Maximize Efficiency: The Ultimate Hydraulic Piston Pump Guide (2025)

Introduction: Navigating the Global Market for hydraulic piston pump

In the dynamic landscape of industrial machinery, sourcing hydraulic piston pumps that meet specific operational needs can be a daunting challenge for international B2B buyers. With applications spanning construction, manufacturing, and agriculture, these pumps are vital for ensuring efficiency and reliability in hydraulic systems. However, navigating the global market for hydraulic piston pumps requires a comprehensive understanding of various types, their applications, and the nuances of supplier vetting.

This guide serves as a vital resource for B2B buyers from Africa, South America, the Middle East, and Europe, including markets like Indonesia and the UAE. We will explore the different types of hydraulic piston pumps, including fixed and variable displacement options, and delve into their specific applications across various industries. Additionally, we’ll provide insights on evaluating suppliers, understanding cost structures, and identifying the best purchasing strategies tailored to your regional market dynamics.

By equipping you with actionable insights, this guide empowers you to make informed purchasing decisions that not only meet your immediate operational requirements but also position your business for long-term success in an increasingly competitive landscape. Whether you’re looking to optimize your existing hydraulic systems or explore new technologies, understanding the global market for hydraulic piston pumps is essential for driving efficiency and growth.

Understanding hydraulic piston pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Displacement Piston Pump | Constant flow rate; simple design; lower cost | Construction, agriculture, mining | Pros: Cost-effective; reliable. Cons: Limited flexibility in flow control. |

| Variable Displacement Piston Pump | Adjustable flow rate; higher efficiency; complex design | Mobile machinery, industrial equipment | Pros: Energy-efficient; versatile. Cons: Higher initial investment; maintenance complexity. |

| Axial Piston Pump | Piston arrangement allows for compact design; high efficiency | Aerospace, automotive | Pros: Space-saving; high power-to-weight ratio. Cons: Can be sensitive to contamination. |

| Radial Piston Pump | Radial arrangement of pistons; high pressure capabilities | Heavy machinery, hydraulic systems | Pros: Robust; capable of high pressures. Cons: Bulkier than axial designs; potential for wear. |

| Swash Plate Piston Pump | Utilizes a swash plate for variable displacement; smooth operation | Construction, material handling | Pros: Smooth flow; good for variable speed applications. Cons: More complex; requires precise alignment. |

What are the Characteristics of Fixed Displacement Piston Pumps?

Fixed displacement piston pumps are characterized by their constant flow output, making them ideal for applications requiring steady hydraulic power. These pumps are typically simpler in design and more affordable than their variable counterparts. B2B buyers should consider their specific flow requirements, as these pumps do not allow for flow rate adjustments. They are particularly suitable for industries like construction and agriculture, where consistent performance is essential.

How Do Variable Displacement Piston Pumps Benefit Businesses?

Variable displacement piston pumps offer adjustable flow rates and are known for their energy efficiency. This flexibility allows businesses to optimize performance based on varying operational demands. While they tend to have a higher upfront cost and require more complex maintenance, the long-term savings from reduced energy consumption make them a valuable investment for industries such as mobile machinery and industrial equipment. Buyers should evaluate their operational needs and budget constraints when considering these pumps.

Why Choose Axial Piston Pumps for Aerospace Applications?

Axial piston pumps feature a compact design with pistons arranged in a line, enabling high efficiency and a high power-to-weight ratio. This makes them particularly advantageous in aerospace and automotive applications where space and weight are critical factors. However, buyers must be cautious about potential contamination issues, as these pumps can be sensitive to dirt and debris. It is essential to implement effective filtration systems to protect the pump’s integrity.

What Makes Radial Piston Pumps Suitable for Heavy Machinery?

Radial piston pumps are distinguished by their radial arrangement of pistons, allowing them to handle higher pressures effectively. This robustness makes them ideal for heavy machinery and hydraulic systems where durability is paramount. B2B buyers should consider the pump’s bulkiness and potential wear over time, which may necessitate more frequent maintenance. Understanding the operational environment and expected pressure requirements will guide buyers in their selection process.

How Does a Swash Plate Piston Pump Operate?

Swash plate piston pumps utilize a swash plate mechanism to enable variable displacement, resulting in smooth and consistent hydraulic flow. This feature is particularly beneficial for applications involving variable speed operations, such as in construction and material handling. While the complexity of design can lead to alignment issues, the operational advantages often outweigh the drawbacks. Buyers should assess their specific application needs and consider the importance of smooth flow in their hydraulic systems.

Key Industrial Applications of hydraulic piston pump

| Industry/Sector | Specific Application of Hydraulic Piston Pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Concrete Pumping | Efficient concrete placement in high-rise projects | Pump pressure ratings, compatibility with concrete mixtures, and ease of maintenance. |

| Agriculture | Irrigation Systems | Enhanced water distribution for crop irrigation | Flow rate requirements, durability in harsh environments, and energy efficiency. |

| Manufacturing | CNC Machinery Operation | Precision control of hydraulic tools | Compatibility with existing machinery, pressure requirements, and reliability standards. |

| Oil & Gas | Hydraulic Fracking | Effective extraction of oil and gas resources | Pump capacity, resistance to corrosive fluids, and maintenance support. |

| Mining | Mineral Processing | Improved efficiency in ore extraction | Durability under extreme conditions, service availability, and technical support. |

How is Hydraulic Piston Pump Used in Construction?

