Solve Sourcing Issues: The Complete 3 Prong Range Cord Guide (2025)

Introduction: Navigating the Global Market for 3 prong range cord

In the rapidly evolving landscape of global commerce, sourcing a reliable 3-prong range cord can pose significant challenges for international B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. The complexities involved in selecting the right power cord—considering factors such as compatibility, safety standards, and pricing—can lead to costly procurement errors. This guide serves as a comprehensive resource, addressing various types of range cords, their applications, and essential supplier vetting processes.

As you navigate this intricate market, understanding the nuances of the 3-prong range cord will empower you to make informed purchasing decisions. From evaluating the technical specifications to assessing the credibility of suppliers, this guide covers everything you need to know. We delve into critical aspects such as cost analysis, shipping logistics, and compliance with international standards, ensuring that your procurement process is seamless and efficient.

Whether you’re a buyer in Turkey looking for high-quality cords for your kitchen appliances or a distributor in South America seeking to expand your product offerings, this guide is tailored to meet your needs. Equip yourself with the knowledge to confidently engage with suppliers and optimize your sourcing strategies, ultimately enhancing your business’s operational efficiency and profitability.

Understanding 3 prong range cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 50 Amp 3-Prong Range Cord | Heavy-duty, typically 6 ft long, 6/3 gauge wire | Commercial kitchens, large appliances | Pros: High capacity for power-hungry appliances. Cons: May be overkill for smaller setups. |

| 40 Amp 3-Prong Range Cord | Moderate capacity, usually 4 ft long, 6/2 gauge | Residential kitchens, mid-range appliances | Pros: Suitable for most home ranges. Cons: Limited length may require extension. |

| 30 Amp 3-Prong Range Cord | Lightweight, often 4 ft or 6 ft, 10/3 gauge | Small commercial setups, residential use | Pros: Cost-effective and versatile. Cons: Lower capacity may not support larger appliances. |

| 3-Prong Range Cord Extension | Additional length, 10 ft or more, 10/3 gauge | Situations where distance from outlet is an issue | Pros: Flexible installation options. Cons: May lead to voltage drop if excessively long. |

| Universal 3-Prong Adapter Cord | Adaptable for different appliances, various lengths | Diverse appliance compatibility | Pros: Versatile for various equipment. Cons: Compatibility issues with specific models. |

What Are the Characteristics of a 50 Amp 3-Prong Range Cord?

The 50 Amp 3-Prong Range Cord is designed for heavy-duty applications, commonly used in commercial kitchens and for larger residential appliances. With a gauge of 6/3, it can handle high power loads, making it ideal for electric ranges that require significant energy. B2B buyers should ensure they have appropriate outlets and consider the cord’s length, typically around 6 feet, to accommodate their installation needs.

How Does a 40 Amp 3-Prong Range Cord Compare?

The 40 Amp 3-Prong Range Cord is suitable for mid-range appliances, often found in residential settings. This cord typically features a 6/2 gauge and is commonly 4 feet long. It strikes a balance between power and flexibility, making it an excellent choice for buyers looking for a reliable option for standard kitchen ranges. B2B purchasers should evaluate the specific power requirements of their appliances to ensure compatibility.

What Makes a 30 Amp 3-Prong Range Cord Ideal for Smaller Applications?

The 30 Amp 3-Prong Range Cord is lightweight and generally comes in 4 ft or 6 ft lengths. It is often made with a 10/3 gauge wire, making it suitable for small commercial setups or residential use. Its cost-effectiveness and versatility appeal to B2B buyers who need reliable power for smaller appliances. However, it’s essential to assess whether the lower capacity meets the specific needs of the equipment being used.

When Should You Use a 3-Prong Range Cord Extension?

A 3-Prong Range Cord Extension is ideal for situations where appliances need to be placed further from the outlet. Typically available in lengths of 10 feet or more and made with a 10/3 gauge, this extension allows for flexible installation options. Buyers should be aware of potential voltage drops with longer cords and ensure that the extension is suitable for their specific power needs.

What Are the Benefits of a Universal 3-Prong Adapter Cord?

The Universal 3-Prong Adapter Cord offers adaptability for various appliances, making it a versatile choice for businesses with diverse equipment. Available in multiple lengths, this cord can accommodate different installation scenarios. However, B2B buyers should verify compatibility with specific models to avoid potential issues. This adaptability can streamline operations, particularly in settings where equipment changes frequently.

