The Ultimate Guide to Locking Mechanisms (2025)

Introduction: Navigating the Global Market for locking mechanisms

Navigating the global market for locking mechanisms presents a significant challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The need for secure and reliable locking solutions is paramount, yet sourcing the right products can be complex due to the diverse types and applications available. From traditional mechanical locks to advanced electronic systems, understanding the nuances of locking mechanisms is essential for making informed purchasing decisions. This guide aims to demystify the various types of locks, their applications, and the critical factors to consider when evaluating suppliers.

In this comprehensive resource, you will discover in-depth insights into the different locking mechanisms, including mechanical, keyless, and electronic options, as well as their respective benefits and limitations. We will cover essential topics such as supplier vetting processes, cost considerations, and market trends to empower you in your procurement journey. By providing actionable insights and expert guidance, this guide equips B2B buyers with the knowledge to navigate the complexities of the locking mechanisms market confidently. Whether you are a buyer in the bustling markets of the UAE or the emerging economies of Kenya, understanding these elements will enhance your ability to secure the best locking solutions for your business needs.

Understanding locking mechanisms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pin Tumbler Locks | Uses pins of varying lengths to block bolt movement | Commercial buildings, offices | Pros: High security, widely available. Cons: Vulnerable to bumping and picking. |

| Electronic Locks | Operated via keypads or biometric systems | Hotels, high-security facilities | Pros: Keyless convenience, audit trails. Cons: Requires power, potential for cyber threats. |

| Deadbolt Locks | Provides additional security by extending a bolt | Residential and commercial doors | Pros: High resistance to forced entry. Cons: Installation may require professional help. |

| Magnetic Locks | Utilizes electromagnetic force to secure doors | Access control systems, gates | Pros: Seamless integration with security systems. Cons: Power failure can lead to security risks. |

| Smart Locks | Connects to mobile devices for remote access | Smart homes, modern offices | Pros: Remote control, integration with smart home devices. Cons: Dependency on technology, potential hacking risks. |

What are Pin Tumbler Locks and Their B2B Relevance?

Pin tumbler locks are among the most common locking mechanisms, featuring a series of pins that must be aligned to allow the bolt to move. They are widely used in commercial settings due to their reliability and availability. B2B buyers should consider the security level required, as these locks can be vulnerable to techniques like bumping. For businesses in regions with higher security risks, investing in high-quality pin tumbler locks with advanced features is advisable.

How Do Electronic Locks Enhance Security for Businesses?

Electronic locks provide a modern solution for securing premises, operated through keypads or biometric systems. They are particularly useful in hotels and high-security facilities, where tracking access is crucial. B2B buyers should weigh the benefits of keyless convenience against the potential risks of cyber threats. Regular maintenance and updates are essential to ensure security and functionality, making them a long-term investment for businesses prioritizing safety.

Why Choose Deadbolt Locks for Enhanced Security?

Deadbolt locks offer an additional layer of security by extending a solid bolt into the door frame, making them difficult to force open. They are commonly used in both residential and commercial applications. For B2B buyers, the strength and durability of deadbolts can significantly reduce the risk of break-ins. However, installation may require professional assistance, which should be factored into overall costs.

What are the Advantages of Magnetic Locks in Access Control?

Magnetic locks utilize electromagnetic force to secure doors, making them ideal for access control systems. They are widely used in gates and high-security areas due to their seamless integration with security measures. While they offer significant advantages, including a clean aesthetic and high reliability, B2B buyers must consider the implications of power outages, which can compromise security. Ensuring a backup power solution is critical for businesses relying on this technology.

How Do Smart Locks Transform Business Security?

Smart locks represent the forefront of locking technology, allowing remote access through mobile devices. They are increasingly popular in smart homes and modern offices, where convenience and integration with other smart devices are priorities. For B2B buyers, the ability to control access remotely can enhance operational efficiency. However, the reliance on technology and the potential for hacking are significant considerations. Businesses must implement robust cybersecurity measures to protect against these risks.

