The Ultimate Guide to Electrical Motor Parts (2025)

Introduction: Navigating the Global Market for electrical motor parts

In the ever-evolving landscape of global commerce, sourcing high-quality electrical motor parts can pose significant challenges for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The need for reliable and efficient components is paramount, as these parts are critical for the seamless operation of various industries, including manufacturing, energy, and transportation. This comprehensive guide serves as a vital resource, addressing the diverse types of electrical motor parts, their applications, and the nuances of supplier vetting to ensure optimal performance and reliability.

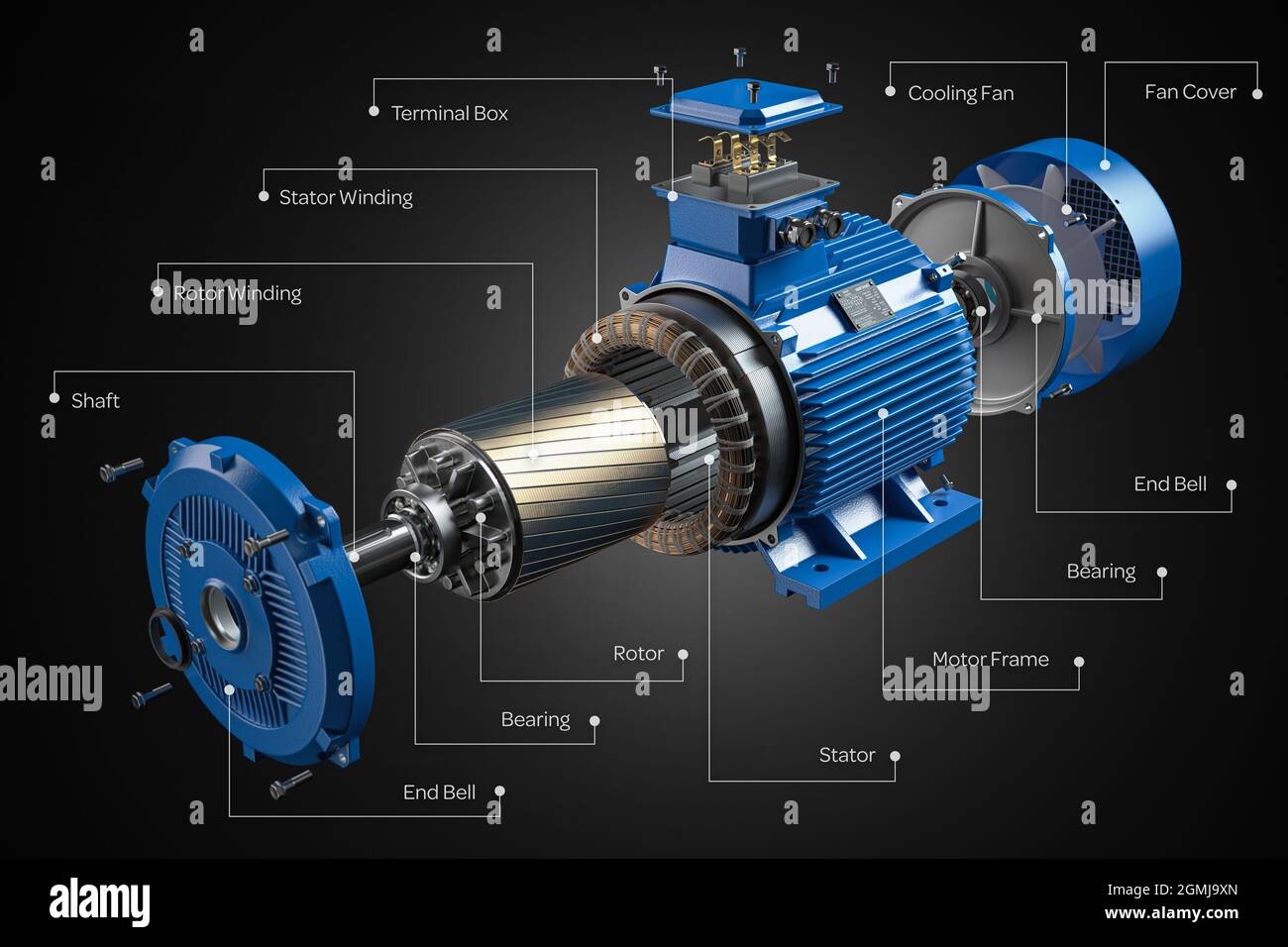

Buyers will gain insights into the essential components such as rotors, stators, and bearings, and learn how to identify the right specifications for their unique operational needs. The guide also delves into cost considerations and strategies for negotiating favorable terms, empowering buyers to make informed purchasing decisions. Additionally, it highlights the importance of understanding regional market dynamics and supplier capabilities, which can greatly influence procurement outcomes.

By equipping B2B buyers with actionable insights and practical knowledge, this guide fosters confidence in navigating the global market for electrical motor parts. Whether you’re in Kenya, Argentina, or any other locale, leveraging this information can streamline your sourcing process, enhance operational efficiency, and ultimately drive business growth in a competitive environment.

