Improve Efficiency: The Complete Ball Screw Guide (2025)

Introduction: Navigating the Global Market for ball screw

The global market for ball screws presents a complex landscape for international B2B buyers seeking reliable, high-performance solutions for their machinery and automation needs. Sourcing the right ball screw can be a daunting task, especially when considering factors such as precision, load capacity, and compatibility with existing systems. This guide aims to simplify the process by providing an in-depth analysis of various types of ball screws, their applications across different industries, and the critical considerations for supplier vetting.

Whether you are operating in Africa, South America, the Middle East, or Europe, understanding the nuances of ball screw technology is crucial for making informed purchasing decisions. This guide covers essential topics, including the different types of ball screws such as rolled and precision ground variants, their specific applications in sectors like CNC machining and robotics, and the key metrics to evaluate when assessing suppliers. Additionally, we delve into cost factors and the implications of regional market dynamics, ensuring that you are equipped with the knowledge necessary to navigate this competitive landscape effectively.

By the end of this guide, you will possess the actionable insights needed to select the right ball screw for your operational needs, fostering efficiency and performance in your projects. This comprehensive resource empowers B2B buyers to make strategic decisions that align with their business objectives and technical requirements.

Understanding ball screw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Precision Ground Ball Screw | High accuracy with ground threads; low friction | CNC machinery, aerospace, robotics | Pros: Excellent precision; Cons: Higher cost |

| Rolled Ball Screw | Rolled threads for faster production; moderate precision | General manufacturing, automation systems | Pros: Cost-effective; Cons: Lower precision than ground screws |

| Miniature Ball Screw | Compact design; lightweight; optimized for tight spaces | Medical devices, small machinery | Pros: Space-saving; Cons: Limited load capacity |

| High-Speed Ball Screw | Designed for high-speed applications; reduced inertia | High-speed machining, packaging machines | Pros: Increased efficiency; Cons: May require specialized components |

| Double Nut Ball Screw | Two nuts for improved load distribution; enhanced rigidity | Heavy machinery, industrial automation | Pros: Higher load capacity; Cons: Bulkier design |

What Are the Characteristics of Precision Ground Ball Screws?

Precision ground ball screws are engineered for high accuracy and low friction, making them ideal for applications requiring meticulous motion control. The threads are ground to ensure tight tolerances, which is crucial in industries such as aerospace and robotics where precision is paramount. When considering these screws, buyers should evaluate the application’s tolerance requirements and the potential need for higher initial investment due to their superior performance.

How Do Rolled Ball Screws Differ from Other Types?

Rolled ball screws are manufactured through a rolling process, which allows for quicker production and a more cost-effective solution compared to precision ground options. They are suitable for general manufacturing and automation systems, where moderate precision is acceptable. Buyers should weigh the benefits of cost savings against the slightly reduced precision when selecting rolled ball screws for their applications.

In What Scenarios Are Miniature Ball Screws Most Suitable?

Miniature ball screws are designed for compact applications, making them ideal for industries such as medical devices and small machinery. Their lightweight and space-saving design allows for integration in tight environments. However, buyers should be mindful of their limited load capacity and ensure that the chosen miniature screw meets the specific requirements of their application.

What Advantages Do High-Speed Ball Screws Offer?

High-speed ball screws are tailored for applications that demand rapid motion and reduced inertia, such as high-speed machining and packaging machines. They enhance operational efficiency and can significantly boost productivity. Buyers should consider the compatibility of these screws with existing machinery and the potential need for specialized components to support their high-speed operation.

Why Choose Double Nut Ball Screws for Heavy Applications?

Double nut ball screws feature two nuts that distribute loads more evenly, resulting in enhanced rigidity and increased load capacity. This makes them particularly beneficial in heavy machinery and industrial automation applications. However, their bulkier design may require more space, so buyers should assess the physical constraints of their systems when opting for double nut configurations.

Key Industrial Applications of ball screw

| Industry/Sector | Specific Application of Ball Screw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| CNC Machining | Precision positioning of cutting tools in CNC machines | Enhanced accuracy and efficiency in machining operations | Compatibility with existing systems and load capacity |

| Robotics | Actuation in robotic arms and automation systems | Improved motion control and reduced friction for longer lifespan | Customization options and integration with control systems |

| Aerospace | Linear motion in aircraft assembly lines | High reliability and performance under stringent conditions | Compliance with international aerospace standards |

| Manufacturing Equipment | Material handling systems and conveyor belts | Increased throughput and reduced downtime | Durability and maintenance requirements for heavy usage |

| Medical Devices | Movement in surgical robots and imaging equipment | Precision and reliability in critical applications | Regulatory compliance and biocompatibility considerations |

How is Ball Screw Used in CNC Machining and What Problems Does it Solve?

