Master the Market for 4 Axis CNC Machines: Your Complete

Introduction: Navigating the Global Market for 4 axis cnc machine

In today’s competitive manufacturing landscape, the 4-axis CNC machine stands as a pivotal technology that enhances precision, efficiency, and versatility in production processes. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of this machinery is essential for optimizing operations and maintaining a competitive edge. The ability to machine complex geometries and intricate designs with accuracy not only reduces lead times but also minimizes material waste, making it a strategic investment for any manufacturing entity.

This comprehensive guide delves into the critical aspects of 4-axis CNC machines, offering valuable insights into various types available in the market, the materials they can handle, and the manufacturing and quality control processes that ensure optimal performance. Furthermore, it provides an overview of suppliers and their unique offerings, along with a detailed analysis of cost factors and market trends that influence purchasing decisions.

By equipping B2B buyers with the necessary knowledge, this guide empowers them to make informed sourcing decisions that align with their operational goals. Whether you are a seasoned manufacturer or a newcomer to CNC technology, understanding the capabilities and applications of 4-axis CNC machines will enable you to harness their full potential, paving the way for innovation and growth in your business.

Understanding 4 axis cnc machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Axis CNC | Incorporates a rotating axis for complex shapes | Aerospace, automotive, and molds | Pros: Enhanced design capabilities; Cons: Higher initial investment. |

| Vertical CNC Mill | Vertical orientation with a 4th axis for depth control | Metalworking, woodworking | Pros: Precision and versatility; Cons: Limited to specific materials. |

| Horizontal CNC Mill | Horizontal spindle with 4-axis capabilities | Heavy-duty machining, large parts | Pros: Efficient for large volumes; Cons: Requires more floor space. |

| CNC Router | Uses a spindle for routing with 4-axis functionality | Sign making, cabinetry, and arts | Pros: Cost-effective for non-metal materials; Cons: Less robust for metals. |

| CNC Lathe | Combines turning and milling with a 4th axis | Precision components, automotive | Pros: High precision and efficiency; Cons: Limited to cylindrical parts. |

Rotary Axis CNC

Rotary axis CNC machines integrate a rotating axis that enables the production of intricate shapes and designs. This type is particularly suitable for industries like aerospace and automotive, where complex geometries are crucial. When considering a purchase, buyers should evaluate the machine’s rotational speed, torque, and compatibility with existing workflows to ensure it meets their specific production requirements.

Vertical CNC Mill

Vertical CNC mills feature a vertical spindle and a fourth axis that allows for depth control in machining processes. This type is widely used in metalworking and woodworking applications, making it ideal for producing detailed components. B2B buyers should consider the machine’s rigidity, tooling options, and material compatibility to maximize efficiency and output quality.

Horizontal CNC Mill

Horizontal CNC mills are designed with a horizontal spindle and a 4-axis capability, making them suitable for heavy-duty machining tasks, particularly for large parts. These machines are favored for their efficiency in high-volume production environments. Buyers should assess the machine’s footprint, as it often requires more floor space, and ensure that it aligns with their production capacities.

CNC Router

CNC routers are versatile machines that employ a spindle to perform routing tasks, with the added benefit of a fourth axis for enhanced functionality. They are commonly used in sign making, cabinetry, and artistic applications. Buyers looking for cost-effective solutions for non-metal materials will find CNC routers appealing, but should also consider their limitations in handling more robust materials like metals.

CNC Lathe

CNC lathes combine turning and milling capabilities, incorporating a fourth axis to enhance precision in machining cylindrical parts. This type is particularly relevant for producing high-precision components in industries such as automotive and aerospace. B2B buyers should focus on the machine’s precision, tooling options, and overall versatility when making a purchasing decision to ensure it meets their specific manufacturing needs.

