Master Sourcing Concrete CNC Machines: Essential Insights

Introduction: Navigating the Global Market for concrete cnc machine

In the contemporary landscape of construction and manufacturing, concrete CNC machines have become pivotal in achieving precision, efficiency, and versatility. As global demand for customized concrete components grows, these machines empower businesses to produce intricate designs with unmatched accuracy, catering to various sectors including construction, architecture, and infrastructure development. For international B2B buyers, particularly from emerging markets in Africa and South America, as well as established industries in Europe and the Middle East, understanding the nuances of sourcing concrete CNC machines is essential for maintaining a competitive edge.

This comprehensive guide delves into the critical aspects of concrete CNC machinery, encompassing various types of machines, optimal material selection, and advanced manufacturing processes. It provides insights into quality control practices that ensure product consistency, supplier evaluation criteria to identify reliable partners, and cost optimization strategies that enhance your procurement decisions. Additionally, it highlights current market trends and regional considerations that are vital for navigating the complexities of global supply chains.

By leveraging the actionable insights presented in this guide, B2B buyers from countries such as Brazil, Colombia, Nigeria, and Germany will be equipped to make informed sourcing decisions. This not only mitigates risks but also enables the establishment of robust partnerships that drive innovation and operational excellence in the concrete manufacturing sector.

Understanding concrete cnc machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concrete 3D Printer | Uses additive manufacturing to build structures layer by layer | Construction, architecture, art | Rapid prototyping; high initial investment |

| CNC Concrete Router | Employs rotary cutting tools for shaping concrete | Custom molds, signage, architectural features | High precision; limited to specific shapes |

| CNC Concrete Milling Machine | Multi-axis operation for detailed shaping and finishing | Infrastructure components, custom parts | Versatile; requires skilled operators |

| Concrete Laser Cutter | Utilizes lasers for cutting intricate designs in concrete | Decorative elements, complex patterns | Clean edges; not suitable for thick materials |

| Concrete CNC Drilling Machine | Precision drilling for reinforcement placement | Pre-cast elements, structural components | Enhanced accuracy; slower compared to other methods |

Concrete 3D Printer

Concrete 3D printers utilize additive manufacturing techniques to layer concrete materials, allowing for the creation of complex structures without traditional formwork. This technology is particularly suitable for the construction and architectural industries, enabling rapid prototyping of building components and artistic installations. B2B buyers should consider the printer’s build size, material compatibility, and the potential for scalability in production. While the initial investment can be substantial, the long-term savings in labor and materials can provide a significant ROI.

CNC Concrete Router

CNC concrete routers employ rotary cutting tools to shape and engrave concrete surfaces, making them ideal for custom molds and architectural features. These machines are particularly suited for projects requiring high precision and intricate designs, such as signage and decorative elements. Buyers should evaluate the machine’s cutting speed, tool compatibility, and software capabilities to ensure it meets specific project requirements. While they offer high precision, their utility may be limited to specific shapes and designs, necessitating a broader range of machines for diverse applications.

CNC Concrete Milling Machine

CNC concrete milling machines are designed for multi-axis operations, allowing for detailed shaping and finishing of concrete components. They are commonly used in the production of infrastructure components and custom parts where precision is crucial. For B2B buyers, assessing the machine’s axis capabilities, material compatibility, and local support is essential for ensuring operational efficiency. Although these machines require skilled operators, their versatility makes them a valuable investment for companies focused on quality and customization.

Concrete Laser Cutter

Concrete laser cutters use concentrated laser beams to cut intricate designs in concrete, making them ideal for decorative elements and complex patterns. This technology allows for clean edges and high-speed processing, particularly beneficial in artistic and architectural applications. B2B buyers should consider the laser power, bed size, and material thickness compatibility when selecting a machine. While laser cutters provide high precision, they may not be suitable for thicker concrete materials, which can limit their application scope.

Concrete CNC Drilling Machine

Concrete CNC drilling machines are designed for precision drilling into concrete, particularly for the placement of reinforcements in pre-cast elements and structural components. Their enhanced accuracy ensures that holes are drilled to exact specifications, which is critical in construction projects. Buyers should evaluate the machine’s drilling speed, bit compatibility, and software integration for optimal performance. While these machines may operate slower than other types, their precision makes them indispensable for applications where accuracy is paramount.