In CNC machining, ball screws are essential for the precise positioning of cutting tools. They convert rotary motion from the motor into linear motion with minimal friction, which enhances the accuracy of machining operations. This precision is crucial for producing components that meet tight tolerances. International buyers should consider compatibility with existing machinery and the load capacity required for their specific applications when sourcing ball screws for CNC systems.

What Role Does Ball Screw Play in Robotics Applications?

Ball screws are integral to the actuation systems in robotic arms and automation solutions. They facilitate smooth and precise linear movements, which are vital for tasks like assembly, welding, and packaging. The reduced friction in ball screws extends the lifespan of robotic systems by minimizing wear and tear. Buyers from regions like Africa and South America should prioritize sourcing options that offer customization for specific robotic applications and ensure seamless integration with control systems.

How Are Ball Screws Utilized in the Aerospace Industry?

In the aerospace sector, ball screws are used for linear motion in aircraft assembly lines, where reliability and performance are paramount. They help in the precise positioning of components during assembly, contributing to the overall safety and functionality of aircraft. Buyers must ensure that the ball screws meet stringent international aerospace standards and can withstand the operational demands of the industry.

Why Are Ball Screws Important for Manufacturing Equipment?

Ball screws play a critical role in material handling systems and conveyor belts within manufacturing environments. They increase throughput by enabling rapid and accurate movement of materials, thus reducing downtime. When sourcing ball screws for manufacturing equipment, businesses should focus on durability and maintenance requirements, particularly in high-use applications where reliability is essential.

How Do Ball Screws Impact Medical Device Applications?

In the medical field, ball screws are utilized in surgical robots and imaging equipment, where precision and reliability are crucial. They enable accurate movements that can significantly impact patient outcomes. Buyers in this sector need to consider regulatory compliance and biocompatibility when sourcing ball screws, ensuring that the components meet the necessary health and safety standards for medical applications.

3 Common User Pain Points for ‘ball screw’ & Their Solutions

Scenario 1: Inconsistent Performance in High-Precision Applications

The Problem: For manufacturers in sectors like aerospace and automotive, maintaining consistent performance is critical. A common challenge they face is the unpredictability of ball screw performance due to variations in load capacity and precision. This inconsistency can lead to inaccuracies in machining processes, resulting in defective products that necessitate costly rework or replacements.

The Solution: To ensure reliable performance, it is essential to select ball screws that are specifically designed for high-precision applications. B2B buyers should consider sourcing precision-ground ball screws that adhere to stringent quality standards, such as ISO 3408. Additionally, specifying the correct diameter and lead length for the application can significantly enhance performance. Implementing regular maintenance checks, including lubrication and alignment verification, will also help sustain accuracy. Collaborating with suppliers who provide detailed performance specifications can further mitigate risks associated with inconsistent operations.

Scenario 2: Difficulty in Integration with Existing Machinery

The Problem: Many businesses, especially in regions like Africa and South America, face challenges when integrating new ball screws into existing machinery. This can stem from compatibility issues, such as mismatched dimensions or differing load capacities, which can lead to operational delays and increased costs.

The Solution: Before purchasing ball screws, it is crucial to conduct a thorough compatibility assessment with existing machinery. This includes measuring critical dimensions such as shaft diameter, lead, and the type of support units required. Buyers should opt for suppliers that offer customizable solutions, including finished shaft ends tailored to specific machinery needs. Additionally, investing in pre-assembled ball screw kits can streamline the integration process, reducing assembly time and ensuring that all components work cohesively. Engaging with suppliers who provide technical support and installation guidance will also enhance the integration experience.

Scenario 3: Limited Availability of Spare Parts

The Problem: Companies operating in remote areas or emerging markets often struggle with the availability of spare parts for ball screws, which can lead to prolonged downtimes during repairs. This unavailability can significantly impact productivity and profitability, especially in industries with tight production schedules.

The Solution: To combat spare parts scarcity, B2B buyers should establish relationships with multiple suppliers who have a robust inventory of ball screws and related components. Investing in a proactive inventory management system that tracks the usage and lifespan of ball screws can also help anticipate when replacements are needed. Furthermore, implementing a preventive maintenance strategy that includes routine inspections and early detection of wear can minimize the likelihood of sudden failures. Buyers should also consider sourcing modular ball screw systems that allow for easy replacement of individual components, reducing downtime and ensuring continuous operation.

Strategic Material Selection Guide for ball screw

What Are the Common Materials Used for Ball Screws?

