Save Costs with Tape Roll: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for tape roll

Navigating the global market for tape rolls presents a unique set of challenges for international B2B buyers. With a plethora of options available, sourcing the right tape roll for packaging, shipping, or office use can be daunting. This guide addresses the complexities of selecting the appropriate type of tape, whether it be heavy-duty packing tape, transparent office tape, or specialty adhesive solutions. It covers critical aspects such as various tape types and their applications, supplier vetting processes, cost considerations, and sustainability factors.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe—particularly in countries such as Egypt and Australia—will find tailored insights that enhance their purchasing strategies. By understanding the nuances of the tape market, buyers can make informed decisions that align with their operational needs and budget constraints. This comprehensive guide not only empowers buyers to identify reliable suppliers and negotiate better terms but also highlights emerging trends in the adhesive industry, such as eco-friendly alternatives and innovative packaging solutions.

Equipped with this knowledge, businesses can streamline their procurement processes, ensuring they choose the right products that meet quality standards and operational demands. The objective is clear: to facilitate effective sourcing that drives efficiency and enhances competitive advantage in the global marketplace.

Understanding tape roll Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Packing Tape | Heavy-duty, strong adhesion, often clear or brown | Shipping, packaging, moving | Pros: Durable, secure seal; Cons: Can be difficult to tear by hand. |

| Masking Tape | Available in various colors, easy to tear, low adhesive | Painting, labeling, light-duty tasks | Pros: Easy to use, versatile; Cons: Not suitable for heavy-duty applications. |

| Duct Tape | Strong, fabric-reinforced, waterproof | Repairs, bundling, construction | Pros: Extremely durable; Cons: Not always aesthetically pleasing. |

| Double-Sided Tape | Adhesive on both sides, often thin and clear | Crafting, mounting, displays | Pros: Invisible finish, strong hold; Cons: Limited weight capacity. |

| Electrical Tape | Insulating properties, available in various colors | Electrical repairs, wire bundling | Pros: Good insulation, flexible; Cons: Not suitable for heavy-duty applications. |

What Are the Key Characteristics of Packing Tape for B2B Buyers?

Packing tape is a vital tool in logistics and shipping, designed to securely seal packages for transport. Typically made from polypropylene or polyester, it offers heavy-duty adhesion and durability, making it ideal for sealing boxes and cartons. When selecting packing tape, B2B buyers should consider the tape’s thickness, tensile strength, and whether it comes with a dispenser for ease of application. The ability to choose between clear and brown options can also affect branding and presentation.

How Does Masking Tape Suit Different Business Needs?

Masking tape is a versatile option widely used in various applications, from painting to labeling. Its easy-to-tear design and low adhesive quality make it suitable for temporary applications, ensuring clean lines during painting or easy removal without damage. For B2B buyers, the choice of color and width can enhance organizational tasks, while the tape’s ease of use can improve operational efficiency. However, it’s essential to note that masking tape is not recommended for heavy-duty tasks.

Why Choose Duct Tape for Industrial Applications?

Duct tape is renowned for its exceptional strength and versatility, making it a favorite in construction and repair industries. It is fabric-reinforced, waterproof, and available in various colors, allowing for both functional and aesthetic applications. For B2B buyers, duct tape is ideal for situations requiring a robust, reliable solution, such as bundling materials or making quick repairs. However, its appearance may not be suitable for all applications, particularly in customer-facing environments.

What Advantages Does Double-Sided Tape Offer for Businesses?

Double-sided tape is a specialized adhesive that features adhesive on both sides, providing a clean and invisible finish. This tape is commonly used in crafting, mounting pictures, and displays. B2B buyers should consider the tape’s thickness and adhesive strength when purchasing, as these factors influence its weight capacity. While double-sided tape offers aesthetic advantages, it may not hold up under heavy loads, making it crucial to match the tape type with the intended application.

When Should Electrical Tape Be Used in Business Settings?

Electrical tape is specifically designed for electrical applications, providing insulation and protection for wires and connections. Available in various colors, it allows for easy identification of wire types or phases. B2B buyers in industries like construction or maintenance should prioritize the tape’s insulation properties and flexibility. While effective for electrical tasks, it is important to note that electrical tape should not be used for heavy-duty applications, as it may not provide the necessary strength for such uses.

Key Industrial Applications of tape roll

| Industry/Sector | Specific Application of Tape Roll | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Shipping | Securing packages for transport | Ensures safe delivery and protects goods during transit | Consider tape strength, adhesive quality, and roll size |

| Construction & Renovation | Joining materials and surfaces | Provides reliable bonding for structural integrity | Evaluate durability, weather resistance, and ease of use |

| Manufacturing | Masking and surface protection during production | Protects surfaces from damage and ensures clean finishes | Look for specific tape types suited for various materials |

| Retail | Packaging and branding of products | Enhances product presentation and secures packaging | Assess print quality, tape design options, and eco-friendliness |

| Office Supplies | Organizing documents and materials | Improves efficiency in workspace and document management | Focus on tape visibility, strength, and compatibility with dispensers |

How is Tape Roll Used in Logistics & Shipping?

