Improve Water Quality: The Complete Water System Filter Guide (2025)

Introduction: Navigating the Global Market for water system filter

Navigating the complexities of the global market for water system filters can be a daunting task for international B2B buyers, especially when sourcing reliable solutions to ensure clean and safe water. With varying water quality challenges across regions in Africa, South America, the Middle East, and Europe, understanding the nuances of different water filtration systems is crucial. This comprehensive guide delves into the diverse types of water filters available, their specific applications, and the importance of supplier vetting. It also addresses cost considerations and best practices for installation and maintenance, allowing businesses to make informed decisions that align with their unique operational needs.

The guide empowers B2B buyers to navigate the intricacies of selecting the right water filtration systems by providing actionable insights tailored to their regional contexts. Whether you’re a buyer in Brazil seeking a robust whole-house filtration solution or a procurement manager in South Africa looking for specialized water treatment systems, this resource equips you with the knowledge necessary to enhance water quality and operational efficiency. By understanding the key features, benefits, and potential challenges associated with various water filters, businesses can avoid common pitfalls and ensure they invest in systems that deliver long-term value.

Understanding water system filter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Whole House Water Filters | Filters water at the main supply line for the entire building. | Residential buildings, hotels, industrial sites. | Pros: Comprehensive filtration, improved appliance lifespan. Cons: Higher upfront cost, requires space for installation. |

| Reverse Osmosis Systems | Utilizes a semi-permeable membrane to remove contaminants. | Laboratories, food and beverage industries. | Pros: High purity water, effective against a wide range of pollutants. Cons: Slower filtration rate, requires regular maintenance. |

| Under Sink Water Filters | Compact systems installed beneath sinks for point-of-use. | Restaurants, cafes, offices. | Pros: Space-saving, easy installation. Cons: Limited capacity, may require frequent filter changes. |

| Carbon Water Filters | Uses activated carbon to absorb impurities and chemicals. | Residential, commercial kitchens, aquariums. | Pros: Effective against chlorine and odors, relatively low cost. Cons: Limited lifespan, may not remove all contaminants. |

| Well Water Filtration Systems | Designed specifically for private well water sources. | Rural homes, agricultural businesses. | Pros: Targets specific well-related contaminants, protects plumbing. Cons: Initial testing required, may need multiple filtration stages. |

What Are Whole House Water Filters and Their B2B Applications?

Whole house water filters are designed to treat water at the point of entry, ensuring that every faucet and appliance in a building receives filtered water. They are ideal for residential buildings, hotels, and industrial sites where water quality is critical. B2B buyers should consider the initial investment and space requirements, but the long-term benefits include improved water quality and extended lifespan of plumbing and appliances.

How Do Reverse Osmosis Systems Work for B2B Buyers?

Reverse osmosis (RO) systems employ a semi-permeable membrane to effectively remove a wide range of contaminants from water, making them particularly suitable for laboratories and the food and beverage industry. Buyers should weigh the high purity water output against the slower filtration rate and maintenance needs. RO systems can be a vital investment for businesses requiring stringent water quality standards.

Why Choose Under Sink Water Filters for Commercial Use?

Under sink water filters are compact and can be easily installed in kitchens and offices, providing point-of-use filtration. They are particularly advantageous for restaurants and cafes where space is limited. B2B buyers should consider the filter’s capacity and replacement frequency, as these systems may require more frequent maintenance compared to whole-house solutions.

What Are the Benefits of Carbon Water Filters?

Carbon water filters utilize activated carbon to effectively absorb impurities, especially chlorine and odors, making them popular in residential settings and commercial kitchens. Their low cost and ease of installation make them appealing to B2B buyers. However, it is essential to note that these filters may have a limited lifespan and may not eliminate all types of contaminants.

How Do Well Water Filtration Systems Address Specific Needs?

Well water filtration systems are tailored for private well water sources, addressing unique contaminants found in rural or agricultural settings. These systems are crucial for protecting plumbing and ensuring safe drinking water. B2B buyers should conduct initial water quality testing to identify specific issues, which may necessitate multiple filtration stages for optimal results.

Key Industrial Applications of water system filter

| Industry/Sector | Specific Application of Water System Filter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Water filtration for beverage production | Ensures product quality, compliance with health regulations, and enhances taste | Certifications (e.g., NSF), filter lifespan, and maintenance needs |

| Agriculture | Irrigation water filtration | Prevents clogging of irrigation systems, improves crop yield, and enhances soil health | Local water quality analysis, filter type compatibility, and durability |

| Pharmaceuticals | Purification of water for drug manufacturing | Guarantees high purity standards, essential for product efficacy and safety | Compliance with industry standards, ease of maintenance, and cost-effectiveness |

| Hospitality | Water filtration in hotels and restaurants | Enhances guest experience, reduces bottled water costs, and ensures safe drinking water | Scalability, maintenance requirements, and integration with existing systems |

| Industrial Manufacturing | Process water filtration for production lines | Increases equipment lifespan, reduces downtime, and improves product quality | Customization options, availability of replacement parts, and supplier reliability |

How Are Water System Filters Used in the Food and Beverage Industry?

