Improve Efficiency: The Ultimate DC Machine Motor Guide (2025)

Introduction: Navigating the Global Market for dc machine motor

As international B2B buyers delve into the complex landscape of sourcing DC machine motors, a pivotal challenge lies in identifying the right solutions that align with their operational needs and budget constraints. The demand for efficient and reliable DC motors spans diverse industries, from agricultural equipment in Africa to automation technologies in Europe and the Middle East. This guide offers a comprehensive exploration of DC machine motors, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

Understanding the intricacies of DC motors is crucial for buyers looking to enhance their operational efficiency and reduce energy consumption. This guide aims to empower decision-makers by providing actionable insights tailored to the unique challenges faced by businesses in regions like South America, Turkey, and the UAE. Through in-depth analysis, buyers will learn how to assess various motor types, including permanent magnet and gearmotors, and their suitability for specific applications, whether in renewable energy systems or industrial automation.

Additionally, we will delve into effective strategies for supplier evaluation, ensuring that international buyers can confidently select partners who meet their quality and service standards. By the end of this guide, you will be equipped with the knowledge necessary to make informed purchasing decisions that drive innovation and success in your business operations.

Understanding dc machine motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Permanent Magnet DC Motor (PMDC) | High efficiency, compact size, and high starting torque. | Robotics, medical devices, warehouse automation | Pros: Cost-effective, reliable performance. Cons: Limited speed range. |

| Series DC Motor | Simple design, high starting torque, and variable speed. | Elevators, cranes, and traction applications | Pros: High torque at low speeds. Cons: Less efficient under varying loads. |

| Shunt DC Motor | Constant speed, good for stable applications. | Conveyor systems, fans, and pumps | Pros: Excellent speed regulation. Cons: Lower starting torque compared to series motors. |

| Compound DC Motor | Combines features of series and shunt motors for versatility. | Industrial machinery, electric vehicles | Pros: High torque and good speed regulation. Cons: More complex and costly. |

| Brushless DC Motor | No brushes, longer lifespan, and reduced maintenance. | HVAC systems, electric bikes, and drones | Pros: Higher efficiency and reliability. Cons: Typically more expensive upfront. |

What Are the Characteristics of Permanent Magnet DC Motors?

Permanent Magnet DC Motors (PMDC) utilize permanent magnets to create the magnetic field, which results in high efficiency and compact design. They are ideal for applications requiring high starting torque and consistent performance, such as robotics and warehouse automation. When purchasing PMDC motors, buyers should consider voltage ratings and the need for speed control options, as these factors can influence overall system performance.

How Do Series DC Motors Work and Where Are They Used?

Series DC Motors are characterized by their simple design, where the field winding is in series with the armature. This configuration provides high starting torque, making them suitable for applications like elevators and cranes. Buyers should evaluate the motor’s torque characteristics and ensure compatibility with their load requirements, especially in varying load conditions, where efficiency may decline.

What Are the Benefits of Shunt DC Motors in Industrial Applications?

Shunt DC Motors feature a field winding connected in parallel with the armature, providing stable speed under varying load conditions. They are commonly used in conveyor systems and fans, where consistent speed is crucial. Buyers should focus on the motor’s speed regulation capabilities and consider the trade-off between starting torque and efficiency when selecting shunt motors for their applications.

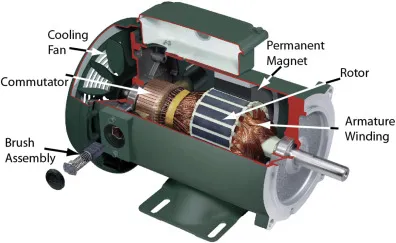

A stock image related to dc machine motor.

Why Choose Compound DC Motors for Versatile Solutions?

Compound DC Motors combine the features of both series and shunt motors, offering flexibility for various applications such as industrial machinery and electric vehicles. They provide high torque and good speed regulation, making them suitable for tasks requiring both characteristics. Buyers should assess the complexity and cost of these motors, as they may require more investment compared to simpler motor types.

What Advantages Do Brushless DC Motors Offer for Modern Applications?

Brushless DC Motors eliminate the need for brushes, resulting in longer lifespans and reduced maintenance needs. They are increasingly used in HVAC systems, electric bikes, and drones due to their higher efficiency and reliability. While the initial investment may be higher, buyers should weigh the long-term benefits of reduced operational costs and maintenance when considering brushless DC motors for their projects.