In the construction industry, hydraulic piston pumps are vital for concrete pumping applications. They enable the efficient transfer of concrete to elevated areas, reducing labor costs and time delays. These pumps can handle high pressures, making them suitable for large-scale projects such as skyscrapers. For international buyers, especially in emerging markets like Africa and South America, sourcing pumps that meet specific pressure ratings and are compatible with various concrete mixtures is essential to ensure operational efficiency and minimize downtime.

What Role Does Hydraulic Piston Pump Play in Agriculture?

Hydraulic piston pumps are increasingly used in agricultural irrigation systems, allowing for precise control over water distribution. These pumps can efficiently move water across vast fields, ensuring crops receive adequate hydration, which is crucial for yield maximization. Buyers in regions like the Middle East and Africa should consider factors such as flow rate requirements and pump durability, especially in areas with harsh weather conditions. Energy efficiency is also a significant concern, as it directly impacts operational costs.

How Does Hydraulic Piston Pump Enhance Manufacturing Processes?

In the manufacturing sector, hydraulic piston pumps are integral to the operation of CNC machinery. They provide precise hydraulic pressure, enabling the accurate functioning of tools and machines. This precision leads to improved product quality and reduced waste. For B2B buyers in Europe, understanding the compatibility of these pumps with existing machinery and their adherence to reliability standards is crucial to maintaining production efficiency and reducing maintenance costs.

Why is Hydraulic Piston Pump Important in Oil & Gas?

In the oil and gas industry, hydraulic piston pumps are essential for hydraulic fracking operations. They facilitate the effective extraction of hydrocarbons by generating the high pressures needed to fracture rock formations. Buyers from regions like the Middle East should focus on sourcing pumps with high capacity and resistance to corrosive fluids, as these factors significantly affect operational efficiency and safety. Additionally, having robust maintenance support is critical to prevent costly downtimes.

How is Hydraulic Piston Pump Used in Mining?

In mining applications, hydraulic piston pumps are used in mineral processing to enhance ore extraction efficiency. They help in the transportation of slurries and other materials, ensuring that the mining process is streamlined. For international buyers in South America and Africa, it’s important to consider the durability of these pumps under extreme conditions, as well as the availability of technical support and service. Selecting pumps that can withstand harsh environments will lead to improved productivity and lower operational risks.

3 Common User Pain Points for ‘hydraulic piston pump’ & Their Solutions

Scenario 1: Inconsistent Pump Performance Leading to Downtime

The Problem: B2B buyers often face the frustration of hydraulic piston pumps that underperform, resulting in inconsistent flow rates and pressures. This inconsistency can lead to equipment malfunctions and production halts, especially in industries like construction and manufacturing, where hydraulic systems are crucial. Buyers might struggle to identify whether the issue stems from the pump itself, the hydraulic fluid, or external factors like temperature and pressure fluctuations.

The Solution: To combat inconsistent performance, buyers should first ensure that they are selecting the right hydraulic piston pump for their specific application. This includes evaluating the pump’s specifications such as flow rate (GPM), pressure ratings (PSI), and compatibility with the hydraulic fluid being used. Conducting a thorough analysis of the system’s requirements and consulting with manufacturers or suppliers can help in making informed decisions. Additionally, regular maintenance, including fluid checks and filter replacements, can enhance the pump’s efficiency. For real-time monitoring, investing in sensors that track pressure and flow can alert operators to issues before they escalate, minimizing downtime.

Scenario 2: Difficulty in Sourcing Replacement Parts

The Problem: Another common pain point for B2B buyers is the challenge of sourcing replacement parts for hydraulic piston pumps. When pumps break down, waiting for parts can lead to extended periods of inactivity, which is costly for businesses. Buyers often find that local suppliers do not stock the necessary components, or they face long lead times when ordering from manufacturers.

The Solution: To mitigate sourcing issues, buyers should establish relationships with multiple suppliers and distributors who specialize in hydraulic components. This not only broadens the network for obtaining parts but also provides options for expedited shipping. Additionally, buyers can consider purchasing pumps and parts from manufacturers that offer comprehensive support, including extensive inventories of replacement parts. Implementing a predictive maintenance program can also help identify parts that may need replacement before they fail, allowing for proactive sourcing and reducing unexpected downtime.

Scenario 3: High Operational Costs Due to Inefficiency

The Problem: High operational costs are a significant concern for B2B buyers using hydraulic piston pumps. Inefficient pumps can lead to excessive energy consumption, increased wear and tear, and higher maintenance costs. Buyers may not fully understand how to optimize their hydraulic systems for energy efficiency, resulting in inflated operational expenses.

The Solution: To reduce operational costs, buyers should consider investing in variable displacement hydraulic piston pumps, which adjust their output based on system demand. This adaptability leads to lower energy consumption compared to fixed displacement pumps. Additionally, implementing a system for monitoring and analyzing the hydraulic system’s performance can reveal inefficiencies. Buyers can engage with hydraulic consultants to assess their current systems and identify areas for improvement, such as optimizing hose lengths, minimizing bends, and ensuring proper fluid viscosity. Regular training for operators on best practices in using hydraulic systems can also enhance overall efficiency, driving down operational costs significantly.

