Solve Water Quality Issues: The Ultimate Water Filtering Guide (2025)

Introduction: Navigating the Global Market for water filtering

Navigating the complexities of the global market for water filtering presents a significant challenge for international B2B buyers, particularly those sourcing solutions in regions like Africa, South America, the Middle East, and Europe. The increasing demand for clean, safe drinking water has heightened the need for effective water filtration systems. This guide provides a comprehensive overview of the various types of water filters available, including pitcher filters, whole-house systems, and industrial-grade solutions, along with their specific applications across diverse sectors.

B2B buyers will find detailed insights into supplier vetting processes, enabling them to select trustworthy manufacturers and distributors. Additionally, the guide offers a thorough analysis of cost considerations, ensuring that procurement decisions are both economically viable and aligned with quality standards. By addressing key challenges such as varying water quality needs and regulatory compliance in different markets, this resource empowers buyers to make informed purchasing decisions.

Whether you are operating in the bustling markets of Mexico or the emerging economies of Africa, understanding the nuances of water filtration technologies can enhance your sourcing strategies. With actionable insights and expert recommendations, this guide equips you to navigate the global water filtering landscape with confidence, ensuring that you secure the best solutions for your organization’s needs.

Understanding water filtering Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Activated Carbon Filters | Utilizes activated carbon to adsorb impurities; effective against chlorine and volatile organic compounds (VOCs). | Food and beverage industry, hospitality | Pros: Cost-effective, improves taste; Cons: Limited lifespan, not effective against all contaminants. |

| Reverse Osmosis Systems | Employs a semi-permeable membrane to remove a wide range of contaminants, including salts, heavy metals, and certain pathogens. | Manufacturing, pharmaceuticals | Pros: High contaminant removal efficiency; Cons: Waste water generation, requires more maintenance. |

| Ultraviolet (UV) Water Purifiers | Uses UV light to disinfect water by inactivating bacteria, viruses, and other microorganisms. | Healthcare, food processing | Pros: Chemical-free disinfection, low maintenance; Cons: Does not remove chemical contaminants. |

| Whole House Filtration Systems | Provides comprehensive filtration for all water sources in a property, addressing multiple contaminants. | Residential and commercial buildings | Pros: Protects plumbing and appliances; Cons: Higher initial investment, may require professional installation. |

| Ion Exchange Systems | Exchanges harmful ions (like calcium and magnesium) with less harmful ones, often used for softening hard water. | Agriculture, industrial applications | Pros: Reduces scale buildup, improves efficiency of appliances; Cons: Regular salt replenishment needed, not suitable for all water types. |

What are Activated Carbon Filters and Their B2B Suitability?

Activated carbon filters are widely used for their ability to adsorb impurities effectively, particularly chlorine and VOCs, making them ideal for the food and beverage industry as well as hospitality. These filters enhance water taste and quality, which is critical in sectors where customer satisfaction is paramount. When purchasing, B2B buyers should consider the filter’s lifespan and replacement frequency, as well as the specific contaminants that need to be addressed.

How Do Reverse Osmosis Systems Work for B2B Applications?

Reverse osmosis systems are known for their ability to remove a wide array of contaminants, including salts and heavy metals, making them suitable for industries such as manufacturing and pharmaceuticals. These systems provide high-quality water essential for production processes. However, buyers should be aware of the potential for water wastage and the need for regular maintenance, which can impact operational costs.

Why Choose Ultraviolet (UV) Water Purifiers for Your Business?

UV water purifiers utilize ultraviolet light to effectively disinfect water, rendering harmful microorganisms inactive without the use of chemicals. This technology is particularly beneficial for industries like healthcare and food processing, where water safety is critical. B2B buyers should evaluate the system’s capacity to handle peak water demands and ensure that it meets the specific disinfection needs of their operations.

What are the Benefits of Whole House Filtration Systems?

Whole house filtration systems provide comprehensive water treatment, safeguarding all water sources within a property. This is especially important for residential and commercial buildings where water quality impacts plumbing and appliance longevity. Although the initial investment can be significant, the long-term benefits, such as reduced maintenance costs and improved water quality, make it a valuable consideration for B2B buyers.

How Do Ion Exchange Systems Benefit Various Industries?

Ion exchange systems are particularly effective in reducing water hardness by exchanging harmful ions with less harmful alternatives. This makes them suitable for agricultural and industrial applications where equipment efficiency is vital. When considering ion exchange systems, B2B buyers should factor in the ongoing need for salt replenishment and ensure compatibility with their specific water quality requirements.

