Optimize Performance: The Ultimate Dynamometer Test Guide (2025)

Introduction: Navigating the Global Market for dynamometer test

In today’s competitive global market, sourcing reliable dynamometer tests can be a significant challenge for international B2B buyers. As businesses across Africa, South America, the Middle East, and Europe strive to enhance their product performance, understanding the intricacies of dynamometer testing becomes essential. This guide serves as a comprehensive resource, detailing the various types of dynamometers, their applications, and the critical process of supplier vetting.

By addressing key considerations such as the calibration standards, testing protocols, and cost implications, this guide equips buyers with the knowledge necessary to make informed purchasing decisions. Whether you are in the automotive industry in the UAE, the manufacturing sector in Egypt, or any other field requiring precise measurement of force and power, having a thorough understanding of dynamometer tests is vital.

Moreover, this resource emphasizes the importance of reliability and validity in test results, ensuring that buyers can confidently choose suppliers who meet international standards. As you navigate the complexities of the global market, this guide will empower you to select the right dynamometer solutions that align with your operational needs and enhance your product development processes.

Understanding dynamometer test Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Dynamometer | Measures engine torque and power output | Automotive testing, engine performance analysis | Pros: Accurate power measurements; Cons: High initial cost. |

| Chassis Dynamometer | Assesses the entire vehicle’s powertrain performance | Vehicle emissions testing, performance tuning | Pros: Comprehensive data; Cons: Requires specialized setup. |

| Eddy Current Dynamometer | Utilizes electromagnetic induction to measure torque | Electric motor testing, machinery performance | Pros: No mechanical friction; Cons: Limited to specific applications. |

| Handgrip Dynamometer | Measures isometric strength of hand and forearm muscles | Sports science, rehabilitation, ergonomic studies | Pros: Simple and cost-effective; Cons: Limited to grip strength. |

| Universal Dynamometer | Can operate in both driving and absorbing modes | Versatile testing for various machinery | Pros: Flexible applications; Cons: Complexity in operation. |

What Are the Key Characteristics of Engine Dynamometers?

Engine dynamometers are specialized devices designed to measure the torque and power output of internal combustion engines. They are essential for automotive manufacturers and performance tuning shops, allowing for precise assessments of engine performance under various conditions. When purchasing, buyers should consider the dynamometer’s calibration capabilities, load capacity, and integration with data acquisition systems to ensure accurate and reliable testing results.

How Do Chassis Dynamometers Work for Vehicle Testing?

Chassis dynamometers evaluate the power output and performance of an entire vehicle, simulating road conditions while measuring torque and horsepower at the wheels. This type of dynamometer is crucial for emissions testing and performance tuning, especially for regulatory compliance in regions like Europe and the Middle East. Buyers should assess the dynamometer’s size, weight capacity, and software compatibility to ensure it meets their testing requirements.

What Makes Eddy Current Dynamometers Unique?

Eddy current dynamometers employ electromagnetic induction to measure torque without mechanical contact, making them ideal for testing electric motors and other machinery. Their unique design reduces wear and tear, providing long-term reliability. B2B buyers should consider the specific applications for which they need the dynamometer, as well as the initial investment and maintenance costs associated with this technology.

Why Choose Handgrip Dynamometers for Strength Testing?

Handgrip dynamometers are designed to measure the isometric strength of the hand and forearm, commonly used in sports science and rehabilitation settings. They provide quick and straightforward assessments of grip strength, which can indicate overall physical fitness. Buyers should focus on the ease of use, calibration options, and data recording features when selecting a handgrip dynamometer to ensure it aligns with their testing needs.

What Are the Advantages of Universal Dynamometers?

Universal dynamometers can operate in both driving and absorbing modes, making them versatile tools for various machinery testing applications. This flexibility allows manufacturers to conduct comprehensive performance assessments across multiple systems. Buyers should evaluate the dynamometer’s operational complexity, compatibility with existing systems, and the range of tests it can perform to make an informed purchasing decision.

Key Industrial Applications of dynamometer test

| Industry/Sector | Specific Application of Dynamometer Test | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Performance Testing | Optimizes engine efficiency and reduces emissions | Calibration standards, testing environment conditions |

| Manufacturing | Machinery Load Testing | Ensures machinery operates within safe load limits | Dynamometer capacity, precision, and durability |

| Aerospace | Propulsion System Evaluation | Validates thrust and performance of engines | Compliance with aerospace standards, data accuracy |

| Renewable Energy | Wind Turbine Performance Measurement | Enhances energy output and operational reliability | Environmental conditions, data acquisition systems |

| Heavy Equipment | Load and Torque Testing for Construction Machinery | Improves safety and performance of heavy machinery | Load capacity, portability, and ease of use |

How is Dynamometer Testing Used in the Automotive Industry?

In the automotive sector, dynamometer testing is essential for evaluating engine performance. By measuring torque and power output, manufacturers can optimize engine designs, leading to improved fuel efficiency and reduced emissions. For international buyers, particularly in regions like Africa and South America, sourcing dynamometers that meet local emissions regulations and standards is crucial. Considerations should include the dynamometer’s ability to simulate various driving conditions and its compatibility with different engine types.

