Master Your Costs: The Complete Boiler Diagram Guide (2025)

Introduction: Navigating the Global Market for boiler diagram

In the ever-evolving landscape of industrial equipment, international B2B buyers often face the daunting challenge of sourcing the right boiler diagram to suit their specific operational needs. Understanding the intricacies of boiler systems, including their types and applications, is crucial for making informed purchasing decisions. This guide delves into the essential components of boiler diagrams, covering various boiler types such as fire tube and water tube boilers, their operational efficiencies, and their roles in different industries.

By providing a comprehensive overview of boiler systems, this resource empowers buyers from diverse regions—including Africa, South America, the Middle East, and Europe—to navigate the complexities of sourcing and procurement. With insights on supplier vetting, cost considerations, and maintenance best practices, this guide equips decision-makers with the knowledge necessary to select the most suitable boiler solutions for their projects. Whether you are based in Nigeria, the UAE, or anywhere across Europe, understanding boiler diagrams will help you mitigate risks, optimize operational efficiency, and ultimately enhance your bottom line.

Through this guide, we aim to demystify the boiler selection process, ensuring that every B2B buyer can approach their procurement with confidence and clarity.

Understanding boiler diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fire Tube Boiler | Hot flue gases flow inside tubes submerged in water | Small to medium industrial applications | Pros: Lower initial cost, simple operation. Cons: Limited steam pressure, risk of explosion. |

| Water Tube Boiler | Water flows through tubes surrounded by hot gases | High-capacity industrial processes | Pros: Rapid heat transmission, high efficiency. Cons: Higher initial cost, more complex operation. |

| Electric Boiler | Uses electric elements to heat water | Residential heating, small commercial use | Pros: Environmentally friendly, low maintenance. Cons: Limited capacity, potential scale buildup. |

| Steam Boiler | Generates steam for power and heating | Power generation, food processing | Pros: Versatile applications, efficient energy conversion. Cons: Requires careful monitoring and maintenance. |

| Hot Water Boiler | Transfers heat to water for heating applications | HVAC systems, residential heating | Pros: Consistent temperature control, lower operating costs. Cons: Limited to hot water applications only. |

What Are the Key Characteristics of Fire Tube Boilers?

Fire tube boilers are characterized by their design where hot flue gases pass through tubes that are submerged in water. This type of boiler is typically used in small to medium industrial applications, making it ideal for businesses that require moderate steam output. Buyers should consider the lower initial costs and simpler operation, but be wary of the limited steam pressure and potential risks associated with explosion due to the design.

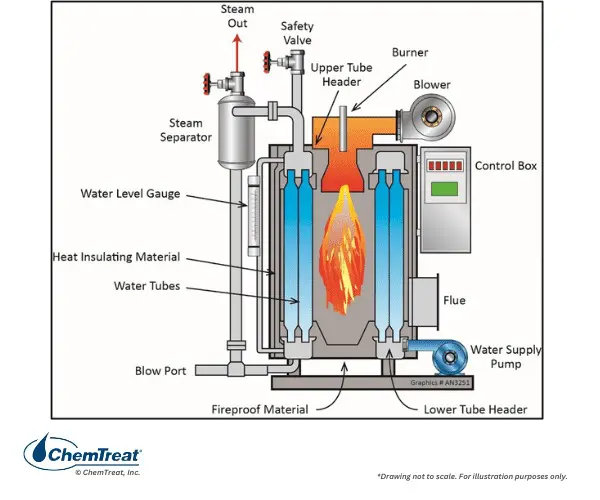

How Do Water Tube Boilers Differ from Fire Tube Boilers?

Water tube boilers operate by having water flow through tubes that are surrounded by hot combustion gases. This design allows for higher capacity and efficiency, making it suitable for high-demand industrial processes. B2B buyers should note that while water tube boilers offer rapid heat transmission and high efficiency, they come with a higher initial investment and require more sophisticated operational controls.

What Are the Advantages of Electric Boilers?

Electric boilers utilize electrical components to generate heat, providing an environmentally friendly alternative to traditional fuel-based systems. They are particularly suitable for residential heating and small commercial applications due to their ease of use and low maintenance requirements. However, buyers should keep in mind the limitations in capacity and the potential for scale buildup in the water storage tank.

