Improve Quality with Butt Hinges: The Complete Guide (2025)

Introduction: Navigating the Global Market for butt hinges

In an increasingly interconnected global market, sourcing high-quality butt hinges can pose significant challenges for B2B buyers. From ensuring compatibility with various door styles to navigating diverse supplier landscapes across Africa, South America, the Middle East, and Europe, the process can be daunting. This comprehensive guide aims to equip international buyers with the essential knowledge needed to make informed decisions regarding butt hinges, covering everything from the different types and applications to supplier vetting and cost considerations.

Understanding the nuances of butt hinges—such as material types, weight capacities, and finishes—is crucial for ensuring optimal performance and longevity in various settings, whether residential or commercial. The guide not only delves into the technical specifications of butt hinges but also provides insights on market trends, regional variations, and best practices for purchasing.

By addressing common queries and concerns, this resource empowers B2B buyers to navigate the complexities of the global hinge market effectively. With actionable strategies tailored to the unique needs of buyers from diverse regions like Germany, France, and beyond, this guide serves as a vital tool for enhancing procurement strategies and achieving operational efficiency. Ultimately, it seeks to streamline the purchasing process, fostering confidence and clarity in every decision made regarding butt hinges.

Understanding butt hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Butt Hinges | Simple design, typically made of steel; available in various finishes | Residential doors, light commercial | Pros: Cost-effective, easy to install. Cons: Limited load capacity compared to heavier variants. |

| Ball Bearing Butt Hinges | Incorporate ball bearings for smoother operation; suitable for heavier doors | Commercial applications, heavy doors | Pros: Enhanced durability, reduced friction. Cons: Higher initial cost than standard hinges. |

| Continuous Hinges | Long, continuous design providing uniform support along the door edge | High-traffic commercial doors | Pros: Provides stability and security, minimizes sagging. Cons: Requires precise installation, may be more expensive. |

| Security Butt Hinges | Feature additional locking mechanisms or tamper-resistant designs | Secure access points, gates | Pros: Increased security, deter unauthorized access. Cons: Can be more complex to install and maintain. |

| Specialty Butt Hinges | Customized designs for specific applications (e.g., concealed, offset) | Unique projects, custom furniture | Pros: Tailored solutions for unique needs. Cons: Potentially higher costs and longer lead times. |

What are the Characteristics of Standard Butt Hinges?

Standard butt hinges are the most common type used in residential settings. They are typically made of steel and come in various finishes such as brass, chrome, and nickel. These hinges are ideal for light to moderate door weights and are easy to install, making them a go-to choice for many B2B buyers in construction and renovation. When purchasing, consider the size, finish, and load capacity to ensure they meet the specific requirements of your project.

How Do Ball Bearing Butt Hinges Enhance Performance?

Ball bearing butt hinges are designed to handle heavier loads and provide smoother operation compared to standard hinges. The inclusion of ball bearings reduces friction, which is particularly beneficial in commercial settings where doors are frequently used. Buyers should prioritize these hinges for applications involving heavy doors or high-traffic areas. The investment in ball bearing hinges can lead to long-term savings due to their durability and reduced maintenance needs.

What are the Benefits of Continuous Hinges?

Continuous hinges, also known as piano hinges, run the entire length of the door, providing uniform support that minimizes sagging and enhances security. They are particularly well-suited for high-traffic commercial environments, such as schools and hospitals, where doors are subject to heavy use. When selecting continuous hinges, B2B buyers should consider the material and finish to ensure they are compatible with the overall design and functionality of the door system.

How Do Security Butt Hinges Provide Enhanced Protection?

Security butt hinges are specifically designed to offer increased protection against tampering and unauthorized access. They often feature additional locking mechanisms or reinforced materials. These hinges are ideal for applications where security is a paramount concern, such as gates or secure access points. Buyers should evaluate the installation requirements and maintenance considerations, as these hinges may require more complex setups than standard options.

What are Specialty Butt Hinges and When Should They be Used?

Specialty butt hinges encompass a variety of custom designs tailored for specific applications, including concealed hinges for aesthetic purposes or offset hinges for unique architectural needs. These hinges allow for greater flexibility in design and function, making them suitable for custom furniture and unique projects. However, B2B buyers should be aware of potentially higher costs and longer lead times associated with these specialized products. Ensuring compatibility with existing systems is crucial when selecting specialty hinges.