What Role Does Dynamometer Testing Play in Manufacturing?

Manufacturers utilize dynamometer tests to assess the load capacity of machinery. This testing ensures that equipment operates within specified limits, preventing overloads that could lead to equipment failure or safety hazards. For B2B buyers, particularly in the Middle East, understanding the specific load requirements of their machinery is vital. When sourcing dynamometers, businesses should prioritize models that offer high precision and reliability under varying operational conditions.

How is Dynamometer Testing Applied in Aerospace?

In the aerospace industry, dynamometer testing is critical for evaluating propulsion systems, including jet engines. By measuring thrust and performance metrics, manufacturers can ensure their engines meet stringent safety and efficiency standards. Buyers in Europe and the UAE should focus on sourcing dynamometers that comply with international aerospace testing standards and provide accurate data for regulatory compliance. Additionally, the ability to conduct tests under various environmental conditions is a key factor.

What is the Importance of Dynamometer Testing in Renewable Energy?

Dynamometer testing is increasingly used in the renewable energy sector, particularly for wind turbine performance measurement. By assessing the torque and power output of turbines, companies can enhance energy production and improve operational reliability. B2B buyers in regions like Africa, where renewable energy projects are expanding, should seek dynamometers that can operate effectively in diverse environmental conditions. It is also important to consider data acquisition capabilities for real-time performance monitoring.

How Does Dynamometer Testing Benefit Heavy Equipment Operations?

In the heavy equipment sector, dynamometer testing is crucial for load and torque testing of construction machinery. This testing helps improve the safety and performance of equipment by ensuring it can handle specified loads without risk of failure. Buyers in South America and the Middle East should focus on sourcing portable dynamometers that can be easily transported to job sites. Additionally, ease of use and the ability to quickly set up tests are important factors to consider.

3 Common User Pain Points for ‘dynamometer test’ & Their Solutions

Scenario 1: Challenges in Calibration and Consistency of Results

The Problem: One of the most significant challenges faced by B2B buyers in industries such as automotive, aerospace, and manufacturing is the calibration of dynamometers. Inconsistent calibration can lead to inaccurate readings, which can impact product development and compliance with industry standards. For instance, a manufacturer in the UAE testing engine power output may find that their results vary significantly between tests, resulting in wasted resources and potential delays in product launch.

The Solution: To ensure accurate and consistent results, it is crucial to establish a rigorous calibration schedule for the dynamometers used in testing. Buyers should source dynamometers from reputable manufacturers that provide detailed calibration procedures and documentation. Regular maintenance checks should also be scheduled to verify that the dynamometers are functioning correctly. Additionally, utilizing calibration weights and following standardized testing protocols will help mitigate discrepancies. Implementing a quality assurance program that includes regular training for staff on calibration techniques will further enhance the reliability of test results.

Scenario 2: Understanding the Complexity of Test Procedures

The Problem: Many B2B buyers face difficulties in understanding the complex procedures associated with dynamometer testing. For example, a company in South America may struggle with the technical aspects of setting up a dynamometer for testing engine performance. This can lead to improper setup, resulting in invalid test results and a lack of confidence in the data collected.

The Solution: Buyers should invest in comprehensive training programs for their technical staff, focusing on the specific procedures required for dynamometer testing. Manufacturers often provide training resources, including manuals and video tutorials, which can be invaluable. Additionally, engaging with industry consultants who specialize in dynamometer testing can provide tailored guidance to streamline the setup process. By creating a standardized procedure checklist that outlines each step of the testing process, companies can enhance the understanding of their staff and improve overall test accuracy.

Scenario 3: High Initial Investment and ROI Concerns

The Problem: The high initial investment required for purchasing a high-quality dynamometer can be a significant barrier for many B2B buyers, particularly in emerging markets such as Africa and the Middle East. Companies may hesitate to invest in such equipment due to concerns about achieving a satisfactory return on investment (ROI) and the ongoing operational costs associated with dynamometer testing.

The Solution: To address this concern, buyers should conduct a thorough cost-benefit analysis before making a purchase. This analysis should consider not only the upfront costs but also the potential savings in product development time and improved quality assurance. Exploring financing options, such as leasing or renting dynamometers, can also reduce the financial burden. Buyers should seek out manufacturers that offer comprehensive warranties and support packages, ensuring that they receive assistance in case of technical issues. Furthermore, companies can optimize their testing process by integrating dynamometer testing with other production workflows, thereby maximizing the utility of the equipment and enhancing overall efficiency.

Strategic Material Selection Guide for dynamometer test

What Are the Key Materials Used in Dynamometer Testing?

When selecting materials for dynamometer tests, understanding the properties, advantages, and limitations of each material is crucial. This analysis focuses on four common materials: aluminum, stainless steel, high-strength polymers, and carbon fiber composites. Each material has unique characteristics that can significantly impact the performance and suitability of dynamometers in various applications.