In the logistics and shipping sector, tape rolls are crucial for securing packages to prevent damage during transit. Heavy-duty packing tape provides a reliable seal, ensuring that boxes remain intact and that contents are protected from environmental factors. International B2B buyers should prioritize sourcing tapes that offer high adhesion and tear resistance, especially for long-distance shipments. Understanding local regulations regarding packaging materials can also inform sourcing decisions, particularly for buyers from Africa and South America.

What Role Does Tape Roll Play in Construction & Renovation?

In construction and renovation, tape rolls are used for joining materials, such as drywall or insulation, and for surface protection during painting or finishing. The right tape can enhance structural integrity and minimize waste, which is critical for project efficiency. Buyers should consider the tape’s durability, weather resistance, and ease of application, especially in regions with varying climates like the Middle East and Europe. Additionally, sourcing from manufacturers that provide detailed specifications can help ensure the right fit for specific projects.

How is Tape Roll Utilized in Manufacturing Processes?

Manufacturers use tape rolls for masking surfaces during painting or coating processes, ensuring clean lines and protecting non-target areas from overspray. This application is vital in maintaining product quality and reducing rework costs. B2B buyers should evaluate the tape’s compatibility with various substrates and its ability to withstand production conditions. Buyers from diverse regions, including Europe and the Middle East, should seek suppliers that offer tailored solutions for their manufacturing environments.

How Does Tape Roll Enhance Retail Packaging?

In retail, tape rolls are essential for securing packages and enhancing product branding. Custom-branded tape not only secures items but also serves as a marketing tool, reinforcing brand identity. Buyers should assess the print quality, design options, and eco-friendliness of the tape, as sustainability is becoming increasingly important in global markets, especially in Europe. Understanding customer preferences in packaging can help buyers select the most effective tape solutions.

What is the Importance of Tape Roll in Office Supplies?

In office environments, tape rolls are used to organize documents, secure packages for shipping, and perform various other tasks. Clear and strong tape helps maintain the professional appearance of documents and ensures they are protected from wear and tear. B2B buyers should focus on tape visibility, adhesive quality, and compatibility with dispensers to enhance workplace efficiency. Buyers in regions like Africa and South America may also want to consider local availability and pricing when sourcing these supplies.

3 Common User Pain Points for ‘tape roll’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Tape for Specific Applications

The Problem: B2B buyers often face confusion when selecting the appropriate tape roll for their specific packaging or sealing needs. With numerous options available—ranging from heavy-duty packaging tape to clear adhesive tape—buyers may struggle to determine which type will best meet their requirements. This can lead to using the wrong tape, resulting in poor adhesion, damaged goods, and increased shipping costs. For businesses in sectors like logistics, e-commerce, or manufacturing, the wrong tape choice can translate to significant operational inefficiencies.

The Solution: To overcome this challenge, buyers should conduct a thorough assessment of their specific needs before purchasing tape rolls. Start by evaluating the weight and type of items being packaged, as well as the environmental conditions they will face during transit (e.g., moisture, temperature fluctuations). For heavier items, consider using heavy-duty packing tape with a higher tensile strength and adhesive quality. Furthermore, leveraging product specifications from suppliers can help buyers match tape features—such as width, roll length, and adhesive type—to their specific use cases. Creating a standard operating procedure (SOP) for tape selection based on these criteria can streamline purchasing decisions and improve overall packaging effectiveness.

Scenario 2: Inconsistent Tape Quality from Different Suppliers

The Problem: Another prevalent issue among B2B buyers is the inconsistency in tape quality when sourcing from different suppliers. Variations in adhesive strength, durability, and ease of use can lead to frustrations during packing processes. For companies that rely on consistent packaging standards—like those in the retail or export sectors—this inconsistency can result in damaged shipments, increased returns, and ultimately, loss of customer trust.

The Solution: To ensure consistency in tape quality, B2B buyers should establish long-term relationships with reputable suppliers known for their reliable products. Conducting supplier audits and requesting product samples before committing to bulk purchases can provide valuable insights into the quality of the tape. Additionally, buyers should consider investing in branded or well-reviewed products from recognized manufacturers like 3M or Scotch. Implementing quality control measures, such as regular evaluations of tape performance during packaging operations, can further help in maintaining standards and ensuring that any issues are addressed promptly with suppliers.

Scenario 3: Inefficient Tape Application Processes Leading to Wasted Time

The Problem: Many businesses experience inefficiencies in their packing processes due to improper tape application techniques. Employees may spend excessive time trying to get tape to stick properly or may struggle with dispensing the tape, leading to wasted materials and labor costs. For companies with high-volume shipping needs, these inefficiencies can accumulate quickly, affecting overall productivity and profitability.

The Solution: To address these inefficiencies, businesses should invest in tape dispensers that are suited to their specific tape rolls. Automatic or handheld tape dispensers can significantly reduce application time and improve the accuracy of tape placement. Training staff on best practices for tape application—such as ensuring surfaces are clean and dry before application—can further enhance efficiency. Additionally, consider using pre-cut tape strips for certain applications to save time during the packing process. Regularly reviewing and optimizing packing workflows can help identify bottlenecks and further streamline operations, ultimately leading to cost savings and improved performance in shipping and logistics.

Strategic Material Selection Guide for tape roll

What Are the Key Materials Used in Tape Rolls?