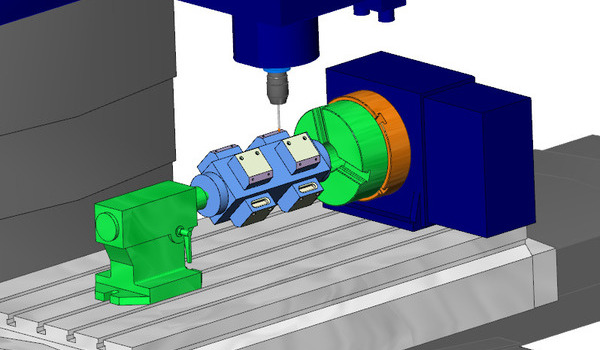

Related Video: How milling on a 4-axis CNC machine works

Key Industrial Applications of 4 axis cnc machine

| Industry/Sector | Specific Application of 4 axis CNC Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | High accuracy and reduced waste, leading to cost savings | Supplier certifications, technology compatibility, lead times |

| Automotive | Engine component production | Enhanced production speed and customization capabilities | Material specifications, tooling options, after-sales support |

| Medical Devices | Custom surgical instruments and implants | Tailored solutions for specific medical needs | Compliance with health regulations, precision requirements |

| Electronics | Housing and enclosures for electronic devices | Streamlined production and improved product durability | Electronic component compatibility, material selection |

| Furniture and Woodworking | Complex designs for bespoke furniture | Unique product offerings and increased market competitiveness | Wood types, finishing options, machine adaptability |

Aerospace Applications

In the aerospace industry, 4 axis CNC machines are instrumental in manufacturing precision components such as brackets, housings, and turbine blades. These machines enable manufacturers to achieve high tolerances and intricate geometries that are essential for safety and performance. For international buyers, particularly those in Africa and the Middle East, sourcing from suppliers with certifications like AS9100 can ensure compliance with stringent aerospace standards.

Automotive Applications

Automotive manufacturers utilize 4 axis CNC machines for producing complex engine components and transmission parts. The ability to machine multiple sides of a component in a single setup significantly reduces production time and enhances efficiency. Buyers from Europe and South America should consider suppliers that offer flexibility in tooling options and can meet specific material requirements to cater to diverse automotive applications.

Medical Devices Applications

In the medical sector, 4 axis CNC machines are used to create custom surgical instruments and implants tailored to individual patient needs. This capability not only improves patient outcomes but also allows manufacturers to differentiate their offerings in a competitive market. Buyers must ensure that their suppliers comply with regulations such as ISO 13485, which governs quality management systems in medical device manufacturing.

Electronics Applications

The electronics industry benefits from 4 axis CNC machines through the production of intricate housing and enclosures for various devices. These machines facilitate the creation of durable and reliable products, which are crucial for maintaining the integrity of electronic components. International buyers should evaluate suppliers based on their ability to provide compatible materials and ensure the precision necessary for electronic applications.

Furniture and Woodworking Applications

In furniture manufacturing, 4 axis CNC machines enable the production of complex and bespoke designs, allowing businesses to offer unique products that stand out in the market. This capability can lead to increased customer satisfaction and loyalty. Buyers in South America and Europe should focus on suppliers that can work with various wood types and provide finishing options to enhance the aesthetic appeal of their products.

Strategic Material Selection Guide for 4 axis cnc machine

When selecting materials for a 4-axis CNC machine, it is essential to consider various factors that influence performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in CNC machining, focusing on their properties, advantages and disadvantages, and specific considerations for international B2B buyers.

Aluminum Alloys

Key Properties: Aluminum alloys are lightweight yet strong, with excellent corrosion resistance and good thermal conductivity. They typically have a temperature rating of up to 150°C and can withstand moderate pressures.

Pros & Cons: The primary advantage of aluminum alloys is their ease of machining, which leads to lower manufacturing complexity and costs. However, they may not be suitable for high-stress applications due to lower tensile strength compared to other metals.

Impact on Application: Aluminum is compatible with various media, making it ideal for industries such as automotive and aerospace. Its lightweight nature also enhances the performance of parts in dynamic applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and EN for aluminum alloys. In regions like Europe and South America, specific alloy grades may be preferred based on local industry practices.