Related Video: I Printed A Better CNC Mill

Key Industrial Applications of concrete cnc machine

| Industry/Sector | Specific Application of concrete cnc machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Custom precast concrete elements | Reduced labor costs, increased precision | Supplier’s ability to meet local regulations and standards, machine capabilities for large-scale production |

| Landscaping | Decorative concrete features | Enhanced aesthetic value, quick turnaround | Material compatibility, design flexibility, and production speed |

| Infrastructure | Concrete forms for bridges and tunnels | Improved structural integrity, cost efficiency | Quality assurance processes, certification for safety standards, and local supply chain reliability |

| Art and Design | Artistic sculptures and installations | Unique design opportunities, enhanced market appeal | Supplier’s portfolio of past projects, customization options, and lead times |

| Urban Development | Urban furniture and public installations | Increased community engagement, aesthetic enhancement | Durability of materials, compliance with urban regulations, and supplier’s innovation capabilities |

Key Industrial Applications of Concrete CNC Machines

Construction

Concrete CNC machines are instrumental in producing custom precast concrete elements, such as beams, columns, and panels. By leveraging CNC technology, manufacturers can achieve high precision and consistency, which drastically reduces labor costs and minimizes waste. For international buyers, especially in regions like Africa and South America, sourcing from suppliers who understand local construction codes and can deliver on time is crucial. Ensuring that the machinery can handle large-scale production while adhering to stringent quality standards is also essential.

Landscaping

In landscaping, concrete CNC machines create decorative features like planters, water fountains, and pathways. These machines enable rapid production of intricate designs that enhance aesthetic value while maintaining structural integrity. B2B buyers should focus on suppliers that offer material compatibility and design flexibility, as well as the ability to meet tight deadlines, especially in fast-developing urban areas. This adaptability is vital for landscaping firms looking to differentiate their projects.

Infrastructure

Concrete CNC machines are utilized to fabricate complex concrete forms for infrastructure projects, including bridges and tunnels. This application not only improves the structural integrity of these projects but also enhances cost efficiency by reducing the need for extensive manual labor. Buyers in the Middle East and Europe should prioritize suppliers with robust quality assurance processes and certifications that comply with safety standards, ensuring that the components meet all regulatory requirements.

Art and Design

In the realm of art and design, concrete CNC machines enable the creation of unique sculptures and installations. This application provides artists and designers with the tools to push creative boundaries, resulting in distinctive pieces that can attract attention and enhance market appeal. Buyers in this sector should evaluate suppliers based on their portfolio of past projects, customization options available, and their ability to meet specific artistic visions within reasonable lead times.

Urban Development

Concrete CNC machines play a pivotal role in producing urban furniture and public installations, such as benches, tables, and barriers. These elements not only serve functional purposes but also contribute to the overall aesthetic of urban environments, fostering community engagement. B2B buyers should consider the durability of materials used, compliance with urban regulations, and the supplier’s innovation capabilities to ensure that the final products are both appealing and long-lasting.

Related Video: How does the CNC Fiber laser cutting machine work? – Factories

Strategic Material Selection Guide for concrete cnc machine

When selecting materials for concrete CNC machines, international B2B buyers must consider various factors such as durability, cost, and the specific applications of the machine. The following analysis highlights four common materials used in concrete CNC machining, providing insights into their properties, advantages, disadvantages, and considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

Steel

Key Properties: Steel is renowned for its high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures, which is crucial in concrete machining processes. Corrosion resistance can be enhanced through coatings or alloying.

Pros & Cons: Steel’s primary advantage is its strength and longevity, which translates to less frequent replacements and repairs. However, it can be more expensive than other materials and may require complex machining processes, increasing manufacturing costs. Additionally, its weight can complicate transportation and installation.

Impact on Application: Steel is ideal for components that require high structural integrity, such as frames and support structures in CNC machines. Its compatibility with various media, including abrasive concrete mixtures, further enhances its utility.