Key Industrial Applications of butt hinges

| Industry/Sector | Specific Application of Butt Hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Door installations in residential and commercial buildings | Provides durability and ease of operation, enhancing security and accessibility | Material quality (stainless steel for longevity), load capacity, and finish options to match design aesthetics |

| Furniture Manufacturing | Cabinet and drawer assembly | Enables smooth opening and closing, contributing to functionality and user experience | Size specifications, weight capacity, and aesthetic compatibility with furniture designs |

| Automotive | Vehicle doors and hatches | Ensures reliable operation under various environmental conditions, contributing to vehicle safety | Resistance to corrosion, ability to withstand heavy loads, and compliance with automotive standards |

| Industrial Equipment | Access panels and machinery covers | Facilitates maintenance and access, improving operational efficiency | Customization options for size and load requirements, as well as durability against harsh environments |

| Retail and Hospitality | Display cases and service counters | Enhances customer interaction and product visibility while ensuring security | Aesthetic appeal, locking mechanisms, and ease of installation for rapid deployment in commercial settings |

How Are Butt Hinges Used in Construction Projects?

In the construction industry, butt hinges are essential for door installations in both residential and commercial buildings. They offer durability and smooth operation, ensuring that doors can withstand frequent use while providing security. For international buyers, particularly those in Africa and the Middle East, sourcing hinges that meet local building codes and environmental conditions is crucial. Buyers should consider the material quality, such as stainless steel, to prevent corrosion and ensure longevity in diverse climates.

What Role Do Butt Hinges Play in Furniture Manufacturing?

In furniture manufacturing, butt hinges are commonly used in the assembly of cabinets and drawers. They allow for seamless opening and closing, which enhances the overall functionality and user experience of furniture pieces. B2B buyers from South America and Europe should focus on size specifications and weight capacities to ensure that the hinges can support the intended use. Additionally, aesthetic compatibility with furniture designs is vital, as it impacts the overall appeal of the product.

How Are Butt Hinges Applied in the Automotive Industry?

The automotive sector utilizes butt hinges for vehicle doors and hatches, ensuring reliable operation under various environmental conditions. These hinges are critical for safety and ease of access, making them a key component in vehicle design. Buyers in Europe, especially in countries like Germany and France, should prioritize sourcing hinges that resist corrosion and can withstand heavy loads, adhering to stringent automotive standards.

What Are the Benefits of Butt Hinges in Industrial Equipment?

In industrial applications, butt hinges are used for access panels and machinery covers, facilitating maintenance and access to critical components. This application improves operational efficiency by reducing downtime. International buyers must consider customization options for size and load requirements, as well as durability against harsh environments. Sourcing hinges that can withstand operational stresses is essential for maintaining equipment functionality.

How Do Butt Hinges Enhance Retail and Hospitality Environments?

In the retail and hospitality sectors, butt hinges are employed in display cases and service counters, enhancing customer interaction and product visibility. The right hinge can also improve security features, safeguarding valuable merchandise. Buyers should focus on aesthetic appeal and locking mechanisms to ensure that the hinges align with the overall design of the retail space. Additionally, ease of installation is a key consideration for rapid deployment in commercial settings.

3 Common User Pain Points for ‘butt hinges’ & Their Solutions

Scenario 1: Squeaky Hinges Leading to Operational Disruptions

The Problem: In commercial settings, such as offices or hotels, the constant use of doors can lead to wear and tear, resulting in squeaky hinges. This issue not only causes discomfort to employees and guests but also signals a lack of maintenance, which can reflect poorly on the business. B2B buyers often face the challenge of sourcing durable butt hinges that can withstand heavy usage while minimizing noise and maintenance.

The Solution: To address this problem, businesses should consider investing in high-quality, ball-bearing butt hinges designed for heavy-duty use. These hinges provide smoother operation and significantly reduce friction, which in turn minimizes noise. When sourcing, look for options that are specifically marketed as “squeak-free” or those that include lubricating features. It’s also advisable to implement a regular maintenance schedule to inspect and lubricate hinges, ensuring longevity and optimal performance. For businesses operating in regions with high humidity, such as parts of Africa and South America, opting for stainless steel or corrosion-resistant finishes will enhance durability and prevent rusting.

Scenario 2: Misalignment Issues Causing Door Malfunction

The Problem: Misalignment of doors is a common issue that can occur due to improper installation or the natural settling of buildings over time. This misalignment can lead to increased friction on butt hinges, causing doors to stick, which can be particularly problematic in commercial environments where accessibility is critical. B2B buyers often struggle with finding the right specifications to ensure that their hinges can accommodate potential misalignment.

The Solution: To mitigate misalignment issues, it is essential to choose butt hinges with adjustable features. Look for hinges that allow for vertical and horizontal adjustments after installation. Additionally, sourcing hinges that are designed to handle a wider range of tolerances can be beneficial. When specifying butt hinges, consider including a slight over-sizing to allow for any building movement. It’s also wise to conduct a thorough assessment of the door frame and surrounding structure before installation. Collaborating with a professional installer can ensure that adjustments are made correctly, reducing the likelihood of future issues.

Scenario 3: Difficulty in Selecting the Right Finish and Size for Butt Hinges

The Problem: B2B buyers often encounter confusion when it comes to selecting the appropriate finish and size for butt hinges, especially when dealing with diverse environments such as hotels, offices, or industrial settings. The wrong choice can lead to aesthetic mismatches or functional inadequacies, affecting the overall appeal and functionality of the doors.