Key Industrial Applications of water filtering

| Industry/Sector | Specific Application of Water Filtering | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Filtration in Beverage Production | Ensures product safety and quality; enhances taste | Certifications for food safety, TDS levels, and contaminant removal efficiency |

| Healthcare | Water Purification for Medical Facilities | Protects patient health; meets regulatory standards | Compliance with health regulations; ease of maintenance and filter longevity |

| Agriculture | Irrigation Water Treatment | Improves crop yield; reduces soil salinity | Filtration capacity for specific contaminants; sustainability and environmental impact |

| Hospitality | Water Filtration in Hotels and Restaurants | Enhances guest experience; reduces bottled water costs | System scalability; filtration quality; maintenance support |

| Industrial Manufacturing | Process Water Filtration | Increases equipment lifespan; reduces downtime | Durability under industrial conditions; customization options; supplier reliability |

How is Water Filtering Used in the Food and Beverage Industry?

In the food and beverage sector, water filtering is crucial for ensuring the purity and safety of products. Filtration systems remove impurities, such as chlorine, heavy metals, and microorganisms, which can affect taste and safety. For international B2B buyers, particularly in regions like Africa and South America, it is essential to source systems that comply with local food safety regulations and have the ability to efficiently handle varying water quality. The ability to provide certifications for the filtration process can significantly enhance buyer confidence and ensure compliance with industry standards.

What Role Does Water Purification Play in Healthcare Facilities?

Water purification in healthcare settings is vital for maintaining hygiene and protecting patient health. Hospitals and clinics require high-quality water for various applications, including sterilization, laboratory testing, and patient care. B2B buyers from the Middle East and Europe need to prioritize systems that meet strict health regulations and provide consistent performance. Additionally, ease of maintenance and the longevity of filters are crucial factors, as these systems must operate continuously without interruption to prevent any risk to patient safety.

How Does Water Filtering Benefit Agriculture?

In agriculture, water filtering is used to treat irrigation water, enhancing crop yield and quality. Filtration removes contaminants that can harm plants or degrade soil quality, such as salts and pesticides. For buyers in regions with challenging water conditions, like parts of Africa, selecting a filtration system that can handle specific local contaminants is essential. Sustainability practices are also increasingly important, so buyers should consider systems that minimize environmental impact while maximizing agricultural productivity.

Why is Water Filtration Important in Hospitality?

In the hospitality industry, water filtration enhances the guest experience by providing clean and safe drinking water while reducing reliance on bottled water. Hotels and restaurants benefit from systems that ensure consistent water quality throughout their facilities. International buyers, particularly in Europe and South America, should look for scalable solutions that can adapt to fluctuating demand and ensure high filtration quality. Additionally, good after-sales support and maintenance services are crucial to minimize downtime and maintain guest satisfaction.

How is Water Filtration Applied in Industrial Manufacturing?

In industrial manufacturing, water filtration is essential for process water used in production lines. Clean water ensures that machinery operates efficiently and reduces the risk of downtime due to equipment failure caused by contaminated water. B2B buyers from various regions should focus on sourcing durable filtration systems that can withstand industrial conditions and offer customization options to meet specific process requirements. Supplier reliability and the ability to provide technical support are also key considerations for maintaining operational efficiency.

3 Common User Pain Points for ‘water filtering’ & Their Solutions

Scenario 1: Inconsistent Water Quality Affecting Operations

The Problem:

B2B buyers in industries such as food and beverage, pharmaceuticals, and hospitality often face the challenge of inconsistent water quality. Variability in water source contaminants—like chlorine, heavy metals, and pathogens—can lead to product spoilage, equipment damage, and compromised health standards. For instance, a beverage manufacturer relying on municipal water may experience fluctuations in water quality due to seasonal changes, which can affect the taste and safety of their products.

The Solution:

To combat inconsistent water quality, businesses should invest in comprehensive water testing and filtration solutions tailored to their specific needs. First, conduct a thorough analysis of the local water supply, focusing on Total Dissolved Solids (TDS) and specific contaminants. Based on the results, select a robust filtration system, such as a whole-house or point-of-use system that employs multi-stage filtration technologies like reverse osmosis or ion-exchange. Additionally, consider integrating real-time monitoring systems that can provide data on water quality and filter performance, allowing for timely adjustments and maintenance.

Scenario 2: High Maintenance Costs and Equipment Failures

The Problem:

Another significant pain point for B2B buyers is the high maintenance costs associated with water filtration systems. Many businesses overlook the long-term costs tied to frequent filter replacements, equipment failures, and downtime caused by inadequate filtration. For example, a hotel might find that their water filtration system is not performing optimally, leading to scaling in pipes and appliances, which can necessitate costly repairs and maintenance.

The Solution:

To minimize maintenance costs, B2B buyers should prioritize investing in high-quality, durable filtration systems that offer extended filter life and low maintenance requirements. When sourcing equipment, look for systems that feature advanced filtration technologies with longer-lasting filters, such as those that reduce chlorine and sediment while minimizing scale buildup. Implementing a preventive maintenance program can further enhance system longevity. Schedule regular inspections and cleaning of filtration units to ensure optimal performance. Additionally, consider using water softeners or conditioners to protect plumbing and appliances from scale-related damage, thereby extending their lifespan and reducing overall costs.