When selecting tape rolls for various applications, the material used in their construction plays a crucial role in determining performance, durability, and suitability for specific tasks. Below are four common materials used in tape rolls, analyzed from a B2B perspective to provide actionable insights for international buyers.

How Does Polypropylene Impact Tape Performance?

Polypropylene is a widely used material for packing and shipping tape due to its excellent balance of strength and flexibility. It typically has a temperature rating of up to 80°C (176°F) and offers good resistance to moisture and chemicals, making it suitable for various environments.

Pros: Polypropylene tape is lightweight, cost-effective, and easy to handle. It adheres well to a variety of surfaces, including cardboard and plastic, making it ideal for packaging.

Cons: However, it may not perform well under extreme temperatures or heavy loads, which can lead to tape failure. Additionally, its UV resistance is limited, making it less suitable for outdoor applications.

International Considerations: For buyers in regions like Africa and the Middle East, where high temperatures are common, it is essential to ensure that the tape can withstand local climate conditions. Compliance with local standards, such as ASTM D-1974 for packaging, should also be verified.

What Are the Advantages of PVC in Tape Rolls?

Polyvinyl chloride (PVC) is another popular material used in tape manufacturing, particularly for electrical and safety applications. PVC tape can handle temperatures ranging from -10°C to 90°C (14°F to 194°F) and offers excellent insulation properties.

Pros: PVC tape is highly durable, resistant to abrasion, and provides good adhesion. Its versatility allows it to be used for both indoor and outdoor applications, making it a favorite among electrical contractors.

Cons: The primary drawback of PVC tape is its higher cost compared to polypropylene. Additionally, it can be less environmentally friendly due to the production process.

International Considerations: Buyers in Europe should be aware of regulations regarding the use of PVC, especially concerning environmental impact. Compliance with standards such as DIN EN 60454 is crucial for ensuring product acceptance in the market.

How Does Paper Tape Compare for Eco-Friendly Options?

Paper tape, often made from recycled materials, is gaining popularity due to its eco-friendly characteristics. It typically has a lower temperature resistance of around 60°C (140°F) but offers good adhesion for lightweight packaging.

Pros: The main advantage of paper tape is its biodegradability, making it an excellent choice for companies looking to enhance their sustainability profile. It also adheres well to surfaces without leaving a residue.

Cons: However, paper tape is less durable than plastic options and may not be suitable for heavy-duty applications or in environments with high humidity.

International Considerations: For businesses in South America and Africa, where sustainability is increasingly becoming a priority, using paper tape can enhance brand reputation. Compliance with local eco-labeling standards can further strengthen market positioning.

What Role Does Cloth Tape Play in Heavy-Duty Applications?

Cloth tape, often made from cotton or polyester, is designed for heavy-duty applications where high tensile strength is required. It can withstand temperatures up to 100°C (212°F) and provides excellent tear resistance.

Pros: The durability and strength of cloth tape make it ideal for industrial applications, such as bundling and securing heavy items. It also offers good resistance to moisture and chemicals.

Cons: The main limitation is its higher cost and the complexity of manufacturing, which can impact supply chain logistics.

International Considerations: Buyers in regions with stringent industrial standards, such as Europe, must ensure that cloth tape meets relevant regulations like JIS Z 1707 for adhesive tapes. Understanding local labor and environmental regulations can also impact sourcing decisions.

Summary Table of Tape Roll Materials

| Material | Typical Use Case for tape roll | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Packing and shipping | Lightweight and cost-effective | Limited UV resistance | Low |

| PVC | Electrical and safety applications | Excellent durability and insulation | Higher cost and environmental concerns | Medium |

| Paper | Eco-friendly packaging | Biodegradable and sustainable | Less durable for heavy-duty use | Low |

| Cloth | Heavy-duty industrial applications | High tensile strength | Higher cost and complex manufacturing | High |

This material selection guide provides a comprehensive understanding of the various tape roll materials available in the market, helping international B2B buyers make informed decisions tailored to their specific needs and regional considerations.

