Improve Efficiency: The Ultimate Diaphragm Valve Guide (2025)

Introduction: Navigating the Global Market for diaphragm valve

In the complex landscape of industrial procurement, sourcing diaphragm valves can present significant challenges for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. Understanding the nuances of diaphragm valves—ranging from their design variations to material compatibility—is crucial for optimizing operational efficiency and ensuring compliance with regional standards. This guide serves as a comprehensive resource, delving into the various types of diaphragm valves, their specific applications across industries, and practical insights on supplier vetting processes.

International B2B buyers will benefit from actionable strategies on how to effectively navigate the procurement process, including evaluating cost factors and understanding the long-term implications of valve selection on system performance. By addressing key considerations such as durability, maintenance, and compatibility with existing systems, this guide empowers buyers to make informed purchasing decisions that align with their operational needs and budgetary constraints.

Furthermore, we will highlight regional suppliers and manufacturers, providing insights into their offerings and how they cater to the unique requirements of markets in the UAE, Poland, and beyond. With this knowledge, B2B buyers can streamline their sourcing efforts, mitigate risks, and ultimately enhance their supply chain resilience.

Understanding diaphragm valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Diaphragm Valves | Operated by hand; simple design; cost-effective. | Water treatment, food and beverage. | Pros: Low cost, easy maintenance. Cons: Slower operation, not suitable for automation. |

| Pneumatic Diaphragm Valves | Actuated by compressed air; quick response time. | Chemical processing, pharmaceuticals. | Pros: Fast operation, suitable for automation. Cons: Requires air supply, higher initial cost. |

| Electric Diaphragm Valves | Electrically actuated; offers precise control. | Semiconductor manufacturing, laboratory use. | Pros: High precision, programmable. Cons: More complex, potential for electrical issues. |

| Sanitary Diaphragm Valves | Designed for hygienic applications; smooth surfaces. | Food processing, biotech. | Pros: Easy to clean, prevents contamination. Cons: Higher cost, specific material requirements. |

| High-Purity Diaphragm Valves | Suitable for ultra-clean applications; low dead volume. | UHP chemical distribution, research labs. | Pros: Ensures purity, minimizes contamination risk. Cons: Expensive, requires careful handling. |

What are the Characteristics of Manual Diaphragm Valves?

Manual diaphragm valves are characterized by their straightforward design and hand-operated mechanism. They are often used in applications like water treatment and food and beverage processing where cost-effectiveness is a priority. Buyers should consider the ease of maintenance and low initial investment, but be aware that these valves may not be suitable for processes requiring rapid or automated operation.

How Do Pneumatic Diaphragm Valves Function in B2B Settings?

Pneumatic diaphragm valves utilize compressed air for actuation, allowing for quick and reliable operation. They are commonly employed in industries such as chemical processing and pharmaceuticals, where speed and efficiency are essential. While they enable automation and faster response times, buyers must factor in the need for a compressed air supply and the higher initial costs associated with these systems.

What Makes Electric Diaphragm Valves a Precise Choice?

Electric diaphragm valves offer precise control through electrical actuation, making them ideal for applications that require exact flow regulation, such as semiconductor manufacturing and laboratory environments. Their programmability allows for sophisticated control systems. However, buyers should be cautious of the increased complexity and potential electrical issues that could arise.

Why Choose Sanitary Diaphragm Valves for Hygienic Applications?

Sanitary diaphragm valves are specifically designed to meet the stringent cleanliness standards of the food processing and biotech industries. They feature smooth surfaces that facilitate easy cleaning and minimize contamination risk. While they provide significant advantages in hygiene, buyers should be prepared for a higher price point and specific material requirements that may limit their options.

What are the Benefits of High-Purity Diaphragm Valves in Critical Applications?

High-purity diaphragm valves are engineered for ultra-clean applications, ensuring minimal dead volume and contamination risk. They are essential in sectors like UHP chemical distribution and research labs, where maintaining purity is critical. Although these valves can be costly and require careful handling, their benefits in safeguarding product integrity make them a valuable investment for businesses operating in sensitive environments.

Key Industrial Applications of diaphragm valve

| Industry/Sector | Specific Application of Diaphragm Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Controlling sterile fluid transfer in manufacturing processes | Ensures product purity and compliance with regulations | Material compatibility (e.g., PTFE), certifications (FDA, ISO), and automation options |

| Water Treatment | Regulating chemical dosing in water purification systems | Enhances efficiency and accuracy of chemical dosing | Corrosion resistance, size specifications, and actuator types |

| Food and Beverage | Managing flow of liquids in processing and bottling lines | Prevents contamination and maintains product quality | Compliance with food safety standards, material selection (e.g., FDA-approved), and ease of cleaning |

| Chemical Processing | Isolation of corrosive substances in pipelines | Protects equipment and personnel from hazardous materials | Durability of materials (e.g., PVC, CPVC), pressure ratings, and valve actuation options |

| Oil and Gas | Flow control in upstream and downstream applications | Increases operational efficiency and safety | High-pressure ratings, resistance to harsh chemicals, and reliability under extreme conditions |

How Are Diaphragm Valves Used in the Pharmaceutical Industry?