Key Industrial Applications of 3 prong range cord

| Industry/Sector | Specific Application of 3 Prong Range Cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Connecting commercial ranges and ovens in restaurants | Ensures reliable power for cooking equipment, reducing downtime. | Compliance with local electrical standards; durability for heavy use. |

| Manufacturing | Powering industrial cooking equipment in food production facilities | Enhances efficiency in food processing, ensuring consistent output. | Sourcing from certified manufacturers for safety and reliability. |

| Construction | Installing kitchen appliances in residential and commercial builds | Facilitates quick setup of essential appliances for new homes. | Availability of various lengths and amperages; regional electrical codes. |

| Retail | Powering display cooking appliances in food retail environments | Attracts customers with live cooking demonstrations, increasing sales. | Compatibility with local outlets and appliances; flexible sourcing options. |

| Hospitality | Supplying power to catering equipment at events | Enables seamless service delivery, enhancing customer experience. | Focus on quality and safety certifications; bulk purchasing options. |

How is the 3 Prong Range Cord Used in the Food Service Industry?

In the food service industry, 3 prong range cords are essential for connecting commercial ranges and ovens. These cords ensure that cooking equipment receives a stable power supply, which is critical for food preparation. Reliability in power translates to reduced downtime, allowing restaurants to maintain high service levels. International buyers should consider local electrical standards and the durability of the cords, as they must withstand heavy daily use.

What Role Does the 3 Prong Range Cord Play in Manufacturing?

In manufacturing, particularly in food production facilities, 3 prong range cords are used to power industrial cooking equipment. This application is vital for ensuring efficient processing and consistent output, which are key to meeting production targets. Buyers in this sector should prioritize sourcing cords from certified manufacturers to guarantee safety and reliability, given the demanding operational environment.

How is the 3 Prong Range Cord Utilized in Construction?

During the construction of residential and commercial buildings, 3 prong range cords are used to install kitchen appliances. This application facilitates the quick setup of essential appliances, allowing for faster project completion. International buyers must ensure the cords meet regional electrical codes and are available in various lengths and amperages to suit different project needs.

How Do Retailers Benefit from 3 Prong Range Cords?

In the retail sector, especially in food retail environments, 3 prong range cords power display cooking appliances. This application helps attract customers through live cooking demonstrations, enhancing the shopping experience and potentially increasing sales. Retailers should focus on compatibility with local outlets and appliances while considering flexible sourcing options to accommodate various store layouts.

What is the Importance of 3 Prong Range Cords in Hospitality?

In the hospitality industry, 3 prong range cords supply power to catering equipment used at events. This application is crucial for delivering seamless service, which significantly enhances customer satisfaction. Buyers should emphasize quality and safety certifications when sourcing these cords, as well as explore bulk purchasing options to meet the demands of large-scale events.

3 Common User Pain Points for ‘3 prong range cord’ & Their Solutions

Scenario 1: Compatibility Issues with Electrical Outlets

The Problem: A common challenge faced by B2B buyers, especially those in regions like Africa and the Middle East, is the inconsistency in electrical outlet standards. Many buyers may source 3-prong range cords that do not match the outlet specifications in their facilities. This can lead to operational delays and increased costs as appliances may not function properly or require additional modifications.

The Solution: To avoid compatibility issues, it’s essential to conduct a thorough assessment of the electrical standards in your target market. Buyers should ensure that the 3-prong range cords they are sourcing meet the local electrical codes and standards. Collaborating with reputable suppliers who can provide detailed specifications about their products is crucial. Additionally, consider investing in universal range cords that accommodate various outlet types, or ensure that your range cords come with adapters that can bridge the gap between differing standards. This proactive approach can save time and resources while ensuring operational efficiency.

Scenario 2: Quality and Safety Concerns

The Problem: International B2B buyers often face the dilemma of sourcing high-quality 3-prong range cords that adhere to safety regulations. In regions such as South America and Europe, there are strict compliance requirements for electrical components. Poor-quality cords can lead to electrical failures, posing safety risks to both personnel and equipment.

