperature Sensors?

Key Properties: Platinum is the most commonly used material for RTD sensors due to its excellent thermal stability and repeatability. It typically has a temperature range from -200°C to 850°C and offers a high degree of accuracy with a temperature coefficient of resistance (TCR) of 0.00385 ohm/ohm/°C.

Pros & Cons: The primary advantage of Platinum is its durability and resistance to corrosion, making it suitable for harsh environments. However, it is also the most expensive material, which can increase the overall cost of the sensor. Manufacturing complexity is moderate, requiring specialized techniques to ensure purity and consistency.

Impact on Application: Platinum RTDs are ideal for applications requiring high precision, such as laboratory settings and industrial processes. They are compatible with a wide range of media, including gases and liquids.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN when sourcing Platinum RTDs. Countries like Nigeria and Spain may have specific regulations regarding the use of Platinum in industrial applications.

What About Nickel as a Material for RTD Sensors?

Key Properties: Nickel RTDs, typically with a base resistance of 120 ohms, can operate effectively within a temperature range of -60°C to 200°C. They have a higher TCR of approximately 0.00672 ohm/ohm/°C compared to Platinum.

Pros & Cons: Nickel sensors are less expensive than Platinum, making them a cost-effective option for applications where extreme accuracy is not critical. However, they are less stable over time and can be more susceptible to oxidation, which may limit their lifespan in corrosive environments.

Impact on Application: Nickel RTDs are suitable for general-purpose applications, such as HVAC systems and food processing, where high precision is not the primary requirement. They are best used in non-corrosive media.

Considerations for International Buyers: Buyers should check for compliance with local standards, as Nickel sensors may not be accepted in all regions for critical applications.

How Does Copper Compare in RTD Temperature Sensors?

Key Properties: Copper RTDs typically have a base resistance of 10 ohms at 25°C and can operate in a temperature range from -200°C to 260°C. They exhibit a TCR of around 0.00427 ohm/ohm/°C.

Pros & Cons: The main advantage of Copper is its low cost and good thermal conductivity. However, its accuracy and stability are inferior to Platinum and Nickel, making it less suitable for precision applications. Copper is also more prone to oxidation, which can affect its performance over time.

Impact on Application: Copper RTDs are best suited for applications in controlled environments where cost is a significant factor, such as in educational settings or basic industrial processes.

Considerations for International Buyers: Buyers should be cautious about using Copper RTDs in environments with high humidity or corrosive substances. Compliance with local standards is essential, especially in regions with stringent regulations.

What Role Does Stainless Steel Play in RTD Temperature Sensors?

Key Properties: Stainless Steel RTDs are often used as protective housings for the sensing elements. They can withstand high temperatures and pressures, with a temperature range typically up to 600°C.

Pros & Cons: The primary advantage of Stainless Steel is its corrosion resistance and mechanical strength, providing durability in harsh environments. However, the cost can be moderate to high, depending on the grade of Stainless Steel used.

Impact on Application: Stainless Steel RTDs are commonly used in food processing, chemical industries, and oil and gas applications, where durability and resistance to corrosion are critical.

Considerations for International Buyers: When sourcing Stainless Steel RTDs, buyers should ensure that the material meets the appropriate standards for their specific application, particularly in industries with strict compliance requirements.

Summary Table of Material Selection for RTD Temperature Sensors

| Material | Typical Use Case for RTD Temperature Sensor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Platinum | Laboratory and industrial processes | Excellent accuracy and stability | High cost and moderate manufacturing complexity | High |

| Nickel | HVAC systems and food processing | Cost-effective for general applications | Less stable and susceptible to oxidation | Medium |

| Copper | Educational settings and basic industrial processes | Low cost and good thermal conductivity | Inferior accuracy and prone to oxidation | Low |

| Stainless Steel | Food processing and chemical industries | Corrosion resistance and mechanical strength | Moderate to high cost based on grade | Medium to High |

This comprehensive analysis provides valuable insights for international B2B buyers, enabling informed decisions based on material properties, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rtd temperature sensor

What Are the Main Stages of Manufacturing RTD Temperature Sensors?