In the pharmaceutical sector, diaphragm valves are critical for controlling the sterile transfer of fluids during manufacturing processes. Their design minimizes contamination risks, ensuring that products meet stringent regulatory standards. Buyers from regions such as Africa and Europe should prioritize valves made from materials like PTFE, which offer excellent chemical resistance and compliance with FDA regulations. Automation options are also essential to enhance process efficiency and reduce manual handling.

What Role Do Diaphragm Valves Play in Water Treatment?

Diaphragm valves are utilized in water treatment facilities to regulate the dosing of chemicals, such as chlorine or coagulants, essential for purification. Their ability to provide precise control significantly enhances the effectiveness of treatment processes, ensuring safe drinking water. When sourcing these valves, international buyers should consider factors like corrosion resistance and the specific size requirements for their systems to ensure compatibility and performance.

Why Are Diaphragm Valves Important in Food and Beverage Processing?

In the food and beverage industry, diaphragm valves manage the flow of liquids in processing and bottling lines. They are designed to prevent contamination, maintaining the integrity and quality of consumable products. Buyers should focus on sourcing valves that comply with food safety standards and are made from FDA-approved materials. Additionally, ease of cleaning is crucial to meet hygiene requirements in production facilities.

How Do Diaphragm Valves Enhance Safety in Chemical Processing?

Diaphragm valves are essential in chemical processing for isolating corrosive substances within pipelines. Their robust construction protects both equipment and personnel from hazardous materials, ensuring safe operation. For international buyers, key considerations include the durability of materials, such as PVC or CPVC, and the pressure ratings that align with their specific applications to prevent leaks and failures.

What Advantages Do Diaphragm Valves Offer in Oil and Gas Applications?

In the oil and gas industry, diaphragm valves are employed for flow control in both upstream and downstream operations. Their reliability under extreme conditions and ability to handle high-pressure applications make them indispensable for maintaining operational efficiency and safety. Buyers should ensure that the valves sourced can withstand harsh chemicals and high-pressure environments, which are critical for preventing operational disruptions and ensuring safety in the field.

3 Common User Pain Points for ‘diaphragm valve’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Diaphragm Material for Specific Applications

The Problem: When sourcing diaphragm valves, many B2B buyers struggle to choose the appropriate diaphragm material that will withstand the specific conditions of their applications. For instance, industries in Africa dealing with corrosive chemicals may require materials like PTFE, while buyers in South America might need EPDM for its flexibility and durability in varying temperatures. This indecision can lead to operational inefficiencies, unexpected maintenance costs, and even product failures, jeopardizing project timelines and budgets.

The Solution: To effectively select the right diaphragm material, buyers should conduct a thorough analysis of the operating environment, including temperature ranges, chemical compatibility, and pressure conditions. Start by consulting with manufacturers’ datasheets and industry standards to understand the properties of different materials such as EPDM, FPM, and PTFE. Additionally, engaging with suppliers who provide sample materials for testing can help ascertain the best fit for your specific needs. It’s also beneficial to create a specification checklist based on operational requirements to streamline the selection process and ensure alignment with industry best practices.

Scenario 2: Overcoming Installation and Maintenance Challenges

The Problem: Many B2B buyers face challenges during the installation and maintenance of diaphragm valves. Complex installation processes can lead to improper setup, which in turn affects performance and reliability. Buyers from the Middle East, for example, may find that local technical expertise is limited, resulting in prolonged downtime and increased costs due to maintenance issues or improper handling of the valves.

The Solution: To mitigate installation and maintenance challenges, it is crucial for buyers to invest in comprehensive training for their technical teams. Suppliers often provide installation manuals and operational training sessions; take advantage of these resources to enhance your team’s skills. Additionally, consider the benefits of pneumatic actuation for diaphragm valves, as this can simplify operation and maintenance. Regular maintenance schedules should be established, and buyers should keep an inventory of essential spare parts, such as diaphragm and seal kits, to minimize downtime during repairs. Implementing a preventive maintenance program will not only prolong the lifespan of the valves but also ensure optimal performance.

Scenario 3: Managing Supply Chain Issues and Lead Times

The Problem: International B2B buyers often encounter significant supply chain challenges, especially when sourcing diaphragm valves from global suppliers. This can lead to extended lead times that disrupt project timelines and result in financial penalties or lost business opportunities. For instance, buyers in Europe may experience delays due to fluctuating transportation costs and customs regulations, making it difficult to plan projects effectively.