Scenario 3: Regulatory Compliance Challenges

The Problem:

International B2B buyers, especially in regions with stringent regulatory standards, face compliance challenges regarding water quality. Companies in the food, beverage, and healthcare sectors must adhere to specific regulations regarding contaminant levels and water safety. Failing to meet these standards can result in penalties, loss of certification, or even legal issues. For example, a beverage manufacturer in South America may struggle to meet local regulations concerning lead levels in drinking water.

The Solution:

To address regulatory compliance challenges, businesses should engage with certified water filtration suppliers who can provide systems that meet or exceed local and international standards. Conduct a gap analysis to identify the specific regulatory requirements applicable to your industry and region. This will guide your selection of filtration technologies that are certified to remove harmful contaminants like lead, mercury, and PFAS. Regularly update your compliance knowledge and ensure that your water filtration systems are tested and certified by independent laboratories. Maintain thorough documentation of water quality testing and filtration system performance to demonstrate compliance during audits or inspections. By proactively addressing compliance needs, businesses can avoid penalties and ensure the safety and quality of their products.

Strategic Material Selection Guide for water filtering

When selecting materials for water filtering systems, international B2B buyers must consider various factors to ensure optimal performance and compliance with local standards. Here, we analyze four common materials used in water filtration applications, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Activated Carbon in Water Filtration?

Activated carbon is widely used in water filtration due to its high adsorption capacity, which effectively removes contaminants such as chlorine, volatile organic compounds (VOCs), and other impurities. It operates efficiently at ambient temperatures and pressures, making it suitable for various applications. The material is also resistant to corrosion, ensuring longevity in water systems.

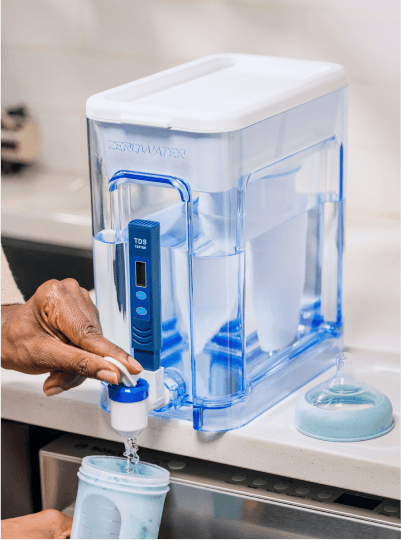

A stock image related to water filtering.

Pros: Activated carbon is relatively inexpensive and easy to manufacture, making it a cost-effective choice for many filtration systems. Its ability to improve taste and odor is a significant advantage for consumer-facing products.

Cons: While activated carbon is effective for many contaminants, it may not remove heavy metals or certain pathogens, necessitating additional filtration steps. The material also has a limited lifespan and requires regular replacement to maintain effectiveness.

Impact on Application: Activated carbon is compatible with various media, including granular and block forms, allowing flexibility in design. However, its adsorption capacity can be affected by the presence of competing contaminants.

Considerations for International Buyers: Buyers should ensure that activated carbon meets local health and safety standards, such as those outlined by ASTM or DIN. In regions like Africa and South America, where water quality may vary significantly, it is crucial to select activated carbon that is certified for specific contaminants.

How Does Polypropylene Compare as a Filter Material?

Polypropylene is a thermoplastic polymer commonly used in water filtration systems, particularly in filter cartridges and membranes. It boasts excellent chemical resistance and can withstand a wide range of temperatures, making it suitable for various applications.

Pros: Polypropylene is durable and has a long service life, which can reduce maintenance costs. It is also lightweight and easy to handle during installation.

Cons: The manufacturing process for polypropylene can be complex, leading to higher initial costs compared to simpler materials. Additionally, while it is effective for particulate filtration, it may not be suitable for removing dissolved contaminants.

Impact on Application: Polypropylene is often used in conjunction with other materials to enhance filtration performance. Its compatibility with different filtration media allows for customized solutions.

Considerations for International Buyers: Buyers should verify that polypropylene filters comply with international standards for drinking water, especially in regions with strict regulations, such as Europe. Understanding local waste disposal regulations for polypropylene products is also essential.

What Are the Advantages of Stainless Steel in Water Filtration Systems?

Stainless steel is favored for its strength, durability, and resistance to corrosion, making it an excellent choice for structural components in water filtration systems. It can withstand high pressures and temperatures, ensuring reliability in demanding environments.

Pros: Stainless steel is highly durable and can last for decades with proper maintenance. Its resistance to corrosion makes it suitable for both residential and industrial applications.

Cons: The initial cost of stainless steel can be high compared to other materials. Additionally, it may require specialized manufacturing techniques, which can complicate production.

Impact on Application: Stainless steel is often used for housings and tanks in filtration systems, providing structural integrity and protection for internal components. Its compatibility with various filtration media enhances overall system performance.

Considerations for International Buyers: Buyers should ensure that stainless steel components meet local standards for food-grade materials, particularly in regions with stringent health regulations. Understanding the alloy specifications is crucial for ensuring compatibility with local water quality.