The manufacturing process for Resistance Temperature Detectors (RTDs) involves several critical stages, each ensuring the sensor’s accuracy, reliability, and longevity. Understanding these stages is essential for international B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe.

Material Preparation: What Materials Are Used in RTD Manufacturing?

The first stage of manufacturing involves selecting high-quality materials. RTDs are typically made from platinum, nickel, or copper. Platinum is the most common due to its superior stability and linearity in resistance changes over a wide temperature range. The preparation of these materials often includes:

- Purity Testing: Ensuring the metal used is of high purity (typically 99.99% for platinum) to guarantee consistent performance.

- Cutting and Shaping: Raw materials are cut into specific shapes and sizes suitable for sensor elements, often in the form of thin wires or films.

How Is the Forming Process Conducted for RTDs?

Once the materials are prepared, the forming process begins. This involves:

- Wire Winding: For wire-type RTDs, platinum wires are wound around a ceramic or glass core. This process requires precision to ensure uniformity in resistance.

- Film Deposition: In thin-film RTDs, a platinum film is deposited onto a substrate using techniques such as sputtering or chemical vapor deposition (CVD). This method is increasingly popular due to its ability to produce smaller and more sensitive sensors.

What Does the Assembly Process Involve for RTD Sensors?

The assembly process is crucial in ensuring the final product functions correctly. This includes:

- Sensor Element Encapsulation: The formed sensor elements are encapsulated in protective materials, which can include stainless steel or glass. This step is vital for protecting the sensor from harsh environments and ensuring longevity.

- Lead Connection: Lead wires are connected to the sensor element, typically using soldering techniques that maintain electrical integrity and thermal stability.

What Are the Finishing Techniques Applied to RTD Sensors?

The final stage of manufacturing involves several finishing techniques that enhance the sensor’s performance and reliability:

- Calibration: Each RTD sensor is calibrated against standard temperature references to ensure accuracy. This often involves exposing the sensor to controlled temperature environments and adjusting its output to match known values.

- Coating: Protective coatings may be applied to resist corrosion and mechanical wear, particularly for sensors intended for industrial applications.

What International Standards Should Buyers Look for in RTD Quality Assurance?

Quality assurance in the manufacturing of RTD sensors is governed by international standards that ensure consistency and reliability. For B2B buyers, particularly in regions like Nigeria, Spain, and other parts of Europe, understanding these standards is crucial.

Which International Quality Standards Apply to RTD Sensors?

- ISO 9001: This standard outlines criteria for a quality management system (QMS) that focuses on continuous improvement and customer satisfaction. Manufacturers should be certified under ISO 9001 to ensure they maintain high-quality processes.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For RTDs used in oil and gas applications, adherence to American Petroleum Institute (API) standards is essential, ensuring that sensors can withstand extreme conditions.

What Are the Key Quality Control Checkpoints in RTD Manufacturing?

Quality Control (QC) is integral to the manufacturing process, and several checkpoints are established to monitor quality throughout the production stages:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before entering the production process.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed at various stages to identify and rectify issues early in the process.

- Final Quality Control (FQC): After assembly and calibration, each sensor undergoes comprehensive testing to ensure it meets the required specifications before shipment.

What Common Testing Methods Are Used to Verify RTD Accuracy?

To ensure accuracy and reliability, several testing methods are commonly employed in the quality assurance phase:

- Resistance Measurement: Using precision instruments, manufacturers measure the resistance of the RTD at various temperatures to verify its performance against standard curves.

- Thermal Shock Testing: Sensors are subjected to rapid temperature changes to test their resilience and stability.

- Long-Term Stability Testing: RTDs are exposed to extended periods of operation at specific temperatures to assess long-term performance and drift.

