Master Lead Screws: The Complete Guide to Cost Efficiency (2025)

Introduction: Navigating the Global Market for lead screw

Navigating the global market for lead screws can be a daunting challenge for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. With an array of choices available, including variations in thread design, materials, and sizes, sourcing the right lead screw for specific applications can significantly impact operational efficiency and product performance. This guide offers a comprehensive exploration of lead screws, detailing their types, applications, and essential factors to consider when vetting suppliers.

By delving into critical areas such as cost analysis, compatibility with machinery, and the implications of material selection, this guide empowers B2B buyers to make informed purchasing decisions. For instance, understanding the differences between lead screws and other mechanical components, such as ball screws, can help buyers select the most suitable option for their needs. Additionally, insights into supplier certifications, lead times, and quality assurance processes will equip buyers with the knowledge necessary to mitigate risks associated with international procurement.

In a rapidly evolving market, leveraging this guide will enable businesses from regions like Egypt and Mexico to navigate complexities, ensuring that their sourcing strategies align with both their immediate requirements and long-term goals. Whether you are looking to enhance manufacturing capabilities or optimize existing systems, this resource serves as your roadmap to successful lead screw procurement.

Understanding lead screw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acme Lead Screw | Trapezoidal thread profile, high load capacity | CNC machines, automation equipment | Pros: Good wear resistance; Cons: Higher friction compared to ball screws. |

| Square Thread Lead Screw | Square thread geometry for efficient power transfer | Heavy-duty machinery, jacks | Pros: Excellent for high load applications; Cons: More complex manufacturing. |

| Round Thread Lead Screw | Rounded threads, lower friction, less efficient power transfer | Light-duty applications, 3D printers | Pros: Smooth operation; Cons: Lower load capacity. |

| Self-Lubricating Lead Screw | Integrated lubrication system, reduced maintenance needs | Robotics, medical devices | Pros: Minimal maintenance; Cons: Higher upfront cost. |

| Miniature Lead Screw | Compact design, smaller diameters (e.g., 2mm-10mm) | Precision instruments, small machinery | Pros: Space-saving; Cons: Limited load capacity. |

What Are the Key Characteristics of Acme Lead Screws?

Acme lead screws feature a trapezoidal thread profile that provides a robust solution for high load applications. Their design allows for greater load capacity and efficiency in transferring power, making them ideal for CNC machines and automation equipment. When purchasing Acme lead screws, consider the required load specifications and the potential for increased friction, which may affect performance in high-speed applications.

How Do Square Thread Lead Screws Benefit Heavy-Duty Applications?

Square thread lead screws are characterized by their square thread geometry, which facilitates efficient power transfer while handling substantial loads. This type is particularly suited for heavy-duty machinery and applications such as screw jacks. Buyers should evaluate the complexity of manufacturing and potential costs associated with square thread lead screws, as they may have higher production costs compared to simpler designs.

In What Situations Are Round Thread Lead Screws Most Effective?

Round thread lead screws are designed with rounded threads that provide smoother operation but are less efficient in power transfer compared to other types. They are commonly used in light-duty applications, such as 3D printers, where precision and smooth movement are essential. When considering round thread lead screws, buyers should weigh the benefits of smoother operation against their lower load capacity, ensuring they meet the specific requirements of their applications.

What Advantages Do Self-Lubricating Lead Screws Offer?

Self-lubricating lead screws incorporate a lubrication system that reduces maintenance needs, making them particularly attractive for robotics and medical devices. This feature can significantly lower operational costs over time due to decreased maintenance requirements. However, buyers should be aware of the higher upfront costs associated with these lead screws and assess whether the long-term savings justify the investment.

Why Choose Miniature Lead Screws for Precision Instruments?

Miniature lead screws are designed for compact applications, with diameters typically ranging from 2mm to 10mm. They are ideal for precision instruments and small machinery where space is at a premium. While their size allows for versatile applications, buyers must consider the limitations in load capacity when selecting miniature lead screws for their projects, ensuring that they can still achieve the desired performance without compromising on strength.

Key Industrial Applications of lead screw

| Industry/Sector | Specific Application of Lead Screw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machining Systems | Enhances precision in automated machining processes, improving product quality and reducing waste. | Ensure compatibility with existing machinery; consider lead screw size, material, and thread type for optimal performance. |

| Robotics | Robotic Arm Actuation | Provides accurate and repeatable motion control, essential for precision tasks in assembly and manufacturing. | Assess load capacity and speed requirements; select high-quality materials for durability in dynamic environments. |

| Medical Equipment | Surgical Table Adjustments | Facilitates smooth and precise adjustments, improving surgical outcomes and patient safety. | Focus on sterilizable materials; ensure compliance with medical standards and regulations. |

| Aerospace | Aircraft Control Systems | Delivers reliable motion in flight control mechanisms, enhancing safety and performance. | Prioritize lightweight materials and corrosion resistance; consider strict industry certifications. |

| Packaging | Automated Packaging Machines | Increases efficiency and speed in packaging processes, leading to higher throughput. | Evaluate the lead screw’s ability to handle varying loads; consider maintenance requirements for continuous operation. |

How Are Lead Screws Used in CNC Machining Systems?