Strategic Material Selection Guide for hydraulic piston pump

When selecting materials for hydraulic piston pumps, it is crucial to understand the properties and implications of different materials. This guide analyzes four common materials used in hydraulic piston pump construction: aluminum, cast iron, stainless steel, and composite materials. Each material has distinct advantages and challenges that can significantly impact performance and application suitability.

What are the Key Properties of Aluminum in Hydraulic Piston Pumps?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically has a temperature rating up to 150°C and can handle pressures of around 3000 PSI. The material is also non-magnetic, making it suitable for applications where magnetic interference must be minimized.

Pros: Aluminum is cost-effective and easy to machine, which simplifies manufacturing processes. Its lightweight nature reduces the overall weight of the hydraulic system, enhancing efficiency.

Cons: While aluminum has good corrosion resistance, it may not withstand aggressive chemicals or extreme temperatures as well as other materials. Additionally, it can be less durable under high-stress conditions.

Impact on Application: Aluminum is compatible with a wide range of hydraulic fluids but may not be suitable for applications involving abrasive or highly corrosive media.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is essential. Buyers in regions like Africa and the Middle East should verify local sourcing capabilities to ensure material quality.

How Does Cast Iron Perform in Hydraulic Piston Pumps?

Cast iron is widely used due to its strength and durability. It can withstand high pressures (up to 5000 PSI) and has a temperature rating of about 200°C. Cast iron is also known for its excellent wear resistance, making it suitable for demanding applications.

Pros: The material is highly durable and resistant to deformation under stress. Its ability to dampen vibrations enhances the longevity of hydraulic systems.

Cons: Cast iron is heavier than aluminum, which may not be ideal for applications where weight is a concern. It is also more challenging to machine, leading to higher manufacturing costs.

Impact on Application: Cast iron is compatible with various hydraulic fluids, but care must be taken with corrosive media, as it may rust if not properly coated.

Considerations for International Buyers: Buyers should be aware of regional standards, such as DIN or JIS, that may dictate material specifications. The availability of cast iron components may vary significantly across different markets.

What Advantages Does Stainless Steel Offer for Hydraulic Piston Pumps?

Stainless steel is renowned for its corrosion resistance and strength. It can handle temperatures up to 300°C and pressures exceeding 5000 PSI, making it suitable for high-performance applications.

Pros: The material’s resistance to corrosion and high temperatures makes it ideal for harsh environments. Stainless steel also has excellent mechanical properties, ensuring reliability.

Cons: The primary drawback is the higher cost compared to aluminum and cast iron. Additionally, its machining can be more complex, increasing production times.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including aggressive chemicals, making it versatile for various applications.

Considerations for International Buyers: Compliance with international standards is critical, especially for industries requiring stringent quality controls. Buyers should also consider the availability of stainless steel components in their region.

How Do Composite Materials Enhance Hydraulic Piston Pump Performance?

Composite materials, often a blend of polymers and fibers, are becoming increasingly popular in hydraulic applications due to their lightweight and corrosion-resistant properties. They can handle moderate pressures (up to 3000 PSI) and temperatures around 120°C.

Pros: Composites offer excellent resistance to corrosion and are significantly lighter than metals, which can enhance overall system efficiency. They can also be tailored for specific applications.

Cons: The primary limitation is their lower pressure and temperature ratings compared to metals. Additionally, composites can be more expensive and complex to manufacture.

Impact on Application: While composites are suitable for non-abrasive fluids, they may not be ideal for high-pressure applications or those involving harsh chemicals.

Considerations for International Buyers: Buyers should ensure that composite materials meet local and international standards. The availability of composite components may be limited in certain regions, necessitating careful sourcing.

Summary Table of Material Selection for Hydraulic Piston Pumps

| Material | Typical Use Case for Hydraulic Piston Pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight hydraulic systems | Excellent strength-to-weight ratio | Limited high-temperature resistance | Low |

| Cast Iron | Heavy-duty industrial applications | High durability and wear resistance | Heavier and harder to machine | Medium |

| Stainless Steel | Corrosive environments | Superior corrosion resistance | Higher cost and complex machining | High |

| Composite | Lightweight and corrosion-sensitive systems | Lightweight and customizable | Lower pressure and temperature ratings | Medium |

This guide provides a comprehensive overview of material selection for hydraulic piston pumps, enabling international B2B buyers to make informed decisions based on performance, application, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic piston pump

What Are the Main Stages of Manufacturing Hydraulic Piston Pumps?