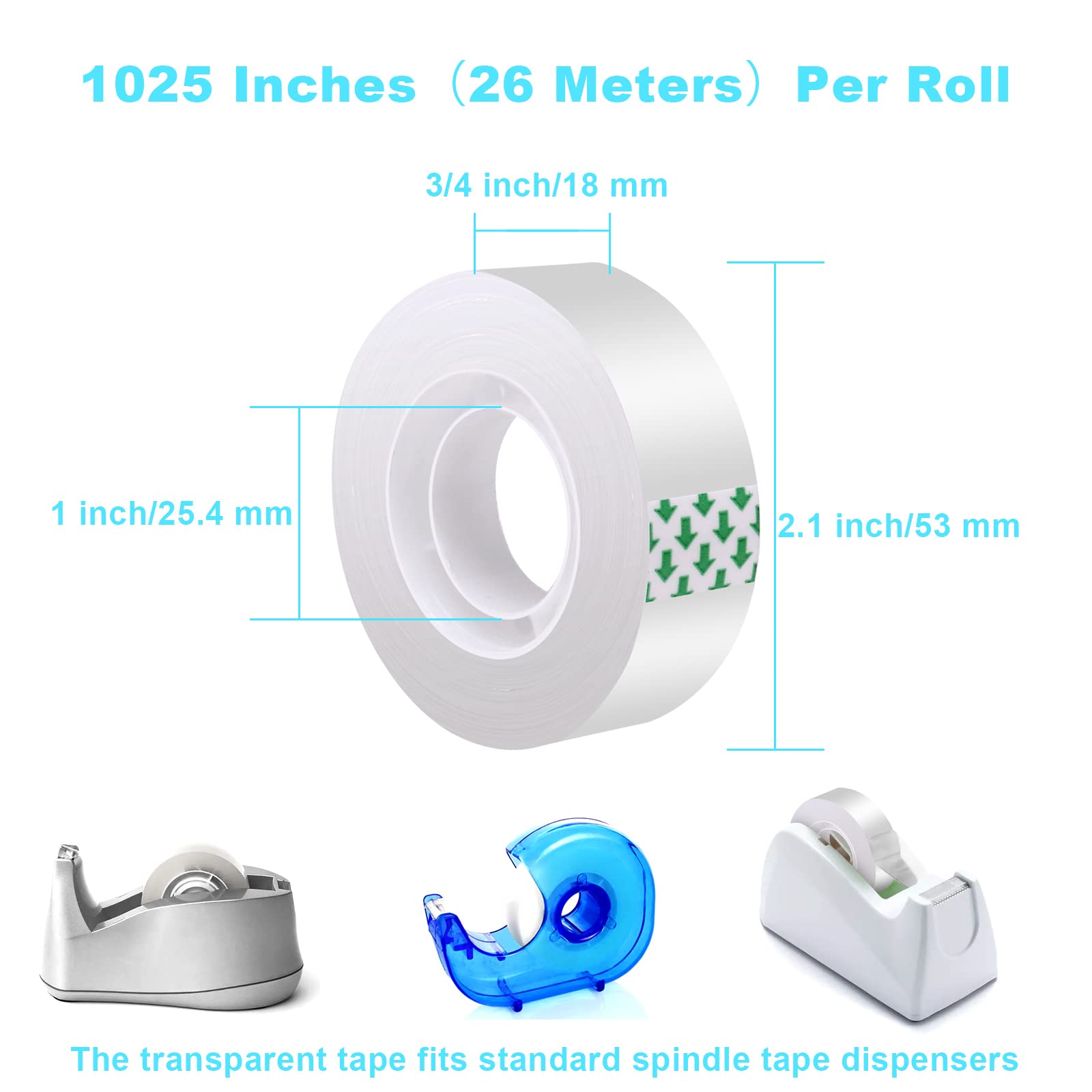

A stock image related to tape roll.

In-depth Look: Manufacturing Processes and Quality Assurance for tape roll

What Are the Main Stages in the Manufacturing Process of Tape Rolls?

The manufacturing process of tape rolls is a sophisticated operation that involves several crucial stages to ensure product quality and reliability. Understanding these stages can help B2B buyers from regions such as Africa, South America, the Middle East, and Europe make informed purchasing decisions.

Material Preparation: What Materials Are Used in Tape Roll Production?

The first stage in tape manufacturing is the preparation of raw materials. This typically includes selecting high-quality substrates such as plastic films (e.g., polypropylene or polyethylene) and adhesives (e.g., acrylic or rubber-based). The choice of materials significantly impacts the tape’s performance, durability, and adhesion properties. B2B buyers should inquire about the types of materials used, as they can affect the tape’s usability in specific applications, such as packaging or industrial use.

How Is the Forming Process Conducted in Tape Roll Production?

The forming stage involves the application of adhesive to the substrate. This can be achieved through various techniques, including:

- Coating: The adhesive is applied uniformly onto the substrate using methods like gravure or slot die coating.

- Lamination: For double-sided tapes, two adhesive layers may be applied to both sides of a substrate.

After the adhesive application, the substrate is cured to ensure proper bonding. This stage is critical as any inconsistencies can lead to product failure, resulting in significant costs for B2B buyers.

What Does the Assembly Process Involve for Tape Rolls?

Once the tape is formed, it goes through an assembly process where it is rolled onto cores. The rolls are then cut to specific lengths based on customer specifications. This stage may also involve the addition of dispensers or packaging. Buyers should confirm the availability of custom sizes and packaging options to meet their specific needs.

What Finishing Techniques Are Used in Tape Manufacturing?

Finishing techniques enhance the tape’s usability and aesthetic appeal. Common finishing processes include:

- Trimming: Ensuring that the edges are smooth and consistent.

- Labeling: Providing important product information and branding.

- Quality Testing: Preliminary checks are conducted to ensure the tape meets specifications.

B2B buyers should request details on available finishes and customizations to align with their branding requirements.

How Is Quality Assurance Implemented in Tape Manufacturing?

Quality assurance (QA) is a critical aspect of tape roll production, ensuring that the final product meets international standards and customer expectations.

Which International Standards Are Relevant for Tape Quality Assurance?

Many manufacturers comply with international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (for European markets) or API (for certain industrial applications) may apply. B2B buyers should verify that suppliers possess these certifications, as they reflect a commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Tape Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and correct defects in real time.