The Solution: To make informed decisions, buyers should begin by clearly defining their requirements based on the environment and type of door being used. For instance, in high-traffic areas, opting for larger, heavier-duty hinges is advisable. Additionally, consider the finish that will best complement the existing decor while also providing durability. For example, matte black or brushed nickel finishes are popular in modern designs, while polished brass can enhance traditional aesthetics. It’s crucial to consult with suppliers who provide samples or comprehensive guides on hinge specifications. Engaging with industry experts can also provide insights into the latest trends and best practices for selecting finishes that will maintain their appearance over time, especially in climates prone to corrosion.

Strategic Material Selection Guide for butt hinges

What Are the Key Materials Used for Butt Hinges?

When selecting butt hinges for various applications, understanding the materials used is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials: stainless steel, brass, steel, and plastic, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Stainless Steel Perform in Butt Hinges?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°F (427°C) and is suitable for environments with high humidity or exposure to chemicals.

Pros & Cons: The primary advantage of stainless steel butt hinges is their durability and resistance to rust, making them ideal for outdoor and marine applications. However, they tend to be more expensive than other materials, which can impact budget considerations for large projects.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and various chemicals, making it suitable for industrial applications.

Considerations for International Buyers: In Europe, compliance with standards such as DIN EN 1935 is essential for quality assurance. Buyers in Africa and South America should consider local availability and import regulations, as stainless steel can be costlier due to shipping.

What Advantages Does Brass Offer for Butt Hinges?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent machinability and resistance to corrosion, particularly in marine environments. It has a moderate temperature rating and is less likely to tarnish compared to other metals.

Pros & Cons: Brass butt hinges are aesthetically pleasing and provide good durability, making them suitable for decorative applications. However, they are softer than stainless steel and may not hold up well under heavy loads.

Impact on Application: Brass is often used in residential settings, particularly for interior doors where aesthetics are a priority. It is less suitable for heavy-duty applications.

Considerations for International Buyers: European buyers often prefer brass for its aesthetic qualities, while buyers in the Middle East may need to consider the impact of high temperatures on brass’s structural integrity.

Why Choose Steel for Butt Hinges?

Key Properties: Steel is a robust material that offers high strength and load-bearing capacity. It is often coated with zinc or other finishes to enhance corrosion resistance, but its base metal is susceptible to rust without proper treatment.

Pros & Cons: Steel butt hinges are cost-effective and suitable for heavy-duty applications. However, they require regular maintenance to prevent rust, particularly in humid environments.

Impact on Application: Steel is ideal for commercial and industrial applications where strength is critical. However, it may not be suitable for environments with high moisture without additional protective coatings.

Considerations for International Buyers: Buyers in regions with high humidity should prioritize galvanized or coated steel options. Compliance with ASTM standards can also be a factor in procurement decisions.

What Role Does Plastic Play in Butt Hinges?

Key Properties: Plastic hinges are lightweight and resistant to corrosion, making them suitable for specific applications. They can withstand moderate temperatures but are generally less durable than metal options.

Pros & Cons: The primary advantage of plastic butt hinges is their low cost and lightweight nature. However, they lack the strength and durability of metal hinges, making them unsuitable for heavy-duty applications.

Impact on Application: Plastic hinges are often used in lightweight applications such as cabinets or indoor doors where aesthetics and weight are more critical than strength.

Considerations for International Buyers: Plastic hinges may not meet the same durability standards as metal hinges, which could be a concern in regions with stringent building codes, such as Germany and France.

Summary Table of Material Selection for Butt Hinges

| Material | Typical Use Case for Butt Hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and marine applications | Excellent corrosion resistance | Higher cost compared to other metals | High |

| Brass | Residential and decorative doors | Aesthetic appeal and machinability | Softer, not suitable for heavy loads | Medium |

| Steel | Commercial and industrial settings | High strength and load-bearing | Susceptible to rust without treatment | Low |

| Plastic | Lightweight applications like cabinets | Low cost and lightweight | Less durable than metal options | Low |

This strategic material selection guide provides essential insights for international B2B buyers in Africa, South America, the Middle East, and Europe, enabling informed decisions that align with specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for butt hinges

What Are the Key Stages in the Manufacturing Process of Butt Hinges?

The manufacturing of butt hinges involves several critical stages, each requiring precision and attention to detail to ensure the final product meets international quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality raw materials, typically stainless steel, brass, or zinc-plated steel. The selected materials are inspected for defects and then cut into appropriate sizes. For stainless steel, properties such as corrosion resistance and tensile strength are crucial, especially for applications in humid or outdoor environments.

-

Forming: The prepared metal sheets undergo forming processes, which can include stamping, bending, or forging. Stamping is commonly used to create the hinge leaves, where metal sheets are pressed into molds to achieve the desired shape. Precision is key in this stage, as any inaccuracies can affect the hinge’s functionality.