The manufacturing of hydraulic piston pumps involves several critical stages that ensure both performance and reliability. Understanding these stages is essential for B2B buyers, particularly those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

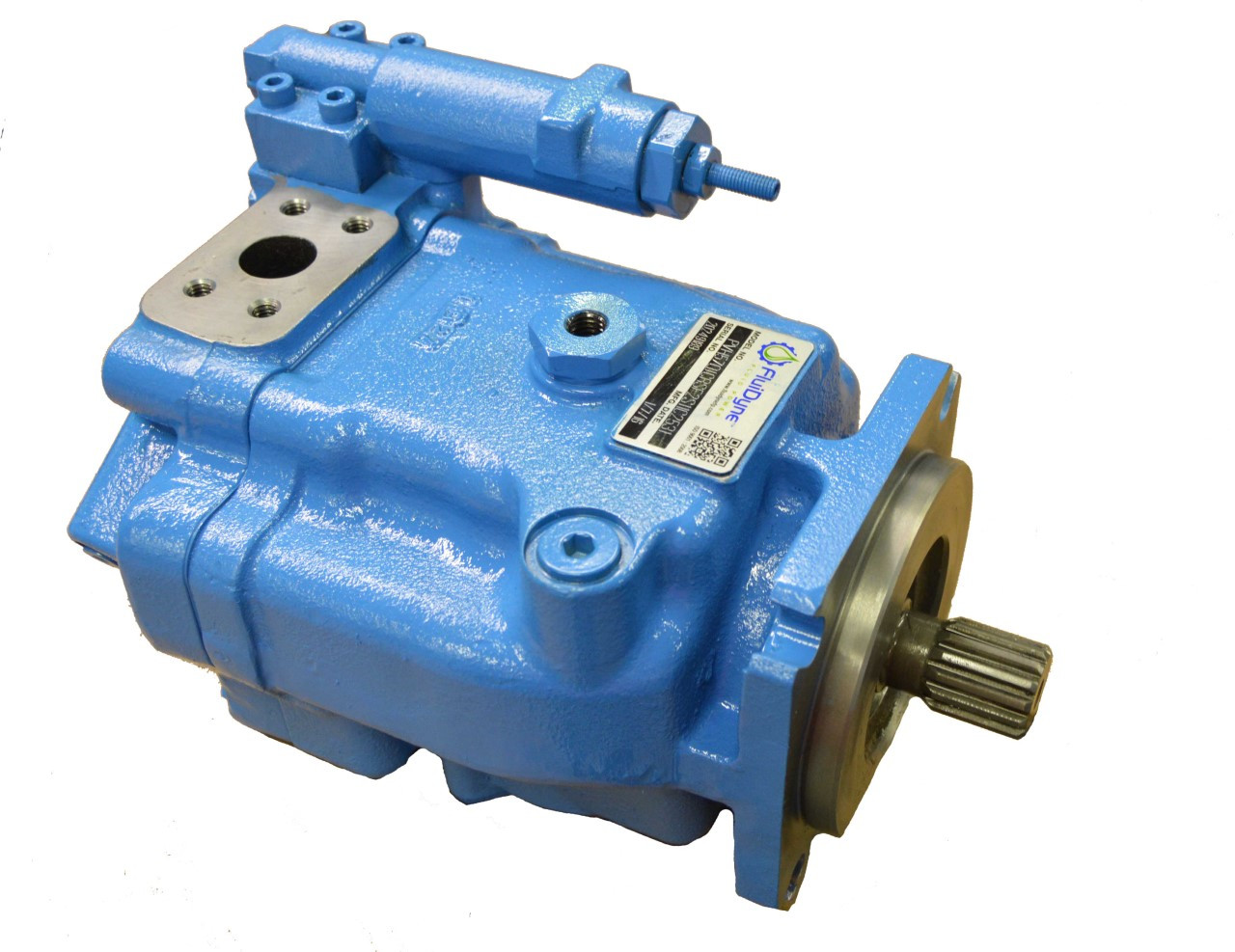

A stock image related to hydraulic piston pump.

Material Preparation: What Materials Are Used in Hydraulic Piston Pumps?

The first stage in the manufacturing process is material preparation. Hydraulic piston pumps typically require high-quality materials to withstand high pressures and ensure durability. Common materials include:

- Aluminum Alloys: Lightweight and resistant to corrosion, aluminum is often used for the pump body.

- Cast Iron: Known for its strength and durability, cast iron is frequently utilized for components that must endure high stress.

- Steel Alloys: Essential for internal components like pistons and shafts due to their superior tensile strength.

Before manufacturing begins, these materials undergo rigorous quality checks to ensure they meet industry standards.

How Are Hydraulic Piston Pumps Formed?

After material preparation, the next phase is forming. This involves several key techniques:

- Casting: For components like pump housings, casting is a common method. It allows for complex shapes and high levels of precision.

- Machining: Post-casting, components often require machining to achieve specific tolerances. CNC machining is widely used for its accuracy.

- Forging: For parts like shafts, forging enhances strength through deformation at high temperatures.

Each technique is carefully chosen based on the component’s requirements, affecting both performance and manufacturing cost.

What Is the Assembly Process for Hydraulic Piston Pumps?

Once individual components are formed, assembly takes place. This stage is critical for ensuring that all parts fit together correctly to function effectively. Key steps include:

- Component Inspection: Each part undergoes an inspection to verify dimensions and surface finishes.

- Sub-Assembly: Components may be pre-assembled before being fitted into the main assembly. This includes assembling pistons, springs, and valves.

- Final Assembly: The pump body is assembled with all internal components. This stage often involves the use of automated assembly lines to enhance efficiency.