How Can International B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure that the RTD sensors meet their needs. Here are actionable steps:

- Conduct Supplier Audits: Request an audit of the manufacturing facilities to review their processes, standards, and certifications.

- Request Quality Reports: Suppliers should provide quality assurance documentation, including test results and compliance certificates.

- Engage Third-Party Inspectors: Employ independent third-party inspectors to verify the quality and compliance of the RTD sensors before shipment.

What QC and Certification Nuances Should Buyers Consider When Sourcing RTDs?

When sourcing RTDs internationally, buyers should be aware of specific nuances that may affect their purchasing decisions:

- Regional Regulations: Different regions may have unique regulations regarding product safety and environmental impact. Understanding these can help avoid compliance issues.

- Currency Fluctuations: When dealing with suppliers in different regions, currency fluctuations can affect pricing and contracts, making it essential to negotiate terms that account for these variances.

- Supply Chain Reliability: Assessing the reliability of the supply chain is crucial, especially in regions with less stable logistics and infrastructure. Understanding the supplier’s sourcing and distribution practices can mitigate risks.

By focusing on these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when procuring RTD temperature sensors, ensuring that they receive products that meet their operational requirements and regulatory standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rtd temperature sensor’

Introduction

Sourcing Resistance Temperature Detectors (RTDs) is a critical process for businesses that rely on precise temperature measurements. This guide outlines essential steps to ensure you procure the right RTD temperature sensors that meet your specific requirements. Whether you’re located in Africa, South America, the Middle East, or Europe, following this checklist will help streamline your purchasing process, reduce risks, and enhance operational efficiency.

Step 1: Define Your Technical Specifications

Before beginning your search for RTD temperature sensors, clearly outline your technical specifications. This includes determining the temperature range, accuracy requirements, and environmental conditions where the sensors will be used.

- Temperature Range: Identify the minimum and maximum temperatures the sensor will encounter.

- Accuracy Needs: Decide on the required accuracy levels based on your application. Higher precision may necessitate Class A RTDs over Class B or C.

Step 2: Research Compliance and Standards

Ensure that the RTD sensors you are considering comply with relevant international standards. This is especially crucial for industries such as food processing, pharmaceuticals, or any sector where regulatory compliance is mandatory.

- Standards to Consider: Look for compliance with DIN, IEC, or specific industry standards relevant to your operations.

- Certification Verification: Ask suppliers for certification documents to confirm compliance.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. This can help mitigate risks associated with low-quality products or poor service.

- Request Documentation: Ask for company profiles, product catalogs, and references from other businesses within your industry.

- Assess Experience: Look for suppliers with a proven track record in providing RTDs, especially those familiar with your regional needs.

Step 4: Check Customization Options

Depending on your application, you may need customized RTD sensors. Inquire about the supplier’s ability to provide tailored solutions that meet specific requirements.

- Customization Aspects: Consider lead configurations, protective housings, and special materials that may be necessary for your environment.

- Prototyping Availability: Check if the supplier can provide prototypes for testing before full-scale orders.

Step 5: Assess Quality Control Processes

Understanding a supplier’s quality control processes is vital to ensure the longevity and reliability of your RTD sensors.

- Quality Assurance Measures: Inquire about their testing procedures, calibration methods, and any certifications that validate their quality practices.

- Return and Warranty Policies: Ensure that the supplier has clear return policies and warranties that cover defects and performance failures.

Step 6: Negotiate Pricing and Terms

Once you have shortlisted potential suppliers, it’s time to discuss pricing and payment terms.

- Pricing Transparency: Request detailed quotations that break down costs, including shipping, customs, and taxes.

- Payment Flexibility: Negotiate payment terms that suit your cash flow, such as partial payments or extended payment periods.

Step 7: Plan for Ongoing Support and Maintenance

Finally, consider the level of support the supplier offers post-purchase.

- Technical Support: Ensure that the supplier provides adequate technical support for installation and troubleshooting.