- Final Quality Control (FQC): Comprehensive testing of finished products before they are shipped. This may include adhesion tests, tensile strength tests, and roll length checks.

B2B buyers should ask for detailed QC reports from suppliers to understand how these checkpoints are implemented.

What Common Testing Methods Are Used to Ensure Tape Quality?

Testing methods can vary, but common techniques include:

- Peel Adhesion Tests: Evaluating the tape’s ability to adhere to different surfaces.

- Tensile Strength Tests: Measuring how much force the tape can withstand before breaking.

- Environmental Testing: Assessing the tape’s performance under various temperature and humidity conditions.

By understanding these methods, B2B buyers can better assess the quality of the tape they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Verifying a supplier’s quality control measures is crucial for mitigating risks associated with product failures. Here are some effective methods:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should look for:

- Documentation: Ensure suppliers maintain detailed records of their QC processes.

- Certifications: Confirm that suppliers are certified under relevant quality standards.

- On-Site Visits: Whenever possible, visit manufacturing facilities to observe processes firsthand.

How Can Third-Party Inspections Aid in Quality Assurance?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct audits and product tests to verify compliance with quality standards. B2B buyers should consider this option, especially when sourcing from new or international suppliers.

What Nuances Should International B2B Buyers Consider Regarding Quality Certification?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding regional certification requirements is vital. Different countries may have specific regulations governing product safety and quality. Buyers should:

- Research Local Regulations: Familiarize themselves with local standards that may impact the use of tape products.

- Communicate with Suppliers: Discuss any specific compliance requirements that may be necessary for their region.

- Evaluate Supply Chain Risks: Assess how geopolitical factors may affect the reliability of suppliers and their adherence to quality standards.

By focusing on these aspects, B2B buyers can make more informed decisions when sourcing tape rolls, ensuring they select suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tape roll’

The following guide provides a practical checklist for international B2B buyers looking to procure tape rolls. This step-by-step approach ensures that you make informed decisions throughout the sourcing process, ultimately leading to successful procurement.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for the tape rolls you need is crucial. This includes determining the type of tape (e.g., packing, masking, or duct tape), dimensions (width and length), and material properties (e.g., heavy-duty or eco-friendly). This clarity helps in narrowing down potential suppliers who can meet your specific needs.

- Consider the application: Different applications may require different adhesive properties or durability levels.

- Include regulatory standards: Ensure your specifications align with any industry-specific standards relevant to your region.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers who specialize in tape rolls. Look for manufacturers and distributors with a solid reputation in your target markets, including Africa, South America, the Middle East, and Europe. Supplier credibility can significantly influence the quality and reliability of your procurement.

- Utilize trade platforms: Websites like Alibaba or industry-specific directories can provide valuable insights into various suppliers.

- Check online reviews: Seek feedback from other B2B buyers to gauge supplier performance and product quality.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. Certifications such as ISO 9001 can indicate a commitment to quality management, while environmental certifications (e.g., FSC, EcoLabel) can be important for sustainability-conscious buyers.

- Request documentation: Suppliers should be able to provide proof of certifications upon request.

- Consider local regulations: Ensure that suppliers are compliant with the regulations of the regions where you operate.

Step 4: Request Samples

Before placing a bulk order, always request samples of the tape rolls. Testing samples allows you to evaluate the product’s performance in real-world applications, ensuring that it meets your expectations in terms of adhesion, durability, and ease of use.

- Conduct practical tests: Use the samples in your intended applications to assess their effectiveness.

- Evaluate packaging: Ensure that the packaging meets your shipping and storage requirements.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. Establishing clear terms can help prevent misunderstandings and ensure a smooth procurement process.

- Discuss bulk discounts: Many suppliers offer lower prices for larger orders, so inquire about potential savings.

- Clarify payment methods: Ensure the payment terms align with your financial processes to avoid delays.

Step 6: Finalize the Order and Monitor Delivery

After agreeing on terms, finalize the order and maintain communication with the supplier regarding delivery schedules. Monitoring the shipment can help you address any potential issues proactively, such as delays or discrepancies.

- Use tracking systems: Request tracking information to monitor the shipment’s progress.

- Prepare for receipt: Ensure your receiving department is ready for the incoming shipment, including any necessary documentation.

Step 7: Review Supplier Performance Post-Delivery

After receiving the tape rolls, evaluate the supplier’s performance based on product quality, delivery time, and service. This assessment is essential for future procurement decisions and building long-term relationships with reliable suppliers.

- Gather feedback from users: Collect insights from your team regarding the tape’s performance.

- Document any issues: Keep records of any problems encountered to inform future negotiations or supplier selections.

Following this checklist will help you streamline your procurement process for tape rolls, ensuring that you choose the right suppliers and products for your business needs.

Comprehensive Cost and Pricing Analysis for tape roll Sourcing

What Are the Key Cost Components in Tape Roll Manufacturing?

Understanding the cost structure of tape rolls is essential for international B2B buyers. The primary components include:

-

Materials: The type of adhesive, backing material (plastic, paper, etc.), and additional features (such as UV resistance) significantly influence costs. High-quality materials may lead to higher initial pricing but can reduce long-term costs through durability.