How Does Aluminum Perform in Dynamometer Tests?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. Its typical use case in dynamometer testing includes components like housings and frames.

Key Properties: Aluminum can withstand moderate temperatures and pressures, making it suitable for many testing environments. It is also resistant to rust and corrosion, which is essential for maintaining the integrity of the dynamometer.

Pros & Cons: The primary advantage of aluminum is its low weight, which facilitates easier handling and installation. However, its lower tensile strength compared to steel can limit its use in high-stress applications. Additionally, aluminum can be more expensive than other metals, depending on the alloy used.

Impact on Application: Aluminum’s compatibility with various media is generally favorable, but care must be taken in high-temperature applications to prevent deformation.

Considerations for International Buyers: For buyers in regions like Africa and the Middle East, compliance with local standards such as ASTM and DIN is essential. Aluminum is widely accepted and often preferred for its lightweight properties.

What Role Does Stainless Steel Play in Dynamometer Testing?

Stainless steel is another popular choice for dynamometer components, particularly in environments requiring high strength and corrosion resistance.

Key Properties: With a high-temperature rating and excellent resistance to rust and oxidation, stainless steel is ideal for demanding applications. It can handle significant pressure, making it suitable for high-performance tests.

Pros & Cons: The durability of stainless steel is a significant advantage, ensuring long-term performance. However, it is heavier than aluminum and can be more expensive. Manufacturing complexity can also increase due to the need for specialized tools for cutting and shaping.

Impact on Application: Stainless steel’s compatibility with various fluids and gases makes it versatile. However, it may not be suitable for applications involving highly corrosive substances without additional protective coatings.

Considerations for International Buyers: Buyers from Europe and South America should ensure that the stainless steel grades used comply with international standards, as variations in composition can affect performance.

How Do High-Strength Polymers Benefit Dynamometer Testing?

High-strength polymers, such as polycarbonate and nylon, are increasingly used in dynamometer applications due to their lightweight and durable nature.

Key Properties: These materials can withstand a range of temperatures and pressures, depending on the specific polymer used. They also offer excellent chemical resistance.

Pros & Cons: The main advantage of high-strength polymers is their low weight and ease of manufacturing, which can reduce costs. However, they may not perform well under extreme temperatures or high-pressure conditions.

Impact on Application: Polymers are often used in non-structural components of dynamometers, such as housings or protective casings, where weight reduction is critical.

Considerations for International Buyers: Compliance with local regulations regarding the use of polymers in industrial applications is essential, especially in regions with stringent environmental laws.

Why Are Carbon Fiber Composites Gaining Popularity in Dynamometer Testing?

Carbon fiber composites are known for their exceptional strength-to-weight ratio and stiffness, making them ideal for high-performance dynamometer applications.

Key Properties: These composites can withstand high temperatures and pressures, making them suitable for rigorous testing environments. They also exhibit excellent fatigue resistance.

Pros & Cons: The primary advantage of carbon fiber is its lightweight nature combined with high strength, which can enhance the overall performance of the dynamometer. However, they are significantly more expensive than metals and require specialized manufacturing processes.

Impact on Application: Carbon fiber composites are particularly beneficial in applications where reducing weight is crucial, such as in automotive and aerospace testing.

Considerations for International Buyers: Buyers in regions like the UAE and Egypt should be aware of the higher costs associated with carbon fiber and ensure that their suppliers can meet quality standards.

Summary Table of Material Selection for Dynamometer Tests

| Material | Typical Use Case for dynamometer test | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and frames | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Stainless Steel | Structural components | High strength and durability | Heavier and more expensive | High |

| High-Strength Polymers | Non-structural components | Low weight and cost-effective | Limited high-temperature performance | Low |

| Carbon Fiber Composites | High-performance applications | Exceptional strength-to-weight ratio | High cost and manufacturing complexity | High |

This comprehensive analysis of material selection for dynamometer tests provides international B2B buyers with actionable insights to make informed decisions tailored to their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for dynamometer test

What Are the Key Stages in the Manufacturing Process of Dynamometers?

The manufacturing of dynamometers involves several critical stages that ensure the final product meets the required performance specifications. These stages include material preparation, forming, assembly, and finishing.

