Master Electric Plug Prongs: Your Complete Sourcing Guide (2025)

Introduction: Navigating the Global Market for electric plug prongs

Navigating the global market for electric plug prongs presents a unique set of challenges for international B2B buyers, especially those sourcing components for diverse applications across various regions, including Africa, South America, the Middle East, and Europe. Understanding the nuances of different plug types, their specifications, and compliance with local regulations can be daunting. This guide provides a comprehensive overview of electric plug prongs, detailing their types, applications, and critical factors for supplier vetting, as well as cost considerations.

B2B buyers face the critical challenge of ensuring compatibility and safety when selecting electric plug prongs for their products. With a multitude of configurations—from two-prong to three-prong designs—each region has its standards and requirements that must be adhered to. This guide aims to empower buyers by elucidating the complexities involved in sourcing these components, offering actionable insights that facilitate informed purchasing decisions.

Furthermore, we delve into the importance of evaluating suppliers based on quality, reliability, and compliance with international safety standards. By leveraging this guide, B2B buyers can navigate the intricacies of the global market for electric plug prongs, ensuring that their sourcing strategies align with both operational needs and regulatory frameworks in their respective regions. This strategic approach not only mitigates risk but also enhances the overall quality and safety of the electrical products they deliver to their customers.

Understanding electric plug prongs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA Plugs | Various configurations (e.g., NEMA 5-15, NEMA 14-30) | Commercial appliances, heavy equipment | Pros: Standardized, widely available. Cons: Limited compatibility with non-North American devices. |

| Type C (Europlug) | Two round prongs, often ungrounded | General electronics, small appliances | Pros: Versatile, accepted in many countries. Cons: Not suitable for high-power devices. |

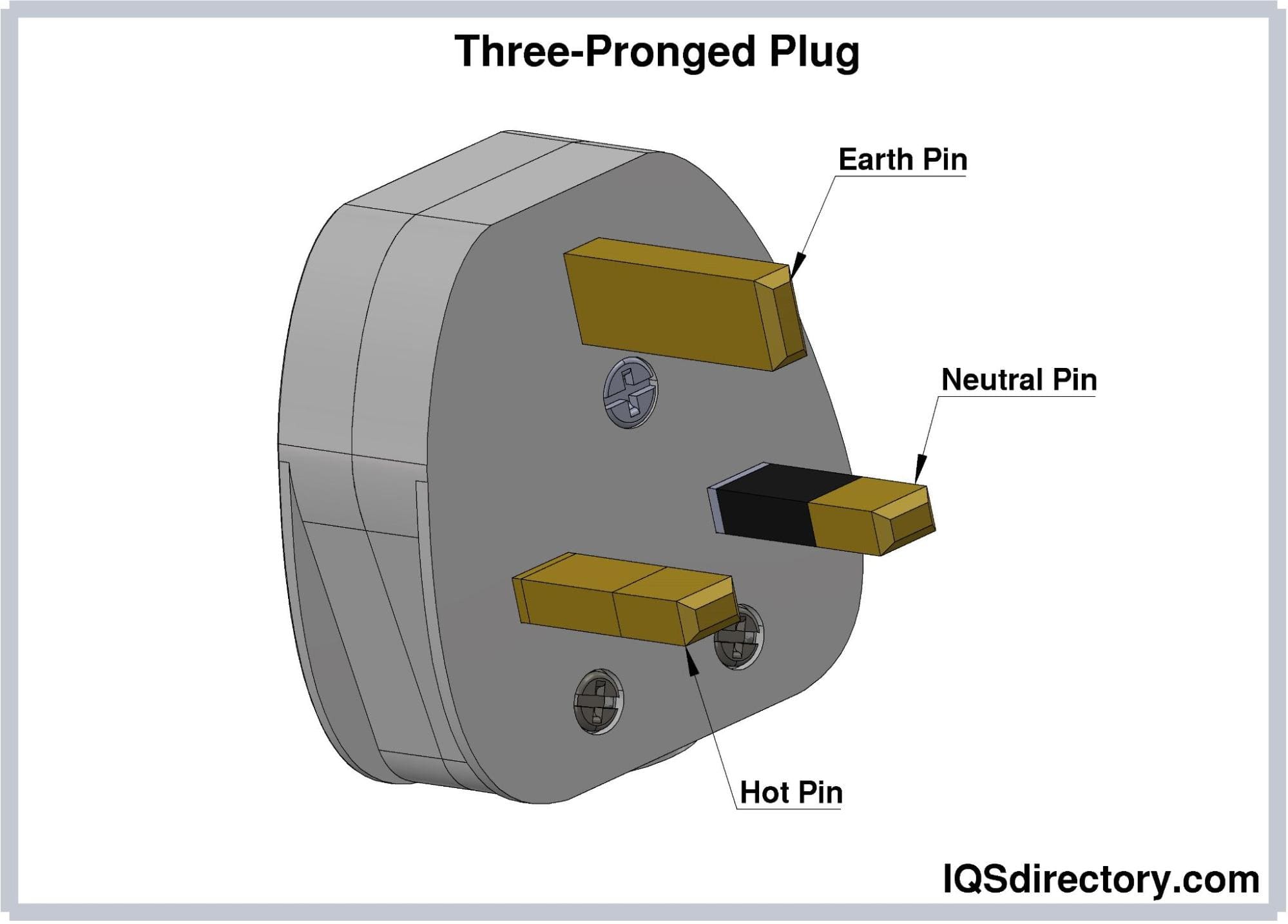

| Type G (UK Plug) | Three rectangular prongs, fused for safety | Industrial machinery, consumer electronics | Pros: Enhanced safety features, robust design. Cons: Bulky, may require adapters in other regions. |

| Type I (Australian Plug) | Two flat prongs in a V-shape, one vertical | Electrical tools, household appliances | Pros: Safe and effective grounding. Cons: Limited use outside Australia and New Zealand. |

| IEC 60320 (C13/C14) | Standardized connectors for computer equipment | IT equipment, servers, and data centers | Pros: Universally compatible in IT, reliable. Cons: Requires specific socket types, limited to lower amperage. |