In the food and beverage sector, water system filters are essential for ensuring the quality and safety of products. They are employed to filter water used in beverage production, including soft drinks, juices, and alcoholic beverages. By removing impurities and contaminants, these filters help maintain flavor integrity and meet stringent health regulations. International buyers should prioritize sourcing filters with relevant certifications, such as NSF, to ensure compliance with local standards and regulations.

What Role Do Water Filters Play in Agriculture?

Water system filters are critical in agriculture, particularly for irrigation systems. They prevent sediment and contaminants from clogging irrigation lines, which can adversely affect crop yield and soil health. By utilizing high-quality filtration systems, farmers can optimize water usage and promote sustainable agricultural practices. Buyers in this sector should consider local water quality assessments and choose filters that are compatible with their irrigation systems to ensure efficiency and longevity.

How Are Water Filters Essential in Pharmaceuticals?

In the pharmaceutical industry, water filtration systems are vital for producing high-purity water required in drug manufacturing processes. These systems help eliminate bacteria, viruses, and other contaminants that could compromise product safety and efficacy. Buyers must focus on compliance with industry-specific standards and certifications, such as cGMP, to ensure that their filtration systems meet the rigorous demands of pharmaceutical applications. Additionally, ease of maintenance and filter longevity are crucial factors to consider.

Why Are Water Filters Important for the Hospitality Sector?

Hotels and restaurants use water filtration systems to enhance guest experience by providing clean and safe drinking water. By installing these systems, businesses can reduce reliance on bottled water, leading to cost savings and a lower environmental impact. International buyers should look for scalable solutions that can accommodate varying water demands and assess maintenance requirements to ensure uninterrupted service.

How Do Water System Filters Benefit Industrial Manufacturing?

In industrial manufacturing, water filtration systems are used to purify process water, which is critical for maintaining equipment performance and product quality. These filters help prevent scaling and corrosion, thereby extending the lifespan of machinery and reducing downtime. When sourcing filtration systems, businesses should consider customization options that meet specific manufacturing needs, as well as the availability of replacement parts to ensure ongoing operational efficiency.

3 Common User Pain Points for ‘water system filter’ & Their Solutions

Scenario 1: Inconsistent Water Quality Compromising Operations

The Problem: For many businesses, especially in sectors like food and beverage or pharmaceuticals, the quality of water used in production is critical. B2B buyers often face challenges with inconsistent water quality due to fluctuating local supply conditions, such as high levels of contaminants like chlorine, heavy metals, or bacteria. This inconsistency can lead to production delays, compromised product quality, and even regulatory penalties, creating significant operational headaches.

The Solution: To address this issue, businesses should invest in a robust whole house water filtration system. These systems can be customized to target specific contaminants based on local water quality reports. B2B buyers should conduct a thorough analysis of their water source and opt for systems that utilize multiple stages of filtration—such as sediment, activated carbon, and UV light—to ensure comprehensive purification. Additionally, regular maintenance and timely replacement of filter cartridges should be emphasized to maintain optimal performance. Partnering with reliable suppliers who offer installation and support services can further ensure that the filtration system operates efficiently, providing a consistent quality of water for all operational needs.

Scenario 2: High Maintenance Costs Due to Inefficient Filters

The Problem: B2B buyers often find themselves facing unexpectedly high maintenance costs associated with water filtration systems. This can happen when filters are not well-suited to the specific contaminants present in the water supply, leading to frequent clogging and the need for premature replacements. These costs can quickly add up, straining budgets and impacting overall profitability.

The Solution: To mitigate this issue, buyers should invest time in selecting the right filtration system tailored to their specific water challenges. Conducting a water quality test before purchasing a system is crucial; this will help identify the types and concentrations of contaminants that need to be filtered out. Once identified, buyers can choose systems designed for those specific needs, such as iron and manganese filters for well water or reverse osmosis systems for municipal supplies with high TDS (total dissolved solids). Additionally, establishing a scheduled maintenance plan with a certified technician can prevent operational downtime and further reduce unexpected costs. Implementing these strategies not only enhances the lifespan of the filters but also optimizes the total cost of ownership.

Scenario 3: Compliance Challenges with Water Quality Standards

The Problem: Companies, especially those in regulated industries such as healthcare and food production, must adhere to strict water quality standards. B2B buyers often struggle to keep up with evolving regulations and ensure that their water filtration systems meet these standards. Non-compliance can lead to legal issues, fines, and damage to the company’s reputation.

The Solution: To stay compliant, it’s essential for buyers to select water filtration systems that are certified by recognized standards, such as NSF/ANSI. These certifications indicate that the products have been rigorously tested and proven to meet specific contaminant reduction claims. Additionally, buyers should engage with suppliers who provide documentation and support regarding compliance and regulatory updates. Regular training for staff on water quality management and maintenance practices can further bolster compliance efforts. Implementing a proactive approach that includes regular water quality testing and adjustments to the filtration system as needed will ensure that businesses remain compliant while also safeguarding their operations and reputation.

By addressing these pain points with targeted solutions, international B2B buyers can significantly improve their water quality management strategies, ensuring operational efficiency and regulatory compliance.

Strategic Material Selection Guide for water system filter

What Are the Key Materials Used in Water System Filters?

