Solve Common Issues: The Complete Cyl Head Gasket Guide (2025)

Introduction: Navigating the Global Market for cyl head gasket

Navigating the global market for cylinder head gaskets presents unique challenges for B2B buyers, particularly those sourcing for automotive applications in regions like Africa, South America, the Middle East, and Europe, including Poland and Spain. The complexities of selecting the right head gasket—essential for sealing the combustion process in engines—require a thorough understanding of material types, manufacturing standards, and market trends. This guide offers a comprehensive look into various gasket types, their applications across different vehicle models, and key considerations for vetting suppliers effectively.

International buyers often face difficulties in ensuring product quality while managing costs and logistics. With a focus on actionable insights, this guide empowers you to make informed purchasing decisions by detailing critical aspects such as supplier reliability, pricing structures, and the implications of gasket material choices on engine performance. Whether you’re a fleet manager in Johannesburg or a parts distributor in Madrid, understanding these factors can significantly impact your operational efficiency and cost management.

Moreover, the guide will help you navigate the nuances of sourcing head gaskets from diverse markets, ensuring you can secure reliable components that meet your specific needs. By leveraging the knowledge presented here, you will enhance your procurement strategy, ultimately leading to improved engine longevity and performance in the vehicles you support.

Understanding cyl head gasket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Multi-Layer Steel | Composed of multiple steel layers with elastomer | Automotive, Heavy Machinery | Pros: Durable, high resistance to leakage; Cons: Higher cost compared to simpler types. |

| Composite | Made from a blend of materials like fiber and rubber | Automotive, Marine Applications | Pros: Lightweight, good thermal stability; Cons: May not withstand extreme pressures. |

| Copper | Made from copper sheets, often used in performance applications | Racing, High-Performance Vehicles | Pros: Excellent thermal conductivity; Cons: Requires precise installation to avoid leaks. |

| Graphite | Engineered from graphite, often used in older models | Classic Cars, Vintage Vehicles | Pros: Good thermal resistance; Cons: Prone to wear and less durable than modern options. |

| Asbestos-Free | Modern alternative to asbestos-based gaskets | General Automotive | Pros: Safer to handle, reduced health risks; Cons: May have lower performance in high-heat applications. |

What are the Characteristics of Multi-Layer Steel Head Gaskets?

Multi-layer steel (MLS) head gaskets are engineered with several layers of steel, often combined with elastomer materials. This design provides exceptional durability and resistance to leakage, making them ideal for modern automotive applications. B2B buyers should consider MLS gaskets for vehicles that experience high pressure and temperature variations, such as heavy-duty trucks and performance cars. The initial cost may be higher, but the long-term savings from reduced maintenance and repairs can offset this investment.

When to Choose Composite Head Gaskets?

Composite head gaskets are made from a combination of materials, including fibers and rubber, which offer a lightweight solution with good thermal stability. These gaskets are suitable for a variety of applications, including marine engines and standard automotive uses. Buyers should consider composite gaskets for vehicles that do not operate under extreme conditions. While they are cost-effective, it is essential to evaluate the specific vehicle requirements, as they may not handle high-pressure environments as effectively as MLS gaskets.

Why Consider Copper Head Gaskets for High-Performance Applications?

Copper head gaskets are favored in racing and high-performance applications due to their excellent thermal conductivity and ability to withstand extreme conditions. These gaskets are often used in modified engines where precise sealing is crucial. However, B2B buyers should be aware that copper gaskets require meticulous installation to avoid leaks. They are an excellent choice for buyers looking to enhance engine performance, but the need for skilled installation can increase overall costs.

What are the Benefits of Graphite Head Gaskets?

Graphite head gaskets, although more common in older vehicle models, are known for their good thermal resistance and ability to handle moderate pressure. These gaskets are often used in classic cars and vintage vehicles where authenticity is a concern. For B2B buyers, the primary consideration should be the compatibility with specific engine designs. While they offer decent performance, buyers should be cautious of their wear over time and consider modern alternatives for newer applications.

How Do Asbestos-Free Gaskets Compare in Safety and Performance?

Asbestos-free gaskets are the modern alternative to traditional asbestos-based options, providing a safer choice for manufacturers and mechanics. These gaskets are widely used in general automotive applications and are designed to meet contemporary safety standards. B2B buyers should prioritize these gaskets for their reduced health risks, though they may not perform as well in extreme heat situations compared to other types. Evaluating the specific application and environment will help in selecting the most suitable gasket type.

Key Industrial Applications of cyl head gasket

| Industry/Sector | Specific Application of cyl head gasket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Sealing in internal combustion engines | Ensures optimal engine performance and longevity | Material quality, compatibility with engine design |

| Heavy Machinery | Used in industrial engines for construction equipment | Reduces downtime due to engine failures | Durability under high stress, resistance to thermal expansion |

| Marine Engineering | Application in marine engines for boats and ships | Enhances fuel efficiency and reduces emissions | Corrosion resistance, ability to withstand harsh conditions |

| Renewable Energy | Used in biofuel engines and generators | Supports sustainable energy solutions | Compliance with environmental regulations, reliability |

| Aerospace | Critical component in aircraft engine assemblies | Ensures safety and performance in aviation applications | Precision engineering, lightweight materials, certification standards |

How is the cyl head gasket utilized in the automotive manufacturing industry?

In the automotive manufacturing sector, the cylinder head gasket is a crucial component that seals the internal combustion engine. It prevents the mixing of oil and coolant while maintaining the pressure needed for efficient combustion. This is vital for ensuring the engine operates at optimal performance levels, which directly affects vehicle reliability and longevity. For international buyers, particularly those in Africa and South America, sourcing high-quality gaskets that meet specific engine designs is essential to avoid costly repairs and maintain competitive production costs.

What role does the cyl head gasket play in heavy machinery applications?

