The Ultimate Guide to Ball Valves (2025)

Introduction: Navigating the Global Market for ball valves

In today’s rapidly evolving industrial landscape, sourcing high-quality ball valves can pose significant challenges for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the intricacies of ball valve types, applications, and specifications is crucial for making informed purchasing decisions. This guide aims to demystify the global market for ball valves, providing a comprehensive overview of the various types available, their specific applications across industries, and essential considerations for supplier vetting.

International buyers often grapple with issues such as varying standards, material quality, and pricing disparities. This guide addresses these concerns by presenting actionable insights into the procurement process, including how to evaluate suppliers based on reliability and product quality. From understanding the different construction materials—such as stainless steel, brass, and PVC—to recognizing the importance of port profiles and pressure ratings, this resource equips B2B buyers with the knowledge needed to navigate their purchasing journey confidently.

Furthermore, we delve into cost analysis and shipping logistics tailored for buyers in regions like Nigeria and Thailand, ensuring that you are well-prepared to make strategic decisions that align with your operational needs. By leveraging the information provided in this guide, you will be empowered to optimize your sourcing strategies and secure the best ball valves for your projects.

Understanding ball valves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Ball Valve | Full port design, quick operation (90° turn) | Water supply, oil and gas, HVAC systems | Pros: Low pressure drop, reliable; Cons: Limited flow control. |

| Reduced Port Ball Valve | Smaller port size, compact design | Chemical processing, plumbing | Pros: Cost-effective, space-saving; Cons: Higher friction loss. |

| V-Port Ball Valve | V-shaped port for precise flow control | Water treatment, food processing | Pros: Excellent flow regulation; Cons: More complex, higher cost. |

| Trunnion Ball Valve | Mounted ball design, suitable for high pressure and large sizes | Oil and gas, power generation | Pros: Handles high pressure, durable; Cons: More expensive, complex installation. |

| Floating Ball Valve | Ball floats to seal against the seat, versatile | HVAC, water distribution | Pros: Simple design, easy maintenance; Cons: Limited high-pressure applications. |

What Are the Key Characteristics of Standard Ball Valves?

Standard ball valves feature a full port design that allows the fluid to flow freely with minimal resistance. They are operated by a simple 90° turn, making them ideal for applications requiring quick shut-off capabilities, such as water supply and HVAC systems. When purchasing, buyers should consider the valve’s material compatibility with the fluids involved, as well as its pressure and temperature ratings. Standard ball valves are reliable but may not offer the flow control needed in more complex systems.

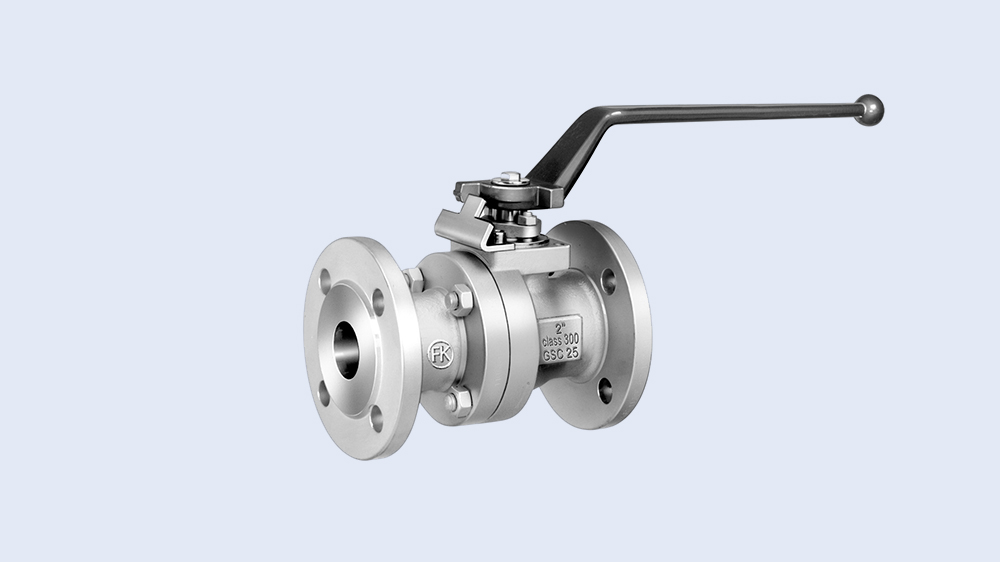

A stock image related to ball valves.

How Do Reduced Port Ball Valves Differ in Application?

Reduced port ball valves have a smaller opening, which makes them more compact and cost-effective. They are commonly used in chemical processing and plumbing systems where space is a constraint. While they are generally less expensive than their full port counterparts, buyers should be aware of the potential for increased friction loss, which could affect flow rates. It’s essential to evaluate the specific requirements of the application to ensure these valves meet operational needs.