Selecting the right material for ball screws is crucial for ensuring optimal performance in various applications. Different materials offer unique properties that can significantly affect the durability, efficiency, and suitability of the ball screw for specific tasks. Below, we analyze four common materials used in ball screw manufacturing, highlighting their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Impact Ball Screw Performance?

Key Properties:

Steel, particularly alloy steel, is widely used for ball screws due to its high tensile strength and hardness. It typically has a temperature rating of up to 300°C and can withstand significant pressure. Steel can also be treated for improved wear resistance and fatigue strength.

Pros & Cons:

The primary advantage of steel ball screws is their durability and ability to handle high loads. However, they can be susceptible to corrosion if not properly treated or coated. The manufacturing complexity is moderate, as steel can be machined into precise dimensions, but heat treatment processes can add to production time and costs.

Impact on Application:

Steel ball screws are suitable for applications requiring high load capacities, such as CNC machines and robotics. However, they may not be ideal for environments with high humidity or corrosive media without additional protective coatings.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A108 or DIN 17200 for steel grades. In regions like Africa and South America, sourcing locally available materials can reduce costs and lead times.

What Role Does Stainless Steel Play in Ball Screw Applications?

Key Properties:

Stainless steel offers excellent corrosion resistance, making it suitable for harsh environments. It can withstand temperatures up to 500°C and is often used in applications involving moisture or chemicals.

Pros & Cons:

The key advantage of stainless steel ball screws is their resistance to rust and corrosion, which extends their lifespan in challenging conditions. However, they are generally more expensive than standard steel and can be more challenging to machine, increasing manufacturing complexity.

Impact on Application:

Stainless steel ball screws are ideal for food processing, pharmaceuticals, and marine applications where cleanliness and corrosion resistance are paramount.

Considerations for International Buyers:

Compliance with standards such as ASTM A276 and ISO 3506 is crucial. Buyers in Europe and the Middle East often prefer stainless steel for its hygiene properties, especially in food-related industries.

How Does Aluminum Affect Ball Screw Design?

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating up to 200°C. It is less dense than steel, making it suitable for applications where weight is a critical factor.

Pros & Cons:

The primary advantage of aluminum ball screws is their low weight, which can enhance system dynamics and reduce energy consumption. However, they have lower load capacities compared to steel and stainless steel, which may limit their use in heavy-duty applications.

Impact on Application:

Aluminum ball screws are commonly used in lightweight machinery, automation systems, and applications where speed is more critical than load capacity.

Considerations for International Buyers:

Buyers should consider the specific alloy used, as different aluminum grades have varying mechanical properties. Compliance with standards like ASTM B221 is essential for ensuring quality.

What Benefits Does Plastic Offer for Ball Screws?

Key Properties:

Plastic ball screws, often made from engineering plastics such as PEEK or nylon, provide excellent corrosion resistance and are lightweight. They can operate effectively at temperatures up to 150°C.

Pros & Cons:

The main advantage of plastic ball screws is their resistance to chemicals and low friction properties, which can lead to energy savings. However, they typically have lower load capacities and are less durable than metal alternatives, which may limit their application scope.

Impact on Application:

Plastic ball screws are suitable for applications in clean rooms, medical devices, and environments where metal contamination must be avoided.

Considerations for International Buyers:

Buyers should ensure that the selected plastic material meets relevant standards, such as FDA compliance for medical applications. Sourcing from reputable manufacturers is crucial for ensuring quality.

Summary Table of Ball Screw Materials

| Material | Typical Use Case for Ball Screw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | CNC machines, robotics | High load capacity | Susceptible to corrosion | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Lightweight machinery, automation | Low weight | Lower load capacity | Medium |

| Plastic | Clean rooms, medical devices | Chemical resistance and low friction | Lower durability and load capacity | Low |

This material selection guide provides international B2B buyers with crucial insights into the properties and implications of various materials used in ball screws, aiding in informed decision-making tailored to specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ball screw

What Are the Main Stages of Ball Screw Manufacturing?

The manufacturing process of ball screws involves several critical stages that ensure their performance and reliability. Understanding these stages is essential for B2B buyers looking to source high-quality ball screws.

Material Preparation: Which Materials Are Commonly Used for Ball Screws?

The first step in manufacturing ball screws is the selection and preparation of raw materials. Typically, high-carbon steel or stainless steel is used due to their strength and resistance to wear. The selected materials undergo processes like heat treatment to enhance hardness and durability. For specialized applications, manufacturers may also consider alloys that provide specific properties, such as corrosion resistance or increased load capacity.