-

Labor: Labor costs vary based on the manufacturing region. For buyers in Africa or South America, sourcing from local manufacturers may lower costs due to reduced labor expenses compared to Europe or the Middle East, where labor costs are typically higher.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Efficient manufacturing processes can minimize overhead, impacting the final price.

-

Tooling: The initial investment in machinery and tools affects the cost of production. Custom tooling for specialized tape rolls may increase upfront costs but can lead to cost efficiencies in large production runs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can add to manufacturing costs. Buyers should assess whether the quality certifications (ISO, ASTM) justify the additional expense.

A stock image related to tape roll.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors like distance, shipping method, and customs duties can significantly affect the final price.

-

Margin: Suppliers will include their desired profit margin in the final pricing. Understanding the competitive landscape can help buyers negotiate better terms.

How Do Price Influencers Affect Tape Roll Sourcing?

Several factors influence the pricing of tape rolls that international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Buyers should evaluate their needs and negotiate MOQs to optimize costs.

-

Specifications and Customization: Custom tape rolls with specific features or branding may incur additional charges. Buyers should balance the need for customization against potential cost increases.

-

Materials and Quality Certifications: The choice of materials and certifications can significantly affect pricing. Buyers in Europe may prioritize eco-friendly materials, while those in the Middle East might focus on durability.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge a premium for their guarantees of quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. They define responsibilities for shipping, insurance, and tariffs, impacting the total landed cost of products.

What Buyer Tips Can Help Optimize Tape Roll Costs?

B2B buyers can employ several strategies to maximize cost-efficiency:

-

Negotiation Techniques: Engaging in transparent discussions with suppliers about pricing and terms can yield better deals. Highlighting long-term relationships may encourage suppliers to offer more favorable pricing.

-

Total Cost of Ownership (TCO): Consider the total cost, including purchase price, shipping, storage, and disposal. A lower purchase price does not always equate to a better deal if the product’s quality leads to higher operational costs.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, tariffs, and local market conditions that can impact pricing. Building relationships with local agents or distributors can provide insights into these dynamics.

-

Research and Comparison: Leverage online resources to compare prices across multiple suppliers. Platforms like Home Depot, Walmart, and Staples offer varying pricing and products, allowing buyers to gauge market rates.

-

Disclaimer for Indicative Prices: Prices may fluctuate based on market conditions, so it’s advisable for buyers to obtain quotes tailored to their specific needs before making purchasing decisions.

By understanding these cost components and pricing influencers, international B2B buyers can make informed decisions that enhance their sourcing strategies for tape rolls.

Alternatives Analysis: Comparing tape roll With Other Solutions

When considering packaging solutions, it’s essential to evaluate alternatives to traditional tape rolls. These alternatives can vary widely in terms of performance, cost, and practicality, making it crucial for international B2B buyers to understand their options. Below, we compare tape rolls against two viable alternatives: adhesive sheets and heat sealing technology.

| Comparison Aspect | Tape Roll | Adhesive Sheets | Heat Sealing Technology |

|---|---|---|---|

| Performance | Reliable for sealing boxes and packages | Excellent for flat surfaces, less effective on edges | Very strong, ideal for bulk packaging |

| Cost | $5 – $20 per pack (varies by brand) | $10 – $30 per box (depending on size) | $500 – $2,000 for equipment + materials |

| Ease of Implementation | Easy to use with minimal training | Requires manual application, can be tedious | Requires training for machine operation |

| Maintenance | Low maintenance, easy to store | Low maintenance, but requires space | High maintenance, machinery upkeep needed |

| Best Use Case | General packaging and shipping | Crafting, labeling, and small item packaging | High-volume production environments |

What Are the Pros and Cons of Adhesive Sheets as an Alternative to Tape Rolls?

Adhesive sheets provide a unique solution for specific packaging needs. They excel in applications requiring a flat surface, such as crafting or labeling. Their ease of application on flat surfaces makes them a popular choice for businesses that prioritize aesthetics. However, their effectiveness diminishes on edges or irregular shapes, and they can be more costly compared to tape rolls, especially for larger projects. Businesses in creative industries may find adhesive sheets beneficial, but they may not be ideal for shipping or bulk packaging.

How Does Heat Sealing Technology Compare to Tape Rolls?

Heat sealing technology offers a robust alternative, particularly for businesses engaged in high-volume production. This method creates a secure seal by applying heat and pressure, resulting in a strong bond that is less likely to fail during transit. However, the initial investment in heat sealing machinery can be substantial, making it more suitable for larger companies with consistent packaging needs. Maintenance and operator training are also significant considerations, as improper use can lead to equipment malfunctions or product damage. Companies focused on mass production may find heat sealing to be a worthwhile investment, while smaller businesses may benefit more from the flexibility of tape rolls.

How Should B2B Buyers Choose the Right Packaging Solution?

Choosing the right packaging solution depends on several factors, including budget, intended use, and operational capacity. B2B buyers should assess their specific requirements, such as the types of products being packaged and the volume of items shipped. Tape rolls offer a cost-effective, versatile solution for general packaging needs, while adhesive sheets may be better suited for detailed, aesthetic applications. Heat sealing technology, while more costly, provides unmatched strength for high-volume operations. By understanding the strengths and limitations of each option, buyers can make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for tape roll

What Are the Essential Technical Properties of Tape Rolls?