Stainless Steel

Key Properties: Stainless steel is renowned for its high corrosion resistance and durability, with temperature ratings often exceeding 300°C. It can withstand high pressures, making it suitable for demanding environments.

Pros & Cons: The key advantage of stainless steel is its robustness, which allows for the production of long-lasting components. However, the material is more challenging to machine, resulting in higher manufacturing costs and complexity.

Impact on Application: Stainless steel is ideal for applications in the medical, food processing, and chemical industries due to its non-reactive nature. Its compatibility with harsh environments enhances its utility.

Considerations for International Buyers: Buyers from the Middle East and Africa should be aware of local regulations regarding food-grade materials and chemical resistance. Compliance with ASTM and ISO standards is critical for ensuring product quality and safety.

Plastics (e.g., Nylon, Polycarbonate)

Key Properties: Plastics like nylon and polycarbonate offer excellent impact resistance and are lightweight. They typically have a lower temperature rating (around 80-100°C) but are suitable for low-pressure applications.

Pros & Cons: The main advantage of plastics is their versatility and lower cost compared to metals. However, they may not be suitable for high-temperature or high-stress applications, limiting their use in certain industries.

Impact on Application: Plastics are commonly used in consumer goods, electronics, and automotive components where weight reduction is critical. Their chemical resistance makes them suitable for various media.

Considerations for International Buyers: Buyers should consider compliance with local environmental regulations regarding plastic use, especially in Europe, where restrictions may apply. Understanding the specific grades and their properties is essential for ensuring suitability for intended applications.

Titanium Alloys

Key Properties: Titanium alloys are known for their high strength-to-weight ratio and excellent corrosion resistance, with temperature ratings that can exceed 600°C. They are capable of withstanding extreme pressures.

Pros & Cons: The primary advantage of titanium is its exceptional durability and lightweight properties, making it ideal for aerospace and medical applications. However, the machining process is complex and costly, which can be a significant drawback for budget-conscious buyers.

Impact on Application: Titanium is particularly suited for applications requiring high strength and lightweight components, such as in aerospace and military sectors. Its compatibility with corrosive environments enhances its appeal.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of the higher costs associated with titanium and the need for specialized machining capabilities. Compliance with international standards such as ASTM and JIS is crucial for quality assurance.

| Material | Typical Use Case for 4 axis cnc machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Automotive parts, aerospace components | Lightweight and easy to machine | Lower tensile strength | Medium |

| Stainless Steel | Medical devices, food processing equipment | High corrosion resistance | Higher manufacturing complexity | High |

| Plastics | Consumer goods, electronic housings | Cost-effective and versatile | Limited high-temperature use | Low |

| Titanium Alloys | Aerospace components, medical implants | Exceptional strength-to-weight ratio | High machining costs | High |

This guide should assist international B2B buyers in making informed material selections for their 4-axis CNC machining needs, considering both performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 4 axis cnc machine

Understanding the Manufacturing Processes of 4 Axis CNC Machines

The production of 4 axis CNC machines involves several critical stages, each contributing to the overall functionality, precision, and quality of the final product. For international B2B buyers, understanding these processes can help in making informed purchasing decisions and ensuring that the machines meet specific operational needs.

Key Manufacturing Stages

-

Material Preparation

– The first step in the manufacturing process is the selection and preparation of raw materials, typically high-grade metals such as aluminum, steel, or titanium.

– Cutting and Shaping: Materials are cut into manageable sizes using techniques like plasma cutting or waterjet cutting, ensuring that they conform to design specifications. -

Forming

– This stage involves forming the prepared materials into the desired shapes. Common methods include:- CNC Machining: Utilizing precision CNC lathes and mills to shape components accurately.

- Casting and Forging: Some components may be cast or forged for strength and durability, especially in high-stress areas.

-

Assembly

– Once the components are formed, they are assembled into the machine. This includes:- Sub-assembly: Initial assembly of components such as the frame, axis, and spindle.

- Final Assembly: Integrating electronic systems, wiring, and software, ensuring all parts fit together seamlessly.