When selecting materials for water system filters, it is crucial to understand the various options available and their implications on performance, durability, and compliance with international standards. Here, we analyze four common materials used in water filtration systems: plastic, stainless steel, activated carbon, and ceramic. Each material has distinct properties that affect its suitability for different applications, particularly in the international B2B market.

How Does Plastic Perform in Water Filtration Systems?

Key Properties: Plastic materials, such as polypropylene and PVC, are lightweight and resistant to corrosion, making them suitable for various water filtration applications. They can handle moderate temperature and pressure ratings, typically up to 60°C (140°F) and 10 bar (145 psi).

Pros & Cons: Plastic is generally low in cost and easy to manufacture, allowing for mass production. However, it may not be as durable as metal options and can degrade under UV exposure or extreme temperatures. This can lead to leaching of harmful substances into the filtered water, raising health concerns.

Impact on Application: Plastic filters are often used in residential and light commercial applications. They are compatible with various filtration media but may not be suitable for high-pressure systems.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding plastic materials, particularly in regions like Europe, where stringent health and safety standards apply.

What Are the Benefits of Stainless Steel in Water Filtration?

Key Properties: Stainless steel is known for its high strength, corrosion resistance, and ability to withstand high temperatures and pressures, often rated above 100°C (212°F) and 20 bar (290 psi).

Pros & Cons: The durability and longevity of stainless steel make it an excellent choice for industrial applications. However, it is more expensive than plastic and may require more complex manufacturing processes.

Impact on Application: Stainless steel filters are ideal for high-capacity systems and environments where hygiene is critical, such as in food and beverage industries.

Considerations for International Buyers: Compliance with standards like ASTM or DIN is essential when sourcing stainless steel components. Buyers should also consider the specific grades of stainless steel required for their applications, as this can vary by region.

How Does Activated Carbon Enhance Water Filtration?

Key Properties: Activated carbon is a porous material with a high surface area, allowing it to effectively adsorb contaminants. It is typically used in granular or block form and can operate effectively at ambient temperatures and pressures.

Pros & Cons: Activated carbon filters are excellent for removing chlorine, volatile organic compounds (VOCs), and bad odors. However, they have a limited lifespan and require regular replacement to maintain effectiveness.

Impact on Application: These filters are commonly used in both residential and commercial applications, particularly in systems designed for improving taste and odor.

Considerations for International Buyers: Buyers should verify that the activated carbon meets local standards for drinking water safety, especially in regions with rigorous regulations like Europe.

What Role Does Ceramic Play in Water Filtration Systems?

Key Properties: Ceramic filters are made from natural clay materials and are known for their fine pore structure, which can filter out bacteria and sediments effectively. They can withstand moderate temperatures and pressures.

Pros & Cons: Ceramic filters are reusable and can be cleaned, extending their lifespan. However, they can be brittle and may require careful handling during installation.

Impact on Application: These filters are particularly useful in rural or developing regions where water quality is compromised, making them suitable for point-of-use applications.

Considerations for International Buyers: Buyers should ensure that ceramic filters comply with local health regulations and standards, particularly in regions like Africa and South America, where water quality issues are prevalent.

Summary of Material Selection for Water System Filters

| Material | Typical Use Case for Water System Filter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Residential and light commercial filters | Low cost and lightweight | Less durable, potential leaching | Low |

| Stainless Steel | Industrial and high-capacity systems | High strength and corrosion resistance | Higher cost and complex manufacturing | High |

| Activated Carbon | Taste and odor improvement | Effective at removing VOCs and chlorine | Limited lifespan, requires regular replacement | Medium |

| Ceramic | Point-of-use filtration | Reusable and effective against bacteria | Brittle, requires careful handling | Medium |

This guide provides a comprehensive overview of the strategic material selection for water system filters, equipping international B2B buyers with the insights needed to make informed decisions tailored to their specific regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for water system filter

What Are the Main Stages of Manufacturing Water System Filters?

The manufacturing process of water system filters involves several critical stages, each essential for ensuring the quality and effectiveness of the final product. Understanding these stages is crucial for B2B buyers looking to source reliable filtration systems.

Material Preparation: What Materials Are Used in Water Filters?

The first stage in the manufacturing process is material preparation. Water filters typically utilize a combination of materials, including:

- Activated Carbon: Essential for removing impurities and chemicals, activated carbon is often used in various filter types, such as carbon block and granular activated carbon filters.

- Membrane Materials: In reverse osmosis systems, semi-permeable membranes are vital for separating contaminants from water.

- Polypropylene: Commonly used for filter housings and cartridges, polypropylene is durable and resistant to corrosion.

- Ceramics: Employed in some filters for their ability to filter out bacteria and sediments.

Each of these materials must meet specific quality standards to ensure they perform effectively. B2B buyers should inquire about the origin and quality certification of these materials from suppliers.

Forming: How Are Water Filters Shaped and Structured?

Once the materials are prepared, the next stage is forming. This involves shaping the materials into the desired filter forms. Key techniques used in this stage include:

- Extrusion: This process is often used for forming activated carbon blocks and membranes, where raw materials are pushed through a die to create specific shapes.

- Molding: For polypropylene and other plastic components, injection molding is commonly employed to produce precise and consistent parts.