Why Choose V-Port Ball Valves for Precise Flow Control?

V-port ball valves are designed with a V-shaped opening, allowing for precise flow control, making them suitable for applications such as water treatment and food processing. Their ability to regulate flow accurately is a significant advantage, especially in processes where flow rates must be monitored closely. However, buyers should consider the complexity and cost associated with these valves, as they may require specialized installation and maintenance.

What Are the Advantages of Trunnion Ball Valves for High-Pressure Applications?

Trunnion ball valves are mounted securely, making them ideal for high-pressure applications, such as in the oil and gas industry. Their robust construction allows them to handle larger sizes and higher pressures compared to standard ball valves. While they provide excellent performance and durability, buyers should note that trunnion valves can be more expensive and may require more complex installation procedures. It’s crucial to assess the operational environment to determine if the investment is justified.

What Makes Floating Ball Valves Versatile for Various Industries?

Floating ball valves utilize a design where the ball floats to seal against the seat, making them versatile for applications like HVAC and water distribution. Their simple design allows for easy maintenance and operation, which can be a significant advantage in environments requiring frequent valve adjustments. However, buyers should be cautious about their limitations in high-pressure situations, as they may not perform as well as trunnion designs. Evaluating the specific pressure and flow requirements will help ensure the right choice.

Key Industrial Applications of ball valves

| Industry/Sector | Specific Application of Ball Valves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Flow control in pipelines for crude oil and gas | Ensures safe and efficient flow management | Material compatibility with hydrocarbons; high-pressure ratings |

| Water Treatment | Isolation and control in water purification systems | Enhances operational efficiency and safety | Corrosion resistance; compliance with drinking water standards |

| Chemical Processing | Regulation of chemical flows in reactors | Prevents leaks and maintains process integrity | Chemical compatibility; high temperature and pressure ratings |

| HVAC Systems | Control of air and refrigerant flow | Improves energy efficiency and system reliability | Material selection for temperature extremes; ease of maintenance |

| Agriculture | Irrigation systems for water distribution | Maximizes crop yield through efficient water use | Durability against environmental factors; size and connection type |

How Are Ball Valves Used in the Oil and Gas Industry?

In the oil and gas sector, ball valves are crucial for controlling the flow of crude oil and natural gas through pipelines. Their ability to provide a tight seal and minimal flow resistance reduces the risk of leaks and ensures safe operations. International buyers must consider the valve’s material compatibility with hydrocarbons and its pressure rating, as these factors are critical for maintaining safety and efficiency in high-stakes environments.

What Role Do Ball Valves Play in Water Treatment Applications?

Ball valves serve a vital function in water treatment facilities, where they are used to isolate and control the flow of water during purification processes. By providing reliable shut-off capabilities, these valves help enhance operational efficiency and ensure compliance with safety standards. Buyers in regions such as Africa and South America should prioritize corrosion-resistant materials and valves that meet local drinking water regulations to ensure safety and longevity.

How Are Ball Valves Essential in Chemical Processing?

In chemical processing applications, ball valves are employed to regulate the flow of various chemicals in reactors and pipelines. Their robust design prevents leaks and maintains process integrity, which is essential for safety and compliance in this highly regulated industry. B2B buyers must focus on sourcing valves that are compatible with specific chemicals and can withstand high temperatures and pressures, ensuring optimal performance in demanding environments.

In What Ways Do Ball Valves Improve HVAC Systems?

Ball valves are integral to HVAC systems for controlling the flow of air and refrigerants. They help improve energy efficiency by allowing for precise control of flow rates, which can lead to significant cost savings. Buyers should consider the material selection for extreme temperatures and ensure that the valves are easy to maintain to minimize downtime and operational disruptions.

Why Are Ball Valves Important in Agricultural Irrigation?

A stock image related to ball valves.

In agriculture, ball valves are used in irrigation systems to manage water distribution effectively. Their ability to provide quick shut-off and reliable flow control maximizes crop yield by ensuring that water is delivered efficiently. For international buyers, sourcing durable valves that can withstand environmental factors, as well as selecting the appropriate size and connection type, is crucial for maintaining effective irrigation practices.

3 Common User Pain Points for ‘ball valves’ & Their Solutions

Scenario 1: Sourcing Quality Ball Valves in Emerging Markets

The Problem: Many B2B buyers in regions like Africa and South America face challenges when sourcing high-quality ball valves. They often encounter a myriad of suppliers, but the quality and reliability of products can vary significantly. This inconsistency can lead to operational disruptions, increased maintenance costs, and ultimately, loss of revenue due to system failures or leaks.

The Solution: To mitigate these issues, buyers should prioritize suppliers with a proven track record and established reputations. Conduct thorough research by reviewing customer testimonials and case studies. Additionally, consider suppliers that offer certifications for their products, such as ISO or ANSI standards, which indicate adherence to international quality benchmarks. Engage in direct communication with potential suppliers to discuss their manufacturing processes, materials used, and warranty offerings. Establishing long-term relationships with reliable vendors can ensure a steady supply of quality ball valves, thereby enhancing operational efficiency.