- Maintenance Services: Ask if they offer maintenance services or training for your staff to ensure optimal sensor performance over time.

By following this comprehensive sourcing checklist, you can confidently procure RTD temperature sensors that meet your operational needs, ensuring reliability and accuracy in your temperature measurement processes.

Comprehensive Cost and Pricing Analysis for rtd temperature sensor Sourcing

What Are the Key Cost Components for RTD Temperature Sensors?

When sourcing RTD temperature sensors, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. For instance, platinum elements are more expensive than nickel or copper due to their superior accuracy and stability. RTD sensors often use a platinum resistance temperature detector (PT100), which provides high precision but comes at a higher material cost.

-

Labor: Labor costs can vary based on the region of production. In countries with lower wage standards, labor costs may be reduced, but this can also affect the quality and expertise of the workforce.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and administrative expenses. Efficient manufacturing processes can lower these costs, making it crucial for buyers to evaluate supplier capabilities.

-

Tooling: Tooling costs involve the initial setup and maintenance of manufacturing equipment. For custom or specialized RTD sensors, these costs can be substantial.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability and compliance with industry standards. However, stringent QC protocols can increase overall costs, which buyers need to factor into their sourcing decisions.

-

Logistics: Shipping and handling costs can vary greatly depending on the destination. International buyers should consider freight charges, customs duties, and taxes, which can substantially affect total costs.

-

Margin: Suppliers typically include a profit margin that varies based on market conditions, demand, and competition. Understanding the typical margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect RTD Temperature Sensor Costs?

Several factors can influence the pricing of RTD temperature sensors:

-

Volume/MOQ (Minimum Order Quantity): Larger orders usually command lower unit prices due to economies of scale. Buyers should evaluate their demand and negotiate MOQs accordingly.

-

Specifications and Customization: Custom features such as specific temperature ranges, lead wire configurations, or unique materials can drive up costs. Buyers need to clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Sensors that meet higher quality standards or certifications (e.g., ISO, CE) often come with a premium price. Buyers should assess the necessity of certifications based on their application.

-

Supplier Factors: The reputation and reliability of the supplier can impact costs. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the distribution of shipping responsibilities and costs. Buyers should understand the implications of terms like FOB (Free on Board) and CIF (Cost Insurance and Freight) to evaluate total costs effectively.

What Are Effective Tips for Negotiating RTD Temperature Sensor Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost-efficiency strategies are crucial:

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes installation, maintenance, and operational costs over the product’s lifespan. This holistic approach can justify higher initial costs if the sensor offers better reliability and lower long-term expenses.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Buyers should negotiate for extended payment periods or discounts for upfront payments.

-

Research Market Prices: Conducting thorough market research to understand prevailing prices can empower buyers during negotiations. Awareness of industry benchmarks can lead to more favorable terms.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and enhanced cooperation on customization.

-

Be Aware of Pricing Nuances: International buyers should account for currency fluctuations, import tariffs, and local taxes that may affect the final price. Staying informed about these factors can aid in budgeting and negotiations.

Disclaimer on Indicative Prices

Prices for RTD temperature sensors can vary significantly based on the factors outlined above. It is advisable for buyers to obtain multiple quotes from different suppliers and conduct a thorough analysis before making purchasing decisions.

Alternatives Analysis: Comparing rtd temperature sensor With Other Solutions

When evaluating temperature measurement technologies, it is crucial for B2B buyers to consider various options that can meet their specific needs. Resistance Temperature Detectors (RTDs) are widely recognized for their accuracy and stability; however, other alternatives may be better suited depending on the application, budget, and environmental conditions. Below, we compare RTD temperature sensors with two viable alternatives: Thermocouples and Thermistors.

