Maximize Efficiency: The Ultimate Metal Grate Guide (2025)

Introduction: Navigating the Global Market for metal grate

Navigating the global market for metal grates presents a unique challenge for international B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe. Sourcing high-quality metal grates that meet specific application requirements can be daunting, especially with varying standards and availability. This comprehensive guide aims to demystify the complexities of the metal grate market by exploring a wide array of types—including bar grating, safety grating, and expanded metal grating—and their respective applications in industrial settings.

In the subsequent sections, we will delve into essential factors such as supplier vetting, cost considerations, and compliance with regional standards. This guide empowers B2B buyers by providing actionable insights that streamline the decision-making process, ensuring that you select the right products for your projects. Whether you’re in the UAE seeking durable solutions for construction, or in Argentina looking for efficient drainage systems, understanding the nuances of metal grating will enhance your sourcing strategies.

By leveraging the information within this guide, you will be equipped to make informed purchasing decisions that align with your business goals while navigating the intricacies of the global metal grate market effectively.

Understanding metal grate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bar Grating | Parallel metal bars joined by perpendicular bars | Fire escapes, safety fences, bridges | Pros: High strength, customizable sizes. Cons: May require maintenance if not galvanized. |

| Safety Grating | Slip-resistant surface, often serrated | Industrial flooring, walkways | Pros: Enhanced safety, ideal for high-traffic areas. Cons: Can be more expensive than standard grating. |

| Plank Grating | Wider bearing bars, often used for walkways | Catwalks, platforms | Pros: High load capacity, stable footing. Cons: Heavier than other types, may require more support. |

| Expanded Metal Grating | Mesh-like structure with high open area | Ventilation, drainage systems | Pros: Lightweight, excellent drainage. Cons: Limited load-bearing capacity compared to solid grating. |

| Fiberglass Grating | Corrosion-resistant, lightweight, non-conductive | Chemical plants, marine applications | Pros: Durable in harsh environments, low maintenance. Cons: Higher initial cost than metal options. |

What Are the Characteristics of Bar Grating?

Bar grating consists of parallel metal bars welded or otherwise joined by perpendicular bars, creating a grid-like structure. Its strength and versatility make it suitable for various applications, including fire escapes and safety fences. When purchasing bar grating, buyers should consider the material type, as options like aluminum, mild steel, or galvanized steel can affect durability and maintenance needs. Custom sizing is an advantage, allowing for tailored solutions for specific projects.

How Does Safety Grating Enhance Workplace Safety?

Safety grating features a slip-resistant surface, often incorporating serrated edges to improve traction. This type is ideal for environments with heavy foot traffic or where spills are common, such as industrial floors and walkways. When evaluating safety grating, buyers should weigh the cost against the safety benefits it provides. While it may have a higher initial price, the potential reduction in workplace accidents can lead to long-term savings.

Why Choose Plank Grating for Heavy-Duty Applications?

Plank grating is characterized by wider bearing bars, making it suitable for heavy-duty applications like catwalks and platforms. Its robust design allows for high load capacities, ensuring stability and safety in demanding environments. Buyers should consider the weight and support requirements of plank grating, as its heavier nature may necessitate additional structural support. Customization options are often available, enhancing its adaptability for specific needs.

What Are the Benefits of Expanded Metal Grating?

Expanded metal grating features a mesh-like structure with a high percentage of open area, promoting excellent drainage and ventilation. This type is commonly used in applications like drainage systems and ventilation grates. Buyers should note that while expanded metal grating is lightweight and easy to install, it may not support as much weight as solid grating types. Understanding the load requirements of the application is crucial when selecting this option.

When Should You Consider Fiberglass Grating?

Fiberglass grating is a corrosion-resistant alternative to metal grating, making it suitable for harsh environments, including chemical plants and marine applications. Its lightweight nature and non-conductive properties are significant advantages. However, buyers should be aware that fiberglass grating typically comes at a higher initial cost compared to metal options. Evaluating the long-term benefits, such as reduced maintenance and replacement costs, can help justify the investment.

Key Industrial Applications of metal grate

| Industry/Sector | Specific Application of Metal Grate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Flooring and Walkways | Enhanced safety and durability in high-traffic areas | Material strength, load capacity, and slip-resistance ratings |

| Oil and Gas | Draining Platforms and Grating Systems | Efficient drainage and maintenance in hazardous areas | Corrosion resistance, compliance with safety standards |

| Mining | Safety Walkways and Platforms | Improved worker safety and operational efficiency | Custom sizing, load specifications, and impact resistance |

| Agriculture | Livestock Feeders and Equipment Platforms | Increased productivity and reduced contamination risks | Material type (e.g., galvanized vs. stainless steel), hygiene standards |

| Water Treatment Facilities | Grating for Wastewater Treatment Systems | Enhanced flow management and reduced clogging risks | Open area percentage, chemical resistance, and load-bearing capabilities |

How is Metal Grate Used in Construction and What Are the Benefits?