Considerations for Buyers: Buyers should ensure compliance with international standards such as ASTM A36 or DIN 17100, particularly in regions with strict quality regulations. Understanding local sourcing options can also help mitigate costs associated with transportation.

Aluminum

Key Properties: Aluminum is lightweight yet strong, offering excellent corrosion resistance, which is particularly beneficial in humid environments. Its thermal conductivity is also advantageous for heat dissipation during machining operations.

Pros & Cons: The primary benefit of aluminum is its low weight, which facilitates easier handling and reduces the overall weight of the CNC machine. However, it may not be as durable as steel under high-stress conditions and can be more expensive than other lightweight materials.

Impact on Application: Aluminum is well-suited for components that require precision and are subject to lower stress, such as housings and covers. Its resistance to corrosion makes it suitable for environments where moisture is prevalent, such as coastal regions.

Considerations for Buyers: Buyers should consider the availability of aluminum grades that meet specific requirements, such as 6061 or 7075. Compliance with standards like ASTM B221 is crucial, especially in regions like Europe where material specifications are strictly enforced.

Composite Materials

Key Properties: Composites, such as fiberglass-reinforced plastics (FRP), offer a unique combination of lightweight and high strength. They exhibit excellent resistance to corrosion and chemical exposure, making them suitable for various harsh environments.

Pros & Cons: The lightweight nature of composites allows for easier installation and transportation. They also provide excellent thermal and electrical insulation properties. However, composites can be more expensive to manufacture and may require specialized machining techniques, which could increase production complexity.

Impact on Application: Composites are ideal for parts that need to withstand harsh chemicals or moisture, such as enclosures and protective covers. Their compatibility with various media types, including aggressive concrete mixtures, enhances their application scope.

Considerations for Buyers: Buyers should ensure that the composite materials used comply with relevant standards such as ASTM D638 for tensile properties. Understanding the local market for composites and their suppliers is essential, especially in regions where traditional materials may be less accessible.

Cast Iron

Key Properties: Cast iron is known for its excellent wear resistance and ability to absorb vibrations, making it suitable for heavy machinery applications. It also has good thermal stability, which is beneficial in machining processes.

Pros & Cons: The main advantage of cast iron is its durability and ability to maintain dimensional stability over time. However, it is heavier than other materials, which can complicate logistics and installation. Additionally, cast iron can be brittle, making it susceptible to cracking under certain conditions.

Impact on Application: Cast iron is often used for machine beds and bases in CNC machines, providing stability and reducing vibrations during operation. Its compatibility with various concrete formulations makes it a reliable choice for concrete CNC applications.

Considerations for Buyers: Buyers should consider the specific grade of cast iron, such as gray or ductile iron, to ensure it meets their application needs. Compliance with standards like ASTM A48 is important, particularly in regions with stringent manufacturing regulations.

| Material | Typical Use Case for concrete cnc machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frames and support structures | High strength and durability | Higher cost and complex machining | High |

| Aluminum | Housings and covers | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Composite Materials | Enclosures and protective covers | Excellent corrosion resistance | Higher manufacturing costs | High |

| Cast Iron | Machine beds and bases | Vibration absorption and stability | Heavy and brittle | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for concrete cnc machine

The manufacturing processes and quality assurance protocols for concrete CNC machines are critical for international B2B buyers aiming to ensure reliability, efficiency, and compliance in their sourcing strategies. This section provides an in-depth exploration of the typical manufacturing stages, quality control measures, and verification methods that can help buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions.

Manufacturing Processes for Concrete CNC Machines

The production of concrete CNC machines typically involves several key stages, each crucial for achieving the desired performance and quality.

1. Material Preparation

The first stage involves sourcing high-quality raw materials such as steel, aluminum, and specialized composites for the machine’s frame and components. Buyers should ensure that suppliers adhere to international material standards to avoid defects. It is essential to verify the material certifications, including tensile strength and corrosion resistance, as these will impact the machine’s durability and performance.

2. Forming

In this stage, the raw materials are shaped using various techniques, including:

- CNC Machining: Utilized for precise cutting and shaping of machine components. This technique allows for high tolerances and complex geometries, ensuring that parts fit together seamlessly.