How Does Ceramic Material Enhance Water Filtration?

Ceramic filters are known for their ability to remove bacteria, sediment, and other particulate matter effectively. They are typically made from natural clay and can be used in gravity-fed systems, making them suitable for various applications.

Pros: Ceramic filters are highly effective at removing pathogens and are often used in point-of-use systems. They are also reusable after cleaning, which can lower long-term costs.

Cons: The filtration rate can be slower compared to other materials, and they may not be effective against dissolved contaminants. Additionally, ceramic filters can be fragile and require careful handling.

Impact on Application: Ceramic filters are often used in combination with other filtration technologies to enhance overall effectiveness. Their compatibility with gravity-fed systems makes them ideal for rural or off-grid applications.

Considerations for International Buyers: Buyers should verify that ceramic filters are tested and certified for specific contaminants, especially in regions with varying water quality. Understanding local preferences for filtration technology is also vital for market acceptance.

Summary Table of Material Selection for Water Filtering

| Material | Typical Use Case for Water Filtering | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Activated Carbon | Point-of-use filters | High adsorption capacity | Limited lifespan | Low |

| Polypropylene | Filter cartridges | Durable and lightweight | Complex manufacturing process | Medium |

| Stainless Steel | Structural components | Highly durable and corrosion-resistant | High initial cost | High |

| Ceramic | Gravity-fed systems | Effective against bacteria | Slower filtration rate | Medium |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions regarding water filtration systems, ensuring compliance, performance, and cost-effectiveness in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for water filtering

What Are the Main Stages of Manufacturing Water Filters?

The manufacturing process for water filters is intricate and involves several key stages to ensure product quality and effectiveness. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation

The first step in the manufacturing process is material preparation, which involves sourcing high-quality materials essential for effective filtration. Common materials include activated carbon, ion-exchange resins, and various polymer membranes. Suppliers should verify that these materials meet industry standards, as the efficacy of the water filter largely depends on the quality of the raw materials.

Forming Techniques

Once the materials are prepared, the next stage is forming. This can include processes like extrusion, molding, or casting to create filter components. For instance, activated carbon may be extruded into pellets or granules, while membranes are often cast into sheets. Advanced techniques such as electrospinning are also employed for producing nanofibrous membranes that enhance filtration performance. Buyers should inquire about the technologies used by suppliers to ensure they utilize the most effective and innovative forming techniques.

Assembly of Filter Components

After forming, the filter components are assembled. This stage is crucial as it determines the filter’s final performance. Different assembly techniques may be utilized, including automated assembly lines or manual assembly for more complex filters. B2B buyers should assess whether the supplier employs rigorous assembly protocols, as any lapses could lead to compromised filter integrity.

Finishing Processes

Finishing processes enhance the filter’s performance and aesthetics. This can include surface treatments to improve the filter’s hydrophilicity or the application of antimicrobial coatings to prevent bacterial growth. Additionally, manufacturers often conduct final inspections during this stage to ensure that the product meets specified dimensions and performance standards. It is advisable for buyers to ask for details regarding finishing processes to ensure that the filters will perform reliably in their intended applications.

How Is Quality Assurance Implemented in Water Filter Manufacturing?

Quality assurance (QA) in water filter manufacturing is critical to ensuring product reliability and safety. Various international and industry-specific standards guide QA processes.

What Are the Relevant International Standards for Quality Assurance?

One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system. Companies that are ISO-certified demonstrate a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE marking (for compliance with European standards) and API standards (for the oil and gas sector) may also apply, depending on the filter’s intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers should verify that materials meet specified standards before they enter production.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves monitoring production parameters to ensure consistent quality. This can include checks on dimensions, weights, and performance characteristics at various stages of production.

-

Final Quality Control (FQC): At the end of the manufacturing process, FQC involves rigorous testing of the finished product. This may include performance tests to measure flow rates, contaminant removal efficiency, and pressure drop across the filter.

B2B buyers should ensure that their suppliers adhere to these checkpoints to maintain high-quality products.

What Common Testing Methods Are Used in Water Filter Quality Control?

Testing methods play a vital role in validating the effectiveness of water filters. Common testing methods include:

-

Flow Rate Testing: Measures the amount of water that can pass through the filter in a specified time frame. This ensures that the filter meets performance expectations.

-

Contaminant Removal Testing: Involves testing the filter against a range of contaminants, such as lead, chlorine, and PFAS (per- and polyfluoroalkyl substances). Suppliers should provide documentation of these tests to verify claims.

-

Durability Testing: Assesses how well the filter performs over time under various conditions, including pressure and temperature fluctuations. This testing ensures that the filter will maintain performance throughout its intended lifespan.

Buyers should ask for test reports and certifications from suppliers to confirm compliance with testing standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying supplier quality control practices is essential to ensure product reliability and compliance with local regulations.