What Are NEMA Plugs and Their B2B Importance?

NEMA plugs are standardized connectors widely used in North America, available in various configurations to suit different amperage and voltage requirements. Commonly found in commercial appliances and heavy equipment, these plugs ensure safety and compatibility across a range of devices. B2B buyers should consider the specific NEMA configuration that matches their equipment needs, as using the wrong type can lead to electrical hazards or equipment damage.

How Do Type C (Europlug) Plugs Work in B2B Settings?

The Type C plug, or Europlug, features two round prongs and is commonly used across Europe and in many other regions. This plug is versatile and can fit into various socket types, making it ideal for general electronics and small appliances. B2B buyers should note that while Type C plugs are convenient, they are not suitable for high-power applications, which may necessitate additional considerations for devices requiring more robust connections.

What Makes Type G (UK Plug) Essential for Businesses?

Type G plugs, characterized by three rectangular prongs and a built-in fuse, are mandatory in the UK and several other countries. Their robust design and safety features make them suitable for industrial machinery and consumer electronics alike. B2B buyers should prioritize Type G plugs for environments where safety is paramount, but they should also be aware of the potential need for adapters when operating in regions with different plug types.

Why Choose Type I (Australian Plug) for Your Equipment?

The Type I plug, featuring two flat prongs arranged in a V-shape with an additional vertical prong for grounding, is primarily used in Australia and New Zealand. It is favored for electrical tools and household appliances due to its effective grounding capabilities. B2B buyers should consider Type I plugs when sourcing equipment for these markets, as they ensure safety and compliance with local electrical standards.

What Is the Role of IEC 60320 Connectors in IT and Data Centers?

IEC 60320 connectors, such as C13 and C14, are standardized for computer equipment and are commonly used in IT environments and data centers. These connectors provide a reliable power connection for servers and other electronic devices. B2B buyers should focus on these connectors for their compatibility with various IT equipment, but they must ensure that the appropriate socket types are available in their operational environments to avoid compatibility issues.

Key Industrial Applications of electric plug prongs

| Industry/Sector | Specific Application of electric plug prongs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering heavy machinery and equipment | Ensures reliable operation and productivity | Compliance with local electrical standards and safety regulations |

| Healthcare | Connecting medical devices and equipment | Enhances safety and reliability for patient care | Hospital-grade plugs for enhanced safety; voltage requirements |

| Construction | Temporary power supply for tools and lighting | Facilitates efficient project execution | Durability and weather resistance for outdoor use |

| Telecommunications | Powering telecom infrastructure and equipment | Supports uninterrupted service and connectivity | Compatibility with local power standards and configurations |

| Hospitality | Powering appliances in hotels and restaurants | Improves guest experience through reliable service | Variety of plug types for different appliances; aesthetic considerations |

How Are Electric Plug Prongs Used in Manufacturing?

In the manufacturing sector, electric plug prongs are crucial for powering heavy machinery and equipment. They are designed to handle high amperage loads necessary for industrial applications. By ensuring reliable connections, these plugs help mitigate downtime caused by electrical failures, thus enhancing productivity. For B2B buyers, it is essential to ensure that the plugs comply with local electrical standards and safety regulations to avoid operational risks and legal liabilities.

What Role Do Electric Plug Prongs Play in Healthcare?

In healthcare settings, electric plug prongs are vital for connecting medical devices and equipment. The reliability of these connections is paramount, as any power interruption can jeopardize patient care. Healthcare facilities often require hospital-grade plugs that provide enhanced safety features, such as grounding and surge protection. International buyers must consider voltage requirements and ensure that the plugs meet stringent healthcare regulations in their respective countries, particularly in regions with varying electrical standards.

How Are Electric Plug Prongs Utilized in Construction?

Electric plug prongs are extensively used in the construction industry to provide temporary power supply for tools and lighting. This application is critical for facilitating efficient project execution, especially on job sites where reliable electricity is not readily available. B2B buyers should focus on sourcing plugs that are durable and weather-resistant, as construction environments often expose equipment to harsh conditions. Ensuring that the plugs meet local safety standards can also prevent accidents and equipment damage.

Why Are Electric Plug Prongs Important for Telecommunications?

In the telecommunications sector, electric plug prongs power essential infrastructure and equipment, ensuring uninterrupted service and connectivity. The reliability of these connections is crucial, as any disruption can lead to significant business losses. Buyers in this industry must ensure compatibility with local power standards and configurations, as well as consider the potential need for specialized plugs that can handle varying voltage levels across different regions.

How Do Electric Plug Prongs Enhance Hospitality Services?