-

Finishing

– The finishing stage involves several processes to enhance the machine’s appearance and functionality:- Surface Treatment: Techniques such as anodizing, powder coating, or painting to protect against corrosion and wear.

- Calibration: Fine-tuning the machine settings and conducting initial tests to ensure operational precision.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital in the production of 4 axis CNC machines to guarantee that they meet international standards and customer specifications. Buyers must understand the various QA processes and how to verify them.

International Standards and Certifications

- ISO 9001: This standard focuses on quality management systems, emphasizing consistent quality in manufacturing processes. Suppliers with ISO 9001 certification demonstrate a commitment to quality and continuous improvement.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For machines used in the oil and gas sector, adherence to American Petroleum Institute (API) standards can be crucial.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Before production, raw materials are inspected to verify they meet specified standards. This includes checking material certifications and conducting tests for chemical composition. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, various checkpoints ensure that components are being produced correctly. This includes monitoring machining processes and conducting dimensional checks. -

Final Quality Control (FQC)

– After assembly, the complete machine undergoes rigorous testing. This includes:- Functional Tests: Verifying that all machine functions operate as intended.

- Performance Testing: Assessing the machine’s speed, accuracy, and load capacity.

Common Testing Methods

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or radiographic inspection assess material integrity without damaging the components.

- CMM Inspection: Coordinate Measuring Machines (CMM) are used to measure the physical geometrical characteristics of a machine, ensuring precision.

- Load Testing: Evaluating the machine’s ability to operate under specified loads to prevent failures during usage.

Verifying Supplier Quality Control

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is essential. Here are actionable steps to ensure quality compliance:

-

Conduct Supplier Audits

– Regular audits can provide insights into a supplier’s manufacturing and quality assurance practices. This includes reviewing production processes, quality documentation, and compliance with international standards. -

Request Quality Reports

– Ask suppliers for comprehensive quality reports that detail testing results, inspection findings, and certifications. This transparency is crucial for assessing their capabilities. -

Third-Party Inspections

– Engage third-party inspection agencies to perform independent assessments of the manufacturing processes and final products. This adds an additional layer of assurance regarding quality.

Quality Control Nuances for International Buyers

International buyers must also be aware of specific nuances in quality control that may vary by region:

- Cultural Considerations: Different regions may have varying attitudes towards quality control. Understanding these cultural differences can enhance communication and negotiation with suppliers.

- Regulatory Compliance: Buyers need to be aware of local regulations that may affect machine usage and certification. For example, certain countries may have additional compliance requirements for safety and environmental standards.

- Logistical Challenges: Shipping and handling can impact machine integrity. Ensure that suppliers have robust packaging and transportation protocols to mitigate risks during transit.

Conclusion

A thorough understanding of the manufacturing processes and quality assurance practices for 4 axis CNC machines is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside implementing stringent quality control measures, buyers can ensure they select suppliers that meet their operational requirements and maintain high standards of quality. By actively engaging in supplier audits, requesting detailed reports, and understanding regional nuances, international buyers can foster successful partnerships and enhance their procurement strategies.

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

Comprehensive Cost and Pricing Analysis for 4 axis cnc machine Sourcing

Understanding the comprehensive cost structure and pricing for sourcing a 4-axis CNC machine is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This analysis breaks down the various components that contribute to the total cost, identifies factors influencing pricing, and offers strategic tips for effective negotiation.

Cost Components

-

Materials: The raw materials used in the manufacturing of a 4-axis CNC machine significantly impact the overall cost. High-quality steel, aluminum, and electronic components can vary greatly in price based on global market trends and local availability. Buyers should consider sourcing materials locally to reduce costs.

-

Labor: Labor costs are a major factor in the pricing of CNC machines. Regions with lower labor costs may offer more competitive pricing, but it’s essential to evaluate the skill level and training of the workforce. A higher initial cost for skilled labor may result in better quality and reduced long-term operational costs.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment depreciation. Understanding the overhead rates of potential suppliers is essential, as these can vary widely based on location and operational efficiencies.