Understanding electrical motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotor | Rotating component of the motor; types include squirrel-cage and permanent magnet. | Manufacturing, Automotive, HVAC | Pros: High efficiency; Cons: Can be costly to replace. |

| Stator | Stationary part generating magnetic field; variations include distributed and concentrated windings. | Power Generation, Industrial Machinery | Pros: Durable; Cons: May require specialized maintenance. |

| Bearings | Supports rotor’s shaft; crucial for reducing friction. | Robotics, Aerospace, Automotive | Pros: Enhances motor lifespan; Cons: Can wear out over time. |

| End Plate/Bracket | Provides structural support and alignment for stator and rotor. | Elevators, Conveyors, Industrial Equipment | Pros: Increases stability; Cons: Limited impact on performance. |

| Lead Wire | Connects motor to power supply; essential for operation. | All electrical applications | Pros: Easy to replace; Cons: Vulnerable to damage if not protected. |

What Are the Key Characteristics of Rotors in Electrical Motors?

The rotor is a pivotal component that converts electrical energy into mechanical energy. Types such as squirrel-cage rotors are renowned for their robustness and efficiency, making them ideal for applications in manufacturing and HVAC systems. When purchasing rotors, buyers should consider factors like efficiency ratings, material quality, and compatibility with existing motor systems to ensure optimal performance and longevity.

How Do Stators Differ and What Applications Do They Serve?

Stators are integral for generating the magnetic fields necessary for rotor motion. They come in various designs, such as distributed or concentrated windings, each suited for different applications like power generation and industrial machinery. Buyers should evaluate the stator’s winding type, insulation materials, and thermal ratings, as these factors significantly influence the motor’s operational efficiency and suitability for specific tasks.

Why Are Bearings Important for Electrical Motors?

Bearings play a critical role in supporting the rotor shaft, allowing for smooth rotation and minimizing friction. Commonly found in robotics and aerospace applications, they enhance the overall lifespan of the motor. When sourcing bearings, buyers should focus on load ratings, material specifications, and lubrication options to ensure they meet the demands of their specific applications while maintaining cost-effectiveness.

What Role Do End Plates and Brackets Play in Motor Design?

End plates or brackets provide essential structural support for the motor’s internal components, ensuring proper alignment and stability. While they may not directly affect motor performance, their quality can impact the overall durability and maintenance ease of the motor. Buyers should assess the material strength and design compatibility with existing systems when purchasing these components.

How Do Lead Wires Affect the Functionality of Electrical Motors?

Lead wires are crucial for connecting the motor to its power supply, thus playing a fundamental role in its operation. They need to be durable and resistant to environmental factors, especially in industrial settings. Buyers should consider the wire gauge, insulation type, and length to ensure compatibility with their specific motor applications, as this can affect both performance and safety.

Key Industrial Applications of electrical motor parts

| Industry/Sector | Specific Application of Electrical Motor Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automation Systems | Increased efficiency and reduced labor costs | Quality assurance, compatibility with existing systems |

| Oil & Gas | Pumping Systems | Reliable operation in harsh environments | Durability, resistance to corrosion, and OEM standards |

| Agriculture | Irrigation Equipment | Enhanced crop yield through efficient water management | Energy efficiency, local regulations compliance |

| Transportation | Electric Vehicles | Reduced emissions and operational costs | Battery compatibility, weight considerations |

| Marine | Propulsion Systems | Improved fuel efficiency and vessel performance | Marine-grade certifications, resistance to saltwater |

What are the key applications of electrical motor parts in manufacturing?

In the manufacturing sector, electrical motor parts are crucial in automation systems that drive production lines and machinery. These components, including rotors and stators, enhance operational efficiency by minimizing downtime and labor costs. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality OEM parts ensures compatibility with existing equipment and adherence to local manufacturing standards.

How do electrical motor parts enhance operations in the oil and gas industry?

In the oil and gas industry, electrical motor parts are integral to pumping systems that transport liquids and gases. These motors must operate reliably in harsh environments, often exposed to extreme temperatures and corrosive substances. Buyers from the Middle East, where oil extraction is prevalent, should prioritize sourcing durable and corrosion-resistant components that meet OEM specifications to ensure longevity and efficiency.

What role do electrical motor parts play in agricultural applications?

Electrical motor parts are essential in agricultural irrigation equipment, where they drive pumps that manage water distribution. Efficient motors can significantly enhance crop yield by ensuring timely irrigation, which is particularly vital in regions like sub-Saharan Africa facing water scarcity. Buyers should focus on energy-efficient models that comply with local regulations, as this can lead to long-term cost savings and sustainability.

How are electrical motor parts transforming the transportation sector?

In the transportation sector, especially with the rise of electric vehicles (EVs), electrical motor parts play a pivotal role in propulsion systems. These components contribute to reduced emissions and lower operational costs, appealing to buyers across Europe and South America who are increasingly prioritizing sustainability. Key considerations for sourcing include battery compatibility and weight, as these factors directly impact vehicle performance and efficiency.

Why are electrical motor parts critical in marine applications?

In marine applications, electrical motor parts are vital for propulsion systems that improve fuel efficiency and overall vessel performance. Motors used in this sector must meet specific marine-grade certifications to withstand the corrosive nature of saltwater. Buyers should ensure that sourced components are designed for durability and efficiency, as this can significantly impact operational costs and vessel reliability.