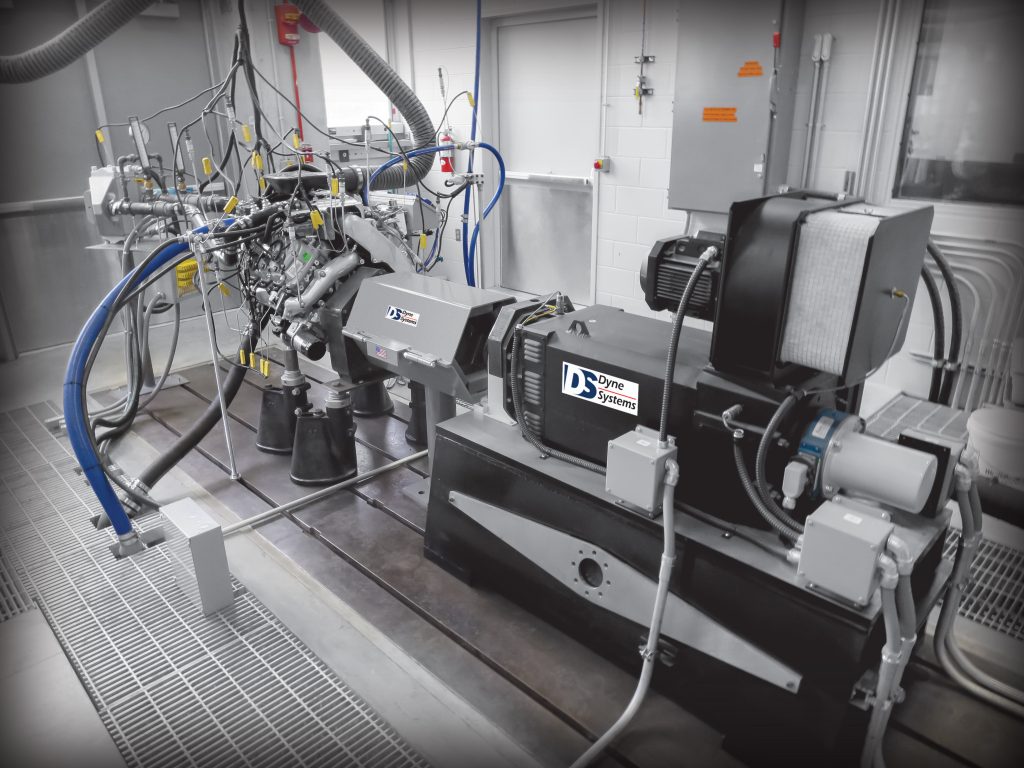

A stock image related to dynamometer test.

Material Preparation: What Materials Are Used in Dynamometer Manufacturing?

The first step in dynamometer manufacturing is the selection and preparation of materials. High-quality metals such as aluminum, steel, and specialized alloys are often used for their strength and durability. The materials undergo various treatments to enhance their mechanical properties, such as heat treatment and surface hardening.

Moreover, electronic components, such as sensors and microcontrollers, are sourced from reputable suppliers to ensure accuracy and reliability in measurements. Proper documentation and traceability of materials are crucial at this stage to comply with international quality standards.

How Is the Forming Process Executed for High-Precision Dynamometers?

Once the materials are prepared, they are subjected to forming processes such as machining, casting, or forging. Machining involves cutting and shaping the materials to create specific geometries needed for the dynamometer’s components.

Casting can also be utilized for complex shapes, while forging is preferred for components that require enhanced strength. Precision in forming is essential, as it directly impacts the dynamometer’s performance and accuracy.

What Does the Assembly Process Entail for Dynamometers?

A stock image related to dynamometer test.

The assembly stage involves bringing together all the components, including mechanical parts and electronic systems. A cleanroom environment is often maintained to prevent contamination during assembly.

Skilled technicians follow detailed assembly instructions, ensuring that each component is fitted correctly. This stage often incorporates automated tools for precision and efficiency, especially in high-volume manufacturing. Quality control checkpoints are established throughout the assembly process to catch defects early.

How Is the Finishing Process Important for the Performance of Dynamometers?

The finishing process includes surface treatments such as anodizing, painting, or coating to enhance corrosion resistance and aesthetic appeal. Calibration of the dynamometer is also part of this stage, where instruments are adjusted to ensure accurate readings.

This is crucial for B2B buyers, as the performance of the dynamometer will significantly affect their applications, whether in automotive testing, industrial machinery, or other uses.

What Are the Quality Assurance Processes for Dynamometers?

Quality assurance (QA) is a critical aspect of dynamometer manufacturing, ensuring that products meet both international and industry-specific standards.

Which International Standards Should B2B Buyers Consider When Evaluating Dynamometer Suppliers?

B2B buyers should look for suppliers that adhere to international quality standards such as ISO 9001, which outlines quality management systems. Compliance with ISO standards indicates a commitment to consistent quality and continuous improvement.

In addition to ISO, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications are essential. These certifications assure buyers of the product’s safety and performance in its intended application.

What Are the Key Quality Control Checkpoints in Dynamometer Manufacturing?

Quality control (QC) in dynamometer manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage focuses on inspecting raw materials and components upon arrival at the manufacturing facility. It ensures that all materials meet the required specifications before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to monitor production quality. This includes checking for dimensional accuracy and compliance with design specifications.

-

Final Quality Control (FQC): After assembly, the completed dynamometers undergo rigorous testing to verify functionality and performance. This includes calibration tests and stress testing to ensure reliability under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

What Methods Can Buyers Use to Ensure Supplier Compliance with Quality Standards?

B2B buyers from Africa, South America, the Middle East, and Europe can verify supplier QC practices through several methods:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control systems in place. This provides a comprehensive view of the supplier’s commitment to quality.

