Master G Code: The Complete Guide to Optimize Your Processes (2025)

Introduction: Navigating the Global Market for g code

In today’s competitive landscape, understanding G-code is essential for international B2B buyers looking to optimize their operations with CNC machines and 3D printers. G-code, or Geometric Code, serves as the backbone of these technologies, dictating machine movements, speed, and precision. As companies from Africa, South America, the Middle East, and Europe (including markets like Colombia and the UK) seek to enhance their manufacturing capabilities, the challenge often lies in sourcing the right G-code solutions that align with their specific applications and technologies.

This comprehensive guide addresses the complexities of G-code, covering everything from the various types and commands to practical applications in different manufacturing settings. It also emphasizes the importance of supplier vetting, cost considerations, and the latest trends in G-code technology. By providing actionable insights and detailed explanations, this guide empowers B2B buyers to make informed purchasing decisions that enhance efficiency and productivity in their operations.

Whether you’re navigating the intricacies of G-code commands or seeking reliable suppliers, our guide equips you with the knowledge needed to leverage G-code effectively, ensuring your business stays ahead in the global market. With a focus on specific regional challenges and opportunities, this resource is tailored to meet the needs of diverse international buyers, enabling smarter, more strategic investments in technology.

Understanding g code Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| G-Code (Standard) | Basic commands for movement and positioning | CNC machining, 3D printing | Pros: Widely used, easy to learn. Cons: Limited flexibility for complex tasks. |

| G-Code (Marlin) | Extended G-code commands for 3D printing and robotics | 3D printing, robotics automation | Pros: Supports advanced features like auto bed leveling. Cons: Can be complex for beginners. |

| G-Code (GRBL) | Optimized for CNC applications with a focus on simplicity | CNC milling, engraving | Pros: Lightweight, fast, and easy to implement. Cons: Limited to basic functionalities. |

| G-Code (Fanuc) | Proprietary G-code variant with advanced features | Industrial CNC machining | Pros: High precision and reliability. Cons: Higher cost and learning curve. |

| G-Code (HeeksCAD) | User-friendly interface for creating G-code | Small-scale manufacturing | Pros: Simplifies G-code generation. Cons: May lack advanced features of other variants. |

What Are the Characteristics of Standard G-Code for B2B Buyers?

Standard G-code is the foundational programming language used for CNC machines and 3D printers. It comprises basic commands that dictate machine movements, such as linear interpolation (G01) and rapid positioning (G00). This type is suitable for buyers looking for a straightforward solution for CNC machining or 3D printing applications. However, while it is widely adopted and easy to learn, it may not offer the flexibility needed for more complex tasks, which could limit its utility in advanced manufacturing environments.

How Does Marlin G-Code Enhance 3D Printing Capabilities?

Marlin G-code extends the standard G-code with commands tailored for 3D printing and robotics. This variant is particularly beneficial for businesses in the additive manufacturing sector, as it includes advanced features like auto bed leveling and control of multiple extruders. While it provides significant advantages for sophisticated 3D printing setups, the complexity of its commands may pose a challenge for users unfamiliar with programming, necessitating careful consideration during the purchasing process.

Why Choose GRBL G-Code for CNC Applications?

GRBL G-code is designed specifically for CNC applications, focusing on simplicity and performance. It is lightweight and optimized for Arduino-based CNC machines, making it a great choice for small to medium-sized enterprises involved in milling or engraving. Buyers appreciate its quick setup and ease of use; however, its functionality is somewhat limited compared to more advanced G-code variants, which may restrict its application in highly complex projects.

What Are the Advantages of Using Fanuc G-Code in Industrial Settings?

Fanuc G-code is a proprietary variant known for its precision and reliability, making it a preferred choice for industrial CNC machining. It supports advanced functionalities that enhance operational efficiency, such as dynamic toolpath generation and high-speed machining. While the benefits are compelling, buyers should be prepared for a steeper learning curve and potential higher costs associated with acquiring Fanuc-compatible machinery and training.

How Does HeeksCAD G-Code Simplify Manufacturing Processes?

HeeksCAD G-code provides a user-friendly interface for generating G-code, making it accessible for small-scale manufacturers and hobbyists. This variant allows users to easily create toolpaths and optimize their designs without deep programming knowledge. While it simplifies the G-code generation process, businesses should note that it may lack some advanced features found in other G-code types, which could limit its effectiveness in more complex manufacturing applications.

Key Industrial Applications of g code

| Industry/Sector | Specific Application of g code | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision Machining of Components | Ensures high accuracy and quality in parts | Look for suppliers with advanced CNC capabilities and certifications. |

| Automotive | Tool Path Programming for Manufacturing | Reduces production time and enhances efficiency | Evaluate suppliers based on their experience with automotive standards. |

| Medical Devices | Custom Prosthetics and Implants | Offers tailored solutions for patient needs | Ensure compliance with medical regulations and material quality. |

| Electronics | Circuit Board Fabrication | Increases speed and precision of electronic components | Source from suppliers with robust quality control processes. |

| Consumer Goods | 3D Printing of Prototypes | Speeds up product development cycles | Assess suppliers on their 3D printing technology and material options. |

How is G-code Used in Aerospace Precision Machining?