In CNC machining, lead screws play a crucial role in converting rotational motion into precise linear movement, allowing for accurate positioning of cutting tools. This precision is essential for producing high-quality components with minimal waste, leading to cost savings and improved efficiency. For international buyers, particularly in regions like Africa and South America, sourcing lead screws that meet specific size and material requirements is vital for compatibility with existing machinery and ensuring optimal performance.

What Role Do Lead Screws Play in Robotic Arm Actuation?

Lead screws are integral to robotic arms, enabling precise motion control necessary for tasks such as assembly and material handling. They provide a mechanical advantage, allowing robots to handle heavy loads while maintaining accuracy. Buyers from the Middle East and Europe should consider the load capacity and speed of the lead screws, ensuring they select high-quality materials that can withstand the rigors of dynamic operation in robotic systems.

Why Are Lead Screws Important for Surgical Table Adjustments?

In the medical sector, lead screws are used to adjust surgical tables, ensuring precise positioning for optimal patient care. Their ability to provide smooth and accurate adjustments enhances surgical outcomes and patient safety. For buyers in regions like Egypt and Mexico, it is essential to focus on sourcing lead screws made from sterilizable materials that comply with stringent medical standards, ensuring both safety and performance in healthcare applications.

How Do Lead Screws Enhance Aircraft Control Systems?

In aerospace applications, lead screws are critical for actuating flight control surfaces, providing reliable motion that is essential for aircraft safety and performance. Their design must accommodate strict industry regulations regarding weight and durability. International buyers in this sector should prioritize sourcing lightweight yet strong materials with corrosion resistance, ensuring compliance with aerospace certifications and the ability to perform under various environmental conditions.

What Benefits Do Lead Screws Offer in Automated Packaging Machines?

Lead screws are vital in automated packaging machines, facilitating rapid and efficient movement for packaging processes. By increasing throughput and reducing manual labor, businesses can achieve significant cost savings. Buyers should evaluate the lead screw’s load-handling capabilities and maintenance needs, ensuring that the selected components can sustain continuous operation in high-demand packaging environments, particularly in fast-growing markets across South America and Africa.

3 Common User Pain Points for ‘lead screw’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision in Motion Control

The Problem: Many B2B buyers in sectors like automation and manufacturing often struggle with achieving high precision in linear motion control. When using lead screws, the common issue arises from backlash—an unwanted movement that occurs when the direction of motion is reversed. This can result in inaccuracies in applications such as CNC machines or robotics, where precision is paramount. Buyers may find themselves facing increased production costs and longer lead times due to the need for constant recalibration and adjustments.

The Solution: To mitigate backlash, B2B buyers should consider sourcing precision lead screws designed with anti-backlash nuts. These nuts incorporate a spring mechanism that maintains constant pressure against the screw, effectively eliminating play. When specifying a lead screw for your application, prioritize suppliers who offer customization options, including thread pitch and material selection, to better align with your operational needs. Additionally, implementing regular maintenance routines, such as lubrication and inspection of wear, can extend the lifespan and maintain the performance of your lead screw systems.

Scenario 2: Overcoming Material Wear and Tear in Harsh Environments

The Problem: For industries operating in challenging environments—such as those in the Middle East or regions with high humidity—wear and tear on mechanical components is a significant concern. Buyers often encounter lead screws that degrade quickly due to corrosion, which can lead to operational failures and costly downtimes. This is especially problematic in applications where lead screws are subject to heavy loads or extreme temperatures.

The Solution: To address this issue, international B2B buyers should opt for lead screws made from corrosion-resistant materials, such as stainless steel or specially coated alloys. Additionally, consider lead screws with PTFE-based coatings to enhance durability in harsh environments. When sourcing these components, request detailed specifications on the materials used and ask for test results that demonstrate their resistance to environmental stressors. Implementing regular inspections and using protective covers can further safeguard lead screws from exposure to damaging conditions, ensuring longevity and reliability in operations.

Scenario 3: Complications in Sizing and Compatibility with Existing Systems

The Problem: A common pain point for B2B buyers is the challenge of selecting lead screws that fit seamlessly into their existing machinery or applications. Often, buyers find that standard lead screw dimensions do not align with their systems, leading to compatibility issues that can halt production and require expensive modifications.

The Solution: To effectively resolve sizing issues, it’s crucial for buyers to take comprehensive measurements of their current systems before sourcing lead screws. Utilize tools like CAD modeling to visualize how new lead screws will integrate with existing machinery. Additionally, work with suppliers who offer a wide range of sizes and customization options, enabling you to specify exact dimensions, thread types, and materials suited for your needs. When placing orders, be transparent about your application requirements and ask for prototypes or samples to test compatibility before committing to bulk purchases. This approach not only streamlines the selection process but also minimizes the risk of operational disruptions.