3 Common User Pain Points for ‘electrical motor parts’ & Their Solutions

Scenario 1: Sourcing High-Quality Replacement Parts for Electric Motors

The Problem:

B2B buyers often face the challenge of sourcing high-quality replacement parts for electric motors. In regions such as Africa and South America, where local suppliers may lack the necessary expertise or inventory, finding reliable parts becomes a daunting task. Poor-quality components can lead to operational inefficiencies, increased downtime, and even damage to the entire motor system. This is particularly critical in industries like manufacturing and energy, where consistent performance is essential for productivity.

The Solution:

To overcome sourcing challenges, international buyers should establish relationships with reputable manufacturers and distributors who specialize in electric motor parts. Conduct thorough research to ensure they provide OEM (Original Equipment Manufacturer) quality components. Attend trade shows or industry conferences in Europe and the Middle East, where many top manufacturers showcase their products. Additionally, leverage online platforms that aggregate suppliers, allowing you to compare specifications and prices. Ensure that the supplier can provide certifications or guarantees of quality, as this can help mitigate risks associated with subpar parts.

Scenario 2: Understanding Specifications and Compatibility of Motor Components

The Problem:

A common issue faced by B2B buyers is the lack of clarity regarding the specifications and compatibility of different motor components. This confusion can lead to incorrect purchases, resulting in wasted resources and time. For example, a buyer might mistakenly order a stator that does not match the rotor type, leading to assembly issues or performance failures.

The Solution:

To avoid compatibility issues, buyers should invest time in understanding the technical specifications of their electric motors. Create a detailed inventory that includes the make, model, and specifications of each motor in use. Utilize resources such as manufacturer websites, technical datasheets, and engineering handbooks to gain insights into the various types of rotors and stators. When sourcing parts, always consult with the supplier’s technical support team to confirm compatibility. Additionally, consider working with an electrical engineer or motor specialist who can provide expert guidance, ensuring that all components fit seamlessly together.

Scenario 3: Managing Lead Times and Supply Chain Disruptions

The Problem:

Supply chain disruptions can significantly affect the availability of electric motor parts, leading to longer lead times and potential production halts. This issue is particularly prevalent in regions like the Middle East and Africa, where logistics can be unpredictable. Delays in receiving crucial components can result in costly downtime, particularly in sectors such as oil and gas or manufacturing.

The Solution:

To mitigate the impact of lead times, buyers should adopt a proactive inventory management strategy. Maintain a safety stock of critical components to buffer against unexpected delays. Establish relationships with multiple suppliers to diversify your sourcing options, thereby reducing reliance on a single source. Implement a just-in-time (JIT) inventory system where feasible, allowing you to adjust orders based on real-time demand. Additionally, leverage technology, such as supply chain management software, to monitor inventory levels and supplier performance. Engaging in regular communication with suppliers regarding their lead times and potential disruptions can help buyers plan more effectively and minimize operational risks.

Strategic Material Selection Guide for electrical motor parts

What Are the Key Materials Used in Electrical Motor Parts?

When selecting materials for electrical motor components, it’s crucial to consider their properties, advantages, disadvantages, and the specific needs of international B2B buyers. Here, we analyze four common materials: copper, aluminum, silicon steel, and high-performance plastics.

How Does Copper Benefit Electrical Motor Parts?

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can withstand high temperatures, making it suitable for various motor applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances motor efficiency. However, copper is relatively expensive and can add to the overall cost of the motor. Additionally, its weight may be a concern for applications requiring lightweight materials.

Impact on Application: Copper is ideal for windings and connections in motors, ensuring efficient energy transfer. Its compatibility with various media makes it versatile for different environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the availability of copper and its compliance with international standards such as ASTM B170 for copper wire. Additionally, fluctuations in copper prices can affect budgeting.

What Role Does Aluminum Play in Electrical Motor Parts?

Key Properties: Aluminum is lightweight, has good electrical conductivity, and offers decent resistance to corrosion, making it a popular choice for various motor components.

Pros & Cons: The main advantage of aluminum is its low weight, which can improve motor efficiency. It is also less expensive than copper, making it an attractive option for cost-sensitive projects. However, aluminum’s conductivity is lower than that of copper, which may impact performance in high-demand applications.

Impact on Application: Aluminum is often used in the rotor and housing of motors, where weight savings are critical. Its corrosion resistance is beneficial in humid or corrosive environments.

Considerations for International Buyers: For buyers in the Middle East and Europe, compliance with standards like EN 573 for aluminum alloys is essential. Additionally, understanding local supply chains for aluminum can help mitigate costs.

Why Is Silicon Steel Essential for Electrical Motor Parts?

Key Properties: Silicon steel is a magnetic material that enhances the efficiency of electric motors. It has excellent magnetic permeability and low hysteresis loss, which are critical for motor performance.

Pros & Cons: The key advantage of silicon steel is its ability to reduce energy losses in motors, leading to improved efficiency. However, it can be more expensive than standard steel and may require specialized manufacturing processes.

Impact on Application: Silicon steel is primarily used in the stator and rotor cores of motors, where magnetic properties are crucial for performance. Its compatibility with high-frequency applications makes it suitable for modern motor designs.

Considerations for International Buyers: Buyers should ensure that silicon steel complies with standards like ASTM A677. Additionally, understanding the local manufacturing capabilities for silicon steel can influence procurement strategies.

How Do High-Performance Plastics Fit Into Electrical Motor Parts?

Key Properties: High-performance plastics, such as polyimide or PEEK, offer excellent thermal stability, chemical resistance, and electrical insulation properties.