- Cutting and Shaping: After molding, the components may be cut and shaped to fit specific filter designs.

These techniques must be executed with precision to ensure that each filter functions as intended. Buyers should assess the manufacturing capabilities of their suppliers to ensure they can produce high-quality products.

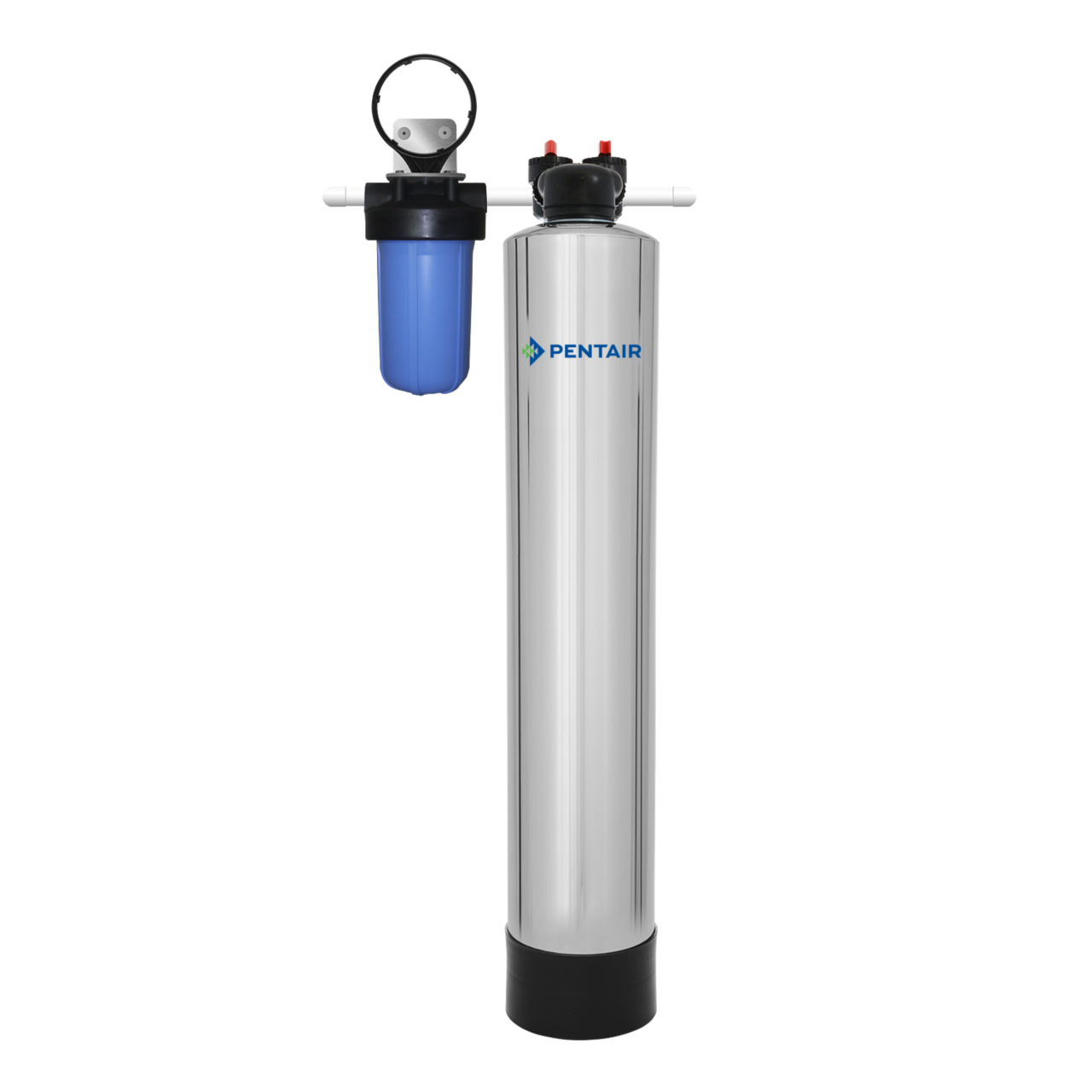

A stock image related to water system filter.

Assembly: What Is Involved in the Assembly of Water Filters?

The assembly stage is where all the components come together to create the finished water filter. This stage typically includes:

- Component Integration: All parts, including the filter media, housing, and fittings, are assembled according to strict specifications.

- Sealing: Proper sealing is crucial to prevent leaks and ensure the integrity of the filter. This may involve the use of O-rings or gaskets.

- Quality Checks During Assembly: Manufacturers often conduct in-process quality checks to ensure that each assembled unit meets design specifications.

B2B buyers should look for suppliers that have a well-defined assembly process with quality checks in place to minimize defects.

Finishing: What Final Touches Are Applied to Water Filters?

The finishing stage involves preparing the filters for packaging and shipment. This includes:

- Cleaning: Ensuring that all components are free from contaminants and residues before packaging.

- Labeling: Each filter must be accurately labeled with specifications, certifications, and usage instructions.

- Packaging: Proper packaging protects filters during transportation and storage, maintaining their integrity until they reach the end user.

Buyers should inquire about the finishing processes and materials used in packaging to ensure the filters are delivered in optimal condition.