Strategic Material Selection Guide for lead screw

When selecting materials for lead screws, international B2B buyers must consider various factors that impact performance, durability, and cost. The choice of material can significantly influence the lead screw’s application suitability, especially in diverse environments across Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in lead screw manufacturing, highlighting their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Stainless Steel for Lead Screws?

Stainless steel is a popular choice for lead screws due to its excellent corrosion resistance and strength. It typically withstands temperatures ranging from -200°C to 800°C, making it suitable for various environments. The most commonly used grades include 304 and 316, with 316 offering better corrosion resistance, especially in saline or acidic conditions.

Pros: Stainless steel lead screws provide high durability and resistance to wear, making them ideal for applications requiring longevity. They are also relatively easy to machine and maintain.

Cons: The primary drawback is the higher cost compared to other materials like carbon steel. Additionally, stainless steel can be heavier, which may not be suitable for applications where weight is a critical factor.

Impact on Application: Stainless steel lead screws are well-suited for environments exposed to moisture or chemicals, such as food processing or marine applications.

Considerations for International Buyers: Buyers from regions with stringent compliance standards, such as Europe, should ensure that the stainless steel used meets ASTM or DIN specifications. In countries like Egypt and Mexico, local sourcing may also affect pricing and availability.

How Does Carbon Steel Compare as a Material for Lead Screws?

Carbon steel is another common material for lead screws, known for its high strength and affordability. It typically has a temperature tolerance of up to 300°C but lacks the corrosion resistance of stainless steel unless treated.

Pros: Carbon steel lead screws are cost-effective and provide good mechanical properties, making them suitable for many applications.

Cons: Their susceptibility to rust and corrosion limits their use in humid or wet environments unless coated or treated. This can increase manufacturing complexity and cost.

Impact on Application: Carbon steel lead screws are ideal for indoor applications or environments where exposure to moisture is minimal, such as in machinery or automotive components.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to enhance corrosion resistance. Compliance with local standards, such as JIS in Japan or ASTM in the U.S., is also essential for quality assurance.

What Are the Advantages of Using Aluminum for Lead Screws?

Aluminum is increasingly used for lead screws due to its lightweight and good corrosion resistance. It typically operates effectively at temperatures up to 150°C.

Pros: The primary advantage of aluminum lead screws is their low weight, which can significantly reduce the overall weight of machinery. They also offer good machining properties and are resistant to corrosion.

Cons: However, aluminum is generally less strong than steel, which may limit its use in high-load applications. Additionally, it can be more expensive than carbon steel.

Impact on Application: Aluminum lead screws are ideal for applications requiring lightweight components, such as in aerospace or robotics.

Considerations for International Buyers: Buyers should consider the specific alloy used, as different aluminum grades offer varying properties. Compliance with local manufacturing standards is crucial, especially in industries such as aerospace.

Why Choose Plastic Lead Screws for Specific Applications?

Plastic lead screws, often made from materials like acetal or nylon, are suitable for low-load applications. They are lightweight and can operate in temperatures ranging from -40°C to 100°C.

Pros: The primary advantage of plastic lead screws is their low friction and self-lubricating properties, which can reduce the need for additional lubrication. They are also resistant to corrosion and chemical attacks.

Cons: Plastic lead screws are generally not suitable for high-load applications due to their lower strength and wear resistance compared to metal alternatives.

Impact on Application: They are ideal for applications in clean environments, such as in medical devices or electronic equipment.

Considerations for International Buyers: Buyers must ensure that the plastic materials comply with relevant health and safety standards, particularly in medical or food-related applications.

Summary Table of Material Selection for Lead Screws

| Material | Typical Use Case for Lead Screw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine applications, food processing | High corrosion resistance | Higher cost than carbon steel | High |

| Carbon Steel | Machinery, automotive components | Cost-effective, high strength | Susceptible to corrosion | Low |

| Aluminum | Aerospace, robotics | Lightweight, good corrosion resistance | Lower strength than steel | Medium |

| Plastic | Medical devices, electronics | Low friction, self-lubricating | Not suitable for high-load applications | Low |

This strategic material selection guide provides B2B buyers with essential insights into choosing the right lead screw material based on application requirements, performance characteristics, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for lead screw

What Are the Key Manufacturing Processes for Lead Screws?

The manufacturing of lead screws involves several critical stages that ensure precision and quality. Understanding these processes is vital for B2B buyers aiming to procure reliable components.

Material Preparation: What Materials Are Typically Used for Lead Screws?

Lead screws are predominantly made from materials like stainless steel, carbon steel, and aluminum. The choice of material affects the screw’s durability, strength, and resistance to corrosion.

-

Material Selection: The first step involves selecting high-quality raw materials. Stainless steel offers excellent corrosion resistance, making it suitable for harsh environments, while carbon steel is often used for applications requiring high strength.

-

Material Inspection: Before processing, materials undergo rigorous inspections to ensure they meet specified standards. This step often includes checking for defects, mechanical properties, and chemical composition.

How Is the Forming Process Conducted for Lead Screws?

