Master Industrial Air Compressor Parts Sourcing for Optimal

Introduction: Navigating the Global Market for industrial air compressor parts

Navigating the complexities of the global market for industrial air compressor parts is crucial for B2B buyers seeking efficiency and reliability in their operations. Industrial air compressors are essential components in various industries, powering everything from manufacturing processes to construction equipment. The performance of these compressors heavily relies on the quality of their parts, which can significantly influence operational costs and downtime.

This guide is designed to equip international buyers—particularly those from Africa, South America, the Middle East, and Europe (including Italy and the UAE)—with the knowledge necessary to make informed sourcing decisions. We will delve into various aspects of industrial air compressor parts, covering types of components, materials used in manufacturing, quality control measures, and insights into reliable suppliers. Additionally, we will explore cost considerations and market trends, providing a comprehensive overview that addresses common FAQs.

By understanding these critical factors, buyers can not only streamline their procurement processes but also enhance their operational efficiency. This guide aims to empower you with actionable insights that lead to better purchasing decisions, ensuring that your investments in industrial air compressor parts yield optimal performance and value. With a focus on quality, reliability, and cost-effectiveness, you will be well-positioned to navigate the global market successfully.

Understanding industrial air compressor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reciprocating | Uses pistons driven by a crankshaft; versatile | Manufacturing, automotive, food processing | Pros: High pressure, flexible. Cons: Noisy, requires maintenance. |

| Rotary Screw | Continuous flow design with two rotating screws | Oil & gas, construction, textiles | Pros: Efficient, low maintenance. Cons: Higher initial cost. |

| Centrifugal | Utilizes high-speed rotating impellers | Chemical processing, HVAC systems | Pros: High volume, low noise. Cons: Less effective at low pressure. |

| Scroll | Two spiral-shaped scrolls compress air | Medical, laboratories, light industrial | Pros: Quiet, compact. Cons: Limited output capacity. |

| Diaphragm | Uses a flexible diaphragm to compress air | Laboratory, pharmaceutical, food & beverage | Pros: Clean air, low contamination. Cons: Limited pressure range. |

Reciprocating Compressors

Reciprocating compressors are characterized by their use of pistons driven by a crankshaft, making them highly versatile. They are suitable for applications requiring high pressure and are commonly found in manufacturing, automotive, and food processing sectors. When purchasing, buyers should consider the noise levels and maintenance needs, as these compressors can be quite loud and require regular upkeep to ensure optimal performance.