In the construction industry, metal grates are primarily utilized for flooring and walkways, providing a robust solution for high-traffic areas. Their slip-resistant surface enhances safety, while their lightweight yet strong design allows for easy installation. International buyers should consider the material strength and load capacity to ensure compliance with local regulations. Additionally, the grating’s ability to withstand environmental conditions is critical, especially in regions with extreme weather patterns.

What Role Does Metal Grate Play in the Oil and Gas Industry?

In the oil and gas sector, metal grating is essential for creating draining platforms and grating systems that facilitate efficient drainage in hazardous environments. This application minimizes the risk of spills and enhances safety protocols, which are crucial in this industry. Buyers must focus on sourcing materials with high corrosion resistance and compliance with stringent safety standards, particularly in regions like the Middle East where exposure to harsh chemicals is common.

How is Metal Grate Beneficial in Mining Operations?

Metal grates serve a vital role in mining by being used in safety walkways and platforms that ensure worker safety and operational efficiency. These grates provide a stable surface that can support heavy loads while allowing for the safe passage of personnel. When sourcing metal grating for mining applications, businesses should prioritize custom sizing and specifications that meet load-bearing requirements, as well as high impact resistance to withstand the rigors of the mining environment.

How Can Metal Grate Enhance Agricultural Operations?

In agriculture, metal grates are commonly used in livestock feeders and equipment platforms, helping to increase productivity while reducing the risk of contamination. These grates allow for easy cleaning and maintenance, which is vital for livestock health. For international buyers, sourcing considerations should include the choice of material, such as galvanized or stainless steel, to ensure longevity and hygiene compliance, particularly in regions like South America where agricultural practices are pivotal to the economy.

What Are the Advantages of Metal Grate in Water Treatment Facilities?

Metal grating is crucial in wastewater treatment facilities, where it is used to enhance flow management and reduce clogging risks. Its open area design allows for optimal water flow while preventing debris accumulation. When sourcing metal grating for water treatment applications, businesses should evaluate the open area percentage and the material’s chemical resistance, ensuring that it meets the specific requirements of wastewater environments across different international markets.

3 Common User Pain Points for ‘metal grate’ & Their Solutions

Scenario 1: Ensuring Safety in High-Traffic Areas

The Problem:

B2B buyers often face the challenge of ensuring safety in high-traffic areas where metal grates are installed. For instance, in industrial settings like factories or warehouses, inadequate grip on metal grates can lead to slips and falls, resulting in serious injuries and potential legal repercussions. Buyers must navigate complex safety regulations while balancing the need for durability and functionality in their selections.

The Solution:

To address safety concerns, opt for slip-resistant grating options, such as serrated or raised grating designs. These types provide better traction, which is crucial in areas prone to spills or where workers frequently walk. When sourcing metal grates, ensure they meet local safety standards and certifications, such as ANSI or OSHA guidelines. Additionally, conduct regular inspections and maintenance to ensure the integrity of the grates over time. Training staff on the importance of maintaining these safety features can also foster a culture of safety within the organization.

Scenario 2: Managing Corrosion in Harsh Environments

The Problem:

In industries located in coastal regions or environments with high humidity, metal grates are often susceptible to corrosion. Buyers may find that standard steel grates quickly degrade, leading to costly replacements and safety hazards. This scenario is particularly pressing for B2B buyers in sectors like oil and gas, where exposure to corrosive substances is common.

The Solution:

To mitigate corrosion issues, invest in galvanized or stainless steel grates, which are specifically designed to withstand harsh conditions. Galvanization involves coating the steel with zinc, providing a protective layer that resists rust. When specifying your metal grate needs, consider the environmental factors at play and request samples or data sheets from suppliers that demonstrate their products’ corrosion resistance. Furthermore, implementing a routine maintenance schedule that includes cleaning and inspections can prolong the lifespan of metal grates, ensuring they remain functional and safe in the long term.

Scenario 3: Custom Sizing and Fit for Unique Applications

The Problem:

Many B2B buyers encounter difficulties when standard metal grates do not fit specific project requirements, leading to delays and increased costs. This is particularly common in sectors such as construction and architecture, where unique dimensions are often necessary for compliance with design specifications or local building codes.