The Solution: To navigate supply chain issues, it is advisable for buyers to build strong relationships with multiple suppliers and manufacturers. Diversifying your supplier base can reduce reliance on a single source and mitigate the risk of delays. Additionally, negotiating favorable terms for faster shipping or prioritizing orders for critical projects can be beneficial. Keeping an open line of communication with suppliers about lead times and potential disruptions will help in adjusting project timelines accordingly. Moreover, considering local suppliers or manufacturers, particularly for standard diaphragm valve models, can significantly reduce lead times and improve responsiveness to urgent needs. Establishing a just-in-time inventory system can also help in managing stock levels effectively and ensuring that you have the necessary components available when required.

Strategic Material Selection Guide for diaphragm valve

What are the Key Properties of Common Diaphragm Valve Materials?

When selecting diaphragm valves, the choice of material is crucial for ensuring optimal performance across various applications. Here, we will analyze four common diaphragm materials: EPDM, FPM (Fluoroelastomer), PTFE (Polytetrafluoroethylene), and PVC (Polyvinyl Chloride). Each material has unique properties that affect its suitability for specific environments and applications.

EPDM: A Versatile and Cost-Effective Choice

Key Properties: EPDM is known for its excellent temperature resistance, typically ranging from -40°F to 250°F (-40°C to 121°C). It also exhibits good resistance to water, steam, and various chemicals, making it suitable for a wide range of applications.

Pros & Cons: The advantages of EPDM include its low cost and good elasticity, which enhances its durability. However, it may not perform well in environments with petroleum-based fluids or high temperatures beyond its rated limits.

Impact on Application: EPDM is ideal for water-based applications and is widely used in industries such as wastewater treatment and food processing. International buyers should ensure compliance with local standards for food-safe materials.

Considerations for International Buyers: Buyers in regions like Africa and South America should verify that EPDM meets ASTM D2000 standards for rubber materials. In Europe, compliance with REACH regulations is essential.

FPM: High Performance in Harsh Environments

Key Properties: FPM, or fluoroelastomer, offers exceptional chemical resistance and can withstand temperatures from -15°F to 400°F (-26°C to 204°C). Its strong resistance to solvents, oils, and fuels makes it a preferred choice for demanding applications.

Pros & Cons: The key advantage of FPM is its durability and resilience under extreme conditions. However, it is more expensive than other materials, which may impact budget-sensitive projects.

Impact on Application: FPM is particularly suited for chemical processing and petroleum applications, where exposure to aggressive media is common. Its ability to maintain integrity in high-pressure situations is a significant benefit.

Considerations for International Buyers: Buyers in the Middle East, where oil and gas applications are prevalent, should ensure that FPM components comply with relevant industry standards, such as API and ISO certifications.

PTFE: The Ultimate in Chemical Resistance

Key Properties: PTFE is renowned for its outstanding chemical resistance and can operate effectively at temperatures from -450°F to 500°F (-268°C to 260°C). Its non-stick properties also prevent media buildup, enhancing performance.

Pros & Cons: The primary advantage of PTFE is its ability to handle a wide range of aggressive chemicals without degradation. However, it is generally more expensive and can be challenging to manufacture due to its unique properties.

Impact on Application: PTFE is ideal for pharmaceutical and semiconductor industries, where purity and chemical compatibility are critical. Its use in high-purity applications makes it a preferred choice for international buyers focusing on quality.

Considerations for International Buyers: Buyers from Europe should look for PTFE products that meet stringent standards like FDA and USP Class VI for pharmaceutical applications. Compliance with DIN standards is also essential for industrial applications.

PVC: Economical and Effective for General Use

Key Properties: PVC is a cost-effective material with a temperature range of 32°F to 140°F (0°C to 60°C). It exhibits good resistance to many acids and bases, making it suitable for less aggressive environments.

Pros & Cons: PVC is widely used due to its low cost and ease of manufacturing. However, it is less durable in high-temperature applications and may not be suitable for all chemical environments.

Impact on Application: PVC is commonly used in irrigation, water treatment, and general industrial applications. Its affordability makes it attractive for projects with budget constraints.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that PVC products comply with local environmental regulations and standards such as ASTM D1784.

Summary Table of Diaphragm Valve Materials

| Material | Typical Use Case for diaphragm valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EPDM | Water-based applications, wastewater treatment | Cost-effective, good elasticity | Limited temperature and chemical resistance | Low |

| FPM | Chemical processing, petroleum applications | High chemical resistance, durability | Higher cost, limited temperature range | High |

| PTFE | Pharmaceutical, semiconductor industries | Outstanding chemical resistance | Expensive, manufacturing complexity | High |

| PVC | Irrigation, general industrial use | Low cost, easy to manufacture | Poor performance in high temperatures | Low |

This guide serves as a strategic material selection resource for B2B buyers, helping them make informed decisions based on application requirements, material properties, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for diaphragm valve

What Are the Main Stages in the Manufacturing Process of Diaphragm Valves?