Scenario 2: Understanding Ball Valve Specifications for Different Applications

The Problem: B2B buyers often struggle with selecting the right type of ball valve for specific applications, particularly when there are various specifications to consider, such as material compatibility, pressure ratings, and temperature tolerances. Misunderstanding these specifications can lead to costly mistakes, including the installation of valves that are unsuitable for the intended medium or operating conditions.

The Solution: To overcome this challenge, buyers must invest time in understanding the specific requirements of their applications. This includes conducting a thorough analysis of the fluids or gases that will pass through the valve, as well as the environmental conditions (temperature and pressure) in which the valve will operate. Utilize resources such as technical datasheets and application guides provided by manufacturers to make informed decisions. Additionally, consult with industry experts or engineers who can provide insights on selecting the right valve type, such as full-port versus reduced-port valves, depending on the flow requirements. This proactive approach ensures that buyers choose the appropriate ball valve, minimizing the risk of operational failures.

Scenario 3: Managing Costs and Reducing Total Ownership Expenses

The Problem: For international B2B buyers, managing costs associated with ball valves can be a significant pain point. While the initial purchase price is important, the total cost of ownership—including maintenance, energy consumption, and replacement costs—can significantly impact the bottom line. Buyers often overlook these aspects, leading to higher long-term expenses.

The Solution: To effectively manage costs, buyers should adopt a holistic approach to purchasing ball valves. Start by evaluating the long-term performance of different valve types and materials. For example, stainless steel ball valves may have a higher upfront cost but offer superior durability and lower maintenance needs compared to plastic alternatives. Implementing predictive maintenance strategies can also help reduce unexpected costs associated with valve failures. Additionally, buyers can negotiate bulk purchase agreements with suppliers to secure better pricing and reduce per-unit costs. Lastly, consider investing in smart valve technologies that provide real-time monitoring and data analytics, which can further optimize operational efficiency and reduce total ownership expenses. By focusing on the overall lifecycle costs, buyers can make more informed purchasing decisions that contribute to sustainable business operations.

Strategic Material Selection Guide for ball valves

What Are the Key Properties of Common Ball Valve Materials?

When selecting ball valves for various applications, the material of construction plays a crucial role in determining performance, durability, and suitability for specific environments. Below, we analyze four common materials used in ball valves: stainless steel, brass, PVC, and bronze.

How Does Stainless Steel Perform in Ball Valve Applications?

Key Properties: Stainless steel ball valves typically offer excellent corrosion resistance, high strength, and the ability to withstand high temperatures and pressures (up to 400°F and 6000 PSI).

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it ideal for harsh environments. However, it is more expensive than other materials and can be challenging to manufacture, which may lead to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, oil, and gas, making it suitable for various industrial applications. It is particularly favored in the oil and gas sector and food processing industries due to its hygienic properties.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and the Middle East should ensure that suppliers can meet local regulatory requirements for food-grade applications.

What Are the Advantages of Brass in Ball Valve Manufacturing?

Key Properties: Brass ball valves are known for their good corrosion resistance and mechanical strength, operating effectively at temperatures up to 250°F and pressures around 600 PSI.

Pros & Cons: Brass is relatively cost-effective and easy to machine, which simplifies manufacturing. However, it is less resistant to corrosion compared to stainless steel, especially in aggressive environments, which can limit its application scope.

Impact on Application: Brass is commonly used in plumbing and heating applications, making it suitable for water and gas services. It is also often used in residential and commercial settings.

Considerations for International Buyers: Buyers should be aware of the lead content in brass and ensure compliance with local regulations, especially in regions like Europe, where lead-free options are increasingly mandated.

How Does PVC Compare for Ball Valve Applications?

Key Properties: PVC ball valves are lightweight, resistant to corrosion, and can handle temperatures up to 140°F and pressures around 150 PSI.

Pros & Cons: The main advantage of PVC is its low cost and ease of installation. However, its temperature and pressure limitations can restrict its use in high-stress applications.

Impact on Application: PVC is ideal for water treatment, irrigation, and chemical handling, making it suitable for agricultural and industrial applications.

Considerations for International Buyers: Buyers should verify compliance with local environmental regulations, especially in South America, where PVC usage is often scrutinized for environmental impact.

What Are the Benefits of Using Bronze for Ball Valves?

Key Properties: Bronze ball valves offer good corrosion resistance and can operate effectively at temperatures up to 400°F and pressures around 600 PSI.

Pros & Cons: The primary advantage of bronze is its durability and resistance to seawater, making it suitable for marine applications. However, it can be more expensive than brass and has a higher manufacturing complexity.

Impact on Application: Bronze is commonly used in marine, oil, and gas applications due to its resistance to corrosion in harsh environments.