Forming: What Techniques Are Employed in Ball Screw Fabrication?

Once the materials are prepared, they are subjected to forming processes, which may include:

- Machining: This includes turning, milling, and grinding to create the screw threads and nut profiles. Precision is key here, as the thread geometry directly impacts the ball screw’s efficiency and load capacity.

- Rolling: In some cases, rolled ball screws are produced, where the thread is formed by rolling the material between dies. This method can enhance the fatigue strength of the screw while minimizing manufacturing costs.

These forming techniques are critical to achieving the necessary tolerances and surface finishes that define high-quality ball screws.

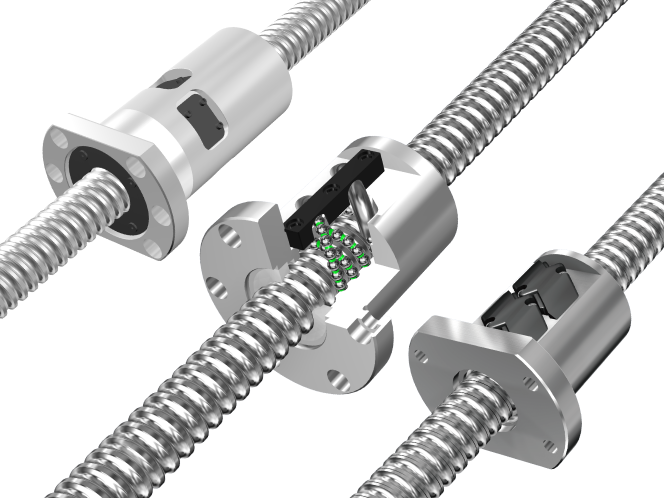

Assembly: How Are Ball Screws Assembled for Optimal Performance?

The assembly stage involves combining the screw, nut, and ball bearings. The balls are inserted into the nut, which is then mounted on the threaded shaft. A ball return mechanism is installed to ensure the balls circulate effectively without falling out during operation. This assembly requires precision, as any misalignment can lead to increased friction and reduced lifespan of the ball screw.

What Quality Assurance Practices Are Essential for Ball Screw Manufacturing?

Quality assurance (QA) is vital throughout the manufacturing process to ensure that the final product meets international standards and customer expectations.

What International Standards Should B2B Buyers Look For?

B2B buyers should prioritize suppliers that adhere to recognized quality standards. Key international standards include:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly relevant in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas sector, manufacturers may need to comply with American Petroleum Institute (API) specifications.

These certifications provide assurance that the supplier follows stringent quality protocols.

What Are the Key Quality Control Checkpoints in Ball Screw Manufacturing?

Quality control checkpoints throughout the manufacturing process help identify defects early on:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to monitor dimensions and tolerances.

- Final Quality Control (FQC): Once the ball screws are assembled, a thorough inspection is performed to check for functional performance, dimensional accuracy, and surface finish.

By implementing these checkpoints, manufacturers can mitigate the risk of defects in the final product.

What Testing Methods Are Commonly Used to Ensure Ball Screw Quality?

To verify the quality and performance of ball screws, various testing methods are employed:

- Load Testing: This test evaluates the load-bearing capacity of the ball screw under specified conditions, ensuring it meets the required dynamic and static load ratings.

- Runout and Accuracy Testing: These tests assess the precision of the ball screw in terms of linear motion and rotational accuracy.

- Surface Roughness Testing: This ensures that the surface finish of the screw and nut meets the necessary specifications, which is crucial for reducing friction.

B2B buyers can request detailed reports of these tests from suppliers to ensure transparency and accountability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks. Here are actionable steps:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment and quality control practices directly. This is particularly important for high-stakes applications.

- Requesting Quality Reports: Buyers should ask for documentation of quality tests performed on the ball screws, including certificates of compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges regarding quality control, including differing regulations and standards. Here are a few considerations:

- Understanding Local Standards: Buyers should familiarize themselves with the local quality standards in their respective regions, as these may differ significantly from those in the supplier’s country.

- Cultural Differences in Manufacturing Practices: Buyers should be aware that manufacturing practices may vary based on cultural norms and business practices. Building a strong relationship with suppliers can facilitate better communication and understanding.

- Logistics and Supply Chain Considerations: Ensure that quality control measures extend beyond manufacturing to include packaging, shipping, and handling. This can prevent damage and maintain quality throughout the supply chain.