Specialized tools are used to ensure that components are torqued to the manufacturer’s specifications, which is vital for preventing leaks and ensuring operational integrity.

What Finishing Techniques Are Applied to Hydraulic Piston Pumps?

The finishing stage is essential for enhancing the pump’s performance and longevity. Common finishing techniques include:

- Surface Treatment: Treatments such as anodizing, plating, or painting improve corrosion resistance and aesthetic appeal.

- Quality Coatings: Applying special coatings can reduce friction and wear, enhancing the pump’s efficiency.

Finishing touches are not merely cosmetic; they play a significant role in the pump’s functionality and lifespan.

How Is Quality Assurance Implemented in Hydraulic Piston Pump Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of hydraulic piston pumps to ensure they meet both performance and safety standards. For B2B buyers, understanding QA practices can help in selecting reliable suppliers.

What International Standards Should Buyers Consider?

International standards such as ISO 9001 are vital for ensuring a consistent quality management system. Compliance with these standards indicates that the manufacturer has established processes for maintaining quality throughout production.

In addition to ISO standards, industry-specific certifications like CE marking and API (American Petroleum Institute) standards are significant for hydraulic components, particularly in regions like Europe and the Middle East where regulatory compliance is mandatory.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints play a pivotal role in the production process. Typical checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, components are regularly checked to identify defects early in the process.

- Final Quality Control (FQC): After assembly, the completed pumps undergo comprehensive testing, including pressure tests and performance evaluations.

These checkpoints help mitigate risks and ensure that only high-quality products reach the market.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to verify the functionality and safety of hydraulic piston pumps. Common techniques include:

- Hydrostatic Testing: Pumps are subjected to high-pressure water tests to check for leaks and structural integrity.

- Performance Testing: Assessing flow rates and pressure outputs against specified benchmarks.

- Durability Testing: Simulating long-term use to evaluate wear and performance over time.

These testing methods not only assure quality but also provide documentation that can be crucial for B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are actionable steps to consider:

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and operational processes.

- Requesting Quality Reports: Buyers should ask for detailed QC reports that outline testing results and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing practices and product quality.

By implementing these strategies, buyers can mitigate risks associated with purchasing hydraulic piston pumps and ensure they receive high-quality products that meet their operational needs.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in Hydraulic Piston Pumps

Understanding the manufacturing processes and quality assurance practices for hydraulic piston pumps is critical for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous QC measures, buyers can ensure they select suppliers capable of delivering reliable and high-performing hydraulic solutions. This knowledge not only aids in making informed purchasing decisions but also fosters stronger partnerships with manufacturers worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic piston pump’

The procurement of hydraulic piston pumps is a critical process for businesses in various sectors, particularly in manufacturing, construction, and agriculture. This step-by-step checklist is designed to guide B2B buyers through the sourcing process, ensuring that they make informed decisions that align with their operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to sourcing the right hydraulic piston pump. Consider factors such as the required flow rate (GPM), pressure rating (PSI), and displacement type. This clarity will help you avoid costly mismatches and ensure the pump integrates seamlessly with your existing systems.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing can empower your negotiation strategy. Conduct thorough research on the average costs of hydraulic piston pumps and identify any seasonal fluctuations that may affect prices. Utilize industry reports and online resources to gather insights on the latest technological advancements that may influence your purchasing decision.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with proven track records of quality and reliability, and ensure they have a robust support system for after-sales service.

- Key Questions to Ask:

- What is the supplier’s experience in your industry?

- Can they provide testimonials or case studies from satisfied clients?

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering meet relevant industry standards and certifications. Compliance with ISO standards or other regulatory requirements not only guarantees quality but also reduces risks associated with product liability and recalls. Request documentation to verify these certifications.

Step 5: Assess Warranty and After-Sales Support

A strong warranty and comprehensive after-sales support are indicators of a supplier’s confidence in their products. Look for suppliers that offer extended warranties and have a dedicated customer service team to assist with installation, maintenance, and troubleshooting. This can significantly reduce downtime and repair costs in the long run.

Step 6: Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the hydraulic piston pumps you are considering. This allows you to assess the product’s performance firsthand and determine if it meets your operational needs. Additionally, it provides an opportunity to evaluate the supplier’s responsiveness and customer service approach.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a supplier, engage in negotiations to finalize terms that are favorable for your business. Discuss pricing, delivery timelines, payment terms, and any additional services included in the purchase. Clear communication during this phase can lead to a mutually beneficial agreement that enhances your long-term business relationship.

By following this checklist, international B2B buyers can confidently navigate the sourcing process for hydraulic piston pumps, ensuring they select the right product and supplier to meet their needs.

Comprehensive Cost and Pricing Analysis for hydraulic piston pump Sourcing

What Are the Key Cost Components of Hydraulic Piston Pumps?

When sourcing hydraulic piston pumps, understanding the underlying cost structure is crucial for effective budgeting and decision-making. The primary cost components typically include:

-

Materials: The choice of materials significantly affects the cost. High-grade metals and specialized alloys, which offer better durability and performance, can lead to higher prices. Conversely, opting for standard materials may reduce costs but could impact longevity.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. It’s essential to consider the skill level of the workforce when evaluating labor expenses.