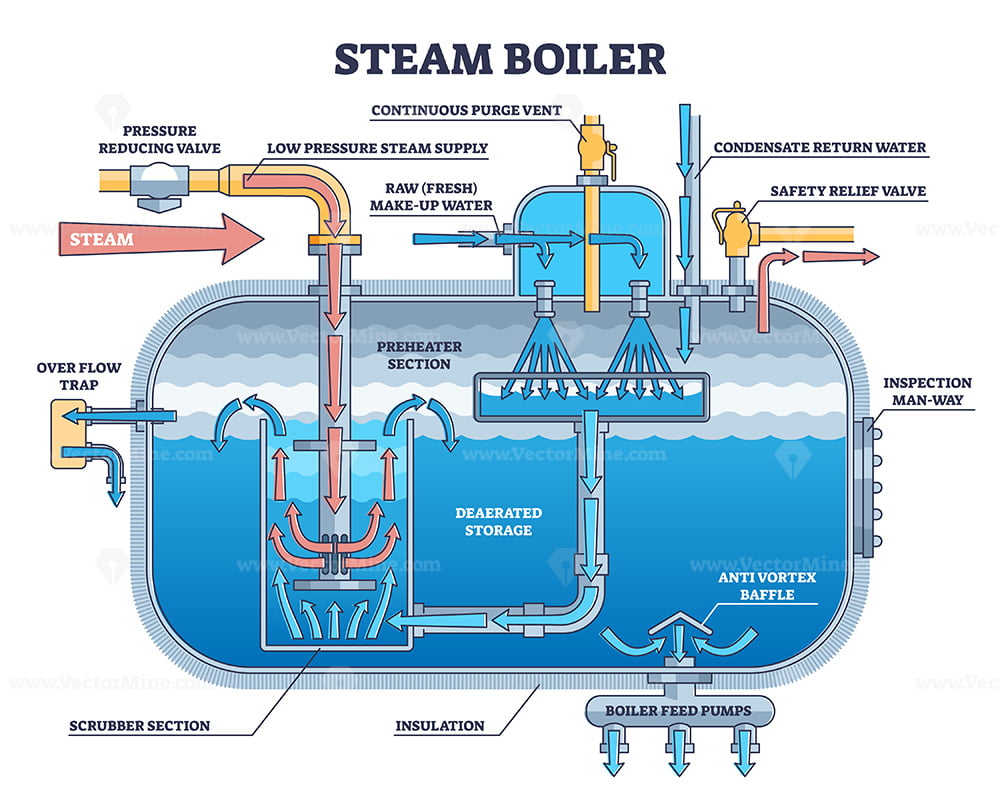

Why Are Steam Boilers Important in Industrial Applications?

Steam boilers are essential for generating steam, which can be utilized for various industrial purposes, including power generation and food processing. Their versatility makes them a preferred choice for many sectors. However, potential buyers must consider the need for careful monitoring and maintenance to ensure efficient and safe operation.

In What Scenarios Are Hot Water Boilers Used?

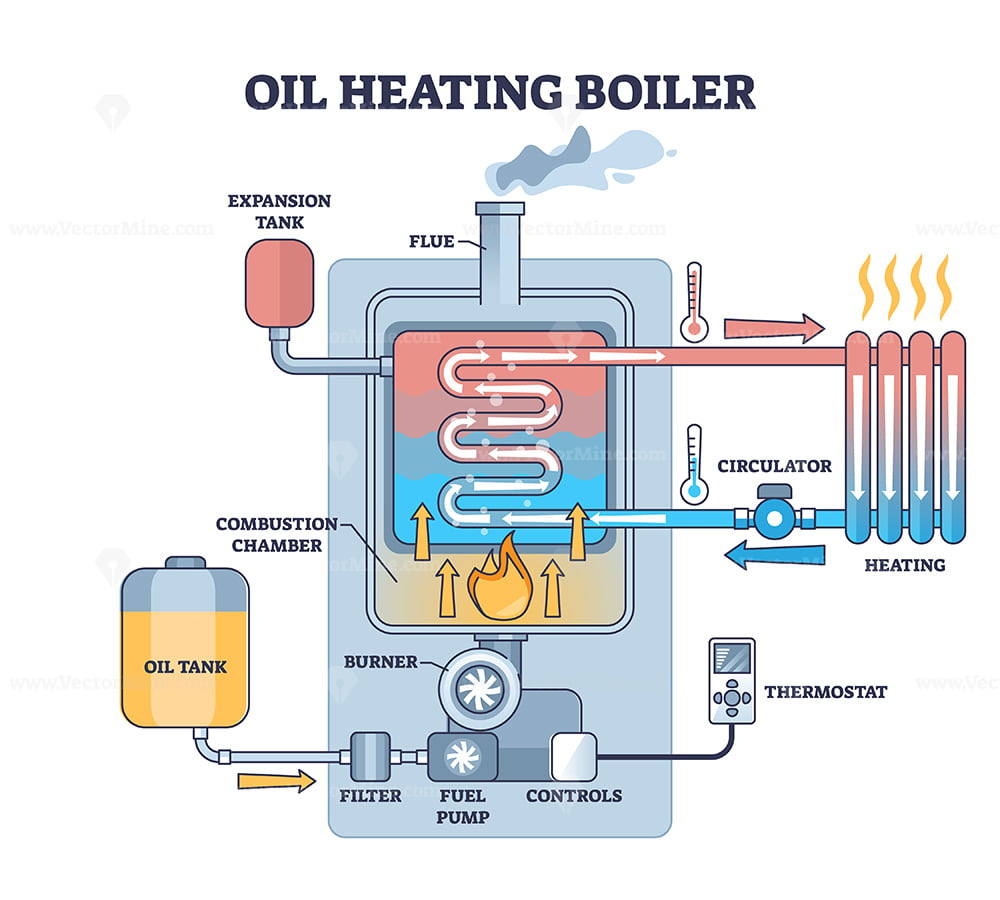

Hot water boilers are designed to transfer heat to water for heating applications, commonly found in HVAC systems and residential heating setups. They offer consistent temperature control and lower operating costs, making them attractive for long-term investments. However, their use is limited to hot water applications, which may not suit all industrial needs.

Key Industrial Applications of boiler diagram

| Industry/Sector | Specific Application of boiler diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Process steam generation for production lines | Increases efficiency and reduces downtime | Ensure compatibility with existing systems and fuel types |

| Food and Beverage | Sterilization and pasteurization processes | Enhances product safety and extends shelf life | Focus on sanitary design and compliance with health regulations |

| Power Generation | Steam cycle for electricity generation | Maximizes energy output and operational efficiency | Consider boiler size, fuel flexibility, and emissions standards |

| Oil and Gas | Enhanced oil recovery through steam injection | Improves extraction rates and reduces operational costs | Evaluate pressure ratings and material durability |

| Chemical Processing | Heat supply for chemical reactions | Increases reaction efficiency and product yield | Assess process-specific requirements and safety standards |

How is the ‘boiler diagram’ used in Manufacturing Applications?