-

Assembly: Once the individual components are formed, they are assembled. This typically involves attaching the hinge leaves with a pin or a screw mechanism. Ball bearing hinges may also incorporate bearings during this stage to enhance smooth operation. Automated assembly lines are often used to improve efficiency, but manual checks are essential to ensure proper alignment and function.

-

Finishing: The finishing stage involves applying protective coatings or treatments to enhance durability and aesthetics. Common finishes include powder coating, oil rub, or chrome plating, which not only provide a decorative touch but also protect against corrosion. This stage may also include polishing to achieve a smoother surface.

How Is Quality Assurance Ensured During Butt Hinge Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that butt hinges meet specific international and industry standards. Key QA practices include adherence to standards such as ISO 9001, which outlines quality management systems, and CE marking for compliance with European safety and environmental requirements.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers must provide certificates of compliance to verify that materials meet specified standards. This step is crucial for preventing defects that could arise from inferior materials.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs at various stages. This includes checking dimensions, tolerances, and the integrity of welds or bonds. Automated systems can aid in real-time monitoring, allowing for immediate corrective actions if deviations are detected.

-

Final Quality Control (FQC): Once the butt hinges are fully assembled, they undergo final inspections. This includes functional testing, where hinges are opened and closed multiple times to assess performance. Visual inspections are also conducted to identify any surface defects or inconsistencies in finish.

What International Standards and Certifications Should B2B Buyers Consider?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding relevant standards and certifications is essential. Compliance with these standards not only ensures product quality but also facilitates smoother international trade.

-

ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Buyers should verify that suppliers hold current ISO 9001 certification.

-

CE Marking: For buyers in Europe, CE marking is mandatory for many products, indicating compliance with health, safety, and environmental protection standards. This mark is particularly relevant for butt hinges used in construction and industrial applications.

-

API Standards: For specialized applications, such as those in the oil and gas sector, manufacturers may need to comply with API (American Petroleum Institute) standards. These standards ensure that products can withstand specific operational conditions, which may be critical for certain buyers.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers should conduct thorough due diligence, which can include:

-

Supplier Audits: Regular audits of manufacturing facilities can help buyers understand the production processes and quality control measures in place. This includes reviewing documentation related to quality management systems and production methodologies.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s performance over time. This may include data on defect rates, corrective actions taken, and improvements made.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes. Such inspections can be particularly valuable for large orders or when entering into new supply agreements.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International buyers should be aware of several nuances in quality control that may vary by region:

-

Cultural Differences in Quality Perception: Different regions may have varying standards for what constitutes acceptable quality. Buyers should communicate their specific requirements clearly to avoid misunderstandings.

-

Regulatory Compliance: Each country may have unique regulatory requirements that affect quality assurance. For example, materials used in construction in Europe may need to comply with stricter environmental regulations compared to those in Africa or South America.

-

Logistics and Transportation Considerations: Quality control doesn’t end at manufacturing. Buyers should consider how products are packaged and shipped, as improper handling can lead to damage. Ensuring that suppliers use appropriate packaging materials can help maintain product integrity during transit.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing butt hinges, ultimately leading to successful partnerships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘butt hinges’

In the realm of B2B procurement, sourcing butt hinges requires careful consideration to ensure quality, compatibility, and value. This practical sourcing guide outlines the essential steps to effectively procure butt hinges that meet your business needs.