What Are Effective Methods for Supplier Verification?

-

Conducting Audits: Regular audits of suppliers can help buyers assess compliance with quality standards. This can include reviewing production processes, quality control measures, and documentation practices.

-

Requesting Quality Reports: Suppliers should provide comprehensive quality reports that detail their QC processes, testing methods, and results. Buyers should review these documents to ensure transparency and accountability.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. These inspectors can conduct thorough evaluations of manufacturing processes and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges when it comes to quality control.

Understanding Regional Regulations

Each region may have specific regulations regarding water filtration systems, which can impact the quality assurance processes. Buyers should be familiar with these regulations and ensure that their suppliers comply with local standards.

Language and Cultural Barriers

Language differences can hinder effective communication regarding quality standards. Buyers should consider establishing clear communication channels with suppliers to minimize misunderstandings and ensure that quality expectations are met.

Currency and Payment Risks

Currency fluctuations can impact the cost of quality assurance practices. Buyers should negotiate clear terms regarding quality assurance costs to avoid unexpected expenses.

A stock image related to water filtering.

By being aware of these nuances and taking proactive measures, B2B buyers can ensure they select high-quality water filtering solutions that meet their needs and comply with relevant standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water filtering’

Introduction

This practical sourcing guide serves as a comprehensive checklist for international B2B buyers focused on procuring effective water filtering solutions. Whether you are looking for residential, commercial, or industrial-grade filters, following these steps will help ensure that you make informed decisions that align with your specific water quality needs and regulatory requirements.

1. Identify Your Water Quality Needs

Understanding the specific contaminants present in your water supply is crucial for selecting the right filtration system. Conduct water quality tests to identify pollutants such as heavy metals, bacteria, and chemicals like PFAS. Knowing your water’s Total Dissolved Solids (TDS) levels will guide you in choosing a filtration system that effectively addresses these issues.

2. Define Your Technical Specifications

Establish clear technical specifications for your water filtering system based on the identified contaminants and the volume of water you need to filter. Consider factors such as flow rate, filter lifespan, and maintenance requirements. These specifications will help you narrow down your options and ensure that the system meets your operational needs.

3. ✅ Verify Supplier Certifications

Before engaging with potential suppliers, ensure that they hold relevant certifications from recognized bodies. Look for certifications such as NSF/ANSI standards, which indicate that the filters meet rigorous testing requirements. This step is vital to ensure that the products you are considering are safe and effective.

4. Evaluate Potential Suppliers

Conduct thorough due diligence on suppliers to gauge their reliability and reputation. Request company profiles, case studies, and references from buyers in similar industries or regions. Additionally, check online reviews and industry reports to assess their track record in delivering quality products and customer service.

5. Request Product Samples

Before making a bulk purchase, request samples of the water filtering products you are considering. Testing these samples in your specific environment can provide valuable insights into their performance and compatibility with your existing systems. Look for improvements in water taste, clarity, and safety.

6. Understand the Total Cost of Ownership

Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, replacement filters, and energy consumption. A lower upfront cost might come with higher long-term expenses. Evaluate warranty and service options as well to ensure ongoing support.

7. Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to secure the best terms and conditions. This includes price, delivery timelines, payment terms, and after-sales support. Clear and favorable agreements can lead to a better partnership and ensure that you receive consistent quality and service.

By following this structured checklist, B2B buyers can confidently navigate the complexities of sourcing water filtering solutions, ensuring that they select systems that are effective, reliable, and tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for water filtering Sourcing

What Are the Key Cost Components in Water Filtering Sourcing?

When sourcing water filtering systems, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of materials significantly impacts the price. For instance, high-grade carbon filters or advanced ion-exchange resins typically lead to higher costs. Buyers should consider sourcing from regions with lower material costs without compromising quality.

-

Labor: Labor costs vary greatly depending on the country of production. Countries in Africa and South America may offer lower labor costs compared to Europe, but this can also influence the skill level and quality of workmanship.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, thus lowering overall product costs.

-

Tooling: Custom tooling for specialized products can increase upfront costs. However, it may provide cost savings in the long run if the tooling is used for high-volume production.

-

Quality Control (QC): Implementing stringent QC measures can increase costs but is essential for ensuring product reliability, especially when dealing with health-related products like water filters.

-

Logistics: Transportation costs can vary based on the shipping method, distance, and current global shipping rates. Buyers should factor in these costs when evaluating suppliers.

-

Margin: Suppliers typically include a profit margin that can range from 10% to 30% depending on market conditions and competition.

How Do Price Influencers Impact Water Filtering Costs?

Several factors can influence the pricing of water filtration systems:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often results in lower per-unit costs. Buyers should negotiate MOQs that align with their needs to maximize savings.

-

Specifications and Customization: Customized solutions can lead to higher costs due to additional materials and labor. However, tailored products may provide better performance and customer satisfaction, justifying the expense.