In the manufacturing sector, boiler diagrams are pivotal for process steam generation, which is crucial for various production lines. These diagrams help visualize the flow of steam and water, aiding in the design and operation of steam systems that enhance efficiency. By ensuring that the boiler can meet the specific steam demand, businesses can significantly reduce downtime and increase productivity. International buyers should pay attention to compatibility with existing systems and the types of fuels available in their region, particularly in diverse markets like Nigeria or Brazil.

What Role Does the ‘boiler diagram’ Play in Food and Beverage Processing?

In the food and beverage industry, boiler diagrams are instrumental in designing systems for sterilization and pasteurization. These processes are essential for ensuring product safety and extending shelf life. A well-structured boiler diagram allows for the efficient transfer of heat, ensuring that products are heated to the required temperatures without compromising quality. B2B buyers must focus on sanitary designs and compliance with health regulations, especially in regions with strict food safety standards, such as the EU.

How is the ‘boiler diagram’ Essential in Power Generation?

For power generation, boiler diagrams illustrate the steam cycle used to generate electricity. These diagrams help optimize the design and operation of boilers, maximizing energy output while minimizing fuel consumption. This is crucial for meeting increasing energy demands sustainably. When sourcing boilers for power generation, businesses should consider the size, fuel flexibility, and emissions standards to ensure compliance with environmental regulations, particularly in the Middle East where energy efficiency is a priority.

What is the Importance of ‘boiler diagrams’ in Oil and Gas Industry?

In the oil and gas sector, boiler diagrams are vital for applications like enhanced oil recovery (EOR) through steam injection. These diagrams provide a clear overview of how steam is generated and injected into reservoirs, significantly improving extraction rates and reducing operational costs. International buyers should evaluate the pressure ratings and material durability of boilers to ensure they can withstand the harsh conditions often found in oil fields, particularly in regions like the UAE.

How Do ‘boiler diagrams’ Benefit Chemical Processing Operations?

Boiler diagrams are crucial in chemical processing, where they illustrate the heat supply necessary for various chemical reactions. By optimizing the design and operation of boilers, companies can increase reaction efficiency and product yield. Buyers in this sector should assess process-specific requirements, such as temperature and pressure conditions, along with safety standards, to ensure that the selected boiler meets the stringent demands of chemical production, especially in emerging markets in South America.

3 Common User Pain Points for ‘boiler diagram’ & Their Solutions

Scenario 1: Difficulty Understanding Boiler Diagrams for Equipment Selection

The Problem: International B2B buyers often encounter challenges when interpreting boiler diagrams, especially when selecting the appropriate type for specific industrial applications. This confusion can lead to misinformed purchasing decisions, resulting in inefficiencies, increased operational costs, and potential safety hazards. For instance, a buyer from Nigeria may be unsure whether to opt for a fire tube or water tube boiler based on the diagram, leading to a mismatch between the boiler’s capabilities and the facility’s steam requirements.

The Solution: To address this issue, buyers should invest time in understanding the fundamental components and functions depicted in boiler diagrams. A good starting point is to engage with suppliers who provide comprehensive resources, including detailed explanations of each component (burners, combustion spaces, etc.) and their roles in boiler operation. Additionally, potential buyers can request training sessions or webinars offered by manufacturers or industry experts. These sessions can demystify boiler diagrams, making it easier to match the right boiler type to specific operational needs. By doing so, buyers not only gain confidence in their purchasing decisions but also ensure that they select the most efficient and safe boiler system for their facilities.

Scenario 2: Inconsistent Quality and Performance Due to Poor Diagram Interpretation

The Problem: Another common pain point arises when buyers misinterpret boiler diagrams, leading to the installation of systems that do not perform as expected. For instance, a buyer in the UAE may rely on a poorly designed diagram that fails to accurately represent the required connections and controls, ultimately resulting in operational inefficiencies and increased downtime. This miscommunication can stem from language barriers or inadequate documentation, particularly when sourcing equipment from international suppliers.

The Solution: To mitigate these risks, buyers should prioritize sourcing from reputable suppliers who provide clear, standardized boiler diagrams along with accompanying documentation in multiple languages, including the buyer’s native language. It is also beneficial to establish a line of communication with technical support teams who can clarify any uncertainties regarding the diagrams. Implementing a thorough review process where installation teams cross-reference the boiler diagrams with actual site conditions can further enhance accuracy. By taking these proactive steps, buyers can ensure that the installation aligns with the specifications outlined in the diagrams, ultimately leading to improved performance and reliability.

Scenario 3: Lack of Customization Options in Boiler Diagrams

The Problem: Many B2B buyers face limitations when they find that the standard boiler diagrams do not cater to their unique operational requirements. For example, a manufacturing facility in South America may need a customized boiler system that accommodates specific fuel types or pressure requirements. Standard diagrams often do not provide the necessary flexibility, leading to frustration and delays in project timelines.