The manufacturing process for diaphragm valves typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensuring the final product meets the necessary performance and quality standards.

Material Preparation: How Is It Done?

The first stage in the manufacturing of diaphragm valves is material preparation. High-quality materials such as PVC, CPVC, EPDM, PTFE, and FPM are selected based on the specific application requirements. Suppliers must ensure that the materials comply with international standards, such as ASTM D1784 for PVC and CPVC, which helps in guaranteeing the durability and reliability of the valves.

During this stage, materials are often subjected to a thorough inspection to identify any defects. This can include visual checks and dimensional measurements to ensure that the materials meet the required specifications.

What Techniques Are Used for Forming Diaphragm Valves?

Once the materials are prepared, the next stage is forming. This typically involves processes like injection molding for plastic components, which allows for precise shaping and consistency. For metal components, techniques such as machining and stamping are often employed.

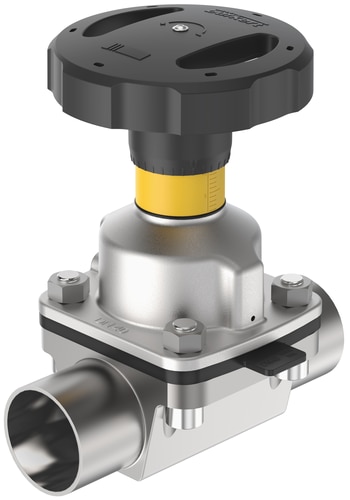

A stock image related to diaphragm valve.

In diaphragm valve manufacturing, forming also includes creating the diaphragm itself. This is a critical component, as it must provide a reliable seal. Techniques such as die-cutting or automated molding may be used to achieve the necessary thickness and flexibility, ensuring that the diaphragm can withstand the operational pressures and temperatures.

How Is Assembly Conducted for Diaphragm Valves?

The assembly stage involves the combination of all components into a complete diaphragm valve. This includes fitting the diaphragm, valve body, and actuator (if applicable).

During assembly, manufacturers often utilize jigs and fixtures to ensure precise alignment and secure fitting of components. Automated assembly lines can enhance efficiency and reduce human error, which is particularly important in high-volume manufacturing environments.

Quality checks are integrated into the assembly process. For example, visual inspections may be performed to verify that components are assembled correctly, and torque specifications are checked to ensure that fittings are secure.

What Finishing Processes Are Applied to Diaphragm Valves?

Finishing is the final stage in the manufacturing process, which involves surface treatments and coatings to enhance durability and corrosion resistance. Techniques such as polishing, coating with protective finishes, or applying lubricants may be employed.

A stock image related to diaphragm valve.

Additionally, manufacturers may conduct leak tests or pressure tests during this stage to ensure that the valves perform as expected under operational conditions. These tests are crucial for verifying that the diaphragm can maintain a proper seal, preventing leaks that could compromise system integrity.

What Are the Key Quality Assurance Measures for Diaphragm Valves?

Quality assurance (QA) is paramount in diaphragm valve manufacturing. International standards like ISO 9001 are widely adopted to ensure consistent quality management systems are in place. Moreover, specific industry standards such as CE marking for European markets or API standards for the oil and gas sector may also apply.

How Are Quality Control Checkpoints Established?

Quality control (QC) checkpoints are strategically integrated into the manufacturing process. These include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. Tests may include chemical composition analysis and physical property evaluations.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to ensure that processes are being followed correctly and that products are being produced to specifications. This can involve monitoring machine settings and conducting spot checks on assembled products.

-

Final Quality Control (FQC): After the assembly and finishing stages, a comprehensive inspection is performed. This includes functional testing, dimensional checks, and visual inspections to ensure that the product meets all specifications and standards.

What Testing Methods Are Commonly Used?

Testing methods for diaphragm valves can vary depending on the intended application but generally include:

-

Pressure Testing: This tests the valve’s ability to withstand operational pressures without leaking.

-

Cycle Testing: Valves may be cycled through their full range of motion to ensure durability and performance under repeated use.

-

Leak Testing: This involves using methods such as water immersion or gas detection to identify any potential leaks in the valve assembly.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies to ensure supplier compliance and quality:

-

Conduct Audits: Schedule regular audits of suppliers to evaluate their manufacturing processes, quality control measures, and adherence to international standards.

-

Request Documentation: Suppliers should provide documentation demonstrating compliance with relevant standards (e.g., ISO certifications, test reports).