In the hospitality industry, electric plug prongs are used to power various appliances in hotels and restaurants, from kitchen equipment to guest room amenities. Reliable power connections are essential for maintaining high service standards and enhancing the guest experience. B2B buyers should consider the variety of plug types needed for different appliances, as well as any aesthetic considerations that may be relevant in guest-facing areas. Ensuring that the plugs are compliant with local electrical codes is also crucial for operational safety.

A stock image related to electric plug prongs.

3 Common User Pain Points for ‘electric plug prongs’ & Their Solutions

Scenario 1: Compatibility Issues with Local Standards

The Problem:

For international B2B buyers, one of the most pressing challenges is ensuring that the electric plug prongs they source are compatible with local electrical standards. In regions like Africa and South America, where multiple plug types exist, importing equipment with mismatched plug configurations can lead to operational delays, increased costs, and potentially unsafe conditions. Buyers often find themselves in situations where they have to either invest in costly adapters or modify their electrical infrastructure, which can be both time-consuming and risky.

The Solution:

To mitigate compatibility issues, it is crucial for buyers to conduct thorough research on the specific plug types and electrical standards in their target markets. Utilizing resources such as the International Electrotechnical Commission (IEC) standards can provide clarity on the various plug configurations. When sourcing electric plug prongs, buyers should work with suppliers who offer a wide range of international plug types and can customize products to meet local requirements. Additionally, consider engaging local electrical engineers during the procurement process to ensure compliance with regional codes and safety regulations. This proactive approach can save time and reduce the risk of electrical failures.

Scenario 2: Durability and Environmental Resistance Concerns

The Problem:

B2B buyers often face challenges related to the durability of electric plug prongs, particularly in industries where equipment is subjected to harsh environmental conditions. For instance, in the Middle East, where temperatures can soar, or in South America with its humid climates, standard plug prongs may degrade quickly, leading to frequent replacements and operational downtimes. This not only affects productivity but also increases operational costs significantly.

The Solution:

To address durability concerns, buyers should prioritize sourcing electric plug prongs made from high-quality, weather-resistant materials. Look for products that are rated for specific environmental conditions, such as high-temperature resistance or moisture-proof designs. Engaging with manufacturers that specialize in industrial-grade components can provide options that are specifically engineered for rugged environments. Additionally, implementing a regular maintenance schedule to inspect and replace worn-out plugs can extend the lifespan of your electrical systems, ultimately safeguarding against unexpected failures.

Scenario 3: Safety and Compliance Risks

The Problem:

Safety is a paramount concern for B2B buyers, especially in industries that handle heavy machinery or sensitive electronic equipment. Improper use of electric plug prongs can lead to electrical shocks, fires, or equipment damage. Many buyers are unaware of the specific safety regulations that govern the use of electrical components in their regions, which can result in non-compliance with local laws and increased liability risks.

The Solution:

To enhance safety and ensure compliance, buyers should familiarize themselves with local and international electrical safety standards, such as the National Electrical Code (NEC) in the U.S. or the European Union’s Low Voltage Directive (LVD). When sourcing electric plug prongs, opt for products that are certified by recognized safety organizations, such as UL or CE markings, which indicate that the product has been tested for safety. Additionally, consider investing in training programs for employees on the proper use of electrical equipment, emphasizing the importance of using the right plug prongs for specific applications. This comprehensive approach not only protects your workforce but also reinforces your commitment to safety and compliance within your organization.

Strategic Material Selection Guide for electric plug prongs

When selecting materials for electric plug prongs, international B2B buyers must consider various factors that influence performance, safety, and compliance with regional standards. Here, we analyze four common materials used in the manufacturing of electric plug prongs, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Brass for Electric Plug Prongs?

Brass is an alloy primarily composed of copper and zinc, known for its excellent electrical conductivity and corrosion resistance. It typically operates well within a temperature range of -40°C to 120°C (-40°F to 248°F), making it suitable for various environments.

Pros: Brass prongs are durable and provide reliable electrical connections. They are also relatively easy to manufacture, allowing for precise designs that meet specific requirements.

Cons: The primary drawback of brass is its cost, which can be higher than other materials. Additionally, brass can tarnish over time, potentially affecting conductivity if not properly maintained.

Impact on Application: Brass is compatible with most electrical media and is commonly used in household and industrial applications.

Considerations for International Buyers: Compliance with standards such as ASTM B453 and DIN 17660 is crucial. Buyers should also consider the local climate, as brass may require protective coatings in humid regions to prevent corrosion.

How Does Stainless Steel Perform as a Material for Electric Plug Prongs?

Stainless steel is known for its strength and corrosion resistance, making it an attractive option for electric plug prongs. With a temperature rating of up to 300°C (572°F), stainless steel can withstand high thermal environments.

Pros: The durability and resistance to rust and corrosion make stainless steel prongs ideal for long-term use. They also provide a robust mechanical structure that can endure physical stress.

Cons: The downside is that stainless steel has lower electrical conductivity compared to brass, which can lead to increased resistance and heat generation during operation. Additionally, the manufacturing process can be more complex and costly.

Impact on Application: Stainless steel is suitable for applications where durability is essential, such as in outdoor or industrial settings.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM A240 and ISO 9445. In regions with high humidity, stainless steel’s corrosion resistance can be a significant advantage.

