Master Electrical Plug Prongs: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for electrical plug prongs

Navigating the global market for electrical plug prongs can be a daunting challenge for international B2B buyers, especially when sourcing reliable and compliant products for diverse applications. With varying standards and specifications across regions, understanding the intricacies of electrical plug types, their applications, and safety requirements is essential. This comprehensive guide delves into the different types of electrical plug prongs, their applications in various industries, and critical factors such as supplier vetting, pricing, and regulatory compliance.

International buyers from Africa, South America, the Middle East, and Europe, including countries like the UK and Brazil, will benefit from actionable insights tailored to their unique market needs. By addressing key considerations such as voltage requirements, amperage ratings, and the importance of grounding, this guide equips businesses with the knowledge to make informed purchasing decisions. Additionally, it highlights the significance of aligning with suppliers who not only provide high-quality products but also understand local regulations and standards.

Empowering B2B buyers with this essential information ensures that they can navigate the complexities of sourcing electrical plug prongs effectively, minimizing risks and maximizing operational efficiency in their respective markets. Whether you are looking to expand your product offerings or ensure compliance with international standards, this guide serves as your roadmap to successful procurement in the electrical components sector.

Understanding electrical plug prongs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA Plugs | Standardized configurations, varying amperages | Industrial equipment, appliances | Pros: Widely recognized, safety standards. Cons: Limited compatibility in some regions. |

| Schuko Plugs | Round pins, grounding feature, high amperage | European appliances, tools | Pros: Robust design, high current capacity. Cons: May require adapters for non-European devices. |

| BS 1363 Plugs | Square pins, fused, includes safety shutter | UK appliances, consumer electronics | Pros: Safety features, universal in the UK. Cons: Bulky design may not fit all outlets. |

| Type C Plugs | Two round pins, lightweight, no grounding | General electronics, travel | Pros: Compact, versatile. Cons: No grounding, less safe for high-power devices. |

| Type G Plugs | Three rectangular prongs, fuse protection | UK, Middle East appliances | Pros: High safety standards, durable. Cons: Incompatibility with non-Type G sockets. |

What are NEMA Plugs and Their Key Characteristics?

NEMA (National Electrical Manufacturers Association) plugs are designed with standardized configurations for various amperages, typically ranging from 15A to 50A. They are widely used in North America for industrial equipment and larger appliances. When purchasing NEMA plugs, B2B buyers should consider the specific amperage requirements of their devices and the compatibility with local electrical standards, particularly when sourcing products for international markets.

How Do Schuko Plugs Work in B2B Applications?

Schuko plugs are characterized by their round pins and grounding feature, making them suitable for high-amperage applications across Europe. These plugs are commonly used in industrial settings and for power tools. B2B buyers should evaluate the compatibility of Schuko plugs with their equipment, especially if they are importing devices from non-European regions, as adapters may be necessary.

What Makes BS 1363 Plugs Unique?

BS 1363 plugs feature square pins and include a fuse, providing an additional safety layer. They are the standard in the UK and are used for a wide range of appliances and consumer electronics. When considering BS 1363 plugs, B2B buyers should assess the fuse rating and ensure compliance with UK safety regulations, especially when dealing with high-power devices.

Why Choose Type C Plugs for General Electronics?

Type C plugs are lightweight with two round pins, making them a popular choice for general electronics and travel. They are versatile and can fit into various sockets, but they lack a grounding feature, which could pose safety risks for high-power devices. B2B buyers should prioritize Type C plugs for low-power applications while considering the safety implications for more demanding equipment.

What are the Benefits of Using Type G Plugs?

Type G plugs, with three rectangular prongs and built-in fuse protection, are commonly used in the UK and the Middle East. Their robust design and high safety standards make them ideal for both residential and commercial applications. Buyers should ensure that their electrical systems can accommodate Type G plugs and consider sourcing compatible devices to maintain safety and functionality across their operations.

Key Industrial Applications of electrical plug prongs

| Industry/Sector | Specific Application of electrical plug prongs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial machinery connection | Ensures stable power supply for operational efficiency | Compliance with local voltage and amperage standards |

| Healthcare | Medical equipment power supply | Critical for patient safety and operational reliability | Need for hospital-grade plugs to prevent electrical hazards |

| Construction | Power tools and site equipment | Enhances productivity and reduces downtime | Durability against environmental conditions (weatherproof) |

| Hospitality | Appliances in hotels and restaurants | Improved guest experience through reliable power | Consideration for energy efficiency and compatibility |

| Telecommunications | Data center equipment and servers | Supports continuous operation and data integrity | High-quality connectors to withstand high electrical loads |

How Are Electrical Plug Prongs Used in Manufacturing?

In the manufacturing sector, electrical plug prongs are crucial for connecting industrial machinery to power sources. The stability of these connections ensures that equipment operates efficiently, reducing the risk of downtime due to power failures. International buyers must ensure that the plugs meet local electrical standards, particularly in terms of voltage and amperage, to avoid potential operational issues. Additionally, sourcing durable plugs that can withstand the rigors of a manufacturing environment is essential for maintaining productivity.