Key Industrial Applications of dc machine motor

| Industry/Sector | Specific Application of dc machine motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems | Enhances efficiency and reduces labor costs | Voltage ratings, torque requirements, and environmental conditions |

| Warehousing & Logistics | Automated guided vehicles (AGVs) | Increases operational efficiency and reduces downtime | Size, weight, and compatibility with existing systems |

| Medical Equipment | Portable medical devices | Ensures reliability and precision in medical procedures | Low voltage options, compliance with medical standards |

| Manufacturing | Conveyor systems | Streamlines production processes and increases throughput | Adjustable speed capabilities and durability under load |

| Renewable Energy | Solar-powered applications | Supports sustainable practices and reduces energy costs | Compatibility with solar systems and energy management features |

How Are DC Machine Motors Used in Agriculture?

In the agriculture sector, DC machine motors are integral to automated irrigation systems. These motors provide reliable power to pumps, enabling precise control over water distribution. This efficiency not only conserves water but also reduces labor costs, which is particularly beneficial for regions in Africa and South America where labor may be scarce or expensive. Buyers should consider voltage ratings and torque requirements to ensure that the motors can handle the specific demands of their irrigation systems, especially in remote areas.

What Role Do DC Motors Play in Warehousing and Logistics?

DC motors are vital for the operation of Automated Guided Vehicles (AGVs) in warehousing and logistics. These vehicles rely on DC motors for smooth and efficient navigation through warehouses, allowing for the automatic transport of goods. This leads to increased operational efficiency and reduced downtime, essential for businesses aiming to optimize their supply chains. Buyers should focus on size, weight, and compatibility with existing systems to ensure seamless integration of these motors into their operations.

How Are DC Motors Applied in Medical Equipment?

In the medical sector, DC machine motors are used in portable medical devices such as infusion pumps and ventilators. These motors must provide reliable and precise control to ensure that medical procedures are carried out accurately. The reliability of these devices is paramount, as any failure can have serious consequences. Buyers in this sector should prioritize low voltage options and ensure compliance with medical standards, particularly when sourcing motors for critical applications.

Why Are DC Motors Important in Manufacturing?

Manufacturing processes often utilize DC motors in conveyor systems, where they drive the movement of materials and products along production lines. The use of DC motors in these applications streamlines production processes and increases throughput, making them essential for manufacturers looking to enhance productivity. When sourcing DC motors for manufacturing, it is crucial to consider adjustable speed capabilities and the durability of the motors under load, as these factors directly impact the efficiency of the production line.

How Do DC Motors Contribute to Renewable Energy Solutions?

DC machine motors are increasingly being used in solar-powered applications, where they help in the operation of devices that rely on renewable energy. These motors support sustainable practices by enabling efficient energy use, which can significantly reduce operational costs. For international buyers, particularly in regions like the Middle East and Europe, it is important to ensure that the motors are compatible with solar systems and feature energy management capabilities to optimize performance in off-grid scenarios.

3 Common User Pain Points for ‘dc machine motor’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable DC Motors for Industrial Applications

The Problem: International B2B buyers often face challenges in sourcing reliable DC motors that meet specific application requirements. For instance, a manufacturing company in South Africa may need motors for automated machinery but struggles to find suppliers who can provide high-efficiency models with adequate support for local regulations. This can lead to delays in production, increased costs, and a reliance on subpar components that may not perform reliably.

The Solution: To overcome sourcing difficulties, buyers should establish relationships with reputable suppliers who specialize in DC motors and understand the local market. Engage in thorough research to identify manufacturers known for their quality and customer service. Utilize platforms like industry-specific directories and trade shows to connect with potential suppliers. Request samples and performance data to ensure the motors meet the required specifications, such as voltage ratings and torque requirements. Additionally, buyers should inquire about after-sales support and warranty options, ensuring they have a reliable partner for ongoing maintenance and troubleshooting.

Scenario 2: Challenges in Integrating DC Motors with Existing Systems

The Problem: Integration issues often arise when companies attempt to incorporate new DC motors into their existing systems. For example, a logistics company in Brazil may find that the new motors they purchased are not compatible with their current power supply or control systems. This can result in operational disruptions, costly modifications, and wasted investment.

The Solution: Before purchasing DC motors, it is essential to conduct a comprehensive assessment of the existing systems. Buyers should collaborate with their engineering teams to define integration requirements, including compatibility with current controllers and power supplies. When selecting motors, choose models that offer flexible voltage ratings and are designed for easy integration with popular control systems. Furthermore, consider working with suppliers that provide technical support during the integration process, including guidance on wiring and programming. Leveraging simulation tools to model the integration can also help identify potential issues before they arise, ensuring a smoother implementation.

Scenario 3: High Operational Costs Due to Inefficient Motor Selection

The Problem: Many businesses experience high operational costs stemming from inefficient motor selection, particularly in energy-intensive applications. For instance, a textile manufacturer in Turkey might choose a low-cost DC motor without considering energy efficiency, leading to increased energy bills and frequent maintenance issues. This not only affects profit margins but also hinders the company’s sustainability goals.