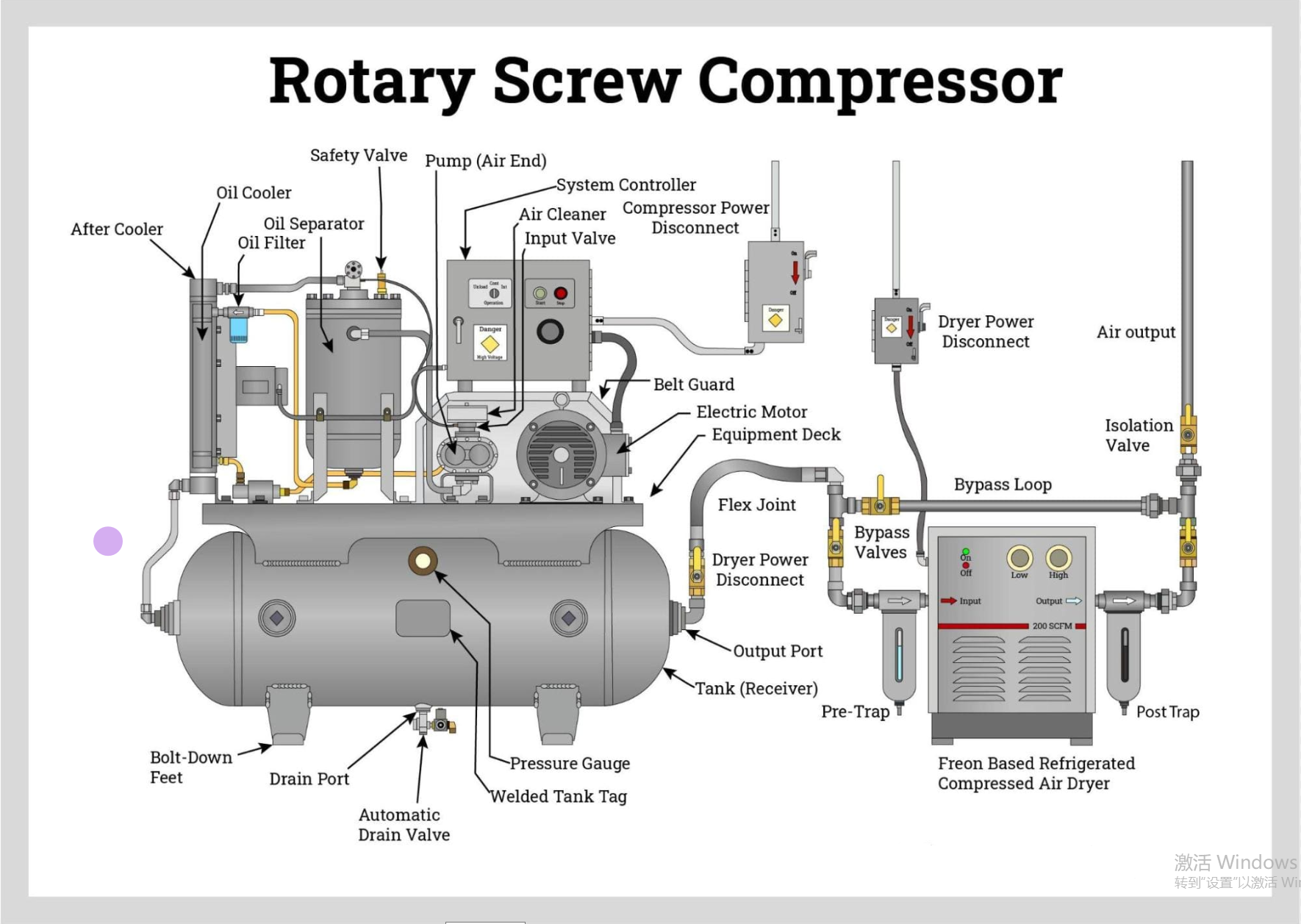

Rotary Screw Compressors

Rotary screw compressors feature a continuous flow design with two interlocking screws that compress air. This type is ideal for industries such as oil and gas, construction, and textiles, where efficiency and reliability are paramount. Buyers should weigh the initial investment against long-term operational costs, as these compressors tend to have a higher upfront cost but lower maintenance needs, making them a cost-effective choice over time.

Centrifugal Compressors

Centrifugal compressors operate using high-speed rotating impellers to compress air, making them suitable for applications in chemical processing and HVAC systems. They excel in delivering high volume and operate at lower noise levels. However, potential buyers should consider their effectiveness at low pressures; these compressors may not be the best choice for applications requiring lower pressure outputs.

Scroll Compressors

Scroll compressors utilize two spiral-shaped scrolls to compress air, making them particularly compact and quiet. They are commonly used in medical applications, laboratories, and light industrial settings. Buyers should consider the output capacity, as scroll compressors are generally limited in volume compared to other types. Their low noise operation and clean air output make them attractive for sensitive environments.

Diaphragm Compressors

Diaphragm compressors compress air using a flexible diaphragm, making them ideal for applications in laboratories, pharmaceuticals, and food and beverage industries where air purity is critical. While they provide clean air with low contamination risk, buyers should note that these compressors have a limited pressure range and may not be suitable for all industrial applications.

Related Video: The Name of Different Parts of The Air Compressor.