-

Manufacturing Overhead: This includes costs associated with the factory’s operations, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thereby reducing overall costs.

-

Tooling: The initial investment in tooling can be significant, especially for custom designs. Buyers should factor in these costs, as they often influence the final price, particularly for low-volume orders.

-

Quality Control (QC): Implementing robust QC processes is essential for ensuring product reliability. While this can increase upfront costs, it mitigates the risk of future failures and associated warranty claims.

-

Logistics: Transportation and warehousing costs can vary widely depending on the supplier’s location and the buyer’s destination. International shipping, in particular, can introduce additional complexities and costs.

-

Margin: Suppliers will typically add a margin to their costs to ensure profitability. This margin can vary based on the supplier’s market position, brand reputation, and the level of service provided.

How Do Price Influencers Affect Hydraulic Piston Pump Costs?

Several factors influence the pricing of hydraulic piston pumps, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom specifications can significantly impact price. Tailoring pumps to specific applications may involve additional engineering costs, while standard models tend to be more affordable.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO standards) often come at a premium. Buyers should assess whether these certifications are essential for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record and customer service capabilities.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can influence the total cost.

What Buyer Tips Can Enhance Cost Efficiency?

To maximize cost efficiency when sourcing hydraulic piston pumps, international buyers should consider the following tips:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, MOQs, and payment terms with suppliers. Building a good relationship can lead to better deals over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider ongoing maintenance, operational efficiency, and potential downtime costs. Investing in a slightly more expensive pump with a longer lifespan may yield savings in the long run.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on geographic location and market conditions. For instance, sourcing from local suppliers in Africa or South America might reduce shipping costs and lead times compared to sourcing from Europe or Asia.

-

Research Supplier Backgrounds: Investigate potential suppliers’ backgrounds, including their manufacturing practices and quality control measures. A supplier with a strong reputation for quality may justify a higher price.

-

Stay Informed About Market Trends: Regularly monitor market conditions, as prices for raw materials and components can fluctuate. Being informed allows for timely purchasing decisions that can save costs.

Disclaimer on Pricing

Please note that the prices mentioned in this analysis are indicative and may vary based on current market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and updated pricing information.

Alternatives Analysis: Comparing hydraulic piston pump With Other Solutions

Understanding Alternative Solutions to Hydraulic Piston Pumps

When considering hydraulic systems, it’s essential to evaluate various solutions that can meet operational requirements effectively. Hydraulic piston pumps are known for their efficiency and reliability, but alternatives may offer different advantages, such as cost-effectiveness or simplicity of use. This section delves into a comparison between hydraulic piston pumps and two viable alternatives: gear pumps and diaphragm pumps.

Comparison Table of Hydraulic Piston Pump and Alternatives

| Comparison Aspect | Hydraulic Piston Pump | Gear Pump | Diaphragm Pump |

|---|---|---|---|

| Performance | High pressure, precise flow control | Moderate pressure, steady flow | Variable flow, low to moderate pressure |

| Cost | Higher initial investment | Lower initial cost | Moderate cost |

| Ease of Implementation | Requires precise setup | Simple installation | Moderate complexity |

| Maintenance | Regular maintenance needed | Low maintenance | Moderate maintenance |

| Best Use Case | Heavy-duty applications requiring precise control | General-purpose applications | Chemical handling, where contamination is a concern |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of Gear Pumps?

Gear pumps are widely used in various industries due to their simplicity and reliability. They operate by using interlocking gears to move fluid, making them suitable for a range of applications. The primary advantage of gear pumps is their lower initial cost compared to hydraulic piston pumps, making them an attractive option for budget-conscious buyers. Additionally, they require minimal maintenance due to fewer moving parts. However, gear pumps typically offer lower pressure capabilities and may not provide the precision required for specialized hydraulic applications.

How do Diaphragm Pumps Compare in Terms of Performance?

Diaphragm pumps utilize a flexible diaphragm to create a vacuum that draws fluid into the pump chamber. This design allows them to handle various fluids, including those that are abrasive or corrosive. Diaphragm pumps are advantageous for applications where contamination is a concern, as they prevent fluid from coming into contact with the mechanical parts of the pump. While they offer moderate costs and maintenance levels, they generally operate at lower pressures than hydraulic piston pumps, which may limit their use in high-demand environments.

Conclusion: How to Choose the Right Hydraulic Solution for Your Business

When selecting a hydraulic solution, B2B buyers must consider their specific operational needs, including pressure requirements, fluid types, and budget constraints. Hydraulic piston pumps are ideal for high-pressure applications requiring precise flow control, making them suitable for heavy-duty industries. Alternatively, gear pumps can provide a cost-effective solution for general-purpose applications, while diaphragm pumps excel in handling sensitive fluids without risk of contamination. By understanding the strengths and limitations of each option, buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for hydraulic piston pump

What Are the Essential Technical Properties of Hydraulic Piston Pumps?

When considering hydraulic piston pumps for industrial applications, several key technical properties are crucial for ensuring optimal performance and reliability. Understanding these specifications can aid international B2B buyers in making informed purchasing decisions.

1. Pressure Rating (PSI)

A stock image related to hydraulic piston pump.