Pros & Cons: These materials are lightweight and can withstand extreme temperatures, making them suitable for various motor applications. However, high-performance plastics can be costly and may require specialized processing techniques.

Impact on Application: High-performance plastics are often used for insulation components and housings, where electrical insulation and thermal management are critical.

Considerations for International Buyers: Buyers in Europe and South America should be aware of compliance with standards such as ISO 9001 for quality management. Additionally, sourcing these materials may involve navigating complex supply chains.

Summary Table of Material Selection for Electrical Motor Parts

| Material | Typical Use Case for electrical motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings, electrical connections | Superior electrical conductivity | High cost and weight | High |

| Aluminum | Rotor, housing | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Silicon Steel | Stator and rotor cores | Reduces energy losses | Higher cost and specialized processes | Medium to High |

| High-Performance Plastics | Insulation components, housings | Excellent thermal stability | High cost and processing complexity | High |

This strategic material selection guide provides international B2B buyers with essential insights into choosing the right materials for electrical motor parts, ensuring optimal performance and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical motor parts

What Are the Main Stages in the Manufacturing Process of Electrical Motor Parts?

The manufacturing process for electrical motor parts typically involves several key stages, each critical to the overall quality and functionality of the final product. Understanding these stages can help B2B buyers from regions such as Africa, South America, the Middle East, and Europe make informed purchasing decisions.

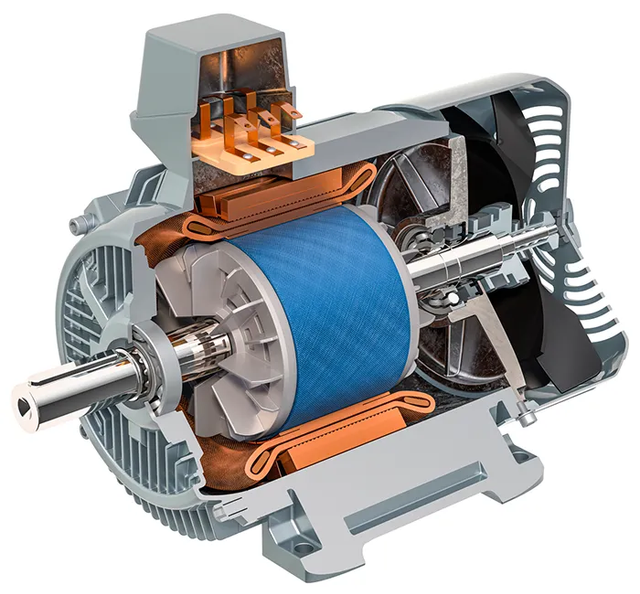

Material Preparation: What Materials Are Used for Electrical Motor Parts?

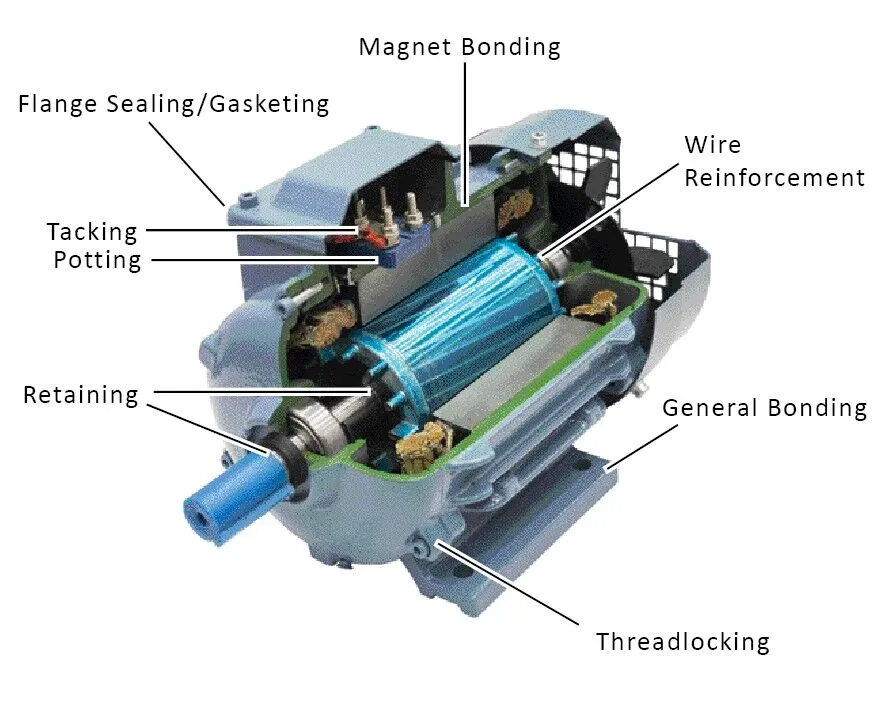

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, which often include copper for windings, iron or silicon steel for cores, and various insulating materials such as rubber or glass fiber. The choice of materials is crucial, as they directly influence the motor’s efficiency and durability. B2B buyers should inquire about the sourcing and specifications of these materials to ensure they meet industry standards.

How Are Electrical Motor Parts Formed?

Once materials are prepared, the forming process begins. This stage includes methods such as stamping, casting, and machining. For instance, rotor and stator components are often stamped from laminated sheets of silicon steel to reduce energy losses. Machining processes may also be employed to achieve precise dimensions and tolerances. Buyers should consider suppliers that utilize advanced forming techniques and equipment to ensure high-quality components that fit seamlessly into their applications.