Key Industrial Applications of industrial air compressor parts

| Industry/Sector | Specific Application of Industrial Air Compressor Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pneumatic tools and machinery operation | Enhanced productivity and efficiency in production lines | Quality certifications, compatibility with existing systems |

| Food and Beverage | Packaging and bottling processes | Improved hygiene and reduced contamination risks | Compliance with food safety standards, energy efficiency |

| Construction | Concrete mixing and pneumatic conveying | Faster project completion and reduced labor costs | Durability in harsh environments, maintenance support |

| Automotive | Paint spraying and assembly line automation | Superior finish quality and reduced waste | Precision engineering, supplier reliability |

| Oil and Gas | Drilling and extraction processes | Increased operational efficiency and safety | Availability of specialized parts, robust supply chains |

Manufacturing

In the manufacturing sector, industrial air compressor parts are crucial for operating pneumatic tools and machinery. These compressors provide the necessary power to tools like drills, hammers, and conveyors, which are integral to production lines. By leveraging high-quality compressor parts, manufacturers can significantly enhance productivity and operational efficiency. International buyers, particularly from regions like Europe and South America, should prioritize sourcing parts that are compatible with their existing machinery and come with quality certifications to ensure reliability and performance.

Food and Beverage

The food and beverage industry relies heavily on industrial air compressors for packaging and bottling processes. Compressed air is used to power equipment that seals packages, ensuring products remain fresh and contamination-free. This application not only improves hygiene but also streamlines production processes. Buyers in Africa and the Middle East must consider suppliers that comply with stringent food safety standards and offer energy-efficient solutions to reduce operational costs while maintaining quality.

Construction

In the construction industry, industrial air compressor parts are essential for concrete mixing and pneumatic conveying systems. These compressors facilitate the efficient transport of materials, enabling faster project completion and reducing labor costs. For international buyers from regions with challenging climates, such as the Middle East, it is crucial to source durable compressor parts designed to withstand harsh environments. Additionally, suppliers should offer comprehensive maintenance support to minimize downtime on job sites.

Automotive

The automotive sector utilizes industrial air compressor parts primarily for paint spraying and assembly line automation. High-quality compressed air systems ensure superior finish quality while minimizing waste, which is vital for maintaining competitiveness in this industry. Buyers from Europe, especially in Italy, should focus on suppliers that provide precision-engineered components and demonstrate a strong track record of reliability. This focus on quality can lead to significant cost savings and enhanced product quality.

Oil and Gas

In the oil and gas industry, industrial air compressor parts are integral to drilling and extraction processes. These compressors enhance operational efficiency and safety by providing reliable power to critical equipment. International buyers, particularly from regions with extensive oil reserves, should prioritize sourcing specialized parts that meet the unique demands of this sector. Robust supply chains and availability of technical support are essential considerations to ensure continuous operation and minimize downtime.

Related Video: Air Compressor (Basics, Parts, Diagram, Working & Applications) Explained with Animation

Strategic Material Selection Guide for industrial air compressor parts

When selecting materials for industrial air compressor parts, it is crucial to consider the specific properties, advantages, and limitations of each material. The choice of material impacts not only the performance and durability of the components but also compliance with international standards and suitability for diverse operating environments. Below, we analyze several common materials used in the manufacturing of air compressor parts, focusing on their key attributes and implications for international B2B buyers.

Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, have good corrosion resistance, and can withstand moderate temperatures and pressures. They are often used in components such as compressor housings and end plates.

Pros & Cons: The primary advantage of aluminum alloys is their weight, which contributes to lower energy consumption during operation. They are also relatively easy to machine, reducing manufacturing complexity. However, aluminum alloys have lower strength compared to steel and can be more expensive, particularly when high-performance grades are used.

Impact on Application: Aluminum is compatible with air and non-corrosive gases, making it suitable for many industrial applications. However, it may not perform well in environments with high humidity or corrosive media without proper coatings.

Considerations for International Buyers: Buyers should ensure that aluminum components comply with standards such as ASTM B209 for aluminum sheet and plate. In regions like Europe and the Middle East, familiarity with the EN standards for aluminum can be beneficial.

Cast Iron

Key Properties: Cast iron is known for its excellent wear resistance, high compressive strength, and ability to withstand high temperatures. It is commonly used for cylinder blocks and compressor bases.