The pressure rating, often measured in pounds per square inch (PSI), indicates the maximum pressure the pump can handle safely. Higher PSI ratings typically correlate with increased performance and efficiency in demanding applications. For buyers, selecting a pump with an appropriate pressure rating is critical to avoid equipment failure and ensure system integrity, particularly in high-pressure environments often encountered in industries like construction and manufacturing.

2. Flow Rate (GPM)

Flow rate, expressed in gallons per minute (GPM), measures the volume of fluid that the pump can move. This specification is vital for determining the pump’s ability to meet the operational demands of machinery. Buyers should assess their specific application requirements, as insufficient flow rates can lead to inadequate system performance, while excessively high rates may cause waste and inefficiency.

3. Displacement Volume (CID)

Displacement volume, often referred to as cubic inches per revolution (CID), indicates the volume of fluid displaced with each pump cycle. This specification is essential for understanding the pump’s efficiency and its capability to generate the necessary hydraulic power. For B2B buyers, knowing the CID helps in selecting a pump that matches their machinery’s requirements for torque and speed.

4. Shaft Configuration

The shaft configuration, including dimensions and mounting type, is critical for compatibility with existing machinery. Common configurations include straight keyed shafts and spline shafts. Buyers must ensure that the chosen pump’s shaft matches their equipment to facilitate installation and maintain operational efficiency. Mismatched configurations can lead to additional costs and downtime.

5. Material Grade

The material grade of the pump components affects durability and resistance to wear and corrosion. Common materials include aluminum, cast iron, and various alloys, each offering different benefits. Buyers should consider the operational environment—such as exposure to harsh chemicals or extreme temperatures—to select a pump that will withstand the conditions and minimize maintenance costs.

Which Trade Terminology Should B2B Buyers Know for Hydraulic Piston Pumps?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hydraulic piston pumps, buyers often source OEM components to ensure compatibility and quality. Understanding OEM relationships can help buyers navigate supply chains and guarantee product reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is vital for buyers to understand MOQs to avoid overstocking or understocking issues. B2B buyers should negotiate MOQs that align with their operational needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. Buyers should prepare detailed RFQs to ensure they receive accurate and competitive quotes from multiple vendors, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities, which are crucial for cross-border transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning and managing inventory effectively. Buyers should inquire about lead times during the procurement process to align their operations with supply chain capabilities.

6. Aftermarket Support

Aftermarket support encompasses services provided after the sale, such as maintenance, repairs, and spare parts supply. B2B buyers should consider the availability and quality of aftermarket support when selecting suppliers, as robust support can significantly enhance the longevity and reliability of hydraulic piston pumps.

By grasping these technical properties and trade terminologies, international B2B buyers can streamline their purchasing processes, ensuring they select the right hydraulic piston pumps for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the hydraulic piston pump Sector

What Are the Current Market Dynamics and Key Trends in the Hydraulic Piston Pump Sector?

The hydraulic piston pump market is experiencing significant growth, driven by the increasing demand for automation across various industries, including construction, agriculture, and manufacturing. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek efficient and reliable hydraulic solutions, understanding the market dynamics is crucial. Technological advancements, such as the integration of IoT (Internet of Things) and smart sensors, are enhancing the functionality of hydraulic piston pumps, allowing for predictive maintenance and real-time performance monitoring. This trend not only improves operational efficiency but also reduces downtime, making these pumps more appealing to buyers.

Additionally, the shift toward variable displacement pumps is gaining momentum. These pumps offer flexibility in operation and energy savings, aligning with the global push for sustainability. Buyers should consider suppliers that provide customizable options to meet specific operational requirements. The rise of online platforms for sourcing hydraulic components has also streamlined the purchasing process, enabling buyers to compare prices, specifications, and availability quickly. However, buyers must remain vigilant regarding supply chain disruptions, which may arise from geopolitical tensions and fluctuations in raw material costs.

How Are Sustainability and Ethical Sourcing Influencing the Hydraulic Piston Pump Market?

Sustainability is becoming a pivotal factor in the decision-making process for B2B buyers in the hydraulic piston pump sector. The environmental impact of manufacturing processes and the lifecycle of hydraulic pumps are under scrutiny, leading to a demand for sustainable practices. Buyers are increasingly looking for suppliers that prioritize eco-friendly materials and processes, such as recyclable components and energy-efficient manufacturing methods.

Ethical sourcing is also gaining traction, with companies expected to demonstrate responsible practices throughout their supply chains. Buyers should seek out suppliers that hold certifications such as ISO 14001 (Environmental Management) or those that adhere to the principles of the Circular Economy. These certifications indicate a commitment to minimizing environmental impact and promoting sustainability. Furthermore, selecting hydraulic piston pumps made from ‘green’ materials not only aligns with corporate social responsibility goals but can also enhance brand reputation in increasingly eco-conscious markets.

What Is the Evolution of Hydraulic Piston Pumps and Its Relevance to Current B2B Practices?

The hydraulic piston pump has evolved significantly since its inception, transitioning from mechanical to hydraulic systems, which have vastly improved efficiency and performance. Initially, these pumps were primarily used in industrial applications; however, their versatility has led to widespread adoption in various sectors, including agriculture, automotive, and aerospace.

A stock image related to hydraulic piston pump.