-

Reviewing Quality Reports: Suppliers should provide detailed QC reports, including data from IQC, IPQC, and FQC stages. Buyers should request these reports to assess the supplier’s track record of meeting quality standards.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of the supplier’s manufacturing processes and quality assurance practices. This can be particularly useful for buyers unfamiliar with local suppliers.

What Are the Specific QC and Certification Nuances for International Buyers?

International B2B buyers must be aware of specific nuances when dealing with suppliers across different regions. For example, in the UAE and Egypt, local regulations may require additional certifications or compliance with regional standards that differ from international ones.

Buyers should also consider the logistics of quality assurance, including the impact of shipping and handling on product integrity. Ensuring that suppliers have robust packaging and handling processes can mitigate risks associated with international transport.

Conclusion: How Can Buyers Leverage Quality Assurance for Better Procurement Decisions?

Understanding the manufacturing processes and quality assurance protocols for dynamometers is essential for international B2B buyers. By focusing on the stages of manufacturing, adhering to quality standards, and verifying supplier practices, buyers can make informed procurement decisions that enhance operational efficiency and product reliability.

Investing time in evaluating suppliers based on these criteria not only safeguards against potential quality issues but also fosters long-term partnerships built on trust and performance excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dynamometer test’

In the evolving landscape of industrial testing and measurement, acquiring a dynamometer for testing purposes requires careful planning and execution. This guide aims to provide international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, with a practical checklist to ensure a successful sourcing experience.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for identifying the right dynamometer for your testing needs. Consider factors such as the type of measurement required (e.g., torque, power), the operating environment, and the capacity of the machine under test. Additionally, determine if you need an engine dynamometer, a chassis dynamometer, or a universal dynamometer to accommodate various testing scenarios.

Step 2: Research Supplier Options

Conduct thorough research on potential suppliers that specialize in dynamometer testing equipment. Look for companies with a solid reputation in the industry, especially those that have experience working with clients in your geographical region. Utilize online platforms, industry forums, and trade shows to gather information about their product offerings and customer feedback.

Step 3: Verify Supplier Certifications

It’s essential to ensure that the suppliers you consider are certified and comply with international testing standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Additionally, inquire about specific certifications related to dynamometer testing to ensure that the equipment meets the required safety and performance standards.

Step 4: Evaluate Potential Suppliers

Before committing to a purchase, vet suppliers thoroughly. Request company profiles, case studies, and references from other buyers in similar industries or regions. Assess their customer service responsiveness and their ability to provide support during and after the purchase. This diligence will help you avoid potential pitfalls down the line.

Step 5: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals that outline pricing, delivery timelines, and warranty conditions. Compare these proposals not just on cost but on the value they offer, including after-sales support and maintenance services. Ensure that all aspects of the dynamometer test you need are covered in the proposal.

Step 6: Conduct a Site Visit

If feasible, arrange a site visit to the supplier’s facility to see the dynamometers in action. This firsthand experience allows you to evaluate the equipment’s performance, understand the manufacturing process, and meet the team behind the product. It’s also an opportunity to clarify any doubts regarding the specifications and functionality of the dynamometers.

Step 7: Finalize the Purchase Agreement

Before finalizing the purchase, review all contractual terms carefully. Ensure that the agreement includes clear terms regarding delivery, installation, training, and warranty. It’s wise to negotiate terms that allow for future upgrades or additional services, especially if your testing needs evolve over time.

Following this checklist will empower B2B buyers to make informed decisions when sourcing dynamometer testing equipment, ultimately enhancing their operational capabilities and ensuring compliance with testing standards.

Comprehensive Cost and Pricing Analysis for dynamometer test Sourcing

What Are the Key Cost Components for Dynamometer Testing?

When sourcing dynamometer testing services, understanding the cost structure is crucial. The primary components that contribute to the overall cost include:

-

Materials: The quality and type of materials used in the dynamometer can significantly affect pricing. High-precision components often come at a premium but ensure accurate measurements.

-

Labor: Skilled technicians are required to operate dynamometers, analyze data, and maintain equipment. Labor costs can vary based on location and the expertise of the workforce.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and administrative expenses. A well-managed facility can minimize these costs, but they still play a critical role in pricing.

-

Tooling: Depending on the specifications, specialized tools may be necessary to ensure precise measurements. Tooling costs can escalate if customization is required.

-

Quality Control (QC): Implementing robust QC measures ensures that the results are reliable. However, this can add to the overall cost, especially if third-party certifications are needed.

-

Logistics: Transportation of equipment, especially for international buyers, can incur significant costs. It’s essential to consider the shipping methods and distances involved.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely based on market competition and demand.

How Do Price Influencers Impact Dynamometer Testing Costs?

Several factors can influence the pricing of dynamometer testing services:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually benefit from economies of scale, allowing for reduced per-unit costs. Understanding the supplier’s MOQ can help in negotiating better pricing.