The forming stage is crucial in shaping the lead screw accurately.

-

Turning and Threading: The primary method for forming lead screws is through CNC turning and threading. CNC machines create precise threads on the screw shaft, ensuring consistent quality across batches. For complex designs, multi-axis CNC machines may be employed.

-

Heat Treatment: After forming, lead screws often undergo heat treatment to enhance their mechanical properties. This process involves heating the material to a specific temperature and then cooling it rapidly, which increases strength and hardness.

-

Surface Treatments: Surface finishing techniques such as grinding, anodizing, or coating may be applied to improve wear resistance and reduce friction. PTFE-based coatings are popular for applications requiring low friction and self-lubrication.

What Are the Assembly Techniques Used in Lead Screw Manufacturing?

Assembly involves combining various components to create a functional lead screw system.

-

Nut Attachment: The nut, which interacts with the screw, is often made from self-lubricating materials like bronze or plastic. Proper alignment during assembly is critical to minimize backlash and ensure smooth operation.

-

Precision Alignment: Ensuring that the screw and nut are perfectly aligned is vital for performance. Misalignment can lead to increased wear and reduced lifespan.

How Does Finishing Enhance the Quality of Lead Screws?

Finishing processes are essential for achieving the desired surface quality and functionality.

-

Final Inspection: After assembly, lead screws undergo a final inspection to verify dimensions and thread quality. This is often performed using advanced measurement equipment to ensure compliance with specifications.

-

Packaging: Quality assurance extends to packaging, which must protect the screws during transportation. Proper packaging prevents damage and contamination, ensuring that the product reaches the buyer in optimal condition.

What Quality Assurance Measures Are Essential for Lead Screw Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that lead screws meet international standards.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers must be familiar with relevant international quality standards that impact lead screw manufacturing.

-

ISO 9001 Certification: This standard focuses on quality management systems and ensures that manufacturers follow best practices in production and service delivery. Buyers should prioritize suppliers with ISO 9001 certification as it indicates a commitment to quality.

-

Industry-Specific Standards: Depending on the application, other certifications may be relevant, such as CE marking for products sold in Europe or API standards for oil and gas applications. Understanding these requirements is crucial for compliance in different markets.

What Are the Key Quality Control Checkpoints in Lead Screw Manufacturing?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process.

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before production begins. Materials are evaluated against predefined standards to ensure they are suitable for manufacturing.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor dimensions, thread quality, and surface finish. This ongoing evaluation helps identify any deviations early, reducing waste and rework.

-

Final Quality Control (FQC): After assembly and finishing, a final inspection is performed. This includes dimensional checks, functional testing, and verification against customer specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should take proactive steps to ensure their suppliers adhere to high-quality standards.

-

Supplier Audits: Conducting regular audits of suppliers is an effective way to verify their quality control processes. Audits should assess adherence to international standards, production capabilities, and quality management systems.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline inspection results, material certifications, and any non-conformance incidents. These documents provide transparency and assurance of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the quality of lead screws. These independent evaluations help ensure that the products meet international standards and specifications.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances in quality control when sourcing lead screws.

-

Cultural Differences: Different regions may have varying expectations regarding quality and compliance. Understanding these differences can help buyers navigate supplier relationships more effectively.

-

Logistics and Supply Chain: The complexity of international logistics can impact quality assurance. Buyers should consider how transportation and storage conditions may affect product quality and ensure that suppliers have adequate measures in place.

-

Regulatory Compliance: Different markets have specific regulatory requirements that must be adhered to. B2B buyers must ensure that their suppliers are compliant with local regulations to avoid any legal complications.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing lead screws, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lead screw’

Introduction

Sourcing lead screws for your industrial applications requires careful planning and consideration. This step-by-step checklist aims to guide B2B buyers, particularly from Africa, South America, the Middle East, and Europe, through the procurement process. By following these actionable steps, you can ensure that you select the right lead screws that meet your technical requirements and budget constraints.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it is vital to articulate your technical requirements clearly. Consider factors such as the dimensions (diameter and length), material (stainless steel, aluminum), and the specific thread type (e.g., ACME, square-threaded).

- Identify the load capacity and the precision level required for your application.

- Specify the environment in which the lead screw will operate, as this influences material choice and durability.

Step 2: Research Potential Suppliers

Take the time to identify and research suppliers who specialize in lead screws. Look for manufacturers with a strong reputation and experience in your industry.

- Utilize platforms like LinkedIn, industry forums, and trade shows to find credible suppliers.

- Consider suppliers who can provide customization options to better fit your unique specifications.

Step 3: Evaluate Supplier Certifications and Compliance

It’s crucial to verify that potential suppliers adhere to international quality standards and regulations. Certifications like ISO 9001 can indicate a commitment to quality management.

- Ask for documentation that proves compliance with industry-specific standards (e.g., RoHS, CE marking).

- Ensure that the materials used in the lead screws meet any relevant safety and environmental regulations.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the lead screws to test their performance in your application.