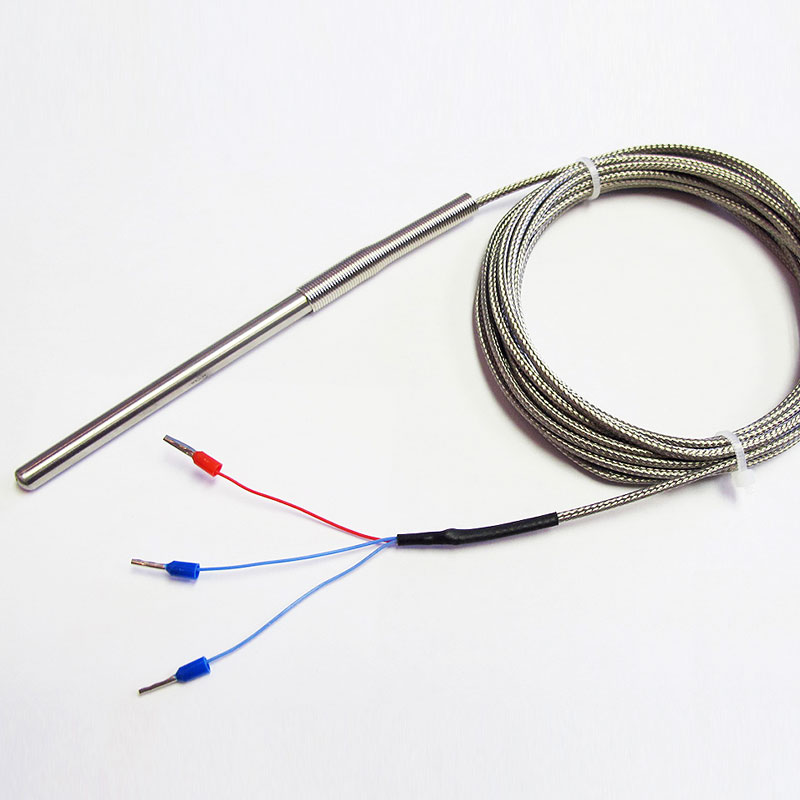

A stock image related to rtd temperature sensor.

Comparison Table: RTD Temperature Sensor vs. Alternatives

| Comparison Aspect | RTD Temperature Sensor | Thermocouple | Thermistor |

|---|---|---|---|

| Performance | High accuracy and stability; limited to lower temperature range | Wide temperature range; less accurate than RTDs | High sensitivity; limited range |

| Cost | Moderate to high cost | Low cost | Moderate cost |

| Ease of Implementation | Requires specific wiring and calibration | Simple installation; versatile | Simple installation; requires calibration |

| Maintenance | Low maintenance; long lifespan | Low maintenance; rugged | Moderate maintenance; can be sensitive |

| Best Use Case | Industrial processes requiring precision | General-purpose applications; high temperature | Medical devices and consumer electronics requiring rapid response |

Detailed Breakdown of Alternatives

What are Thermocouples and When Should They Be Used?

Thermocouples consist of two different metals joined at one end, producing a voltage that correlates with temperature changes. They can measure a wide range of temperatures, from -200°C to over 1,800°C, making them suitable for extreme conditions. While they are less accurate than RTDs, thermocouples excel in applications where rapid temperature changes occur and budget constraints are a concern. Their low cost and ruggedness make them ideal for industries such as manufacturing and HVAC. However, buyers should note that the accuracy may not meet the standards required in precision-sensitive applications.

How Do Thermistors Compare in Temperature Measurement?

Thermistors are temperature-sensitive resistors that exhibit a significant change in resistance with temperature fluctuations. They are known for their high sensitivity and quick response times, making them suitable for applications like medical devices and temperature monitoring in consumer electronics. However, thermistors have a limited temperature range, typically between -55°C and 125°C, and their non-linear resistance characteristics require calibration for accurate readings. While they are moderately priced, the need for recalibration and their sensitivity can be a drawback in demanding industrial environments.

How Can B2B Buyers Choose the Right Temperature Sensor?