How Is Quality Assurance Managed in Water Filter Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for water system filters. It ensures that products meet international and industry-specific standards, providing confidence to B2B buyers.

What International Standards Should B2B Buyers Consider?

International standards play a significant role in ensuring the quality and safety of water filters. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to ensure consistent quality in their processes.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- NSF/ANSI Standards: These standards certify that water filters meet specific performance criteria and safety requirements.

B2B buyers should verify that their suppliers hold relevant certifications, as this can significantly impact the reliability of the filters.

What Quality Control Checkpoints Are Essential?

Quality control (QC) checkpoints are integral to maintaining high manufacturing standards. Common QC checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify and rectify issues before the final product is completed.

- Final Quality Control (FQC): A thorough inspection of the finished products ensures that they meet all specifications before packaging.

B2B buyers should ask potential suppliers about their QC processes and how they handle discrepancies in product quality.

What Common Testing Methods Are Used in Water Filter Manufacturing?

Testing methods are vital in ensuring the performance and safety of water filters. Common testing methods include:

- Flow Rate Testing: This evaluates how quickly water can pass through the filter, ensuring it meets performance specifications.

- Contaminant Reduction Testing: Testing how effectively the filter removes specific contaminants (e.g., chlorine, heavy metals) is crucial for compliance with health standards.

- Durability Testing: Assessing how filters perform under various conditions helps ensure they can withstand typical usage scenarios.

B2B buyers should request testing reports and certifications from suppliers to verify the effectiveness of their filters.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure they receive reliable products. Strategies include:

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing processes, quality control systems, and compliance with standards.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC results.

- Engaging Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of the supplier’s quality control practices.

Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers with robust quality assurance measures in place to mitigate risks associated with product quality.

What Nuances Should International Buyers Be Aware Of?

International B2B buyers must be aware of specific nuances that can affect their purchasing decisions:

- Regulatory Compliance: Different regions have varying regulations regarding water filter performance and safety. Buyers should ensure that their suppliers comply with local laws.

- Cultural and Logistical Considerations: Understanding the local context in which suppliers operate can help buyers navigate potential challenges related to shipping, customs, and communication.

- Sustainability Practices: Increasingly, buyers are looking for suppliers that prioritize sustainable manufacturing practices, which can impact their sourcing decisions.

By taking these factors into account, B2B buyers can make informed decisions when sourcing water system filters that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water system filter’

Introduction

In the global marketplace, procuring a reliable water system filter is crucial for ensuring the safety and quality of water supplies in various applications, from industrial operations to municipal services. This step-by-step checklist will guide international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—through the essential steps of sourcing water filtration systems. By following these guidelines, you can make informed decisions that meet your organization’s specific needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to clearly define your technical specifications. Consider factors such as the type of contaminants you need to filter (e.g., heavy metals, chlorine, sediments), the required flow rate, and the volume of water to be processed.

– Identify the source of your water—whether municipal or well water—as this influences the filtration system’s design.

– Ensure your specifications align with local regulations regarding water quality.

Step 2: Research Available Filtration Technologies

Understanding the different filtration technologies available is crucial for making an informed choice. Common types include reverse osmosis, activated carbon filters, and whole-house filtration systems.

– Evaluate the pros and cons of each technology based on your defined specifications.

– Look for systems that offer multiple stages of filtration for enhanced effectiveness.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge reliability and performance.

– Verify their experience with the specific filtration technology you require.

– Check for industry certifications that indicate compliance with safety and quality standards.

Step 4: Assess Product Quality and Durability

Quality and durability are paramount when selecting a water filtration system. Look for products made from robust materials that can withstand the environmental conditions of your location.

– Consider systems with warranties that reflect the manufacturer’s confidence in their product.

– Investigate user reviews and testimonials to gain insights into long-term performance.

Step 5: Understand Maintenance Requirements

Maintenance plays a critical role in the longevity and efficiency of water filtration systems. Familiarize yourself with the maintenance protocols for the systems you are considering.

– Determine the frequency of filter replacements and the ease of access to components for servicing.

– Choose systems that offer user-friendly maintenance procedures to minimize downtime.

Step 6: Compare Pricing and Total Cost of Ownership

While initial pricing is a consideration, it’s essential to look at the total cost of ownership, including installation, maintenance, and operational costs over time.

– Request detailed quotes from multiple suppliers to compare pricing effectively.

– Factor in potential savings from reduced bottled water usage or improved appliance efficiency.

Step 7: Negotiate Terms and Place Your Order

Once you have selected a supplier, engage in negotiations to secure favorable terms, including pricing, delivery timelines, and payment conditions.

– Ensure clarity on warranty coverage and post-purchase support.

– Confirm all specifications and agreements in writing to avoid misunderstandings.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring water system filters and ensure they select the best solutions for their operational needs.

Comprehensive Cost and Pricing Analysis for water system filter Sourcing

What Are the Key Cost Components for Water System Filters?

When sourcing water system filters, it is crucial to understand the various cost components that contribute to the overall pricing. The primary components include:

-

Materials: The choice of materials significantly impacts cost. Common materials for filter media include activated carbon, ceramic, and membranes for reverse osmosis systems. Premium materials often lead to higher filtration efficiency and longevity but come at a higher initial cost.