- Casting: Often used for larger components, casting can be advantageous for creating intricate shapes with minimal waste. Buyers should assess the foundry’s capabilities and quality controls during this process.

3. Assembly

Assembly is a critical phase where all components come together. Key practices include:

- Modular Assembly: This approach allows for easier upgrades and repairs. Buyers should inquire about the modular design of the CNC machine, as it can enhance maintenance efficiency.

- Integration of Electronics: The incorporation of control systems, sensors, and software is vital for the machine’s functionality. Buyers should ensure that the electronic components comply with international standards and are sourced from reputable suppliers.

4. Finishing

The finishing stage includes surface treatments and coatings that enhance durability and aesthetic appeal. Common techniques include:

- Powder Coating: This method provides a robust finish that resists chipping, scratching, and fading. It is essential for machines exposed to harsh environments.

- Anodizing: For aluminum components, anodizing increases corrosion resistance and surface hardness. Buyers should verify that suppliers use environmentally friendly practices during this process.

Quality Assurance Protocols

Quality assurance is paramount in ensuring that concrete CNC machines meet industry standards and customer expectations. Key components of an effective quality assurance program include:

International Standards

Adhering to international standards such as ISO 9001 ensures that the manufacturing processes are consistent and meet customer requirements. Additional certifications relevant to specific markets may include:

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Particularly important for machines used in the oil and gas industry, ensuring that products meet specific performance and safety criteria.

Quality Control Checkpoints

Quality control is typically structured around several critical checkpoints:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should verify that suppliers conduct thorough IQC checks and maintain documentation.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. Buyers can request access to IPQC reports to understand how suppliers maintain quality during production.

- Final Quality Control (FQC): At this stage, the finished product undergoes comprehensive testing to ensure it meets all specifications. Documentation of FQC results should be made available to buyers.

Common Testing Methods

Testing methods used in quality assurance can include:

- Dimensional Inspection: Ensures that all parts meet the specified tolerances using tools like calipers and coordinate measuring machines (CMM).

- Functional Testing: Verifies that the CNC machine operates correctly under various conditions, including speed, load, and precision tests.

Verification of Supplier Quality Control

For B2B buyers, verifying the quality control practices of suppliers is crucial to mitigate risks. Here are some effective strategies:

Supplier Audits

Conducting regular audits of suppliers can provide insights into their quality control processes. Buyers should look for:

- Documented Procedures: Ensure that suppliers have well-defined quality control procedures in place.

- Staff Training: Assess whether employees are trained in quality management principles and practices.

Reports and Certifications

Buyers should request quality control reports and certifications from suppliers to validate compliance with international standards. Key documents include:

- Quality Management System (QMS) Certificates: Such as ISO 9001, which demonstrates the supplier’s commitment to quality.

- Test Reports: Documentation showing that products have passed relevant quality tests.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can be conducted at various stages of production and are particularly beneficial for international buyers who may not have local representation.

Navigating Quality Control Nuances

B2B buyers from diverse regions face unique challenges in ensuring quality control. For example:

- Africa and South America: Buyers should consider local regulations and standards that may differ from international norms. Establishing clear communication with suppliers about these requirements is vital.

- Middle East and Europe: Buyers may have higher expectations regarding compliance and certification due to stringent regulations. Suppliers should be prepared to demonstrate adherence to these standards.

By understanding the manufacturing processes and quality assurance protocols involved in sourcing concrete CNC machines, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This knowledge not only enhances supplier relationships but also contributes to achieving long-term business success in a competitive global market.

Related Video: Amazing Large Scale Ready Mixed Concrete Mass Production Process. Excellent Mix Concrete Factory

Comprehensive Cost and Pricing Analysis for concrete cnc machine Sourcing

In the international B2B market for concrete CNC machines, understanding the cost structure and pricing dynamics is essential for making informed sourcing decisions. This analysis outlines the key components of costs, the factors influencing pricing, and actionable tips for buyers from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials used in concrete CNC machines include steel, aluminum, and high-grade plastics for structural components. The choice of materials impacts both the initial cost and the longevity of the machine. Buyers should consider the source of materials, as local suppliers may offer cost advantages due to reduced shipping expenses.