-

Materials and Quality Certifications: Filters with certifications (e.g., NSF, WQA) typically command higher prices due to the assurance of performance and safety. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their experience and product quality.

-

Incoterms: Understanding delivery terms is essential. Costs can vary significantly between FOB (Free on Board) and CIF (Cost, Insurance, and Freight) terms, impacting the total landed cost of products.

What Negotiation Tips Should Buyers Consider for Cost Efficiency?

To maximize cost efficiency, international B2B buyers should adopt several strategies:

-

Conduct Market Research: Understanding market trends and competitor pricing helps buyers negotiate better deals. Knowledge of local pricing in Africa, South America, the Middle East, and Europe can provide leverage.

-

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Suppliers may offer discounts for repeat business or bulk orders.

-

Calculate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, replacement parts, and operational costs over time. A lower initial cost may not always equate to lower long-term expenses.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures influenced by local economic conditions, tariffs, and trade agreements. Buyers should be prepared to adjust their strategies accordingly.

Conclusion: Navigating the Complex Landscape of Water Filtering Costs

Understanding the comprehensive cost and pricing analysis of water filtering systems is essential for international B2B buyers. By focusing on key cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember to seek multiple quotes and perform due diligence on suppliers to ensure you receive the best possible value.

Alternatives Analysis: Comparing water filtering With Other Solutions

Exploring Alternatives to Water Filtering for B2B Buyers

In the quest for clean and safe drinking water, international B2B buyers have several options beyond traditional water filtering systems. Understanding the strengths and weaknesses of these alternatives can guide businesses in selecting the most suitable solution for their specific needs. This analysis will compare water filtering with two viable alternatives: reverse osmosis systems and ultraviolet (UV) water purification.

| Comparison Aspect | Water Filtering | Reverse Osmosis System | Ultraviolet (UV) Purification |

|---|---|---|---|

| Performance | Removes most contaminants; effective against chlorine and sediments | Removes up to 99% of dissolved solids, heavy metals, and certain pathogens | Kills 99.99% of bacteria and viruses, but does not remove chemical contaminants |

| Cost | Moderate initial cost, with ongoing filter replacements | Higher initial investment; requires maintenance | Lower operational costs; moderate initial investment |

| Ease of Implementation | Simple installation; user-friendly | More complex installation; may require professional help | Easy to install; requires electricity |

| Maintenance | Regular filter replacements needed | Membrane replacement needed every 2-3 years | Minimal maintenance; UV lamp replacement every 12 months |

| Best Use Case | Residential and small commercial setups needing routine filtration | Industrial applications requiring high purity water | Water sources with microbiological concerns but low chemical contamination |

What Are the Pros and Cons of Reverse Osmosis Systems?

Reverse osmosis (RO) systems are renowned for their ability to provide high-quality water by removing a vast majority of contaminants. They work by pushing water through a semi-permeable membrane, effectively filtering out impurities.

Pros:

– High Purity: RO systems excel in removing dissolved solids, heavy metals, and some microorganisms, making them ideal for industries that require ultra-pure water.

– Versatile Applications: Suitable for both residential and commercial uses, especially in food and beverage industries.

Cons:

– Cost: The initial investment and maintenance can be significant, which may not be ideal for all businesses.

– Water Waste: RO systems typically waste a considerable amount of water during the filtration process.

How Does Ultraviolet (UV) Purification Compare?

UV purification is a technology that uses ultraviolet light to eliminate bacteria, viruses, and other pathogens in water. This method is particularly effective in ensuring microbiological safety.

Pros:

– Effectiveness Against Microorganisms: UV purification is exceptional in disinfecting water, making it a great choice for areas with microbiological contamination concerns.

– Chemical-Free: It does not involve any chemicals, which can be advantageous for businesses looking to maintain eco-friendly practices.

Cons:

– Limited Contaminant Removal: UV systems do not remove dissolved solids, chemicals, or heavy metals, which may necessitate additional filtration methods for comprehensive purification.

– Dependence on Electricity: These systems require a constant power supply, which can be a limitation in areas with unstable energy sources.

How to Choose the Right Water Solution for Your Business Needs?

When selecting the right water purification solution, B2B buyers should assess their unique requirements, including the types of contaminants present, budget constraints, and operational capabilities. For businesses needing comprehensive contaminant removal, a reverse osmosis system may be the best choice despite its higher cost. Conversely, for those primarily concerned with microbial safety, UV purification can provide an effective and eco-friendly solution. Ultimately, understanding the specific water quality needs and operational context will guide the decision-making process for the best water treatment solution.

Essential Technical Properties and Trade Terminology for water filtering

What Are the Key Technical Properties of Water Filtering Systems?