Today, the focus is on enhancing the efficiency and adaptability of hydraulic piston pumps, with innovations such as variable displacement technology and integration with digital monitoring systems. Understanding this evolution is essential for B2B buyers, as it highlights the importance of selecting suppliers who are not only aware of historical advancements but also committed to ongoing innovation. By partnering with forward-thinking manufacturers, buyers can ensure they are investing in the most reliable and advanced hydraulic solutions available, positioning their operations for future success.

In conclusion, navigating the hydraulic piston pump market requires a keen understanding of current trends, sustainability practices, and the historical context that shapes modern developments. International B2B buyers must leverage this knowledge to make informed purchasing decisions that align with their operational goals and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic piston pump

-

How do I choose the right hydraulic piston pump for my application?

Choosing the right hydraulic piston pump involves assessing your specific application requirements, including flow rate, pressure rating, and mounting compatibility. Consider the type of hydraulic system you are using, as well as the fluid viscosity and temperature range. It’s also crucial to evaluate the pump’s displacement and efficiency ratings, as these factors will influence performance and longevity. Consulting with suppliers or manufacturers can provide insights based on their expertise and product offerings. -

What are the key features to look for in a hydraulic piston pump?

When sourcing a hydraulic piston pump, prioritize features such as variable displacement capability, high-pressure ratings, and compatibility with your hydraulic system. Look for pumps that offer robust construction materials, which enhance durability and resistance to wear. Additionally, consider ease of maintenance, availability of spare parts, and manufacturer support. A pump with a proven track record in similar applications can also provide added assurance of reliability. -

What are the common payment terms for international B2B purchases of hydraulic piston pumps?

Payment terms for international B2B transactions typically include options like advance payment, letter of credit, or net payment terms (e.g., net 30, net 60). Advance payments are common for new suppliers, while established relationships may allow for more flexible terms. Always ensure that the payment method you choose offers security and aligns with your cash flow needs. Additionally, clarify any currency exchange implications or transaction fees that may apply. -

What should I consider regarding minimum order quantities (MOQ) when sourcing hydraulic piston pumps?

Minimum order quantities (MOQ) can significantly impact your sourcing strategy. Many manufacturers set MOQs to cover production costs, which may range from a few units to several hundred. When sourcing from suppliers, inquire about their MOQ policies and assess whether they align with your project needs. If your demand is low, consider negotiating with suppliers or seeking distributors who can accommodate smaller orders without compromising on quality. -

How can I vet suppliers when sourcing hydraulic piston pumps internationally?

Vetting suppliers involves a thorough assessment of their credentials, including certifications, production capabilities, and customer reviews. Request references from previous clients and verify their experience in your industry. Conducting site visits or audits can further ensure that the supplier meets quality standards. Additionally, leverage trade platforms and industry networks to gather insights about supplier reliability and reputation. -

What are the logistics considerations when importing hydraulic piston pumps?

Logistics considerations include shipping methods, lead times, and customs clearance processes. Choose a shipping method that balances cost and delivery speed, such as sea freight for larger orders or air freight for urgent needs. Ensure compliance with local regulations and tariffs that may apply to hydraulic equipment. Partnering with a logistics provider experienced in international trade can simplify the import process and help navigate any potential challenges. -

How do I ensure quality assurance for hydraulic piston pumps sourced internationally?

To ensure quality assurance, establish clear specifications and standards before placing orders. Request samples or prototypes to evaluate performance and compatibility with your systems. Implement a quality control process that includes third-party inspections and certifications, particularly for critical components. Regular communication with your supplier during production can also help address issues proactively and ensure adherence to quality standards. -

Can hydraulic piston pumps be customized for specific applications?

Yes, many manufacturers offer customization options for hydraulic piston pumps to meet specific application needs. Customizations can include changes to displacement, pressure ratings, and mounting configurations. Discuss your requirements with potential suppliers and inquire about their capabilities for design modifications. Keep in mind that custom orders may have longer lead times and higher costs, so plan accordingly to align with your project timeline.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hydraulic piston pump

As global industries increasingly rely on hydraulic systems, the strategic sourcing of hydraulic piston pumps has never been more critical. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these essential components can lead to significant operational efficiencies and cost savings.

What Are the Key Takeaways for Sourcing Hydraulic Piston Pumps?

Investing time in evaluating suppliers based on their manufacturing capabilities, pricing structures, and customer service is essential. Buyers should also consider the importance of lead times and availability, particularly when dealing with complex hydraulic systems. Establishing strong relationships with suppliers can result in favorable terms and improved support, ensuring that your operations remain uninterrupted.

How Can Strategic Sourcing Impact Your Business?

By adopting a strategic sourcing approach, companies can enhance their supply chain resilience and maintain competitive advantages in their respective markets. This proactive strategy not only mitigates risks associated with supply chain disruptions but also opens avenues for innovation and collaboration.

What’s Next for B2B Buyers in the Hydraulic Market?

As demand for hydraulic solutions continues to grow, now is the time for international buyers to leverage strategic sourcing practices. Engage with suppliers, evaluate options, and be prepared to adapt to market changes. Take action today to secure the hydraulic piston pumps that will drive your business forward in the global marketplace.