What Are the Advantages of Using Copper for Electric Plug Prongs?

A stock image related to electric plug prongs.

Copper is one of the most conductive materials available, making it an ideal choice for electric plug prongs. It has a high melting point of around 1,085°C (1,985°F) and excellent thermal and electrical conductivity.

Pros: The primary advantage of copper is its superior conductivity, which minimizes energy loss and heat generation. It is also relatively easy to work with, allowing for versatile designs.

Cons: Copper is prone to oxidation, which can affect performance over time. Additionally, it is more expensive than some alternative materials, and its softness may lead to wear in high-stress applications.

Impact on Application: Copper is particularly suitable for high-performance applications where efficient energy transfer is critical.

Considerations for International Buyers: Compliance with international standards such as ASTM B170 and IEC 60228 is necessary. Buyers should also be aware of local market preferences, as some regions may favor copper for its performance benefits.

Why Choose Thermoplastic for Electric Plug Prongs?

Thermoplastic materials, such as polycarbonate and nylon, are increasingly used for plug prongs due to their lightweight and insulating properties. They can withstand temperatures up to 120°C (248°F).

Pros: Thermoplastics are cost-effective and offer excellent electrical insulation. They are also resistant to impact and can be molded into complex shapes, making them versatile for various applications.

Cons: However, thermoplastics generally have lower mechanical strength compared to metals and can degrade under extreme temperatures or prolonged exposure to UV light.

Impact on Application: These materials are ideal for consumer electronics and applications where weight and insulation are critical.

Considerations for International Buyers: Compliance with UL 94 and IEC 60695 standards is essential. Buyers should also consider the environmental impact and recycling options for thermoplastic materials.

Summary Table of Material Selection for Electric Plug Prongs

| Material | Typical Use Case for Electric Plug Prongs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Household and industrial applications | Excellent electrical conductivity | Can tarnish and is relatively costly | Medium |

| Stainless Steel | Outdoor and industrial settings | High strength and corrosion resistance | Lower conductivity and higher cost | High |

| Copper | High-performance applications | Superior conductivity | Prone to oxidation and expensive | High |

| Thermoplastic | Consumer electronics | Lightweight and excellent insulation | Lower mechanical strength | Low |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electric plug prongs

What Are the Key Manufacturing Processes for Electric Plug Prongs?

The manufacturing of electric plug prongs involves several critical stages that ensure the final product meets both safety and functionality standards. Understanding these processes can help B2B buyers make informed decisions when sourcing from international suppliers.

How Is Material Prepared for Electric Plug Prongs?

The first step in the manufacturing process is material preparation. High-quality materials such as copper, brass, or aluminum are often used for the prongs due to their excellent conductivity and corrosion resistance. Suppliers should ideally provide detailed specifications regarding the grade and sourcing of these materials.

-

Material Sourcing: Buyers should verify that materials comply with international standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). This ensures that the materials are safe and environmentally friendly.

-

Material Testing: Conducting tests such as tensile strength and conductivity tests is crucial. Buyers can request test reports from suppliers to confirm that the materials meet the necessary standards.

What Techniques Are Used in the Forming Stage?

Forming is a critical stage where raw materials are transformed into the desired shapes. Various techniques are employed in this phase:

-

Stamping: This process involves cutting and shaping metal sheets into prongs using a die. It is efficient for mass production and ensures uniformity in dimensions.

-

Injection Molding: For plastic components, injection molding is commonly used. It allows for intricate designs and is suitable for high-volume production.

-

Machining: Fine-tuning the prongs may require machining processes to achieve precise dimensions and finishes. This can include drilling, milling, or grinding, depending on the specifications.

How Does the Assembly Process Work?

The assembly process involves combining the various components of the electric plug prong, including the prongs, casing, and any internal wiring.

-

Automated Assembly Lines: Many manufacturers utilize automated assembly lines to enhance efficiency and reduce human error. This can include robotic arms for precise placement and soldering of components.

-

Manual Assembly: For more complex designs or lower-volume products, manual assembly may be employed. Workers should be adequately trained to ensure quality and safety.

-

Quality Checks During Assembly: Implementing checks at this stage can help catch defects early. For example, verifying the alignment of prongs and ensuring proper solder joints are essential.

What Finishing Techniques Are Commonly Used?

Finishing processes enhance the appearance and performance of the electric plug prongs.

-

Plating: Nickel or chrome plating can be applied to improve corrosion resistance and conductivity. Buyers should inquire about the plating thickness and adherence tests to ensure longevity.

-

Surface Treatments: Processes such as anodizing or powder coating can enhance durability and aesthetic appeal. Understanding the types of treatments available can help buyers select the right products for their needs.

-

Final Inspection: A thorough inspection post-finishing is crucial. This can include visual inspections for defects and functional tests to ensure that the prongs operate as intended.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is critical in manufacturing electric plug prongs, especially for international buyers who must navigate various standards and regulations.

Which International Standards Are Relevant for Electric Plug Prongs?

-

ISO 9001: This standard outlines the requirements for a quality management system. Buyers should verify if their suppliers are ISO 9001 certified, indicating a commitment to quality and continuous improvement.

-

CE Marking: For products sold in Europe, CE marking is mandatory. It signifies that the product meets EU safety, health, and environmental requirements. Buyers should check for proper documentation and compliance.