In the aerospace sector, G-code is critical for the precision machining of components like turbine blades and structural parts. CNC machines interpret G-code to perform intricate cutting, shaping, and drilling operations. This level of precision is essential for ensuring that components meet strict safety and performance standards. International buyers should focus on sourcing from suppliers who possess advanced CNC machinery and relevant industry certifications to guarantee quality and reliability.

A stock image related to g code.

What are the Applications of G-code in Automotive Manufacturing?

A stock image related to g code.

G-code plays a significant role in automotive manufacturing, particularly in tool path programming for machining parts such as engine blocks and transmission housings. By utilizing G-code, manufacturers can optimize their machining processes, reducing production times while maintaining high-quality standards. B2B buyers in this sector should prioritize suppliers with proven expertise in automotive manufacturing and compliance with industry regulations to enhance operational efficiency.

How is G-code Applied in the Production of Medical Devices?

In the medical device industry, G-code is used for the fabrication of custom prosthetics and implants. CNC machines can create highly personalized solutions that cater to individual patient needs, improving the overall effectiveness of medical treatments. Buyers must ensure that their suppliers adhere to stringent medical regulations and utilize high-quality materials to ensure patient safety and product efficacy.

What Role Does G-code Play in Electronics Circuit Board Fabrication?

For electronics manufacturers, G-code is essential in circuit board fabrication, where it directs CNC machines to create intricate pathways for electrical connections. This technology enhances the speed and precision of producing electronic components, which is vital in today’s fast-paced tech environment. When sourcing suppliers, businesses should focus on those with robust quality control processes to ensure that the final products meet industry standards.

How is G-code Transforming Prototyping in Consumer Goods?

In the consumer goods sector, G-code is pivotal for 3D printing prototypes, allowing companies to rapidly develop and test new products. This capability accelerates product development cycles and enables businesses to respond quickly to market demands. When selecting suppliers, B2B buyers should evaluate their 3D printing technology and the variety of materials they offer to ensure compatibility with their design requirements.

3 Common User Pain Points for ‘g code’ & Their Solutions

Scenario 1: Difficulty Understanding G-code Syntax and Structure

The Problem: Many B2B buyers, especially those new to CNC machining or 3D printing, often struggle with the intricacies of G-code syntax. This can lead to miscommunication with machines, resulting in production errors, wasted materials, and increased costs. The complexity of G-code can be overwhelming, particularly for teams without a dedicated programming background. Buyers from regions like Africa and South America, where access to technical training may be limited, face additional challenges in acquiring the necessary skills to write or modify G-code effectively.

The Solution: To address this issue, organizations should invest in comprehensive training programs focused on G-code understanding. Collaborating with local technical institutes or online platforms that offer tailored courses can bridge the skills gap. Additionally, implementing user-friendly software that translates G-code into visual representations can help users grasp the commands better. For instance, programs that simulate the toolpath before execution allow operators to visualize movements, reducing errors significantly. Encouraging peer-to-peer mentorship within the organization can also foster a culture of knowledge sharing, enabling less experienced staff to learn from seasoned professionals.

Scenario 2: Inefficient G-code Generation for Complex Parts

The Problem: In industries requiring high precision, such as aerospace or medical device manufacturing, generating efficient G-code for complex parts can be a daunting task. Buyers often find themselves manually tweaking G-code, which is time-consuming and prone to errors. This inefficiency not only delays production timelines but also raises the risk of producing subpar components that don’t meet stringent quality standards. Companies from Europe and the Middle East, where competition is fierce, cannot afford these setbacks.

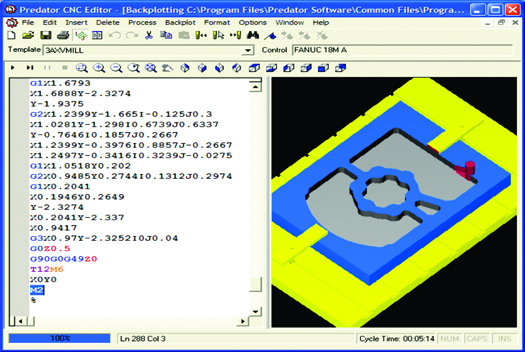

The Solution: To streamline G-code generation, companies should invest in advanced CAM (Computer-Aided Manufacturing) software that automates the G-code creation process. These tools can optimize tool paths and reduce machining time while maintaining accuracy. Moreover, integrating software that uses artificial intelligence to analyze designs can further enhance efficiency by suggesting the most effective machining strategies. Regularly updating and maintaining this software ensures compatibility with the latest machining technologies and keeps the team informed about new features that could simplify their workflows. Additionally, establishing a feedback loop where operators can share their insights on G-code effectiveness can lead to continuous improvement in processes.