-

Labor: Labor costs can vary significantly based on the region and the complexity of the machine. Skilled labor is necessary for both the manufacturing and maintenance of CNC machines. In regions like Europe, labor costs may be higher, whereas countries in Africa and South America may have more competitive rates.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Buyers should inquire about how these costs are calculated and whether they are included in the quoted price.

-

Tooling: Tooling costs involve the specialized equipment needed for producing specific parts. For customized machines, buyers should factor in the expense of creating unique tooling setups, which can significantly increase the total cost.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that machines meet industry standards. This may include testing, certifications, and compliance with regulations. Buyers should understand the QC protocols of their suppliers, as they can impact both the price and the reliability of the machine.

-

Logistics: Shipping costs can be substantial, especially for large CNC machines. Factors such as distance, mode of transport, and customs duties should be considered. Incoterms play a critical role in defining shipping responsibilities and costs between buyer and seller.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the typical margins in your target market can help in negotiations.

Price Influencers

-

Volume/MOQ: Larger orders often qualify for volume discounts. Buyers should assess their production needs and negotiate minimum order quantities (MOQs) that align with their budgets.

-

Specifications/Customization: Custom machines tailored to specific applications can lead to higher prices. Buyers should evaluate whether the customization is necessary or if standard models can meet their needs.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., ISO standards) can increase costs. Buyers should weigh the benefits of enhanced quality against the budget constraints.

-

Supplier Factors: The reputation, reliability, and geographical location of suppliers can significantly affect pricing. Local suppliers may offer better logistics and lower shipping costs.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the cost and risk at various points in the shipping process. This can influence overall pricing and total cost of ownership.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing structures and be prepared to negotiate based on volume, specifications, and payment terms. Establishing a long-term relationship can also lead to better pricing over time.

-

Cost-Efficiency: Consider the total cost of ownership, including maintenance, energy consumption, and potential downtime. Sometimes a higher upfront cost can lead to lower operational costs in the long run.

-

Pricing Nuances: For international buyers, currency fluctuations and local economic conditions can affect pricing. It’s advisable to secure quotes in your local currency and understand the impact of exchange rates on your budget.

Disclaimer

Prices for concrete CNC machines can vary widely based on specifications, supplier, and market conditions. The analysis provided is indicative and should be used as a guide for understanding potential costs rather than as definitive pricing. Always request detailed quotes from multiple suppliers to ensure competitive pricing and comprehensive understanding of the cost structure.

Spotlight on Potential concrete cnc machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘concrete cnc machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for concrete cnc machine

Concrete CNC machines are specialized equipment designed for precise cutting, shaping, and finishing of concrete materials. Understanding their technical properties and the associated trade terminology is crucial for international B2B buyers, particularly in emerging markets. Here’s a breakdown of essential specifications and common industry terms relevant to sourcing concrete CNC machines.

Key Technical Properties

-

Material Grade

– Definition: This refers to the quality and type of materials used in the construction of the CNC machine, including the frame, spindle, and cutting tools.

– B2B Importance: High-grade materials ensure durability, performance, and resistance to wear and tear. Buyers should prioritize machines made from robust materials to minimize maintenance costs and maximize longevity. -

Tolerance

– Definition: Tolerance indicates the permissible limit or limits of variation in a physical dimension, typically measured in millimeters or inches.

– B2B Importance: Precision in tolerance is crucial for ensuring the accuracy of cuts and finishes in concrete applications. For industries requiring high precision, such as construction and architecture, understanding and specifying tolerance levels can significantly affect project outcomes. -

Cutting Speed

– Definition: This specification refers to the speed at which the machine can cut through concrete, usually measured in meters per minute.

– B2B Importance: Higher cutting speeds can improve production efficiency and reduce operational costs. Buyers should assess the cutting speed in relation to their specific production needs to optimize throughput. -

Axis Configuration

– Definition: This describes the number of axes the CNC machine operates on, which can range from 3-axis to 5-axis or more.