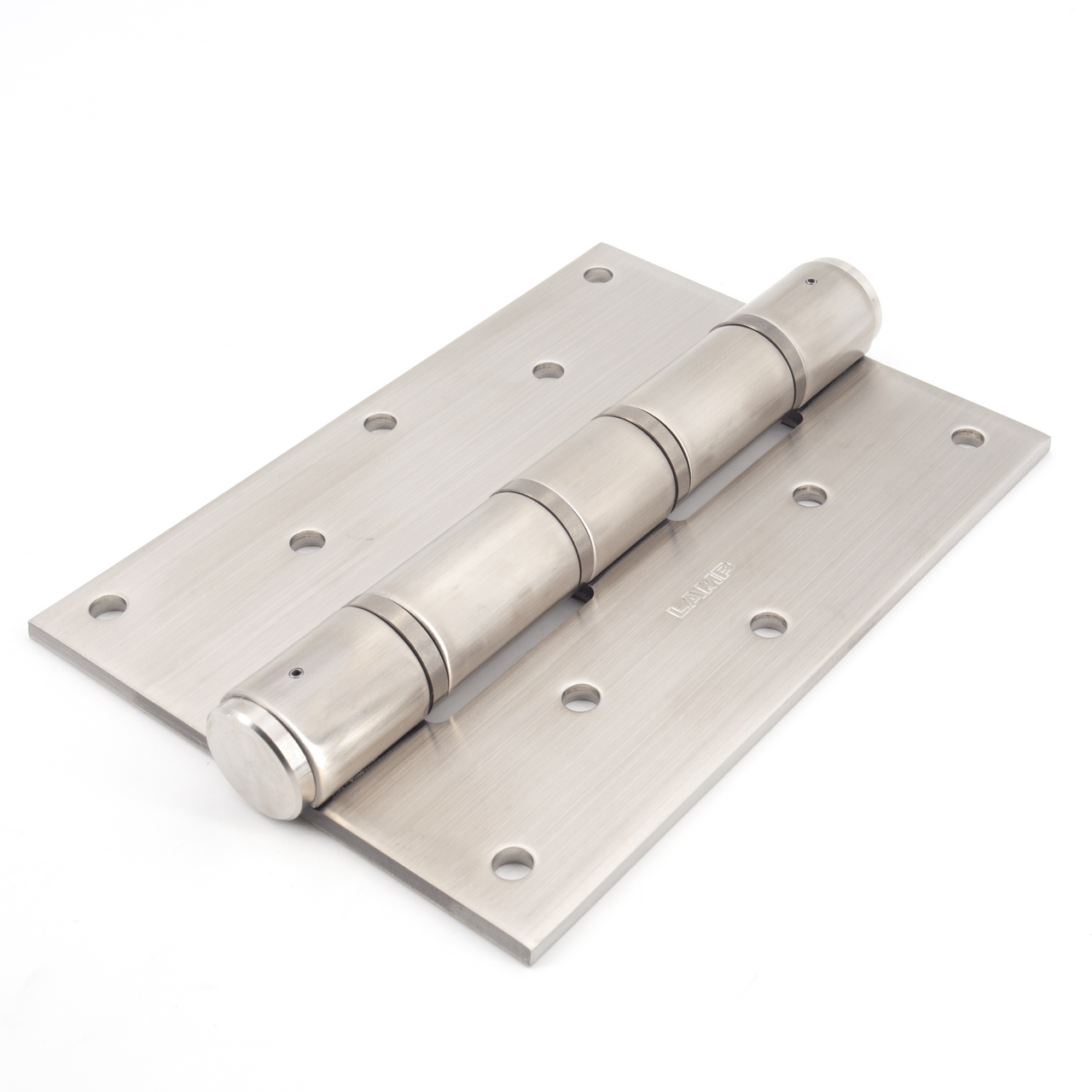

A stock image related to butt hinges.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the butt hinges will perform effectively for your intended application. Consider factors such as:

– Size and Dimensions: Measure the door or application to determine the appropriate hinge size.

– Weight Capacity: Ensure the hinges can support the weight of the door or gate.

– Material Type: Choose between stainless steel, brass, or other materials based on durability requirements and environmental factors.

Step 2: Research Available Finishes and Styles

Understanding the various finishes and styles available will help you select hinges that not only function well but also match your aesthetic preferences. Consider:

– Finish Options: Common finishes include satin nickel, oil-rubbed bronze, and polished chrome. Each finish offers different aesthetic qualities and corrosion resistance.

– Style Compatibility: Ensure the hinge style complements the design of the doors and surrounding architecture.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is vital to conduct thorough evaluations. This step ensures that you partner with a reliable source that can meet your quality and delivery standards. Look for:

– Company Reputation: Research supplier reviews and ratings, particularly from businesses in similar industries.

– Product Range: A supplier with a diverse inventory can provide flexibility for future projects and needs.

Step 4: Request Samples and Product Specifications

Always request samples or detailed product specifications before finalizing your order. This step allows you to assess the quality and suitability of the hinges. Pay attention to:

– Material Quality: Examine the sample for robustness and craftsmanship.

– Design Features: Check for essential features such as bearing types (plain vs. ball-bearing) that affect performance.

Step 5: Verify Supplier Certifications

Certifications can provide assurance regarding the quality and safety standards of the hinges. Look for suppliers that hold relevant certifications such as:

– ISO Certification: Indicates adherence to international quality management standards.

– Product-Specific Certifications: Depending on your region, certain certifications may be required for specific applications, particularly in commercial settings.

Step 6: Understand Pricing and Payment Terms

Having a clear understanding of pricing structures and payment terms is crucial for budgeting and financial planning. When evaluating suppliers, consider:

– Bulk Pricing Options: Inquire if discounts are available for larger orders.

– Payment Flexibility: Understand payment terms, including deposits, net payment periods, and accepted payment methods.

Step 7: Plan for Shipping and Delivery

Finally, consider logistics and delivery timelines to ensure your project remains on schedule. Key points to assess include:

– Lead Times: Confirm how long it will take for your order to be processed and shipped.

– Shipping Costs: Evaluate shipping options and costs to avoid unexpected expenses.

A stock image related to butt hinges.

By following these steps, B2B buyers can make informed decisions when sourcing butt hinges, ensuring they meet both operational requirements and aesthetic preferences while maintaining budgetary constraints.