Selecting the right temperature sensor depends on several factors, including the specific application, environmental conditions, and budget constraints. For industries requiring high precision and stability, RTDs are often the best choice despite their higher cost. Conversely, for applications needing a broader temperature range and lower initial investment, thermocouples may be more appropriate. Thermistors are excellent for applications where quick response times are critical, such as in medical equipment. Ultimately, B2B buyers should assess their unique requirements and consider both performance and cost-effectiveness when making their decision.

Essential Technical Properties and Trade Terminology for rtd temperature sensor

What Are the Key Technical Properties of RTD Temperature Sensors?

A stock image related to rtd temperature sensor.

When evaluating RTD (Resistance Temperature Detector) temperature sensors for your business needs, understanding their essential technical properties is crucial. Here are several critical specifications to consider:

1. What Material Grade Should I Look For in RTDs?

The most commonly used material in RTD sensors is platinum, specifically the 100-ohm variety with a temperature coefficient of 0.00385 Ohm/Ohm/°C. Platinum offers excellent stability and accuracy over a wide temperature range, making it ideal for various industrial applications. For B2B buyers, selecting the right material grade ensures long-term reliability and lower maintenance costs.

2. Why Is Temperature Tolerance Important for RTD Sensors?

RTDs are categorized into different tolerance classes, such as Class A, B, and C, which define their accuracy. Class A sensors have a tighter tolerance, making them suitable for applications requiring high precision, while Class B is more suited for less critical measurements. Understanding these tolerances helps buyers choose sensors that meet their specific operational requirements, thus minimizing errors in temperature readings.

A stock image related to rtd temperature sensor.

3. How Does Lead Configuration Affect RTD Performance?

RTD sensors come in various lead configurations, including two, three, and four-wire setups. A two-wire configuration is simplest but less accurate due to lead resistance. In contrast, three-wire and four-wire configurations provide better accuracy by compensating for lead resistance. Selecting the appropriate configuration is vital for ensuring measurement precision, particularly in industrial environments where accuracy is paramount.

4. What Is the Significance of Temperature Range in RTDs?

The temperature range of an RTD sensor typically spans from -196°C to 850°C, with some specialized designs extending beyond this range. Knowing the operational temperature limits is essential for buyers in sectors like food processing, pharmaceuticals, and manufacturing, where temperature extremes can significantly impact product quality and safety.

5. Why Is Calibration Temperature Important?

RTDs are generally calibrated at 0°C, and their accuracy may vary with temperature changes. Buyers must consider the calibration temperature when selecting sensors for specific applications, as deviations can lead to increased tolerance bands and reduced measurement accuracy. This understanding aids in choosing sensors that maintain performance across their intended temperature range.

What Are Common Trade Terms Related to RTD Temperature Sensors?

Familiarizing yourself with industry-specific jargon is vital for effective communication and negotiation in the B2B marketplace. Here are several common terms:

1. What Does OEM Mean in the Context of RTDs?

OEM stands for Original Equipment Manufacturer. In the context of RTD sensors, this term refers to companies that design and manufacture sensors to be integrated into other products. Understanding OEM relationships can help buyers identify reliable suppliers and quality products tailored to their specific needs.

2. How Is MOQ Relevant to My Purchases?

MOQ, or Minimum Order Quantity, signifies the smallest amount of a product that a supplier is willing to sell. For RTD sensors, MOQs can impact purchasing decisions, particularly for smaller businesses or those with limited budgets. Knowing the MOQ helps buyers plan their inventory and manage cash flow effectively.

3. What Is an RFQ and How Is It Used?

An RFQ, or Request for Quotation, is a document issued by buyers to solicit price quotes from suppliers. For RTD temperature sensors, issuing an RFQ enables buyers to compare pricing, specifications, and terms from multiple vendors, facilitating informed purchasing decisions.