The Solution: To overcome this challenge, buyers should actively seek suppliers who offer customizable boiler solutions and accompanying diagrams. When engaging with manufacturers, it is essential to communicate specific operational needs clearly and inquire about options for bespoke designs. Furthermore, buyers can request 3D modeling or simulation software that allows them to visualize how modifications to the boiler diagram will impact performance. This collaborative approach not only fosters innovation but also ensures that the final product meets the buyer’s specifications, leading to enhanced operational efficiency and satisfaction. By being proactive in their discussions with suppliers, buyers can secure a boiler system that is tailored to their unique business needs.

Strategic Material Selection Guide for boiler diagram

What Are the Common Materials Used in Boiler Diagrams?

When selecting materials for boiler construction, it’s crucial to consider their properties and suitability for specific applications. Here, we analyze four common materials used in boiler diagrams: carbon steel, stainless steel, cast iron, and copper. Each material has unique characteristics that can significantly impact performance, durability, and compliance with international standards.

A stock image related to boiler diagram.

How Does Carbon Steel Perform in Boiler Applications?

Key Properties: Carbon steel is known for its excellent strength and high-temperature resistance, making it suitable for high-pressure applications. It typically has a temperature rating of up to 400°C and can handle pressures exceeding 20 bar.

Pros & Cons: The advantages of carbon steel include its low cost and ease of manufacturing. However, it is susceptible to corrosion, especially in high-moisture environments, which can lead to premature failure.

Impact on Application: Carbon steel is compatible with various media, but its corrosion susceptibility means that it may require additional protective coatings or treatments, particularly in humid climates.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards such as ASTM A106 or DIN 17175 for carbon steel pipes. Understanding the local environment’s impact on material longevity is also essential.

What Are the Advantages of Using Stainless Steel in Boiler Construction?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures (up to 600°C) and pressures (up to 30 bar). Its alloying elements, such as chromium and nickel, enhance its durability.

Pros & Cons: The primary advantage of stainless steel is its longevity and low maintenance requirements. However, it comes at a higher cost compared to carbon steel, and its manufacturing processes can be more complex.

Impact on Application: Stainless steel is suitable for a wide range of media, including corrosive substances, making it ideal for diverse industrial applications.

Considerations for International Buyers: Buyers from Europe and South America should look for compliance with standards such as ASTM A312 or EN 10216-5. The initial investment may be higher, but the long-term savings in maintenance can justify the cost.

Why Is Cast Iron a Popular Choice for Boiler Components?

Key Properties: Cast iron is known for its excellent thermal conductivity and ability to withstand high temperatures (up to 300°C) and pressures (around 10 bar). It is often used in the construction of boiler components like heat exchangers.

Pros & Cons: Cast iron is durable and cost-effective, but it is brittle and can crack under high stress. Its weight can also complicate installation.

Impact on Application: Cast iron is ideal for applications requiring good heat retention, but its brittleness limits its use in high-pressure environments.

Considerations for International Buyers: Buyers in regions with stringent safety regulations should ensure compliance with standards such as ASTM A48. The weight of cast iron components may also affect shipping and handling costs.

How Does Copper Compare in Boiler Applications?

Key Properties: Copper has excellent thermal conductivity and can operate at temperatures up to 250°C and pressures around 10 bar. It is often used in smaller, residential boilers.

Pros & Cons: The main advantage of copper is its thermal efficiency and resistance to corrosion. However, it is more expensive than other materials and can be prone to erosion in high-velocity applications.

Impact on Application: Copper is suitable for low-pressure applications and is commonly used in domestic hot water systems.

Considerations for International Buyers: Buyers in Europe and South America should ensure compliance with standards such as ASTM B280. The higher cost of copper may be a consideration for budget-conscious projects.

Summary Table of Material Selection for Boiler Diagrams

| Material | Typical Use Case for boiler diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | High-pressure steam boilers | Low cost and easy to manufacture | Susceptible to corrosion | Low |

| Stainless Steel | Corrosive environments | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Cast Iron | Heat exchangers | Good thermal conductivity | Brittle and heavy | Med |

| Copper | Residential hot water systems | High thermal efficiency | Expensive and prone to erosion | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions when sourcing materials for boiler applications. Understanding the properties, advantages, and limitations of each material will help ensure optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for boiler diagram

What Are the Main Stages in Boiler Manufacturing Processes?

The manufacturing of boilers involves several critical stages that ensure the final product meets the required standards for safety, efficiency, and functionality. Understanding these stages is essential for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe.

-

Material Preparation

– The process begins with selecting high-quality raw materials, primarily steel, which is essential for the boiler’s durability and performance.

– Material testing is conducted to verify compliance with international standards, ensuring that the metal can withstand high pressures and temperatures.

– Suppliers should provide Material Test Reports (MTRs) to verify the specifications of the materials used. -

Forming

– The forming stage involves shaping the raw materials into the required components. Techniques such as rolling, bending, and cutting are employed to create the boiler shell and tubes.

– Advanced technologies like CNC (Computer Numerical Control) machining may be utilized to enhance precision and reduce waste.

– Buyers should inquire about the forming equipment used and the experience level of the workforce involved in this critical phase. -

Assembly

– After forming, the components are assembled. This stage may involve welding, which is a crucial process for ensuring the integrity of the boiler.

– Different welding techniques are used depending on the type of boiler being manufactured. For instance, TIG (Tungsten Inert Gas) welding is often preferred for its precision.

– Quality checks are performed at various points during assembly to ensure that all components fit correctly and meet design specifications. -

Finishing

– The finishing stage includes surface treatment processes such as painting, coating, or galvanizing to protect against corrosion and enhance the boiler’s aesthetic appeal.