The Solution: To mitigate high operational costs, it is crucial for buyers to prioritize energy efficiency when selecting DC motors. They should look for motors with high efficiency ratings and features such as adjustable speed drives that allow for optimized power consumption based on operational needs. Conduct a total cost of ownership (TCO) analysis to compare not just the initial purchase price but also the long-term energy costs and maintenance requirements. Additionally, consider investing in advanced technologies like brushless DC motors, which offer superior efficiency and lower maintenance compared to traditional brushed models. Educating the procurement team on energy-efficient practices and involving them in the selection process can further enhance the overall decision-making strategy.

Strategic Material Selection Guide for dc machine motor

What Are the Key Materials Used in DC Machine Motors?

When selecting materials for DC machine motors, it is crucial to consider their properties and how they affect performance, durability, and cost. The following analysis highlights four common materials used in the construction of DC motors, focusing on their advantages, disadvantages, and implications for international B2B buyers.

Copper: The Preferred Conductor

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and ductility. It can withstand high temperatures up to 200°C without losing its conductive properties, making it ideal for high-performance applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances motor efficiency and performance. However, it is relatively expensive compared to other conductive materials like aluminum. Additionally, copper is susceptible to corrosion, which can affect long-term reliability.

Impact on Application: In environments where high temperatures and humidity are prevalent, such as in some regions of Africa and South America, copper’s thermal properties can be beneficial. However, buyers must consider protective coatings to mitigate corrosion.

Considerations for International Buyers: Compliance with international standards such as ASTM B170 for copper wire is essential. Buyers should also be aware of local sourcing options to reduce costs and ensure quality.

Steel: The Structural Backbone

Key Properties: Steel offers a high tensile strength and durability, making it suitable for motor frames and other structural components. It can withstand significant mechanical stress and has good magnetic properties, which enhance motor efficiency.

Pros & Cons: The key advantage of steel is its strength and cost-effectiveness. However, it is heavier than other materials, which can impact the overall weight of the motor. Additionally, steel may corrode if not properly treated or coated.

Impact on Application: Steel is suitable for industrial applications requiring robust motors, such as in manufacturing and construction. Its strength makes it ideal for environments with high mechanical loads.

Considerations for International Buyers: Buyers should ensure that steel components meet relevant standards, such as DIN 17100 for structural steel, especially in regions like Europe and the Middle East, where regulations can be stringent.

Aluminum: The Lightweight Alternative

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can operate effectively in temperatures up to 150°C, making it suitable for various applications.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can lead to reduced energy consumption in applications requiring mobility. However, it is less conductive than copper, which may impact performance in high-efficiency applications.

Impact on Application: Aluminum is often used in portable and battery-operated devices, making it a good choice for applications in remote areas, such as solar-powered equipment in Africa.

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum extrusions is vital. Buyers should also consider the availability of aluminum in their local markets to avoid supply chain issues.

Insulation Materials: Ensuring Safety and Efficiency

Key Properties: Insulation materials, such as thermoplastics and epoxy resins, provide electrical insulation and thermal stability. They can withstand temperatures up to 180°C and are crucial for preventing short circuits.

Pros & Cons: The key advantage of high-quality insulation materials is their ability to enhance motor safety and efficiency. However, they can add to manufacturing complexity and costs.

Impact on Application: In humid or corrosive environments, effective insulation is critical for ensuring motor longevity and reliability.

Considerations for International Buyers: Buyers should verify that insulation materials comply with international safety standards, such as IEC 60085, particularly in regions with strict electrical safety regulations.

Summary Table of Material Selection for DC Machine Motors

| Material | Typical Use Case for dc machine motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance motors | Superior electrical conductivity | Expensive and corrosion-prone | High |

| Steel | Industrial applications | High strength and cost-effective | Heavier and corrosion risk | Medium |

| Aluminum | Portable devices | Lightweight and corrosion-resistant | Less conductive than copper | Medium |

| Insulation | All DC motors | Enhances safety and efficiency | Adds manufacturing complexity | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dc machine motor

What Are the Key Stages in the Manufacturing Process of DC Machine Motors?

Manufacturing DC machine motors involves a series of well-defined stages, each critical to ensuring the final product meets the required performance standards. The typical process includes:

-

Material Preparation: This initial stage involves selecting high-quality raw materials, primarily copper for windings, magnetic steel for the stator and rotor, and various alloys for components like bearings. Suppliers often conduct stringent material inspections to ensure compliance with specifications.