-

Tooling: Custom tooling may be required for specific machining tasks. The cost of tooling can vary based on complexity and material. Buyers should inquire about tooling options and consider whether investing in specialized tooling could lead to greater efficiency and reduced cycle times.

-

Quality Control (QC): Rigorous quality control processes ensure that the machines meet industry standards. Suppliers may charge more for enhanced QC measures, but this can be a worthwhile investment in the long run to avoid costly defects and downtime.

-

Logistics: Transporting a CNC machine involves significant logistics costs, including shipping, customs duties, and insurance. The choice of Incoterms can greatly affect these expenses, so understanding the implications of terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is vital for budgeting.

-

Margin: Supplier margins can vary based on competition, brand reputation, and market demand. Buyers should be aware that established brands may command higher prices due to perceived reliability and service support.

Price Influencers

-

Volume/MOQ: Ordering in larger quantities often leads to better pricing. Establishing a minimum order quantity (MOQ) with suppliers can leverage economies of scale.

-

Specifications/Customization: Customized machines tailored to specific needs can significantly impact the price. Buyers should clearly define their requirements to avoid unforeseen costs.

-

Quality/Certifications: Machines with higher quality standards or certifications (ISO, CE) typically come at a premium. However, these certifications can enhance resale value and operational reliability.

-

Supplier Factors: Consideration of the supplier’s reputation, financial stability, and after-sales support can influence pricing and overall satisfaction.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of market prices and be prepared to discuss terms. Leveraging multiple quotes can strengthen your position.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider maintenance, energy consumption, and potential downtime in your analysis.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe might have higher standards but also higher costs compared to those in emerging markets in Africa or South America.

-

Market Research: Conduct thorough market research to understand regional trends, which can aid in identifying potential suppliers and negotiating better deals.

Disclaimer

Prices and cost structures are indicative and can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. It is advisable to conduct up-to-date research and obtain multiple quotes to ensure accurate budgeting.

Spotlight on Potential 4 axis cnc machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘4 axis cnc machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 4 axis cnc machine

Key Technical Properties of 4 Axis CNC Machines

Understanding the essential technical properties of 4 axis CNC machines is crucial for making informed purchasing decisions. Here are several critical specifications that every buyer should consider:

-

Material Grade

The material grade of the machine’s construction, often specified as cast iron or aluminum, affects its durability and stability. Higher-grade materials can withstand heavier loads and vibrations, which is vital for precision machining. For international buyers, especially in regions with varying environmental conditions, selecting a machine with a robust material grade ensures longevity and reliability. -

Tolerance Levels

Tolerance refers to the allowable deviation from a specified measurement. In CNC machining, tighter tolerances yield more precise components, crucial for industries like aerospace and medical manufacturing. Buyers should assess their project requirements against the machine’s tolerance capabilities to ensure they meet regulatory standards and customer expectations. -

Axis Configuration

The configuration of the axes (X, Y, Z, and the additional rotational axis) determines the machine’s ability to perform complex machining operations. A 4 axis CNC machine allows for intricate designs, making it suitable for diverse applications, from automotive parts to artistic sculptures. Buyers must evaluate their specific needs to ensure the machine can handle the required complexity. -

Spindle Speed

Spindle speed, usually measured in revolutions per minute (RPM), is a critical factor in determining the machining efficiency and material compatibility. Higher spindle speeds can enhance productivity but may require more advanced cooling systems to prevent overheating. Buyers should consider their material choices and the required processing speed to select the right spindle specifications. -

Feed Rate

The feed rate is the speed at which the cutting tool moves through the material. It significantly impacts the surface finish and machining time. Understanding the optimal feed rate for different materials will help buyers achieve desired results while maximizing efficiency. Buyers in regions with specific material preferences should ensure the machine supports their feed rate requirements.