Comprehensive Cost and Pricing Analysis for butt hinges Sourcing

What Are the Key Cost Components of Butt Hinges?

When sourcing butt hinges, understanding the breakdown of costs is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Stainless steel and brass are common choices, with stainless steel typically being more expensive due to its durability and resistance to corrosion.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Automated production can reduce labor costs, while handcrafted finishes may increase them.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient production processes can lower overhead, which may be reflected in the pricing.

-

Tooling: The cost of molds and dies for producing specific hinge designs can be substantial, particularly for custom orders. Standardized products generally have lower tooling costs.

-

Quality Control (QC): Ensuring that hinges meet industry standards and specifications can add to production costs. Certifications such as ISO can enhance the perceived value but also increase prices.

-

Logistics: Shipping costs, including freight and import duties, play a significant role in the overall cost structure, especially for international transactions.

-

Margin: Suppliers will add a profit margin on top of their costs, which can vary widely based on market demand and competition.

How Do Price Influencers Affect Butt Hinge Sourcing?

Several factors can influence the pricing of butt hinges, particularly for international buyers:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or special finishes typically incur higher costs. Buyers should evaluate if standard options meet their requirements to avoid unnecessary expenses.

-

Material Selection: The choice between different materials can lead to significant price variations. For example, opting for a more economical material could lead to cost savings, but may compromise durability.

-

Quality and Certifications: Higher-quality hinges with certifications will naturally be more expensive. Buyers should assess the trade-off between cost and quality based on application needs.

-

Supplier Factors: Established suppliers may command higher prices due to their reputation and reliability. However, newer suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital for determining who bears the cost and risk during shipping, which can influence overall pricing.

What Are the Best Buyer Tips for Cost-Efficient Butt Hinge Sourcing?

To ensure a smart purchasing decision when sourcing butt hinges, consider the following tips:

-

Negotiate: Always negotiate pricing, especially for large orders. Suppliers may have flexibility in pricing that can lead to significant savings.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes installation, maintenance, and potential replacement costs over time.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures based on local manufacturing costs and market conditions. For instance, buyers in Europe may encounter higher prices due to stringent quality standards, while sourcing from regions like Africa or South America could offer competitive pricing.

-

Research and Compare Suppliers: Spend time evaluating multiple suppliers. Look for those that provide transparent pricing structures, favorable payment terms, and good customer service.

-

Stay Informed on Market Trends: Keeping abreast of industry trends can help buyers anticipate price changes and make informed sourcing decisions.

Disclaimer on Indicative Prices

Prices for butt hinges can fluctuate based on the factors outlined above. The indicative prices mentioned in various sources should be treated as a guideline rather than fixed costs. Always confirm current pricing with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing butt hinges With Other Solutions

When considering the best solutions for door mechanisms, it’s essential to evaluate alternatives to butt hinges. While butt hinges are a popular choice for their simplicity and reliability, various alternatives may better suit specific applications, depending on performance requirements, budget constraints, and maintenance needs. This analysis will provide insights into how butt hinges compare with other hinge types, particularly in the context of international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Comparison Table of Butt Hinges and Alternatives

| Comparison Aspect | Butt Hinges | Continuous Hinges | Pivot Hinges |

|---|---|---|---|

| Performance | Good for standard door applications | Excellent for heavy and high-use doors | Ideal for specialized door designs |

| Cost | Generally low to moderate | Moderate to high | Moderate |

| Ease of Implementation | Easy installation | Requires precision during installation | More complex installation |

| Maintenance | Low maintenance | Low, but may require adjustments | Moderate, depending on design |

| Best Use Case | Residential and light commercial | Commercial and heavy-duty applications | Specialty doors (e.g., revolving) |

A stock image related to butt hinges.

What Are the Benefits and Drawbacks of Continuous Hinges?

Continuous hinges, also known as piano hinges, are long, narrow hinges that run the entire length of a door. They provide superior strength and stability, making them ideal for high-traffic environments such as schools, hospitals, and industrial facilities. The continuous design helps distribute weight evenly, reducing wear and tear on the door and frame.

Pros:

– Enhanced load-bearing capacity for heavy doors.

– Greater durability and longevity due to reduced stress points.

– Less susceptibility to misalignment over time.

Cons:

– Higher initial cost compared to butt hinges.

– Installation can be more complicated, requiring precise cutting and alignment.

How Do Pivot Hinges Compare to Butt Hinges?

Pivot hinges are designed to allow a door to pivot on a point at the top and bottom rather than on the side. This design is common in specialty applications such as revolving doors or large, heavy doors where traditional hinges may not provide adequate support.

Pros:

– Suitable for large or heavy doors, allowing for smooth operation.

– Offers a unique aesthetic appeal for architectural designs.

– Can save space in tight areas where standard hinges may not fit.

Cons:

– Installation is more complex and often requires professional assistance.