Pros & Cons: The durability of cast iron makes it ideal for heavy-duty applications, providing long service life. However, it is heavier than other materials, which can lead to increased shipping costs. Additionally, cast iron is more brittle and can crack under stress if not properly handled.

Impact on Application: Cast iron is suitable for high-pressure applications and can handle a variety of gases, including those that may be abrasive. Its thermal conductivity also aids in heat dissipation, which is advantageous in high-performance scenarios.

Considerations for International Buyers: Compliance with standards like ASTM A48 for gray iron is essential. Buyers in regions such as South America and Africa should consider the availability of local suppliers who can meet these standards to reduce lead times.

Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, high strength, and the ability to withstand extreme temperatures and pressures. It is often used in valves, fittings, and piping.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to oxidation, making it suitable for harsh environments. However, it is more expensive than both aluminum and cast iron, and its machining can be more complex, leading to higher manufacturing costs.

Impact on Application: Stainless steel is highly compatible with a range of gases and fluids, including corrosive media. Its ability to maintain integrity under varying temperatures makes it a preferred choice for applications where reliability is critical.

Considerations for International Buyers: Buyers should be aware of the various grades of stainless steel, such as 304 and 316, and their respective compliance with standards like ASTM A240. In Europe, adherence to EN 10088 standards is crucial for ensuring quality.

Composite Materials

Key Properties: Composite materials, such as fiberglass-reinforced plastics, provide a unique combination of lightweight and high strength, along with excellent corrosion resistance.

Pros & Cons: The lightweight nature of composites can lead to significant energy savings in operation. They can also be molded into complex shapes, allowing for innovative designs. However, composites can be more expensive and may have limitations in high-temperature applications.

Impact on Application: Composites are ideal for applications involving corrosive environments, such as chemical processing. Their compatibility with various gases makes them versatile, but they may not be suitable for high-pressure scenarios.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM D638 for tensile properties of plastics. Understanding local regulations regarding composite materials in regions like the Middle East and Europe is also important for ensuring compliance.

Summary Table

| Material | Typical Use Case for industrial air compressor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Compressor housings, end plates | Lightweight and good corrosion resistance | Lower strength compared to steel | Medium |

| Cast Iron | Cylinder blocks, compressor bases | Excellent durability and wear resistance | Heavier and brittle | Low |

| Stainless Steel | Valves, fittings, piping | High strength and corrosion resistance | Higher cost and complex machining | High |

| Composite Materials | Chemical processing components | Lightweight and corrosion-resistant | More expensive and limited high-temp use | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials used in industrial air compressor parts, facilitating informed decision-making that aligns with performance requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for industrial air compressor parts

The manufacturing of industrial air compressor parts involves a series of meticulous processes and stringent quality assurance protocols. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these processes can significantly influence procurement decisions and supplier evaluations.

Manufacturing Processes

Manufacturing industrial air compressor parts typically comprises four main stages: material preparation, forming, assembly, and finishing. Each stage employs specific techniques that ensure the parts meet both functional and quality standards.

Material Preparation

The initial phase involves selecting appropriate materials, often metals like aluminum, steel, or cast iron, depending on the specific application of the compressor part. Material testing is crucial at this stage, ensuring that the raw materials meet specified mechanical and chemical properties. Common methods include:

- Spectrometric analysis for chemical composition

- Tensile testing for mechanical strength

- Hardness testing to ensure durability

Buyers should verify that suppliers conduct these tests and provide certification documentation.

Forming

The forming stage shapes the materials into desired components using various techniques. Common forming methods include:

- Casting: Ideal for complex shapes, often used for compressor housings.

- Machining: Precision cutting, drilling, and milling to achieve tight tolerances.

- Forging: Enhances strength and durability, typically used for high-stress parts like crankshafts.

Each method has unique advantages, and buyers should consider the supplier’s capabilities in these areas to ensure alignment with their needs.

Assembly

Assembly involves fitting together the formed parts, which may require welding, bolting, or other fastening techniques. Attention to detail is paramount; incorrect assembly can lead to operational failures. Key considerations include:

- Precision alignment: Ensuring components fit together without stress.