Scenario 3: Compatibility Issues Between G-code and Different CNC Machines

The Problem: International B2B buyers often encounter compatibility issues when using G-code across different CNC machines. Each manufacturer might have slight variations in how G-code is interpreted or executed, leading to discrepancies in performance. This situation can be particularly frustrating for companies that operate a diverse range of equipment, as it complicates the programming and setup processes. For businesses in South America and Africa, where investment in multiple machine types is common, this incompatibility can hinder operational efficiency and escalate costs.

The Solution: To mitigate compatibility issues, buyers should prioritize sourcing CNC machines that support standardized G-code commands or those that allow for customization of command sets. Before making a purchase, conducting thorough research on machine compatibility and reaching out to manufacturers for detailed specifications can save future headaches. Additionally, creating a library of commonly used G-code snippets tailored for different machines can facilitate smoother transitions between equipment. Implementing a robust software solution that can translate or adjust G-code for different machines will also significantly reduce setup time and ensure consistency in production quality. Regularly scheduled training for operators on how to adapt G-code for various machines can further enhance adaptability and efficiency.

A stock image related to g code.

Strategic Material Selection Guide for g code

When selecting materials for G-code applications, particularly in CNC machining and 3D printing, it is essential to consider the properties, advantages, and limitations of each material. This analysis will focus on four common materials: PLA, ABS, Nylon, and Aluminum. Each material has unique characteristics that can significantly impact the performance and suitability of the end product.

What are the Key Properties of PLA for G-code Applications?

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. Its key properties include a low melting temperature (around 180-220°C), which makes it suitable for 3D printing applications. PLA exhibits good rigidity and minimal warping, making it easy to work with.

Pros: PLA is cost-effective and widely available, making it an attractive option for prototyping and low-volume production. It also has excellent surface finish and is compatible with a variety of printing technologies.

Cons: However, PLA has lower heat resistance and can deform at temperatures above 60°C. Its brittleness may not be suitable for applications requiring high impact resistance.

How Does ABS Compare in Terms of Performance?

Acrylonitrile Butadiene Styrene (ABS) is another popular thermoplastic known for its strength and durability. It has a higher melting temperature (around 210-250°C) compared to PLA, making it suitable for functional parts that require higher heat resistance.

Pros: ABS is known for its toughness and impact resistance, which makes it ideal for automotive and consumer goods applications. It can also be easily post-processed, allowing for improved aesthetics.

Cons: The primary drawback of ABS is its tendency to warp during the cooling process, which can complicate the printing process. Additionally, it emits fumes during printing, necessitating proper ventilation.

What Advantages Does Nylon Offer in G-code Applications?

Nylon is a versatile polymer known for its strength, flexibility, and abrasion resistance. It is often used in applications requiring durability and resilience, such as gears and mechanical parts.

Pros: Nylon has excellent chemical resistance and can withstand high temperatures, making it suitable for demanding applications. Its flexibility allows for the production of parts that can endure significant stress without breaking.

Cons: The main limitation of Nylon is its hygroscopic nature, meaning it absorbs moisture from the air, which can affect print quality. Additionally, its higher cost compared to PLA and ABS may deter some buyers.

Why is Aluminum a Preferred Material for CNC Machining?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It is commonly used in CNC applications for producing high-precision components.

Pros: Aluminum offers a favorable strength-to-weight ratio, making it suitable for aerospace and automotive applications. Its ability to be anodized enhances its corrosion resistance and aesthetic appeal.

Cons: However, aluminum can be more expensive than plastic materials, and its machining process can be complex, requiring specialized tools and techniques.

Considerations for International B2B Buyers

When selecting materials, international buyers from regions such as Africa, South America, the Middle East, and Europe must consider compliance with local standards (e.g., ASTM, DIN, JIS) and regulations. Material sourcing should also account for availability and import tariffs, which can affect overall costs. Understanding regional preferences for specific materials can guide purchasing decisions and ensure product compatibility.

| Material | Typical Use Case for g code | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, low-volume production | Biodegradable, easy to print | Low heat resistance, brittleness | Low |

| ABS | Functional parts, consumer goods | Toughness, impact resistance | Warping, fumes during printing | Medium |

| Nylon | Gears, mechanical parts | Strength, flexibility | Hygroscopic, higher cost | High |

| Aluminum | High-precision components | Lightweight, corrosion resistance | Higher cost, complex machining | High |

This table summarizes the essential attributes of each material, providing a quick reference for B2B buyers looking to make informed decisions regarding G-code applications.