-

UL Certification: In North America, UL certification is crucial for electrical products, including plug prongs. It ensures that products have been tested for safety and performance.

What Are the Key Quality Control Checkpoints?

Implementing quality control (QC) checkpoints throughout the manufacturing process is essential for maintaining high standards.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. Buyers should request IQC reports to ensure that materials meet specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections should occur to monitor production quality. This can include dimensional checks and functionality tests at various stages.

-

Final Quality Control (FQC): Before shipment, a comprehensive inspection should take place. This includes testing the final product against relevant standards and conducting random sampling for thorough quality checks.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that their suppliers maintain rigorous quality control standards.

What Methods Can Buyers Use for Supplier Verification?

-

Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should establish a checklist based on relevant standards and practices.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess the effectiveness of their QC processes. This includes data on defect rates, testing results, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control. This is particularly beneficial for international transactions where buyers may not have direct oversight.

What Are the Unique QC Considerations for International Buyers?

When sourcing electric plug prongs from global suppliers, B2B buyers must navigate additional QC nuances.

-

Cultural and Regulatory Differences: Understanding the local manufacturing practices and regulatory requirements is essential. Buyers should familiarize themselves with the standards in the supplier’s country and the import regulations in their own.

-

Communication: Clear communication regarding quality expectations and standards is vital. Establishing a mutual understanding can help prevent discrepancies and ensure product compliance.

-

Long-Term Relationships: Building long-term relationships with suppliers can foster better quality assurance practices. Regular feedback and collaboration can lead to continuous improvement in manufacturing processes.

By comprehensively understanding the manufacturing processes and quality assurance standards for electric plug prongs, B2B buyers can make informed decisions that enhance their supply chain and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric plug prongs’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure electric plug prongs. Whether you are operating in Africa, South America, the Middle East, or Europe, having a clear understanding of the sourcing process will help you make informed decisions that align with your business needs. This checklist will navigate you through essential steps to ensure that you select the right products and suppliers.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the electric plug prongs you need. Consider factors such as amperage, voltage ratings, and plug configurations (e.g., NEMA types).

- Amperage Ratings: Determine the maximum amperage your application requires to avoid overheating and ensure safety.

- Voltage Compatibility: Verify the voltage requirements based on the regions where your products will be used.

Step 2: Research Local and International Standards

Understanding the local and international standards for electric plug prongs is crucial to ensure compliance and safety. Different regions may have specific regulations regarding electrical components.

- Regulatory Compliance: Familiarize yourself with standards such as IEC, UL, or CE marks, depending on your target market.

- Safety Protocols: Ensure that the products you source meet safety protocols to minimize risks associated with electrical hazards.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to establish reliability and quality. This step is critical to ensure that you are partnering with reputable manufacturers who can meet your specifications.

- Company Profiles: Request detailed company profiles, including their manufacturing capabilities and experience in the industry.

- References and Case Studies: Ask for references from other businesses in your region or industry to gauge the supplier’s reliability and product quality.

Step 4: Request Samples for Testing

Before placing a large order, always request samples of the electric plug prongs. Testing these samples will help you assess their quality and suitability for your applications.

- Quality Assessment: Inspect the physical attributes of the samples, including material durability and design.

- Functional Testing: Conduct electrical testing to ensure that the prongs function correctly under load conditions.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms and conditions to establish a mutually beneficial agreement. This includes pricing, delivery schedules, and payment terms.

- Volume Discounts: Inquire about bulk purchasing options or discounts for larger orders.

- Delivery Timelines: Ensure that the supplier can meet your delivery requirements to avoid project delays.

Step 6: Verify After-Sales Support and Warranty

Confirm that the supplier offers adequate after-sales support and warranty for their products. This is essential for addressing any issues that may arise post-purchase.

- Customer Service: Assess the supplier’s customer service responsiveness and support channels.

- Warranty Terms: Understand the warranty coverage for defects or performance issues to safeguard your investment.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with your supplier can lead to better pricing, priority service, and improved collaboration on future projects.

A stock image related to electric plug prongs.

- Regular Communication: Maintain open lines of communication to discuss any changes in your requirements or market conditions.

- Feedback Mechanism: Provide feedback on their products and services to foster continuous improvement.

By following this checklist, B2B buyers can streamline their sourcing process for electric plug prongs and ensure they partner with the right suppliers, ultimately enhancing their operational efficiency and safety standards.

Comprehensive Cost and Pricing Analysis for electric plug prongs Sourcing

What Are the Key Cost Components in Electric Plug Prongs Sourcing?

When sourcing electric plug prongs, it’s essential to understand the various cost components involved in the manufacturing process. These include:

-

Materials: The primary materials used in electric plug prongs include metals (such as copper and brass), plastics, and insulating materials. The quality and source of these materials significantly impact the overall cost. For instance, high-grade metals that comply with international safety standards may incur higher costs but also provide better durability and safety.

-

Labor: Labor costs vary by region and can significantly affect the pricing structure. In countries with lower labor costs, such as some regions in Africa and South America, you may find more competitive pricing. However, the trade-off can be variations in quality and adherence to international standards.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient production processes can help minimize these costs, but it often requires investment in technology and skilled labor.

-

Tooling: The cost of molds and tools necessary for manufacturing plug prongs can be substantial. Custom tooling for specific designs or high-volume orders can lead to significant up-front costs, but these may be offset by lower per-unit costs in larger production runs.