Considerations for International Buyers: Buyers should ensure that bronze valves meet international standards and certifications, especially in Europe, where stringent quality regulations apply.

Summary Table of Ball Valve Materials

| Material | Typical Use Case for ball valves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil & gas, food processing | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Plumbing and heating applications | Cost-effective and easy to machine | Less corrosion resistant | Medium |

| PVC | Water treatment, irrigation | Low cost and lightweight | Limited temperature and pressure tolerance | Low |

| Bronze | Marine, oil, and gas applications | Good corrosion resistance in seawater | Higher cost and complexity | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on material properties, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ball valves

What Are the Main Stages of Ball Valve Manufacturing?

Manufacturing ball valves involves several key stages that ensure the final product meets industry standards and customer requirements. The typical process includes:

-

Material Preparation

The manufacturing of ball valves begins with selecting the appropriate materials, which can range from stainless steel and brass to PVC and other alloys. The choice of material is influenced by the intended application, including factors like pressure, temperature, and the type of fluid being controlled. Once the materials are sourced, they undergo initial inspections to confirm quality and specifications. -

Forming

The forming process can involve various techniques such as casting, forging, or machining. In casting, molten metal is poured into molds to create the valve body, while forging involves shaping metal using compressive forces. Machining processes, including CNC milling and turning, are used to achieve precise dimensions and tolerances for the valve components, such as the ball, seats, and body. -

Assembly

After forming, the individual components are assembled. This stage typically includes the installation of the ball, stem, and seals. The assembly process must ensure that all parts fit together correctly to prevent leaks and ensure smooth operation. Gaskets or O-rings are often used to provide a tight seal, and the components may be lubricated to facilitate movement. -

Finishing

The finishing stage involves surface treatments such as polishing, coating, or plating. These processes enhance the valve’s durability and corrosion resistance, which is particularly important for applications in harsh environments. Quality checks are performed during this phase to ensure that surface finishes meet the specified requirements.

How Is Quality Assurance Implemented in Ball Valve Manufacturing?

Quality assurance (QA) is critical in the manufacturing of ball valves to ensure reliability and compliance with international standards. Key aspects of QA include:

-

International Standards Compliance

Many manufacturers adhere to international quality management systems such as ISO 9001, which outlines criteria for effective quality management. Additionally, certifications such as CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) standards for valves in the oil and gas industry ensure that products meet specific safety and performance criteria. -

Quality Control Checkpoints

Quality control (QC) processes are implemented at various stages of production, including:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify any deviations from quality standards before the product moves to the next stage.

- Final Quality Control (FQC): The completed valves undergo rigorous testing to confirm they meet all design specifications and quality standards.

- Common Testing Methods

Manufacturers employ several testing methods to validate the performance and safety of ball valves. Common tests include:

- Hydrostatic Testing: Ensures the valve can withstand pressure without leaking.

- Functional Testing: Confirms the valve operates correctly under various conditions.

- Material Testing: Assesses the properties of materials used, including tensile strength and corrosion resistance.

A stock image related to ball valves.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure supplier reliability:

-

Supplier Audits

Conducting audits of the manufacturing facility can provide insights into the supplier’s quality management practices. This includes evaluating production processes, quality control measures, and compliance with international standards. -

Requesting Quality Reports

Buyers should request detailed quality assurance reports from suppliers. These documents should outline the QC processes in place, results from testing, and any certifications obtained. -

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control. These services can provide reports on the manufacturing processes and product testing, ensuring that the supplier meets required standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing ball valves internationally, buyers should be aware of specific nuances related to quality control:

-

Understanding Regional Standards

Different regions may have varying standards and regulations governing valve manufacturing. For instance, European standards may differ from those in the Middle East or Africa. Buyers should familiarize themselves with relevant local regulations to ensure compliance. -

Cultural and Communication Considerations

Effective communication is crucial in international transactions. Cultural differences may affect how quality is perceived and managed. Establishing clear expectations and protocols can help bridge these gaps. -

Logistical Challenges

The logistics of transporting valves across borders can introduce risks related to quality. Buyers should ensure that the packaging and shipping methods used protect the integrity of the valves during transit. It may be beneficial to include quality checks upon arrival to confirm that products have not been damaged.

Conclusion

Understanding the manufacturing processes and quality assurance measures for ball valves is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as implementing robust quality control practices, suppliers can deliver reliable products. Buyers should actively verify supplier quality through audits, reports, and third-party inspections, while also navigating the specific quality control nuances relevant to their regions. This proactive approach will help ensure that the ball valves sourced meet both industry standards and operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ball valves’

Introduction

Sourcing ball valves for industrial applications involves careful consideration of various factors to ensure quality, performance, and compatibility. This step-by-step checklist aims to guide B2B buyers from Africa, South America, the Middle East, and Europe through the procurement process, helping you make informed decisions that align with your operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial for successful procurement. Identify the application for the ball valves, including the type of fluid (e.g., water, gas, oil) and the operating conditions such as pressure and temperature limits. Additionally, determine the necessary materials (brass, stainless steel, PVC) based on compatibility with the fluids and environmental conditions.