Key Industrial Applications of locking mechanisms

| Industry/Sector | Specific Application of locking mechanisms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Securing machinery and equipment | Prevents unauthorized access, reducing theft and liability risks | Compliance with safety standards, durability under harsh conditions |

| Logistics and Warehousing | Locking storage units and containers | Enhances inventory security and minimizes loss due to theft | Compatibility with various container types, ease of use for staff |

| Healthcare | Locking medication cabinets | Ensures patient safety and compliance with regulations | Certifications for medical use, ease of access for authorized personnel |

| Hospitality | Securing guest room doors | Increases guest safety and enhances property reputation | Aesthetic appeal, integration with electronic systems for keyless entry |

| Retail | Locking display cases | Protects valuable merchandise while allowing customer access | Versatility in design, ease of installation and maintenance |

How Are Locking Mechanisms Used in Manufacturing?

In the manufacturing sector, locking mechanisms play a crucial role in securing machinery and equipment. By preventing unauthorized access, these mechanisms help reduce the risk of theft and liability claims. International B2B buyers must consider the compliance of locking solutions with safety standards and their durability, especially in environments subject to wear and tear. For businesses in regions like Africa and South America, sourcing locks that can withstand extreme conditions is vital for maintaining operational efficiency.

What Role Do Locking Mechanisms Play in Logistics and Warehousing?

Locking mechanisms are essential in logistics and warehousing, particularly for securing storage units and containers. They enhance inventory security, minimizing losses due to theft. Buyers in this sector should prioritize compatibility with various container types and ease of use for staff, ensuring that locks can be quickly engaged and disengaged during high-traffic periods. In the Middle East, where logistics hubs are booming, investing in robust locking solutions can significantly protect assets and streamline operations.

Why Are Locking Mechanisms Critical in Healthcare?

In healthcare, locking mechanisms are vital for securing medication cabinets and sensitive equipment. They ensure patient safety and compliance with stringent regulations regarding drug storage. B2B buyers in this sector need to source locks that have certifications for medical use and allow easy access for authorized personnel while preventing unauthorized entry. As healthcare facilities in Europe increasingly adopt advanced security measures, the demand for reliable locking solutions is on the rise.

How Do Locking Mechanisms Enhance Security in Hospitality?

The hospitality industry utilizes locking mechanisms primarily to secure guest room doors. This enhances guest safety and contributes to the property’s reputation for security and trustworthiness. Buyers should consider aesthetic appeal and the ability to integrate with electronic systems for keyless entry, which is becoming a popular trend in modern hotels. In regions like the UAE, where tourism is vital, investing in advanced locking solutions can significantly elevate guest experiences.

What Benefits Do Locking Mechanisms Provide to Retail?

In retail, locking mechanisms are used to secure display cases, protecting valuable merchandise while still allowing customer access. This balance between security and accessibility is crucial for maintaining inventory integrity. Retailers should look for locking solutions that are versatile in design and easy to install and maintain. As South American markets grow, the need for innovative locking mechanisms that cater to diverse retail environments becomes increasingly important.

3 Common User Pain Points for ‘locking mechanisms’ & Their Solutions

Scenario 1: Struggles with Key Management and Theft Prevention

The Problem:

In many businesses, especially in sectors such as hospitality or retail, managing physical keys for locking mechanisms can become chaotic. Multiple employees require access to secure areas, and keeping track of who has which key can lead to significant vulnerabilities. This lack of control increases the risk of theft or unauthorized access, which can result in financial losses and damaged reputations. Furthermore, traditional locking mechanisms can be compromised if keys are lost or duplicated without proper oversight.

The Solution:

To address this challenge, B2B buyers should consider investing in keyless locking systems, such as electronic locks with access control features. These systems allow for customized access levels and can easily be updated when an employee leaves or if a key is lost. When sourcing these locking mechanisms, look for products that offer robust software solutions for key management, enabling tracking of access logs and real-time alerts for unauthorized access attempts. Additionally, ensure the chosen system integrates seamlessly with existing security infrastructure to enhance overall security without requiring extensive retraining of staff.

Scenario 2: Difficulty in Ensuring Compliance with Security Standards

The Problem:

In industries like finance, healthcare, and manufacturing, compliance with security standards is critical. Many B2B buyers find themselves grappling with locking mechanisms that do not meet the required security certifications, leading to potential legal repercussions and financial penalties. This can be particularly concerning for companies operating in multiple regions, where security standards may vary significantly.