In heavy machinery, such as construction equipment, the cylinder head gasket plays a critical role in sealing the engine and ensuring efficient operation under extreme conditions. These engines often face high stress and temperature fluctuations, making it imperative for the gaskets to be durable and resistant to thermal expansion. For buyers in the Middle East and Europe, it is important to consider gaskets that are designed for high-performance applications and can withstand the rigors of heavy-duty use, thereby minimizing equipment downtime and maintenance costs.

How is the cyl head gasket essential for marine engineering?

In marine engineering, the cylinder head gasket is used in engines powering boats and ships. It helps to enhance fuel efficiency and reduce harmful emissions, which is increasingly important in environmentally-conscious markets. Buyers in Europe, especially in countries with stringent environmental regulations like Spain, need to ensure that the gaskets they procure are not only effective but also compliant with international standards for emissions and safety.

Why is the cyl head gasket important in renewable energy applications?

The cylinder head gasket is also utilized in renewable energy sectors, particularly in biofuel engines and generators. These applications require gaskets that can withstand unique fuel compositions and high operating temperatures. For international buyers, especially in developing regions, sourcing reliable and compliant gaskets is critical to support sustainable energy initiatives and ensure the longevity of renewable energy equipment.

How does the cyl head gasket contribute to aerospace applications?

In the aerospace industry, the cylinder head gasket is a vital component in aircraft engine assemblies. It is essential for maintaining the integrity of the engine under high-pressure conditions, ensuring both safety and performance. Buyers in this sector must focus on precision-engineered gaskets that utilize lightweight materials and meet rigorous certification standards, which is particularly crucial for international procurement in regions like Europe where aviation regulations are stringent.

3 Common User Pain Points for ‘cyl head gasket’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Cylinder Head Gaskets

The Problem: International B2B buyers often face challenges in sourcing high-quality cylinder head gaskets. Many suppliers may offer low-cost options that compromise on material quality, leading to premature failures. This issue is particularly acute for buyers in regions like Africa and South America, where access to reliable suppliers can be limited. When a gasket fails, it can lead to significant engine damage, resulting in costly repairs and prolonged downtime. For businesses relying on vehicles for logistics, this can severely impact operational efficiency and profitability.

The Solution: To mitigate this risk, buyers should prioritize sourcing from reputable manufacturers that adhere to international quality standards. Conduct thorough due diligence by checking certifications such as ISO 9001 and looking for suppliers with a proven track record in the automotive industry. Utilizing platforms like Alibaba or ThomasNet can help identify trustworthy suppliers. Furthermore, consider forming strategic partnerships with local distributors who can provide ongoing support and guidance. Request samples and conduct rigorous testing before placing bulk orders to ensure that the gaskets meet your specific requirements. Establishing clear communication with suppliers about your quality expectations will also help in securing better products.

Scenario 2: Understanding Compatibility Issues with Cylinder Head Gaskets

The Problem: Compatibility between cylinder head gaskets and engine types can be a significant hurdle for B2B buyers. For instance, buyers may mistakenly purchase a gasket designed for one engine model and attempt to use it on another, leading to installation issues and potential engine damage. This is especially problematic in diverse markets where multiple vehicle types are prevalent, such as in the Middle East and Europe. The complexity of engine designs, including variations in materials and dimensions, can exacerbate the situation.

The Solution: To navigate compatibility issues effectively, buyers should maintain a detailed database of the engine models and their corresponding gasket specifications. This database should include dimensions, material types, and manufacturer part numbers. Additionally, collaborating with knowledgeable mechanics or automotive engineers can provide valuable insights into compatibility. Suppliers should also be asked to provide detailed product specifications and compatibility charts. Before making a purchase, it’s advisable to consult the supplier or manufacturer to verify that the gasket is suitable for your specific engine type. This proactive approach can save time and reduce the risk of costly errors.

Scenario 3: Managing the Aftermath of a Blown Head Gasket

The Problem: The aftermath of a blown head gasket can be a nightmare for fleet operators and automotive repair businesses. Once a head gasket fails, it can lead to severe engine damage, including warped cylinder heads or compromised engine blocks. For B2B buyers, the challenge lies not only in repairing the immediate issue but also in minimizing the impact on their operations. Delays in repairs can lead to lost revenue and dissatisfied customers, particularly in competitive markets like Spain and Poland.

The Solution: To manage this effectively, B2B buyers should implement a preventive maintenance strategy that includes regular engine inspections and coolant level checks. Educating drivers and maintenance staff on the signs of a failing head gasket—such as overheating or unusual engine noises—can facilitate early detection and intervention. Additionally, investing in high-quality head gaskets that are engineered for greater durability can reduce the likelihood of future failures. Establishing relationships with reliable mechanics who can provide prompt repair services is essential. Finally, keeping a stock of essential components, including head gaskets, can significantly decrease downtime and ensure that repairs can be executed swiftly.

Alternatives Analysis: Comparing cyl head gasket With Other Solutions

Understanding Alternatives to Cylinder Head Gaskets

In the realm of engine management and repair, the cylinder head gasket plays a crucial role in maintaining the integrity of the engine’s combustion process. However, there are alternative solutions and technologies that can also address similar issues related to sealing and engine performance. This section explores various alternatives to cylinder head gaskets, providing a comprehensive analysis for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Comparison Table of Cylinder Head Gasket Alternatives

| Comparison Aspect | Cyl Head Gasket | Composite Gasket | Metal Gasket |

|---|---|---|---|

| Performance | High, but sensitive to overheating | Good, suitable for moderate pressure | Excellent, high durability under extreme conditions |

| Cost | Moderate | Lower than metal, higher than traditional | Higher, due to material quality |

| Ease of Implementation | Requires precision installation | Easier to install, flexible | More complex, requires specialized tools |

| Maintenance | Minimal, but needs timely replacement | Moderate, may require regular checks | Low, highly durable with minimal wear |

| Best Use Case | High-performance engines | Standard vehicles with moderate performance | Heavy-duty applications, racing, high-performance engines |

Exploring Alternative Solutions in Detail

What Are Composite Gaskets and When Should They Be Used?