What Role Do Electrical Plug Prongs Play in Healthcare?

In healthcare, electrical plug prongs are integral for powering medical equipment, such as imaging devices and life-support systems. Ensuring a reliable power supply is critical for patient safety, as any interruption can have severe consequences. Buyers in this sector should prioritize hospital-grade plugs that offer enhanced safety features, such as surge protection and grounding. Compliance with healthcare regulations and standards is essential for any electrical components used in medical settings, making sourcing from reputable suppliers a necessity.

How Are Electrical Plug Prongs Utilized in Construction?

Construction sites rely heavily on electrical plug prongs to power tools and heavy machinery. The reliable connection provided by these plugs enhances productivity and minimizes downtime caused by electrical failures. Buyers in this sector should consider sourcing weather-resistant and durable plugs, as construction environments can be harsh and unpredictable. Additionally, understanding the specific power requirements of various tools is essential to ensure compatibility and safety.

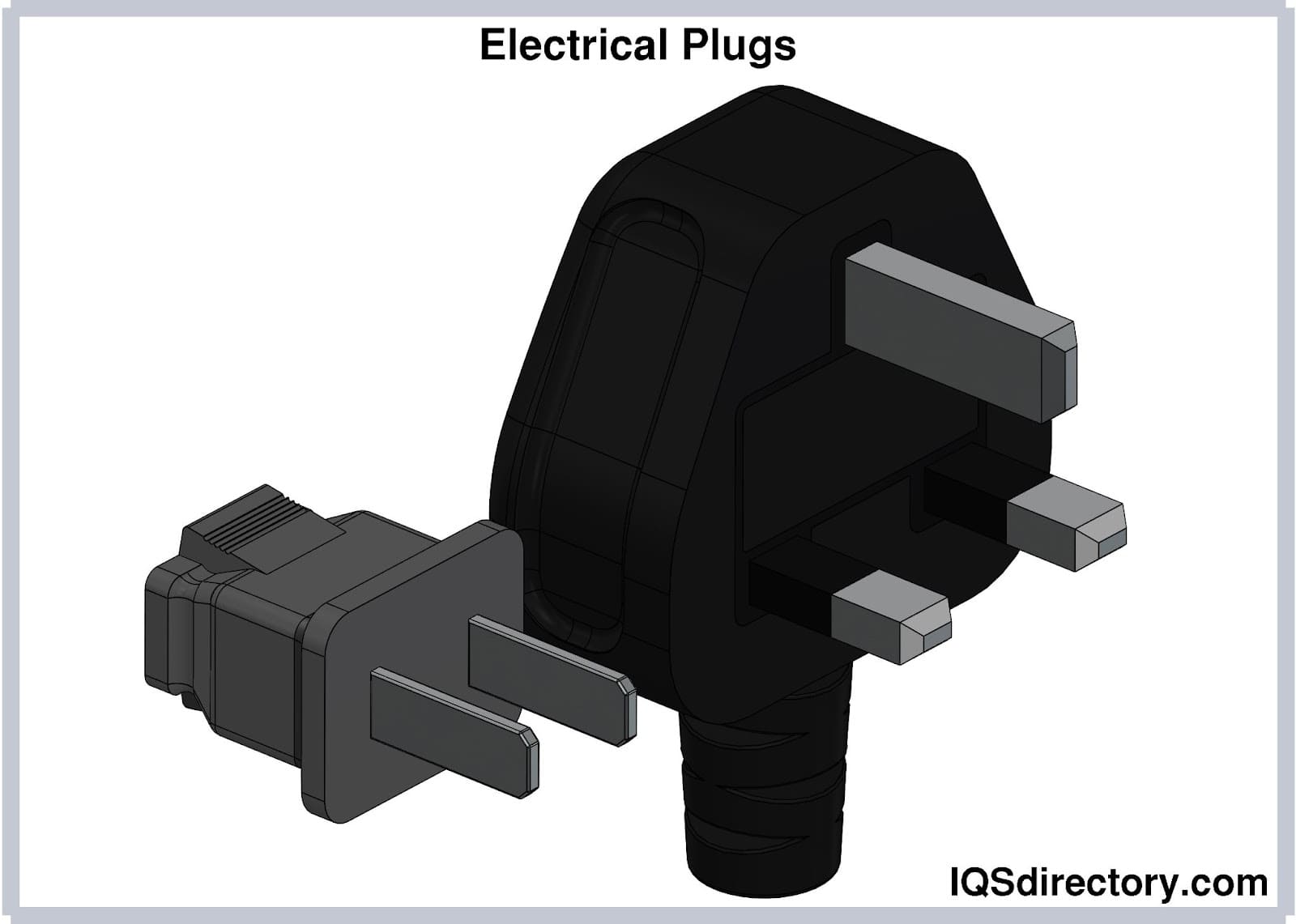

A stock image related to electrical plug prongs.

What Is the Importance of Electrical Plug Prongs in the Hospitality Industry?