What Is Involved in the Assembly of Electrical Motor Parts?

After forming, the assembly phase brings together all individual components. This typically includes installing bearings, windings, and connecting lead wires. The assembly process is often done using automated systems to enhance consistency and reduce human error. B2B buyers should look for suppliers that have implemented lean manufacturing principles to optimize their assembly lines, which can lead to faster delivery times and lower costs.

What Are the Finishing Techniques Applied to Electrical Motor Parts?

The final stage of the manufacturing process is finishing, which involves surface treatments and coatings to enhance durability and performance. Common techniques include painting, anodizing, and applying anti-corrosive coatings. These processes not only improve aesthetics but also protect against environmental factors. When sourcing electrical motor parts, buyers should ask about the finishing techniques used and their effectiveness in specific environments.

How Is Quality Assurance Implemented in the Manufacturing of Electrical Motor Parts?

Quality assurance (QA) is essential to ensuring that electrical motor parts meet both international and industry-specific standards. Buyers must understand the QA measures in place at their chosen supplier to guarantee product reliability.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 set the framework for quality management systems and are critical for ensuring consistent quality in manufacturing processes. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the motor parts. B2B buyers should verify that their suppliers are certified to these standards, as this demonstrates a commitment to quality and compliance.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that components meet specified requirements. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

- Final Quality Control (FQC): A comprehensive inspection of finished products before shipment ensures they meet all specifications.

B2B buyers should inquire about the QC processes their suppliers have in place and request documentation of inspections and test results.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to assess the quality of electrical motor parts. Common tests include:

- Electrical Testing: Ensures that components function correctly under electrical loads.

- Mechanical Testing: Assesses the physical strength and durability of parts.

- Thermal Testing: Evaluates performance under temperature variations.

Buyers should ask suppliers for details about the testing methods used and the results of any recent tests to ensure the parts will perform reliably in their specific applications.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is crucial for B2B buyers. Here are several methods to ensure that a supplier meets quality standards:

What Role Do Audits Play in Supplier Quality Assurance?

Conducting audits, either internally or through third-party services, can provide insights into a supplier’s manufacturing processes and quality control measures. Regular audits help identify areas for improvement and ensure compliance with international standards. Buyers should consider establishing a routine audit schedule as part of their supplier management strategy.

How Can Buyers Access Quality Reports and Certifications?

Buyers should request access to quality reports and certifications from suppliers. These documents provide evidence of compliance with industry standards and can include test results, inspection reports, and certification documents. A transparent supplier will readily provide this information, which can be critical for buyers in regulated industries.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control across different regions is essential. Variations in manufacturing standards, quality expectations, and regulatory requirements can impact product quality. Buyers should engage with suppliers who have experience exporting to their region and can navigate these complexities effectively. Additionally, considering third-party inspections can further validate the quality of products before they reach the buyer’s location.

Conclusion: Making Informed Decisions in Electrical Motor Parts Procurement

In conclusion, understanding the manufacturing processes and quality assurance practices for electrical motor parts is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly processes, and finishing methods, along with rigorous quality control measures, buyers can ensure they are sourcing reliable and high-quality components. Engaging with suppliers who adhere to international standards and maintain transparency in their quality control processes will ultimately lead to better procurement decisions and improved operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical motor parts’

In the competitive landscape of international B2B procurement, particularly for electrical motor parts, having a structured approach is essential. This guide offers a practical checklist to ensure that buyers can source the right components effectively, meeting both technical specifications and business needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s vital to have a clear understanding of your technical requirements. This includes identifying the specific types of motor parts needed, such as rotors, stators, bearings, or lead wires.

– Consider compatibility with existing machinery and the operational demands of your business.

– Document specifications such as dimensions, material types, and performance standards to facilitate precise communication with suppliers.

Step 2: Research Potential Suppliers

Identifying reliable suppliers is crucial for maintaining operational efficiency. Start by conducting thorough research on potential vendors.

– Look for established companies with a proven track record in supplying electrical motor parts to industries similar to yours.

– Utilize online platforms and industry directories to compile a list of potential suppliers, focusing on those with positive reviews and strong reputations.

Step 3: Evaluate Supplier Certifications and Quality Standards

Before finalizing a supplier, it’s essential to verify their certifications and adherence to quality standards. This step ensures that the components meet international safety and quality regulations.

– Request documentation such as ISO certifications, which indicate a commitment to quality management.

– Inquire about their testing procedures to ensure that their products can withstand the demands of your applications.

Step 4: Request Samples for Testing

Once you have narrowed down potential suppliers, request samples of the motor parts for evaluation. Testing samples can prevent costly mistakes in bulk orders.

– Assess the quality and performance of samples in real-world applications or simulations.

– Check for compatibility with your existing systems to avoid future operational disruptions.

Step 5: Negotiate Pricing and Terms

After selecting a preferred supplier based on quality and reliability, engage in negotiations regarding pricing and payment terms.

– Discuss bulk purchase discounts or long-term supply agreements to optimize costs.

– Clarify shipping and delivery timelines to ensure that your operations remain uninterrupted.

Step 6: Establish Clear Communication Channels

Effective communication with your suppliers is essential for a smooth procurement process. Set up clear channels for ongoing dialogue to address any issues that may arise.