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This can include pre-shipment inspections to verify that products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing diaphragm valves internationally, buyers must be aware of specific nuances that can impact quality control. For example:

-

Regional Standards: Different regions may have varying standards and regulations. Buyers should ensure that suppliers can meet the specific requirements for their target market, whether it be CE marking in Europe or compliance with local regulations in Africa or South America.

-

Communication Barriers: Language differences and cultural nuances can affect the clarity of quality expectations. Establishing clear communication channels and documentation can help mitigate misunderstandings.

A stock image related to diaphragm valve.

- Supply Chain Transparency: Ensure that suppliers provide visibility into their supply chains, including sourcing of materials and subcontractors. This can help identify potential quality risks.

By understanding the manufacturing processes and quality assurance measures associated with diaphragm valves, international B2B buyers can make informed decisions, ensuring that they procure reliable and high-quality products for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diaphragm valve’

To effectively procure diaphragm valves for your business needs, it is essential to follow a structured approach. This guide provides a step-by-step checklist to ensure you make informed decisions that align with your operational requirements and compliance standards.

Step 1: Define Your Technical Specifications

Understanding your specific needs is crucial before initiating the procurement process. Clearly outline the technical specifications for the diaphragm valves, including:

– Size and Material: Determine the appropriate size (e.g., 1/2 in. to 6 in.) and material (e.g., PVC, CPVC, PTFE) based on your application.

– Operating Conditions: Consider factors such as pressure, temperature, and the type of media the valve will handle. This will help narrow down suitable options.

Step 2: Research Available Types of Diaphragm Valves

Different diaphragm valves serve various functions, from manual to pneumatic actuation. Familiarize yourself with the different types to identify which best suits your needs:

– Manual vs. Automated: Decide if you require manual control or automated solutions for efficiency.

– Application-Specific Features: Look for features like position indicators or vapor barriers that may be critical for your specific application.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is necessary. This helps ensure reliability and quality:

– Supplier Background: Request company profiles, certifications, and case studies relevant to your industry.

– References: Seek references from other buyers, especially those within your region (e.g., Africa, South America, Middle East, Europe), to gauge supplier reliability.

Step 4: Request Samples and Technical Documentation

Acquiring samples is vital for assessing quality and suitability. Request the following:

– Product Samples: Test the diaphragm valves under your specific conditions to ensure they meet performance expectations.

– Technical Manuals: Obtain installation and operation manuals to understand maintenance needs and ensure compatibility with your existing systems.

Step 5: Assess Compliance and Certifications

Ensuring that your diaphragm valves comply with industry standards is crucial for operational safety and quality assurance:

– Regulatory Certifications: Check for relevant certifications (e.g., ISO, ASTM) that guarantee adherence to quality standards.

– Material Safety Data Sheets (MSDS): Request MSDS for the valve materials to understand the safety measures required during handling.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to discuss terms:

– Pricing and Discounts: Negotiate prices, including bulk order discounts or payment terms.

– Delivery and Lead Times: Clarify delivery schedules to ensure they align with your project timelines.

Step 7: Finalize the Purchase and Plan for Maintenance

After finalizing your order, establish a maintenance plan to ensure longevity and performance:

– Regular Maintenance Checks: Schedule routine inspections and maintenance to prevent downtime.

– Spare Parts Availability: Confirm the availability of spare parts and accessories to facilitate quick repairs when needed.

Following this structured checklist will help you navigate the complexities of sourcing diaphragm valves effectively, ensuring that your procurement process is smooth and aligned with your operational goals.

Comprehensive Cost and Pricing Analysis for diaphragm valve Sourcing

Understanding the cost structure and pricing analysis for diaphragm valve sourcing is crucial for international B2B buyers. This section delves into the various components influencing costs, factors affecting pricing, and strategic insights to optimize purchasing decisions.

What Are the Key Cost Components for Diaphragm Valves?

-

Materials: The choice of materials significantly impacts the overall cost. Diaphragm valves can be made from PVC, CPVC, or high-end materials like PTFE and FPM. These materials offer different levels of durability and resistance, which can affect pricing. For instance, PTFE valves are generally more expensive due to their superior chemical resistance.

-

Labor: Labor costs vary by region and can affect the total manufacturing cost. In countries with higher wage standards, labor-intensive processes may increase the price of diaphragm valves. Understanding labor costs in the supplier’s location is essential for accurate budgeting.

-

Manufacturing Overhead: This includes costs associated with utilities, facilities, and indirect labor that contribute to the production of diaphragm valves. Efficient manufacturing processes can help reduce overhead costs, which may be passed on to buyers.

-

Tooling: The initial setup costs for molds and tooling can be substantial, especially for custom valve designs. These costs are often amortized over production runs, meaning higher volumes can lead to lower per-unit costs.

-

Quality Control (QC): Investing in robust QC processes ensures that the valves meet industry standards, which can add to the overall cost. Buyers should consider the implications of quality on operational efficiency and long-term costs, as inferior products may lead to higher maintenance expenses.