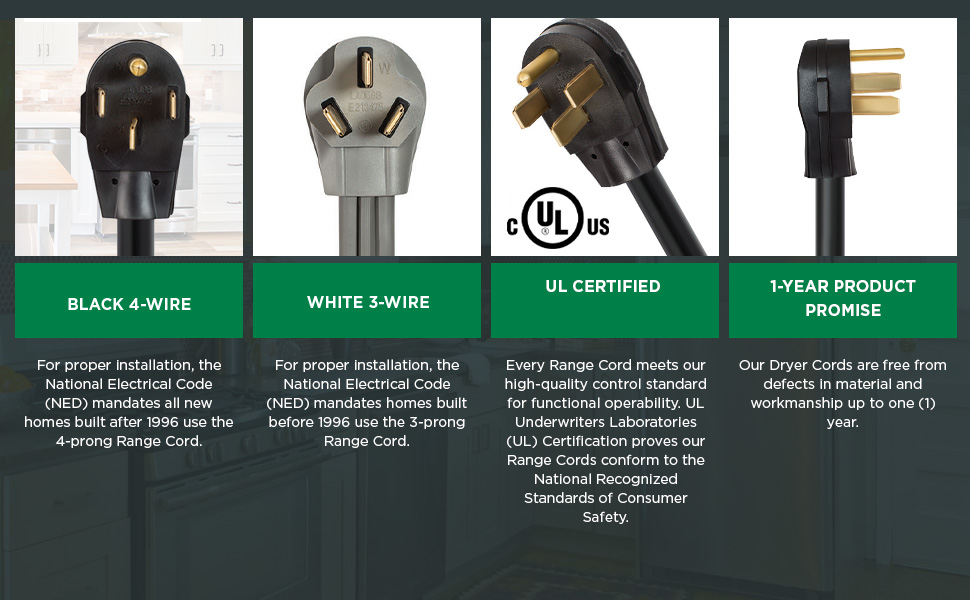

The Solution: To mitigate safety concerns, buyers should prioritize sourcing 3-prong range cords from manufacturers who provide certifications such as UL (Underwriters Laboratories) or CE (Conformité Européenne). These certifications indicate that the products meet rigorous safety standards. Establishing a quality assurance process that includes testing samples from suppliers can also help ensure the cords perform reliably under load conditions. Additionally, conducting periodic audits of suppliers can ensure they maintain high manufacturing standards and comply with safety regulations, thereby protecting your business from potential liabilities.

Scenario 3: Length and Installation Challenges

The Problem: Another significant pain point for B2B buyers is selecting the appropriate cord length for their specific installation needs. Short cords may not provide enough reach, forcing companies to use extension cords, which can be unsafe and non-compliant with electrical codes. Conversely, overly long cords can create clutter and increase the risk of tripping hazards.

The Solution: To address length and installation challenges, buyers should carefully analyze the layout of their kitchens or appliance installation areas. Measure the distance from the outlet to the appliance to determine the optimal cord length needed. When selecting 3-prong range cords, consider purchasing a few different lengths to accommodate varying installation scenarios. Additionally, consider investing in installation services that can offer expert advice on proper cord installation and management, ensuring that your setup is not only functional but also adheres to safety standards. This attention to detail can greatly enhance operational efficiency and workplace safety.

Strategic Material Selection Guide for 3 prong range cord

What Are the Key Materials Used in 3 Prong Range Cords?

When selecting materials for 3 prong range cords, B2B buyers must consider various factors that affect performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these cords: PVC, rubber, thermoplastic elastomer (TPE), and silicone.

How Does PVC Perform in 3 Prong Range Cords?

Key Properties: PVC (Polyvinyl Chloride) is known for its excellent electrical insulation properties and resistance to moisture. It can typically withstand temperatures up to 60°C (140°F).

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for budget-conscious buyers. However, it is less durable than other materials, particularly in extreme temperatures or exposure to UV light, which can lead to cracking over time.

Impact on Application: PVC is suitable for indoor applications where moisture is present but may not be ideal for outdoor use due to its susceptibility to environmental factors.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that PVC cords meet local electrical safety standards, such as IEC or ANSI, to avoid compliance issues.

What Advantages Does Rubber Offer for 3 Prong Range Cords?

Key Properties: Rubber is highly flexible and can withstand a wide range of temperatures, typically from -40°C to 90°C (-40°F to 194°F). It also has excellent abrasion and tear resistance.

Pros & Cons: The primary advantage of rubber is its durability and flexibility, making it ideal for heavy-duty applications. However, it is generally more expensive to produce than PVC and may require more complex manufacturing processes.

Impact on Application: Rubber is particularly effective in environments where cords are subjected to mechanical stress or extreme temperatures, making it suitable for both indoor and outdoor applications.

Considerations for International Buyers: Buyers should look for rubber cords that comply with ASTM or IEC standards, ensuring they are suitable for the intended use and environment.

Why Choose Thermoplastic Elastomer (TPE) for 3 Prong Range Cords?

Key Properties: TPE combines the properties of rubber and plastic, offering excellent elasticity and chemical resistance. It can typically handle temperatures ranging from -40°C to 120°C (-40°F to 248°F).

Pros & Cons: TPE is lightweight and offers superior flexibility, making it easier to handle and install. However, it can be more costly than PVC and may not be as widely available in all regions.

Impact on Application: TPE is ideal for applications requiring flexibility and resistance to chemicals, making it suitable for both residential and commercial use.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that TPE materials comply with RoHS and REACH regulations, which govern the use of hazardous substances.