In the hospitality sector, electrical plug prongs are used extensively to connect appliances in hotels and restaurants, from kitchen equipment to lighting systems. Reliable power connections enhance the guest experience by ensuring that all amenities function smoothly. When sourcing plugs for this industry, it is vital to consider energy efficiency and compatibility with various electrical systems to optimize operational costs. Additionally, choosing aesthetically pleasing designs can align with the branding of the hospitality establishment.

How Do Electrical Plug Prongs Support Telecommunications?

In telecommunications, electrical plug prongs are essential for connecting data center equipment and servers to power sources. These connections are critical for maintaining continuous operation and data integrity, particularly as the demand for high-speed internet and data services increases. International B2B buyers must prioritize high-quality connectors that can handle high electrical loads and ensure minimal disruption to services. Understanding the specific power requirements of telecommunications equipment is crucial for sourcing appropriate plug solutions.

3 Common User Pain Points for ‘electrical plug prongs’ & Their Solutions

Scenario 1: Incompatibility with Local Power Standards

The Problem: International B2B buyers often face significant challenges when sourcing electrical plug prongs due to the varying power standards across regions. For example, a company in Africa might import equipment designed for the European market, only to discover that the plug prongs do not fit local sockets. This incompatibility can halt operations, lead to increased costs for adapters, and create safety concerns due to improper connections.

The Solution: To mitigate this issue, buyers should conduct thorough research on the plug and socket standards specific to their region. It’s crucial to identify the NEMA (National Electrical Manufacturers Association) configurations or equivalent regional standards, such as BS, IEC, or CEE standards. When sourcing electrical plugs, buyers should prioritize manufacturers that offer customizable solutions or a diverse range of products that meet international and local specifications. Additionally, establishing relationships with suppliers who understand the regulatory landscape of each market can streamline the procurement process and ensure compliance with safety standards.

Scenario 2: Safety Risks Due to Poor Quality

The Problem: Another common pain point for B2B buyers is the risk associated with low-quality electrical plug prongs. Inexpensive options may seem attractive initially, but they often lack necessary safety features, such as grounding or surge protection. This can lead to equipment damage, increased maintenance costs, or even fire hazards, posing a severe risk to business operations and employee safety.

The Solution: To address safety concerns, buyers should prioritize sourcing electrical plug prongs from reputable manufacturers known for their quality and compliance with international safety standards. Look for certifications such as UL, CE, or ISO, which indicate adherence to safety regulations. Additionally, investing in higher-quality plugs that include features such as surge protection and tamper resistance can enhance safety. Conducting regular audits of suppliers and their products can also ensure ongoing quality and compliance, reducing the risk of accidents and liabilities.

Scenario 3: Limited Availability of Specialized Plugs

The Problem: B2B buyers often encounter difficulties in finding specialized electrical plug prongs for specific applications, such as industrial machinery or medical equipment. These specialized plugs may not be readily available in local markets, leading to delays in project timelines and increased shipping costs if sourced internationally. This scarcity can hinder production schedules, ultimately affecting a company’s bottom line.

The Solution: To overcome this challenge, buyers should build strategic partnerships with manufacturers and suppliers that specialize in niche electrical components. This approach can provide access to a broader range of products and potentially allow for customization to meet specific operational needs. Additionally, engaging in bulk purchasing agreements can help secure better pricing and availability for specialized plugs. Utilizing online platforms that aggregate suppliers and manufacturers can also simplify the search process, allowing buyers to compare products, prices, and lead times effectively. Finally, staying informed about emerging trends and technologies in electrical connectivity can help buyers anticipate future needs and source accordingly.

Strategic Material Selection Guide for electrical plug prongs

What Are the Key Properties of Common Materials Used for Electrical Plug Prongs?

When selecting materials for electrical plug prongs, it is crucial to consider their properties, which directly influence performance and safety. The most commonly used materials include brass, stainless steel, aluminum, and copper. Each material has distinct characteristics that cater to various applications and market requirements.

How Does Brass Perform as a Material for Electrical Plug Prongs?

Brass is an alloy primarily composed of copper and zinc. It exhibits excellent conductivity and corrosion resistance, making it a popular choice for electrical applications. Its temperature rating typically ranges up to 120°C, which is suitable for most household and commercial environments.

Pros: Brass is durable, resistant to tarnishing, and offers good mechanical strength. Its cost is relatively low, which makes it an economical choice for mass production.

Cons: While brass is corrosion-resistant, it can still be susceptible to dezincification in certain conditions, which may lead to reduced performance over time. Additionally, its manufacturing process can be complex, requiring precise machining.

Impact on Application: Brass prongs are compatible with a variety of electrical devices, particularly in regions with moderate humidity. However, buyers in coastal areas or regions with high salinity should consider alternative materials to avoid corrosion.

What Advantages Does Stainless Steel Offer for Electrical Plug Prongs?

Stainless steel is known for its exceptional corrosion resistance and mechanical strength. It can withstand high temperatures (up to 250°C) and is often used in environments where durability is paramount.