– Define points of contact on both sides to streamline communication.

– Use project management tools to track orders and manage timelines collaboratively.

Step 7: Monitor Supply Chain Performance

After the procurement process, continuously monitor the supplier’s performance. This step ensures that they consistently meet your quality and delivery expectations.

– Solicit feedback from your team on the performance of the motor parts received.

– Conduct regular evaluations to address any emerging issues and maintain a productive supplier relationship.

By following this step-by-step checklist, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can effectively source electrical motor parts, ensuring quality, reliability, and cost-effectiveness in their procurement strategies.

Comprehensive Cost and Pricing Analysis for electrical motor parts Sourcing

What Are the Key Cost Components in Electrical Motor Parts Sourcing?

When sourcing electrical motor parts, understanding the cost structure is essential for effective budgeting and price negotiations. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost of electrical motor parts. Common materials such as copper for windings and high-grade steel for cores are crucial. Fluctuations in the prices of these materials can impact overall costs, so it’s advisable for buyers to stay updated on market trends.

-

Labor: Labor costs vary based on the region and the complexity of manufacturing processes. In regions with lower labor costs, such as parts of Africa and South America, sourcing can be more economical. However, quality must not be compromised; thus, it’s essential to evaluate the skill level of the workforce.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance. Buyers should consider suppliers who have optimized their manufacturing processes to reduce overhead, which can result in better pricing.

-

Tooling: Specific tooling is required for the production of certain parts, which adds to the initial cost. Long-term contracts can help spread these costs over a larger volume of orders, making it more cost-effective.

-

Quality Control (QC): Ensuring the quality of motor parts is non-negotiable, particularly for industrial applications. The costs associated with QC should be factored in, as they contribute to the reliability and longevity of the components.

-

Logistics: Shipping costs can vary widely depending on the distance, shipping method, and Incoterms used. Buyers should evaluate logistics providers to find the most cost-effective solutions while ensuring timely delivery.

-

Margin: Suppliers typically apply a margin based on their operational costs and market competition. Understanding the industry standard margins can help buyers negotiate better deals.

A stock image related to electrical motor parts.

How Do Price Influencers Impact Electrical Motor Parts Costs?

Several factors influence the pricing of electrical motor parts, which international buyers should consider:

-

Volume/MOQ: Larger orders often come with discounts. Buyers should assess their needs and negotiate minimum order quantities (MOQs) to leverage better pricing.

-

Specifications and Customization: Custom parts or specific specifications can lead to higher costs due to the unique tooling and manufacturing processes required. Buyers should evaluate whether customization is necessary or if standard parts can suffice.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (like ISO) can affect both price and reliability. Buyers should prioritize suppliers that offer the right balance of cost and quality.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact total landed costs and should be clearly defined in contracts.

What Are Effective Buyer Tips for Cost-Efficiency?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should adopt several strategies to enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders or long-term contracts. Building a good relationship can lead to better terms and pricing adjustments.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle costs of the motor parts, including installation, maintenance, and energy consumption. This perspective can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and potential tariffs that may impact overall costs. Establishing contracts in stable currencies can mitigate risks.

-

Supplier Audits: Conduct audits or assessments of potential suppliers to ensure they meet your quality and cost expectations. This step can prevent unforeseen costs down the line.

A stock image related to electrical motor parts.

By understanding these cost components, price influencers, and effective buyer strategies, international B2B buyers can make more informed sourcing decisions for electrical motor parts, ultimately improving their operational efficiency and profitability.

Alternatives Analysis: Comparing electrical motor parts With Other Solutions

Understanding the Alternatives to Electrical Motor Parts

In the realm of industrial machinery, electrical motor parts play a critical role in driving efficiency and performance. However, B2B buyers often face the challenge of determining whether traditional electrical motor components are the best fit for their operational needs. Several viable alternatives exist, each with unique benefits and limitations. This analysis delves into a comparative study of electrical motor parts against two alternative solutions: Pneumatic Systems and Hydraulic Systems.

Comparison Table

| Comparison Aspect | Electrical Motor Parts | Pneumatic Systems | Hydraulic Systems |

|---|---|---|---|

| Performance | High efficiency, suitable for precision tasks | Good for high-speed applications, less precise | High torque and power output, suitable for heavy loads |

| Cost | Moderate initial cost, potential for high maintenance | Lower initial cost, costs increase with compressed air supply | High initial investment, but lower long-term maintenance |

| Ease of Implementation | Generally easy to install and integrate | Requires air compressor setup | More complex setup and requires hydraulic pumps |

| Maintenance | Regular maintenance needed for longevity | Minimal maintenance, but air quality control is crucial | Requires regular checks and fluid management |

| Best Use Case | Precision machinery, robotics, and fans | Tools, packaging machines, and assembly lines | Heavy machinery, construction, and manufacturing processes |

Detailed Breakdown of Alternatives

A stock image related to electrical motor parts.

What are the Advantages and Disadvantages of Pneumatic Systems?

Pneumatic systems utilize compressed air to power tools and machinery. They are often favored in environments where mobility and speed are essential. The initial setup cost is lower compared to electrical motor systems, making them appealing for small to medium-sized operations. However, pneumatic systems can lack the precision of electric motors and may incur additional costs related to air supply and maintenance of compressors. Furthermore, air quality control is crucial to avoid contamination, which can lead to equipment failure.