What Are the Benefits of Using Silicone in 3 Prong Range Cords?

Key Properties: Silicone is known for its exceptional temperature resistance, withstanding temperatures from -60°C to 200°C (-76°F to 392°F). It is also highly resistant to UV light and ozone.

Pros & Cons: The main advantage of silicone is its durability and ability to maintain performance in extreme conditions. However, it is the most expensive option among the materials discussed, which may limit its use in budget-sensitive applications.

Impact on Application: Silicone is suitable for high-performance applications where temperature fluctuations are common, making it ideal for industrial settings.

Considerations for International Buyers: Buyers should ensure silicone products meet international safety standards, such as UL or CE, to guarantee compliance across different markets.

Summary Table of Material Properties for 3 Prong Range Cords

| Material | Typical Use Case for 3 Prong Range Cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor applications | Cost-effective and easy to manufacture | Less durable in extreme conditions | Low |

| Rubber | Heavy-duty applications | Highly durable and flexible | More expensive to produce | Med |

| Thermoplastic Elastomer | Residential and commercial use | Superior flexibility and chemical resistance | More costly and less widely available | Med |

| Silicone | High-performance industrial settings | Exceptional temperature resistance | Most expensive option | High |

This analysis provides a comprehensive overview of the materials used in 3 prong range cords, helping international B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 prong range cord

What Are the Key Stages in the Manufacturing Process of 3 Prong Range Cords?

The manufacturing of 3 prong range cords is a meticulous process that involves several key stages. Understanding these stages can empower B2B buyers to make informed decisions when selecting suppliers.

-

Material Preparation: The first stage involves sourcing high-quality raw materials, including copper wire for conductors and thermoplastic or thermoset materials for insulation. Suppliers should ensure that materials meet international standards like IEC 60227, which governs the performance requirements for flexible cables.

-

Forming: In this phase, copper wires are drawn into the desired gauge size, typically 6/3 or 8/3 AWG for range cords. The forming process may also involve twisting multiple strands of wire together to enhance flexibility and conductivity. Manufacturers often employ advanced machinery to ensure precision in forming.

-

Assembly: This stage includes connecting the wires to the prong plugs. A common technique is the use of crimping or soldering for secure connections. Quality assurance is critical at this stage to prevent failures, which can lead to safety hazards.

-

Finishing: The final step includes adding protective coatings and conducting electrical tests. Coatings are applied to prevent abrasion and environmental damage. Manufacturers should also ensure that cords are labeled with relevant safety certifications, such as CE marking for European markets.

How is Quality Assurance Integrated into the Manufacturing of 3 Prong Range Cords?

Quality assurance (QA) is vital in ensuring that 3 prong range cords are safe and reliable. Here’s how QA is typically structured in the manufacturing process:

-

International Standards: Compliance with international standards such as ISO 9001 ensures that manufacturers adhere to quality management principles. This certification is crucial for B2B buyers, as it signifies that a supplier has consistent quality processes.

-

Industry-Specific Standards: Depending on the market, additional certifications such as UL (Underwriters Laboratories) for the U.S. and CE for Europe may be required. These certifications indicate that products meet specific safety and performance criteria.

-

Quality Checkpoints:

– Incoming Quality Control (IQC): At this initial checkpoint, raw materials are inspected for quality and compliance with specifications.

– In-Process Quality Control (IPQC): During manufacturing, random samples are tested to ensure ongoing compliance with quality standards.

– Final Quality Control (FQC): After assembly, finished products undergo rigorous testing, including electrical performance tests and visual inspections.

What Common Testing Methods Are Used in Quality Control for 3 Prong Range Cords?

Testing methods play a pivotal role in quality assurance. Here are some common testing methods used:

-

Electrical Testing: This includes insulation resistance tests and continuity tests to ensure that the cords can handle their rated voltage and current without failure.

-

Mechanical Testing: Cords are subjected to tensile strength tests and bend tests to evaluate their durability under physical stress.

-

Environmental Testing: Products may also undergo thermal cycling tests to assess their performance under extreme temperature variations, which is particularly relevant for regions with harsh climates.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance practices firsthand. This can provide valuable insights into the supplier’s capabilities and compliance with international standards.

-

Quality Control Reports: Requesting documentation such as quality control reports, testing results, and certifications can help buyers verify that the supplier adheres to relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality processes and product reliability. This is particularly important for buyers in Africa, South America, the Middle East, and Europe, where varying regulations and standards may apply.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing 3 prong range cords internationally, B2B buyers should be aware of the following nuances:

-

Regional Standards: Different regions may have specific certification requirements. For example, the Middle East may require conformity with Gulf Standards (GSO), while European buyers must ensure CE compliance.