The Solution:

To overcome sizing challenges, work with suppliers that offer custom-cut metal grates tailored to your project’s specifications. Before placing an order, thoroughly assess your project requirements, including load capacity, spacing, and intended use. Communicate clearly with your supplier about your needs and request detailed CAD drawings to ensure accuracy. Additionally, consider leveraging advanced manufacturing technologies such as laser cutting or waterjet cutting, which provide high precision and flexibility in creating bespoke grating solutions. This proactive approach not only streamlines the procurement process but also helps avoid costly modifications later in the project lifecycle.

Strategic Material Selection Guide for metal grate

What Are the Key Properties of Steel Grating for B2B Applications?

Steel grating is one of the most commonly used materials for metal grates due to its high strength and durability. It typically exhibits excellent temperature resistance, making it suitable for high-heat applications. Steel grating is also resistant to impact and can withstand heavy loads, which is crucial for industrial settings. However, it is prone to corrosion if not properly treated, necessitating coatings such as galvanization for enhanced longevity.

Pros: Steel grating is cost-effective and offers high strength-to-weight ratios, making it ideal for structural applications. Its availability in various sizes and configurations allows for customization based on specific project requirements.

Cons: The main drawback is its susceptibility to rust and corrosion, particularly in humid or marine environments. This can lead to increased maintenance costs over time.

Impact on Application: Steel grating is often used in flooring, walkways, and platforms where heavy machinery operates. Its compatibility with various media, including water and chemicals, depends on the protective coatings applied.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local corrosion resistance standards, such as ASTM or DIN, particularly for projects near coastal areas.

How Does Aluminum Grating Compare in Terms of Performance?

Aluminum grating is known for its lightweight nature and excellent corrosion resistance, making it suitable for environments where moisture is a concern. It can withstand a range of temperatures, although it may not be as strong as steel under heavy loads.

Pros: The primary advantage of aluminum grating is its resistance to rust and corrosion, which reduces maintenance needs. It is also lightweight, making it easier to handle and install.

Cons: The main limitation is its higher cost compared to steel, which can be a significant factor for large-scale projects. Additionally, aluminum may not be suitable for applications requiring high load-bearing capacity.

Impact on Application: Aluminum grating is ideal for pedestrian walkways, platforms, and areas where weight reduction is critical. Its compatibility with various chemicals makes it suitable for use in laboratories and food processing facilities.

Considerations for International Buyers: Buyers in Europe and South America should be aware of the specific aluminum grades that meet local standards for load-bearing and corrosion resistance.

What Are the Advantages of Fiberglass Grating in Industrial Settings?

Fiberglass grating is increasingly popular due to its non-corrosive properties and lightweight design. It is ideal for environments exposed to harsh chemicals or where slip resistance is a priority.

Pros: Fiberglass grating is resistant to a wide range of chemicals, making it suitable for industrial applications such as chemical processing and wastewater treatment. Its slip-resistant surface enhances safety in wet conditions.

Cons: The main disadvantage is its cost, which is generally higher than that of steel or aluminum. Additionally, fiberglass may not withstand extreme temperatures as effectively as metal options.

Impact on Application: Fiberglass grating is often used in chemical plants, food processing facilities, and marine environments. Its compatibility with corrosive media makes it a preferred choice in these sectors.

Considerations for International Buyers: Buyers from regions like the Middle East should ensure compliance with local fire safety regulations, as fiberglass materials may have specific fire ratings.

How Does Stainless Steel Grating Perform in Harsh Environments?

Stainless steel grating combines the strength of steel with enhanced corrosion resistance, making it suitable for a variety of applications, including marine and food processing environments.

Pros: The primary advantage of stainless steel is its durability and resistance to rust, which extends the lifespan of the grating in challenging conditions. It also maintains structural integrity under high temperatures.

Cons: The main limitation is its cost, which is significantly higher than that of carbon steel or aluminum. This can impact budget considerations for large projects.

Impact on Application: Stainless steel grating is ideal for applications where hygiene and corrosion resistance are critical, such as in food processing and pharmaceutical industries.

Considerations for International Buyers: Buyers in Europe should be familiar with the various grades of stainless steel, such as 304 and 316, and their compliance with local health and safety regulations.

Summary of Material Selection for Metal Grate

| Material | Typical Use Case for Metal Grate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty flooring and platforms | High strength-to-weight ratio | Susceptible to corrosion | Medium |

| Aluminum | Pedestrian walkways | Lightweight and corrosion-resistant | Higher cost, lower load capacity | High |

| Fiberglass | Chemical processing facilities | Chemical resistance and slip resistance | Higher cost, limited temperature tolerance | High |

| Stainless Steel | Food processing and marine use | Excellent durability and rust resistance | Higher cost compared to other metals | High |

This comprehensive guide provides actionable insights for international B2B buyers, helping them make informed decisions when selecting materials for metal grates based on their specific applications and regional considerations.