-

Specifications and Customization: Custom requirements can drive up costs. Be clear about your needs to avoid unnecessary expenses. Custom dynamometers or tests may require additional time and resources.

-

Materials Used: The choice of materials affects not only the initial cost but also the longevity and accuracy of the tests. High-quality materials may incur higher upfront costs but can lead to savings in the long term.

-

Quality and Certifications: Suppliers with recognized certifications may charge more due to their proven track record and reliability. While it may seem costlier upfront, investing in certified services can reduce risks.

-

Supplier Factors: The reputation and reliability of the supplier can also affect costs. Established suppliers may charge higher prices but often provide better service and support.

-

Incoterms: Understanding international shipping terms is critical. Costs can fluctuate based on who bears the shipping risk and responsibility. Buyers should negotiate terms that minimize their exposure to unforeseen costs.

What Buyer Tips Can Help Negotiate Better Pricing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies to ensure cost-effective sourcing:

-

Negotiate Terms: Always discuss pricing and terms before finalizing agreements. Leverage your understanding of the market to negotiate better deals.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as maintenance, downtime, and reliability in your calculations.

-

Understand Pricing Nuances: Be aware of market trends and seasonal fluctuations in pricing. This knowledge can provide leverage during negotiations.

-

Establish Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing, more favorable terms, and priority service in the future.

-

Conduct Thorough Research: Investigate multiple suppliers and their offerings. Comparing quotes and services can help you identify the best value for your specific needs.

Conclusion

While this overview provides a foundational understanding of the cost and pricing structure for dynamometer testing, it is essential for buyers to conduct thorough due diligence and tailor their sourcing strategies to their specific market conditions and needs. Always consider the indicative nature of prices and the potential for fluctuations based on global economic conditions.

Alternatives Analysis: Comparing dynamometer test With Other Solutions

Introduction to Alternative Testing Solutions for Dynamometers

When assessing the performance of engines, motors, or other mechanical systems, the dynamometer test stands out as a reliable method. However, various alternative solutions exist that may cater to specific testing needs, operational budgets, or application contexts. Understanding these alternatives enables B2B buyers to make informed decisions based on performance, cost, and practicality.

Comparison Table of Dynamometer Test and Alternatives

| Comparison Aspect | Dynamometer Test | Load Cell Testing | Torque Wrench Testing |

|---|---|---|---|

| Performance | High accuracy in measuring torque and power | Good for static weight measurement, less dynamic | Accurate for torque measurements but limited to static conditions |

| Cost | High initial investment and maintenance costs | Moderate; lower cost for basic models | Low; affordable and widely available |

| Ease of Implementation | Requires specialized setup and calibration | Relatively easy; minimal setup needed | Simple to use; requires training for accurate torque application |

| Maintenance | Regular calibration and upkeep required | Low maintenance; periodic checks recommended | Minimal maintenance; depends on usage |

| Best Use Case | Engine performance testing, research and development | Weighing applications, structural analysis | Assembly processes, automotive applications |

What Are the Advantages and Disadvantages of Load Cell Testing?

Load cell testing employs sensors to measure the weight and force applied to an object, providing a useful alternative for static load applications. Its primary advantage is its moderate cost and ease of implementation, making it accessible for smaller businesses or projects with limited budgets. However, load cell testing may not be suitable for dynamic testing scenarios, such as measuring torque and power in engines. Additionally, while it provides good accuracy, the technology does not capture the performance metrics of moving components as effectively as a dynamometer.

How Does Torque Wrench Testing Compare?

Torque wrench testing is another alternative that focuses on measuring the torque applied during assembly processes. This method is particularly advantageous in automotive and industrial applications where precise torque specifications are crucial. Its affordability and simplicity make it attractive for businesses looking to ensure quality control in production. However, it is limited to static measurements and does not provide insights into the dynamic performance of engines or motors. Thus, while it is effective for specific applications, it does not replace the comprehensive capabilities of dynamometer testing.

Conclusion: Choosing the Right Solution for Your Needs

For international B2B buyers, selecting the right testing solution hinges on understanding the specific requirements of their applications. If dynamic performance and detailed analysis are paramount, the dynamometer test is likely the best choice despite its higher cost and complexity. Conversely, for businesses focused on static measurements or those with budget constraints, load cell or torque wrench testing may offer sufficient functionality. Evaluating the performance needs, cost considerations, and ease of implementation will guide buyers in making a strategic decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for dynamometer test

What Are the Essential Technical Properties of Dynamometer Tests?

When considering dynamometer tests, several technical properties are critical for ensuring accurate and reliable measurements. Understanding these properties not only helps in selecting the right equipment but also aids in negotiating contracts and ensuring compliance with industry standards.

A stock image related to dynamometer test.

1. Measurement Range

The measurement range indicates the minimum and maximum values that the dynamometer can accurately measure. For instance, a dynamometer with a torque range of 0 to 500 Nm (Newton-meters) is suitable for testing medium-sized engines. B2B buyers must assess the measurement range to ensure it aligns with their specific testing requirements, as using a dynamometer outside its range can lead to inaccurate results or equipment damage.