- Evaluate the samples for key parameters such as strength, durability, and ease of installation.

- Conduct stress tests to see how they perform under load conditions that mimic your operational environment.

Step 5: Compare Pricing and Lead Times

Gather quotes from multiple suppliers to compare pricing effectively. While cost is a significant factor, consider the total value, which includes quality and service.

- Check the lead times for delivery to ensure they align with your project timelines.

- Inquire about bulk order discounts or payment terms that can impact your overall budget.

Step 6: Assess After-Sales Support and Warranty Terms

Understanding the after-sales support provided by the supplier can save you time and money in the long run.

- Look for suppliers who offer robust customer service and technical support.

- Evaluate warranty terms to ensure that you are covered in case of defects or performance issues.

Step 7: Finalize the Order and Establish Communication

Once you have selected a supplier, finalize your order with clear terms of delivery, payment, and any other conditions.

- Maintain open lines of communication with the supplier to address any concerns that may arise during production or shipping.

- Establish a point of contact to facilitate efficient coordination and support throughout the procurement process.

By following this checklist, international B2B buyers can navigate the sourcing process for lead screws effectively, ensuring that they find the best products to meet their operational needs.

Comprehensive Cost and Pricing Analysis for lead screw Sourcing

What Are the Key Cost Components in Lead Screw Manufacturing?

When sourcing lead screws, understanding the cost structure is vital for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Lead screws are often made from stainless steel, carbon steel, or aluminum. Specialty coatings for corrosion resistance can also impact costs. Buyers should evaluate the durability and application needs to choose the most cost-effective material.

-

Labor: Labor costs vary by region and manufacturing process. Countries with lower labor costs can offer competitive pricing, but quality should not be compromised. Assessing the skill level of the workforce and the complexity of the lead screw design is essential.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Understanding how these overheads are allocated can help buyers gauge the base price of lead screws.

-

Tooling: The initial investment in tooling for custom lead screws can be substantial. Buyers should consider the tooling costs in relation to their order volume; higher volumes can amortize these costs, leading to better pricing.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, but they can also increase costs. Buyers should inquire about the QC measures in place and how they are factored into pricing.

-

Logistics: Shipping costs can significantly influence the final price, especially for international buyers. Factors such as distance, transport mode, and potential tariffs should be considered.

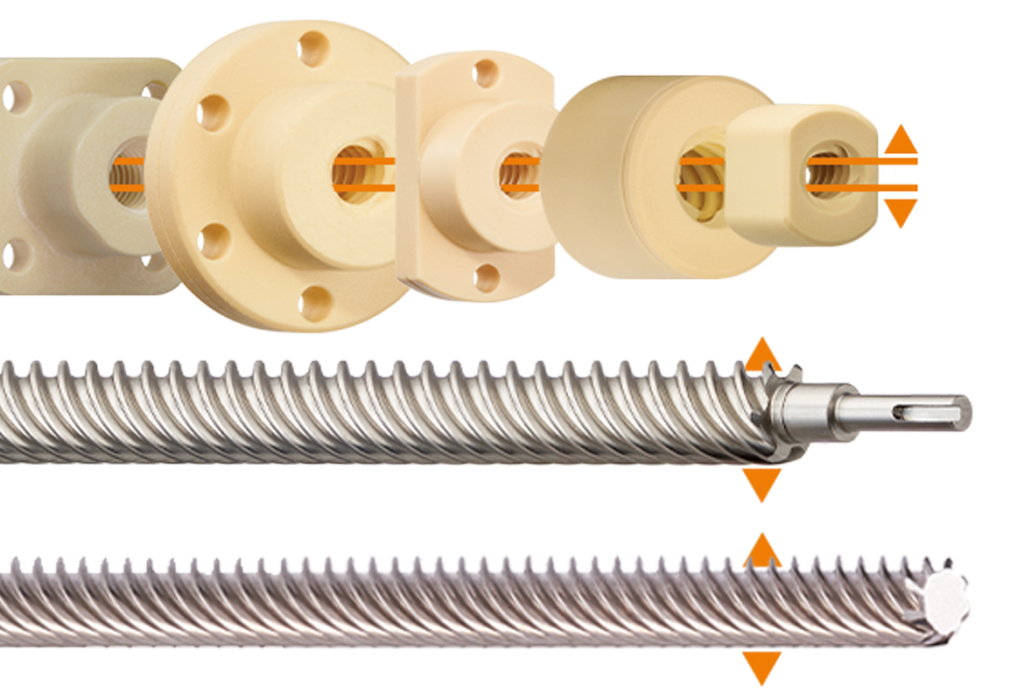

A stock image related to lead screw.

- Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers assess whether a quote is competitive.

How Do Price Influencers Affect Lead Screw Sourcing Decisions?

Several factors can influence the pricing of lead screws, and recognizing these can aid buyers in negotiations:

-

Volume/MOQ: Minimum order quantities (MOQ) can impact pricing significantly. Suppliers often provide better rates for larger orders. Buyers should balance their immediate needs with potential future demand to optimize costs.