-

Forming: The forming process includes several techniques such as stamping, casting, and machining. Stamping is commonly used for creating rotor and stator laminations, while casting may be applied for housing components. Precision machining is vital for parts that require tight tolerances, ensuring that components fit correctly during assembly.

-

Assembly: During assembly, the prepared parts are systematically put together. This stage often employs automated assembly lines to enhance efficiency and reduce human error. Key components such as the rotor, stator, and commutator are assembled with careful attention to alignment and fit.

-

Finishing: The final stage involves surface treatments and coatings that enhance durability and performance. Processes like anodizing, painting, or powder coating protect against corrosion and wear. This stage may also include balancing the rotor to minimize vibrations during operation.

How Is Quality Assurance Integrated into the Manufacturing of DC Machine Motors?

Quality assurance (QA) is paramount in the manufacturing of DC machine motors to ensure reliability and compliance with international standards. Key aspects of QA include:

-

Adherence to International Standards: Manufacturers often comply with ISO 9001, a global standard for quality management systems, which provides a framework for consistent quality in production. Additionally, certifications like CE mark for European markets and API standards for specific applications further validate quality.

-

Quality Control Checkpoints: The QA process incorporates several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to confirm they meet specified standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, critical operations are monitored to detect defects early.

– Final Quality Control (FQC): Once assembly is complete, final inspections and tests ensure the motors meet performance criteria before shipment. -

Common Testing Methods: Various testing methods are employed to verify the functionality and durability of DC motors. These may include electrical testing for insulation resistance, thermal testing for heat dissipation, and dynamic testing for speed and torque performance.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, ensuring the quality of DC machine motors involves proactive verification of supplier practices:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities can provide insights into their manufacturing processes and quality control systems. This can include reviewing documentation related to ISO certifications, quality manuals, and process flow diagrams.

-

Requesting Quality Reports: Buyers should request quality assurance reports, including IQC, IPQC, and FQC data. These reports should detail the results of inspections and tests conducted at various stages of production.

-

Engaging Third-Party Inspection Services: Employing independent third-party inspectors can add an extra layer of assurance. These inspectors can verify compliance with international standards and provide objective assessments of the manufacturing process.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control in different regions can help B2B buyers make informed decisions when sourcing DC machine motors:

-

Regional Standards and Compliance: Buyers from Europe may prioritize CE certifications, while those in the Middle East might focus on local compliance standards. It’s essential to understand the specific regulations that apply to your region and industry to ensure that suppliers can meet these requirements.

-

Cultural Considerations in Quality Management: Different regions may have varying attitudes toward quality management. Buyers should be aware of these cultural differences when evaluating suppliers. For instance, some manufacturers may have a more rigid approach to quality control, while others may adopt a more flexible methodology.

-

Communication and Collaboration: Establishing clear communication channels with suppliers can facilitate better understanding and management of quality expectations. Regular updates and collaborative problem-solving can help address quality issues proactively.

How Can Buyers Ensure Continuous Quality Improvement from Suppliers?

To foster long-term relationships with suppliers and ensure continuous quality improvement, B2B buyers can implement several strategies:

-

Setting Clear Quality Expectations: Clearly outline quality requirements in contracts, including performance metrics and compliance with international standards. This sets a benchmark for suppliers to meet.

-

Feedback Mechanisms: Establish feedback loops where buyers can provide input on product performance and quality issues. This feedback is crucial for suppliers to understand areas needing improvement.

-

Incentivizing Quality Performance: Consider implementing performance-based contracts where suppliers are rewarded for meeting or exceeding quality standards. This approach encourages suppliers to invest in quality improvements.

Conclusion: Building Trust Through Quality Assurance in DC Machine Motor Manufacturing

For international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance protocols of DC machine motors is vital. By emphasizing stringent quality control measures, conducting thorough supplier evaluations, and fostering open communication, buyers can ensure they source reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc machine motor’

In the competitive landscape of international B2B procurement, particularly for DC machine motors, having a structured approach to sourcing is essential. This guide provides a step-by-step checklist to assist buyers from Africa, South America, the Middle East, and Europe in effectively procuring DC motors that meet their specific needs.

Step 1: Define Your Technical Specifications

Start by outlining the technical requirements of the DC motor you need. Consider factors such as voltage (e.g., 12V, 24V, 90V), torque ratings, speed (RPM), and application specifics. This clarity will not only streamline your sourcing process but also ensure that you select a motor that optimally fits your operational needs.

- Voltage Requirements: Determine if your application requires low-voltage models ideal for battery-powered systems or higher voltage options for industrial use.

- Torque and Speed Needs: Identify the torque and speed necessary for your equipment to function efficiently, as these specifications are critical for performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the DC motor market. Utilize online directories, trade shows, and industry networks to compile a list of potential vendors.