- Quality of fasteners: Using industry-grade fasteners that meet or exceed specifications.

Buyers should inquire about the supplier’s assembly processes and the qualifications of their workforce, as skilled labor significantly impacts quality.

Finishing

The final stage enhances the part’s functionality and appearance. Common finishing processes include:

- Surface treatment: Techniques like anodizing or powder coating to improve corrosion resistance.

- Painting: For aesthetic purposes and additional protection.

- Final inspection: A thorough check for defects before shipping.

This stage is critical for ensuring that parts meet the environmental and operational conditions they will face.

Quality Assurance

Quality assurance (QA) in manufacturing is essential to guarantee that products meet international standards. For industrial air compressor parts, several international and industry-specific standards are relevant.

International Standards

- ISO 9001: A globally recognized standard that outlines requirements for a quality management system (QMS). Suppliers with ISO 9001 certification demonstrate their commitment to quality and continuous improvement.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

- API Standards: The American Petroleum Institute (API) provides standards for products used in the oil and gas industry, which may be relevant depending on the application of the air compressor parts.

QC Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Verifies the quality of incoming materials before they enter production.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing to ensure adherence to specifications.

- Final Quality Control (FQC): A comprehensive review of finished products before shipment.

Buyers should ensure that suppliers have robust QC processes in place at these checkpoints.

Common Testing Methods

To validate the quality of air compressor parts, suppliers typically employ several testing methods:

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or magnetic particle inspection to detect internal flaws without damaging the parts.

- Pressure Testing: Ensures that components can withstand operational pressures without leaking.

- Functional Testing: Simulating operating conditions to confirm performance standards.

Buyers should request documentation of these tests to verify compliance with quality expectations.

Verifying Supplier QC

International B2B buyers must adopt a proactive approach to verify supplier quality assurance practices. Here are actionable strategies:

- Conduct Supplier Audits: Regular audits of suppliers’ facilities can help assess their adherence to quality standards and manufacturing processes.

- Request Quality Reports: Suppliers should provide detailed reports of their QC processes, including test results and certifications.

- Engage Third-Party Inspectors: Hiring independent inspectors can provide an unbiased assessment of the supplier’s quality practices.

QC and Certification Nuances

For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of quality certifications is crucial. Different regions may have varying standards and expectations. For instance, European buyers may prioritize CE marking, while Middle Eastern buyers might emphasize compliance with local regulations.

Additionally, it is essential to consider the supply chain’s complexity. Delays or failures in quality can arise from various sources, including transportation and local regulations. Buyers should build relationships with suppliers who understand these challenges and can adapt their processes accordingly.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance protocols for industrial air compressor parts is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, and emphasizing international standards and rigorous QC processes, buyers can make informed decisions that ensure they source high-quality, reliable components for their operations.

Related Video: Air Compressor Working Principle | How does an Air compressor work? | (compressor types)

Comprehensive Cost and Pricing Analysis for industrial air compressor parts Sourcing

Understanding the Cost Structure of Industrial Air Compressor Parts

When sourcing industrial air compressor parts, understanding the cost structure is crucial for international B2B buyers. The main components that contribute to the total cost include:

-

Materials: The choice of raw materials significantly affects the pricing of compressor parts. Common materials include aluminum, steel, and composites. Prices can fluctuate based on global market trends, so it’s vital to stay informed about material costs.

-

Labor: Labor costs can vary widely between regions. For instance, manufacturing in countries with lower labor costs may present savings, but this can come with trade-offs in quality or lead times.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, facility expenses, and administrative costs. Understanding how a supplier allocates these costs can help buyers assess overall pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. Buyers should consider whether the tooling costs are included in the part price or if they are charged separately.

-

Quality Control (QC): Investments in quality assurance processes are essential for ensuring reliability. Suppliers with robust QC measures might charge higher prices, but this often translates into lower failure rates and maintenance costs.

-

Logistics: Transportation costs can vary based on distance, shipping methods, and the complexity of the supply chain. Buyers should evaluate these costs as part of their total expenditure.