By focusing on these areas, B2B buyers can make informed decisions when sourcing ball screws, ultimately leading to more reliable and high-performing solutions for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ball screw’

When sourcing ball screws for industrial applications, it’s essential to follow a systematic approach to ensure you select the right product for your needs. This guide provides a practical checklist that international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, can use to streamline their procurement process.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the foundation of your sourcing process. Ball screws vary in terms of diameter, lead, length, load capacity, and precision. Clearly define specifications such as:

– Load Capacity: Assess the dynamic and static load requirements for your application.

– Speed and Stroke Length: Determine the necessary operating speeds and travel distances.

This clarity will help you communicate effectively with suppliers and avoid mismatches.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers who specialize in ball screws. Consider factors such as:

– Industry Reputation: Look for suppliers with a solid track record in your industry.

– Global Compliance: Ensure they meet international quality standards like ISO certifications, which can impact product reliability.

Utilizing industry directories and trade shows can also lead to discovering reputable manufacturers.

Step 3: Evaluate Supplier Capabilities and Offerings

Before committing, assess each supplier’s capabilities. Evaluate their product range, manufacturing processes, and technological advancements. Key points to consider include:

– Customization Options: Verify if the supplier can meet your specific needs, such as custom dimensions or materials.

– Production Capacity: Ensure they have the ability to fulfill your order volume within your required timeframe.

This step is critical to avoid delays in your production schedule.

Step 4: Request Samples and Conduct Testing

Request samples of the ball screws from shortlisted suppliers. Testing these samples in your operational environment can provide insights into performance and compatibility. Focus on:

– Performance Metrics: Evaluate factors such as efficiency, noise levels, and durability during tests.

– Feedback from Engineering Teams: Involve your technical team to ensure the samples meet the operational standards.

This real-world assessment can prevent costly mistakes later.

Step 5: Verify Supplier Certifications and Quality Assurance Practices

Quality assurance is paramount in ensuring the reliability of ball screws. Verify that your chosen suppliers adhere to strict quality control measures. Consider:

– ISO Certifications: Suppliers with ISO 9001 or specific industry certifications demonstrate a commitment to quality.

– Testing Protocols: Inquire about their testing methods and quality assurance processes.

This diligence helps mitigate risks associated with product defects.

Step 6: Understand Pricing Structures and Terms

Pricing can vary significantly based on specifications, volume, and supplier location. Ensure you understand the pricing structures and terms of each supplier. Pay attention to:

– Hidden Costs: Look for additional charges such as shipping, customs, or tariffs that may apply.

– Payment Terms: Clarify payment schedules and conditions to avoid cash flow issues.

Being well-informed about costs will aid in budgeting and financial planning.

Step 7: Establish a Communication Plan

Effective communication is key throughout the sourcing process. Establish a clear line of communication with your chosen supplier to facilitate:

– Regular Updates: Keep track of production timelines, shipping, and any potential issues.

– Feedback Mechanisms: Ensure you can provide feedback on product performance and service quality.

A strong communication plan fosters a collaborative relationship, enhancing overall satisfaction.

By following these steps, international B2B buyers can ensure a streamlined and effective sourcing process for ball screws, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for ball screw Sourcing

What Are the Key Cost Components in Ball Screw Manufacturing?

When sourcing ball screws, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include:

-

Materials: The type of steel used significantly affects costs. High-quality alloys that resist wear and provide durability can increase material costs but offer better performance in the long run.

-

Labor: Skilled labor is required for manufacturing precision components. Labor costs can vary widely based on the region, impacting the overall cost of production.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can help mitigate these expenses.

-

Tooling: Custom tooling may be necessary for specific designs or specifications, adding to initial costs. Investing in efficient tooling can reduce costs over time.

-

Quality Control (QC): Ensuring the precision and reliability of ball screws is crucial. QC costs can vary depending on the complexity of the product and the standards required.

-

Logistics: Shipping and handling costs can be significant, especially for international shipments. Factors such as distance, weight, and packaging impact logistics costs.

-

Margin: Suppliers will add a markup to their costs to ensure profitability. Understanding typical margins in the industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Ball Screw Sourcing?

Several factors can influence the pricing of ball screws, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their operational needs to maximize cost efficiency.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The choice of materials directly impacts pricing. Premium materials may offer better performance but at a higher cost.

-

Quality and Certifications: Higher quality products often come with certifications that assure performance standards. While these may increase initial costs, they can lead to lower Total Cost of Ownership (TCO) over time.

-

Supplier Factors: Supplier reputation, location, and reliability can influence pricing. Established suppliers with proven track records may charge a premium but can reduce risks associated with sourcing.

-

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly affect total landed costs.

What Are the Best Practices for Negotiating Ball Screw Prices?