- Supplier Reputation: Look for companies with a strong presence and positive reviews in the industry.

- Product Range: Ensure suppliers offer a variety of DC motors that can cater to different applications, including gearmotors and specialized designs.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with international quality standards. This step is crucial to ensure that the motors you procure meet safety and performance regulations.

- ISO Certifications: Check for ISO 9001 or similar certifications that indicate a commitment to quality management.

- Industry-Specific Standards: Depending on your region, look for compliance with local electrical standards or certifications relevant to your industry.

Step 4: Request Samples or Prototypes

Once you have narrowed down your supplier list, request samples or prototypes of the DC motors. This allows you to assess the quality, performance, and suitability of the motors for your specific application.

- Testing Procedures: Conduct thorough tests to evaluate the motor’s performance under expected operational conditions.

- Compatibility Check: Ensure the motor integrates well with your existing systems or equipment.

Step 5: Analyze Pricing and Payment Terms

Compare pricing structures among your shortlisted suppliers. Keep in mind that the lowest price does not always equate to the best value.

- Total Cost of Ownership: Consider not only the initial purchase price but also potential maintenance costs, energy efficiency, and longevity of the motor.

- Flexible Payment Options: Discuss payment terms and conditions, ensuring they align with your financial capabilities and procurement policies.

Step 6: Negotiate Terms and Conditions

Engage in negotiations with your selected supplier to finalize terms, including delivery schedules, warranty provisions, and after-sales support.

- Clear Agreements: Make sure all terms are documented clearly to avoid disputes later.

- Support Services: Inquire about the availability of technical support and service options post-purchase.

Step 7: Finalize the Order and Monitor Delivery

After all terms are agreed upon, finalize your order. Maintain regular communication with the supplier to monitor the delivery process and address any potential issues promptly.

- Logistics Planning: Ensure that the logistics are in place for timely delivery, especially if sourcing internationally.

- Receiving Inspection: Upon arrival, inspect the motors thoroughly to confirm they meet the agreed specifications and quality standards.

By following this comprehensive checklist, international B2B buyers can streamline their procurement process for DC machine motors, ensuring they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for dc machine motor Sourcing

What are the Key Cost Components in DC Machine Motor Sourcing?

When sourcing DC machine motors, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. High-quality copper windings, durable magnets, and robust casing materials contribute to performance but also increase costs. Buyers should consider the balance between quality and price to ensure long-term reliability.

-

Labor: Labor costs can vary widely based on geographic location and the complexity of the motor’s design. Regions with lower labor costs may offer competitive pricing, but this could affect the quality and precision of manufacturing.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, which can be a point of negotiation for buyers.

-

Tooling: Custom tooling for specific motor designs can represent a significant initial investment. Buyers should evaluate whether the tooling costs can be amortized over large production runs to make custom solutions more economical.

-

Quality Control (QC): Implementing rigorous QC processes ensures that motors meet specified standards. While this may increase initial costs, it helps avoid higher costs associated with defects and returns in the long run.

-

Logistics: Shipping costs, including freight, insurance, and duties, can vary based on the destination. Buyers should consider local regulations and tariffs, particularly when importing motors from different regions.

-

Margin: Supplier margins can influence the final price. Understanding the supplier’s pricing strategy can help buyers negotiate better terms.

What Influences Pricing for DC Machine Motors?

Several factors influence the pricing of DC machine motors:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their needs against MOQs to optimize pricing.

-

Specifications and Customization: Customized motors that meet specific applications will generally cost more. Buyers should clearly define their requirements to avoid unnecessary expenses on features that are not needed.

-

Material Quality and Certifications: High-quality materials and certifications (like ISO) can justify higher prices due to enhanced performance and reliability. Buyers in sectors with stringent quality demands should prioritize certified suppliers.

-

Supplier Factors: The supplier’s reputation, experience, and location can affect pricing. Established suppliers may offer better reliability but at a premium price.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital, as they dictate responsibilities and costs during shipping. This knowledge can help buyers negotiate better shipping arrangements.

How Can Buyers Negotiate for Better Pricing on DC Machine Motors?

International B2B buyers can enhance their purchasing strategy by implementing several best practices:

-

Leverage Volume Discounts: Consolidating purchases can help achieve better pricing. Engaging in long-term contracts with suppliers can also secure favorable terms.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, energy consumption, and lifespan. A slightly higher upfront cost can result in lower TCO if the motor is more efficient or durable.

-

Explore Multiple Suppliers: Don’t rely solely on one supplier. Comparing quotes from multiple vendors can provide leverage in negotiations and reveal pricing trends.