-

Logistics: Shipping costs can vary widely based on the supplier’s location and the buyer’s destination. Factors such as distance, shipping method, and import duties will influence the total cost of acquisition.

-

Margin: Suppliers typically add a markup to cover their costs and profit margins. Understanding the market dynamics and average margins in the diaphragm valve industry can aid buyers in evaluating price competitiveness.

How Do Price Influencers Affect Diaphragm Valve Costs?

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs) that can influence pricing. Larger orders may qualify for bulk discounts, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom valves with specific features or materials will incur higher costs due to the additional engineering and manufacturing required. Buyers should clearly define their specifications to avoid unnecessary expenses.

-

Material Quality and Certifications: Valves that meet specific industry certifications (e.g., ISO, FDA) may command higher prices. However, investing in certified products can reduce risks related to compliance and operational failures.

-

Supplier Factors: The reputation, reliability, and location of the supplier can greatly affect pricing. Established suppliers may charge a premium, but they often provide better support and product reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for assessing the total landed cost of diaphragm valves. Different terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall pricing.

What Are Effective Tips for Buyers Negotiating Diaphragm Valve Prices?

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building long-term relationships can lead to better deals and more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and potential downtime costs. A higher upfront investment may be justified if it leads to lower long-term costs.

-

Research Market Trends: Stay informed about market prices and trends in diaphragm valve sourcing. This knowledge can enhance negotiation leverage and help identify fair pricing.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers allows buyers to compare costs and identify the best value. Be sure to evaluate the total cost, including shipping and duties.

-

Consider Regional Factors: For buyers from Africa, South America, the Middle East, and Europe, regional market conditions and trade agreements can impact pricing. Understanding these nuances can lead to more informed purchasing decisions.

Disclaimer on Pricing

It’s important to note that prices for diaphragm valves can vary significantly based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and consult multiple suppliers for the most accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing diaphragm valve With Other Solutions

Exploring Alternatives to Diaphragm Valves: What Are Your Options?

In the realm of fluid control, diaphragm valves are widely recognized for their versatility and reliability. However, B2B buyers should consider various alternatives that may better suit specific applications or operational needs. This section provides a comparative analysis of diaphragm valves against two notable alternatives: Ball Valves and Gate Valves. Each option has unique advantages and potential drawbacks that can influence procurement decisions.

Comparison Table

| Comparison Aspect | Diaphragm Valve | Ball Valve | Gate Valve |

|---|---|---|---|

| Performance | Excellent for throttling and flow control | Ideal for on/off control with minimal pressure drop | Suitable for full flow applications |

| Cost | Generally moderate to high | Typically lower cost, depending on size | Moderate cost, varies with material and size |

| Ease of Implementation | Requires proper installation and alignment | Easier to install, compact design | Installation can be complex, requires space |

| Maintenance | Regular maintenance needed for diaphragm replacement | Low maintenance, durable with fewer moving parts | Moderate maintenance, prone to wear over time |

| Best Use Case | Ideal for corrosive, viscous, or sanitary applications | Best for quick shut-off in clean systems | Best for high-flow, low-pressure drop applications |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Ball Valves?

Ball valves are highly favored for their straightforward design and efficiency in applications requiring rapid opening and closing. They achieve minimal pressure drop, making them suitable for systems where flow rate is critical. However, they are not ideal for throttling purposes, as partially opened ball valves can lead to turbulence and flow instability. Additionally, while ball valves are generally lower in cost, they may not perform well in applications involving corrosive materials unless specifically designed for such environments.

How Do Gate Valves Compare to Diaphragm Valves?

Gate valves are designed to provide a straight-line flow path, making them excellent for applications where full flow is required. They are particularly advantageous in high-flow scenarios, such as in water supply systems. However, gate valves lack the throttling capabilities of diaphragm valves, which can be a significant drawback in processes requiring precise flow control. Maintenance can also be a concern, as gate valves may experience wear over time due to their sliding mechanism, especially in high-frequency applications.

Conclusion: How to Choose the Right Valve for Your Needs

When selecting a valve solution, B2B buyers must consider the specific requirements of their applications. Diaphragm valves excel in situations where flow control and the handling of corrosive substances are paramount. In contrast, ball valves may be more cost-effective and easier to implement for straightforward on/off applications. Gate valves, while effective for high-flow scenarios, may not be the best choice for systems requiring throttling. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for diaphragm valve

What Are the Key Technical Properties of Diaphragm Valves?