-

Specifications and Customization: Custom designs or specific thread geometries can increase costs. It’s crucial for buyers to clearly define their specifications to avoid unexpected price hikes.

-

Materials: As previously mentioned, the choice of materials plays a critical role. Premium materials or specialized coatings will add to the cost.

-

Quality and Certifications: Certifications (such as ISO) that ensure quality and compliance with international standards can also influence pricing. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven track record and customer service.

-

Incoterms: Understanding shipping terms (such as FOB, CIF) is essential. They dictate who is responsible for shipping costs and risk, which can affect the total landed cost of lead screws.

What Buyer Tips Can Enhance Cost-Efficiency in Lead Screw Sourcing?

B2B buyers can employ several strategies to enhance cost-efficiency when sourcing lead screws:

-

Negotiation: Effective negotiation can lead to better pricing. Buyers should come prepared with market research and be willing to discuss terms that benefit both parties.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and performance. A lower upfront cost may result in higher TCO if the lead screws fail prematurely.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of potential import duties, tariffs, and currency fluctuations that can impact final pricing. Establishing relationships with local suppliers can mitigate some of these costs.

-

Requesting Quotes: Obtaining multiple quotes can provide a clearer picture of market rates. Always ask for detailed breakdowns to understand the pricing components.

-

Regular Review: Periodically reviewing suppliers and contracts can uncover opportunities for cost savings as market conditions change.

Conclusion

While sourcing lead screws, understanding the comprehensive cost structure and pricing influencers is crucial for making informed purchasing decisions. By applying the outlined strategies, international B2B buyers can optimize their sourcing process, ensuring they receive quality products at competitive prices. Remember, indicative prices can vary significantly based on the aforementioned factors, so continual assessment and negotiation are key to achieving cost-effectiveness in lead screw procurement.

Alternatives Analysis: Comparing lead screw With Other Solutions

Understanding Alternative Solutions to Lead Screws

In the pursuit of efficient motion control systems, B2B buyers often encounter various technologies that can serve as alternatives to lead screws. Each solution has its unique strengths and weaknesses, making it essential for buyers to understand how these options compare in terms of performance, cost, and application suitability. This analysis will focus on two viable alternatives: Ball Screws and Linear Actuators.

Comparison Table

| Comparison Aspect | Lead Screw | Ball Screw | Linear Actuator |

|---|---|---|---|

| Performance | Good for light to medium loads; moderate speed | High efficiency; low friction; suitable for high speeds | Excellent for precise control and automation |

| Cost | Generally lower cost | Higher initial investment | Moderate to high, depending on complexity |

| Ease of Implementation | Simple design; easy to install | Requires precise alignment | Typically user-friendly with built-in controls |

| Maintenance | Moderate maintenance; lubrication needed | Low maintenance; self-lubricating options available | Minimal maintenance; often maintenance-free |

| Best Use Case | Applications requiring moderate precision | High-load applications needing high precision | Automated systems requiring fast and precise movements |

What Are the Pros and Cons of Ball Screws?

Ball screws represent a significant advancement over lead screws, particularly in applications demanding high efficiency and low friction. They utilize ball bearings to facilitate movement, drastically reducing wear and energy consumption. However, this advanced technology comes with a higher initial investment and requires precise installation to avoid misalignment. Their ideal applications include CNC machinery and robotics, where precision and speed are critical.

How Do Linear Actuators Compare to Lead Screws?

Linear actuators are versatile devices that convert rotational motion into linear motion, similar to lead screws. They often come equipped with built-in controls, making them user-friendly and suitable for automation. Linear actuators excel in applications that require precise control and rapid movements, such as in robotic arms and conveyor systems. However, they may come at a higher cost and can be more complex to integrate into existing systems compared to lead screws.

Making the Right Choice for Your Application

When selecting the appropriate motion control solution, B2B buyers must consider their specific needs. Lead screws are a cost-effective choice for moderate applications where precision is not the highest priority. In contrast, ball screws offer superior efficiency and speed but require a greater investment and careful installation. Linear actuators provide advanced automation capabilities but may involve complexity and higher costs. By evaluating these factors, buyers can make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for lead screw

What Are the Essential Technical Properties of Lead Screws?

Understanding the critical technical properties of lead screws is vital for B2B buyers, especially when assessing their suitability for specific applications. Here are some essential specifications:

1. Material Grade: Why Is It Important?

Lead screws are commonly made from materials like stainless steel, carbon steel, and aluminum. The choice of material affects the screw’s strength, corrosion resistance, and wear characteristics. For instance, stainless steel lead screws are ideal for environments exposed to moisture or chemicals, while carbon steel may be suitable for applications requiring high strength but less corrosion resistance. Selecting the right material is crucial for ensuring durability and performance, thereby reducing maintenance costs over time.

2. Screw Diameter: How Does It Impact Performance?

The diameter of a lead screw typically ranges from 2mm to 25mm. A larger diameter can handle higher loads but may also require more torque to operate effectively. Understanding the load requirements of your application will guide you in selecting the appropriate screw diameter, ensuring optimal performance and longevity.