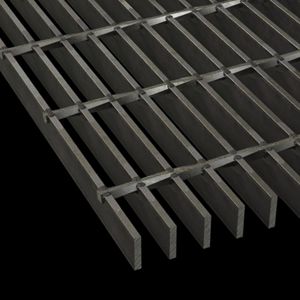

A stock image related to metal grate.

In-depth Look: Manufacturing Processes and Quality Assurance for metal grate

What Are the Key Stages in the Manufacturing Process of Metal Grate?

The manufacturing process of metal grates involves several critical stages that ensure the final product meets industry standards and customer specifications. Understanding these stages is vital for B2B buyers looking to source high-quality metal grates.

1. Material Preparation

The first step in manufacturing metal grates is material preparation. Manufacturers typically use high-grade steel, aluminum, or stainless steel, depending on the intended application. This stage includes:

- Material Selection: Choosing the right alloy based on corrosion resistance, strength, and weight considerations.

- Cutting and Sizing: Raw materials are cut to predetermined sizes using advanced technologies such as plasma cutting, laser cutting, or waterjet cutting. This precision ensures that the components fit together seamlessly in later stages.

2. Forming Techniques for Metal Grates

Once the materials are prepared, various forming techniques are employed to create the structure of the metal grate. These include:

- Welding: The most common method, where bars are joined through different welding techniques such as MIG, TIG, or resistance welding. The choice of welding method depends on the material thickness and type.

- Press-Locking and Swage-Locking: These methods are employed for specific grate designs, providing both strength and flexibility in applications where weight and load-bearing capacity are critical.

- Extrusion and Molding: For specialized designs, particularly in fiberglass grating, extrusion and molding processes are utilized to create unique shapes and features.

3. Assembly of Metal Grates

After forming, the individual components are assembled into the final grate structure. This stage involves:

- Alignment and Fitting: Ensuring that all parts are correctly aligned and fitted together. This may include the addition of safety features like serrated edges or grip struts.

- Inspection: Conducting preliminary inspections to verify that assembly meets specified tolerances.

4. Finishing Processes to Ensure Durability

The finishing stage is crucial for enhancing the durability and aesthetics of metal grates. Common finishing processes include:

- Galvanization: A process where the grates are coated with a layer of zinc to prevent corrosion, particularly important in outdoor and industrial environments.

- Powder Coating: This provides a protective and decorative finish, available in various colors, which also enhances the grate’s resistance to weathering and UV rays.

- Surface Treatment: Techniques such as shot blasting or polishing may be used to enhance surface quality and performance.

How Is Quality Assurance Implemented in Metal Grate Manufacturing?

Quality assurance (QA) is integral to ensuring that metal grates meet both international and industry-specific standards. Here’s how QA is typically structured:

Relevant International Standards for Metal Grate Manufacturing

B2B buyers should be aware of the international standards that govern metal grate quality, including:

- ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is applicable to any organization, regardless of its size or industry. Compliance indicates a commitment to quality and customer satisfaction.

- CE Marking: Particularly relevant for European buyers, CE marking signifies that products meet EU safety, health, and environmental protection standards.

- API Standards: For applications in oil and gas, API standards ensure that products are suitable for rigorous industrial environments.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented through various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and ensure adherence to specifications.

- Final Quality Control (FQC): At this stage, completed grates undergo rigorous testing for structural integrity, dimensional accuracy, and surface finish before they are shipped.

What Testing Methods Are Commonly Used for Metal Grates?

To ensure that metal grates perform as expected, several testing methods are employed:

- Load Testing: This assesses the strength and durability of the grate under specified loads, crucial for applications in high-traffic areas.

- Corrosion Resistance Testing: Particularly important for grates exposed to harsh environments, this testing evaluates how well the material withstands corrosion.

- Slip Resistance Testing: Ensures that the grate surface provides adequate traction, reducing the risk of accidents in wet or slippery conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of suppliers is essential. Here are actionable insights:

- Conduct Supplier Audits: Schedule regular audits to assess the manufacturing processes, quality control systems, and compliance with international standards.

- Request Quality Assurance Documentation: Suppliers should provide detailed QA reports, including certifications, test results, and compliance with relevant standards.

- Utilize Third-Party Inspections: Engage third-party inspection agencies to conduct independent assessments of the manufacturing process and final products.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing metal grates from suppliers in different regions, international buyers should consider:

- Cultural and Regulatory Differences: Quality standards may vary significantly across regions. Understanding local regulations in Africa, South America, the Middle East, and Europe can help buyers navigate potential compliance challenges.