– May require more maintenance to ensure smooth operation.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between butt hinges and their alternatives, B2B buyers should consider the specific requirements of their projects. Factors such as the weight and size of the doors, frequency of use, budget, and aesthetic preferences will play significant roles in the decision-making process.

For residential projects or light commercial applications, butt hinges may suffice due to their cost-effectiveness and ease of installation. However, for high-traffic areas or specialized architectural designs, investing in continuous or pivot hinges may provide long-term benefits in terms of durability and performance. Ultimately, understanding the unique needs of each project will help buyers make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for butt hinges

What Are the Key Technical Properties of Butt Hinges?

Understanding the technical properties of butt hinges is crucial for international B2B buyers, especially when making informed purchasing decisions. Here are the essential specifications to consider:

-

Material Grade

– Butt hinges are commonly manufactured from various materials, including stainless steel, brass, and zinc-plated steel. The choice of material affects durability, corrosion resistance, and aesthetic appeal. For instance, stainless steel is preferred for outdoor applications due to its weather resistance, while brass is often chosen for its decorative qualities in interior settings. -

Hinge Size

– The size of the hinge is defined by its width and height, typically measured in inches. Common sizes include 3.5″, 4″, and 4.5″. The correct size is vital for ensuring the proper fit and function, particularly for heavy doors or gates. An incorrect size can lead to operational issues or structural failure. -

Hinge Radius

– The hinge radius refers to the rounded edges of the hinge leaf. Common radii include 1/4″ and 5/8″. This specification is critical for compatibility with the door frame and the overall aesthetic of the installation. A mismatch can lead to difficulties in installation or an unsightly appearance. -

Load Capacity

– Load capacity indicates the maximum weight the hinge can support without bending or breaking. This specification is particularly important for commercial applications where doors may be heavier due to materials or design. Ensuring that the load capacity aligns with the intended use is essential for safety and longevity. -

Pin Type

– The type of pin used in butt hinges can vary, including removable and non-removable options. Removable pins allow for easy maintenance and door removal, while non-removable pins offer enhanced security. Understanding the implications of each pin type is essential for both functionality and security considerations.

What Are Common Trade Terms Used in the Butt Hinge Industry?

Familiarizing yourself with industry-specific terminology can facilitate smoother transactions and better communication with suppliers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of butt hinges, understanding whether a supplier is an OEM can influence quality expectations and compatibility with existing products. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units that a supplier is willing to sell. This is particularly relevant for international buyers looking to optimize inventory and minimize costs. Knowing the MOQ helps in planning purchases and understanding cost implications. -

RFQ (Request for Quotation)

– An RFQ is a standard business process to invite suppliers to bid on specific products or services. For buyers of butt hinges, issuing an RFQ can lead to better pricing and terms, especially when purchasing in bulk. -

Incoterms (International Commercial Terms)

– These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with relevant Incoterms is crucial for ensuring that all parties understand their obligations in international transactions. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to its delivery. Understanding lead times is essential for inventory management and project planning, as delays can impact business operations.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions, fostering successful and efficient procurement processes.

Navigating Market Dynamics and Sourcing Trends in the butt hinges Sector

What Are the Current Market Dynamics and Key Trends in the Butt Hinges Sector?

The global market for butt hinges is experiencing robust growth, driven by several factors including the rising demand for residential and commercial construction, advancements in manufacturing technologies, and an increasing focus on customization. Regions such as Africa, South America, the Middle East, and Europe are witnessing significant investments in infrastructure, leading to a surge in the need for durable and reliable hardware solutions like butt hinges.

Emerging trends include the adoption of smart technologies and automation in manufacturing processes, which enhance efficiency and precision. International B2B buyers are increasingly looking for suppliers who can offer not just standard products but also customized solutions tailored to specific applications. In Europe, particularly in Germany and France, there is a growing emphasis on energy efficiency and sustainability, influencing the choice of materials and manufacturing processes for butt hinges.

Furthermore, the rise of e-commerce platforms has transformed sourcing practices. Buyers can now access a wider range of products and suppliers globally, allowing for better price comparisons and enhanced procurement strategies. As such, international B2B buyers must stay informed about market shifts, technological advancements, and the competitive landscape to make informed sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact the Butt Hinges Sector?

Sustainability is becoming a critical consideration for B2B buyers in the butt hinges sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, is under scrutiny. As consumers and businesses alike prioritize eco-friendly practices, suppliers are expected to adopt sustainable methods, including the use of recycled materials and energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction. Buyers are increasingly demanding transparency in the supply chain, seeking suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and various green certifications can enhance a supplier’s credibility and appeal to conscientious buyers.

Moreover, the trend toward “green” materials—such as those that reduce carbon footprints or utilize sustainable resources—can significantly influence purchasing decisions. By choosing suppliers committed to sustainability, international B2B buyers can not only reduce their environmental impact but also align with the values of their customers and stakeholders.

What Is the Evolution and History of Butt Hinges Relevant to Today’s B2B Buyers?