The Solution:

To overcome compliance challenges, businesses should conduct thorough research to identify locking mechanisms that are certified to meet international security standards such as UL, EN, or ANSI. Collaborate with suppliers who can provide documentation of compliance and who stay updated on changes in regulations across different markets. Furthermore, consider investing in modular locking systems that can be easily upgraded or adjusted to meet evolving standards, ensuring that your security remains robust and compliant without the need for complete replacements.

Scenario 3: Inefficiency in Locking Mechanism Maintenance and Downtime

The Problem:

Many businesses experience significant downtime due to malfunctioning locking mechanisms, which can disrupt operations and reduce productivity. This issue is particularly prevalent in facilities with heavy traffic, where locks are frequently used and may wear out quickly. For B2B buyers, the challenge lies in balancing the cost of high-quality locking systems with the potential for increased maintenance and repair costs.

The Solution:

To mitigate maintenance-related issues, B2B buyers should prioritize the selection of durable locking mechanisms that are designed for high-traffic environments. Look for locks made from corrosion-resistant materials, such as stainless steel, which are less likely to fail over time. Additionally, establish a regular maintenance schedule that includes inspections and servicing of locks to prevent issues before they arise. Partnering with a reputable locksmith or security provider can also ensure that any repairs are handled promptly, minimizing downtime and maintaining operational efficiency. Consider implementing a predictive maintenance program that uses IoT technology to monitor the status of locks in real time, allowing for proactive maintenance before any breakdown occurs.

Strategic Material Selection Guide for locking mechanisms

What Are the Key Properties of Common Materials Used in Locking Mechanisms?

When selecting materials for locking mechanisms, several factors must be considered, including durability, corrosion resistance, and temperature ratings. Here, we analyze four common materials used in the manufacturing of locks: steel, brass, aluminum, and plastic.

How Does Steel Perform in Locking Mechanisms?

Steel is a widely used material in locking mechanisms due to its high strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for various environments. Steel locks can withstand significant force, which enhances security.

Pros: Steel is highly durable and resistant to physical attacks, making it an ideal choice for high-security applications. It is also relatively cost-effective, especially in bulk manufacturing.

Cons: Steel can be prone to corrosion if not adequately treated, which may limit its use in humid or coastal environments. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Steel is compatible with most locking applications, including commercial and residential uses. However, buyers must consider the local climate and potential for corrosion when selecting steel locks.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the steel used complies with local standards such as ASTM or DIN. Corrosion-resistant coatings may also be necessary for specific environments.

What Are the Benefits of Brass in Locking Mechanisms?

Brass, an alloy of copper and zinc, is another popular material for locks. It offers excellent corrosion resistance, which makes it suitable for outdoor applications. Brass also has a good aesthetic appeal, often used in decorative locks.

Pros: Brass is highly resistant to corrosion and tarnishing, making it an excellent choice for locks exposed to the elements. It is also relatively easy to machine, allowing for intricate designs.

Cons: While brass is durable, it is softer than steel, making it less resistant to physical attacks. Additionally, brass can be more expensive than steel, which may affect overall project costs.

Impact on Application: Brass locks are commonly used in residential settings and decorative applications. Their corrosion resistance makes them suitable for coastal areas.

Considerations for International Buyers: Buyers should check for compliance with standards like JIS for brass locks. The aesthetic appeal of brass may also influence purchasing decisions in markets like Europe, where design is often prioritized.

Why Choose Aluminum for Locking Mechanisms?

Aluminum is lightweight and resistant to corrosion, making it a viable option for locking mechanisms. It is often used in applications where weight is a concern, such as in automotive or portable devices.

Pros: Aluminum is lightweight and offers excellent corrosion resistance, making it suitable for various environments. It is also relatively easy to machine and can be anodized for additional protection.

Cons: Aluminum is generally not as strong as steel, which may limit its use in high-security applications. It can also be more expensive than steel, depending on the grade.

Impact on Application: Aluminum locks are ideal for lightweight applications but may not be suitable for high-security environments. They are often used in residential and light commercial applications.