3. Lead and Pitch: What’s the Difference?

Lead refers to the linear distance that the nut travels in one complete revolution of the screw, while pitch is the distance between two adjacent threads. A smaller lead allows for finer movement control, making it suitable for applications that require precision, such as CNC machinery. Conversely, a larger lead can facilitate faster movement but may compromise precision. Knowing the specific requirements of your application will help you choose the right lead and pitch for optimal results.

4. Tolerance: Why Is It Critical?

Tolerance indicates the permissible limits of variation in the dimensions of the lead screw. High tolerance levels are essential for applications requiring precise linear motion, such as robotics and automation. A lead screw with inadequate tolerance can lead to misalignment and decreased efficiency. Therefore, understanding the required tolerance levels for your project is key to selecting a lead screw that meets your specifications.

5. Thread Type: How Does It Affect Functionality?

Lead screws can have various thread types, including ACME, square, and trapezoidal. Each thread type has unique advantages: ACME threads are known for their strength and load-bearing capabilities, while square threads offer efficiency in power transmission. Selecting the right thread type for your application can significantly impact performance and efficiency.

What Are Common Trade Terms Related to Lead Screws?

Being familiar with industry terminology can streamline the procurement process and enhance communication with suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce components that are then marketed by another company under its own brand name. In the context of lead screws, understanding OEM relationships can help buyers identify quality manufacturers and ensure that they are sourcing reliable components.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning, especially for small and medium-sized enterprises (SMEs) looking to manage inventory costs effectively.

3. RFQ (Request for Quotation): How Should It Be Used?

An RFQ is a document sent to suppliers requesting pricing and terms for specified quantities of products. For B2B buyers, submitting an RFQ for lead screws can help in comparing offers from different suppliers, ensuring that you get the best price and terms.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade. They clarify who is responsible for shipping, insurance, and tariffs, which is crucial for international B2B transactions involving lead screws, especially for buyers from regions like Africa, South America, and the Middle East.

5. Lead Time: How Does It Affect Project Timelines?

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is critical for project planning, particularly for businesses that rely on just-in-time manufacturing or have tight deadlines.

A stock image related to lead screw.

By familiarizing yourself with these technical properties and trade terminologies, you can make informed decisions when sourcing lead screws, ensuring that your applications are efficient, reliable, and cost-effective.

Navigating Market Dynamics and Sourcing Trends in the lead screw Sector

What Are the Current Market Dynamics and Key Trends in the Lead Screw Sector?

The lead screw market is experiencing robust growth, driven by the increasing demand for automation and precision machinery across various industries, including manufacturing, automotive, and aerospace. A significant trend is the shift towards integrating smart technologies into lead screw systems, enhancing their functionality through IoT (Internet of Things) capabilities. This trend allows for real-time monitoring and predictive maintenance, reducing downtime and operational costs—an essential consideration for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Moreover, the global push for localized sourcing is reshaping market dynamics. Buyers are increasingly seeking suppliers closer to their operational bases to minimize shipping times and costs. This is particularly evident in regions like Egypt and Mexico, where manufacturers are enhancing their supply chains by engaging with local suppliers of lead screws, thus supporting regional economies and ensuring faster delivery times.

Emerging technologies, such as additive manufacturing, are also influencing sourcing trends. This technology allows for customized lead screw designs that meet specific application requirements, providing a competitive edge for businesses that adopt it. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with their operational needs and growth strategies.

A stock image related to lead screw.

How Is Sustainability Influencing Sourcing Decisions in the Lead Screw Market?

In today’s market, sustainability is not just a trend; it has become a fundamental pillar of business strategy for many B2B buyers. The environmental impact of sourcing materials for lead screws is significant, particularly concerning the carbon footprint associated with production and transportation. As such, international buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices.

Ethical sourcing plays a critical role in this landscape. Buyers are seeking out suppliers who adhere to stringent environmental standards and who can provide transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and products made from recycled or sustainably sourced materials are becoming essential criteria for supplier selection. In the lead screw sector, opting for suppliers that utilize environmentally friendly coatings and materials, such as stainless steel or aluminum with low environmental impact, is a growing preference among conscientious buyers.

Furthermore, the demand for ‘green’ certifications is reshaping product offerings. Suppliers are responding by developing lead screws that meet higher environmental standards, which not only appeal to eco-conscious buyers but can also enhance brand reputation. For businesses operating in regions like Europe, where regulatory pressures are higher, aligning sourcing strategies with sustainability goals is not just beneficial—it’s necessary for long-term viability.

What Is the Historical Context of Lead Screws in B2B Applications?

The evolution of lead screws dates back to ancient times, where they were primarily used in simple machines. Over the centuries, their design has advanced significantly, adapting to the needs of various industrial applications. Initially used in manual devices, lead screws have transformed into crucial components in automated systems, reflecting the ongoing demand for precision and efficiency in manufacturing processes.