When selecting water filtration systems, understanding the technical properties is essential for making informed purchasing decisions. Here are some critical specifications:

-

Material Grade

The material grade of filtration systems affects durability and performance. Common materials include polypropylene, activated carbon, and stainless steel. Higher-grade materials often provide better resistance to corrosion and chemical reactions, ensuring longevity and reliability. For B2B buyers, selecting a system made from high-quality materials can reduce maintenance costs and enhance system efficiency. -

Flow Rate

Measured in gallons per minute (GPM), flow rate indicates the volume of water that can be filtered in a specific time frame. A higher flow rate is crucial for commercial applications where water demand is significant. Understanding flow rates allows buyers to choose systems that meet their specific operational needs without sacrificing water quality. -

Filtration Efficiency

This property reflects a filter’s ability to remove contaminants from water. It is often expressed as a percentage, indicating how much of a specific contaminant (like lead or chlorine) the system can eliminate. B2B buyers should prioritize systems with high filtration efficiency to ensure compliance with health regulations and to provide safe drinking water. -

Total Dissolved Solids (TDS) Reduction

TDS refers to the total concentration of dissolved substances in water, including minerals, salts, and metals. Effective filtration systems can significantly reduce TDS levels, enhancing water taste and safety. For international buyers, understanding TDS reduction capabilities is essential, especially in regions where water quality may be compromised. -

Certification Standards

Certifications from recognized bodies (like NSF or WQA) validate that filtration systems meet specific health and safety standards. Buyers should look for certifications relevant to their region, as these can influence marketability and compliance with local regulations.

What Common Trade Terminology Should B2B Buyers Know in Water Filtering?

Familiarizing oneself with industry jargon is crucial for effective communication and negotiation in the water filtering market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts and equipment that are marketed by another company. In water filtration, OEMs often provide components like membranes and filters. Understanding OEM relationships can help buyers identify quality suppliers and negotiate better pricing. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for international B2B buyers, as it can impact inventory management and cash flow. Buyers should be aware of MOQs to avoid overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. B2B buyers use RFQs to compare offers and negotiate better deals. A well-prepared RFQ can streamline the procurement process and enhance supplier relationships. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international shipping that define the responsibilities of buyers and sellers. Understanding Incoterms is vital for international buyers to clarify shipping costs, insurance, and the transfer of risk. This knowledge helps avoid misunderstandings and potential financial disputes. -

Lead Time

Lead time is the duration between placing an order and receiving the product. For water filtration systems, lead times can affect project timelines and operational readiness. Buyers should inquire about lead times to effectively plan their purchasing and installation schedules. -

Contaminant Removal Rate

This rate specifies the percentage of particular contaminants that a filtration system can effectively eliminate. Buyers should prioritize systems with high removal rates for specific contaminants relevant to their water quality needs, ensuring compliance with health standards.

By understanding these essential technical properties and industry terms, international B2B buyers can make more informed decisions, optimize procurement processes, and ensure compliance with local regulations.

Navigating Market Dynamics and Sourcing Trends in the water filtering Sector

What Are the Key Market Drivers and Trends in the Water Filtering Sector?

The global water filtering market is witnessing substantial growth driven by increasing awareness of water quality, rising concerns over contaminants, and stringent regulatory frameworks. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, must navigate these dynamics to make informed sourcing decisions. Emerging technologies such as advanced filtration systems, including reverse osmosis and UV purification, are gaining traction. These innovations not only enhance water quality but also reduce operational costs, making them attractive options for businesses looking to improve their water sourcing strategies.

Additionally, the trend towards smart water filtration systems integrated with IoT capabilities is on the rise. These systems enable real-time monitoring of water quality and filter performance, offering businesses greater control and transparency in their water sourcing processes. As the demand for sustainable practices grows, buyers should also consider suppliers who offer filtration solutions tailored to specific regional needs, addressing unique water quality challenges in their markets.

How Does Sustainability Impact B2B Sourcing in Water Filtering?

Sustainability is increasingly becoming a crucial factor in the sourcing of water filtration products. With growing awareness of environmental issues, B2B buyers are prioritizing suppliers who adhere to ethical sourcing practices and sustainable manufacturing processes. The environmental impact of water filtration systems can be significant, particularly regarding waste management and energy consumption. Therefore, businesses should seek partners that utilize eco-friendly materials and offer solutions that minimize waste, such as refillable filter systems.

Moreover, certifications like NSF/ANSI and ISO 14001 serve as indicators of a supplier’s commitment to sustainability. These certifications assure buyers that products meet rigorous safety and environmental standards. By choosing suppliers with these certifications, businesses can enhance their sustainability profile while ensuring compliance with regulations in their respective regions. This approach not only mitigates risks but also caters to a growing consumer demand for responsible products, ultimately improving brand reputation and customer loyalty.

What Is the Evolution of the Water Filtering Industry and Its Relevance for B2B Buyers?

The water filtering industry has evolved significantly over the past few decades. Initially dominated by basic filtration methods, the sector has transitioned to more sophisticated technologies that address a wider range of contaminants, including heavy metals, bacteria, and chemical pollutants. This evolution is particularly relevant for B2B buyers, as it reflects the increasing complexity of water quality challenges faced in various regions.