Pros: The primary advantage of stainless steel is its longevity and resistance to rust and corrosion, making it ideal for harsh environments. It also provides a sleek appearance, which can be beneficial for consumer-facing products.

Cons: The main drawback is its higher cost compared to brass and aluminum. The manufacturing process can also be more complex, leading to higher production costs.

Impact on Application: Stainless steel is suitable for industrial applications and environments with high moisture levels, such as the Middle East and coastal regions in Europe. Compliance with standards such as ASTM and DIN is essential for international buyers.

Why Is Aluminum Considered a Lightweight Option for Electrical Plug Prongs?

Aluminum is a lightweight metal that offers good conductivity and is resistant to corrosion when anodized. Its temperature rating is typically around 150°C, making it suitable for various applications.

Pros: The lightweight nature of aluminum makes it easy to handle and reduces shipping costs. It is also less expensive than stainless steel, making it a cost-effective option for large-scale production.

Cons: Aluminum can be prone to oxidation, which may affect its conductivity over time. Additionally, it is not as mechanically strong as brass or stainless steel, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum prongs are often used in consumer electronics and appliances. Buyers in regions with less humidity may find aluminum to be a suitable option, but those in more corrosive environments should be cautious.

How Does Copper Compare as a Material for Electrical Plug Prongs?

Copper is renowned for its excellent electrical conductivity, making it a preferred choice for high-performance applications. It can handle temperatures up to 200°C, which is advantageous for high-load scenarios.

Pros: The primary advantage of copper is its superior conductivity, which ensures efficient power transfer. It is also relatively easy to work with during manufacturing.

Cons: Copper is more expensive than brass and aluminum and is prone to corrosion if not properly coated. Its weight may also be a consideration for certain applications.

Impact on Application: Copper prongs are ideal for high-performance electrical devices and are often required in applications that demand reliability. International buyers should ensure compliance with relevant standards to meet safety and performance expectations.

Summary Table of Material Selection for Electrical Plug Prongs

| Material | Typical Use Case for Electrical Plug Prongs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Household and commercial plugs | Good conductivity and cost-effective | Susceptible to dezincification | Low |

| Stainless Steel | Industrial applications | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Consumer electronics and lightweight plugs | Lightweight and cost-effective | Prone to oxidation | Med |

| Copper | High-performance electrical devices | Superior conductivity | Expensive and prone to corrosion | High |

This guide provides international B2B buyers with a comprehensive understanding of material options for electrical plug prongs, emphasizing the importance of selecting the right material based on application and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical plug prongs

What Are the Key Stages in the Manufacturing Process of Electrical Plug Prongs?

Manufacturing electrical plug prongs involves several critical stages, each essential for ensuring the final product meets both safety and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used for Electrical Plug Prongs?

The first stage of manufacturing electrical plug prongs begins with material selection. Common materials include:

- Copper or Brass: These metals are typically used for the prongs due to their excellent conductivity and corrosion resistance.

- Thermoplastics: Used for the body of the plug, these materials provide insulation and protect users from electric shock.

Once the materials are selected, they undergo a thorough inspection to ensure they meet quality standards. This inspection often includes checking for impurities and verifying dimensions, which is crucial for the subsequent stages.

How Are Electrical Plug Prongs Formed?

The forming stage involves shaping the raw materials into the desired plug prong design. This can be accomplished through several techniques, including:

- Stamping: Metal sheets are punched into specific shapes using dies, allowing for high-volume production.

- Die-Casting: This method is particularly useful for creating intricate shapes and is often used for thermoplastic components.

After forming, the prongs are often subjected to further treatments, such as annealing, to improve their mechanical properties and conductivity.

What Is the Assembly Process for Electrical Plug Prongs?

In the assembly stage, individual components are brought together to create a complete electrical plug. This typically includes:

- Inserting the Prongs: The formed prongs are inserted into the plastic body of the plug.

- Screwing or Welding: Depending on the design, prongs may be secured through screws or welding techniques to ensure a strong connection.

This stage is critical as improper assembly can lead to poor electrical performance or safety hazards.

How Does Finishing Enhance the Quality of Electrical Plug Prongs?

Finishing processes are applied to improve the aesthetic appeal and functionality of electrical plug prongs. Common finishing techniques include:

- Plating: Applying a layer of nickel or tin to enhance corrosion resistance.

- Surface Treatments: Techniques such as polishing or coating can be used to improve surface quality.

Finishing not only enhances durability but also ensures that the plugs comply with international safety standards.

What Quality Assurance Measures Are Essential for Electrical Plug Prongs?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that electrical plug prongs meet the necessary safety and performance criteria.

Which International Standards Should B2B Buyers Be Aware Of?

International standards play a crucial role in ensuring the quality of electrical components. Relevant standards for electrical plug prongs include:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate consistent quality.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

Understanding these standards helps buyers assess the credibility of suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify issues early.

- Final Quality Control (FQC): A comprehensive inspection of the finished product before packaging ensures that all specifications are met.

Implementing these checkpoints allows manufacturers to catch defects early, reducing the risk of faulty products reaching the market.