When sourcing tape rolls for B2B applications, understanding the critical technical properties is vital for ensuring product performance and compatibility with your specific needs. Here are some key specifications to consider:

1. Material Grade

The material grade refers to the composition of the tape, which can include polyethylene, polypropylene, or PVC. Each material has unique properties affecting durability, adhesive strength, and resistance to environmental factors. For instance, polypropylene is often favored for its excellent moisture resistance, making it suitable for packaging in humid climates, which is crucial for buyers in regions like Africa and South America.

2. Adhesive Type

Tape rolls can feature various adhesive types, such as acrylic, rubber, or hot melt. Acrylic adhesives are known for their long-term durability and UV resistance, making them ideal for outdoor applications. Rubber adhesives offer superior initial tack and are often preferred for quick sealing tasks. Understanding the adhesive type will help B2B buyers select the right tape for their specific application, whether it be packaging, labeling, or insulation.

3. Roll Width and Length

The dimensions of the tape roll significantly impact its usability. Common widths range from 0.5 inches to 3 inches, while lengths can vary from 30 yards to over 100 yards. Buyers should consider the scale of their operations; larger widths may be necessary for heavy-duty applications, while narrower tapes could suffice for lighter tasks. This consideration is particularly important for businesses in the logistics sector, where tape is essential for securing packages.

4. Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress that a tape can withstand before breaking. This property is crucial for applications that require strong, durable tape to secure heavy packages or withstand rough handling during shipping. A tape with a higher tensile strength is often a better choice for B2B buyers focused on logistics and shipping, ensuring their packages remain intact throughout transit.

5. Temperature Resistance

Temperature resistance indicates the range of temperatures within which the tape maintains its adhesive properties and structural integrity. For instance, tapes that can withstand extreme heat or cold are essential for industries like construction or refrigeration. B2B buyers in these sectors must ensure that the tape they purchase can perform effectively under the environmental conditions specific to their operations.

What Are Common Trade Terms Related to Tape Rolls?

Navigating the procurement process involves familiarity with industry terminology. Here are some common jargon and trade terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For tape rolls, this means sourcing products directly from manufacturers who can provide high-quality and tailored solutions for specific applications. Understanding OEM relationships is essential for buyers seeking customized tape solutions for their businesses.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. This term is critical for B2B buyers as it can impact inventory management and cash flow. Buyers should negotiate MOQs to ensure they are not overcommitting financially while still meeting their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers requesting pricing and terms for specific products. For tape rolls, an RFQ can help buyers compare different suppliers’ offerings, ensuring they secure the best price and conditions for their required tape specifications.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, risk, and insurance. Familiarity with these terms helps B2B buyers understand their obligations and rights when purchasing tape rolls from international suppliers, particularly in regions like Europe and the Middle East where trade regulations may vary.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. For tape rolls, this enables better inventory management and tracking. Understanding SKUs can streamline the procurement process, making it easier for buyers to reorder the correct products.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their business needs, ensuring efficiency and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the tape roll Sector

What Are the Current Market Dynamics and Key Trends Affecting the Tape Roll Sector?

The global tape roll market is experiencing significant growth, driven by an increase in e-commerce, packaging demands, and advancements in adhesive technologies. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions. Notably, the demand for heavy-duty and eco-friendly tape options is surging, as businesses prioritize durability and sustainability.

Emerging technologies such as smart packaging solutions are reshaping the market landscape. These innovations include tamper-evident features and QR codes integrated into packaging tape, providing added security and traceability. Moreover, B2B buyers should be aware of the trend toward customization, with suppliers offering tailored solutions to meet specific business needs, such as branded packaging tape or specialized adhesive properties.

Additionally, fluctuating raw material costs and supply chain challenges necessitate a proactive approach to sourcing. Buyers must cultivate relationships with reliable suppliers and consider regional sourcing options to mitigate risks associated with global supply disruptions. Leveraging analytics and market intelligence tools can help businesses forecast demand and optimize inventory management, ensuring they remain competitive in this evolving market.

How Is Sustainability Shaping the Tape Roll Sector and What Should Buyers Know?

Sustainability is no longer a choice but a necessity for businesses in the tape roll sector. The environmental impact of packaging materials has led to increased scrutiny from consumers and regulators alike. B2B buyers must prioritize suppliers who demonstrate a commitment to sustainable practices, including the use of recycled materials and eco-friendly adhesives.

Certifications such as FSC (Forest Stewardship Council) and Cradle to Cradle are becoming essential indicators of a supplier’s commitment to ethical sourcing. These certifications not only enhance brand reputation but also meet the growing consumer demand for environmentally responsible products. Buyers should inquire about the origin of materials used in tape rolls and seek out options that minimize carbon footprints.

Moreover, as global regulations tighten around plastic use and waste, businesses should consider investing in biodegradable tape products or those made from renewable resources. This shift not only fulfills corporate social responsibility goals but can also lead to cost savings in the long run by reducing waste disposal expenses.

A stock image related to tape roll.

What Has Been the Evolution of the Tape Roll Sector and Its Relevance Today?