– B2B Importance: More axes allow for complex geometries and shapes to be cut with greater precision. Buyers should consider their project requirements and select a machine that can handle the necessary dimensions and intricacies. -

Power Consumption

– Definition: This refers to the amount of energy the machine requires to operate effectively, typically measured in kilowatts (kW).

– B2B Importance: Understanding power consumption is essential for evaluating operational costs. Machines that are energy-efficient can provide significant savings in long-term operational expenses, an important factor for budget-conscious buyers.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Buyers often seek OEMs for reliable parts and support, ensuring quality and consistency in machine performance. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest amount of product a supplier is willing to sell.

– Relevance: Understanding MOQ is vital for buyers to determine budget constraints and inventory needs, especially in bulk purchasing scenarios. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services.

– Relevance: This process helps buyers compare costs and services from various suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: These are predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms can help buyers navigate shipping responsibilities, insurance, and risk management when procuring machinery from overseas.

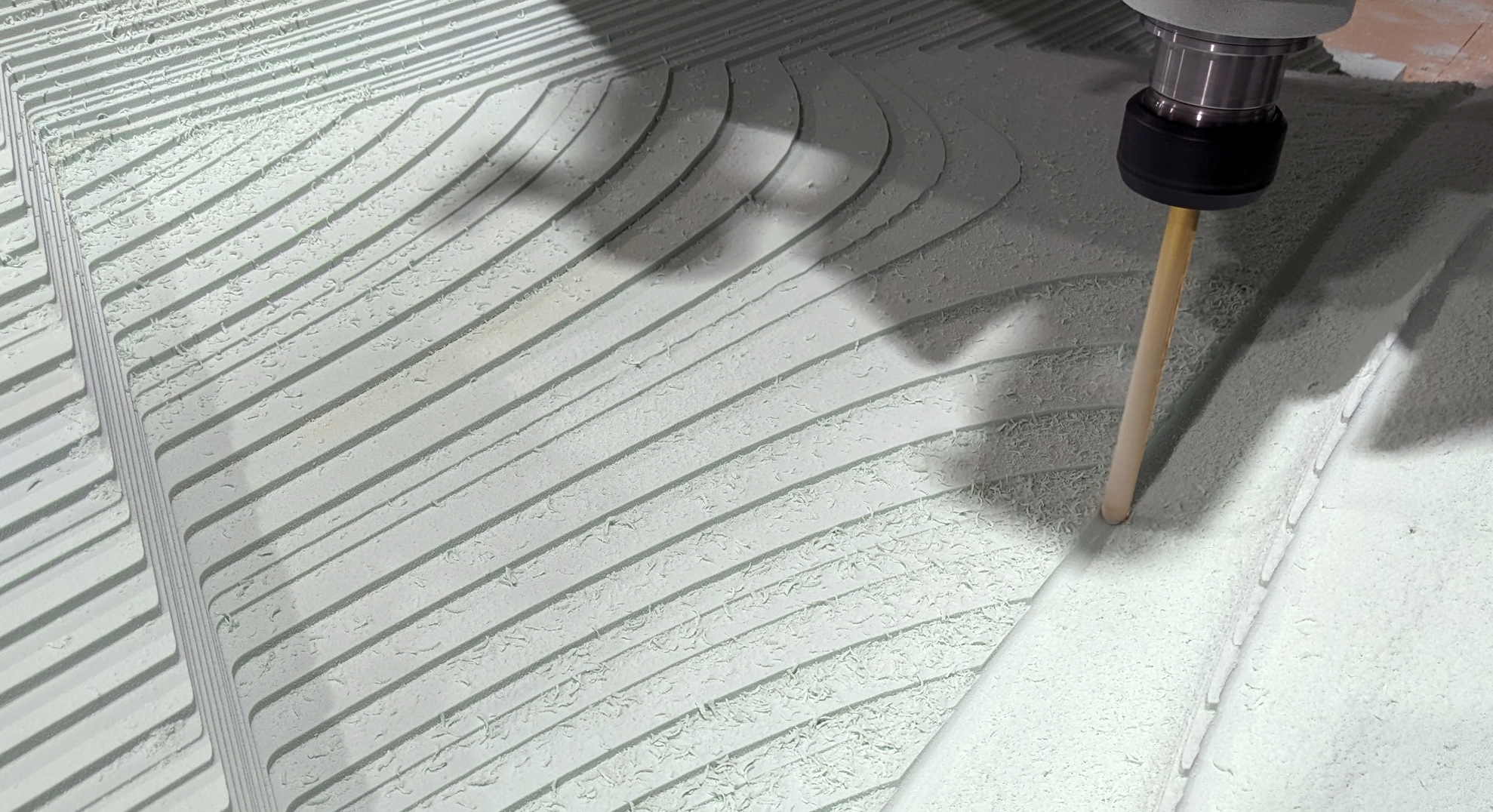

Illustrative Image (Source: Google Search)

- Lead Time

– Definition: Lead time refers to the total time from when an order is placed until the product is delivered.

– Relevance: Knowing the lead time is crucial for project planning and inventory management. Buyers should align lead times with their production schedules to avoid delays.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing concrete CNC machines, ensuring they select equipment that aligns with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the concrete cnc machine Sector

Market Overview & Key Trends

The global market for concrete CNC machines is witnessing transformative growth driven by several factors. Increasing urbanization and infrastructure development, particularly in emerging economies across Africa, South America, and the Middle East, are propelling demand for advanced concrete machining solutions. International B2B buyers are increasingly seeking automation and precision in concrete manufacturing to enhance productivity and reduce labor costs. Additionally, advancements in digital technologies, such as IoT and AI, are streamlining operations, allowing for real-time monitoring and predictive maintenance, which ultimately leads to reduced downtime and increased efficiency.