-

Quality Control (QC): Ensuring that products meet quality standards incurs additional costs. Rigorous QC processes are crucial for international shipments, as they help avoid costly returns and compliance issues.

-

Logistics: Shipping and transportation costs vary widely depending on the origin and destination of the goods. International buyers should consider the logistics costs associated with their suppliers, including customs duties and tariffs.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the typical margins in your specific market can aid in negotiations.

How Do Price Influencers Affect Electric Plug Prongs Sourcing?

Several factors can influence the pricing of electric plug prongs:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders often qualify for bulk discounts, making it essential for buyers to assess their purchasing needs carefully.

-

Specifications and Customization: Custom designs or specific certifications (like CE or UL) can increase costs. Buyers should clarify their requirements upfront to avoid unexpected pricing changes later in the process.

-

Materials: The choice of materials can dramatically alter the cost. For example, opting for weather-resistant or high-temperature materials may increase initial costs but provide long-term savings through durability.

-

Quality and Certifications: Products that meet international quality standards often come at a premium. However, these certifications can be critical for market acceptance, especially in regions with stringent regulations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and service, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms and responsibilities can prevent unexpected costs. Different Incoterms can affect who pays for shipping, insurance, and tariffs, impacting the total cost.

What Are Effective Buyer Tips for Sourcing Electric Plug Prongs?

To optimize costs and ensure successful sourcing of electric plug prongs, international buyers should consider the following strategies:

-

Negotiation: Effective negotiation can lead to better pricing and terms. Building a relationship with suppliers can provide leverage in negotiations, especially for repeat orders.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also shipping, tariffs, and expected lifespan. A higher-quality product may have a lower TCO due to reduced failure rates and longer service life.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and regional economic conditions that may affect pricing. Buyers from Europe, for instance, might find different pricing dynamics compared to those in Africa or South America.

-

Market Research: Conduct thorough market research to understand pricing trends and competitor offerings. This knowledge can provide valuable insights during negotiations and sourcing decisions.

-

Supplier Audits: Regular audits of suppliers can ensure they meet quality standards and adhere to agreed-upon pricing, helping to maintain cost control over time.

Disclaimer

The pricing insights provided are indicative and can vary based on market conditions, specific supplier agreements, and regional economic factors. Always conduct thorough due diligence and consult multiple suppliers to obtain the best pricing for electric plug prongs.

Alternatives Analysis: Comparing electric plug prongs With Other Solutions

In the evolving landscape of electrical solutions, B2B buyers need to consider various alternatives to traditional electric plug prongs. Understanding these alternatives can help businesses make informed decisions that align with their operational needs and safety standards. Below, we explore two viable alternatives to electric plug prongs, examining their performance, cost-effectiveness, ease of implementation, maintenance requirements, and best use cases.

Comparison Table of Electric Plug Prongs and Alternatives

| Comparison Aspect | Electric Plug Prongs | Wireless Charging Technology | Hardwired Connections |

|---|---|---|---|

| Performance | Reliable for low to high voltage applications | Limited to specific devices and distances | Highly reliable, suitable for high power applications |

| Cost | Low initial investment, varies by type | Higher initial costs, but decreasing | Higher installation and material costs |

| Ease of Implementation | Simple installation and replacement | Requires compatible devices, may need infrastructure changes | Complex installation, often requires professional services |

| Maintenance | Minimal maintenance required | Low maintenance, but device compatibility checks needed | Requires periodic inspections and upgrades |

| Best Use Case | General consumer electronics, appliances | Mobile devices, small electronics | Industrial machinery, permanent installations |

What Are the Advantages and Disadvantages of Wireless Charging Technology?

Wireless charging technology utilizes electromagnetic fields to transfer energy between devices. This solution offers significant convenience, especially in environments with frequent device mobility. However, its performance is often limited to certain devices and may not support high-capacity equipment, making it unsuitable for all applications. Additionally, while the initial cost is higher compared to plug prongs, ongoing maintenance is minimal, requiring only occasional checks for device compatibility. This makes it ideal for businesses looking to enhance convenience in consumer electronics and mobile devices.

What Are the Benefits and Drawbacks of Hardwired Connections?

Hardwired connections provide a permanent solution for electrical needs, offering a highly reliable and robust method of power delivery. They are particularly suitable for industrial applications where consistent power supply is critical. However, the installation process can be complex and costly, requiring specialized labor and materials. Maintenance may involve periodic inspections to ensure safety and compliance with regulations. Businesses that prioritize stability and performance in high-power applications may find hardwired connections to be the most effective option.

Conclusion: How to Choose the Right Solution for Your Business Needs?

When selecting the right electrical solution, B2B buyers should assess their specific operational requirements, including the types of devices used, the environment in which they operate, and budget constraints. Electric plug prongs remain a cost-effective and versatile choice for many applications, while alternatives like wireless charging and hardwired connections offer unique advantages for specific use cases. Ultimately, the decision should align with the company’s long-term goals, safety standards, and efficiency needs. Conducting a thorough analysis of each option can lead to smarter investments and improved operational efficiency.

Essential Technical Properties and Trade Terminology for electric plug prongs

What Are the Essential Technical Properties of Electric Plug Prongs?

When sourcing electric plug prongs for B2B applications, understanding the critical technical properties is vital for ensuring safety, compatibility, and performance. Below are some essential specifications to consider:

How Do Material Grades Affect Plug Prong Durability?