-

Understand Pricing Nuances for International Sourcing: Factors like currency fluctuations, local taxes, and shipping costs can all affect the final price. International buyers should factor these elements into their total cost calculations.

-

Establish Clear Communication: Clearly communicate your needs and expectations to suppliers. This transparency can lead to tailored solutions that meet both quality and budgetary requirements.

Conclusion

Sourcing DC machine motors involves navigating a complex landscape of costs and pricing influences. By understanding the key components and implementing strategic negotiation tactics, international buyers, particularly from Africa, South America, the Middle East, and Europe, can make informed purchasing decisions that align with their operational needs and budget constraints. Remember, indicative prices can fluctuate based on market conditions, so always seek updated quotes and clarify terms before finalizing any agreement.

Alternatives Analysis: Comparing dc machine motor With Other Solutions

Understanding Alternatives to DC Machine Motors

When considering the implementation of a DC machine motor, it’s essential for international B2B buyers to explore viable alternatives. Each alternative comes with its own set of advantages and disadvantages that may better suit specific applications, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This section will analyze the performance, cost, ease of implementation, maintenance, and best use cases for DC machine motors compared to other solutions.

Comparison Table

| Comparison Aspect | Dc Machine Motor | AC Induction Motor | Brushless DC Motor |

|---|---|---|---|

| Performance | High starting torque, adjustable speed | Moderate torque, consistent speed | High efficiency, precise control |

| Cost | Moderate initial cost, higher long-term maintenance | Generally lower cost, but less flexible | Higher initial cost, lower maintenance |

| Ease of Implementation | Requires specific controllers | Simpler integration with AC supply | Needs specialized controllers |

| Maintenance | Regular maintenance needed | Low maintenance, robust | Low maintenance, but requires skilled technicians |

| Best Use Case | Adjustable speed applications | Fixed-speed operations | Applications requiring precision and efficiency |

What Are the Advantages and Disadvantages of AC Induction Motors?

AC induction motors are a prevalent alternative to DC machine motors. They are known for their robust design and low maintenance requirements. The initial cost is typically lower than that of a DC motor, making them an attractive option for applications that do not require variable speed control. However, they are less flexible, as they operate best at a fixed speed, which can be a limitation in dynamic environments where variable speed is necessary.

How Do Brushless DC Motors Compare to DC Machine Motors?

Brushless DC motors (BLDC) represent another viable alternative that offers significant benefits, particularly in applications demanding high efficiency and precise speed control. They are generally more efficient than traditional DC motors and have a longer lifespan due to the absence of brushes, which reduces wear and tear. However, the initial investment is higher, and specialized controllers are often necessary for optimal performance, which could complicate implementation in regions with less technical infrastructure.

Conclusion: How to Choose the Right Motor for Your Needs

Selecting the right motor solution requires a careful assessment of your specific operational needs. B2B buyers should consider factors such as the application environment, required performance characteristics, and budget constraints. DC machine motors are excellent for applications needing high starting torque and adjustable speed, while AC induction motors may be more cost-effective for fixed-speed operations. Brushless DC motors are ideal for high-efficiency applications where precision is paramount. By weighing these factors, businesses can make informed decisions that align with their operational goals and regional capabilities.

Essential Technical Properties and Trade Terminology for dc machine motor

What Are the Key Technical Properties of DC Machine Motors?

When evaluating DC machine motors for your business needs, understanding their technical properties is essential. Here are some critical specifications that international B2B buyers should consider:

1. Voltage Ratings

DC motors are available in various voltage ratings, such as low voltage (12V or 24V), standard (130V), and high voltage (90V or 180V). The voltage rating is crucial as it directly impacts the motor’s performance and suitability for specific applications. For instance, low-voltage models are ideal for battery-operated or solar-powered devices, making them essential in regions with limited power supply options, like parts of Africa and South America.

2. Torque Output

Torque is a measure of rotational force and is expressed in units like ounce-inches (oz-in) or Newton-meters (Nm). High starting torque is particularly important for applications requiring initial movement against inertia, such as conveyors or agricultural machinery. Understanding torque specifications helps buyers select motors that meet their operational requirements without underperforming.

3. Speed Ratings (RPM)

Speed ratings, typically measured in revolutions per minute (RPM), indicate how fast the motor can operate. Motors like the Bodine 24A Series can range from 2,500 to 11,500 RPM, making them suitable for a variety of applications. Buyers must match the motor speed with their equipment’s operational needs to ensure efficiency and effectiveness.

4. Duty Cycle

The duty cycle defines how long a motor can operate under load before it needs to cool down. Continuous duty motors can run indefinitely at full load, while others may have intermittent duty cycles. This specification is vital for buyers in industries like manufacturing or logistics, where operational uptime is critical.