In-depth Look: Manufacturing Processes and Quality Assurance for g code

What Are the Main Stages of Manufacturing G-code?

Understanding the manufacturing processes behind G-code is crucial for B2B buyers looking to optimize their operations. The typical manufacturing process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for G-code Applications?

The material preparation stage involves selecting the appropriate materials based on the end product’s requirements. This could include metals, plastics, or composites, depending on the intended application. Proper material selection is essential as it influences the machining parameters set in G-code, such as feed rates and cutting speeds.

Before machining, materials often undergo treatments like annealing or hardening to enhance their properties. This stage may also include cutting the raw material to size, ensuring it meets the specifications outlined in the G-code program. For B2B buyers, verifying the supplier’s material certification (e.g., ASTM, ISO standards) can ensure that the materials used are of high quality.

What Techniques Are Used in the Forming Stage?

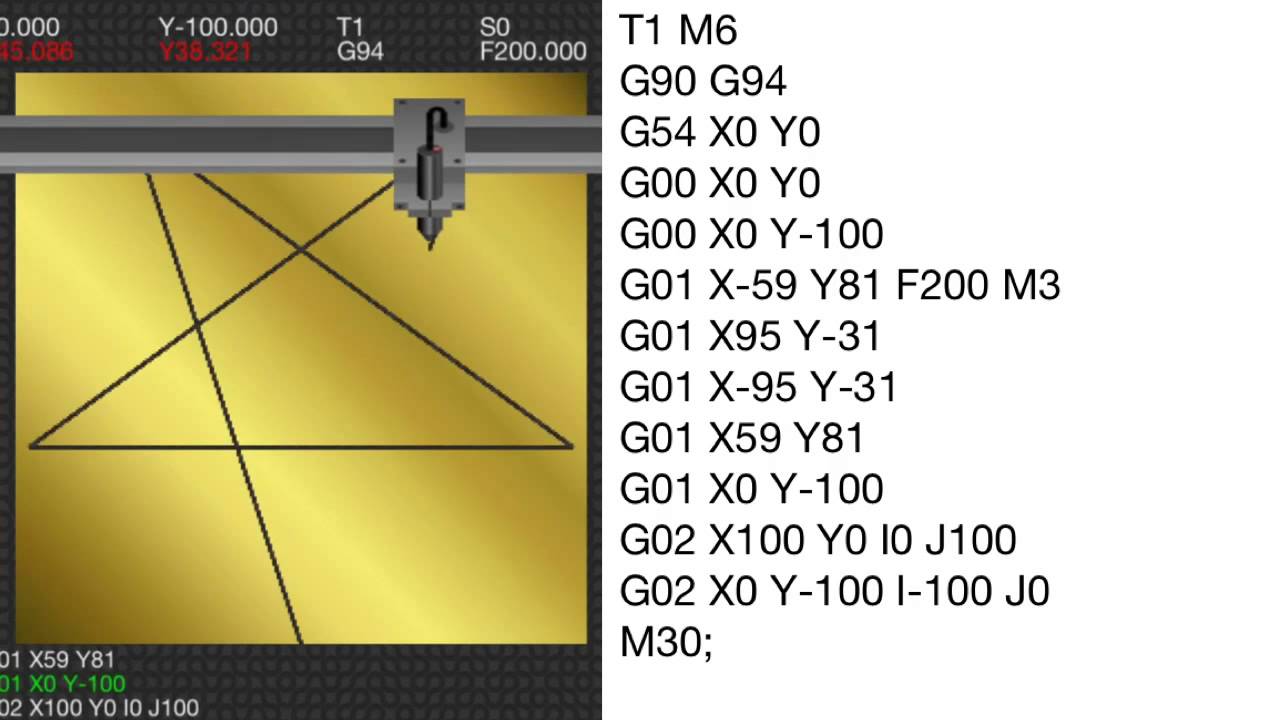

The forming stage of manufacturing utilizing G-code primarily involves CNC (Computer Numerical Control) machining and additive manufacturing. CNC machines interpret G-code to execute precise movements for cutting, drilling, or milling materials. The key techniques in this stage include:

-

CNC Machining: This involves subtractive manufacturing processes where material is removed to achieve the desired shape. Different G-code commands, such as G00 for rapid positioning and G01 for linear interpolation, guide the machine’s movements.

-

3D Printing: In additive manufacturing, G-code commands dictate the layer-by-layer deposition of materials to form complex geometries. This method is increasingly popular for prototyping and low-volume production.

International buyers should ensure that their suppliers have the necessary CNC machinery and technology capable of executing advanced G-code commands, as this directly impacts the quality and precision of the final product.

What Are the Assembly and Finishing Processes for G-code Products?

After forming, products may require assembly, especially if they consist of multiple components. The assembly process can involve manual or automated methods and often relies on G-code for precision placement of parts.