2. Accuracy and Calibration

Accuracy refers to the degree to which the measurement of torque or power reflects the true value. Calibration is the process of adjusting the dynamometer to ensure its measurements are correct. A high-accuracy dynamometer (for example, ±0.5% of full scale) is crucial for applications requiring precision, such as automotive testing. Regular calibration is essential for maintaining accuracy, which can influence product quality and compliance with regulations in various industries.

3. Load Capacity

Load capacity defines the maximum load that the dynamometer can handle without failure. This specification is vital for B2B buyers, as selecting a dynamometer with insufficient load capacity can result in operational failures and costly downtime. Buyers should evaluate the load requirements of their applications and select a dynamometer that exceeds these requirements to ensure durability and reliability.

4. Type of Dynamometer

There are different types of dynamometers, including engine dynamometers, chassis dynamometers, and absorption dynamometers. Each type serves a specific purpose, such as measuring engine output or simulating road conditions. Understanding the type needed for specific applications allows buyers to make informed decisions, ensuring they acquire equipment that meets their testing needs.

5. Data Output and Connectivity

The data output capability of a dynamometer refers to how it reports measurements, including analog or digital formats. Connectivity options, such as USB or wireless interfaces, allow for integration with data analysis software. This feature is increasingly important for businesses looking to streamline their testing processes and enhance data accuracy. Buyers should consider how data will be used in their operations when selecting a dynamometer.

What Are Common Trade Terms Related to Dynamometer Tests?

Familiarity with industry terminology can enhance communication and negotiation processes in B2B transactions. Here are key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of dynamometer tests, it’s crucial to understand whether you’re buying from an OEM or a third-party supplier, as this can affect warranty, service, and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, especially for businesses in regions like Africa or South America, where import costs can be significant. It helps in planning purchases and ensuring that you do not overcommit financially.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. For international B2B buyers, submitting RFQs can facilitate better pricing negotiations and help assess multiple suppliers before making a decision. It’s an essential step in the procurement process, ensuring transparency and competitiveness.

4. Incoterms (International Commercial Terms)

Incoterms are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to manage shipping costs, delivery timelines, and liability during transport.

5. Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension or measurement. In dynamometer testing, knowing the tolerance levels is critical for ensuring that the test results meet industry standards and specifications. This knowledge aids in quality control and helps prevent costly errors.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when procuring dynamometer tests and equipment, ultimately enhancing your operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the dynamometer test Sector

What Are the Current Market Dynamics and Key Trends in the Dynamometer Test Sector?

The dynamometer test sector is witnessing significant growth driven by technological advancements and increasing demand across various industries, including automotive, aerospace, and manufacturing. A notable trend is the rise of digital dynamometers, which offer enhanced data accuracy and ease of integration with IoT systems, allowing for real-time monitoring and analytics. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider investing in these advanced technologies to remain competitive.

Moreover, the global push for electrification in the automotive sector is influencing dynamometer testing. Electric vehicles (EVs) require specialized testing equipment to measure torque and power output effectively, thereby creating a niche market for dynamometers tailored to EV applications. This shift is particularly relevant for buyers in regions like the UAE, where EV adoption is rapidly increasing.

Another critical trend is the emphasis on customized solutions. Buyers are seeking suppliers that can offer tailored dynamometer systems to meet specific testing requirements, improving operational efficiency. Furthermore, the growing importance of compliance with international quality standards means that B2B buyers should prioritize suppliers that adhere to ISO certifications and offer reliable calibration services.

How Does Sustainability and Ethical Sourcing Impact the Dynamometer Test Sector?

Sustainability is becoming a paramount concern in the dynamometer test sector. The environmental impact of manufacturing processes and the lifecycle of testing equipment is under scrutiny. B2B buyers are encouraged to prioritize suppliers who demonstrate a commitment to sustainable practices, such as using eco-friendly materials and minimizing waste during production.

Ethical sourcing is equally important. Buyers should seek suppliers that maintain transparent supply chains and ensure fair labor practices. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility can serve as indicators of a supplier’s commitment to sustainability and ethics.

Moreover, the demand for ‘green’ materials is on the rise. Buyers can enhance their brand reputation by collaborating with suppliers that utilize recyclable components in their dynamometer testing equipment. This not only contributes to environmental conservation but also meets the growing consumer demand for sustainable products.

What Is the Brief Evolution of Dynamometer Technology and Its Relevance to B2B Buyers?

The evolution of dynamometer technology has seen significant advancements since its inception in the late 19th century. Initially used primarily in automotive testing, modern dynamometers now serve a diverse range of industries, including aerospace and manufacturing. Early models were mechanical, relying on simple principles of torque measurement, while today’s dynamometers are highly sophisticated, incorporating digital technology for precise measurements and data analytics.