-

Margin: Supplier profit margins can differ based on market positioning and competition. Understanding these margins helps buyers gauge the fairness of the pricing.

Factors Influencing Pricing

Several key factors can influence the pricing of industrial air compressor parts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, as suppliers benefit from economies of scale. Negotiating MOQ can help reduce costs significantly.

-

Specifications and Customization: Custom parts or specific specifications can increase costs due to the additional engineering and production efforts required. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., ISO, CE) can enhance reliability but typically come at a premium. It is essential to balance quality with budget constraints.

-

Supplier Factors: The supplier’s reputation, location, and experience can impact pricing. Established suppliers may charge more due to their proven track record, but they may also offer better service and reliability.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping costs and responsibilities. Understanding these terms can help buyers clarify who bears the cost and risk at each stage of transportation.

Tips for B2B Buyers

To maximize value in sourcing industrial air compressor parts, consider the following tips:

-

Negotiate Effectively: Leverage your purchasing power, especially when ordering in bulk. Be prepared to discuss pricing transparently and explore various payment terms.

-

Focus on Cost-Efficiency: Analyze not just the purchase price but the Total Cost of Ownership (TCO). This includes maintenance, operational efficiency, and potential downtime costs associated with lower-quality parts.

-

Understand Pricing Nuances: International buyers, particularly from Africa, South America, the Middle East, and Europe, should account for currency fluctuations and regional economic conditions that may affect pricing.

-

Research Suppliers Thoroughly: Assess potential suppliers based on their financial stability, production capabilities, and quality records. Building relationships with reliable suppliers can lead to better pricing over time.

-

Stay Informed about Market Trends: Regularly review industry reports and market analyses to anticipate changes in material costs and supply chain dynamics that could impact pricing.

Disclaimer

The prices discussed in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer needs. Buyers should conduct their own due diligence and market research to obtain accurate and current pricing information.

Spotlight on Potential industrial air compressor parts Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘industrial air compressor parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for industrial air compressor parts

Understanding the technical properties and trade terminology associated with industrial air compressor parts is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also facilitates smoother transactions across diverse markets. Below are key technical specifications and industry terms that are essential for successful procurement.

Essential Technical Properties

-

Material Grade

– Definition: Material grade refers to the specific classification of materials used in manufacturing compressor parts, such as aluminum, steel, or composite materials.

– B2B Importance: Selecting the right material grade affects durability, weight, and resistance to corrosion. Buyers must ensure that the materials meet industry standards for their specific applications, particularly in harsh environments typical in regions like Africa and the Middle East. -

Tolerance

– Definition: Tolerance specifies the allowable variation in dimensions and weight of parts during manufacturing, often expressed in millimeters or microns.

– B2B Importance: Precision in tolerance is critical to ensure that parts fit together correctly and function optimally. Inaccurate tolerances can lead to operational inefficiencies and increased maintenance costs, making it vital for buyers to understand these specifications when evaluating suppliers. -

Pressure Rating

– Definition: This indicates the maximum pressure that a compressor part can safely handle, usually measured in PSI (pounds per square inch).

– B2B Importance: Understanding pressure ratings helps buyers select appropriate components for their applications, particularly in high-demand industries such as manufacturing and construction. Failure to match pressure ratings can result in equipment failure and safety hazards. -

Flow Rate

– Definition: Flow rate measures the volume of air that a compressor can deliver, usually expressed in CFM (cubic feet per minute).

– B2B Importance: A higher flow rate is essential for operations requiring significant air supply. Buyers need to assess their operational needs against flow rates to ensure that the compressors can meet their production demands without delays. -

Energy Efficiency

– Definition: Energy efficiency refers to how effectively a compressor converts electrical energy into usable air power, often expressed as a percentage.

– B2B Importance: With rising energy costs, selecting energy-efficient compressor parts can lead to significant cost savings. Buyers should inquire about energy ratings and certifications to ensure they are investing in sustainable options.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM produces parts that are used in the assembly of a finished product, often under the brand name of another company.