Common Trade Terminology for 4 Axis CNC Machines

Familiarity with trade terminology can streamline communication and negotiation processes. Here are some essential terms for international buyers:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing a 4 axis CNC machine, knowing the OEM can provide insights into the quality and reliability of the equipment. Buyers should consider OEM reputation and support services when making purchasing decisions. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory planning, especially for international buyers who may face shipping constraints. This term can also influence negotiations, as lower MOQs can facilitate trial orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Crafting a detailed RFQ can help buyers receive accurate pricing and terms, ensuring better decision-making. It is advisable for buyers to include technical specifications and desired lead times in their RFQs to get precise responses. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects such as shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and negotiate better shipping arrangements, which is especially important for cross-border transactions. -

Lead Time

Lead time is the time it takes from placing an order to receiving the product. In the context of 4 axis CNC machines, understanding lead times helps buyers plan their production schedules effectively. Buyers should discuss lead times upfront to avoid delays in their projects, particularly when sourcing from international suppliers.

By grasping these technical properties and trade terms, international B2B buyers can enhance their procurement strategies, ensuring they select the right 4 axis CNC machine for their specific needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 4 axis cnc machine Sector

Market Overview & Key Trends

The global market for 4-axis CNC machines is experiencing robust growth, driven by increasing demand for precision engineering and automation across various sectors. Key drivers include advancements in manufacturing technologies, the rise of Industry 4.0, and the need for customized solutions. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are now prioritizing suppliers who can offer cutting-edge technologies that enhance productivity and reduce lead times.

Emerging trends in sourcing include a shift towards digital procurement solutions, which streamline the purchasing process and improve supplier transparency. Platforms that facilitate direct communication between manufacturers and buyers are gaining traction, allowing for better negotiation and quicker responses to market demands. In addition, there is a growing interest in modular and adaptable CNC systems that allow businesses to scale their operations based on specific project requirements.

Furthermore, sustainability is becoming a critical factor in purchasing decisions. Buyers are increasingly looking for suppliers who implement eco-friendly practices and offer energy-efficient machines. This trend is particularly pronounced in Europe, where regulations around emissions and waste management are stringent. Understanding these dynamics can help international buyers make informed decisions that align with both their operational goals and sustainability commitments.

Sustainability & Ethical Sourcing in B2B

Sustainability in the 4-axis CNC machine sector is gaining momentum as businesses recognize the environmental impacts of manufacturing processes. The production and operation of CNC machines can contribute to significant carbon footprints, making it imperative for companies to adopt greener practices. B2B buyers should prioritize suppliers who not only comply with international environmental standards but also actively work to minimize their ecological impact through innovative technologies.

Ethical sourcing is another critical component of sustainable procurement. Buyers must assess the supply chain practices of potential suppliers to ensure they adhere to labor rights and fair trade principles. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are indicators of a supplier’s commitment to ethical practices.

Moreover, the use of sustainable materials in the production of CNC machines is becoming a key consideration. Buyers should inquire about the sourcing of components and whether suppliers utilize recycled or eco-friendly materials. By focusing on sustainability and ethical sourcing, international buyers can not only enhance their brand reputation but also contribute to a more sustainable future for the manufacturing industry.

Brief Evolution/History

The evolution of CNC technology began in the mid-20th century, transforming traditional manufacturing processes. Initially, CNC machines operated on simple 2-axis systems, but as technology advanced, the introduction of 4-axis capabilities allowed for greater complexity in machining. This shift enabled manufacturers to create intricate designs and components with higher precision.

Over the years, the integration of computer technology and software development has further revolutionized the sector. Modern 4-axis CNC machines now feature advanced programming capabilities, allowing for the automation of complex tasks and enhancing operational efficiency. As global markets continue to evolve, understanding the historical context of 4-axis CNC machines can provide B2B buyers with insights into future trends and innovations that will shape the industry.

Related Video: Otomic High Power 4 Axis CNC Machine for Woodworking

Frequently Asked Questions (FAQs) for B2B Buyers of 4 axis cnc machine

-

What should I consider when vetting suppliers for 4 axis CNC machines?

When vetting suppliers, assess their industry experience, certifications, and customer testimonials. Look for suppliers with a proven track record in your specific market, especially if you are in regions like Africa or South America where local support may be crucial. Request references and case studies to evaluate their previous projects. Additionally, consider their manufacturing capabilities, lead times, and after-sales support. A thorough vetting process can mitigate risks and ensure you partner with a reliable supplier. -

Can I customize my 4 axis CNC machine according to specific needs?