The finishing stage is critical in achieving the desired surface quality and functionality. Common finishing techniques include:

- Machining: Additional CNC machining processes may be employed to achieve tighter tolerances or specific surface finishes.

- Coating: Products may be coated for protection against corrosion or wear, which can also be dictated by G-code for precise application.

B2B buyers should inquire about the finishing capabilities of their suppliers, including surface treatment processes and the technologies used.

How Is Quality Assurance Implemented in G-code Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet specified standards and customer expectations. The QA process for G-code products typically adheres to international standards such as ISO 9001 and industry-specific certifications like CE or API.

What Are the Relevant International Standards for G-code Quality Assurance?

ISO 9001 is a widely recognized quality management standard that helps organizations ensure consistent quality in their products and services. For B2B buyers, understanding a supplier’s compliance with ISO 9001 can provide confidence in their manufacturing processes.

In addition to ISO standards, various industry-specific certifications may apply, depending on the application. For example, medical devices might require ISO 13485, while automotive components may need to comply with IATF 16949. Buyers should verify that their suppliers have the relevant certifications for their specific industry.

What Are the Key Quality Control Checkpoints in G-code Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that products meet quality standards. The main QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections and testing are conducted to monitor quality and adherence to G-code specifications.

- Final Quality Control (FQC): Once manufacturing is complete, final inspections and tests are carried out to ensure the product meets all quality standards before shipment.

B2B buyers should request detailed QC reports from suppliers to understand how these checkpoints are implemented and what testing methods are used.

What Common Testing Methods Are Employed in G-code Manufacturing?

Various testing methods are employed to verify the quality of products manufactured using G-code. These may include:

- Dimensional Inspection: Utilizing tools such as calipers and CMM (Coordinate Measuring Machines) to verify that the dimensions meet specifications set out in the G-code.

- Functional Testing: Ensuring that the product performs as intended in real-world applications.

- Non-destructive Testing (NDT): Techniques such as ultrasonic or X-ray testing are used to detect internal flaws without damaging the product.

B2B buyers should inquire about the specific testing methods used by suppliers and ensure that they align with industry best practices.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks. Here are actionable steps to ensure quality assurance:

-

Conduct Supplier Audits: Regular audits can help assess the supplier’s compliance with quality standards and their manufacturing capabilities.

-

Request Quality Reports: Suppliers should provide detailed quality reports, including IQC, IPQC, and FQC results. This transparency allows buyers to gauge the reliability of the supplier’s QC processes.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality.

-

Understand QC Nuances for International Transactions: B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the regulatory requirements and certifications specific to their region to ensure compliance.

Conclusion

Understanding the manufacturing processes and quality assurance measures associated with G-code is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, along with robust quality control practices, buyers can make informed decisions when selecting suppliers. Prioritizing compliance with international standards and establishing clear QC checkpoints will help ensure that products meet the highest quality standards, ultimately leading to successful business partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘g code’

This practical sourcing guide is designed to help B2B buyers effectively procure G-code, a critical programming language used in CNC machines and 3D printers. By following this checklist, international buyers from regions such as Africa, South America, the Middle East, and Europe can ensure they make informed decisions, optimizing their procurement process.

Step 1: Define Your Technical Specifications

Clearly outline your technical requirements before engaging with suppliers. This includes the specific G-code commands you need, compatibility with your machines, and any additional features necessary for your operations. Understanding your specifications helps avoid miscommunication and ensures the product meets your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in G-code solutions. Look for companies with a proven track record in your industry and regions. Utilize online directories, industry forums, and trade shows to gather a list of potential partners.

Step 3: Evaluate Supplier Certifications

Verify the certifications and qualifications of your shortlisted suppliers. This may include ISO certifications, quality management systems, or compliance with international standards. Certifications are a reliable indicator of a supplier’s commitment to quality and can mitigate risks associated with procurement.

Step 4: Request Samples and Demonstrations

Before making a purchase, request G-code samples or demonstrations. This step allows you to evaluate the quality and functionality of the G-code in action. Assess how well the code integrates with your existing systems and whether it meets your performance expectations.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing and payment terms. Be cautious of prices that are significantly lower than the market average, as they may reflect inferior quality. Consider the total cost of ownership, including potential training or support costs, when evaluating quotes.

Step 6: Check Customer Reviews and References

Seek out customer testimonials and references to gauge supplier reliability and service quality. Contacting previous clients can provide insights into their experiences, including support responsiveness and issue resolution. This information is invaluable in assessing whether the supplier aligns with your business values.

Step 7: Negotiate Contract Terms

Once you’ve selected a supplier, carefully negotiate contract terms to protect your interests. Ensure that the agreement includes clear terms on delivery timelines, support services, and any guarantees regarding the G-code’s performance. A well-structured contract can prevent disputes and foster a stronger partnership.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing G-code effectively, ensuring they partner with suppliers who meet their technical and operational needs.