– Importance: Understanding OEM parts ensures buyers are sourcing components that meet original specifications, which can enhance reliability and performance. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchasing strategy and avoid excess inventory costs. It is crucial for cash flow management, especially for small to medium-sized enterprises. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document that buyers send to suppliers to request pricing for specific quantities and specifications of products.

– Importance: Utilizing RFQs helps buyers obtain competitive pricing and better understand the market. It also establishes a formal communication channel with suppliers. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the delivery of goods.

– Importance: Familiarity with Incoterms is essential for international transactions, as they clarify who is responsible for shipping, insurance, and tariffs. This knowledge can prevent misunderstandings and disputes during the procurement process. -

Lead Time

– Definition: Lead time is the amount of time that elapses between placing an order and receiving the goods.

– Importance: Understanding lead times is critical for inventory management and production planning. Buyers should always confirm lead times with suppliers to ensure timely delivery aligned with project schedules.

Illustrative Image (Source: Google Search)

By mastering these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing industrial air compressor parts more effectively, ultimately leading to enhanced operational efficiency and cost management.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the industrial air compressor parts Sector

Market Overview & Key Trends

The industrial air compressor parts market is experiencing significant growth, driven by rising demand across various sectors, including manufacturing, oil and gas, and automotive. As global industries increasingly prioritize efficiency and productivity, the need for high-performance air compressor components is paramount. Key trends shaping the market include the adoption of smart technology and Industry 4.0 principles, which enable real-time monitoring and predictive maintenance of equipment. This trend is particularly relevant for international B2B buyers who seek to enhance operational efficiency and reduce downtime.

In addition, supply chain diversification is becoming crucial for companies sourcing air compressor parts. The pandemic highlighted vulnerabilities in global supply chains, prompting buyers from Africa, South America, the Middle East, and Europe to seek suppliers closer to their operations or to engage in multi-sourcing strategies. This shift not only mitigates risks but also allows companies to better manage costs and lead times.

Emerging markets are also witnessing increased investment in infrastructure, which further fuels demand for industrial air compressor parts. Buyers should be aware of the regional variations in market dynamics; for instance, the UAE’s rapid industrialization contrasts with the slower growth seen in certain African markets. Understanding these nuances will enable buyers to make informed sourcing decisions that align with their strategic objectives.

Sustainability & Ethical Sourcing in B2B

As environmental concerns become more pressing, sustainability is no longer a choice but a necessity for businesses in the industrial air compressor parts sector. The environmental impact of manufacturing processes, including energy consumption and emissions, is under scrutiny. Buyers are increasingly seeking suppliers who demonstrate commitment to sustainability through eco-friendly practices and materials.

Ethical sourcing is also gaining traction, with companies prioritizing suppliers who adhere to fair labor practices and transparent supply chains. This is particularly important for international B2B buyers, who must navigate diverse regulatory landscapes and cultural expectations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are valuable indicators of a supplier’s commitment to sustainable practices.

Moreover, the use of recycled materials and energy-efficient components is becoming more prevalent in the production of industrial air compressor parts. By prioritizing suppliers that utilize such materials, buyers can not only reduce their environmental footprint but also enhance their brand reputation in an increasingly eco-conscious market.

Brief Evolution/History

The evolution of the industrial air compressor parts sector can be traced back to the early days of industrialization when steam-powered compressors were first introduced. Over the decades, technological advancements have led to the development of more efficient and reliable compressor systems, including rotary screw and centrifugal compressors.

In recent years, the rise of digital technology has further transformed the landscape, enabling predictive maintenance and smart monitoring. This historical context is essential for B2B buyers, as it illustrates the continuous innovation that drives the market forward and underscores the importance of selecting suppliers who are not only well-established but also forward-thinking in their approach to technology and sustainability.

Overall, understanding these market dynamics, sustainability imperatives, and historical developments will empower international B2B buyers to make strategic sourcing decisions that align with their operational goals and ethical standards.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of industrial air compressor parts

-

How can I effectively vet suppliers for industrial air compressor parts?