Material Grade: The materials used in the construction of electric plug prongs directly impact their durability and conductivity. Common materials include copper, which offers excellent conductivity, and various grades of plastic for insulation. Higher-grade materials can withstand higher temperatures and resist corrosion, making them essential for industrial applications where plugs may experience extreme conditions.

Why Is Tolerance Important in Electric Plug Prongs?

Tolerance: This refers to the permissible limit or limits of variation in a physical dimension of the plug prong. Tolerances are crucial for ensuring that plugs fit securely into sockets, preventing loose connections that could lead to arcing or overheating. In B2B contexts, tight tolerances can enhance reliability and reduce the risk of electrical failures.

What Is the Significance of Maximum Amperage Ratings?

Maximum Amperage Rating: Each plug prong is designed to handle a specific maximum current, typically measured in amperes. Knowing the amperage rating is critical for matching plugs to their intended applications. For example, a 20-amp plug should not be used in a circuit designed for 15 amps, as this could lead to overheating and potential fire hazards.

How Does Voltage Rating Impact Plug Selection?

Voltage Rating: This specification indicates the maximum voltage the plug can handle safely. Different regions have different voltage standards (e.g., 120V in North America and 230V in Europe). For international buyers, understanding voltage ratings is essential to ensure compatibility with local electrical systems, preventing equipment damage.

What Role Does Grounding Play in Safety?

Grounding: Grounding is a safety feature that protects users from electric shock. Three-pronged plugs include a ground prong that connects to the earth, providing a safe path for excess electricity. B2B buyers should prioritize grounding features, especially for equipment that involves metal casings, to ensure user safety and compliance with electrical codes.

What Are Common Trade Terms Used in Electric Plug Prong Transactions?

Navigating the procurement of electric plug prongs requires familiarity with industry jargon. Here are some common terms that B2B buyers should know:

What Does OEM Mean in the Context of Plug Prongs?

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are sold by another company under its brand name. In the context of electric plug prongs, understanding whether you’re dealing with OEM products can impact quality assurance and compatibility with existing systems.

How Does MOQ Affect Your Purchasing Strategy?

MOQ (Minimum Order Quantity): This is the smallest amount of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is crucial for budgeting and inventory management, as it can affect cash flow and storage capabilities.

What Is an RFQ and Why Is It Important?

RFQ (Request for Quotation): An RFQ is a document sent to suppliers asking for a price quote on specific products. It’s an essential step in the procurement process, allowing buyers to compare prices and terms from different suppliers, ensuring they get the best deal.

How Do Incoterms Influence Shipping Costs and Risks?

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers regarding shipping costs, risks, and logistics. Familiarity with Incoterms can help international buyers negotiate better terms and understand their liabilities during the shipping process.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing electric plug prongs, ensuring safety, compliance, and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the electric plug prongs Sector

What Are the Current Market Dynamics and Key Trends in the Electric Plug Prongs Sector?

The electric plug prongs market is experiencing significant growth driven by various global factors, including the rise of smart home technologies and increased demand for electronic devices. In regions like Africa and South America, rapid urbanization and electrification initiatives are creating opportunities for B2B buyers to source high-quality plug prongs that meet local voltage and amperage requirements. Meanwhile, Europe is seeing a shift towards more standardized plug designs, as regulatory bodies push for interoperability to facilitate cross-border trade and consumer safety.

Emerging technologies, such as IoT-enabled devices, are influencing sourcing trends. B2B buyers are increasingly looking for plug solutions that support smart functionalities, including surge protection and energy monitoring. Additionally, with the advent of electric vehicles (EVs), demand for specialized plug types, such as Type 2 and CCS connectors, is on the rise. International buyers should prioritize suppliers who offer a range of products that comply with regional electrical standards and certifications.

The market is also witnessing a trend towards customization, where manufacturers are willing to adapt plug designs to meet specific buyer needs, such as unique configurations for local applications. This adaptability can be crucial for B2B buyers seeking to differentiate their product offerings in a competitive landscape.

How Can Sustainability and Ethical Sourcing Be Implemented in the Electric Plug Prongs Sector?

Sustainability is becoming a vital consideration for B2B buyers in the electric plug prongs sector. The production of electrical components can have a significant environmental impact, from resource extraction to manufacturing processes. Buyers are increasingly urged to seek suppliers who employ sustainable practices, such as using recycled materials and minimizing waste throughout the production cycle.

Ethical sourcing is also gaining traction, particularly in regions with strict labor laws and environmental regulations. Buyers should prioritize suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly and that workers are treated fairly. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s commitment to ethical practices.

Moreover, the demand for “green” certifications is on the rise. Buyers should look for products that comply with international standards like RoHS (Restriction of Hazardous Substances) and CE marking, which ensure that plug prongs are free from harmful substances and safe for consumer use. Investing in sustainable and ethically sourced products not only enhances brand reputation but also aligns with the growing consumer preference for eco-friendly products.

What Is the Brief Evolution and History of Electric Plug Prongs Relevant to B2B Buyers?

The evolution of electric plug prongs can be traced back to the late 19th century when standardized electrical systems began to emerge. The early plugs were simple, two-pronged designs primarily used in residential settings. Over the decades, as electricity became more widespread and appliances grew in complexity, the need for safer and more reliable plug designs led to the introduction of three-pronged plugs, which incorporated a grounding mechanism to prevent electric shocks.