Comprehensive Cost and Pricing Analysis for g code Sourcing

What Are the Key Cost Components in G-code Sourcing?

When sourcing G-code for CNC machines and 3D printers, international B2B buyers should consider several critical cost components. These include:

-

Materials: The type of material used in the production of CNC machines or 3D printers significantly impacts the overall cost. High-quality materials often lead to better performance and longevity but come at a higher price.

-

Labor: Labor costs can vary widely based on geographical location and the skill level required. In regions like Europe and the Middle East, skilled labor may demand higher wages compared to Africa or South America.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help lower overhead costs.

-

Tooling: The cost of tooling can be substantial, especially for custom G-code solutions. Buyers should account for the investment in specialized tools needed to produce specific components.

-

Quality Control (QC): Implementing stringent QC measures ensures the final product meets required specifications, which can incur additional costs but is essential for maintaining standards.

-

Logistics: Shipping costs, customs duties, and local transportation can add significant expenses, particularly for international transactions. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the standard margins in your industry can help you negotiate better.

How Do Price Influencers Impact G-code Sourcing?

Several factors can influence the pricing of G-code, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should assess their production needs to negotiate better pricing based on volume.

-

Specifications and Customization: Highly customized G-code solutions may incur additional design and programming costs. Clear specifications can streamline this process and reduce expenses.

-

Materials: The choice of materials not only affects the initial cost but also impacts durability and maintenance. Buyers should consider long-term costs associated with material selection.

-

Quality and Certifications: Suppliers who can provide certifications for their materials or processes may charge a premium. However, this investment can lead to improved reliability and reduced failure rates.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers might charge more due to their proven track record, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms can help buyers determine who is responsible for shipping costs, insurance, and tariffs, which ultimately affects the total cost of procurement.

What Are Some Buyer Tips for Cost-Efficiency in G-code Sourcing?

International B2B buyers should consider the following strategies for cost-effective sourcing:

-

Negotiation: Always negotiate pricing and terms. Establishing a good relationship with suppliers can lead to better deals and more favorable payment terms.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and potential downtime costs when evaluating suppliers and products.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and how they can affect pricing. Engaging in contracts that lock in prices or payment terms can mitigate this risk.

-

Research Local Suppliers: Especially in regions like Africa and South America, local suppliers may offer lower logistics costs and quicker turnaround times. This can often offset higher material costs.

-

Utilize Technology: Using software tools for inventory management and procurement can streamline sourcing processes, reduce errors, and lead to cost savings.

Disclaimer for Indicative Prices

Prices for G-code sourcing can vary significantly based on the factors outlined above. Buyers should conduct thorough market research and engage in direct negotiations with suppliers to obtain accurate and indicative pricing.

Alternatives Analysis: Comparing g code With Other Solutions

Exploring Alternatives to G-Code: What Are the Best Options?

In the realm of CNC machining and 3D printing, G-code is the standard programming language used to control machines. However, various alternatives have emerged that cater to specific needs or preferences of manufacturers and designers. This section explores these alternatives, comparing them based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table: G-Code vs. Alternatives

| Comparison Aspect | G-Code | OpenSCAD | HPGL |

|---|---|---|---|

| Performance | High performance in complex tasks | Good for parametric designs | Optimized for plotters and printers |

| Cost | Free (open standard) | Free (open-source) | Free, but proprietary in some cases |

| Ease of Implementation | Requires understanding of syntax | Straightforward for coders | Simple for graphic designers |

| Maintenance | Requires updates for new machines | Low, as code is self-contained | Low, but requires specific drivers |

| Best Use Case | Precision machining and 3D printing | Generative designs and models | Drawing and plotting applications |

What Are the Advantages and Disadvantages of OpenSCAD?

OpenSCAD is a software for creating solid 3D CAD (Computer-Aided Design) objects. Unlike G-code, which is more of a machine control language, OpenSCAD focuses on the design aspect.

Pros:

– Parametric Design: Users can create models based on parameters, making adjustments easy and efficient.

– Open Source: The software is free to use, making it accessible to startups and small businesses.

Cons:

– Learning Curve: While straightforward for coders, those without programming experience might find it challenging.

– Limited Machine Control: OpenSCAD generates designs that must be converted to G-code for machine operation, adding an extra step.

How Does HPGL Compare to G-Code?

HPGL (Hewlett-Packard Graphics Language) is primarily used for controlling plotters, but it also finds applications in some CNC machines.

Pros:

– Simplicity: HPGL commands are relatively easy to understand, making it accessible for graphic designers.

– Good for 2D Applications: Excellent for applications focused on drawing and plotting, such as sign-making.

Cons:

– Limited to 2D: HPGL is not designed for complex 3D operations, making it less versatile than G-code.

– Compatibility Issues: Some machines may require specific drivers or software to interpret HPGL commands correctly.