4. What Are Incoterms and Why Do They Matter?

Incoterms, or International Commercial Terms, are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers, as they clarify shipping responsibilities, insurance, and liability, ultimately affecting the total cost of acquiring RTD sensors.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and budget constraints, ensuring the successful integration of RTD temperature sensors into their processes.

Navigating Market Dynamics and Sourcing Trends in the rtd temperature sensor Sector

What Are the Current Market Dynamics and Key Trends in the RTD Temperature Sensor Sector?

The RTD temperature sensor market is experiencing significant growth driven by the increasing demand for precise temperature measurement across various industries, including manufacturing, food processing, and pharmaceuticals. Global trends indicate a rising emphasis on automation and digitization, particularly in industrial applications. This shift is compelling businesses in Africa, South America, the Middle East, and Europe to adopt advanced temperature monitoring solutions to enhance operational efficiency and quality control.

Emerging technologies, such as IoT-enabled sensors, are reshaping the sourcing landscape. These smart sensors facilitate real-time data transmission and analytics, enabling proactive decision-making. International B2B buyers should consider suppliers that offer integrated solutions, combining RTD sensors with advanced data analytics platforms. This capability not only enhances operational visibility but also supports predictive maintenance strategies, ultimately reducing downtime and associated costs.

Moreover, sustainability is becoming a critical factor in sourcing decisions. With increasing regulatory pressures and consumer awareness regarding environmental impacts, buyers are encouraged to partner with manufacturers that prioritize eco-friendly practices. Understanding local market dynamics, such as the adoption of Industry 4.0 principles in European countries or the growth of the renewable energy sector in South America, can provide valuable insights into sourcing opportunities.

How Can Sustainability and Ethical Sourcing Impact the RTD Temperature Sensor Market?

Sustainability is no longer just an option but a necessity in the global market, particularly for B2B buyers. The environmental impact of manufacturing processes for RTD temperature sensors, including resource extraction and waste generation, is under scrutiny. Buyers must assess their suppliers’ environmental policies and practices to ensure compliance with global standards.

Ethical sourcing involves selecting suppliers who adhere to fair labor practices and contribute positively to their communities. This approach not only mitigates risks but also enhances brand reputation among increasingly conscious consumers and clients. Additionally, certifications such as ISO 14001 for environmental management systems and RoHS compliance for hazardous substances can serve as indicators of a supplier’s commitment to sustainability.

In the context of RTD temperature sensors, opting for components made from recyclable materials or those that utilize energy-efficient manufacturing processes can lead to a reduced carbon footprint. Buyers should engage with suppliers who prioritize sustainability in their product lifecycle, offering “green” certifications and materials that align with their corporate social responsibility (CSR) goals.

What Is the Historical Context of RTD Temperature Sensors for B2B Buyers?

The development of RTD temperature sensors dates back to the early 20th century, rooted in the discovery of the relationship between temperature and electrical resistance. The introduction of platinum as a sensing element in the 1930s established RTDs as a reliable standard in temperature measurement due to their accuracy and stability.

Over the decades, technological advancements have led to the miniaturization of RTD sensors and the incorporation of advanced materials, making them more versatile and applicable across various sectors. The evolution from basic RTD designs to complex, multi-functional sensors capable of integration with IoT platforms reflects the industry’s response to the growing demand for precision and connectivity in temperature monitoring.

Understanding this historical context is crucial for B2B buyers as it highlights the evolution of technology and the importance of selecting suppliers who are not only experienced but also innovative in their offerings. This knowledge can assist buyers in making informed decisions that align with current market demands and future technological trends.

Frequently Asked Questions (FAQs) for B2B Buyers of rtd temperature sensor

-

How do I choose the right RTD temperature sensor for my application?

Choosing the right RTD sensor involves assessing your specific application requirements. Consider factors such as temperature range, accuracy, and the environment in which the sensor will be used. For most industrial applications, a PT100 RTD with a 3-wire configuration is recommended due to its balance of accuracy and ease of use. Additionally, ensure compatibility with your measuring instruments and evaluate the lead wire configuration based on your installation needs. -

What are the standard tolerances for RTD sensors?