- Logistical Considerations: Shipping and handling can impact product quality. Ensure that suppliers have robust packaging and shipping protocols to minimize damage during transit.

- Supplier Relationships: Building strong relationships with suppliers can enhance communication regarding quality expectations and improvements.

By understanding the manufacturing processes and quality assurance protocols in metal grate production, B2B buyers can make informed decisions that align with their specific requirements and standards. This knowledge is crucial for ensuring that sourced products are durable, reliable, and compliant with international expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal grate’

In this practical sourcing guide, we aim to provide international B2B buyers with a comprehensive checklist for procuring metal grates. Whether you are operating in Africa, South America, the Middle East, or Europe, this step-by-step guide will help you navigate the complexities of sourcing high-quality metal grates tailored to your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly outline your technical requirements. This includes determining the type of metal (e.g., aluminum, galvanized steel, stainless steel), dimensions, load-bearing capacity, and any specific compliance standards (like ADA). Having precise specifications ensures that you receive products that meet your operational needs and regulatory requirements.

Step 2: Research Market Trends and Applications

Understanding the current market trends and typical applications for metal grates is critical. Research the various types of metal grates available, such as bar grating, plank grating, and expanded metal grating. Pay attention to industry-specific uses, such as flooring, safety fences, and drainage systems, which can inform your purchasing decisions and enhance your project’s effectiveness.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform a thorough evaluation. Request detailed company profiles, case studies, and references from other buyers in your industry or region. Look for suppliers with a proven track record in delivering quality products and customer service. Additionally, consider their production capabilities and whether they can meet your volume requirements.

- Key Points to Consider:

- ISO certifications and compliance with international standards.

- Availability of custom fabrication services, if needed.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications to guarantee product quality and safety. Certifications such as ISO 9001 indicate adherence to quality management standards. In regions with specific regulatory requirements, check for compliance with local standards, which can vary significantly across continents.

Step 5: Request Samples and Specifications

Request samples of the metal grates to assess their quality before making a bulk purchase. This step allows you to evaluate the material’s durability, finish, and overall construction. Additionally, ask for product specifications and test reports to confirm that the grates meet your project requirements.

Step 6: Negotiate Terms and Pricing

Once you have shortlisted potential suppliers, engage in negotiations to secure favorable terms. Discuss pricing, payment terms, delivery timelines, and any warranties or guarantees. Be prepared to compare offers from multiple suppliers to ensure you are getting the best value for your investment.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics of transporting your metal grates. Discuss shipping options with your supplier, including local delivery capabilities and international shipping arrangements if needed. Timely delivery is critical, so ensure that the supplier can meet your project timelines without compromising quality.

A stock image related to metal grate.

By following this checklist, you can streamline your sourcing process and make informed decisions when procuring metal grates, ultimately ensuring that your projects are completed efficiently and effectively.

Comprehensive Cost and Pricing Analysis for metal grate Sourcing

What Are the Key Cost Components in Metal Grate Sourcing?

When sourcing metal grates, understanding the cost structure is essential for effective budgeting and negotiation. The primary components influencing the cost include:

-

Materials: The type of metal used (aluminum, stainless steel, galvanized steel, etc.) significantly impacts pricing. Aluminum tends to be lighter and resistant to corrosion, while stainless steel offers higher durability but at a premium cost.

-

Labor: Labor costs can vary by region and the complexity of the manufacturing process. Customization or specialized designs typically require more skilled labor, driving up costs.

-

Manufacturing Overhead: This includes indirect costs such as utilities, equipment maintenance, and facility expenses. Facilities with advanced technology may have higher overheads, but they can also offer better efficiencies and quality control.

-

Tooling: Initial tooling costs for molds or dies can be substantial, especially for custom designs. However, once amortized over large production runs, these costs can be minimized.

-

Quality Control (QC): Ensuring that the grates meet industry standards and certifications can add to costs but is crucial for maintaining product integrity and safety.

-

Logistics: Shipping costs, particularly for international buyers, can vary widely based on distance, mode of transport, and the Incoterms agreed upon.

-

Margin: Suppliers typically include a profit margin in their pricing, which can fluctuate based on competition and demand within the market.

How Do Price Influencers Affect Metal Grate Costs?

Several factors can influence the pricing of metal grates, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts, reducing the unit price. Negotiating for a lower MOQ can also be beneficial for smaller buyers.

-

Specifications and Customization: Custom grates designed to meet specific requirements often come at a higher price. Standard sizes and designs are usually more economical.