The tape roll sector has evolved significantly over the decades, transitioning from simple adhesive solutions to complex products tailored for specific applications. Initially designed for basic household uses, modern tape now encompasses a wide array of functionalities, including industrial-grade options for heavy-duty shipping and specialty tapes for electronics and automotive industries.

This evolution is particularly relevant for B2B buyers who require specialized products that meet stringent operational standards. Understanding the historical context of tape development can provide insights into current innovations, helping buyers make informed choices that align with their operational needs and sustainability goals. As the market continues to innovate, staying abreast of these developments will be critical for businesses aiming to maintain a competitive edge in their respective industries.

Frequently Asked Questions (FAQs) for B2B Buyers of tape roll

-

How do I choose the right tape roll for my packaging needs?

Selecting the right tape roll involves considering several factors such as tape type, width, and adhesive strength. For heavy-duty shipping, opt for industrial-grade packing tape that can withstand rough handling and varying climates. For lighter applications, clear or decorative tape may suffice. Always assess the compatibility of the tape with your packaging materials, as some adhesives may not adhere well to certain surfaces. Additionally, consider the roll length and quantity that aligns with your operational volume to optimize costs. -

What is the best tape roll for international shipping?

For international shipping, heavy-duty packing tape is recommended due to its durability and ability to secure packages tightly during transit. Look for tape with a width of at least 1.88 inches, which provides better sealing capabilities. Brands like Scotch and 3M offer reliable options that are widely recognized for their strength. Additionally, ensure the tape is water-resistant and can withstand temperature fluctuations, especially if shipping to regions with extreme weather conditions. -

How can I verify the reliability of a tape supplier?

To verify a tape supplier’s reliability, start by researching their reputation through online reviews and industry ratings. Request references from past clients, and consider their experience in international trade, particularly in the regions you’re targeting (Africa, South America, Middle East, Europe). It’s also beneficial to assess their certifications, such as ISO standards, which indicate quality management. Conducting a factory visit or requesting samples can provide further assurance of their product quality and service reliability. -

What are the minimum order quantities (MOQs) for tape rolls?

Minimum order quantities for tape rolls can vary significantly depending on the supplier and the type of tape. Generally, MOQs can range from 100 to 1,000 rolls, particularly for customized or specialized tapes. It’s advisable to inquire directly with suppliers about their MOQs to avoid overcommitting to large quantities that may not align with your business needs. Additionally, consider negotiating MOQs based on your purchasing frequency and long-term partnership potential. -

What payment terms should I expect when sourcing tape rolls internationally?

Payment terms for international tape roll purchases often include options like advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Suppliers may require a deposit upfront, especially for large orders or custom products. It’s essential to discuss and agree upon payment terms before finalizing any contracts to ensure clarity and avoid potential disputes. Consider using escrow services for higher-value transactions to enhance security. -

How do I ensure quality assurance when buying tape rolls?

To ensure quality assurance, request product samples from suppliers before placing a large order. Check for certifications that verify compliance with international standards, such as ASTM or ISO. Implement a quality control process that includes inspecting the tape for consistency in adhesive strength, width, and length upon delivery. Additionally, consider setting up a third-party inspection service to evaluate the product quality before it ships to your location. -

What logistics considerations should I keep in mind when importing tape rolls?

When importing tape rolls, consider logistics factors such as shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder who can navigate the complexities of international shipping and ensure compliance with import regulations in your country. Be aware of any tariffs or taxes that may apply to your shipment, which can affect overall costs. It’s also wise to maintain clear communication with your supplier regarding shipping schedules to avoid delays. -

Can I customize tape rolls for my brand, and what is the process?

Yes, many suppliers offer customization options for tape rolls, including printing your logo or specific designs. The process typically begins with submitting your design and discussing the specifications, such as tape type, size, and quantity. Suppliers may require a minimum order for customized products. Expect to receive a digital proof before production begins to ensure the design meets your expectations. Custom tape can enhance brand visibility and create a professional appearance for your packaging.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tape roll

As the global market for tape rolls continues to evolve, strategic sourcing emerges as a crucial component for international B2B buyers. By understanding the diverse range of products—ranging from heavy-duty shipping tape to eco-friendly options—buyers can optimize their purchasing decisions. This not only enhances operational efficiency but also ensures that businesses remain competitive in their respective markets.

How Can Strategic Sourcing Enhance Your Supply Chain?

Engaging in strategic sourcing allows companies to build strong relationships with suppliers, ensuring consistent quality and supply chain reliability. For buyers in regions like Africa, South America, the Middle East, and Europe, leveraging local suppliers can also reduce shipping costs and lead times, thereby enhancing overall supply chain agility.

What Does the Future Hold for Tape Roll Buyers?

Looking ahead, the demand for specialized tape rolls is expected to rise, driven by growth in e-commerce and packaging industries. Buyers should stay informed about market trends, technological advancements, and sustainability practices to make informed decisions.

Ready to Optimize Your Tape Roll Sourcing Strategy?

Now is the time for international B2B buyers to reassess their sourcing strategies and align them with market demands. By prioritizing quality, sustainability, and strong supplier relationships, businesses can ensure they are well-positioned for future growth and success in an increasingly competitive landscape.