Key sourcing trends include a shift towards customized solutions tailored to specific project needs, reflecting a growing preference for flexibility among buyers. Moreover, the rising importance of supply chain resilience has led many companies to diversify their supplier networks, ensuring access to reliable sources of machinery and materials. In regions like Brazil and Colombia, where the construction industry is booming, buyers are particularly focused on cost-effective solutions that do not compromise on quality. Sustainability is also becoming a significant consideration, with a noticeable increase in demand for machines that support eco-friendly practices, such as energy efficiency and waste reduction.

Sustainability & Ethical Sourcing in B2B

As environmental concerns gain traction globally, the concrete CNC machine sector is under increasing pressure to adopt sustainable practices. The production of concrete is traditionally associated with high carbon emissions and resource depletion. Therefore, B2B buyers should prioritize ethical sourcing and seek suppliers who demonstrate a commitment to sustainability. This includes utilizing green-certified materials, such as recycled aggregates or eco-friendly cement alternatives, which minimize environmental impact.

Illustrative Image (Source: Google Search)

Furthermore, adopting machines that are energy-efficient can significantly reduce operational costs and carbon footprints. Buyers should inquire about suppliers’ sustainability certifications, such as ISO 14001, which emphasizes effective environmental management systems. Additionally, engaging with suppliers who have transparent supply chains ensures that ethical practices are upheld throughout the production process. By focusing on sustainability, international B2B buyers not only comply with increasing regulatory demands but also enhance their brand reputation and appeal to environmentally-conscious customers.

Brief Evolution/History

The evolution of concrete CNC machines can be traced back to the late 20th century when the introduction of computer numerical control technology revolutionized manufacturing processes. Initially, CNC machines were primarily employed in metalworking; however, as the construction industry expanded, the need for precision in concrete machining became evident. Over the past two decades, significant advancements in technology, including the development of multi-axis machines and enhanced software for design and simulation, have transformed the capabilities of concrete CNC machines. Today, these machines are integral to modern construction, allowing for complex designs and faster production times, thus meeting the demands of an increasingly competitive market. As the industry continues to innovate, the focus on sustainability and efficiency will likely shape the future of concrete CNC machining, offering new opportunities for international B2B buyers.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of concrete cnc machine

-

What should I consider when vetting suppliers for concrete CNC machines?