-

Labor: Labor costs encompass wages for manufacturing workers and any skilled technicians involved in the assembly or quality control (QC) processes. Labor rates can vary by region; for instance, sourcing from countries with lower labor costs may seem advantageous but could compromise quality.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility upkeep. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: The cost of tools and machinery used in the production of filters can be substantial, especially for custom designs. Investing in advanced tooling can enhance production efficiency and product quality.

-

Quality Control: Implementing rigorous QC measures ensures that products meet necessary standards and certifications, which may add to costs but is essential for reliability and safety.

-

Logistics: The cost of shipping and handling, including freight charges and customs duties, plays a crucial role in the final price. Factors such as distance, shipping method, and Incoterms (international commercial terms) can influence logistics costs significantly.

-

Margin: Suppliers typically add a profit margin to cover their expenses and ensure profitability. The margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Water System Filter Sourcing?

Several factors influence the pricing of water system filters, particularly for international B2B buyers:

-

Volume/MOQ: Larger order volumes can lead to lower per-unit costs due to economies of scale. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom filters tailored to specific applications may incur higher costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials and Quality Certifications: Filters that comply with international quality standards (e.g., NSF/ANSI certifications) typically command higher prices. Buyers should evaluate the importance of these certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a proven track record may offer better warranties and support, justifying a higher price.

-

Incoterms: The chosen Incoterms can significantly impact total costs. For instance, choosing “CIF” (Cost, Insurance, and Freight) may include additional costs that affect overall pricing.

What Are Essential Buyer Tips for Cost-Efficiency in Water System Filters?

International B2B buyers should consider the following strategies for cost-efficient sourcing of water system filters:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a good relationship can lead to better deals and discounts.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, replacement, and operational costs associated with the filters. A higher upfront investment in quality products may lead to lower long-term costs.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe may face unique challenges such as currency fluctuations, import tariffs, and varying local regulations. Conducting thorough market research can help navigate these complexities.

-

Request Samples: Before placing a large order, request samples to assess quality and performance. This step can prevent costly mistakes and ensure that the product meets your requirements.

Disclaimer on Indicative Prices

Prices for water system filters can vary widely based on the factors mentioned above. The figures provided in product catalogs or online platforms should be viewed as indicative. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing and evaluate the total cost implications of their sourcing decisions.

Alternatives Analysis: Comparing water system filter With Other Solutions

A stock image related to water system filter.

When considering water purification solutions, international B2B buyers must evaluate various alternatives to water system filters. Each solution has its own set of advantages and disadvantages, and understanding these can help businesses make informed decisions that best fit their needs.

| Comparison Aspect | Water System Filter | Whole House Water Filter | Reverse Osmosis System |

|---|---|---|---|

| Performance | Removes a wide range of contaminants | Comprehensive filtration for the entire home | Excellent for specific contaminants like lead and nitrates |

| Cost | Moderate initial cost, low operating cost | Higher initial investment, long-term savings | Moderate to high initial cost, higher maintenance costs |

| Ease of Implementation | Easy to install and replace | Requires professional installation | Complex installation and setup |

| Maintenance | Requires regular filter replacements | Low maintenance, periodic checks | Frequent filter changes needed |

| Best Use Case | Residential or small commercial settings | Large homes or commercial buildings | Areas with specific contaminant issues |

What Are the Advantages and Disadvantages of Whole House Water Filters?

Whole house water filters are designed to treat water at the point of entry, ensuring that all water sources in a building are clean. They excel in performance by removing a wide variety of contaminants, from chlorine to heavy metals. While the initial investment can be significant, these systems provide long-term savings by reducing plumbing issues and the need for bottled water. The maintenance is relatively low, requiring only periodic checks and filter replacements. However, their installation may require professional assistance, making them less accessible for smaller operations or those with budget constraints.

How Does a Reverse Osmosis System Compare?

Reverse osmosis (RO) systems are known for their ability to remove specific contaminants such as lead, nitrates, and other dissolved solids. This technology is particularly effective in areas where water quality is a significant concern. While RO systems can be installed at the point of use, they can also be used for whole house applications, albeit with a more complex setup. The initial costs are moderate to high, and the maintenance can be demanding, requiring frequent filter changes. RO systems are best suited for businesses that face specific water quality issues and can justify the ongoing maintenance costs.

Conclusion: Which Water Treatment Solution Is Right for Your Business?

Choosing the right water treatment solution requires a thorough analysis of your specific needs, budget, and the quality of your water supply. Water system filters offer a balance of performance and cost-effectiveness for smaller applications. For larger operations, whole house water filters provide comprehensive coverage with long-term benefits. Conversely, reverse osmosis systems are ideal for targeted contaminant removal in areas with known water quality issues. By carefully evaluating these alternatives, B2B buyers can select the most effective solution that aligns with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for water system filter

A stock image related to water system filter.

What Are the Essential Technical Properties of Water System Filters?