- Pressure Ratings: Ensure the valves can handle the maximum pressure of your system.

- Temperature Ratings: Select valves rated for the highest temperatures expected in your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for manufacturers or distributors that specialize in ball valves and have a proven track record in your industry. Utilize online marketplaces, industry directories, and trade shows to gather a list of potential candidates.

- Industry Reputation: Check reviews and testimonials from other B2B buyers to gauge supplier reliability.

- Regional Expertise: Focus on suppliers familiar with local regulations and standards relevant to your region.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier choice, verify their certifications and compliance with industry standards. Ensure they meet necessary quality assurance protocols, such as ISO certifications, which indicate a commitment to maintaining high-quality manufacturing practices.

- Regulatory Compliance: Check if the supplier adheres to local and international regulations, especially for hazardous materials.

- Quality Control: Inquire about their quality assurance processes to ensure that the valves meet performance specifications.

Step 4: Request Samples for Testing

Request samples of the ball valves to conduct performance testing in your operational environment. This step helps you evaluate the valves’ functionality and compatibility with your systems before making a bulk order.

- Functional Testing: Assess the ease of operation, sealing capabilities, and overall performance under simulated conditions.

- Material Inspection: Inspect the quality of materials used to ensure they meet your durability and safety standards.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and payment terms. Consider discussing bulk order discounts, shipping costs, and lead times to ensure that the deal aligns with your budget and schedule.

- Volume Discounts: Leverage your purchasing power to negotiate better rates for larger orders.

- Payment Flexibility: Explore options for installment payments or credit terms to ease cash flow pressures.

Step 6: Review and Finalize Contracts

Before placing your order, carefully review the contract terms and conditions. Ensure that all agreed-upon specifications, pricing, delivery schedules, and warranty information are accurately documented.

- Clear Terms: Verify that the contract includes clauses on liability, returns, and dispute resolution to protect your interests.

- Warranties: Confirm warranty details to understand the support and service you can expect post-purchase.

Step 7: Plan for Logistics and Delivery

Coordinate logistics to ensure timely delivery of your ball valves. Work with your supplier to establish shipping methods, delivery schedules, and any customs documentation needed for international shipments.

- Shipping Methods: Choose reliable shipping options that align with your urgency and budget.

- Customs Clearance: Ensure all necessary paperwork is prepared to avoid delays at customs, particularly for international transactions.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for ball valves, ensuring they select high-quality products that meet their specific operational needs.

Comprehensive Cost and Pricing Analysis for ball valves Sourcing

What Are the Key Cost Components in Ball Valves Sourcing?

Understanding the cost structure for sourcing ball valves is crucial for international B2B buyers, especially when considering multiple regions like Africa, South America, the Middle East, and Europe. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of material significantly influences the overall cost. Common materials include brass, stainless steel, and PVC. Higher-grade materials offer better durability but come at a premium.

-

Labor: Labor costs vary by region. For instance, manufacturing in countries with higher labor costs may lead to increased pricing. Conversely, sourcing from regions with lower labor costs can yield savings.

-

Manufacturing Overhead: This includes factory costs, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads, impacting the final price.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom or specialized ball valves. This cost is often amortized over large production runs, making it essential for buyers to consider order quantities.

-

Quality Control: Ensuring product quality through stringent QC processes incurs additional costs. Certification for quality standards (like ISO) may also add to the expense but is crucial for ensuring reliability.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping methods, and customs duties. For international buyers, understanding Incoterms is vital for determining who bears these costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Ball Valve Costs?

Several factors can influence the pricing of ball valves, and understanding these can aid buyers in making informed decisions.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect unit pricing. Larger orders often qualify for volume discounts, making it beneficial for buyers to consolidate their needs.

-

Specifications and Customization: Custom features or specific material requirements can lead to higher costs. Buyers should clearly define their specifications to avoid unexpected price increases.

-

Quality and Certifications: Valves that meet stringent industry standards or have specific certifications may come with a higher price tag. However, investing in quality can reduce maintenance costs and increase reliability.

-

Supplier Factors: The supplier’s reputation, reliability, and geographic location can affect pricing. Established suppliers may charge more but offer better quality and service.

-

Incoterms: The choice of Incoterms affects shipping and handling costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage their total landed costs effectively.

What Are the Best Practices for Negotiating Ball Valve Prices?

Effective negotiation strategies can lead to better pricing and terms for ball valve sourcing.

-

Leverage Volume: Buyers should negotiate based on volume, highlighting potential future orders to secure better pricing.