Composite gaskets are made from a blend of materials, typically including rubber, fiber, or other composites. They offer good sealing capabilities and are designed to withstand moderate engine pressures. The main advantages include their lower cost and ease of installation, making them suitable for standard vehicles where high performance is not critical. However, they may not hold up as well under extreme conditions compared to metal gaskets. Buyers targeting standard engine repairs may find composite gaskets a cost-effective solution.

Why Consider Metal Gaskets for High-Performance Engines?

Metal gaskets, often made from materials like copper or aluminum, are designed for heavy-duty applications. They excel in high-pressure environments and have excellent thermal conductivity, making them ideal for high-performance and racing engines. While they offer superior durability and require less maintenance, the cost can be a significant factor for buyers. Additionally, the installation process can be more complex, necessitating specialized tools and expertise. For buyers focused on performance and longevity in demanding conditions, metal gaskets represent a worthwhile investment.

How Do Cylinder Head Gaskets Compare to Other Sealing Solutions?

Cylinder head gaskets remain the industry standard for sealing the combustion chamber in most vehicles. They provide a reliable seal, particularly in high-performance engines. However, their sensitivity to overheating and potential for failure under extreme conditions can be a drawback. In contrast, composite and metal gaskets present viable alternatives that cater to specific needs and applications. Buyers should consider the operational environment and performance expectations when making a decision.

Making an Informed Choice for Your Engine Needs

When evaluating alternatives to cylinder head gaskets, international B2B buyers should assess their specific operational requirements, budget constraints, and the intended application of their engines. While cylinder head gaskets are widely used and trusted, alternatives like composite and metal gaskets may offer advantages in terms of cost, ease of installation, and performance under varying conditions. By carefully analyzing these factors, buyers can make informed decisions that best suit their business needs, ultimately enhancing engine performance and reliability.

Strategic Material Selection Guide for cyl head gasket

What Are the Common Materials Used for Cylinder Head Gaskets?

In the realm of cylinder head gaskets, the choice of material is crucial for ensuring optimal performance and longevity. Different materials exhibit varying properties that can significantly affect engine performance, durability, and maintenance costs. Below, we analyze four common materials used in the manufacture of cylinder head gaskets: composite, metal, graphite, and silicone.

How Does Composite Material Perform in Cylinder Head Gaskets?

Composite gaskets are typically made from a blend of materials, including fibers and elastomers. They are designed to withstand high temperatures and pressures while providing excellent sealing capabilities.

- Key Properties: Composite gaskets can handle temperatures up to 250°C (482°F) and pressures around 20 bar. They offer good resistance to corrosion and fluid leakage.

- Pros & Cons: They are relatively inexpensive and easy to manufacture, making them suitable for mass production. However, they may not be as durable as metal gaskets under extreme conditions, leading to potential failures in high-performance applications.

- Impact on Application: Composite gaskets are compatible with a wide range of media, including oil and coolant. However, they may degrade faster in environments with high thermal cycling.

- Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should ensure that the gaskets can withstand local environmental conditions, including temperature and humidity variations.

Why Choose Metal Gaskets for High-Performance Engines?

Metal gaskets, often made from materials like stainless steel or copper, are designed for high-performance applications where durability is paramount.

- Key Properties: Metal gaskets can endure temperatures exceeding 300°C (572°F) and pressures up to 30 bar. They exhibit excellent thermal conductivity and resistance to corrosion.

- Pros & Cons: They are highly durable and suitable for high-performance engines, but they are more expensive and complex to manufacture. Installation requires precision to avoid misalignment.

- Impact on Application: Metal gaskets are ideal for high-compression engines and can handle aggressive media. However, they may not provide adequate sealing for lower-performance applications due to their rigidity.

- Considerations for International Buyers: Buyers in Europe, particularly in countries like Poland and Spain, should verify that metal gaskets meet local automotive standards and regulations, ensuring compatibility with specific engine designs.

What Are the Benefits of Graphite Gaskets?

Graphite gaskets are known for their high-temperature resistance and flexibility, making them a popular choice in various applications.

- Key Properties: Graphite gaskets can withstand temperatures up to 450°C (842°F) and pressures around 25 bar. They are chemically inert and resistant to corrosion.

- Pros & Cons: They provide excellent sealing capabilities and can conform to irregular surfaces, but they may be prone to wear over time and require periodic replacement.

- Impact on Application: Graphite gaskets are suitable for applications involving aggressive chemicals and high temperatures. However, they may not be ideal for low-temperature environments.

- Considerations for International Buyers: Buyers should ensure that graphite gaskets comply with international standards, especially in regions with stringent environmental regulations, such as the EU.

How Does Silicone Material Compare for Cylinder Head Gaskets?

Silicone gaskets are often used in applications requiring flexibility and resilience, particularly in environments with fluctuating temperatures.

- Key Properties: Silicone gaskets can handle temperatures ranging from -60°C to 230°C (-76°F to 446°F) and pressures up to 15 bar. They are resistant to aging and degradation.

- Pros & Cons: They are easy to install and provide good sealing capabilities, but they may not be suitable for high-performance applications due to lower thermal stability compared to metal or graphite gaskets.

- Impact on Application: Silicone gaskets are compatible with various media, including oils and coolants, making them versatile for many applications. However, they may not perform well under extreme conditions.

- Considerations for International Buyers: Buyers should check for compliance with local regulations, especially in the automotive sector, where quality and safety standards are critical.