-

Language and Documentation: Language barriers can complicate the verification process. Buyers should ensure that documentation is available in a language they understand and that it clearly outlines compliance with relevant standards.

-

Regulatory Compliance: Buyers should be aware of import regulations in their respective countries, as non-compliance can lead to delays or product recalls. Working with suppliers who have a good understanding of these regulations can mitigate risks.

Conclusion: Ensuring Quality in 3 Prong Range Cord Procurement

The manufacturing processes and quality assurance practices for 3 prong range cords are critical for ensuring safety and reliability. By understanding the key stages of manufacturing, the importance of quality checkpoints, and the nuances of international certification, B2B buyers can make informed decisions that align with their business needs and regulatory requirements. As international markets continue to evolve, staying updated on these aspects will be essential for successful procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 prong range cord’

To effectively source a 3 prong range cord, it is essential to follow a structured approach that ensures quality, compliance, and compatibility with your specific needs. This guide will provide you with a comprehensive checklist tailored for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Start by establishing the precise technical requirements for the range cord. This includes voltage ratings, amperage, and length specifications. For example, a 50 Amp cord is typically used for high-powered appliances, while a 40 Amp may suffice for standard ranges.

– Voltage Ratings: Ensure that the cord meets the voltage requirements of your appliances (e.g., 240V).

– Amperage: Confirm that the amperage rating matches your appliance needs.

Step 2: Research Compliance Standards

Investigate the local and international compliance standards applicable to electrical products. This is particularly crucial for buyers in diverse markets like Africa and Europe, where safety regulations can vary significantly.

– Certification Marks: Look for products certified by recognized organizations (e.g., UL, CE) to ensure they meet safety standards.

– Regulatory Compliance: Verify that the cords comply with local electrical codes to avoid legal issues.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Supplier Background: Investigate their history in the market and their manufacturing capabilities.

– Client Testimonials: Seek feedback from other businesses to gauge reliability and product quality.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the 3 prong range cords to assess their quality firsthand. This step is vital to ensure that the product meets your specifications and performance expectations.

– Quality Check: Examine the cord for durability, flexibility, and any visible defects.

– Performance Testing: Test the samples with your appliances to ensure proper functionality.

Step 5: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms and pricing. This involves not just the cost per unit but also payment terms, minimum order quantities, and delivery timelines.

– Bulk Discounts: Inquire about discounts for larger orders which can significantly reduce overall costs.

– Shipping Costs: Consider logistics and shipping options, especially for international procurement.

Step 6: Verify Warranty and Support

Before finalizing your purchase, ensure that the supplier offers a robust warranty and customer support. This is crucial for addressing any issues that may arise post-purchase.

– Warranty Terms: Understand the duration and coverage of the warranty.

– Customer Support: Check the availability of technical support for installation or troubleshooting.

Step 7: Plan for Future Procurement

After a successful initial purchase, consider setting up a long-term relationship with your chosen supplier for future needs. Establishing a reliable sourcing channel can streamline your procurement process.

– Reorder Strategies: Discuss options for automatic reordering based on your usage patterns.

– Supplier Development: Work with your supplier to improve product offerings and services over time.

By following this checklist, B2B buyers can navigate the complexities of sourcing a 3 prong range cord effectively, ensuring they meet both technical and regulatory requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 3 prong range cord Sourcing

What are the Key Cost Components for Sourcing a 3-Prong Range Cord?

When sourcing 3-prong range cords, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The primary materials used in manufacturing range cords are copper (for conductors), PVC (for insulation), and sometimes additional materials for shielding. The quality and sourcing of these materials can significantly affect costs. Buyers should consider suppliers that offer high-quality materials that comply with local regulations.

-

Labor: Labor costs can vary significantly based on geographic location. In regions with lower labor costs, such as parts of Africa and South America, manufacturers may have a cost advantage. However, skilled labor is essential for ensuring quality, particularly in assembly and testing processes.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and salaries of non-production staff. Higher overhead can result from advanced machinery or environmentally friendly practices, which may be more common in European manufacturers.

-

Tooling and Setup Costs: Initial setup costs for manufacturing new products can be substantial, particularly for custom orders. Buyers should inquire about these costs and whether they can be amortized over larger orders to reduce unit costs.

-

Quality Control (QC): Investing in quality control processes is essential to ensure product reliability. The costs associated with QC can vary, but they are necessary to prevent defects that could lead to warranty claims or product recalls.

-

Logistics: Shipping costs depend on the distance from the supplier, the volume of the order, and the chosen Incoterms. International buyers should consider logistics providers that offer competitive rates and reliable services.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and perceived product value. Understanding the average margins in different regions can help buyers negotiate better prices.