-

Quality and Certifications: Products that comply with international standards (e.g., ISO, ASTM) may carry a premium. Buyers should consider the long-term value of investing in certified products.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers might charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding shipping terms (like FOB, CIF, etc.) is vital for calculating total costs. These terms dictate who is responsible for shipping, insurance, and tariffs, significantly influencing the final price.

What Tips Can Help Buyers Optimize Costs in Metal Grate Sourcing?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, here are actionable strategies to optimize costs:

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices based on volume and long-term relationships. Don’t hesitate to request quotes from multiple suppliers to compare.

-

Consider Total Cost of Ownership (TCO): Beyond the purchase price, assess maintenance, durability, and potential replacement costs. A higher upfront investment in quality materials may result in lower long-term costs.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing trends and currency fluctuations. Pricing can vary based on local market conditions, so timing your purchase can lead to better deals.

-

Evaluate Local Suppliers: Sourcing locally may reduce logistics costs and lead times. Additionally, local suppliers may offer better insights into regional standards and requirements.

-

Stay Informed on Market Trends: Keep abreast of global supply chain developments, such as material shortages or geopolitical issues, which can impact pricing.

Disclaimer on Indicative Prices

Prices for metal grates can vary widely based on the factors mentioned above. It is crucial for buyers to conduct thorough market research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing metal grate With Other Solutions

Understanding Alternative Solutions to Metal Grate

In the industrial and construction sectors, selecting the right flooring and grating solution is crucial for operational efficiency and safety. While metal grates are a popular choice due to their strength and durability, various alternatives can serve similar purposes. This section explores viable alternatives to metal grates, highlighting their advantages and disadvantages to assist international B2B buyers in making informed decisions.

| Comparison Aspect | Metal Grate | Fiberglass Grating | Plastic Grating |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent drainage | Corrosion-resistant; lightweight; non-conductive | Lightweight; offers good drainage; less durable than metal |

| Cost | Moderate to high; varies with material type | Generally lower than metal; competitive pricing | Low; cost-effective solution |

| Ease of Implementation | Requires structural support; can be heavy | Easy to handle and install; no special tools needed | Very easy to install; lightweight and flexible |

| Maintenance | Low; resistant to wear and tear | Low; resistant to corrosion | Moderate; may require periodic replacement |

| Best Use Case | Heavy-duty applications; industrial settings | Chemical plants; areas with high moisture | Light-duty applications; residential settings |

Pros and Cons of Fiberglass Grating

Fiberglass grating is an alternative that excels in environments where corrosion is a significant concern, such as chemical processing plants or coastal areas. Its lightweight nature makes it easy to handle and install, reducing labor costs. However, while fiberglass is resistant to many chemicals, it may not offer the same level of load-bearing capacity as metal grates, making it less suitable for heavy industrial applications. The initial cost can be lower than metal options, but over time, if subjected to heavy loads, it may require more frequent replacement.

Evaluating Plastic Grating as an Option

Plastic grating is often seen as a cost-effective solution for light-duty applications, such as walkways or drainage covers in residential areas. Its lightweight design simplifies installation and handling. However, plastic grating typically lacks the durability and structural integrity of metal or fiberglass alternatives, making it unsuitable for high-traffic or heavy-load environments. While the initial investment is low, buyers should consider the potential need for more frequent replacements, which can offset initial savings.

Conclusion: Choosing the Right Grating Solution for Your Needs

When selecting between metal grates and alternative solutions like fiberglass or plastic grating, international B2B buyers must evaluate their specific needs, including performance requirements, budget constraints, and installation conditions. Metal grates remain a robust choice for heavy-duty applications, while fiberglass and plastic options may offer advantages in terms of weight and corrosion resistance for less demanding environments. By carefully assessing these factors, businesses can ensure they select the most effective and economical solution for their operational requirements.

Essential Technical Properties and Trade Terminology for metal grate

What Are the Key Technical Properties of Metal Grate?

When sourcing metal grates, understanding their technical properties is crucial for ensuring that the selected product meets specific project requirements. Here are some essential specifications to consider:

1. Material Grade

The material grade of metal grating, which can include options like carbon steel, stainless steel, or aluminum, significantly impacts durability and corrosion resistance. For instance, galvanized steel grating offers enhanced protection against rust, making it suitable for outdoor applications. Buyers must assess the environmental conditions of their projects to select the appropriate material grade, ensuring longevity and performance.

2. Load Capacity

Load capacity refers to the maximum weight that a metal grate can support without deformation. It is typically measured in pounds per square foot (psf) and varies based on the grating’s design, thickness, and material. Understanding load capacity is vital for applications in industrial settings where heavy machinery or foot traffic is common. Failure to account for this can lead to safety hazards and costly replacements.