Summary Table of Material Selection for Cylinder Head Gaskets

| Material | Typical Use Case for cyl head gasket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Composite | General automotive applications | Cost-effective and easy to manufacture | Less durable under extreme conditions | Low |

| Metal | High-performance engines | Highly durable and heat resistant | More expensive and complex to manufacture | High |

| Graphite | High-temperature and chemical applications | Excellent sealing and flexibility | Prone to wear over time | Medium |

| Silicone | Low to medium-performance engines | Easy installation and good sealing | Limited high-temperature performance | Medium |

This guide serves as a strategic resource for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to make informed decisions regarding the selection of materials for cylinder head gaskets. Understanding the properties and applications of each material can lead to better performance, reduced costs, and enhanced reliability in automotive applications.

In-depth Look: Manufacturing Processes and Quality Assurance for cyl head gasket

What Are the Main Stages of the Manufacturing Process for Cylinder Head Gaskets?

Manufacturing cylinder head gaskets involves several critical stages that ensure the production of high-quality components. Each stage is designed to achieve precision and reliability, essential for maintaining engine integrity.

Material Preparation: What Materials Are Used for Cylinder Head Gaskets?

The first step in manufacturing cylinder head gaskets is the selection and preparation of materials. Modern head gaskets are typically made from multi-layer steel (MLS), elastomers, or composite materials.

-

Multi-Layer Steel (MLS): This material consists of several layers of steel, often coated with a polymer to enhance sealing capabilities. It is preferred for its durability and resistance to high temperatures.

-

Elastomers: Used in combination with steel layers, elastomers provide flexibility and resilience. They help in accommodating thermal expansion and contraction.

-

Composite Materials: These include materials like graphite or aramid fibers, which were common in older vehicles but have largely been phased out in modern gaskets due to performance limitations.

Before production, raw materials undergo rigorous quality checks to ensure they meet specific standards for thickness, tensile strength, and thermal resistance.

How Is the Forming Process Executed for Cylinder Head Gaskets?

Once materials are prepared, the forming process begins. This stage typically includes:

-

Cutting and Stamping: Raw materials are cut into the required shape using advanced CNC machines. Stamping processes may also be employed to create precise cutouts for coolant and oil passages.

-

Layer Assembly: For MLS gaskets, the layers are assembled with specific alignment to ensure optimal sealing. This may involve the use of adhesives to keep layers in place during further processing.

-

Heat Treatment: Some manufacturers apply heat treatment to enhance the properties of the gasket, improving its ability to withstand high pressures and temperatures.

What Techniques Are Utilized During the Assembly Stage of Head Gasket Manufacturing?

The assembly stage is crucial for ensuring that all components of the head gasket function effectively together. Key techniques include:

-

Layer Bonding: Advanced bonding methods are used to secure the layers of MLS gaskets. This may involve ultrasonic welding or adhesive bonding to prevent delamination under stress.

-

Final Shaping: The assembled gasket is often subjected to additional machining to ensure it meets precise specifications. This step is vital for achieving the correct thickness and flatness.

-

Surface Treatment: A surface treatment may be applied to enhance the gasket’s sealing performance and resistance to wear.

How Is the Finishing Process Conducted for Cylinder Head Gaskets?

The finishing stage focuses on achieving the required aesthetic and functional qualities. This includes:

-

Inspection: Every gasket undergoes thorough inspection to check for defects such as warping, incorrect dimensions, or surface imperfections.

-

Coating: A protective coating may be applied to prevent corrosion and enhance durability.

-

Packaging: Finally, gaskets are packaged carefully to prevent damage during transportation, ensuring they reach the buyer in pristine condition.

What Quality Assurance Standards Are Relevant for Cylinder Head Gasket Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, especially for components that directly affect engine performance. International and industry-specific standards play a significant role in ensuring product quality.

Which International Standards Should Buyers Be Aware Of?

-

ISO 9001: This is a fundamental quality management standard applicable across industries. It emphasizes a process-oriented approach to quality management, ensuring that manufacturers consistently meet customer requirements.

-

ISO/TS 16949: This standard is specifically tailored for the automotive industry, integrating ISO 9001 with additional automotive-specific requirements.

What Industry-Specific Certifications Are Important for Cylinder Head Gaskets?

-

CE Marking: This certification indicates that the product complies with EU safety, health, and environmental requirements. It’s essential for buyers in Europe, ensuring that the gaskets meet regional regulations.

-

API Certification: For suppliers targeting markets in North America, compliance with the American Petroleum Institute (API) standards can be crucial, especially for gaskets used in engines requiring higher performance specifications.

What Are the Key Quality Control Checkpoints in Cylinder Head Gasket Manufacturing?

Quality control (QC) checkpoints are vital for ensuring that the final product meets all specifications. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves checking raw materials for compliance with specified standards before they enter the production process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor the quality of the assembly and forming stages.

-

Final Quality Control (FQC): Once production is complete, a final inspection assesses the gaskets for defects, dimensional accuracy, and overall quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensure product reliability. Here are several methods to consider:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes, including defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC and certification:

-

Regional Compliance: Ensure that the gaskets comply with local regulations and standards. For example, products sold in the EU must adhere to CE marking requirements.

-

Cultural and Economic Factors: Understanding the local market dynamics, such as economic conditions and infrastructure, can influence the reliability of supply chains and product quality.

-

Communication: Establishing clear communication channels with suppliers can help mitigate misunderstandings regarding quality expectations and specifications.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing cylinder head gaskets, ultimately enhancing their operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cyl head gasket’

To successfully source cylinder head gaskets for your business, it is essential to follow a structured approach that ensures quality, compatibility, and cost-effectiveness. This guide provides a step-by-step checklist tailored for B2B buyers across Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for the cylinder head gasket is crucial. This includes the dimensions, materials (such as multi-layer steel or elastomer), and compatibility with various engine types. Failure to accurately define these specifications can lead to costly mismatches and operational inefficiencies.