To effectively negotiate prices for ball screws, buyers should consider the following strategies:

-

Conduct Market Research: Understanding market trends and pricing benchmarks can empower buyers during negotiations. Researching multiple suppliers can provide leverage.

-

Emphasize Long-Term Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and terms over time. Consider negotiating for volume discounts based on future orders.

-

Evaluate Total Cost of Ownership: Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, efficiency, and potential downtime costs. A higher initial investment may yield better long-term returns.

-

Be Transparent About Needs: Clearly communicate your specifications and requirements. This transparency can foster trust and lead to more favorable terms.

-

Leverage Competition: If possible, gather quotes from multiple suppliers to create competitive pressure. This can help achieve more favorable pricing.

What Should International Buyers Consider When Sourcing Ball Screws?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of specific nuances:

-

Currency Fluctuations: Be aware of exchange rates and their potential impact on pricing. Consider negotiating in a stable currency if possible.

-

Import Duties and Taxes: Understand the customs regulations and potential tariffs that may apply to imported ball screws. These can significantly affect total costs.

-

Cultural Differences in Negotiation: Different regions may have varying negotiation styles. Understanding these can facilitate smoother discussions and agreements.

-

Logistical Challenges: Shipping times and reliability can vary by region. Factor in potential delays and ensure your supplier can meet your timelines.

Disclaimer on Pricing

Prices for ball screws can fluctuate based on market conditions, material costs, and supplier-specific factors. It is advisable for buyers to obtain quotes directly from suppliers to get the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing ball screw With Other Solutions

Understanding Alternatives to Ball Screws

When considering linear motion solutions in industrial applications, ball screws are often a top choice due to their efficiency and precision. However, several alternatives exist that can meet specific needs depending on the application. In this section, we will compare ball screws with two viable alternatives: lead screws and linear motors. This comparison will help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

A stock image related to ball screw.

Comparison Table

| Comparison Aspect | Ball Screw | Lead Screw | Linear Motor |

|---|---|---|---|

| Performance | High efficiency, low friction | Moderate efficiency, higher friction | Very high speed and precision |

| Cost | Higher initial investment | Lower initial cost | High upfront cost |

| Ease of Implementation | Moderate complexity | Simple design, easy to install | Complex installation |

| Maintenance | Low maintenance, long lifespan | Moderate maintenance required | Low maintenance, but requires careful setup |

| Best Use Case | CNC machines, robotics, aerospace | General machinery, low precision tasks | High-speed applications, automation |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Lead Screws?

Lead screws are a simpler alternative that convert rotational motion into linear motion through a threaded rod and nut mechanism. They are generally less expensive than ball screws and easier to implement, making them suitable for applications where high precision is not critical. However, lead screws have higher friction, which can lead to lower efficiency and more wear over time. They are best used in less demanding environments or for applications requiring lower load capacities.

How Do Linear Motors Compare to Ball Screws?

Linear motors offer a unique approach to linear motion by directly converting electrical energy into linear motion without the need for mechanical components like screws. This results in very high speeds and precise positioning, ideal for high-speed automation and applications like assembly lines. However, linear motors tend to have a higher initial investment and require more complex installation and integration processes. Despite these challenges, their low maintenance requirements and high performance make them suitable for advanced manufacturing environments.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right linear motion solution, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and long-term maintenance implications. Ball screws are an excellent choice for high-precision applications, while lead screws may be more suitable for cost-sensitive projects. Linear motors provide unparalleled speed and accuracy but come with higher costs and complexity. By analyzing these alternatives in the context of their unique operational demands, buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, can make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for ball screw

What Are the Key Technical Properties of Ball Screws?

When considering ball screws for industrial applications, it’s essential to understand their critical specifications. These properties not only influence performance but also impact the selection process for international B2B buyers.

What Material Grades Are Commonly Used for Ball Screws?

Ball screws are often made from high-grade materials such as stainless steel or carbon steel. Stainless steel offers excellent corrosion resistance, making it ideal for applications in humid or chemically aggressive environments. In contrast, carbon steel provides high strength and durability, suitable for heavy-duty applications. Choosing the right material grade is crucial for ensuring longevity and reliability, particularly in demanding settings like manufacturing or automation.

How Does Tolerance Affect Ball Screw Performance?

A stock image related to ball screw.

Tolerance refers to the permissible limit of variation in a physical dimension. In ball screws, tight tolerances are vital for achieving high precision and accuracy in motion control. A lower tolerance indicates higher precision, which is essential for applications in robotics, CNC machinery, and aerospace where even minor deviations can lead to significant operational issues. Understanding tolerance specifications can help buyers select ball screws that meet their specific application needs.