When vetting suppliers, start by checking their credentials, including industry certifications like ISO 9001. Look for suppliers with a solid track record in your region, and request references from their previous clients. Utilize platforms such as Alibaba or ThomasNet to read reviews and ratings. Additionally, consider conducting site visits or virtual audits to assess their production capabilities and quality control processes firsthand. -

Can I customize industrial air compressor parts to suit my specific needs?

Many suppliers offer customization options, but it’s crucial to communicate your requirements clearly from the outset. Provide detailed specifications, including dimensions, materials, and performance criteria. Discuss possible modifications and ensure the supplier has the necessary technology and expertise. Request samples before finalizing your order to ensure the product meets your expectations. -

What are typical minimum order quantities (MOQ) and lead times for industrial air compressor parts?

MOQs can vary significantly based on the supplier and the complexity of the parts. Generally, standard parts may have lower MOQs, while customized components might require larger orders. Lead times can range from a few weeks to several months depending on the supplier’s production capacity and your location. Always confirm these details during negotiations to align expectations and plan your inventory accordingly. -

What payment terms are common in international B2B transactions for industrial air compressor parts?

Payment terms can vary widely, but common practices include upfront deposits (typically 30-50%) followed by the balance upon shipment. Consider using secure payment methods like letters of credit or escrow services, especially for first-time transactions. Ensure you discuss payment terms early in negotiations to avoid misunderstandings and protect your financial interests. -

How can I ensure quality assurance and certifications for the parts I purchase?

Request copies of relevant quality assurance certifications and testing reports from suppliers. Look for compliance with international standards such as CE marking for Europe or ASTM standards. Establish clear quality expectations in your contract and consider including a clause for third-party inspections before shipment. This will help mitigate risks related to product quality and performance. -

What logistics considerations should I keep in mind when sourcing from international suppliers?

Logistics can be complex when sourcing internationally. Assess shipping options and choose a reliable freight forwarder who understands customs regulations in your country. Consider the total landed cost, including shipping, tariffs, and insurance. Additionally, factor in potential delays due to customs clearance and plan your inventory levels accordingly to avoid production interruptions. -

How should I handle disputes with suppliers?

To manage disputes effectively, ensure that your contracts include clear terms regarding quality, delivery, and payment. Establish a communication protocol for addressing issues as they arise. If a dispute occurs, try to resolve it amicably through direct negotiation. If necessary, consider mediation or arbitration as alternatives to litigation, especially when dealing with international suppliers. -

What are the best practices for maintaining long-term relationships with suppliers?

Building strong relationships with suppliers involves regular communication and feedback. Schedule periodic reviews to discuss performance, quality, and any potential improvements. Consider establishing a partnership approach where both parties benefit from shared goals. Promptly address any concerns and recognize their contributions to your business, as this fosters loyalty and encourages better service in the future.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for industrial air compressor parts

In the evolving landscape of industrial air compressor parts, strategic sourcing emerges as a critical component for international B2B buyers. By prioritizing supplier relationships, understanding regional market dynamics, and leveraging technological advancements, businesses can enhance their procurement processes. Buyers from Africa, South America, the Middle East, and Europe must focus on establishing partnerships with reliable suppliers who not only meet quality standards but also offer competitive pricing and timely delivery.

Key takeaways for buyers include:

- Diversification: Engage with multiple suppliers to mitigate risks associated with supply chain disruptions.

- Local Insights: Leverage local expertise to navigate regulatory requirements and market trends specific to your region.

- Sustainability: Consider suppliers that prioritize environmentally friendly practices, as this is becoming increasingly important in global markets.

As we look ahead, the future of sourcing industrial air compressor parts will be shaped by innovation and collaboration. Buyers are encouraged to adopt a proactive approach, continuously evaluating their sourcing strategies and embracing new technologies. This not only fosters resilience but also positions companies to capitalize on emerging opportunities in the global marketplace. Embrace strategic sourcing as a cornerstone of your procurement strategy to drive efficiency and growth in an increasingly competitive environment.