How Do Price Influencers Affect the Sourcing of 3-Prong Range Cords?

Several factors can influence the final pricing of 3-prong range cords:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs. Negotiating MOQs can be beneficial, especially for larger buyers who can consolidate orders.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized materials or manufacturing processes. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials (e.g., standard vs. premium copper) and quality certifications (e.g., UL, CE) can significantly impact pricing. Buyers should weigh the importance of certifications against potential cost savings.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Buyers should be aware of how terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) will impact their total costs.

What Tips Can Help Buyers Negotiate Better Prices for 3-Prong Range Cords?

-

Conduct Thorough Market Research: Understanding the average price range for 3-prong range cords in the target market can empower buyers during negotiations.

-

Leverage Total Cost of Ownership (TCO): When evaluating offers, consider not just the purchase price but the total cost of ownership, including shipping, handling, and potential warranty claims.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Regular communication and feedback can strengthen partnerships.

-

Be Open to Different Suppliers: Diversifying suppliers can reduce dependency on a single source and increase bargaining power. This is particularly important for international buyers looking for competitive pricing.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow and make larger orders more feasible. Discussing options such as delayed payments or installment plans can benefit both parties.

Conclusion

Sourcing 3-prong range cords involves understanding the various cost components and price influencers that affect overall pricing. By leveraging negotiation strategies and considering total cost implications, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can make informed purchasing decisions that align with their business objectives. Remember, the prices mentioned in this analysis are indicative and may vary based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing 3 prong range cord With Other Solutions

When considering the procurement of electrical components, particularly for appliances like ranges, it’s essential to evaluate various solutions. While the 3-prong range cord is a popular choice, there are alternative options that may suit different operational needs, budget constraints, or safety considerations.

| Comparison Aspect | 3 Prong Range Cord | Alternative 1: 4 Prong Range Cord | Alternative 2: Hardwired Connection |

|---|---|---|---|

| Performance | Standard for many appliances, suitable for 240V systems | Supports higher safety standards with a neutral wire | Provides a direct connection, often more reliable |

| Cost | Typically ranges from $15 to $50 depending on length and amperage | Slightly higher, around $30 to $70 | Installation costs vary significantly, can be high due to labor |

| Ease of Implementation | Easy to install; plug-and-play design | Requires specific outlet; may need adapters | Requires professional installation, potentially complex |

| Maintenance | Minimal; replace if damaged | Minimal; replace if damaged | Low, but may require professional checks periodically |

| Best Use Case | Residential use with older appliances | Newer appliances with safety compliance | Permanent installations in commercial settings |

What Are the Benefits and Drawbacks of Using a 4 Prong Range Cord?

The 4-prong range cord is increasingly becoming the standard for modern electric ranges due to its enhanced safety features. The additional prong serves as a neutral connection, reducing the risk of electrical shock and allowing for a more stable current. While it might come at a higher upfront cost, the long-term safety benefits can outweigh the initial investment. However, it requires a compatible outlet, which could necessitate additional installation work.

How Does a Hardwired Connection Compare to a 3 Prong Range Cord?

Hardwired connections involve directly connecting the appliance to the electrical supply without a cord. This method is often favored in commercial environments where reliability is critical. The benefits include a more permanent solution and potentially lower chances of disconnection or wear. However, the installation process can be complex and requires professional electrical work, which can significantly increase costs and timeframes.

What Should B2B Buyers Consider When Choosing Between These Solutions?

When selecting the right solution, B2B buyers should carefully assess their specific needs, including appliance compatibility, safety standards, and budget constraints. For businesses operating in regions like Africa and the Middle East, where electrical standards may differ, understanding local regulations is crucial. Additionally, the installation environment—whether residential or commercial—will influence the decision.

In conclusion, while the 3-prong range cord is a reliable option for many applications, evaluating alternatives like the 4-prong cord or hardwired connections can lead to improved safety and performance. Buyers should weigh the pros and cons of each solution in relation to their operational context and future needs.

Essential Technical Properties and Trade Terminology for 3 prong range cord

What Are the Essential Technical Properties of a 3 Prong Range Cord?

When evaluating a 3 prong range cord, several technical properties are critical for ensuring safe and effective operation. Understanding these specifications can significantly impact the purchasing decisions of B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

1. Wire Gauge (AWG)

The American Wire Gauge (AWG) measurement indicates the thickness of the wire used in the range cord. A lower AWG number corresponds to a thicker wire, which can carry more current. For instance, a 6 AWG wire is typically used for 50 Amp cords, while a 10 AWG wire might suffice for lower amperage applications. B2B buyers must consider the wire gauge to ensure compatibility with their appliance and to prevent overheating, which can lead to safety hazards.