The evolution of butt hinges can be traced back to ancient civilizations, where simple pivot mechanisms were employed for doors and gates. Over centuries, the design and materials have advanced significantly, transitioning from wood and basic metals to high-grade stainless steel and other durable alloys. This evolution has been driven by the need for enhanced functionality, security, and aesthetic appeal.

In the modern context, butt hinges are available in various finishes and designs, catering to both residential and commercial applications. The introduction of ball-bearing mechanisms has further improved their performance, making them a preferred choice for high-traffic areas. Understanding this historical context allows international B2B buyers to appreciate the advancements in hinge technology and the importance of selecting the right type for specific applications, ensuring longevity and reliability in their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of butt hinges

-

How do I choose the right butt hinge for my project?

Selecting the appropriate butt hinge involves considering factors such as door weight, material, and usage frequency. For heavy doors, opt for ball-bearing hinges to ensure smooth operation and durability. It’s also crucial to match the hinge size to the door dimensions; standard sizes vary between 3.5 inches to 5 inches. Additionally, consider the finish and material, such as stainless steel or brass, to align with your design and environmental requirements. For commercial applications, ensure the hinges meet load-bearing standards to maintain safety and functionality. -

What are the common materials used for butt hinges?

Butt hinges are typically made from materials like stainless steel, brass, and zinc-plated steel. Stainless steel is favored for its corrosion resistance, making it ideal for outdoor or humid environments. Brass offers aesthetic appeal and is often used in residential settings. Zinc-plated steel provides a cost-effective option for interior applications. When sourcing internationally, verify the material specifications to ensure they meet your local standards and requirements. -

How can I verify the quality of butt hinges from suppliers?

To ensure quality, request samples from potential suppliers before making bulk purchases. Check for certifications that confirm adherence to international quality standards such as ISO 9001. It’s also beneficial to read customer reviews and seek references from other businesses in your region. Additionally, visiting the supplier’s manufacturing facility can provide insights into their production processes and quality control measures. -

What is the minimum order quantity (MOQ) for butt hinges?

MOQs for butt hinges can vary significantly depending on the supplier and the hinge type. Typically, manufacturers may set an MOQ ranging from 100 to 500 units for standard products. Custom designs may require higher MOQs due to the associated production costs. It’s advisable to discuss your needs with suppliers upfront to negotiate favorable terms, especially if you’re a small or medium-sized business. -

What payment terms should I expect when sourcing butt hinges internationally?

Payment terms can vary widely among suppliers. Common options include advance payment, 30% deposit with 70% balance before shipping, or net 30/60 days after delivery. Always clarify payment terms in your contract to avoid misunderstandings. For larger orders, consider using secure payment methods such as letters of credit or escrow services to protect your investment. -

How do I handle logistics and shipping for international orders of butt hinges?

When sourcing butt hinges internationally, it’s essential to collaborate with a reliable logistics provider. Discuss shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Understand the import regulations and customs duties applicable in your region to avoid unexpected costs. Additionally, ensure that your supplier provides all necessary documentation, including invoices and packing lists, to facilitate smooth customs clearance. -

Can I customize butt hinges for specific applications?

Yes, many manufacturers offer customization options for butt hinges to suit specific applications. Customizations can include size, finish, material, and additional features like security pins or non-removable designs. When discussing customization with suppliers, provide detailed specifications and intended use cases to ensure the final product meets your requirements. Be prepared for potential minimum order quantities and longer lead times associated with custom orders. -

What are the best practices for maintaining butt hinges?

Regular maintenance of butt hinges is crucial to ensure longevity and optimal performance. This includes periodic cleaning to remove dust and debris, which can cause wear. Lubricate the hinges with a suitable oil or grease to facilitate smooth movement. Inspect for signs of rust or corrosion, especially in outdoor applications, and replace hinges that show significant wear. Establishing a maintenance schedule can prevent costly repairs and replacements in the long run.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for butt hinges

In conclusion, strategic sourcing of butt hinges offers international B2B buyers significant advantages, including cost savings, improved supply chain efficiency, and access to high-quality products. By leveraging a diverse range of suppliers from regions such as Africa, South America, the Middle East, and Europe, businesses can ensure they meet specific project requirements while also tapping into local manufacturing capabilities.

Understanding the various types of butt hinges, such as those with ball bearings or decorative finishes, allows buyers to make informed decisions that align with their operational needs. Furthermore, establishing long-term relationships with reliable suppliers can enhance product availability and foster innovation in hinge solutions.

As global markets continue to evolve, staying ahead of trends in materials and design will be crucial for maintaining a competitive edge. International B2B buyers are encouraged to proactively engage with suppliers, explore new product lines, and consider sustainability in their sourcing strategies. By doing so, they will not only secure the best products but also contribute to a more sustainable future in the hardware industry. The time to optimize your sourcing strategy for butt hinges is now—start exploring your options today!