5. Efficiency Ratings

Efficiency ratings indicate how effectively a motor converts electrical energy into mechanical energy. Higher efficiency motors reduce energy costs and improve overall system performance. Buyers focused on sustainability and operational cost reduction should prioritize motors with high-efficiency ratings, especially in regions facing energy shortages.

6. Material Composition

The materials used in the construction of DC motors affect durability, performance, and weight. Common materials include high-grade steel for the rotor and non-corrosive materials for the casing. Understanding material composition helps buyers assess the motor’s longevity and suitability for harsh environments.

What Are Common Trade Terms in the DC Motor Industry?

Familiarity with industry-specific jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure they are sourcing quality components for their machinery.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for businesses in Africa and South America, where initial capital may be limited.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products or services. This process is essential for buyers to gather competitive quotes and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms can help buyers understand shipping costs, insurance, and risk management, which is especially important for international transactions.

5. Lead Time

Lead time is the amount of time between placing an order and receiving it. Understanding lead times is crucial for project planning and inventory management, as delays can impact production schedules.

6. Wattage

Wattage indicates the power consumption of the motor and is essential for ensuring compatibility with existing electrical systems. Buyers should consider wattage to avoid overloading circuits and ensure efficient energy use.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring DC machine motors, ultimately enhancing their operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the dc machine motor Sector

What Are the Key Market Dynamics and Trends in the DC Machine Motor Sector?

The global market for DC machine motors is experiencing significant growth driven by several key factors. The increasing demand for automation in industries such as manufacturing, agriculture, and transportation is propelling the adoption of DC motors, particularly in regions like Africa, South America, the Middle East, and Europe. As businesses seek to enhance operational efficiency, DC motors are favored for their high starting torque and adjustable speed capabilities, which are essential in applications ranging from warehouse automation to renewable energy systems.

Emerging trends include the rise of smart technologies and Industry 4.0, which are reshaping sourcing strategies. B2B buyers are increasingly looking for suppliers who offer integrated solutions that combine hardware with advanced control systems. Moreover, the shift towards electric mobility is also influencing sourcing decisions, with DC motors being pivotal in electric vehicles and hybrid systems. Buyers are advised to stay abreast of technological advancements, such as the development of brushless DC motors, which provide higher efficiency and lower maintenance requirements.

In addition to technological trends, supply chain dynamics are evolving. International buyers are focusing on diversifying their supply sources to mitigate risks associated with geopolitical uncertainties and trade regulations. This is particularly relevant for buyers in the Middle East and Europe, where fluctuating tariffs can impact procurement costs. Establishing relationships with manufacturers who have robust global supply chains can provide a competitive advantage.

How Is Sustainability Influencing Sourcing Decisions in the DC Machine Motor Sector?

A stock image related to dc machine motor.

Sustainability is becoming a pivotal concern for B2B buyers in the DC machine motor sector. The environmental impact of manufacturing processes is under scrutiny, and companies are increasingly prioritizing ethical sourcing practices. Buyers are encouraged to seek out suppliers who demonstrate a commitment to reducing their carbon footprint and who utilize sustainable materials in their products. Certifications such as ISO 14001 for environmental management systems are valuable indicators of a supplier’s dedication to sustainability.

The importance of ethical supply chains cannot be overstated. Buyers should conduct due diligence on suppliers to ensure that they adhere to fair labor practices and responsible sourcing of raw materials. This is particularly relevant in regions where supply chains may be less regulated. The use of ‘green’ certifications and materials not only enhances a company’s brand reputation but also aligns with the growing consumer demand for environmentally friendly products.

Moreover, many manufacturers are now integrating energy-efficient designs in their DC motors, which contribute to lower operational costs for end users. By investing in sustainable technologies, businesses can not only comply with regulatory requirements but also capitalize on the emerging market for eco-friendly solutions.

What Is the Historical Context of DC Machine Motors and Their Relevance Today?

A stock image related to dc machine motor.

The evolution of DC machine motors can be traced back to the late 19th century, where they played a critical role in the early days of electric power generation and distribution. Initially, these motors were widely used in various applications due to their simplicity and reliability. Over the decades, advancements in technology have led to the development of more efficient designs, such as permanent magnet DC motors and brushless variants, which have become increasingly popular in modern applications.

Today, the historical significance of DC motors continues to influence their design and application in contemporary markets. They are integral to sectors that demand precision control and high torque at low speeds, such as robotics and automotive. Understanding the historical context of these motors can help B2B buyers appreciate their technological evolution and make informed decisions when sourcing products that meet current industry standards.