- Consider Engine Type: Ensure that the gasket matches the specific engine model and year.

- Material Requirements: Assess whether you need gaskets that are resistant to high temperatures and pressures.

Step 2: Conduct Market Research

Explore the current market landscape for cylinder head gaskets. Identify leading manufacturers and suppliers who specialize in this component. This research will help you understand pricing trends, product availability, and technological advancements.

- Utilize Industry Reports: Reference market analysis reports to gauge demand and emerging trends.

- Check Competitor Sources: Review where similar businesses procure their gaskets for additional insights.

Step 3: Evaluate Potential Suppliers

Before making a purchasing decision, vet potential suppliers thoroughly. Request company profiles, case studies, and references from businesses in similar industries or regions. This step is vital to ensure reliability and product quality.

- Assess Certifications: Verify if the supplier meets international standards such as ISO or equivalent quality certifications.

- Check Reviews and Testimonials: Look for feedback from other buyers regarding product performance and service reliability.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the cylinder head gaskets. Testing samples allows you to assess the quality and compatibility of the gaskets with your applications before committing to larger orders.

- Conduct Performance Tests: Evaluate how the gasket performs under various conditions to ensure it meets your operational standards.

- Review Packaging and Delivery: Ensure that the samples are delivered on time and in good condition, as this reflects the supplier’s overall service quality.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your chosen supplier to secure the best possible pricing and terms. Understanding your budget and the supplier’s cost structure can lead to mutually beneficial agreements.

- Explore Bulk Discounts: Discuss potential discounts for larger orders or long-term contracts.

- Clarify Payment Terms: Ensure that payment terms align with your financial capabilities and cash flow.

Step 6: Finalize the Purchase Agreement

After successful negotiations, finalize the purchase agreement. Make sure the contract includes all necessary details such as delivery timelines, warranty information, and return policies.

- Incorporate Quality Assurance Clauses: Include terms that allow for returns or exchanges if the gaskets do not meet specified quality standards.

- Document Everything: Keep a record of all communications and agreements for future reference.

Step 7: Implement a Quality Control Process

After receiving the gaskets, establish a quality control process to inspect the products before use. This step is critical to ensure that only high-quality components are utilized in your operations.

- Inspect for Defects: Check for any physical damages or discrepancies in specifications.

- Maintain Documentation: Keep a log of inspections to track product quality over time.

By following these steps, B2B buyers can effectively source cylinder head gaskets that meet their technical requirements and ensure operational efficiency.

Comprehensive Cost and Pricing Analysis for cyl head gasket Sourcing

What Are the Key Cost Components for Cylinder Head Gasket Sourcing?

When sourcing cylinder head gaskets, understanding the cost structure is crucial for effective budgeting and decision-making. The primary components that contribute to the overall cost include:

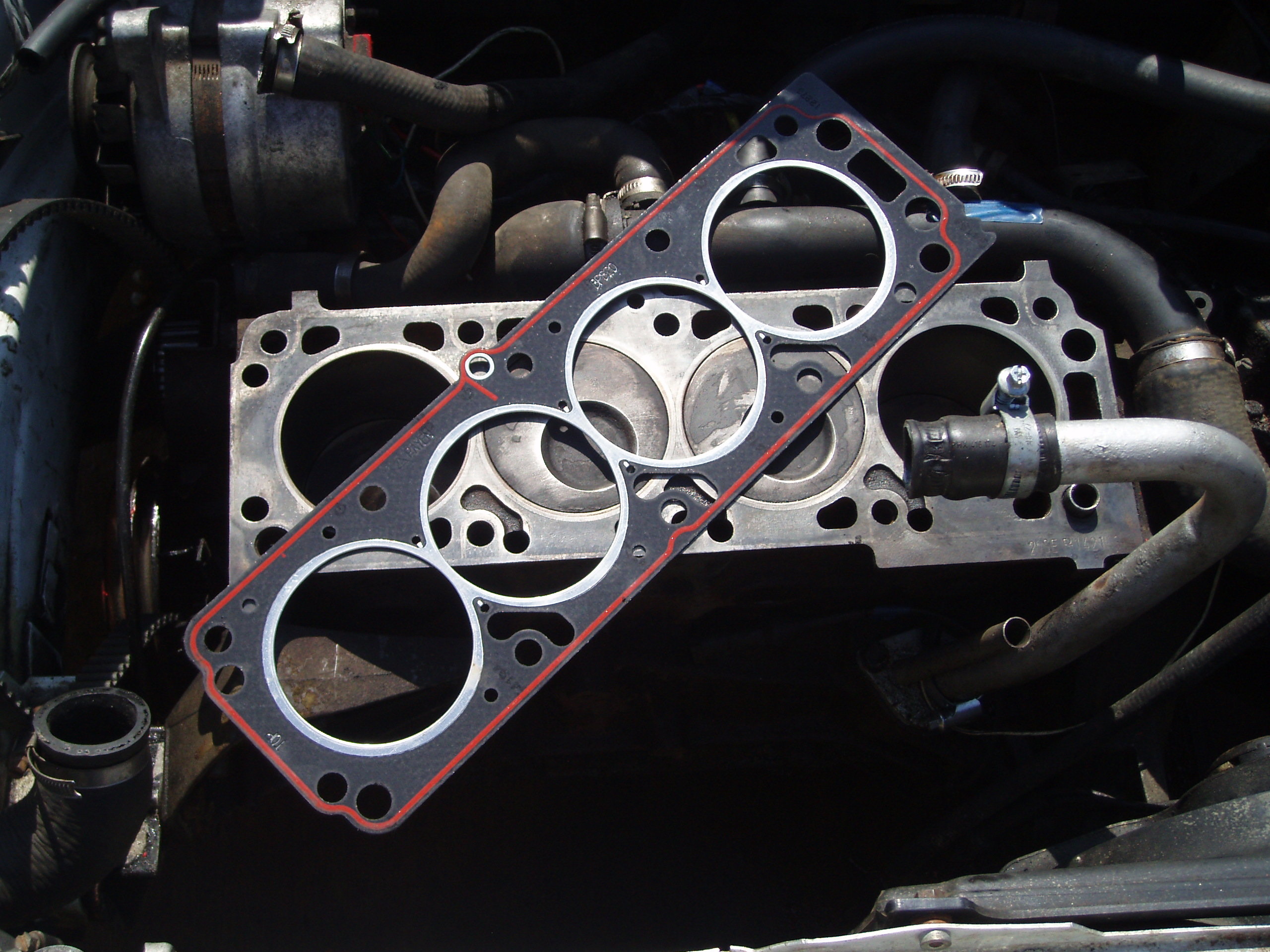

A stock image related to cyl head gasket.

-

Materials: The choice of materials significantly impacts the cost of head gaskets. Modern gaskets are often made from multi-layer steel (MLS) or elastomer composites, which provide better durability and performance. The price can vary based on the material’s availability and market demand.

-

Labor: Labor costs can fluctuate based on the complexity of the gasket design and the manufacturing process. Regions with higher wage standards may see increased labor costs, which can affect the final price for international buyers.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and administrative costs. Manufacturers in regions with higher overheads may pass these costs onto buyers.

-

Tooling: The initial investment in tooling for producing gaskets can be substantial, especially for custom designs. Buyers should inquire about these costs as they can be amortized over larger order volumes, potentially lowering the per-unit price.

-

Quality Control (QC): Ensuring product quality can lead to additional costs. Manufacturers often implement rigorous QC processes, which may include testing for durability and fit. Certifications for quality standards (like ISO) can also add to the overall cost.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. These can vary based on the shipping method, distance, and whether the supplier covers transportation.

-

Margin: Suppliers typically add a profit margin on top of their costs. Understanding the industry standard margins can help buyers negotiate better prices.

What Influences Pricing for Cylinder Head Gaskets?

Several factors can influence the pricing of cylinder head gaskets:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk can lead to significant discounts. Suppliers often have MOQs that buyers must meet to qualify for lower prices.

-

Specifications and Customization: Custom gaskets tailored to specific engine designs often come at a premium. Standardized sizes and designs usually offer more competitive pricing.

-

Material Quality and Certifications: Higher quality materials and certifications typically command higher prices. Buyers should weigh the cost against the expected performance and longevity.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can impact pricing. Established suppliers may offer reliability, while newer suppliers may have more competitive rates but less proven track records.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) affect the total cost to the buyer. Understanding these terms is essential for calculating the landed cost of the gaskets.

How Can International B2B Buyers Optimize Costs When Sourcing Cylinder Head Gaskets?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips for cost optimization:

-

Negotiate Terms and Prices: Engaging suppliers in negotiations can lead to better pricing, especially for larger orders. Consider discussing payment terms, bulk discounts, and delivery schedules.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with the gaskets, including installation, maintenance, and potential failures.

-

Be Aware of Pricing Nuances: Understand that prices may fluctuate due to currency exchange rates, regional economic conditions, and material availability. Staying informed about market trends can aid in timing your purchases.

-

Consider Local Suppliers: Sourcing from local or regional suppliers can reduce shipping costs and lead times, although this may require trade-offs in terms of material quality or specifications.

Disclaimer on Indicative Prices

Prices for cylinder head gaskets can vary widely based on the factors discussed above. Buyers should conduct thorough research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs.

Essential Technical Properties and Trade Terminology for cyl head gasket

What Are the Essential Technical Properties of a Cylinder Head Gasket?

When sourcing cylinder head gaskets, understanding the critical technical properties is vital for ensuring compatibility, durability, and performance. Below are key specifications to consider:

1. Material Composition: What Materials Are Used in Head Gaskets?

Modern cylinder head gaskets are typically made from multi-layer steel (MLS), composite materials, or copper.

– MLS Gaskets: Composed of multiple layers of steel, these gaskets offer superior strength and sealing capabilities, making them ideal for high-performance applications.

– Composite Gaskets: Often made from materials like graphite or elastomer, these gaskets are flexible and easier to install but may not withstand extreme conditions.

– Copper Gaskets: Known for their thermal conductivity and durability, copper gaskets are suitable for high-temperature applications but require precise installation.

Understanding the material composition helps B2B buyers select gaskets that align with their engine specifications and performance needs.

2. Compression Thickness: Why Is It Important?

Compression thickness refers to the thickness of the gasket when compressed between the cylinder head and engine block.

– A typical range is between 0.5 mm to 2.0 mm, depending on the application.

– This property affects the engine’s compression ratio and performance. A thicker gasket can lower the compression ratio, which might be necessary for specific engine configurations.

Choosing the correct compression thickness is crucial for optimizing engine performance and preventing issues like pre-ignition or detonation.

3. Temperature Resistance: What Are the Thermal Limits?

Temperature resistance indicates the maximum temperature the gasket can withstand before it degrades.

– Most head gaskets can handle temperatures up to 200°C (392°F) but high-performance gaskets may exceed this.

– Ensuring that the gasket can withstand the operational temperatures of the engine is vital for longevity and reliability.

For B2B buyers, understanding temperature resistance helps in selecting a gasket that can endure the specific conditions of their engines.

4. Tensile Strength: How Strong Is the Gasket?

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking.

– A high tensile strength is essential for head gaskets, as they must maintain sealing integrity under high pressure and temperature.

– This property directly correlates with the gasket’s ability to prevent leaks and maintain engine performance.

B2B buyers should consider tensile strength when evaluating gaskets for heavy-duty applications or high-performance engines.

5. Surface Finish: Why Does It Matter?

The surface finish refers to the smoothness of the gasket’s mating surfaces.