How Do Hydraulic Systems Compare in Terms of Efficiency?

Hydraulic systems operate by using pressurized fluid to generate force and motion. They excel in applications that require high power and torque, making them ideal for heavy lifting and construction tasks. While the initial investment for hydraulic systems can be significant due to the need for pumps and reservoirs, they typically require less maintenance over time. However, the complexity of their setup can deter some businesses, especially those with limited technical expertise. Additionally, hydraulic systems may not be suitable for applications that require precise control.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between electrical motor parts and alternative solutions such as pneumatic or hydraulic systems, B2B buyers should carefully assess their specific operational needs. Considerations should include the required performance levels, budget constraints, ease of implementation, and long-term maintenance implications. Each solution presents distinct advantages and challenges, so aligning the choice with the operational context is essential for optimizing efficiency and productivity. By conducting a thorough analysis of these alternatives, buyers can make informed decisions that enhance their business operations and drive success.

Essential Technical Properties and Trade Terminology for electrical motor parts

What Are the Essential Technical Properties of Electrical Motor Parts?

Understanding the technical specifications of electrical motor parts is crucial for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. Key properties to consider include:

1. Material Grade

Material grade refers to the specific composition and quality of materials used in motor parts, such as copper for windings or silicon steel for cores. The choice of material affects the motor’s efficiency, durability, and performance. For instance, higher-grade materials can lead to better heat resistance and longevity, making them more suitable for industrial applications in sectors like manufacturing and energy.

2. Tolerance

Tolerance indicates the allowable deviation from a specified dimension in motor components. It is vital for ensuring parts fit and function correctly within the motor assembly. For B2B buyers, understanding tolerance levels is essential, as improper tolerances can lead to mechanical failures, increased maintenance costs, and operational downtime.

3. Horsepower Rating

The horsepower rating of an electric motor specifies its power output. This is critical for buyers to match the motor with the application requirements. For example, motors used in heavy machinery must have higher horsepower ratings to handle significant loads. Selecting the appropriate horsepower ensures optimal performance and efficiency in processes like material handling or power generation.

4. Efficiency Class

Efficiency class refers to the motor’s energy consumption relative to its output. Motors are classified into categories such as IE1, IE2, IE3, and IE4, with IE4 being the most efficient. Understanding these classifications helps buyers choose motors that not only meet performance needs but also align with sustainability goals by reducing energy costs.

5. Insulation Class

The insulation class indicates the thermal endurance of the motor’s windings. Classes range from A (105°C) to H (180°C), with higher classes suitable for more demanding environments. B2B buyers should select insulation classes based on the operating temperature of their application to ensure reliability and prevent premature failure.

What Are Common Trade Terms Used in Electrical Motor Parts?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are marketed by another company. For buyers, sourcing OEM parts often guarantees compatibility and quality assurance, as these components are designed to meet specific manufacturer standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory and avoid overcommitting to large orders that may not align with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. This process is vital for B2B buyers to compare pricing, terms, and conditions from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international sales contracts to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. For international B2B buyers, understanding Incoterms helps clarify cost responsibilities and delivery terms, which is essential in global trade.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is critical for planning and ensuring that production schedules are met without delays, particularly in industries where downtime can be costly.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions, negotiate better contracts, and ultimately enhance their operational efficiency in the procurement of electrical motor parts.

Navigating Market Dynamics and Sourcing Trends in the electrical motor parts Sector

What Are the Current Market Dynamics and Key Trends in the Electrical Motor Parts Sector?

The electrical motor parts sector is experiencing significant growth, driven by an increase in demand for efficient and sustainable energy solutions. Global trends indicate a shift toward automation and the integration of smart technologies in manufacturing processes. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing. Countries like Kenya and Argentina are seeing a rise in industrialization, leading to a greater need for reliable motor components that can enhance operational efficiency.

Emerging technologies such as IoT and AI are reshaping how electrical motor parts are sourced and maintained. Businesses are now favoring suppliers that provide real-time data analytics and predictive maintenance solutions. These technologies not only improve performance but also reduce downtime, which is a critical factor for industries ranging from manufacturing to renewable energy. B2B buyers should consider suppliers that are investing in advanced technologies to stay competitive.

Moreover, the global supply chain has been under pressure due to geopolitical tensions and economic fluctuations. This has led to a reevaluation of sourcing strategies. Buyers are encouraged to diversify their supplier base and consider local manufacturers to mitigate risks associated with international shipping and tariffs. Focusing on suppliers that offer OEM (Original Equipment Manufacturer) and high-quality replacement parts can ensure that businesses operate at peak performance.

How Can Sustainability and Ethical Sourcing Impact the Electrical Motor Parts Sector?

The environmental impact of manufacturing electrical motor parts cannot be overstated. As industries strive for sustainability, the importance of ethical supply chains becomes paramount. B2B buyers should prioritize suppliers that adhere to sustainable practices, such as using recyclable materials and minimizing waste in their production processes. This not only helps in reducing the carbon footprint but also aligns with global sustainability goals.

Incorporating ‘green’ certifications can further enhance a company’s reputation. Certifications like ISO 14001 (Environmental Management) or RoHS (Restriction of Hazardous Substances) signal a commitment to sustainability and can influence purchasing decisions positively. Buyers from regions like Europe are particularly inclined to choose suppliers who can demonstrate compliance with stringent environmental regulations.