By considering market dynamics, sustainability, and historical relevance, international B2B buyers can navigate the complexities of the DC machine motor sector more effectively, ensuring that their sourcing strategies are both innovative and responsible.

Frequently Asked Questions (FAQs) for B2B Buyers of dc machine motor

-

How do I choose the right DC motor for my application?

Choosing the right DC motor involves understanding your specific application needs, including torque requirements, voltage specifications, and speed control. Consider the type of load the motor will drive and whether you need features like adjustable speed or high starting torque. For applications in remote areas, low-voltage options like 12V or 24V may be ideal, particularly for battery or solar-powered systems. Consult with suppliers about their product ranges and customization options to ensure you select a motor that meets your operational demands. -

What are the main types of DC motors available for industrial applications?

The primary types of DC motors include brushed, brushless, and permanent magnet motors. Brushed motors are known for their simplicity and cost-effectiveness, while brushless motors offer higher efficiency and longer lifespan. Permanent magnet DC (PMDC) motors are widely used in applications requiring high torque and speed control. Evaluate your specific needs, such as power output and environmental conditions, to determine which type will provide the best performance for your application. -

What is the minimum order quantity (MOQ) for DC motors when sourcing internationally?

Minimum order quantities (MOQs) for DC motors can vary significantly among suppliers, often ranging from 10 to 100 units. It’s essential to discuss MOQs with potential suppliers during the initial negotiations. Some manufacturers may offer lower MOQs for specific products or allow for mixed orders to meet your needs. Additionally, consider the implications of MOQ on your inventory management and cash flow, especially when entering new markets. -

What payment terms should I expect when buying DC motors internationally?

Payment terms for international purchases of DC motors can vary widely but typically include options like advance payment, letters of credit, or payment on delivery. Many suppliers require a deposit upfront, followed by the balance upon shipment. Discuss payment options early in the negotiation process, ensuring that terms align with your financial practices and provide adequate protection against risks associated with international trade. -

How can I assess the quality of DC motors from potential suppliers?

To assess the quality of DC motors, request product certifications, such as ISO 9001, and inquire about quality assurance processes. Conducting factory audits or visiting production facilities can provide insights into manufacturing practices. Additionally, seek references or reviews from other customers who have sourced motors from the supplier. Testing samples before committing to larger orders can also help ensure that the motors meet your performance specifications. -

What are the logistics considerations when importing DC motors?

When importing DC motors, consider factors such as shipping methods, customs regulations, and delivery times. Choose a reliable freight forwarder who understands the logistics of your target market, whether in Africa, South America, the Middle East, or Europe. Additionally, familiarize yourself with import duties and taxes that may apply, as these can significantly affect your overall costs. Planning for potential delays in customs clearance is also crucial to avoid disruptions in your supply chain. -

Can DC motors be customized to fit specific operational requirements?

Yes, many suppliers offer customization options for DC motors, allowing you to tailor specifications such as voltage, torque ratings, and mounting configurations. Discuss your specific needs with suppliers, including any unique features required for your application. Custom motors may involve longer lead times and potentially higher costs, so factor these considerations into your project timeline and budget. -

What are common applications for DC motors in various industries?

DC motors are widely used across diverse industries, including manufacturing, agriculture, and robotics. Common applications include conveyor systems, automated guided vehicles (AGVs), and portable medical devices. In agriculture, they power equipment like irrigation systems and harvesters. Understanding the specific applications of DC motors can help you identify the right motor type for your needs and explore innovative uses within your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dc machine motor

What Are the Key Takeaways for B2B Buyers of DC Machine Motors?

In conclusion, the strategic sourcing of DC machine motors offers numerous advantages for international B2B buyers. By understanding the diverse types of DC motors available, such as Permanent Magnet DC (PMDC) and gearmotors, businesses can select the most suitable solution for their specific applications. The ability to optimize power management, especially in energy-sensitive environments like agriculture and automation, can lead to significant operational efficiencies.

How Does Strategic Sourcing Enhance Competitive Advantage?

The value of strategic sourcing cannot be overstated; it enables companies to build strong supplier relationships, ensuring access to quality products at competitive prices. By leveraging global sourcing strategies, particularly from regions like Africa, South America, the Middle East, and Europe, buyers can mitigate risks and enhance their supply chain resilience.

What Does the Future Hold for DC Machine Motors?

As industries continue to evolve, the demand for efficient, reliable, and adaptable DC machine motors will only increase. Buyers are encouraged to stay informed about technological advancements and market trends to capitalize on new opportunities. Investing in high-quality DC motors today can set the stage for long-term success and innovation in your operations. Engage with suppliers who share your vision for sustainable and efficient solutions, and take the first step towards enhancing your operational capabilities.