Historically, the demand for clean water was primarily a consumer concern. However, as industries grow and urbanization accelerates, businesses are recognizing the critical need for reliable water filtration solutions. Today, companies are not only investing in filtration technologies for compliance and health standards but also to enhance operational efficiency and sustainability. This shift underscores the importance of partnering with innovative suppliers that can provide tailored solutions to meet specific industrial needs, thereby ensuring long-term success in an increasingly competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of water filtering

-

How do I choose the right water filtering system for my business needs?

Selecting the right water filtering system involves assessing your specific needs, such as the volume of water to be filtered, the quality of your source water, and the contaminants you aim to eliminate. Consider systems that offer certifications for removing specific pollutants like lead or PFAS, which are increasingly important for health compliance. Additionally, inquire about scalability—whether the system can grow with your business—and maintenance requirements to ensure long-term efficiency. -

What types of water filters are best for industrial applications?

For industrial applications, reverse osmosis (RO) systems and whole-house water filtration systems are often the best choices. RO systems are effective at removing a wide range of contaminants, including salts and heavy metals, making them suitable for industries that require high purity water. Whole-house systems provide comprehensive filtration for all water points, ensuring that both operational and employee health standards are met. Evaluate your specific industry requirements to determine the most suitable option. -

What are the key factors to consider when vetting water filter suppliers?

When vetting suppliers, focus on their certifications, experience, and customer reviews. Ensure they comply with local and international water safety standards. Assess their capacity to customize solutions to fit your specific needs, including the ability to provide ongoing support and maintenance. Additionally, consider their logistics capabilities and reliability in delivering timely shipments, especially if you operate in regions with unique challenges, such as Africa or the Middle East. -

What is the typical minimum order quantity (MOQ) for water filtering systems?

Minimum order quantities can vary significantly based on the supplier and the type of filtration system. Typically, for commercial and industrial systems, MOQs can range from one unit for larger systems to several units for smaller, modular filters. Always clarify this with the supplier upfront, as many are willing to negotiate based on your specific requirements and potential for ongoing orders. -

What payment terms should I expect when purchasing water filtering systems internationally?

Payment terms can vary widely among suppliers and regions. Common arrangements include upfront payments, net 30 or net 60 days after delivery, and letters of credit for larger orders. It’s advisable to negotiate terms that align with your cash flow and operational needs. Ensure that the payment method is secure and that you understand any potential additional costs, such as tariffs or shipping fees. -

How can I ensure the quality assurance (QA) of my water filtering systems?

To ensure quality assurance, request documentation of testing and certification from recognized bodies for the filtration systems you are considering. Look for suppliers who implement rigorous QA processes, including regular testing of their products and adherence to international quality standards. Establish clear communication about your quality expectations and consider performing independent testing on samples before making a bulk purchase.

A stock image related to water filtering.

-

What logistics challenges might I face when importing water filtering systems?

Logistics challenges can include customs delays, tariffs, and shipping costs, particularly when importing into regions like Africa or South America. It’s crucial to work with a logistics partner experienced in international trade who understands the specific regulations of your destination country. Additionally, ensure that the supplier provides all necessary documentation to facilitate smooth customs clearance and delivery. -

How can I customize water filtering solutions to meet my business’s unique needs?

Many suppliers offer customization options for their water filtering systems. This can include adjustments in filtration methods, system size, and specific contaminants targeted. Discuss your requirements in detail with potential suppliers and ask about their ability to tailor solutions. It’s also beneficial to collaborate with them on testing prototypes to ensure the final product meets your expectations before full-scale production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for water filtering

What Are the Key Takeaways for B2B Buyers in Water Filtering?

In the evolving landscape of water filtration, strategic sourcing is essential for international B2B buyers to ensure access to high-quality products that meet local standards and consumer needs. Key considerations include understanding regional water quality challenges, such as high total dissolved solids (TDS) or contaminants like PFAS and lead, which are prevalent in various markets across Africa, South America, the Middle East, and Europe. Collaborating with reputable suppliers who offer innovative filtration technologies can significantly enhance product offerings and customer satisfaction.

How Can Strategic Sourcing Enhance Competitive Advantage?

Investing in advanced filtration systems, such as whole-house solutions or multi-stage filters, not only addresses immediate health concerns but also aligns with growing consumer preferences for sustainable and eco-friendly options. By prioritizing suppliers that emphasize rigorous testing and certifications, businesses can differentiate themselves in a crowded marketplace, thus gaining a competitive edge.

What Is the Future Outlook for Water Filtering in Global Markets?

Looking ahead, the demand for effective water filtration solutions will only continue to rise, driven by increasing health awareness and regulatory pressures. B2B buyers are encouraged to adopt a proactive approach in sourcing water filtration products that cater to diverse market needs. Engaging with suppliers now will position businesses to capitalize on future growth opportunities in the water filtering sector. Take the next step in securing your supply chain and enhancing your market presence by exploring innovative water filtration solutions today.