Furthermore, ethical sourcing practices, such as ensuring fair labor conditions and responsible sourcing of raw materials, are increasingly being scrutinized. By selecting suppliers that prioritize ethical standards, businesses can mitigate risks related to reputational damage and enhance their corporate social responsibility (CSR) profile. This is especially relevant for B2B buyers in emerging markets, where establishing strong ethical practices can lead to competitive advantages.

What Is the Historical Context of the Electrical Motor Parts Sector?

The electrical motor parts sector has evolved significantly since the industrial revolution. Initially, the focus was on mechanical efficiency, but with advancements in technology, the sector has shifted toward electrical efficiency and automation. The introduction of AC and DC motors revolutionized the industry, leading to increased applications across various sectors, including manufacturing, transportation, and energy.

In recent decades, the emergence of digital technologies has further transformed the landscape. The integration of electronics into motor designs has led to smarter, more efficient systems that can be controlled remotely. This evolution has paved the way for innovations in motor components, such as brushless motors and advanced materials that improve performance and longevity. For B2B buyers, understanding this historical context is essential for making informed sourcing decisions that align with future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical motor parts

-

How do I solve compatibility issues with electrical motor parts?

To resolve compatibility issues, start by identifying the specific requirements of your existing motor system, including voltage, horsepower, and type of motor (AC or DC). Cross-reference these specifications with the parts you are considering. Engage with suppliers to clarify compatibility and inquire about OEM or equivalent parts. Additionally, consult technical documentation or a professional engineer to ensure seamless integration, particularly when sourcing from international markets where standards may vary. -

What is the best electrical motor part supplier for my business needs?

Choosing the best supplier depends on your specific requirements, including the type of motor parts you need, your location, and your budget. Look for suppliers with a strong reputation in your industry, proven quality assurance processes, and a diverse inventory of OEM parts. Consider suppliers that offer customization options to meet your unique specifications. Reading customer reviews and seeking recommendations from industry peers can also help you make an informed decision. -

How can I verify the quality of electrical motor parts before purchasing?

To ensure quality, request certifications or documentation that proves compliance with international standards such as ISO or CE. Conduct background checks on potential suppliers, looking for reviews and testimonials from other B2B buyers. If possible, request samples or visit the supplier’s facility to inspect their manufacturing processes. Establishing clear quality assurance protocols, including post-purchase inspections, can further mitigate risks associated with low-quality parts. -

What are the minimum order quantities (MOQs) for electrical motor parts?

MOQs can vary significantly depending on the supplier and the specific parts you require. Some suppliers may have low MOQs for standard parts, while specialized components may come with higher MOQs. Always confirm the MOQ before placing an order, and consider negotiating if your needs are below the stated quantity. Understanding your inventory needs can help you balance cost-effectiveness with the flexibility of order sizes. -

What payment terms should I expect when buying electrical motor parts internationally?

Payment terms can vary widely among suppliers. Common options include upfront payment, partial payment upon order confirmation, and payment upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify the terms in advance, and be aware of any currency exchange fees that may apply, especially when dealing with suppliers from different continents. -

How can I ensure timely logistics and delivery for my electrical motor parts?

To guarantee timely logistics, work closely with your supplier to understand their shipping capabilities and lead times. Choose a supplier with a reliable logistics network and inquire about their experience with international shipping. Consider using freight forwarders or logistics companies that specialize in B2B transactions for better tracking and communication. Always plan ahead for customs clearance and potential delays, particularly when sourcing from regions with complex trade regulations. -

What are the common customization options available for electrical motor parts?

Many suppliers offer customization options, including modifications to dimensions, materials, or electrical specifications to meet specific operational requirements. You can request tailored solutions such as unique winding configurations, special coatings for corrosion resistance, or custom mounting arrangements. Discuss your needs with potential suppliers early in the negotiation process to ensure they can accommodate your requests and provide a clear timeline for delivery. -

How do I handle warranty and return policies for electrical motor parts?

When sourcing electrical motor parts, carefully review the warranty and return policies offered by your supplier. Most reputable suppliers will provide a warranty period during which defective parts can be returned or replaced. Ensure that you understand the conditions under which returns are accepted, including any restocking fees or shipping responsibilities. Document all communications regarding warranties and keep records of your purchases to facilitate any future claims.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electrical motor parts

As the global demand for electrical motor parts continues to rise, strategic sourcing becomes essential for international B2B buyers. By leveraging local suppliers from regions such as Africa, South America, the Middle East, and Europe, businesses can not only reduce costs but also enhance supply chain resilience. Engaging with reputable manufacturers of OEM and replacement parts ensures access to high-quality components, which is critical for maintaining operational efficiency in industries ranging from power generation to automotive.

What are the key benefits of strategic sourcing for electrical motor parts? The primary advantages include improved quality control, reduced lead times, and the ability to negotiate better pricing. Additionally, fostering relationships with suppliers can lead to innovation and customization opportunities, allowing businesses to meet specific operational needs.

Looking ahead, international B2B buyers must remain proactive in their sourcing strategies. Embrace digital platforms to connect with suppliers and explore emerging markets. By prioritizing strategic sourcing, you position your business for success in an increasingly competitive landscape. Begin your journey today by evaluating your current supply chain and identifying potential partnerships that can drive growth and efficiency in your operations.