-

Understand Total Cost of Ownership (TCO): When evaluating offers, consider not just the upfront cost but the long-term costs associated with maintenance, downtime, and efficiency.

-

Explore Multiple Suppliers: Engaging with various suppliers can provide leverage in negotiations and ensure competitive pricing.

-

Be Clear About Specifications: Providing detailed specifications upfront helps suppliers offer accurate quotes and prevents misunderstandings that could lead to cost overruns.

-

Consider Local Suppliers: For buyers in Africa and South America, sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall cost-efficiency.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers should be aware of specific pricing nuances that could affect their sourcing strategy.

-

Currency Fluctuations: Exchange rate volatility can impact pricing. Buyers should consider locking in rates or using forward contracts to mitigate this risk.

-

Tariffs and Trade Regulations: Import duties and trade regulations vary by country and can significantly alter the total cost. Staying informed about these regulations is essential for accurate cost assessments.

-

Cultural Differences: Understanding cultural nuances in negotiation styles can facilitate better communication and more favorable terms.

-

Lead Times: Longer lead times can affect project timelines and costs. Buyers should factor in potential delays when planning their purchases.

By comprehensively analyzing these factors, international B2B buyers can make informed decisions that enhance their sourcing strategies for ball valves, ensuring both cost-effectiveness and quality.

Alternatives Analysis: Comparing ball valves With Other Solutions

When selecting the right valve for fluid control in industrial applications, it’s essential to consider various alternatives to ball valves. While ball valves are popular for their reliability and ease of use, other solutions may offer advantages depending on specific operational needs. Below, we compare ball valves to two viable alternatives: gate valves and butterfly valves.

| Comparison Aspect | Ball Valves | Gate Valves | Butterfly Valves |

|---|---|---|---|

| Performance | Excellent for on/off control; minimal pressure drop. | Good for full flow; not ideal for throttling. | Suitable for throttling; quick operation. |

| Cost | Moderate initial cost; long-term value. | Generally lower initial cost but may require more maintenance. | Typically lower cost; economical for large sizes. |

| Ease of Implementation | Straightforward installation; compact design. | Requires more space; can be heavy and cumbersome. | Easy installation; lightweight and compact. |

| Maintenance | Low maintenance; durable materials. | Moderate maintenance; prone to wear over time. | Low maintenance; can wear out if not properly selected. |

| Best Use Case | Ideal for applications needing quick shut-off. | Best for isolation in pipelines. | Ideal for large volume flow control. |

What Are the Advantages and Disadvantages of Gate Valves?

Gate valves are designed to allow or restrict the flow of liquids and gases. They are particularly effective in applications requiring a full flow, as they do not restrict the diameter of the pipe. However, they are not suitable for throttling applications, as partially opening a gate valve can lead to erosion and damage.

Pros:

– Lower initial cost compared to ball valves.

– Minimal pressure drop when fully open, allowing for efficient flow.

Cons:

– Slower operation due to the need for multiple turns to open or close.

– More susceptible to wear and tear, requiring regular maintenance.

How Do Butterfly Valves Compare to Ball Valves?

Butterfly valves utilize a rotating disc to control flow, making them an excellent choice for applications requiring frequent throttling. They are lightweight and can be used in larger sizes, making them suitable for various industrial applications. However, they may not provide the same level of sealing as ball valves.

Pros:

– Quick operation with a simple quarter-turn mechanism.

– Economical for large applications, reducing material costs.

Cons:

– Less effective for high-pressure applications compared to ball valves.

– Potential for leakage if not properly maintained.

How Can B2B Buyers Select the Right Valve Solution?

When selecting a valve for industrial applications, B2B buyers should evaluate their specific needs in terms of performance, cost, and maintenance. For applications requiring reliable shut-off and minimal pressure drop, ball valves may be the best choice. However, if budget constraints are a significant factor, or if the application involves large volumes of fluid, gate or butterfly valves might be more suitable. It is essential to consider the operational environment, fluid characteristics, and frequency of use to make an informed decision. Ultimately, the right valve will enhance operational efficiency and reduce long-term costs.

Essential Technical Properties and Trade Terminology for ball valves

What Are the Essential Technical Properties of Ball Valves?

When considering the purchase of ball valves for industrial applications, understanding their technical specifications is crucial. Here are several key properties that B2B buyers should prioritize:

1. Material Grade: What Materials Are Commonly Used for Ball Valves?

Ball valves are typically constructed from materials such as stainless steel, brass, PVC, and bronze. The choice of material directly influences the valve’s performance, durability, and compatibility with various media. For instance, stainless steel valves are ideal for high-pressure and high-temperature applications, while PVC valves are suitable for less demanding environments. Buyers should assess the chemical compatibility with the fluids being transported, as well as the environmental conditions they will face.