What Common Testing Methods Are Used for Electrical Plug Prongs?

Testing methods are crucial for verifying the safety and performance of electrical plug prongs. Common methods include:

- Electrical Testing: This involves checking the conductivity and insulation resistance of the plugs.

- Mechanical Testing: Assessing the durability and strength of the prongs through stress tests.

- Environmental Testing: Simulating various environmental conditions to ensure the plugs perform reliably under different circumstances.

These tests help ensure that the products are safe for end-users and compliant with international standards.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers should take proactive steps to verify the quality assurance processes of potential suppliers. Here are effective strategies:

- Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and QC practices of suppliers firsthand.

- Requesting Quality Reports: Buyers can ask suppliers for documentation on their quality control procedures and results from recent tests.

- Third-Party Inspections: Engaging an independent third party to evaluate the supplier’s processes can provide an unbiased assessment of quality.

These steps not only help buyers ensure product quality but also build trust with suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. These nuances include:

- Regulatory Compliance: Buyers must be aware of local regulations that may impact product specifications and certifications.

- Cultural Considerations: Different regions may have varying approaches to quality assurance, necessitating an understanding of local practices.

- Supply Chain Transparency: Buyers should ensure that suppliers maintain transparency throughout the supply chain, from raw material sourcing to final product delivery.

By considering these factors, international buyers can better navigate the complexities of quality assurance in the manufacturing of electrical plug prongs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical plug prongs’

In the world of international B2B procurement, sourcing electrical plug prongs requires a systematic approach. This guide offers a step-by-step checklist to help you navigate the complexities of purchasing these essential components, ensuring that your procurement aligns with safety standards and regional requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Identify the types of electrical plug prongs you need based on voltage and amperage requirements. Consider factors such as:

– Type of Appliance: Different appliances may require specific plug configurations (e.g., two-prong vs. three-prong).

– Regional Standards: Understand the electrical standards in your target market, such as NEMA configurations in North America or IEC standards in Europe.

Step 2: Conduct Market Research

Before reaching out to suppliers, perform thorough market research to understand the current landscape. Investigate which manufacturers lead the market in your region and what products are in high demand. Focus on:

– Brand Reputation: Look for brands with a solid track record of quality and reliability.

– Emerging Trends: Be aware of innovations such as smart plugs or energy-efficient designs that could influence your procurement strategy.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider:

– Certifications: Ensure the supplier adheres to international safety standards (e.g., UL, CE).

– Production Capacity: Assess whether the supplier can meet your volume needs, especially if you anticipate scaling your orders.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the electrical plug prongs you intend to purchase. Testing samples can help you:

– Verify Quality: Check for durability, compatibility with your appliances, and adherence to specifications.

– Assess Performance: Ensure that the plugs function correctly under expected load conditions.

Step 5: Check Compliance with Regulatory Standards

Regulatory compliance is non-negotiable in international sourcing. Verify that the electrical plug prongs meet the necessary regulations for your specific market. Pay attention to:

– Safety Standards: Confirm that the products comply with local and international safety regulations to avoid legal issues.

– Import Requirements: Understand any import duties or regulations that may apply when bringing these products into your country.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate favorable terms and conditions. Consider aspects such as:

– Pricing: Aim for a competitive price but balance cost with quality.

– Lead Times: Clarify production and delivery timelines to ensure your supply chain remains uninterrupted.

Step 7: Establish a Quality Assurance Process

After placing your order, set up a quality assurance process to ensure that the received products meet your specifications. This should include:

– Inspection Protocols: Define how and when inspections will occur.

– Feedback Mechanisms: Establish channels for reporting issues and resolving disputes efficiently.

By following this checklist, international B2B buyers can streamline their sourcing process for electrical plug prongs, ensuring that they procure high-quality products that meet their technical needs and regional regulations.

Comprehensive Cost and Pricing Analysis for electrical plug prongs Sourcing

What Are the Key Cost Components for Electrical Plug Prongs?

When sourcing electrical plug prongs, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used—such as thermoplastics, metals (e.g., copper for prongs), and insulation—can significantly impact costs. Higher quality materials often command a premium but can enhance safety and durability.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs, such as those in parts of Africa or South America, may offer competitive pricing, but be mindful of potential trade-offs in quality.

-

Manufacturing Overhead: This includes costs related to the factory’s operation, maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, translating to better pricing for buyers.

-

Tooling: Custom designs or unique specifications may require specialized tooling, which can be a substantial upfront cost. Understanding how tooling costs are amortized over production runs is essential for evaluating overall pricing.

-

Quality Control (QC): Investing in rigorous QC processes ensures product reliability and compliance with international standards. While this may increase initial costs, it can prevent costly returns and liabilities later.

-

Logistics: Shipping and handling costs, particularly for international buyers, can fluctuate based on distance, mode of transport, and shipping terms. Incoterms play a vital role in determining who bears these costs.

-

Margin: Suppliers will include a margin on top of their costs, which can vary widely based on market conditions, competition, and perceived value.