– A finer surface finish improves the gasket’s ability to seal effectively, reducing the likelihood of leaks.

– Manufacturers often specify surface finish requirements in microns, which should be matched with the engine’s surface conditions.

Understanding the surface finish is essential for ensuring compatibility with engine components, which aids in preventing future failures.

What Are Common Trade Terms Related to Cylinder Head Gaskets?

Navigating the world of cylinder head gaskets involves understanding specific trade terminology that can influence purchasing decisions.

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to parts made by the original manufacturer of the vehicle. These parts are often preferred due to their guaranteed fit and performance.

– B2B buyers often seek OEM gaskets for reliability and compatibility with their engines.

2. MOQ (Minimum Order Quantity): What Should Buyers Know?

MOQ is the minimum number of units a supplier requires for an order.

– Understanding MOQ helps buyers plan their inventory and budget, especially when sourcing from international suppliers.

3. RFQ (Request for Quotation): How Is It Used?

An RFQ is a document sent to suppliers requesting a quote for specific products, including pricing and availability.

– Utilizing RFQs can help B2B buyers secure competitive pricing and terms for bulk purchases.

4. Incoterms: How Do They Affect Shipping?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions.

– Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) helps buyers understand shipping costs and risk management.

Understanding these technical properties and trade terms will empower B2B buyers from Africa, South America, the Middle East, and Europe to make informed decisions when sourcing cylinder head gaskets, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the cyl head gasket Sector

What Are the Current Trends in the Global Cyl Head Gasket Market?

The global cylinder head gasket market is currently experiencing significant growth, driven by increasing demand for automotive components and rising vehicle production rates, particularly in emerging markets across Africa, South America, the Middle East, and Europe. This growth is propelled by advancements in automotive technology, including the shift towards electric and hybrid vehicles, which require specialized gaskets that can withstand different thermal and pressure conditions. Additionally, the rising trend of vehicle electrification is influencing the materials used in head gaskets, pushing manufacturers to innovate with lighter and more durable materials, such as multi-layer steel (MLS) gaskets.

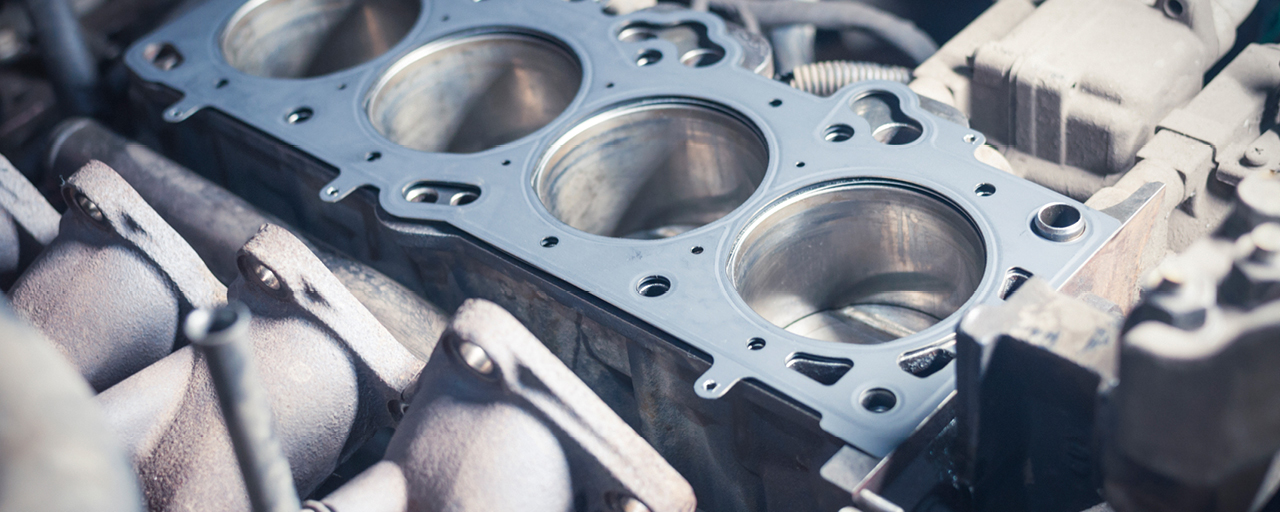

A stock image related to cyl head gasket.

International B2B buyers should also be aware of the ongoing digital transformation in sourcing practices. Technologies like AI and blockchain are being utilized to enhance supply chain transparency and efficiency, allowing buyers to track the provenance of materials and ensure they are sourcing from reliable suppliers. Furthermore, an increasing number of suppliers are adopting e-commerce platforms to facilitate easier transactions, which can simplify the procurement process for buyers across various regions.

How Does Sustainability Influence Sourcing in the Cyl Head Gasket Sector?

Sustainability and ethical sourcing are becoming crucial factors in the cylinder head gasket sector. As environmental concerns gain prominence, both manufacturers and buyers are focusing on reducing their ecological footprints. The production of head gaskets can have significant environmental impacts, particularly when traditional materials like asbestos were used. However, modern gaskets are increasingly being made from eco-friendly materials that are less harmful to the environment, such as composites and aluminum.

B2B buyers should prioritize suppliers that adhere to sustainability certifications, such as ISO 14001, which indicates an effective environmental management system. Furthermore, sourcing from manufacturers that practice responsible waste management and energy-efficient production can enhance a company’s reputation and appeal to environmentally conscious consumers. Transparency in the supply chain is key; buyers should request information on the sourcing of raw materials and the environmental policies of their suppliers to ensure they align with their own sustainability goals.

What Is the Historical Context of the Cyl Head Gasket Market?

The cylinder head gasket has evolved significantly over the years, reflecting advancements in engine technology and material science. Initially, gaskets were made from materials like graphite or asbestos, which posed health risks and were less durable under high stress. The introduction of multi-layer steel gaskets in the late 20th century marked a pivotal shift, offering improved sealing capabilities and resistance to high temperatures and pressures.