2. Pressure Rating: How Does Pressure Rating Affect Ball Valve Selection?

The pressure rating, often measured in PSI (pounds per square inch), indicates the maximum pressure that the valve can handle. Common ratings range from 150 PSI to over 3000 PSI. Understanding the required pressure rating is vital for ensuring safety and preventing leaks or failures in high-pressure systems. Buyers should consider the operational pressures within their systems and choose valves that exceed these requirements for added reliability.

3. Temperature Tolerance: Why Is Temperature Tolerance Important?

Temperature tolerance specifies the maximum and minimum temperatures at which the valve can operate effectively. This is particularly important in applications involving hot liquids or gases. Ball valves made from metal materials typically have higher temperature tolerances compared to plastic options. Buyers must ensure that the selected valve can withstand the thermal conditions of their application to maintain functionality and prevent premature failure.

4. Port Configuration: What Are the Different Types of Port Configurations?

Ball valves can feature various port configurations, such as full port, reduced port, and V-port designs. Full port valves allow for maximum flow with minimal pressure drop, while reduced port valves may introduce slight friction losses but are often more compact. V-port valves enable precise flow control. Understanding these configurations helps buyers select the right type for their specific flow control needs.

5. Connection Types: What Are the Common Connection Types for Ball Valves?

Ball valves come with different connection types, including threaded (FIP, MIP), solder (sweat), and push-to-connect fittings. The choice of connection type affects installation methods and compatibility with existing piping systems. Buyers should assess their current infrastructure and choose valves that will integrate seamlessly without requiring extensive modifications.

What Trade Terminology Should B2B Buyers Understand When Purchasing Ball Valves?

In addition to technical properties, familiarity with industry jargon is essential for effective communication with suppliers and manufacturers. Here are some key terms:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean in the Ball Valve Industry?

OEM refers to companies that produce components or products that are used in another company’s final product. In the context of ball valves, buyers may seek OEM suppliers for custom solutions that fit specific application requirements. Understanding OEM relationships can help buyers secure quality products that meet their exact specifications.

2. MOQ (Minimum Order Quantity): How Does MOQ Impact Purchasing Decisions?

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for international buyers, as it can affect inventory management and cash flow. Buyers should negotiate MOQ terms that align with their operational needs to avoid excess stock or supply shortages.

3. RFQ (Request for Quotation): Why Is RFQ Important in Sourcing Ball Valves?

An RFQ is a document sent to suppliers to request pricing and availability for specific products. When sourcing ball valves, an RFQ can streamline the procurement process by clearly outlining specifications and quantities, allowing suppliers to provide accurate quotes.

4. Incoterms: How Do Incoterms Affect International Shipping of Ball Valves?

Incoterms are a set of international commercial terms that define the responsibilities of buyers and sellers in shipping. Understanding Incoterms is essential for B2B buyers to clarify who is responsible for shipping costs, insurance, and risk during transit. This knowledge helps avoid misunderstandings and ensures smoother transactions.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing ball valves, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the ball valves Sector

What Are the Current Market Dynamics and Key Trends in the Ball Valves Sector?

The global ball valves market is experiencing significant growth, driven by increased demand across various industries such as oil and gas, water treatment, and HVAC systems. Key trends influencing this market include the rise of automation and smart technologies. International B2B buyers should be aware of the integration of IoT capabilities into ball valves, allowing for enhanced monitoring and control of fluid flow. This shift not only boosts operational efficiency but also reduces downtime, making it a crucial consideration for buyers from regions like Africa, South America, the Middle East, and Europe.

Another noteworthy trend is the increasing focus on customization. Suppliers are now offering tailored solutions, enabling buyers to specify materials, sizes, and connection types that best suit their applications. This flexibility is particularly advantageous for industries requiring specific valve characteristics due to environmental or regulatory standards. Additionally, the market is witnessing a shift towards digital platforms for sourcing, making it easier for international buyers to compare products and prices, access technical specifications, and expedite procurement processes.

How Does Sustainability and Ethical Sourcing Impact the Ball Valves Market?

Sustainability has become a pivotal aspect of the ball valves sector, with growing awareness of environmental impacts driving demand for eco-friendly products. B2B buyers are increasingly seeking suppliers who prioritize sustainable manufacturing processes and materials. This includes the use of recyclable materials and technologies that minimize energy consumption during production.

Moreover, the importance of ethical sourcing cannot be overstated. Buyers are now inclined to choose suppliers with transparent supply chains that adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential benchmarks for evaluating suppliers. By opting for ‘green’ certified ball valves, companies not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious clients.

How Has the Ball Valves Industry Evolved Over Time?

The ball valves industry has seen significant evolution since its inception. Initially developed for simple on/off flow control, advancements in materials and design have transformed ball valves into sophisticated components that cater to a variety of applications. The introduction of high-performance materials such as stainless steel, PVC, and specialized alloys has expanded the operational capabilities of ball valves, allowing them to withstand extreme pressures and temperatures.