How Can International B2B Buyers Choose the Right Solution?

Selecting the right programming language or control method depends on specific operational needs. Buyers should consider the nature of their production processes. For high-precision tasks, G-code remains unmatched. If businesses lean towards parametric designs or generative modeling, OpenSCAD might be the better option. Meanwhile, for simple 2D plotting tasks, HPGL could serve effectively.

Ultimately, understanding the unique requirements of your projects and the capabilities of each option will guide you toward making an informed decision that aligns with your operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for g code

What Are the Key Technical Properties of G-Code?

Understanding the technical properties of G-code is crucial for B2B buyers involved in CNC machining and additive manufacturing. Below are essential specifications that play a significant role in ensuring quality and efficiency in production processes.

1. Precision and Tolerance Levels

Precision refers to how accurately a CNC machine can reproduce a specified dimension. Tolerance levels indicate the permissible limit of variation in a physical dimension. In B2B manufacturing, tighter tolerances are often required for components that must fit together precisely. This is especially important for industries like aerospace and automotive, where even minor deviations can lead to significant issues. Buyers should always inquire about the tolerance levels offered by manufacturers to ensure their specifications are met.

2. Feed Rate Specifications

The feed rate is the speed at which the cutting tool moves through the material. This is expressed in units like mm/min or inches/min and directly impacts the efficiency and quality of the machining process. A higher feed rate may increase production speed but can compromise surface finish and tool life. Buyers should evaluate their production needs and discuss optimal feed rates with suppliers to achieve a balance between speed and quality.

3. Material Compatibility

Different G-code commands may behave differently depending on the material being processed. Whether working with metals, plastics, or composites, understanding how each material interacts with G-code commands is essential. For instance, certain materials may require specific cooling settings or adjustments to cutting speeds. Buyers should ensure that their suppliers have the capability to work with their desired materials and understand the implications on G-code execution.

4. Units of Measurement

G-code can be programmed in either millimeters (G21) or inches (G20), depending on the machine and the specific application. Understanding the unit settings is vital to avoid costly mistakes in production. Buyers should confirm the unit preferences with their suppliers and ensure they are consistent throughout the project to prevent discrepancies in machining operations.

What Are Common Trade Terms Related to G-Code?

Familiarity with industry terminology is crucial for effective communication between B2B buyers and suppliers. Here are some key terms that frequently arise in discussions about G-code and manufacturing processes.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of G-code, OEMs often develop proprietary G-code commands tailored to their machines. Understanding OEM specifications helps buyers ensure compatibility and performance in their operations.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. In the CNC and 3D printing sectors, MOQs can affect production planning and inventory management. Buyers should clarify MOQs with suppliers to align their purchasing strategies with production needs, especially for custom G-code applications.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. For buyers, providing detailed G-code specifications in an RFQ can help suppliers give accurate quotes and enhance the decision-making process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. For international B2B transactions involving G-code machinery, understanding Incoterms is essential to avoid misunderstandings and ensure smooth logistics.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions, foster better supplier relationships, and enhance their operational efficiency in the manufacturing sector.

Navigating Market Dynamics and Sourcing Trends in the g code Sector

What Are the Current Market Trends Influencing the G-code Sector?

The global G-code market is experiencing significant growth driven by advancements in automation and precision engineering. The increasing demand for CNC machines and 3D printers across various sectors, such as automotive, aerospace, and manufacturing, is a key driver. In particular, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are recognizing the importance of integrating G-code programming into their operations to enhance productivity and operational efficiency. Emerging trends include the adoption of cloud-based software solutions for G-code generation and simulation, which streamline the design-to-production process, making it more accessible for businesses of all sizes.

Additionally, the rise of Industry 4.0 is transforming how manufacturers approach G-code applications. This shift includes increased connectivity between machines and software, allowing for real-time monitoring and adjustments during production. As international buyers look to enhance their competitive edge, they are also prioritizing technologies that enable predictive maintenance and data analytics, further optimizing their machining processes.

How Is Sustainability Shaping Sourcing Trends in the G-code Sector?

Sustainability has become a pivotal consideration for international B2B buyers, including those sourcing G-code-related products and services. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek out suppliers who prioritize eco-friendly practices. This includes sourcing materials that are recyclable or made from sustainable sources, as well as utilizing energy-efficient machines that reduce carbon footprints.

Furthermore, buyers are increasingly aware of the importance of ethical supply chains. This encompasses not only the environmental aspects but also the social responsibility of suppliers. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming critical indicators of a supplier’s commitment to sustainability. As a result, international buyers are encouraged to engage with suppliers who can demonstrate adherence to these standards, ensuring that their sourcing decisions align with broader sustainability goals.

What Is the Historical Context of G-code and Its Evolution?