– Additional inspections are conducted to check for any defects or inconsistencies that may affect performance.

– Proper documentation regarding the finishing processes should be requested by buyers to ensure compliance with environmental standards.

How Is Quality Assurance Implemented in Boiler Manufacturing?

Quality assurance (QA) in boiler manufacturing is paramount to guarantee safety and performance. It encompasses various international and industry-specific standards, as well as multiple checkpoints throughout the manufacturing process.

-

What International Standards Should B2B Buyers Look For?

– ISO 9001: This is the globally recognized standard for quality management systems. Manufacturers should be certified to demonstrate their commitment to quality.

– CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

– API Standards: The American Petroleum Institute (API) provides standards that are particularly relevant for boilers used in the oil and gas industries. -

What Are the Key QC Checkpoints in Boiler Manufacturing?

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, this step ensures that the assembly and welding processes adhere to established standards.

– Final Quality Control (FQC): This is the last stage where the completed boiler undergoes thorough testing and inspection before shipment. -

What Common Testing Methods Are Used?

– Hydrostatic Testing: This test evaluates the boiler’s ability to withstand pressure by filling it with water and applying pressure.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and radiography are employed to identify internal flaws without damaging the components.

– Performance Testing: This assesses the boiler’s efficiency and output under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially in regions like Nigeria, UAE, and other emerging markets, verifying a supplier’s quality control processes is crucial. Here are actionable strategies:

-

Conduct Supplier Audits

– Regular audits of the manufacturing facility can provide insights into the supplier’s adherence to quality standards and practices. Buyers should consider both on-site inspections and remote audits. -

Request Detailed Quality Reports

– Manufacturers should provide comprehensive quality assurance documentation, including inspection reports, test results, and certificates of compliance. This documentation should be easily accessible and transparent. -

Engage Third-Party Inspection Services

– Utilizing third-party inspection services can offer an unbiased assessment of the manufacturing process. These inspectors can verify compliance with both international and local standards, ensuring that the product meets the buyer’s expectations. -

Understand QC/Certification Nuances for International Buyers

– Different countries may have varying regulations and standards. Buyers should familiarize themselves with the specific requirements in their region and confirm that their suppliers comply with those standards.

– For example, in the EU, compliance with the Pressure Equipment Directive (PED) is essential for boiler manufacturers, while in the Middle East, adherence to local safety standards is critical.

Conclusion: Ensuring Quality in Boiler Procurement

For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance protocols for boilers is vital. By focusing on material preparation, forming, assembly, and finishing stages, alongside rigorous quality control measures and standards, buyers can make informed decisions when selecting suppliers. Engaging in thorough verification processes will further ensure that the boilers procured meet the highest standards of safety and efficiency, ultimately leading to successful business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘boiler diagram’

A stock image related to boiler diagram.

The following practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure boiler diagrams. This guide aims to streamline the sourcing process, ensuring buyers make informed decisions that align with their operational needs and regulatory requirements.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specific technical requirements for the boiler diagram you need. This includes the type of boiler (fire tube or water tube), capacity, and operational pressures. Precise specifications ensure that suppliers can provide diagrams that meet your system’s requirements and comply with local regulations.

- Considerations:

- Identify the intended application (e.g., industrial, commercial).

- Assess compatibility with existing systems to avoid costly modifications.

Step 2: Research Regulatory Compliance

Understanding the regulatory landscape is crucial, especially when sourcing equipment that operates under pressure. Ensure that the boiler diagram complies with local and international standards, such as ASME, EN, or ISO standards, depending on your region.

- Focus Areas:

- Check for any certifications required in your country (e.g., Nigeria, UAE).

- Ensure the supplier is familiar with local regulations and can provide necessary documentation.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they have a proven track record in providing high-quality boiler diagrams. Request company profiles, case studies, and references from businesses in a similar industry or geographical location.

- Key Actions:

- Review supplier portfolios and past projects.

- Assess customer feedback to gauge reliability and service quality.

Step 4: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that include the boiler diagrams along with associated costs, lead times, and terms of service. A comprehensive proposal will help you compare suppliers effectively.

- What to Look For:

- Clarity in pricing and delivery schedules.

- Any additional services offered, such as installation or support.

Step 5: Assess Technical Support and After-Sales Service

Evaluate the level of technical support and after-sales service offered by the suppliers. Reliable support is essential for addressing any issues that may arise post-purchase, particularly in complex installations.

- Considerations:

- Inquire about the availability of technical assistance and training for your team.

- Check warranty terms and conditions to understand your liabilities.

Step 6: Verify Supplier Certifications

Before finalizing your decision, ensure that the supplier holds relevant certifications that verify their credibility and adherence to industry standards. Certifications can indicate a commitment to quality and safety in their processes.

- Key Certifications to Consider:

- ISO 9001 for quality management systems.

- Any industry-specific certifications relevant to your region or sector.

Step 7: Finalize the Agreement

Once you have selected a supplier, finalize the agreement with clear terms regarding delivery, payment, and any contingencies. A well-defined contract helps mitigate risks and ensures both parties are aligned on expectations.

- Important Aspects:

- Include clauses for potential delays or unforeseen circumstances.

- Ensure that both parties agree on the scope of work and responsibilities.

By following this practical checklist, B2B buyers can efficiently navigate the procurement process for boiler diagrams, ensuring that their sourcing decisions contribute positively to their operational objectives and compliance requirements.