Considerations for International Buyers: Buyers should consider the grade of aluminum used and ensure it meets local standards. In regions like South America, where weight and portability are crucial, aluminum may be favored.

What Role Does Plastic Play in Locking Mechanisms?

Plastic is increasingly being used in locking mechanisms, particularly in electronic locks and low-security applications. It is lightweight and can be molded into complex shapes.

Pros: Plastic is lightweight and resistant to corrosion, making it suitable for various environments. It can also be produced at a lower cost compared to metal locks.

Cons: Plastic locks are generally less durable and secure than metal options. They may not withstand physical attacks as well, making them unsuitable for high-security applications.

Impact on Application: Plastic locks are often used in applications where weight and cost are more critical than security, such as in low-security residential settings or electronic devices.

Considerations for International Buyers: Buyers should ensure that the plastic used complies with relevant safety and durability standards. In regions like the Middle East, where extreme temperatures can affect material performance, choosing high-quality plastics is essential.

Summary Table of Material Selection for Locking Mechanisms

| Material | Typical Use Case for locking mechanisms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-security locks, commercial applications | High strength and durability | Prone to corrosion without treatment | Medium |

| Brass | Residential locks, decorative applications | Excellent corrosion resistance | Softer than steel, more expensive | Medium to High |

| Aluminum | Lightweight applications, portable devices | Lightweight and corrosion-resistant | Less secure than steel | Medium |

| Plastic | Low-security applications, electronic locks | Cost-effective and lightweight | Less durable and secure | Low |

This comprehensive analysis of materials provides actionable insights for B2B buyers, helping them make informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for locking mechanisms

What Are the Key Stages in the Manufacturing Process of Locking Mechanisms?

The manufacturing of locking mechanisms involves several critical stages, each playing a vital role in ensuring the final product meets quality and security standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Lock Manufacturing?

The first step in the manufacturing process is material selection. Common materials include steel, brass, and zinc alloys, known for their durability and resistance to corrosion. In some cases, advanced materials like polymers or composites are used for specific applications, such as lightweight locks or those requiring non-metallic properties.