When considering diaphragm valves for your industrial needs, understanding the technical specifications is crucial for ensuring compatibility and functionality. Here are some essential properties to consider:

-

Material Grade

Diaphragm valves can be constructed from various materials, including PVC, CPVC, FPM, EPDM, and PTFE. The choice of material affects the valve’s chemical resistance, temperature tolerance, and overall durability. For instance, PTFE is suitable for aggressive chemicals, making it ideal for applications in the pharmaceutical or chemical processing industries. Selecting the right material grade can prevent costly failures and downtime. -

Size and Flow Rate

Diaphragm valves are available in a range of sizes, typically from 1/2 inch to 6 inches. The size directly influences the flow rate and pressure drop across the valve. It is essential to match the valve size with your system requirements to ensure efficient flow control. Oversized or undersized valves can lead to operational inefficiencies and increased energy costs. -

End Connections

Diaphragm valves come with various end connection types, such as true-union, threaded, or flanged. The choice of connection affects installation flexibility and compatibility with existing piping systems. Understanding the end connection requirements can facilitate smoother integration into your operations, minimizing installation time and costs. -

Actuation Type

Diaphragm valves can be manually operated or actuated pneumatically or electrically. The actuation method impacts the valve’s responsiveness and the degree of automation in your processes. Pneumatic actuation, for example, allows for quicker response times and can be integrated into automated control systems, enhancing operational efficiency. -

Service Life and Maintenance

The expected service life of a diaphragm valve, often quantified in operating cycles, is a critical specification. High-quality valves can operate for up to 100,000 cycles, reducing the frequency of replacements and maintenance. Understanding the maintenance requirements and service life can help you plan for budget allocations and minimize interruptions in your operations.

What Are Common Trade Terms Related to Diaphragm Valves?

Familiarity with industry jargon is important for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end product. When sourcing diaphragm valves, knowing whether a supplier is an OEM can help you assess quality and compatibility with your existing systems. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially if you are operating in markets like Africa or South America, where supply chain dynamics can differ significantly. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. This process is important for comparing costs and ensuring you get the best deal when purchasing diaphragm valves or related components. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms can help avoid misunderstandings regarding shipping, insurance, and delivery responsibilities, particularly important for B2B buyers in regions like the Middle East and Europe. -

CPVC and PVC Cell Class

These terms refer to the classification of the materials used in the construction of diaphragm valves, ensuring compliance with industry standards like ASTM D1784. Understanding these classifications can help you select valves that meet regulatory requirements for your specific application. -

Pneumatic Actuation

This refers to the use of compressed air to operate the valve. It is essential in applications requiring quick and precise control, making it an important consideration when selecting diaphragm valves for automated processes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the diaphragm valve Sector

What Are the Current Market Dynamics and Key Trends in the Diaphragm Valve Sector?

The diaphragm valve market is experiencing significant growth, driven by increasing demand across various industries such as pharmaceuticals, water treatment, and food processing. Key global drivers include the need for precision control in fluid handling and the rising focus on automation and smart manufacturing. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe (notably the UAE and Poland), should be aware of the growing trend towards digitalization in sourcing. Technologies such as IoT and AI are transforming how diaphragm valves are monitored and controlled, enabling predictive maintenance and improved operational efficiency.

Emerging sourcing trends also highlight the shift towards e-commerce platforms, where buyers can easily compare product specifications, prices, and supplier reliability. Additionally, there is a noticeable increase in demand for customizable diaphragm valves tailored to specific industry needs, which can enhance operational efficiency. Buyers should consider suppliers that offer comprehensive product lines, including various materials like PVC, CPVC, EPDM, and PTFE, to ensure compatibility with their processes.

How Is Sustainability and Ethical Sourcing Impacting the Diaphragm Valve Industry?

Sustainability is becoming a pivotal consideration in the diaphragm valve sector, with increasing pressure on manufacturers to minimize environmental impact. Buyers are now prioritizing suppliers that implement sustainable practices, such as using recyclable materials and reducing energy consumption during production. This shift not only aligns with global sustainability goals but also resonates with the growing consumer demand for environmentally friendly products.

Ethical sourcing is equally important, with many B2B buyers seeking transparency in their supply chains. Suppliers that can demonstrate compliance with ‘green’ certifications, such as ISO 14001 for environmental management systems, are more likely to gain trust and preference from international buyers. In this context, diaphragm valves made from certified materials, such as those featuring low volatile organic compounds (VOCs), are increasingly sought after. Buyers should actively seek partnerships with suppliers who prioritize sustainability and ethical practices, as this can enhance their own brand reputation and operational resilience.

What Is the Evolution of the Diaphragm Valve Technology?

The diaphragm valve has evolved significantly since its inception, originally designed for simple on/off applications. Over the years, advancements in materials science and engineering have led to the development of valves capable of handling more complex processes, including those requiring high purity and precise control. The introduction of automation technologies, such as pneumatic and electric actuation, has further enhanced the functionality of diaphragm valves, making them indispensable in industries that demand strict compliance with safety and quality standards.