When selecting a water system filter, understanding its technical properties is crucial for ensuring that the system meets specific needs and regulatory requirements. Here are some key specifications to consider:

1. Material Grade

The material used in a water filter significantly affects its durability and performance. Common materials include activated carbon, ceramic, and various plastics. For B2B buyers, selecting filters made from high-grade materials can result in better contaminant removal and longer lifespan, reducing overall maintenance costs.

2. Filtration Rate

This property refers to the amount of water that can be filtered per hour, typically measured in gallons per minute (GPM). A higher filtration rate is essential for businesses with high water demand, ensuring that operations can run smoothly without interruptions. Understanding this metric helps buyers choose a filter that matches their specific usage needs.

3. Contaminant Removal Efficiency

This specification indicates the percentage of specific contaminants that a filter can remove. For instance, a filter might claim to remove 99% of lead or chlorine. B2B buyers should focus on filters that are certified by recognized standards (e.g., NSF/ANSI) to ensure they meet health and safety regulations, thereby protecting both employees and customers.

4. Service Life

The service life of a filter is the duration it can effectively remove contaminants before needing replacement. This is typically expressed in gallons filtered or time (months/years). For businesses, understanding the service life helps in planning maintenance schedules and budgets, ensuring continuous access to clean water.

5. Pressure Drop

This refers to the loss of pressure as water flows through the filter, which can affect overall water delivery in a system. A high pressure drop may indicate that the filter is too restrictive, which can lead to increased energy costs for pumps. B2B buyers should look for filters with a low pressure drop to optimize efficiency and reduce operational costs.

6. Tolerance Levels

Tolerance levels indicate how well a filter can operate under varying conditions, including temperature and pH levels. Filters with wider tolerance levels are more adaptable to different water sources, making them a better choice for international buyers who may encounter diverse water quality issues in their regions.

What Are Common Trade Terms in the Water Filter Industry?

Understanding industry terminology is vital for effective communication and negotiation with suppliers. Here are some common terms that B2B buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of water filters, an OEM may design and manufacture filters that are branded and sold by larger companies. Knowing the OEM can provide insights into product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and negotiate favorable terms. Smaller businesses, in particular, should be aware of MOQs to avoid overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for specific products. This process is crucial for obtaining competitive pricing and understanding the market landscape. B2B buyers should craft clear and detailed RFQs to ensure accurate responses from suppliers.

4. Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother transactions across borders.

5. Certification Standards

Certification standards, such as NSF/ANSI, indicate that a product meets specific safety and performance criteria. For B2B buyers, choosing certified products ensures compliance with local regulations and enhances the credibility of the business’s operations.

6. Warranty and Service Agreements

These are commitments from the manufacturer regarding the repair or replacement of defective products. Understanding warranty terms is vital for B2B buyers to safeguard their investments and ensure ongoing support for maintenance and repairs.

By grasping these technical properties and industry terminologies, B2B buyers can make informed decisions when sourcing water system filters, ensuring they select the best solutions for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the water system filter Sector

What Are the Current Market Dynamics and Key Trends in the Water System Filter Sector?

The global water system filter market is witnessing significant growth, driven by increasing awareness of water quality issues and rising health concerns. Key trends include the adoption of advanced filtration technologies such as reverse osmosis and UV filtration, which are favored for their effectiveness in removing contaminants like heavy metals, chlorine, and pathogens. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking whole-house filtration systems that provide comprehensive water quality solutions for residential and commercial applications.

Emerging technologies such as IoT-enabled filtration systems are becoming prominent, allowing for real-time monitoring of water quality and filter performance. This shift not only enhances user experience but also aligns with the growing demand for smart home solutions. Additionally, the rise of e-commerce platforms is making it easier for B2B buyers to source water filtration systems and replacement filters, offering a wider selection and competitive pricing.

Market dynamics are also influenced by regional factors. In Africa, for instance, the need for clean drinking water due to limited infrastructure drives demand for portable and affordable filtration solutions. Meanwhile, in Europe and South America, regulatory compliance and sustainability practices are becoming critical, prompting buyers to prioritize products that meet stringent environmental standards. Understanding these dynamics enables B2B buyers to align their sourcing strategies with market demands and capitalize on emerging opportunities.

How Important Is Sustainability and Ethical Sourcing in the Water System Filter Industry?

Sustainability and ethical sourcing are becoming paramount in the water system filter sector, particularly for international B2B buyers. The environmental impact of water filtration systems extends beyond their operational lifespan; it encompasses the entire supply chain, from raw material extraction to product disposal. Buyers are increasingly scrutinizing their suppliers’ practices to ensure they are sourcing materials responsibly and reducing their carbon footprint.

The demand for ‘green’ certifications and materials is rising, with buyers favoring products that are certified by recognized organizations such as NSF International or the Water Quality Association. These certifications not only assure quality and safety but also demonstrate a commitment to environmental stewardship. B2B buyers should look for systems that utilize sustainable materials, such as biodegradable or recyclable components, which can significantly reduce landfill waste.

Furthermore, the push for circular economy principles is influencing procurement strategies. Companies are now seeking suppliers who offer take-back programs or that can demonstrate a commitment to recycling and repurposing used filters. By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation, meet regulatory requirements, and appeal to environmentally conscious consumers.

How Has the Water System Filter Sector Evolved Over Time?