Yes, many manufacturers offer customization options for 4 axis CNC machines. Discuss your specific requirements, such as dimensions, tooling, and software compatibility, during initial negotiations. It’s important to communicate your production needs clearly to the supplier. Some manufacturers may have standard configurations, while others can tailor machines to fit unique applications. Always request detailed documentation of the customization options and any associated costs. -

What are the typical minimum order quantities (MOQs) and lead times for 4 axis CNC machines?

MOQs can vary significantly between suppliers, often depending on their production capacity and the complexity of the machine. For standard models, MOQs may start from one machine, while custom models could require higher quantities. Lead times typically range from a few weeks to several months, influenced by factors such as customization, supply chain logistics, and production schedules. Always confirm these details upfront to align your production planning with supplier capabilities. -

What payment terms should I expect when purchasing a 4 axis CNC machine?

Payment terms vary by supplier and can include upfront deposits, installment payments, or full payment upon delivery. International buyers should negotiate terms that provide security, such as using letters of credit or escrow services. Be aware of potential currency fluctuations when dealing with international suppliers, as this can impact the final cost. Always ensure that payment terms are clearly documented in the purchase agreement to avoid misunderstandings. -

How do I ensure quality assurance and necessary certifications for my CNC machine?

Request copies of quality assurance certifications such as ISO 9001, CE, or specific industry certifications relevant to your application. It’s essential to confirm that the machines meet international safety and quality standards. Inquire about the supplier’s quality control processes, including testing and inspection methods. Conducting a factory visit or engaging a third-party inspection service before shipment can further ensure that the machine meets your standards. -

What logistics considerations should I keep in mind when importing a 4 axis CNC machine?

Logistics play a crucial role in the timely and safe delivery of your CNC machine. Consider factors such as shipping methods, customs regulations, and import duties specific to your country. Work closely with your supplier to understand packaging requirements and transit times. Partnering with a reliable freight forwarder who understands international shipping regulations can streamline the process and help avoid delays or additional costs. -

How can I handle disputes with suppliers effectively?

Disputes can arise over various issues, such as product quality or delivery delays. To manage disputes effectively, ensure that all terms and conditions are clearly defined in your purchase agreement, including dispute resolution procedures. Open communication with the supplier is key; address issues as soon as they arise. If necessary, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. Maintaining a professional relationship can often lead to amicable resolutions. -

What ongoing support should I expect after purchasing a 4 axis CNC machine?

After purchase, you should expect comprehensive support from the supplier, including installation assistance, training for your operators, and access to technical support. Many suppliers offer warranties or service agreements that cover maintenance and repairs. It’s crucial to discuss the terms of these services during negotiations. Ensure you understand the process for obtaining spare parts and the availability of on-site support, especially if you are in remote locations where technical assistance may be limited.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 4 axis cnc machine

In summary, the strategic sourcing of 4-axis CNC machines is pivotal for international buyers aiming to enhance manufacturing capabilities and optimize production costs. Understanding the nuances of the global supply chain, such as identifying reliable suppliers and evaluating the total cost of ownership, empowers B2B buyers to make informed decisions.

Key takeaways include the importance of aligning sourcing strategies with organizational goals, leveraging technology for supplier evaluation, and considering local market conditions in Africa, South America, the Middle East, and Europe. Buyers should also prioritize suppliers that demonstrate sustainability and compliance with international standards, as these factors increasingly influence purchasing decisions.

Illustrative Image (Source: Google Search)

Looking ahead, the demand for advanced machining solutions will continue to rise, particularly in sectors like aerospace, automotive, and electronics. B2B buyers are encouraged to explore partnerships with innovative suppliers who offer flexibility and technological advancements. By taking proactive steps in sourcing, businesses can not only secure competitive advantages but also contribute to a more resilient and efficient manufacturing ecosystem. Engaging with the right partners today will position buyers favorably in an ever-evolving market landscape.