Comprehensive Cost and Pricing Analysis for boiler diagram Sourcing

What Are the Key Cost Components in Boiler Diagram Sourcing?

When considering the sourcing of boiler diagrams, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials used in boiler manufacturing significantly influence costs. Common materials include steel, insulation, and various alloys, with prices varying based on quality and market availability.

-

Labor: Skilled labor is essential for the design and manufacturing of boiler diagrams. Labor costs can vary widely based on geographic location, with regions like Europe often experiencing higher wages compared to Africa and South America.

-

Manufacturing Overhead: This includes costs related to utilities, rent, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be a significant portion of the total price.

-

Tooling: The creation of molds, dies, and other tools required for production can entail substantial upfront costs. These costs are often spread over the production volume, making them more manageable in larger orders.

-

Quality Control (QC): Implementing stringent QC measures is vital for ensuring product reliability and compliance with international standards. These additional costs can influence the final price but are essential for minimizing risks associated with boiler failures.

-

Logistics: Transportation and handling costs, including shipping and customs clearance, can vary significantly based on the Incoterms used and the destination of the product. Understanding these costs can help in budgeting accurately.

-

Margin: Supplier margins can fluctuate based on market conditions and competition. Understanding the typical margins in the boiler industry can provide insights into pricing negotiations.

How Do Price Influencers Affect Boiler Diagram Sourcing?

Several factors influence the pricing of boiler diagrams, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract lower unit costs due to economies of scale. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Customized boiler diagrams tailored to specific applications may incur higher costs. Buyers should evaluate whether standard models can meet their requirements to avoid unnecessary expenses.

-

Material Selection: The choice of materials can significantly impact costs. High-quality materials may lead to better performance and longevity, potentially reducing total cost of ownership (TCO) over time.

-

Quality and Certifications: Products that comply with international quality standards may come at a premium but can offer greater reliability and safety, which is crucial in industries relying on boiler systems.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can influence pricing. Established suppliers may charge more but can offer better service and support.

-

Incoterms: Understanding the implications of different Incoterms (such as FOB, CIF, or DDP) is vital for determining who bears the risk and costs during transport. This can significantly affect the total cost.

What Tips Can Help Buyers Negotiate Better Prices for Boiler Diagrams?

To achieve cost-efficiency in sourcing boiler diagrams, consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a strong relationship can lead to better deals and discounts.

-

Focus on Total Cost of Ownership (TCO): Assess not just the initial purchase price but the long-term costs associated with operation, maintenance, and potential downtime. This holistic view can justify higher upfront costs for better quality products.

-

Leverage Market Research: Stay informed about market trends, material prices, and competitor pricing. This knowledge can empower buyers during negotiations and help them make informed decisions.

-

Explore Multiple Suppliers: Comparing quotes from different suppliers can reveal significant price variations. It also allows buyers to gauge market standards and negotiate better terms.

Disclaimer on Indicative Prices

Prices for boiler diagrams can vary widely based on the aforementioned factors, and the information provided here is meant to serve as a guideline. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for accurate and up-to-date pricing information.

Alternatives Analysis: Comparing boiler diagram With Other Solutions

Introduction to Alternative Solutions in Boiler Systems

When considering heating solutions for industrial applications, understanding the various alternatives to traditional boiler systems is essential for international B2B buyers. These alternatives can offer different performance characteristics, cost structures, and maintenance requirements, allowing businesses to select the most suitable technology based on their specific needs. In this analysis, we will compare the conventional boiler diagram with two viable alternatives: electric boilers and hot water heating systems.

Comparison Table of Boiler Diagram and Alternatives

| Comparison Aspect | Boiler Diagram | Electric Boilers | Hot Water Heating Systems |

|---|---|---|---|

| Performance | High capacity, adaptable to load fluctuations | Quick heating, suitable for small to medium loads | Consistent temperature control, efficient for large spaces |

| Cost | Moderate initial costs, potential for high operational costs | Higher initial investment, lower operational costs | Moderate initial costs, can vary based on installation |

| Ease of Implementation | Requires significant infrastructure | Easier to install, less space required | More complex installation due to piping and tank requirements |

| Maintenance | Regular maintenance required, risk of breakdowns | Minimal maintenance, long lifespan | Regular maintenance necessary, risk of leaks |

| Best Use Case | Heavy industrial applications with fluctuating steam demands | Small to medium industries requiring quick heating | Commercial buildings or large facilities needing consistent heating |

Detailed Breakdown of Alternatives

What are Electric Boilers and Their Advantages?

Electric boilers utilize electric elements to heat water, providing a clean and efficient alternative to traditional boilers. They are particularly advantageous for smaller operations where space is limited, and the heat demand is not excessively high. The main pros include lower operational costs due to the absence of fuel combustion and reduced maintenance needs. However, they can require a higher initial investment and may not be suitable for large-scale operations due to their limited output capacity.

Understanding Hot Water Heating Systems

Hot water heating systems operate by heating water and distributing it through pipes to radiators or heat exchangers. This method is efficient for maintaining consistent temperatures in large spaces, making it ideal for commercial buildings. While they provide reliable performance, the complexity of installation and the necessity for regular maintenance can pose challenges. Additionally, they may have varying costs based on the scale of the system and local regulations concerning water and energy efficiency.

Conclusion: Choosing the Right Solution for Your Needs

In selecting between a boiler diagram and its alternatives, B2B buyers should carefully assess their specific requirements, including performance needs, budget constraints, and maintenance capabilities. The decision should consider not only the initial investment but also long-term operational costs and the complexity of installation. By understanding these elements, businesses from Africa, South America, the Middle East, and Europe can make informed choices that align with their operational goals and contribute to overall efficiency.