The evolution of the water system filter sector has been marked by significant technological advancements and shifting consumer preferences. Initially, water filtration primarily focused on basic sediment and chlorine removal, using simple carbon filters. However, as awareness of waterborne contaminants grew, so did the sophistication of filtration technologies.

In the late 20th century, innovations such as reverse osmosis and UV filtration systems emerged, providing more comprehensive solutions for removing a broader range of impurities. The increasing prevalence of environmental regulations and health standards further propelled advancements in filtration technologies, leading to the development of multi-stage systems that target specific contaminants.

Today, the water filtration market is characterized by a diverse array of products designed to meet varying consumer needs, from whole-house systems to portable filters for on-the-go use. As the sector continues to evolve, international B2B buyers must stay informed about technological developments and market trends to make informed sourcing decisions that align with their operational requirements and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of water system filter

-

How do I solve water quality issues in my region?

To address water quality issues, it’s crucial first to identify the specific contaminants present in your water supply. Conduct water testing to determine the presence of heavy metals, chlorine, sediment, or other impurities. Based on the results, choose a suitable filtration system, such as a whole house water filter or a reverse osmosis system, that targets those specific contaminants. Partnering with a reputable supplier who understands local water issues can also provide tailored solutions that meet your needs. -

What is the best water filtration system for industrial applications?

For industrial applications, a multi-stage filtration system is often the best choice. These systems can handle larger volumes of water and effectively remove a wide range of impurities, including heavy metals, sediment, and chemical contaminants. Consider systems that offer scalability and customization options to cater to your specific industrial processes. It’s also essential to evaluate the system’s maintenance requirements and ensure it aligns with your operational capacity. -

How can I evaluate a supplier of water filtration systems?

When evaluating suppliers, focus on their experience and expertise in the water filtration industry. Check for certifications, customer reviews, and case studies that demonstrate successful installations. It’s also beneficial to inquire about their quality assurance processes and warranties. Establishing clear communication with the supplier can help assess their responsiveness and ability to meet your specific needs. -

What are the typical minimum order quantities (MOQ) for water filtration systems?

Minimum order quantities can vary significantly among suppliers, typically ranging from one unit for smaller systems to bulk orders for larger industrial solutions. It’s crucial to discuss your project requirements with potential suppliers to negotiate terms that suit your needs. Additionally, consider the possibility of sample orders to evaluate the product quality before committing to larger purchases. -

What payment terms should I expect when purchasing water filtration systems?

Payment terms can differ widely based on the supplier’s policies and your relationship with them. Common terms include upfront payments, deposits, or net payment options after delivery. For international transactions, be mindful of factors such as currency exchange rates and potential import duties. Establishing clear payment terms upfront can help prevent misunderstandings and ensure a smooth transaction process. -

How can I ensure the quality of water filtration systems before purchase?

To ensure product quality, request detailed specifications and certifications from the supplier, such as ISO certification or compliance with local health standards. Conduct thorough research on the supplier’s manufacturing processes and quality control measures. If possible, visit their facility or request samples for testing. Partnering with suppliers who have a proven track record can also help guarantee that you receive high-quality systems. -

What logistics considerations should I keep in mind for importing water filtration systems?

Logistics is crucial when importing water filtration systems, especially regarding shipping methods, customs clearance, and delivery timelines. Assess the supplier’s shipping capabilities and ensure they can handle international logistics efficiently. It’s also important to factor in potential delays due to customs and ensure compliance with local regulations. Working with a freight forwarder can help streamline the import process and minimize risks. -

How do I customize a water filtration system for my specific needs?

Customization options vary by supplier but typically include selecting specific filter types, capacities, and additional features like UV purification or salt-free water conditioning. Start by clearly outlining your water quality issues and operational requirements. Engage with the supplier to discuss available options and configurations that best suit your needs. Many suppliers also offer consultation services to help you determine the most effective solutions for your unique situation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for water system filter

Why Is Strategic Sourcing Essential for Water System Filters?

In the competitive landscape of water system filtration, strategic sourcing emerges as a pivotal strategy for B2B buyers aiming to enhance operational efficiency and ensure product reliability. By carefully selecting suppliers that offer advanced filtration technologies—such as whole house systems and reverse osmosis units—businesses can significantly improve water quality while reducing long-term costs.

What Are the Key Benefits of Investing in Quality Water Filters?

Investing in high-quality water filtration systems not only safeguards health and safety but also extends the lifespan of plumbing and appliances. For international buyers from regions like Africa, South America, the Middle East, and Europe, understanding the local water challenges is crucial. Tailoring solutions to address specific contaminants prevalent in these areas ensures compliance with health standards and promotes sustainability.

How Can International Buyers Position Themselves for Future Success?

As global demand for clean water solutions continues to rise, the outlook for water system filters remains positive. International buyers should leverage strategic partnerships with reputable suppliers and stay informed about emerging technologies to maintain a competitive edge. By prioritizing strategic sourcing now, businesses can secure access to innovative filtration systems that meet evolving market needs, positioning themselves as leaders in the water quality sector.

In conclusion, the time to act is now. Engage with trusted suppliers, explore cutting-edge technologies, and ensure your organization is prepared to meet the future challenges of water filtration.