Today, diaphragm valves are not just functional components; they are integral to the automation and digital transformation of industrial processes. As the industry continues to innovate, future developments may focus on integrating smart technologies that provide real-time monitoring and data analysis, further optimizing performance and efficiency. For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of diaphragm valve

-

How do I choose the right diaphragm valve for my application?

Selecting the appropriate diaphragm valve involves considering factors such as the medium being controlled, temperature and pressure requirements, and the environment where the valve will be installed. For example, if you are working with corrosive substances, materials like PTFE or PVDF are recommended. Additionally, assess the valve’s size and connection type—options include threaded, flanged, or true-union socket—to ensure compatibility with your existing piping. Consulting technical datasheets and engaging with suppliers for expert advice can also aid in making an informed decision. -

What are the key features to look for in a diaphragm valve?

When sourcing diaphragm valves, focus on features such as material compatibility, actuation type (manual, pneumatic, or electric), and ease of maintenance. Look for valves that provide visual position indicators for operational clarity. Additionally, ensure the valve design minimizes entrapment areas for better cleaning and flow efficiency, especially in high-purity applications. Finally, consider the service life and warranty offered by the manufacturer, as these can indicate overall quality and reliability. -

What customization options are available for diaphragm valves?

Most manufacturers offer various customization options for diaphragm valves, including material selection, size, end connections, and actuation type. You can also request specific diaphragm materials, such as EPDM, FPM, or PTFE, based on the fluid being handled. For unique applications, some suppliers may provide tailored solutions that meet specific operational requirements, such as increased pressure ratings or specialized coatings for corrosion resistance. Communicating your needs directly with manufacturers can help you find the best solution. -

What are the minimum order quantities (MOQs) for diaphragm valves?

Minimum order quantities for diaphragm valves can vary significantly by manufacturer and product type. While some suppliers may allow orders as low as one unit, others may set MOQs in the hundreds, particularly for specialized or custom products. It’s essential to check with your supplier about their specific MOQ policies, especially if you’re a smaller business or are testing a new product line. Negotiating terms may be possible, especially if you establish a long-term purchasing relationship. -

How can I ensure the quality of diaphragm valves from suppliers?

To ensure quality, verify that suppliers adhere to recognized international standards such as ISO 9001 for quality management systems. Request product certifications and test reports to confirm that the diaphragm valves meet industry-specific requirements. Additionally, consider suppliers that provide detailed product datasheets and offer a clear return or warranty policy. Engaging in supplier audits or asking for references from other customers can further validate the quality of the products offered. -

What payment terms should I expect when sourcing diaphragm valves internationally?

Payment terms for international transactions can vary, but common options include advance payment, letters of credit, and payment upon delivery. For larger orders, suppliers may offer flexible payment terms to facilitate cash flow. It’s crucial to clarify these terms upfront and ensure they align with your budgeting and cash management strategies. Additionally, consider the impact of currency exchange rates and potential fees on your overall costs when negotiating payment arrangements. -

What logistics considerations should I keep in mind when importing diaphragm valves?

When importing diaphragm valves, it’s essential to consider shipping methods, lead times, and customs regulations. Evaluate whether air or sea freight is more cost-effective based on urgency and volume. Ensure compliance with local import regulations and tariffs, which can vary significantly across regions like Africa, South America, the Middle East, and Europe. Collaborating with a reliable freight forwarder can simplify the logistics process and help navigate any potential customs challenges. -

How do I handle warranties and service for diaphragm valves?

Warranties for diaphragm valves generally cover defects in materials and workmanship for a specified period. Always read the warranty terms thoroughly and understand the claims process. For ongoing service, inquire if the supplier offers maintenance training or support to ensure optimal valve performance. Establishing a relationship with the supplier can also facilitate quicker service and access to replacement parts, which is crucial for minimizing downtime in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for diaphragm valve

The diaphragm valve market is poised for growth, driven by increasing demand across various sectors including water treatment, pharmaceuticals, and food processing. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic sourcing of diaphragm valves can significantly enhance operational efficiency and reduce costs. Key considerations should include understanding the specific material and design requirements for your applications, as well as evaluating suppliers’ capabilities in providing reliable products that meet international standards.

Investing in high-quality diaphragm valves, such as those available in PVC, CPVC, and various diaphragm materials, can lead to improved system performance and longevity. Furthermore, leveraging automation technologies can streamline operations, ensuring consistent quality and reducing manual handling risks.

As the market evolves, buyers are encouraged to stay informed about emerging technologies and supplier innovations. Engaging with suppliers who demonstrate a commitment to sustainability and compliance with regulatory standards will be essential. Now is the time to act—explore strategic partnerships and evaluate your sourcing strategies to position your business for success in the diaphragm valve landscape.