In the 20th century, international standardization efforts began, resulting in various plug types across regions, such as Type A, B, C, and others. This diversity can pose challenges for B2B buyers engaged in cross-border trade, as understanding local standards is crucial for compliance and safety.

Today, the market continues to evolve with the advent of new technologies, such as smart home devices and electric vehicles. Buyers must stay abreast of these changes to ensure that their sourcing strategies align with current market demands and regulatory requirements. Understanding the historical context of electric plug prongs can provide valuable insights into future trends and innovations, equipping B2B buyers with the knowledge needed to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of electric plug prongs

-

How do I solve compatibility issues with electric plug prongs for international markets?

To solve compatibility issues with electric plug prongs in international markets, first, understand the specific plug types and voltage requirements of your target countries. Research the local standards, such as NEMA configurations in the USA or CEE standards in Europe. Consider sourcing multi-type adapters or universal plug solutions that can accommodate various configurations. Partnering with suppliers who specialize in international compliance can help ensure that your products meet the necessary regulations, reducing the risk of import/export complications. -

What is the best type of electric plug prong for industrial applications?

The best type of electric plug prong for industrial applications often includes locking and heavy-duty configurations, such as NEMA L-series or IEC 60309 plugs. These designs provide secure connections and can handle higher amperages, which is crucial for industrial equipment. Assess the amperage and voltage needs of your machinery and choose plugs that offer durability and weather resistance, particularly if they will be used outdoors or in harsh environments. Consulting with electrical engineers can also provide insights tailored to your specific use case. -

How can I vet potential suppliers for electric plug prongs?

Vetting potential suppliers involves a thorough evaluation of their credentials, quality assurance practices, and compliance with international standards. Start by checking their certifications, such as ISO 9001, and inquire about their manufacturing processes. Request samples to assess product quality and durability. Additionally, look for reviews or testimonials from other businesses in your industry. Establishing a clear line of communication and visiting their facilities, if possible, can also provide insights into their operational capabilities. -

What customization options are available for electric plug prongs?

Many manufacturers offer customization options for electric plug prongs, including variations in color, material, and configuration. Businesses can request specific amperage ratings, grounding options, or unique branding elements such as logos. Discussing your customization needs with suppliers during the initial sourcing phase can help align their capabilities with your requirements. Be prepared to provide detailed specifications to ensure that the final product meets your expectations and complies with local regulations. -

What are the typical minimum order quantities (MOQ) for electric plug prongs?

Minimum order quantities (MOQ) for electric plug prongs can vary significantly based on the manufacturer and the complexity of the product. Generally, MOQs can range from 100 to 1,000 units for standard items, while customized products may have higher MOQs due to setup costs. When negotiating with suppliers, consider your inventory needs and lead times to find a balance that works for both parties. Some manufacturers may be willing to accommodate smaller orders for a trial run, especially if you plan to establish a long-term partnership. -

What payment terms should I expect when sourcing electric plug prongs internationally?

Payment terms for sourcing electric plug prongs internationally typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit (usually 30% to 50%) before production begins, with the balance due before shipment. It’s crucial to discuss and agree on payment terms upfront to avoid misunderstandings. Additionally, consider using escrow services for large transactions to protect both parties during the payment process. -

How do I ensure quality assurance for electric plug prongs?

Ensuring quality assurance for electric plug prongs involves implementing a robust inspection process both during and after production. Establish quality control checkpoints throughout the manufacturing cycle, including raw material inspections, in-process checks, and final product evaluations. Request certifications and test reports from suppliers to verify compliance with international safety standards. Engaging third-party inspection services can also provide an unbiased assessment of product quality before shipment. -

What logistics considerations should I keep in mind when importing electric plug prongs?

When importing electric plug prongs, logistics considerations include understanding the customs regulations and tariffs of the destination country. Ensure that your products comply with local electrical standards to avoid delays. Work with reliable freight forwarders who specialize in international shipping to navigate customs clearance effectively. Additionally, consider shipping options that balance cost and delivery time, and plan for potential disruptions in the supply chain by maintaining clear communication with your suppliers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric plug prongs

In today’s global marketplace, the strategic sourcing of electric plug prongs is paramount for international B2B buyers. By understanding the technical specifications, safety standards, and regional compliance requirements, businesses can make informed purchasing decisions that enhance product reliability and customer satisfaction.

How Can Strategic Sourcing Enhance Your Supply Chain?

Effective sourcing strategies not only reduce costs but also mitigate risks associated with supply chain disruptions. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate a commitment to quality and compliance with international standards, such as IEC and NEMA configurations. Establishing partnerships with reliable manufacturers can lead to improved product quality and long-term cost savings.

What Should International Buyers Consider Moving Forward?

As markets evolve, so do consumer preferences and regulatory landscapes. B2B buyers must stay abreast of emerging trends, such as the shift towards sustainable materials and smart technology integration in electrical components. Engaging with suppliers who are innovating in these areas can position your business for future growth.

In conclusion, embracing strategic sourcing practices will empower international B2B buyers to navigate the complexities of the electric plug prong market effectively. As you move forward, consider investing in partnerships that align with your business goals and compliance needs. The future of electrical components is bright—take the next step towards optimizing your supply chain today.