How Do Price Influencers Affect Electrical Plug Prong Sourcing?

Several factors can influence the pricing of electrical plug prongs:

-

Volume/MOQ: Minimum order quantities (MOQ) are critical. Higher volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their inventory needs.

-

Specifications and Customization: Custom designs or specific certifications (like UL or CE) can increase costs. Buyers should balance the need for customization with their budget constraints.

-

Materials and Quality: The choice of materials directly affects pricing. High-quality, certified materials will be more expensive but may offer long-term savings through reduced failure rates and warranty claims.

-

Supplier Factors: Supplier reputation, experience, and location can all impact pricing. Established suppliers with proven track records may charge higher prices but offer better reliability and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities for shipping costs, insurance, and risk, which can affect the total landed cost of products.

What Tips Can Help Buyers Optimize Costs?

International B2B buyers can adopt several strategies to optimize their sourcing costs:

-

Effective Negotiation: Always negotiate prices, especially on larger orders. Building a relationship with suppliers can lead to better terms and discounts.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but the long-term costs associated with quality, maintenance, and potential failures. A cheaper option may end up being more expensive over time.

-

Understand Pricing Nuances: Familiarize yourself with market trends and seasonal pricing fluctuations in the electrical components sector. This can help you time your purchases for maximum savings.

-

Leverage Local Insights: Buyers from regions like Africa, South America, and the Middle East should consider local suppliers who understand regional compliance requirements and can offer competitive pricing.

-

Evaluate Supply Chain Options: Investigate various logistics providers and shipping methods. Sometimes, slightly longer shipping times can save significant costs.

Disclaimer

Prices for electrical plug prongs can vary widely based on the factors outlined above. It is advisable to request quotes from multiple suppliers and conduct thorough market research before making purchasing decisions. Always consider that prices may fluctuate due to changes in material costs, labor rates, and international trade policies.

Alternatives Analysis: Comparing electrical plug prongs With Other Solutions

Introduction to Alternatives for Electrical Plug Prongs

When it comes to powering devices in a global marketplace, electrical plug prongs serve as the standard interface for connecting appliances to electrical outlets. However, as international B2B buyers explore options for various applications, it is essential to consider alternative solutions that may offer enhanced performance, safety, and adaptability. This analysis will compare electrical plug prongs with two viable alternatives: Power Distribution Units (PDUs) and Wireless Power Transfer (WPT) systems.

Comparison Table of Electrical Plug Prongs and Alternatives

| Comparison Aspect | Electrical Plug Prongs | Power Distribution Units (PDUs) | Wireless Power Transfer (WPT) |

|---|---|---|---|

| Performance | High; reliable connection | Variable; depends on load capacity | Moderate; efficiency varies with distance |

| Cost | Low initial cost; widespread availability | Moderate; requires installation and infrastructure | High; technology still evolving |

| Ease of Implementation | Easy; plug and play for users | Requires installation and setup | Requires specialized equipment and alignment |

| Maintenance | Minimal; occasional wear and tear | Moderate; regular checks needed | Low; minimal maintenance but limited by technology |

| Best Use Case | Standard appliances, consumer electronics | Data centers, high-power equipment | Mobile devices, short-range applications |

Detailed Breakdown of Alternatives

What Are Power Distribution Units (PDUs)?

Power Distribution Units (PDUs) are designed to distribute electrical power to multiple devices from a single source. They are particularly useful in environments like data centers where multiple servers require reliable power supply. Pros include the ability to manage power loads effectively and monitor energy consumption. However, cons involve higher initial costs and the need for professional installation, which may not be feasible for smaller businesses or in regions with limited electrical infrastructure.

How Does Wireless Power Transfer (WPT) Work?

Wireless Power Transfer (WPT) technology allows for the transmission of electrical energy without the need for physical connectors. This system is gaining traction in mobile charging solutions and other applications where convenience is paramount. The advantages of WPT include eliminating wear and tear on connectors and providing a seamless user experience. However, the disadvantages include higher costs and efficiency losses over longer distances, making it less suitable for high-power applications or where continuous energy supply is critical.

Conclusion: Choosing the Right Solution for Your Needs

For international B2B buyers, the choice between electrical plug prongs and alternative solutions like PDUs or WPT should be based on specific operational requirements and budget constraints. If you require a low-cost and straightforward solution for standard appliances, electrical plug prongs remain the best option. However, for environments needing high power management and monitoring capabilities, investing in PDUs could provide long-term benefits. On the other hand, if convenience and modern technology are priorities, WPT may be the way forward, albeit at a higher cost. Understanding these alternatives will empower businesses to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for electrical plug prongs

What Are the Key Technical Properties of Electrical Plug Prongs?

A stock image related to electrical plug prongs.

When considering electrical plug prongs for your business needs, understanding their technical properties is essential. Here are several critical specifications that every B2B buyer should be aware of:

1. Material Grade: Why Is It Important?

The material used in electrical plug prongs primarily affects durability and conductivity. Common materials include copper, brass, and various alloys. Copper is highly conductive and resistant to corrosion, making it ideal for high-performance applications. Brass, while less conductive than copper, offers excellent corrosion resistance. Selecting the right material ensures reliability and longevity, reducing maintenance costs and potential downtime.