This evolution has been driven by the growing demands of modern engines, which operate at higher efficiencies and require components that can withstand greater thermal expansion. As a result, today’s gaskets are designed not only for performance but also for longevity, significantly reducing the frequency of repairs and replacements. Understanding this historical context is essential for B2B buyers as they assess suppliers and seek components that meet the rigorous demands of contemporary automotive applications.

Frequently Asked Questions (FAQs) for B2B Buyers of cyl head gasket

-

How do I identify a blown head gasket in my engine?

A blown head gasket can manifest through several symptoms. Look for signs such as engine overheating, white or blue smoke from the exhaust, and a noticeable loss of power. Additionally, discolored engine oil resembling chocolate milk may indicate coolant mixing with oil. If any of these symptoms are observed, it’s crucial to conduct an inspection promptly to prevent extensive engine damage. Engaging a professional mechanic familiar with your specific engine type can provide a thorough assessment. -

What is the best material for a cylinder head gasket?

The best material for a cylinder head gasket largely depends on the engine type and operating conditions. Multi-layer steel (MLS) gaskets are popular for modern engines due to their durability and resistance to leaks. For older engines, composite materials may be suitable but tend to be less resilient under high temperatures. It’s important to consult with your supplier to ensure the gasket material aligns with your engine specifications and performance requirements. -

What are the typical minimum order quantities (MOQ) for cylinder head gaskets?

Minimum order quantities (MOQ) for cylinder head gaskets can vary significantly based on the supplier and the type of gasket required. Generally, MOQs can range from 50 to several hundred units. For international buyers, it’s beneficial to negotiate MOQs directly with suppliers, especially if you are interested in a diverse range of products or custom gaskets. Always inquire about bulk discounts to maximize your purchasing efficiency. -

How can I vet suppliers for cylinder head gaskets internationally?

Vetting suppliers involves several steps to ensure reliability and quality. Start by checking their certifications and compliance with international standards, such as ISO 9001. Request samples to evaluate product quality and durability. Additionally, reviewing customer testimonials and conducting background checks on their business history can provide insights into their reliability. Establishing communication and discussing your specific requirements can also help assess their capability to meet your needs. -

What payment terms should I expect when sourcing head gaskets from international suppliers?

Payment terms can vary widely among suppliers, but common practices include upfront payment, 30% deposit with the balance upon shipment, or net 30/60 days terms for established relationships. It’s essential to clarify these terms before placing an order. Additionally, consider using secure payment methods like letters of credit or escrow services to protect your investment, especially when dealing with new suppliers. -

How do I ensure quality assurance for cylinder head gaskets?

To ensure quality assurance, implement a robust quality control process that includes inspecting gaskets upon receipt and prior to installation. Work closely with your supplier to understand their quality assurance protocols, including material sourcing and production processes. Request certifications or test reports that validate the gaskets meet industry standards. Establishing a clear return policy for defective products can also safeguard your investment. -

What logistics considerations should I keep in mind when importing head gaskets?

When importing head gaskets, consider shipping methods, customs regulations, and import duties. Choose a reliable logistics partner experienced in handling automotive parts to ensure timely delivery. It’s also advisable to account for potential delays in customs clearance, particularly in regions with stringent regulations. Familiarize yourself with the import laws of your country to avoid unexpected costs and ensure compliance. -

Can I customize head gaskets for specific engine models?

Yes, many suppliers offer customization options for head gaskets tailored to specific engine models. Customization can include alterations in size, material, and design to meet the unique demands of your engines. When approaching suppliers, provide detailed specifications and requirements to facilitate the customization process. Additionally, inquire about the minimum order quantities for customized gaskets, as they may differ from standard products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cyl head gasket

Why is Strategic Sourcing Essential for Cylinder Head Gaskets?

In summary, strategic sourcing of cylinder head gaskets is crucial for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. By understanding the importance of quality, durability, and compatibility in these components, buyers can mitigate risks associated with engine failures and costly repairs. Identifying reliable suppliers and assessing the material specifications of gaskets—whether they are multi-layer steel or composite—ensures that the products meet the operational demands of diverse automotive markets.

How Can Buyers Position Themselves for Future Success?

As the automotive industry evolves, staying ahead of trends is vital. Emphasizing partnerships with manufacturers that prioritize innovation and sustainability will not only enhance product reliability but also align with global market shifts toward eco-friendly practices. Buyers should engage in regular communication with suppliers to anticipate changes in technology and material science that could impact gasket performance.

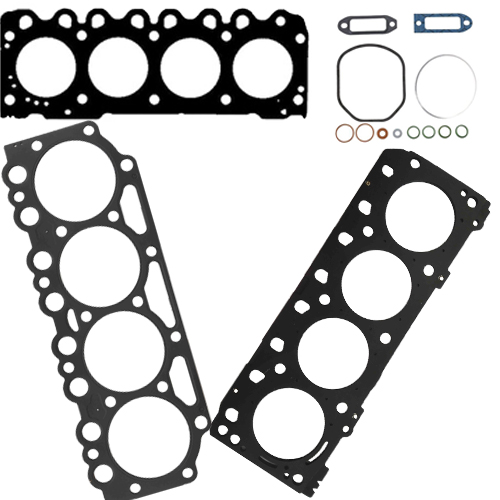

A stock image related to cyl head gasket.

What Steps Should You Take Next?

Moving forward, international buyers are encouraged to adopt a proactive approach in sourcing cylinder head gaskets. Conduct thorough market research, evaluate supplier capabilities, and establish long-term relationships with trusted manufacturers. By doing so, businesses can position themselves competitively in their respective markets, ensuring they have access to high-quality components that support their growth and operational efficiency.