In recent decades, the industry has shifted towards automation, with the integration of actuators and control systems that enable remote operation. This evolution reflects broader trends in industrial automation and the need for more efficient process control. As technology continues to advance, the focus on enhancing performance, durability, and sustainability will likely shape the future of the ball valves market, making it an exciting area for international B2B buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of ball valves

-

How do I choose the right ball valve for my application?

Choosing the right ball valve involves considering several factors such as the type of fluid (gas or liquid), operating pressure, temperature, and the required flow rate. Additionally, assess the valve material compatibility with the fluid—common materials include brass, stainless steel, and PVC. For precise flow control, consider whether you need a full port or reduced port valve. It’s also essential to factor in the specific standards required for your industry, ensuring compliance with local regulations in your region. -

What are the key specifications to look for in a ball valve?

When sourcing ball valves, key specifications include the valve size, connection type (such as FIP or PEX), maximum pressure rating, and temperature range. Additionally, check the valve’s material to ensure it withstands your application’s conditions. The valve’s end connections should match your piping system, and consider whether you need features like a locking handle or a specific actuator type for automation. Always consult the manufacturer’s datasheet for detailed technical specifications. -

What is the typical lead time for ball valve orders?

Lead times for ball valve orders can vary significantly based on factors such as order quantity, customization needs, and supplier location. Standard stock items may ship within a few days, while custom orders or larger quantities can take several weeks. It’s advisable to communicate directly with your supplier to confirm lead times and ensure your project timelines align. Planning for potential delays, especially when importing from international suppliers, is crucial to avoid project setbacks. -

How can I verify the quality of ball valves from suppliers?

To verify the quality of ball valves, request product certifications and compliance documents, such as ISO standards or industry-specific approvals. Conduct a supplier audit, if possible, to assess manufacturing processes and quality control measures. Additionally, consider sourcing samples for testing in your application before committing to larger orders. Customer reviews and testimonials can also provide insights into a supplier’s reliability and product performance. -

What are the common payment terms for international ball valve suppliers?

Payment terms can vary widely among international suppliers but often include options such as advance payment, letters of credit, or payment upon delivery. It’s important to negotiate terms that provide security for both parties. For large orders, consider installment payments linked to production milestones. Be aware of currency exchange rates and potential transaction fees, and ensure that all terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

How do minimum order quantities (MOQs) affect my ball valve sourcing?

Minimum order quantities (MOQs) can significantly impact sourcing decisions, particularly for smaller businesses. Many suppliers set MOQs to ensure cost-effectiveness in production and shipping. If your needs are below the MOQ, consider collaborating with other buyers to meet the requirement or exploring suppliers with lower MOQs. Additionally, some manufacturers may offer flexibility on MOQs for long-term partnerships or repeat orders, making it worthwhile to discuss your specific needs with them. -

What logistics considerations should I keep in mind when importing ball valves?

When importing ball valves, consider logistics factors such as shipping methods, customs duties, and potential tariffs. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but slower. Ensure you have a reliable freight forwarder who can navigate customs regulations in your country. Additionally, factor in lead times for logistics to avoid delays in your supply chain, and confirm that your supplier can provide necessary documentation for customs clearance. -

Can I customize ball valves to meet specific requirements?

Yes, many manufacturers offer customization options for ball valves, allowing you to tailor specifications to meet your project needs. Customizations can include adjustments to size, material, connection types, and even specialized coatings for enhanced durability. When considering customization, discuss your requirements with the supplier early in the process to understand feasibility, lead times, and any additional costs associated with tailored solutions. This approach ensures that the final product aligns perfectly with your application.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ball valves

What Are the Key Takeaways for B2B Buyers in Ball Valve Sourcing?

Strategic sourcing of ball valves is crucial for international buyers aiming to enhance operational efficiency and reduce costs. Understanding the diverse materials and designs available, such as full port and reduced port options, allows buyers to select valves that best suit their specific applications, whether in oil, gas, or water systems. Additionally, sourcing from reputable manufacturers ensures compliance with regional standards and quality benchmarks, which is particularly important for buyers in Africa, South America, the Middle East, and Europe.

How Can Buyers Future-Proof Their Sourcing Strategies?

As industries evolve, the demand for innovative valve solutions will continue to grow. Buyers should prioritize suppliers who demonstrate flexibility in production and the ability to customize products according to emerging market needs. Utilizing digital platforms for sourcing not only streamlines procurement processes but also opens doors to a wider array of suppliers, fostering competitive pricing.

What’s Next for International B2B Buyers?

In conclusion, the strategic sourcing of ball valves presents significant opportunities for cost savings and operational excellence. As markets become increasingly interconnected, international buyers are encouraged to engage with diverse suppliers and leverage technological advancements to enhance their procurement strategies. Stay ahead of the curve by continuously evaluating your sourcing processes and adapting to industry trends. Your proactive approach today can lead to stronger partnerships and greater success tomorrow.