3. Open Area Percentage

The open area percentage indicates the proportion of the grate that is open space, which affects ventilation, drainage, and light penetration. For example, grates with a higher open area are often preferred in drainage applications as they facilitate better water flow. B2B buyers should consider the specific needs of their applications, such as drainage efficiency or aesthetics, when selecting a grating type.

4. Tolerance

Tolerance defines the allowable deviation in dimensions of the grating during manufacturing. This specification is crucial for ensuring that the grating fits precisely into the designated installation area. Tighter tolerances may be necessary for applications requiring a high degree of precision, such as in machinery or heavy traffic areas. Understanding tolerances helps buyers avoid installation issues and ensures compatibility with other components.

5. Surface Finish

The surface finish of metal grates can vary from smooth to textured. Textured surfaces, such as slip-resistant finishes, are essential in environments where safety is a concern, such as stairways or industrial floors. Buyers should assess the specific safety requirements of their projects to determine the best surface finish, balancing aesthetics with functionality.

What Are Common Trade Terms Used in Metal Grating?

Familiarity with industry jargon can streamline the purchasing process and improve communication with suppliers. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of metal grates, an OEM might supply grating components to a larger construction or industrial equipment manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest amount of product a supplier is willing to sell. For metal grates, MOQs can vary significantly based on the material and type of grating. Buyers should inquire about MOQs to avoid overcommitting to unnecessary quantities, especially if they are testing new products or entering smaller projects.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically outlines specifications, quantities, and required delivery timelines. B2B buyers can utilize RFQs to compare offers from different suppliers, ensuring they receive competitive pricing while meeting their project needs.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers operating across borders, as they clarify who bears the risk and costs during shipping. Familiarity with Incoterms helps streamline negotiations and ensures compliance with international shipping regulations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing metal grates, optimizing both cost and performance for their projects.

Navigating Market Dynamics and Sourcing Trends in the metal grate Sector

What Are the Current Market Dynamics and Key Trends in the Metal Grate Sector?

The global metal grate market is experiencing robust growth, driven by increasing urbanization, infrastructure development, and the need for durable flooring solutions across various sectors, including construction, transportation, and industrial applications. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing a shift towards high-strength, lightweight materials that offer enhanced safety features, such as slip resistance and ergonomic designs.

Emerging technologies are reshaping sourcing trends, with advancements in manufacturing processes such as high-definition plasma cutting and laser technology allowing for more precise customizations. Additionally, the rise of e-commerce platforms is making it easier for buyers to source metal grating products globally, enabling competitive pricing and greater access to diverse suppliers. This trend is particularly significant for buyers in regions like the UAE and Argentina, where local suppliers may have limited inventories.

Furthermore, the demand for sustainable solutions is gaining traction. Buyers are increasingly seeking suppliers that can provide eco-friendly materials and practices, reflecting a broader commitment to sustainability in business operations. In summary, B2B buyers should focus on understanding these market dynamics and leverage emerging technologies for more efficient sourcing.

How Important is Sustainability and Ethical Sourcing in the Metal Grate Sector?

Sustainability is becoming a cornerstone of business practices in the metal grate sector. As international regulations tighten and consumers demand greater environmental responsibility, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials that minimize environmental impact, such as recycled steel or aluminum, and utilizing processes that reduce waste and energy consumption.

Ethical sourcing is equally crucial. Buyers are encouraged to engage with suppliers who uphold strong labor standards and fair trade practices. This not only enhances brand reputation but also mitigates risks associated with unethical supply chains, which can lead to legal and financial repercussions.

Moreover, certifications such as ISO 14001 (Environmental Management) and Leadership in Energy and Environmental Design (LEED) can serve as indicators of a supplier’s commitment to sustainability. Buyers should actively seek out partners who possess these certifications, ensuring that their sourcing aligns with environmental goals and contributes to a circular economy.

What is the Evolution of the Metal Grate Industry?

The metal grate industry has evolved significantly over the decades, transitioning from traditional manufacturing methods to advanced technologies. Initially, metal grates were primarily used in heavy-duty applications such as industrial flooring and drainage systems. However, as construction practices evolved, so did the applications of metal grating, expanding into areas such as architectural design, safety features, and aesthetic enhancements in commercial and residential projects.

The introduction of new materials, such as fiberglass and aluminum, has broadened the scope of metal grating applications, allowing for greater flexibility and adaptability in design. Today, the market is characterized by a diverse range of products tailored to specific needs, emphasizing not only functionality but also sustainability and safety. This evolution reflects the industry’s responsiveness to the changing demands of B2B buyers across various regions, aligning with their goals for innovation and responsible sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of metal grate

-

How do I choose the right metal grate for my specific application?