Essential Technical Properties and Trade Terminology for boiler diagram

What Are the Essential Technical Properties of a Boiler Diagram?

When dealing with boiler systems, understanding the technical properties is crucial for international B2B buyers. Here are some key specifications that should be considered:

1. Material Grade

Boilers are typically constructed from high-strength steel or alloy materials, which are designed to withstand high pressures and temperatures. The grade of material used impacts the durability, safety, and efficiency of the boiler. For example, carbon steel is commonly used for fire tube boilers, while stainless steel is preferred for water tube boilers due to its corrosion resistance. Understanding the material grade helps buyers assess the long-term performance and maintenance requirements of the boiler.

2. Design Pressure

The design pressure is the maximum pressure that a boiler can safely operate under. It is a critical specification that influences the choice of boiler type and its application. For instance, fire tube boilers generally operate at lower pressures (up to 10 bar), whereas water tube boilers can handle higher pressures. Buyers must evaluate the design pressure in relation to their operational needs to ensure safety and compliance with industry standards.

3. Heat Transfer Efficiency

This property indicates how effectively a boiler can convert fuel energy into usable heat. Heat transfer efficiency is measured as a percentage and is vital for operational cost calculations. Higher efficiency leads to lower fuel consumption and reduced emissions, making it a key concern for environmentally conscious buyers. Understanding this specification can help companies optimize their energy use and reduce operational costs.

4. Tolerance Levels

Tolerance levels refer to the permissible variations in the dimensions and weight of boiler components. Precise tolerances are essential for ensuring proper fit and function, especially in complex installations. Buyers should seek boilers that comply with strict tolerance standards to minimize the risk of operational failures and enhance the reliability of the system.

5. Capacity

The capacity of a boiler, often measured in tonnes of steam per hour, indicates the amount of steam it can produce within a specific timeframe. This specification is crucial for buyers to align the boiler’s output with their production needs. Understanding capacity helps in selecting the right boiler size for operational efficiency.

What Are Common Trade Terms Related to Boiler Procurement?

Navigating the procurement process for boilers involves familiarizing oneself with specific industry jargon. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the boiler industry, working with OEMs ensures that you receive high-quality components that meet specific performance standards. Buyers should consider OEMs for reliable parts and service continuity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget management, especially for international buyers looking to import boilers or components. This knowledge helps in planning purchases and managing inventory effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. It typically outlines the specifications and quantities required. For B2B buyers, submitting an RFQ is an effective way to compare offers from different manufacturers, ensuring competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. These terms specify who is responsible for shipping, insurance, and tariffs. For buyers in Africa, South America, the Middle East, and Europe, understanding Incoterms is crucial for evaluating total costs and risk management in cross-border transactions.

A stock image related to boiler diagram.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. This metric is critical for project planning and inventory management. Buyers must consider lead times when negotiating contracts to ensure timely delivery of boilers and components.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when selecting and procuring boiler systems, ultimately enhancing operational efficiency and project success.

Navigating Market Dynamics and Sourcing Trends in the boiler diagram Sector

What Are the Current Market Dynamics and Key Trends in the Boiler Diagram Sector?

The boiler diagram sector is witnessing significant transformations driven by global economic conditions and technological advancements. Key trends include a shift towards more efficient and reliable boiler systems, which are essential for industries requiring high steam and heat outputs. International buyers from regions such as Africa, South America, the Middle East, and Europe should note that the increasing demand for energy-efficient systems is fueled by rising energy costs and stringent environmental regulations. For instance, countries like Nigeria and the UAE are heavily investing in modernizing their industrial infrastructure, which directly influences boiler purchasing decisions.

Emerging B2B technologies, such as predictive maintenance and IoT integration, are revolutionizing how boilers operate and are maintained. These innovations not only reduce downtime but also enhance operational efficiency, which is crucial for businesses aiming to optimize their supply chain processes. Furthermore, the market is seeing a rise in automated control systems that allow for real-time monitoring and adjustments, catering to fluctuating energy demands. Buyers should prioritize suppliers that provide these advanced solutions to stay competitive in their respective markets.

How Does Sustainability and Ethical Sourcing Impact the Boiler Diagram Sector?

Sustainability is becoming a cornerstone for B2B buyers in the boiler diagram sector. The environmental impact of boiler operations, particularly regarding emissions and waste management, is under increasing scrutiny. International buyers must prioritize suppliers who adhere to stringent environmental standards and can demonstrate the use of ‘green’ materials in their products. Certifications such as ISO 14001 for environmental management systems or the use of sustainable materials are becoming critical in supplier selection.

Ethical sourcing practices are also gaining traction, as companies seek to ensure their supply chains are transparent and responsible. This involves verifying that materials used in boiler manufacturing are sourced from suppliers who comply with labor and environmental regulations. Buyers from regions with strong regulatory frameworks, such as Europe, may find themselves at an advantage by demanding such standards from their suppliers. Ultimately, choosing ethically sourced and sustainable materials not only helps companies meet regulatory requirements but also enhances their brand reputation in a market increasingly focused on corporate responsibility.

What is the Brief History and Evolution of Boiler Technology?