RTD sensors, particularly those adhering to DIN standards, come with specific tolerance classes that determine their accuracy. Class A offers the tightest tolerances, while Class B and C are more relaxed. Understanding these classes helps in selecting a sensor that meets the precision requirements of your application, particularly in industries such as food processing or pharmaceuticals, where accuracy is critical. -

What customization options are available for RTD temperature sensors?

Many manufacturers offer customization options for RTD sensors, including variations in lead wire length, connector types, and probe designs. Customization can also extend to material selection based on the application environment, such as corrosion-resistant coatings for harsh conditions. Discussing your specific needs with suppliers can lead to tailored solutions that enhance sensor performance and longevity. -

What is the minimum order quantity (MOQ) for RTD temperature sensors?

MOQs for RTD sensors can vary significantly among manufacturers and depend on the complexity of the customization required. While some suppliers may allow orders of just one unit, others might set an MOQ of 50 or more for custom designs. It’s advisable to inquire directly with potential suppliers to understand their policies and find a manufacturer that aligns with your procurement strategy. -

How can I vet suppliers of RTD temperature sensors?

When vetting suppliers, consider their industry experience, certifications, and customer reviews. Look for manufacturers that adhere to international quality standards, such as ISO 9001, which ensures consistent quality in their products. Additionally, request samples or references from previous clients to gauge their reliability and product performance before finalizing your supplier choice. -

What payment terms should I expect when purchasing RTD sensors internationally?

Payment terms can vary widely among suppliers, but common options include upfront payments, partial payments, or payment upon delivery. It’s essential to clarify these terms before placing an order, especially when dealing with international transactions, as currency fluctuations and import duties can impact costs. Utilizing secure payment methods such as letters of credit may also provide additional protection. -

What quality assurance processes should I look for in RTD sensor manufacturing?

Quality assurance is crucial in the manufacturing of RTD sensors. Look for suppliers that implement rigorous testing protocols, including calibration against recognized standards and environmental testing to ensure durability. Ask about their quality control certifications and whether they provide documentation for each batch of sensors, which can be critical for regulatory compliance in industries like pharmaceuticals or food safety. -

How can I manage logistics when sourcing RTD temperature sensors from overseas?

Effective logistics management involves coordinating shipping methods, understanding import regulations, and being aware of lead times. Work closely with your supplier to establish a reliable shipping method that minimizes delays and costs. Additionally, consider engaging a logistics partner familiar with international trade regulations to navigate customs processes smoothly, ensuring that your sensors arrive on time and in good condition.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rtd temperature sensor

What Are the Key Takeaways for B2B Buyers of RTD Temperature Sensors?

In conclusion, strategic sourcing of RTD temperature sensors is essential for international B2B buyers seeking reliability and precision in temperature measurement. With their well-defined resistance-temperature characteristics and various configurations—including two, three, and four-wire designs—RTDs offer flexibility tailored to specific industrial applications. Buyers should prioritize suppliers who adhere to standardized tolerances, such as the DIN specifications, ensuring product consistency and accuracy across diverse environments.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing not only secures high-quality components but also strengthens supplier relationships, leading to better pricing and improved service levels. For businesses in Africa, South America, the Middle East, and Europe, leveraging local suppliers can reduce lead times and shipping costs, making it crucial to evaluate regional market dynamics.

What’s Next for International B2B Buyers?

As the demand for precise temperature control continues to rise across industries, investing in high-quality RTD sensors will be vital. International B2B buyers are encouraged to explore emerging technologies and innovative suppliers that can meet evolving industry standards. By prioritizing strategic sourcing initiatives, businesses can position themselves for success in an increasingly competitive global market. Engage with trusted suppliers today to ensure your operations run smoothly and efficiently tomorrow.