In the modern era, the introduction of materials science has further enhanced the capabilities of lead screws, allowing for the development of high-strength, lightweight options that cater to diverse applications. This evolution has made lead screws indispensable in sectors ranging from robotics to aerospace, where exacting standards of performance are mandatory. Understanding this historical context helps B2B buyers appreciate the technological advancements that inform current product offerings and sourcing strategies in the lead screw market.

Frequently Asked Questions (FAQs) for B2B Buyers of lead screw

-

How do I solve lead screw compatibility issues with my machinery?

To address compatibility issues, first, identify the specifications of your existing machinery, including thread type, lead, and diameter of the lead screw. Consult with potential suppliers to confirm that their lead screws meet these specifications. It may also be beneficial to request samples for testing in your application. Additionally, consider the operational environment—temperature, load, and motion type—as these factors can affect performance. Collaborating with engineers or technical experts from the supplier can provide further insights and solutions tailored to your needs. -

What is the best lead screw type for my application in Africa?

The best lead screw type depends on your specific application requirements. For high-load applications, consider Acme lead screws due to their robust design and efficiency in converting rotational motion into linear movement. If precision is crucial, opt for precision lead screws, which minimize backlash. Additionally, assess environmental factors like humidity or dust, which may necessitate corrosion-resistant materials, such as stainless steel. Supplier guidance can also help in selecting the most suitable lead screw type for your operational needs. -

How can I ensure the quality of lead screws from international suppliers?

To ensure quality, start by vetting suppliers through reviews and certifications, such as ISO standards. Request detailed product specifications, including material composition and manufacturing processes. Conduct factory visits, if feasible, to observe production standards firsthand. Additionally, ask for quality assurance reports and test results from previous batches. Establishing clear communication regarding quality expectations and conducting regular audits can further safeguard your investment in lead screws. -

What customization options are available for lead screws?

Most suppliers offer customization options, including variations in length, diameter, thread type, and material. Some manufacturers can also provide specific coatings for enhanced durability in harsh environments. When discussing customization, clearly communicate your application requirements and any unique specifications to the supplier. It’s advisable to request prototypes before finalizing large orders to ensure that the custom lead screws perform as expected. -

What are the minimum order quantities (MOQ) for lead screws?

Minimum order quantities can vary significantly between suppliers. Many manufacturers set MOQs to optimize production efficiency and reduce costs. Inquire with potential suppliers about their MOQs, and consider negotiating terms if your order volume is below their standard. Some suppliers may offer flexibility, especially for new customers or during promotional periods. It’s also beneficial to explore group purchasing options with other businesses to meet MOQ requirements. -

What payment terms should I expect when sourcing lead screws internationally?

Payment terms vary by supplier and may include options like upfront payments, net 30 or 60 days, or payment upon delivery. When negotiating terms, consider your cash flow and the supplier’s reputation. For larger orders, a letter of credit may provide security for both parties. Always confirm the payment methods accepted (e.g., wire transfer, PayPal) and ensure that all terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

How can I manage logistics when importing lead screws from abroad?

Effective logistics management involves selecting reliable freight forwarders who specialize in international shipping. Discuss shipping options, including air and sea freight, to determine the most cost-effective method for your timeline. Ensure that you understand customs regulations in your country to avoid delays or additional fees. Collaborate with suppliers to obtain necessary documentation, such as bills of lading and customs invoices, to streamline the import process. -

What are the typical lead times for lead screw orders?

Lead times can vary based on factors such as order size, customization, and supplier location. Standard lead times range from a few weeks to several months. When placing an order, request a detailed timeline from your supplier, including production and shipping durations. It’s wise to plan ahead, especially for large projects, to account for any potential delays. Regular communication with the supplier during the process can help mitigate unexpected issues and keep your project on schedule.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lead screw

In the rapidly evolving landscape of industrial components, lead screws remain a critical element in the machinery of various sectors. For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of lead screw applications and sourcing can significantly enhance operational efficiency.

Why is Strategic Sourcing Essential for Lead Screws?

Strategic sourcing enables companies to identify reliable suppliers who can provide high-quality lead screws tailored to specific applications. By focusing on suppliers that offer both metric and imperial sizes, as well as diverse materials like stainless steel and alloys, international buyers can ensure that they meet their precise mechanical requirements. Additionally, leveraging tools such as lead screw calculators can optimize selection processes, reducing errors and improving performance outcomes.

What is the Future Outlook for Lead Screw Technology?

As industries increasingly prioritize automation and precision, the demand for advanced lead screw solutions is expected to rise. Emerging markets in Africa and South America are likely to see significant growth in sectors utilizing lead screws, such as robotics and manufacturing.

How Can You Stay Ahead in Lead Screw Procurement?

B2B buyers are encouraged to actively engage with suppliers, explore innovative designs, and stay informed about advancements in lead screw technology. By doing so, you can secure a competitive edge in your respective markets. Embrace the future of precision engineering—partner with trusted suppliers today to elevate your production capabilities.