The evolution of boiler technology dates back to the early 18th century, where the first steam boilers were developed primarily for locomotion and industrial applications. As the industrial revolution progressed, the demand for more efficient and safer boiler designs led to significant innovations, including the development of fire-tube and water-tube boilers. These designs improved heat transfer efficiency and operational safety, which were paramount for industrial users.

In recent decades, the focus has shifted towards enhancing energy efficiency and reducing emissions, prompted by global environmental concerns. The introduction of advanced materials and automation technology has further propelled the evolution of boiler systems, making them safer and more efficient than ever before. International B2B buyers should consider this historical context when evaluating suppliers, as those with a legacy of innovation are likely to offer more reliable and cutting-edge solutions. Understanding the historical progression of boiler technology can aid buyers in making informed decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of boiler diagram

-

How do I interpret a boiler diagram effectively?

To interpret a boiler diagram, begin by familiarizing yourself with the key components: the burner, combustion space, convection section, stack, air fans, and controls. Each part plays a critical role in the boiler’s operation. Focus on the flow of water and steam, noting how hot gases interact with water. Understanding the layout helps in troubleshooting issues and optimizing performance. Consider consulting with manufacturers or industry experts for detailed explanations tailored to specific boiler types, especially if sourcing from international suppliers. -

What is the best type of boiler for industrial applications?

The best type of boiler for industrial applications often depends on the specific requirements of your operation. Fire tube boilers are suitable for lower pressure needs and are generally simpler to operate, making them ideal for smaller operations. In contrast, water tube boilers offer higher efficiency and are better for large-scale, high-pressure applications. Assess your steam requirements, fuel availability, and space constraints to make an informed choice. Consulting with an experienced supplier can also provide insights tailored to your industry needs. -

What should I consider when sourcing boiler diagrams from international suppliers?

When sourcing boiler diagrams from international suppliers, consider their compliance with local regulations and standards. Check for certifications that ensure safety and efficiency, such as ASME or ISO. Evaluate the supplier’s reputation by reviewing customer feedback and case studies. Additionally, inquire about their experience in your specific industry and their ability to provide technical support. This due diligence will help ensure that you receive high-quality, reliable products that meet your operational requirements. -

How can I customize a boiler diagram for my specific needs?

Customizing a boiler diagram involves working closely with the supplier to align the design with your operational requirements. Begin by outlining your specific steam capacity, pressure needs, and fuel type. Discuss options for integrating advanced control systems or energy-efficient technologies. Ensure that the customization adheres to safety standards and regulations in your region. A collaborative approach with the supplier will help in creating a diagram that optimally fits your operational processes. -

What are the typical minimum order quantities (MOQ) for boiler diagrams?

Minimum order quantities (MOQ) for boiler diagrams can vary significantly based on the supplier and the complexity of the design. Smaller suppliers may offer flexible MOQs, while larger manufacturers might require higher quantities to justify production costs. It is essential to communicate your needs clearly and negotiate terms that work for both parties. Some suppliers may also offer prototypes or sample diagrams before committing to larger orders, which can be beneficial for testing. -

What payment terms should I expect when purchasing boiler diagrams internationally?

Payment terms for international purchases of boiler diagrams typically include options such as upfront payment, letter of credit, or payment upon delivery. It’s common for suppliers to request a deposit before production begins. Ensure you understand the currency fluctuations and any additional fees associated with international transactions. Clear communication with your supplier regarding payment expectations and conditions will help avoid misunderstandings and facilitate a smoother transaction. -

How do I ensure quality assurance for boiler diagrams from overseas suppliers?

To ensure quality assurance for boiler diagrams from overseas suppliers, request detailed documentation of their quality control processes. Verify if they have third-party certifications that attest to their manufacturing practices. It may also be beneficial to conduct factory audits or request samples of previous work. Establishing a clear set of quality criteria and continuous communication with the supplier throughout the production process will help ensure that the final product meets your standards. -

What logistics considerations should I keep in mind when importing boiler diagrams?

When importing boiler diagrams, consider logistics factors such as shipping costs, customs duties, and delivery timelines. Choose a reliable freight forwarder experienced in handling industrial equipment shipments to navigate international regulations. Be aware of the documentation required for customs clearance, including invoices and certificates of origin. Planning ahead for potential delays and ensuring that your supplier provides all necessary shipping information will help streamline the import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for boiler diagram

What Are the Key Takeaways for B2B Buyers in the Boiler Market?

Understanding the intricacies of boiler diagrams is essential for making informed purchasing decisions. Buyers must consider the type of boiler—whether fire tube or water tube—based on their specific operational needs. Fire tube boilers offer simplicity and lower initial costs, while water tube boilers provide higher efficiency and safety, albeit at a higher price point. Evaluating these factors can lead to significant long-term savings and operational efficiency.

How Can Strategic Sourcing Enhance Your Boiler Procurement?

Strategic sourcing is vital for optimizing procurement processes in the boiler market. By establishing strong relationships with suppliers and leveraging market insights, international buyers can negotiate better terms, ensure quality compliance, and gain access to innovative technologies. This approach not only reduces costs but also mitigates risks associated with supply chain disruptions, particularly in regions like Africa, South America, the Middle East, and Europe.

What’s Next for International B2B Buyers in the Boiler Sector?

As industries evolve and sustainability becomes a priority, the demand for efficient boiler systems is expected to rise. Buyers should stay ahead of trends by considering alternative fuels and advanced technologies. Engaging in strategic sourcing will empower businesses to navigate these changes effectively. Take the next step today—assess your boiler needs, explore supplier options, and implement a sourcing strategy that positions your business for future success.