2. Amperage Rating: How Does It Affect Performance?

The amperage rating indicates the maximum current that a plug can handle safely, typically ranging from 15A to 50A. This rating is crucial for determining compatibility with electrical devices and systems. Choosing the correct amperage rating is vital for preventing overheating and ensuring safety, especially in industrial settings where equipment draws significant power.

3. Voltage Rating: What Should You Know?

Voltage rating reflects the maximum voltage the plug can safely handle, with common ratings being 120V and 240V. Understanding voltage compatibility is essential for international buyers, as different regions may use varying voltage standards. Selecting plugs with appropriate voltage ratings ensures operational safety and compliance with local electrical codes.

4. NEMA Configuration: Why Is It Necessary?

The National Electrical Manufacturers Association (NEMA) defines specific configurations for plugs and receptacles. These configurations ensure compatibility between devices and outlets. Familiarity with NEMA configurations is particularly important for international transactions, as different countries may have different standards. Ensuring you choose the correct NEMA configuration can prevent equipment damage and enhance safety.

5. Durability Ratings: What Do They Indicate?

Durability ratings, such as weather-resistant or corrosion-resistant, indicate how well a plug can withstand environmental factors. For businesses operating in harsh conditions, selecting plugs with high durability ratings is essential for minimizing failure rates and prolonging the lifespan of electrical components.

What Are Common Trade Terms Related to Electrical Plug Prongs?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM produces components that are used in another company’s products. For electrical plug prongs, working with an OEM can ensure that you receive high-quality components tailored to your specifications. This is particularly important for businesses looking to maintain brand integrity and product reliability.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for smaller businesses. Ensuring your order meets MOQ can also lead to better pricing and reduced shipping costs.

3. RFQ (Request for Quotation): How Is It Used?

An RFQ is a document sent to suppliers to request pricing and terms for specific quantities of products. It is a vital tool for B2B buyers looking to compare options and negotiate better deals. A well-structured RFQ can expedite the procurement process and lead to more favorable terms.

4. Incoterms (International Commercial Terms): What Are They?

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms can help B2B buyers understand shipping costs, risks, and responsibilities, ensuring smoother international transactions.

5. Compliance Standards: Why Are They Important?

Compliance standards refer to regulations that products must meet to be sold in specific markets. Understanding these standards is crucial for international B2B buyers to ensure that electrical plug prongs meet safety and performance requirements, avoiding costly penalties or recalls.

By grasping these essential technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring the reliability and safety of their electrical systems.

Navigating Market Dynamics and Sourcing Trends in the electrical plug prongs Sector

What Are the Current Market Dynamics and Key Trends in the Electrical Plug Prongs Sector?

The electrical plug prongs market is experiencing significant transformation driven by global demand for energy-efficient solutions and safety standards. As industries and consumers increasingly prioritize sustainability, the emphasis on energy-efficient devices has become a key market driver. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note that there is a growing trend towards the adoption of smart plugs and connectors that integrate IoT technology. This not only enhances energy management but also offers remote control capabilities, catering to the needs of modern businesses.

Another notable trend is the diversification of plug types and configurations to accommodate various voltage standards across different regions. For instance, North America predominantly uses 120V systems, while many European countries use 230V systems. Buyers must be vigilant about compliance with local regulations and standards, such as NEMA configurations in the US and IEC standards in Europe, to ensure compatibility and safety.

Additionally, the rise of e-commerce platforms is reshaping the sourcing landscape, enabling B2B buyers to access a wider range of products and suppliers. This digital shift allows for easier comparison of prices and features, empowering buyers to make informed decisions. However, it is essential to conduct thorough due diligence on suppliers, especially when sourcing from emerging markets where quality standards may vary.

How Can Sustainability and Ethical Sourcing Impact the Electrical Plug Prongs Supply Chain?

Sustainability is becoming a non-negotiable criterion for B2B buyers in the electrical plug prongs sector. The environmental impact of manufacturing processes, including the use of hazardous materials and energy consumption, has prompted increased scrutiny. Buyers should prioritize suppliers who demonstrate a commitment to reducing their carbon footprint and implementing sustainable practices throughout their supply chains.

Ethical sourcing is equally important. Buyers should seek suppliers who adhere to fair labor practices and provide transparency regarding their sourcing materials. Certifications such as RoHS (Restriction of Hazardous Substances) and Energy Star can serve as indicators of a product’s environmental credentials. By choosing products that are certified as environmentally friendly, businesses not only comply with regulations but also enhance their brand reputation in a market that increasingly values corporate social responsibility.

Moreover, investing in products made from recycled or sustainably sourced materials can help reduce overall waste and contribute to a circular economy. This commitment to sustainability not only aligns with global trends but also appeals to environmentally conscious consumers, thereby providing a competitive edge.

What Is the Historical Context of Electrical Plug Prongs in the B2B Market?