For B2B buyers, understanding this evolution is crucial as it highlights the ongoing innovation in the sector. The transition from analog to digital systems not only improves measurement accuracy but also enhances the ability to analyze performance data, leading to better decision-making in product development and quality assurance. Buyers should look for suppliers that offer the latest technology, ensuring they remain at the forefront of industry standards and competitive practices.

Frequently Asked Questions (FAQs) for B2B Buyers of dynamometer test

-

How do I choose the right dynamometer for my testing needs?

Selecting the appropriate dynamometer depends on your specific testing requirements, such as the type of machine being tested (engine, motor, or other mechanical systems) and the parameters you need to measure (torque, power, or force). Consider whether you need a passive, active, or universal dynamometer. Additionally, evaluate the dynamometer’s capacity, accuracy, and compatibility with your existing equipment. Consulting with suppliers who can offer customization options based on your unique needs is also advisable. -

What types of dynamometers are available for purchase?

Dynamometers can be categorized into several types: engine dynamometers, chassis dynamometers, and absorption dynamometers, among others. Engine dynamometers measure the power output of an engine, while chassis dynamometers assess the overall performance of a vehicle. Each type serves different testing purposes, so it is crucial to identify which one aligns with your operational goals. Ensure your supplier provides detailed specifications and use cases for the dynamometers they offer. -

What are the typical lead times for acquiring a dynamometer?

Lead times for dynamometer procurement can vary significantly based on the manufacturer, complexity of the system, and whether customization is required. Standard models may have a lead time of 4-6 weeks, whereas customized or high-capacity models could take up to 12 weeks or longer. It’s essential to discuss timelines upfront with your supplier to avoid delays in your testing schedule. Always confirm shipping options and any potential logistical challenges specific to your region. -

What are the minimum order quantities (MOQs) for dynamometer tests?

Minimum order quantities can differ based on the supplier and the specific dynamometer model you are interested in. Generally, established manufacturers may have MOQs ranging from one unit for standard models to larger quantities for bulk orders. It’s advisable to communicate your needs clearly to the supplier to negotiate favorable terms, especially if you are a smaller business or a new buyer in the market. -

How do I ensure quality assurance when sourcing dynamometers internationally?

To ensure quality assurance, request documentation such as ISO certifications and test reports from potential suppliers. Conduct thorough supplier vetting by checking customer reviews, references, and case studies. Additionally, consider requesting a sample or a demonstration of the dynamometer before making a significant purchase. Establishing a clear quality control protocol and communication plan with your supplier can also help mitigate risks associated with international trade. -

What payment terms should I expect when purchasing dynamometers?

Payment terms for dynamometer purchases can vary widely based on the supplier’s policies and your negotiation. Common options include full payment upfront, a deposit with the balance due upon delivery, or net 30-90 day terms. Discussing payment methods, including wire transfers, letters of credit, or escrow services, can also provide additional security. Be sure to clarify any import duties or taxes that may apply when shipping to your location. -

What logistics considerations should I keep in mind when importing dynamometers?

When importing dynamometers, consider factors such as shipping methods, customs regulations, and potential tariffs specific to your country. It’s essential to work with a logistics provider experienced in handling industrial equipment to ensure smooth transit. Additionally, verify that the dynamometer is appropriately packed to prevent damage during shipping. Understanding your country’s import requirements and ensuring compliance can help avoid unexpected delays or fees. -

Can dynamometers be customized to fit specific testing applications?

Yes, many manufacturers offer customization options for dynamometers to cater to unique testing applications. Custom features may include adjustments in measurement range, specific mounting configurations, or integration with software for data analysis. When discussing customization, provide detailed specifications of your testing needs to the supplier. Collaborating with the manufacturer during the design phase can also lead to a more effective and tailored solution for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dynamometer test

Why is Strategic Sourcing Essential for Dynamometer Testing?

In the realm of dynamometer testing, strategic sourcing is paramount for international B2B buyers. It not only enhances operational efficiency but also ensures the procurement of high-quality equipment tailored to specific testing needs. Buyers from Africa, South America, the Middle East, and Europe must focus on establishing partnerships with reliable suppliers who offer calibrated and versatile dynamometers. This collaboration can lead to improved measurement accuracy and compliance with international standards, ultimately driving better performance outcomes.

What Key Takeaways Should International Buyers Consider?

Investing in advanced dynamometer technology is a crucial step for businesses seeking to enhance their testing capabilities. By prioritizing suppliers that provide comprehensive support—such as calibration services, technical training, and ongoing maintenance—buyers can secure a competitive edge in their respective markets. Additionally, understanding local regulations and standards ensures that the equipment meets necessary compliance, reducing risks associated with non-conformance.

How Can Buyers Prepare for the Future of Dynamometer Testing?

Looking ahead, the dynamometer testing landscape is evolving with technological advancements and increasing demands for precision. International buyers should remain proactive by continuously evaluating their sourcing strategies, exploring innovations in testing methodologies, and engaging in sustainable practices. By doing so, they can position themselves to meet the challenges of tomorrow while enhancing their operational capabilities today. Embrace the future of dynamometer testing and leverage strategic sourcing to drive your business success.