The evolution of G-code traces back to the early days of numerical control (NC) technology in the 1950s. Originally developed for basic automation, G-code has significantly advanced alongside technological innovations in computer-aided design (CAD) and manufacturing (CAM). As CNC machines became more prevalent, G-code evolved into a standardized programming language that allowed for precise control of machine tools.

In recent years, the integration of G-code with additive manufacturing technologies, particularly in 3D printing, has expanded its application beyond traditional machining. This evolution not only highlights the versatility of G-code but also its critical role in modern manufacturing processes, making it an essential area of focus for international B2B buyers seeking to leverage cutting-edge technologies. Understanding this historical context helps buyers appreciate the ongoing advancements in G-code applications and their implications for future sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of g code

-

How do I solve compatibility issues with G-code across different CNC machines?

Compatibility issues can arise due to variations in G-code dialects used by different CNC machine manufacturers. To mitigate this, ensure that your G-code adheres to the standard commands recognized by most machines, such as G00, G01, and G02. Always consult the specific machine’s manual for any unique commands or settings. Additionally, using G-code simulators can help test compatibility before actual machining, allowing for adjustments to be made without risking material or equipment. -

What is the best G-code customization for my specific machining needs?

The best G-code customization depends on your particular machining requirements, such as the material type, machine capabilities, and desired precision. For instance, if you’re working with intricate designs, focus on optimizing commands like G01 for linear movements and G02/G03 for arcs. Additionally, consider adding custom macros for repetitive tasks to enhance efficiency. Collaborating with experienced machinists can provide insights into effective G-code strategies tailored to your operations. -

What are the minimum order quantities (MOQ) for sourcing G-code files or CNC programs?

MOQs for G-code files or CNC programs vary by supplier and complexity of the project. Some suppliers may have no MOQ, allowing for the purchase of individual files, while others may require a minimum number of files or a specific project size to justify production costs. When negotiating with suppliers, clarify your needs and explore options for bulk purchases or long-term contracts, which may lead to better pricing and flexibility. -

What payment terms should I expect when sourcing G-code internationally?

Payment terms can differ significantly among suppliers based on their location and business practices. Common terms include advance payment, net 30, or payment upon delivery. For international transactions, consider utilizing escrow services to protect both parties. It’s also advisable to negotiate terms that align with your cash flow needs and ensure transparency regarding any potential additional fees such as taxes, tariffs, or shipping costs. -

How can I ensure quality assurance (QA) for G-code files sourced from international suppliers?

To ensure quality assurance for G-code files, establish a clear QA process that includes initial testing on a sample project. Request documentation outlining the supplier’s QA procedures, such as inspection methods and compliance with industry standards. Additionally, consider implementing a feedback loop, where you provide performance data back to the supplier, helping them to refine their offerings and address any issues in future orders. -

What logistics considerations should I keep in mind when sourcing G-code?

When sourcing G-code internationally, logistics considerations include shipping time, customs clearance, and potential delays. Choose suppliers with experience in international shipping to streamline the process. Be aware of customs regulations in your country and ensure that the supplier provides all necessary documentation. Additionally, consider using logistics partners that offer tracking and support to manage shipments effectively and mitigate risks associated with international trade. -

How do I vet suppliers for G-code files effectively?

Vetting suppliers for G-code files involves several steps: researching their reputation through reviews and testimonials, checking for industry certifications, and requesting samples of their work. Engage in direct communication to assess their responsiveness and willingness to collaborate. Additionally, consider visiting their facilities if possible, or utilizing online platforms that facilitate supplier evaluations and comparisons, ensuring they meet your specific needs and standards. -

What support should I expect from suppliers after purchasing G-code?

After purchasing G-code, you should expect ongoing support from suppliers, including assistance with troubleshooting, updates for software compatibility, and modifications based on feedback. Many reputable suppliers offer technical support via phone or email and may provide training resources or documentation to help you maximize the use of their products. Ensure that the terms of support are clearly outlined in your agreement to avoid any misunderstandings later on.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for g code

How Can Strategic Sourcing Enhance Your Understanding of G-code?

In conclusion, mastering G-code is pivotal for businesses engaged in CNC machining and 3D printing, particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. By understanding the fundamental G-code commands—such as G00 for rapid positioning and G01 for linear interpolation—companies can significantly enhance production efficiency and precision.

Strategic sourcing not only provides access to high-quality machinery and technology but also cultivates partnerships with suppliers who can offer tailored solutions and technical support. This is particularly beneficial for businesses looking to optimize their manufacturing processes while minimizing costs.

As the global manufacturing landscape evolves, staying ahead of the curve with G-code knowledge will empower buyers to make informed decisions and leverage technological advancements. International B2B buyers are encouraged to invest in training and resources that deepen their understanding of G-code applications. By doing so, you position your business for long-term success in a competitive market. Embrace the future of manufacturing—prioritize G-code education and strategic sourcing today.