What is Lead and Why Is It Important?

The lead of a ball screw is the distance the nut moves along the screw shaft with one complete turn. It is a critical factor in determining the speed and efficiency of motion. A higher lead allows for faster linear movement but may compromise the load-carrying capacity. Buyers must balance lead with load requirements to ensure optimal performance in their machinery.

A stock image related to ball screw.

How Does Load Capacity Impact Ball Screw Selection?

Load capacity refers to the maximum weight a ball screw can support without failure. This includes both dynamic (operating) and static (non-operating) load ratings. Understanding the load capacity is essential for buyers, as it determines whether the ball screw can handle the forces exerted during operation. Selecting a ball screw with inadequate load capacity can result in premature failure, leading to costly downtimes and repairs.

What Are Common Trade Terminologies in the Ball Screw Industry?

Understanding trade terminology is crucial for international B2B buyers to navigate the procurement process effectively. Here are some commonly used terms:

What is an OEM (Original Equipment Manufacturer)?

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of ball screws, working with an OEM can ensure that you receive high-quality, reliable components that meet specific industry standards. This is particularly important for buyers looking for customized solutions in sectors like automotive or aerospace.

What Does MOQ (Minimum Order Quantity) Mean?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers, as it can affect inventory management and overall costs. Understanding the MOQ can help buyers plan their orders more effectively, especially when dealing with international suppliers.

How Do RFQs (Requests for Quotations) Work?

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For ball screws, issuing an RFQ can provide buyers with competitive pricing and terms from multiple suppliers. This is an effective way to ensure you’re making informed purchasing decisions.

What Are Incoterms and Why Are They Important?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify issues such as shipping costs, insurance, and liability during transit. Understanding Incoterms is vital for B2B buyers, especially those importing ball screws from regions like Europe or Asia, as they influence the total cost and delivery timelines.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing ball screws for their applications, ensuring optimal performance and value for their investments.

Navigating Market Dynamics and Sourcing Trends in the ball screw Sector

What Are the Key Market Dynamics and Trends in the Ball Screw Sector?

The ball screw market is currently experiencing a transformative phase driven by technological advancements and shifting global manufacturing demands. Key trends influencing the market include the increasing automation in industries such as robotics, aerospace, and CNC machinery, where precision motion control is paramount. The demand for high-efficiency ball screws is growing, as they significantly reduce energy consumption—by as much as one-third compared to traditional sliding screws. Additionally, the rise of Industry 4.0 and smart manufacturing technologies is pushing manufacturers to adopt more integrated and automated solutions, further boosting the ball screw market.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of the competitive sourcing landscape. Suppliers are increasingly offering customized solutions tailored to specific industry needs, such as miniaturized ball screws for compact machinery or high-load capacity models for heavy-duty applications. Buyers should also pay attention to regional manufacturing capabilities, as local suppliers may offer advantages in lead time and logistics.

Furthermore, the ball screw sector is witnessing a shift toward advanced materials and coatings that enhance performance and durability, catering to industries requiring robust solutions. As buyers evaluate their sourcing strategies, they should consider suppliers that not only meet technical specifications but also align with long-term operational goals in terms of efficiency and sustainability.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Ball Screw Sector?

Sustainability is becoming a critical consideration for B2B buyers in the ball screw sector. The environmental impact of manufacturing processes, material sourcing, and product lifecycle is under increasing scrutiny. Buyers are encouraged to partner with suppliers who prioritize eco-friendly practices, such as using recyclable materials and energy-efficient manufacturing processes. This not only aligns with global sustainability goals but can also enhance a company’s brand reputation and compliance with regulatory requirements.

Moreover, ethical sourcing plays a significant role in building resilient supply chains. Buyers should seek suppliers that maintain transparency in their supply chain operations, ensuring that labor practices are ethical and materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can provide assurance of a supplier’s commitment to sustainable practices.

Investing in suppliers with ‘green’ certifications can lead to long-term cost savings through reduced waste and improved efficiency. Additionally, companies that adopt sustainable practices are often better positioned to meet the demands of increasingly eco-conscious consumers and regulatory bodies.

What Is the Historical Context of Ball Screws in B2B Applications?

The evolution of ball screws can be traced back to the early 20th century when they were first introduced as a solution for high-precision linear motion applications. Initially utilized in aerospace and military applications, their use quickly expanded to various industries, including manufacturing and automation. The design of ball screws has continuously improved, incorporating advanced materials and manufacturing techniques that enhance performance and reliability.