The evolution of electrical plug prongs can be traced back to the late 19th century when the need for standardized electrical connections emerged alongside the widespread adoption of electricity. Initially, plugs were often ungrounded two-prong designs, which posed safety risks. The introduction of the three-prong plug in the 1920s marked a significant advancement in electrical safety, providing grounding to prevent electric shock.

As international trade expanded, the need for standardized plug types became evident, leading to the establishment of various global standards. Organizations like the International Electrotechnical Commission (IEC) began to develop standardized configurations, facilitating safer and more reliable electrical connections worldwide. This historical context is crucial for B2B buyers, as understanding these developments can inform their sourcing decisions and compliance with international safety standards today.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical plug prongs

-

How do I solve compatibility issues with electrical plug prongs in different countries?

To address compatibility issues, first identify the plug type and voltage requirements in your target market. Research the specific standards (like NEMA in the US or BS in the UK) for the countries you are supplying. Consider sourcing multi-standard or universal plugs that can adapt to various outlets. Engaging with local regulatory bodies or consulting with experienced local suppliers can help ensure compliance with local electrical standards, reducing the risk of compatibility issues. -

What is the best electrical plug prong type for industrial applications?

For industrial applications, NEMA configurations such as NEMA L14-30 or NEMA 6-50 are often recommended due to their high amperage ratings and locking features that prevent accidental disconnection. These types are designed to handle heavier loads and provide safety in environments where equipment may be exposed to moisture or dust. Always ensure the plug prongs are rated for the voltage and current of the equipment they will connect to, and consider weather-resistant options for outdoor use. -

What are the typical minimum order quantities (MOQ) for electrical plug prongs?

Minimum order quantities can vary significantly by supplier and region. Generally, MOQs for electrical plug prongs may range from 100 to 1,000 units, depending on the complexity and customization of the product. For international buyers, it’s wise to discuss MOQs upfront with suppliers to negotiate terms that align with your procurement strategy, especially if you are testing a new market or product line. -

How can I verify the quality of electrical plug prongs from suppliers?

To ensure quality, request samples before placing a bulk order. Verify that the products meet international safety standards, such as IEC or UL certifications. It’s also beneficial to conduct factory audits or request third-party inspections to assess manufacturing practices. Establishing a solid quality assurance protocol, including regular inspections throughout the production process, can help mitigate risks associated with product defects. -

What payment terms are common for international purchases of electrical plug prongs?

Common payment terms in international B2B transactions include letters of credit, advance payments, and net payment terms (e.g., net 30, net 60). It’s essential to negotiate terms that protect both parties. Letters of credit provide security for both buyer and seller, while advance payments may be requested for custom orders. Ensure that all payment terms are clearly outlined in the contract to prevent misunderstandings.

A stock image related to electrical plug prongs.

-

How do I manage logistics for sourcing electrical plug prongs internationally?

Managing logistics involves selecting reliable freight forwarders who understand import/export regulations. Consider the total landed cost, including shipping, tariffs, and insurance, to assess the best shipping method—air freight for speed or sea freight for cost-effectiveness. Establish clear timelines and communication channels with your suppliers and logistics partners to ensure timely delivery and minimize disruptions. -

What customization options should I consider for electrical plug prongs?

Customization options can include specific prong configurations, color coding for different voltage ratings, or branding with your company logo. Discuss with suppliers about the feasibility of producing custom designs that meet your specific needs, including any certifications required for safety compliance. Be prepared for potential additional costs and longer lead times associated with custom products. -

How can I stay updated on electrical plug prong regulations in different markets?

Staying informed requires regular monitoring of local regulatory bodies and industry standards organizations in your target markets. Joining industry associations can also provide access to valuable resources and updates. Additionally, consider subscribing to newsletters or following relevant publications that focus on electrical safety standards and regulations to ensure compliance and adapt your products accordingly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electrical plug prongs

Why is Strategic Sourcing Essential for Electrical Plug Prongs?

In the dynamic landscape of electrical plug prongs, strategic sourcing emerges as a critical component for international B2B buyers. By understanding regional electrical standards, voltage requirements, and safety features, businesses can optimize their procurement processes. This ensures not only compliance with local regulations but also enhances operational efficiency and product reliability.

How Can Buyers Leverage Global Markets for Better Sourcing?

For buyers in Africa, South America, the Middle East, and Europe, tapping into global suppliers can yield significant cost savings and access to innovative plug designs. Leveraging diverse sourcing channels allows companies to adapt to varying consumer needs and preferences, while also mitigating risks associated with supply chain disruptions.

What Should Buyers Consider Moving Forward?

As the demand for electrical devices continues to rise, the outlook for plug prongs remains robust. Buyers are encouraged to prioritize quality and safety certifications when selecting suppliers, as this will safeguard their investments and ensure customer satisfaction.

In conclusion, embracing a strategic sourcing approach will empower international B2B buyers to navigate the complexities of the electrical plug market effectively. Take the initiative now to explore your sourcing options, engage with reliable suppliers, and position your business for success in this evolving industry.