Choosing the right metal grate involves assessing your application’s load requirements, environmental conditions, and safety standards. Consider factors like the type of traffic (foot, vehicular, or heavy machinery), the need for drainage or ventilation, and compliance with local regulations. For example, galvanized steel grates are ideal for corrosive environments, while aluminum options are lightweight and resistant to rust. Collaborate with suppliers who can provide technical guidance and custom solutions tailored to your operational needs. -

What is the best type of metal grate for outdoor use in harsh climates?

For outdoor applications in harsh climates, galvanized steel or stainless steel grates are typically the best options. They offer excellent corrosion resistance and durability against extreme weather conditions. Galvanized steel is particularly effective in preventing rust, making it suitable for wet environments, while stainless steel provides superior strength and resistance to harsh chemicals. Always confirm that the selected grate meets any specific regional standards or certifications required for your industry. -

How can I ensure the quality of the metal grates I purchase?

To ensure quality, work with suppliers that are ISO certified and provide certifications for their products. Request samples to evaluate the material’s strength, durability, and finish. Additionally, inquire about their manufacturing processes, such as welding methods and quality control measures. Establishing a clear communication line with your supplier regarding your quality expectations will help mitigate risks associated with defective products. -

What is the minimum order quantity (MOQ) for metal grates?

The minimum order quantity for metal grates can vary significantly based on the supplier and the specific type of grate. Some suppliers may have an MOQ of a few pieces for standard sizes, while custom orders might require a higher MOQ due to production setup costs. It’s advisable to discuss your project needs upfront with suppliers to negotiate favorable terms that align with your budget and project timeline.

A stock image related to metal grate.

-

What are the typical payment terms for international B2B purchases of metal grates?

Payment terms can vary widely among suppliers, but common practices include net 30, net 60, or payment in advance for first-time orders. For larger orders, some suppliers may offer letter of credit options. It’s crucial to clarify payment terms before finalizing agreements, especially for international transactions, as currency exchange rates and potential tariffs can affect overall costs. -

How do I vet suppliers for metal grates in the international market?

When vetting suppliers, consider their reputation, years of experience, and client testimonials. Request references from previous customers, particularly those in your industry. Conduct background checks to ensure they are compliant with international trade regulations and quality standards. Additionally, assess their logistical capabilities, including shipping options, delivery times, and support for customs clearance. -

What logistics considerations should I keep in mind when sourcing metal grates internationally?

Logistics plays a critical role in international sourcing. Ensure that your supplier has experience with export regulations and can handle shipping documentation efficiently. Consider the shipping methods available (air, sea, or land) based on your budget and urgency. Also, discuss warehousing options if you require storage before distribution. Planning for potential delays at customs and having a reliable logistics partner can help streamline the process. -

Can I customize the dimensions and design of metal grates?

Yes, many suppliers offer customization options for metal grates. You can specify dimensions, materials, and design features such as slip-resistant surfaces or specific load-bearing capacities. When requesting customization, provide detailed specifications and discuss lead times, as custom orders may take longer to produce. Collaborating closely with your supplier will ensure that the final product meets your exact requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal grate

As international B2B buyers navigate the complex landscape of metal grating sourcing, several key takeaways emerge. Understanding the diverse types of metal grates—ranging from bar grating to safety grating—is essential for making informed purchasing decisions. Prioritizing high-grade materials, such as galvanized steel and aluminum, not only enhances durability but also ensures compliance with safety standards across various applications, from flooring to stair treads.

Why is Strategic Sourcing Critical for Metal Grate Procurement?

The value of strategic sourcing cannot be overstated. By establishing strong relationships with reliable suppliers, buyers can benefit from custom solutions, timely deliveries, and competitive pricing. Leveraging local suppliers in regions like Africa, South America, the Middle East, and Europe can significantly reduce lead times and logistics costs, which is crucial in today’s fast-paced market.

What Does the Future Hold for Metal Grate Buyers?

Looking ahead, the demand for innovative and sustainable metal grating solutions is expected to grow. Buyers should stay informed about emerging trends, such as eco-friendly materials and advanced manufacturing techniques. Engaging with suppliers who are committed to quality and sustainability will not only enhance operational efficiency but also align with global environmental standards.

In conclusion, as you evaluate your sourcing strategies, consider the long-term benefits of quality and reliability in your metal grate procurement. Take proactive steps today to secure the best solutions for your business needs, ensuring a competitive edge in your market.