2. Ampacity

Ampacity refers to the maximum amount of electrical current a cord can safely carry without overheating. For 3 prong range cords, common ratings are 40 and 50 Amps. This specification is crucial for buyers to match the range cord with the power requirements of their electric ranges. Overloading a cord can not only damage the appliance but also pose serious fire risks.

A stock image related to 3 prong range cord.

3. Cord Length

The length of the range cord can significantly influence installation flexibility. Common lengths include 4 ft, 6 ft, and 10 ft. Longer cords may be necessary for installations where the power source is not conveniently located. Buyers should assess their installation environment to determine the appropriate length, as using a cord that is too short may require the use of extension cords, which can compromise safety.

4. Insulation Material

The insulation material of a range cord affects its durability and resistance to heat and moisture. Common materials include PVC (polyvinyl chloride) and rubber. Buyers should prioritize cords with high-quality insulation to ensure longevity and safety, especially in environments prone to temperature fluctuations or moisture.

5. Connector Type

The connector type, including the arrangement and design of the prongs, is essential for compatibility with electrical outlets. Standard configurations include 3-prong and 4-prong connectors. Understanding the local electrical standards is critical for buyers to avoid mismatches that could lead to installation issues or safety hazards.

What Trade Terms Should B2B Buyers Understand When Purchasing 3 Prong Range Cords?

Familiarity with industry jargon can enhance communication and negotiation during the procurement process. Here are several essential trade terms relevant to 3 prong range cords.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of range cords, knowing whether a product is OEM can assure buyers of its quality and compatibility with specific appliances.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it affects inventory costs and purchasing strategy. Buyers should negotiate MOQs that align with their operational needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits suppliers to provide price quotes for specific goods or services. Issuing an RFQ for 3 prong range cords allows buyers to compare prices, terms, and supplier capabilities, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for B2B buyers to understand shipping liabilities and costs associated with their range cord purchases.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. For B2B buyers, understanding lead times is essential for inventory management and ensuring that supply chains remain uninterrupted.

6. Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product meets specific safety and quality requirements. Buyers should prioritize cords that have relevant certifications to ensure compliance with local regulations and safety standards.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing 3 prong range cords, ultimately enhancing their procurement processes and product reliability.

Navigating Market Dynamics and Sourcing Trends in the 3 prong range cord Sector

What Are the Current Market Trends Influencing the 3-Prong Range Cord Sector?

A stock image related to 3 prong range cord.

The 3-prong range cord market is experiencing dynamic changes driven by several global factors. One significant trend is the increasing demand for energy-efficient appliances, especially in developing regions like Africa and South America, where electrification is on the rise. As more households acquire electric ranges, the need for compatible power cords is escalating. International B2B buyers should note that manufacturers are now focusing on producing cords that not only meet safety standards but also enhance energy efficiency.

Emerging technologies are also reshaping sourcing strategies. For instance, the integration of smart manufacturing techniques has improved the quality and reliability of electrical components, including range cords. Moreover, advancements in e-commerce platforms allow buyers from regions such as the Middle East and Europe to access a broader range of suppliers and products, streamlining procurement processes.

Another key market dynamic is the evolving regulatory landscape. Countries are increasingly enforcing stringent safety and quality regulations for electrical appliances and their accessories. B2B buyers must stay informed about these regulations, particularly in regions like Turkey and Indonesia, to ensure compliance and avoid costly penalties.

How Can Sustainability and Ethical Sourcing Impact Your B2B Purchasing Decisions?

The environmental impact of sourcing materials for 3-prong range cords is becoming a pivotal concern for international B2B buyers. The production of electrical cords often involves non-renewable resources, which can contribute to pollution and waste. As global awareness of sustainability grows, buyers are increasingly prioritizing suppliers that adopt eco-friendly practices.

Ethical sourcing is another essential aspect. Suppliers that demonstrate a commitment to fair labor practices and transparent supply chains not only enhance their brand reputation but also mitigate risks associated with unethical labor practices. Buyers should seek out certifications such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) compliance, which indicate adherence to environmental regulations.

Moreover, the market is seeing a rise in the use of recycled materials in the manufacturing of range cords. These innovations not only reduce the carbon footprint but also appeal to consumers and businesses that prioritize sustainability in their purchasing decisions. Engaging with suppliers who invest in ‘green’ materials can help B2B buyers align with their corporate social responsibility goals.

What Is the Historical Context of the 3-Prong Range Cord Market?