When vetting suppliers, focus on their industry experience, production capabilities, and client testimonials. Verify certifications like ISO or specific industry standards relevant to concrete machining. Assess their technical support and after-sales service to ensure they can assist with installation and maintenance. Additionally, request samples or case studies to evaluate their quality and precision. Establishing clear communication and understanding their responsiveness can also indicate their reliability as a partner. -

Can concrete CNC machines be customized to meet specific project needs?

Yes, many suppliers offer customization options for concrete CNC machines to accommodate unique specifications. This may include modifications in size, tooling, software integration, or additional features like enhanced automation. When discussing customization, ensure that you communicate your requirements clearly and inquire about the supplier’s experience with similar projects. Be mindful that custom solutions can affect lead times and costs, so factor these into your planning. -

What are typical lead times and minimum order quantities (MOQs) for concrete CNC machines?

Lead times for concrete CNC machines can vary significantly based on supplier capabilities, customization levels, and production schedules. Generally, expect lead times ranging from a few weeks to several months. MOQs are typically set based on the complexity of the machine and production costs; many suppliers have flexible MOQs for first-time buyers or pilot projects. Always clarify these aspects upfront to avoid delays in your project timeline and ensure you can meet your production needs. -

What quality assurance practices should I look for in suppliers?

Look for suppliers that implement rigorous quality assurance (QA) protocols throughout their manufacturing process. This includes in-process inspections, final product testing, and adherence to industry standards. Certifications such as ISO 9001 or specific machine-related standards can provide additional assurance of quality. Request documentation detailing their QA processes, including any third-party audits or certifications, to confirm their commitment to maintaining high-quality production standards. -

How do payment terms typically work in international transactions for concrete CNC machines?

Payment terms can vary widely among suppliers, but common practices include upfront deposits followed by balance payments upon delivery or installation. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. It’s crucial to negotiate clear terms regarding currency, payment schedules, and potential penalties for late payments. Always review the supplier’s payment policies in detail to avoid misunderstandings. -

What logistical considerations should I keep in mind when sourcing concrete CNC machines?

Logistics play a critical role in the procurement of concrete CNC machines. Consider factors such as shipping methods, customs clearance processes, and delivery timelines. Ensure the supplier provides comprehensive shipping terms, including responsibilities for insurance and risk during transit. Evaluate the proximity of the supplier to your location to minimize shipping time and costs. Additionally, assess any potential tariffs or duties that may apply to your order, especially when importing from different regions. -

How can I handle disputes with suppliers effectively?

To handle disputes effectively, establish clear communication channels and set expectations upfront regarding deliverables and timelines. If a dispute arises, document all communications and agreements to support your position. Engage in open dialogue with the supplier to seek an amicable resolution. If necessary, refer to any contracts or agreements that outline dispute resolution processes, such as mediation or arbitration. Building a strong relationship with your supplier can also facilitate smoother conflict resolution. -

What certifications should I look for when sourcing concrete CNC machines?

When sourcing concrete CNC machines, look for certifications that indicate compliance with international standards, such as ISO 9001 for quality management systems. Depending on your industry, other relevant certifications may include CE marking for safety and compliance in the European market or specific industry-related standards for construction and manufacturing. Certifications can provide assurance of the machine’s reliability, safety, and performance, making them essential in your evaluation process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for concrete cnc machine

In conclusion, the strategic sourcing of concrete CNC machines offers international B2B buyers a pathway to enhanced efficiency, precision, and competitiveness in today’s dynamic manufacturing landscape. Key takeaways emphasize the importance of understanding the various types of CNC machines and their applications, assessing supplier capabilities, and leveraging local and global resources to mitigate risks.

By adopting a strategic sourcing approach, businesses can secure reliable partnerships that not only meet their production needs but also foster innovation and adaptability in an ever-evolving market. Buyers from Africa, South America, the Middle East, and Europe should prioritize due diligence in supplier evaluation, focusing on quality certifications and proven track records.

As global demand for precision manufacturing continues to rise, now is the time to act. Embrace the opportunities presented by strategic sourcing to optimize your operations, enhance product quality, and drive growth. By investing in the right CNC technology and partnerships, your business can position itself for success in the competitive landscape of concrete machining.