Today, ball screws are integral components in numerous applications, from CNC machinery to robotics, providing efficient motion control with minimal friction. As industries evolve and demand for precision continues to rise, ball screws remain a vital element in facilitating innovation and efficiency across multiple sectors. International B2B buyers must recognize the historical significance of ball screws while evaluating their sourcing strategies to ensure they leverage the latest advancements and maintain competitiveness in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of ball screw

-

How do I select the right ball screw for my application?

Selecting the right ball screw involves considering several key factors: load capacity, precision requirements, and environmental conditions. Evaluate the maximum axial and radial loads your application will encounter, as well as the required speed and accuracy. Additionally, consider whether your application will be exposed to dust, moisture, or extreme temperatures, which may necessitate specific materials or coatings. Consult with manufacturers to review specifications and ensure compatibility with your machinery. -

What is the best ball screw type for high-speed applications?

For high-speed applications, precision ground ball screws are often the best choice due to their superior accuracy and reduced friction. They provide smoother motion and can handle higher speeds without overheating. Additionally, look for ball screws designed for high-speed operation, which may include features like optimized ball return systems and special coatings to enhance performance. Always discuss your specific speed requirements with suppliers to ensure the selected product meets your needs. -

How can I ensure the quality of the ball screws I purchase?

To ensure quality, verify that the ball screws comply with international standards such as ISO 3408. Request certifications from your supplier and inquire about their quality control processes. It’s beneficial to obtain samples for testing before placing a large order. Additionally, consider suppliers who offer warranty options and after-sales support, which can provide assurance of product reliability and performance. -

What are the typical minimum order quantities (MOQs) for ball screws?

Minimum order quantities for ball screws can vary significantly based on the supplier and the type of ball screw. Generally, MOQs may range from a few pieces for standard sizes to larger quantities for custom specifications. Always communicate your needs directly with suppliers to negotiate terms that suit your project, especially if you require smaller quantities for prototyping or testing. -

What payment terms should I expect when sourcing ball screws internationally?

Payment terms can vary based on the supplier’s policies and the buyer’s location. Common terms include payment in advance, letters of credit, or net 30/60 days after delivery. It’s advisable to establish clear payment terms upfront to avoid misunderstandings. Additionally, consider discussing potential discounts for bulk orders or longer payment terms to improve cash flow for your business. -

How do logistics and shipping impact the procurement of ball screws?

Logistics and shipping are critical aspects of sourcing ball screws, particularly for international transactions. Consider factors such as shipping time, customs clearance, and associated costs. Work with suppliers who have experience in international shipping to ensure timely delivery. Additionally, explore options for freight insurance to protect your investment against potential shipping damages or losses. -

What should I look for when vetting suppliers for ball screws?

When vetting suppliers, prioritize their experience, reputation, and production capabilities. Request references and check reviews from previous clients. Ensure they comply with relevant industry standards and certifications. It’s also helpful to inquire about their production processes and lead times, as well as their ability to provide customization options to meet your specific requirements. -

Can ball screws be customized to fit my specific machinery?

Yes, many manufacturers offer customization options for ball screws to suit specific applications. Customizations can include variations in size, lead, material, and coatings. When discussing your needs with suppliers, provide detailed specifications and any design constraints your machinery may have. This will help ensure that the customized ball screws perform optimally within your equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ball screw

Why Is Strategic Sourcing Crucial for Ball Screws?

In the evolving landscape of manufacturing and automation, strategic sourcing of ball screws is not just beneficial; it is essential. By understanding the different types of ball screws—such as precision ground, rolled, and miniature options—B2B buyers can tailor their procurement strategies to meet specific operational needs. This approach not only enhances efficiency but also significantly reduces energy consumption and operational costs.

How Can International Buyers Enhance Their Procurement Strategy?

For international buyers, especially from Africa, South America, the Middle East, and Europe, leveraging local suppliers alongside global manufacturers can lead to a more resilient supply chain. Considerations such as lead times, local regulations, and import tariffs can significantly impact overall costs and project timelines. Engaging in direct dialogues with manufacturers can also unlock customized solutions that align with specific machinery and operational requirements.

What Does the Future Hold for Ball Screw Procurement?

As industries increasingly adopt automation and smart manufacturing technologies, the demand for high-quality ball screws is set to rise. Buyers should stay abreast of technological advancements and emerging trends in ball screw design and application. By proactively investing in strategic sourcing now, international B2B buyers can ensure they remain competitive in a rapidly changing market landscape.

Embrace the opportunity to refine your sourcing strategies and position your business for success in the future. Engage with suppliers, seek out innovative solutions, and optimize your supply chain to harness the full potential of ball screw technology.