The evolution of the 3-prong range cord can be traced back to the mid-20th century when electrical safety standards began to emerge. Initially, electrical cords were often designed without a standardized approach, leading to safety hazards. The introduction of the 3-prong design marked a significant advancement in electrical safety, providing a grounded connection to prevent electrical shocks.

As technology advanced, so did the manufacturing processes for these cords. Today, the market is characterized by enhanced safety features, such as heat resistance and improved insulation materials. This historical context is vital for B2B buyers as it underscores the importance of sourcing cords that meet contemporary safety standards and technological advancements, ensuring both compliance and reliability in their operations.

By understanding these trends and historical insights, international B2B buyers can make informed decisions that align with market demands while fostering sustainable and ethical procurement practices.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 prong range cord

-

How do I choose the right 3 prong range cord for my appliance?

When selecting a 3 prong range cord, consider the amp rating and length required for your specific appliance. Most ranges require cords rated at 40 or 50 amps, depending on their power consumption. Additionally, ensure the cord length is sufficient to reach your outlet without stretching or straining. Always refer to your appliance’s manual for specific recommendations to ensure compatibility and safety. -

What are the standard lengths available for 3 prong range cords?

3 prong range cords typically come in standard lengths of 4, 6, and 10 feet. The length you choose will depend on the distance between your appliance and the power outlet. In some cases, longer cords may be available, but it’s crucial to ensure that the cord is rated for the appropriate amperage to prevent overheating. -

How can I verify the quality of a 3 prong range cord supplier?

To vet a supplier, check their certifications, such as ISO 9001, and seek references or reviews from previous clients. It is also beneficial to request samples for testing before placing a bulk order. Ensure that the supplier complies with international safety standards, particularly those relevant to your market, such as CE marking in Europe or UL certification in the U.S. -

What is the minimum order quantity (MOQ) for 3 prong range cords?

MOQs can vary significantly among suppliers, typically ranging from 100 to 1,000 units for electrical components. It’s advisable to discuss your specific requirements with the supplier to see if they can accommodate smaller orders, especially if you are testing the market or beginning a new project.

A stock image related to 3 prong range cord.

-

What payment terms should I expect when sourcing 3 prong range cords internationally?

Payment terms can vary by supplier and region but generally include options such as advance payment, letter of credit, or payment upon delivery. Establish clear terms upfront to avoid misunderstandings. Consider using escrow services for large transactions to ensure both parties fulfill their obligations. -

How do I ensure compliance with international shipping regulations for range cords?

Compliance with international shipping regulations requires thorough knowledge of both the exporting and importing countries’ laws. Ensure that your products meet the required safety standards and certifications. Work with a reputable freight forwarder who can assist with customs documentation and ensure adherence to regulations, reducing the risk of delays or penalties. -

What should I do if the 3 prong range cord I receive is defective?

Upon receiving a defective product, promptly contact the supplier to report the issue. Most reputable suppliers will have a return or exchange policy in place. Document the defect with photos and provide a clear description when reaching out. Depending on the agreement, you may receive a replacement, credit, or refund. -

How can I customize 3 prong range cords to meet specific needs?

Customization options for 3 prong range cords often include variations in length, gauge, and insulation type. To initiate customization, discuss your requirements with potential suppliers, providing details on your application and any specific standards you need to meet. Many manufacturers can accommodate custom requests, especially for larger orders, but be prepared for longer lead times.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 3 prong range cord

What Are the Key Takeaways for B2B Buyers of 3-Prong Range Cords?

In summary, strategic sourcing of 3-prong range cords is essential for international B2B buyers seeking to optimize their supply chain and enhance operational efficiency. Buyers should focus on evaluating supplier reliability, product specifications, and compliance with local electrical standards, which can vary significantly across regions like Africa, South America, the Middle East, and Europe. Understanding the nuances of different cord types, such as ampacity and length, ensures that businesses select the right products for their specific needs.

How Can International Buyers Enhance Their Sourcing Strategy?

As the market for electrical components continues to evolve, leveraging strategic sourcing practices can provide a competitive edge. Establishing long-term relationships with manufacturers and suppliers not only ensures product quality but also facilitates better pricing and access to the latest innovations. Buyers should also consider sustainability practices in their sourcing decisions, as eco-friendly products are increasingly preferred in global markets.

What’s Next for B2B Buyers in the 3-Prong Range Cord Market?

Looking ahead, the demand for reliable and efficient range cords is expected to grow, driven by the increasing adoption of electric appliances. International B2B buyers are encouraged to stay proactive by continuously assessing market trends and exploring emerging suppliers to enhance their procurement strategies. Now is the time to invest in robust sourcing frameworks that align with future market needs, ensuring your business remains agile and competitive in this dynamic landscape.