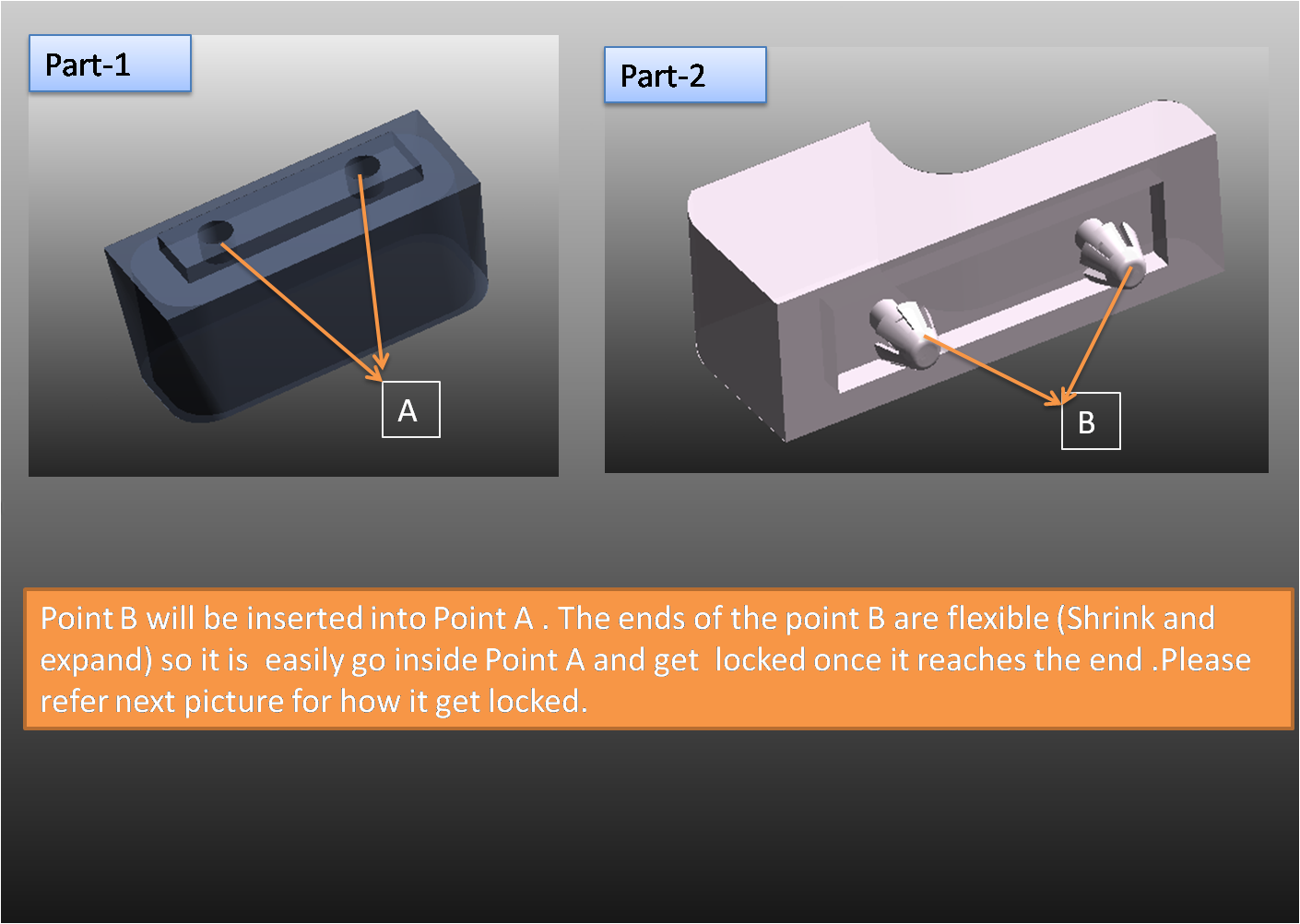

A stock image related to locking mechanisms.

Once materials are chosen, they undergo preparation, which may involve cutting, machining, or surface treatment to enhance their properties. For instance, steel components may be heat-treated to improve hardness and tensile strength, ensuring they can withstand tampering.

How Are Locking Mechanisms Formed?

Forming is the next stage, where raw materials are shaped into the desired components. This process can involve various techniques, including:

- Casting: Molten metal is poured into molds to create complex shapes.

- Forging: Metal is shaped through mechanical deformation, providing superior strength.

- Machining: Components are precisely cut and finished using CNC (Computer Numerical Control) machines for accuracy.

Each technique has its advantages and is selected based on the specific requirements of the locking mechanism being produced.

What Are the Assembly and Finishing Processes for Locking Mechanisms?

How Are Locking Mechanisms Assembled?

The assembly stage involves combining the various components created during the forming phase. This includes integrating the lock body, tumblers, pins, springs, and any electronic components if applicable. Precision is crucial here, as even minor misalignments can compromise the lock’s functionality.

Automated assembly lines are increasingly common, ensuring consistent quality and speed. However, manual assembly may still be used for more intricate or custom locks, where skilled craftsmanship is required.

What Finishing Techniques Are Employed?

Finishing processes are essential for both aesthetics and functionality. Common finishing techniques include:

- Coating: Applying protective coatings like powder coating or electroplating to enhance corrosion resistance and appearance.

- Polishing: Buffing surfaces to achieve a smooth, attractive finish.

- Quality Markings: Adding certifications or branding to components, which can be important for traceability and brand recognition.

These finishing touches not only improve the lock’s durability but also contribute to its marketability.

What Quality Assurance Measures Are Essential for Locking Mechanisms?

Quality assurance is vital in the manufacturing of locking mechanisms, particularly given the security implications of these products. International standards such as ISO 9001 provide a framework for quality management systems, while industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application.

What Are the Key QC Checkpoints in Lock Manufacturing?

Quality Control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to monitor compliance with quality standards.

- Final Quality Control (FQC): Comprehensive testing of the finished product before it leaves the factory.

These checkpoints help identify defects early, reducing waste and ensuring only high-quality products reach the market.

What Testing Methods Are Commonly Used for Locking Mechanisms?

Testing methods vary based on the type of lock but often include:

- Functional Testing: Ensuring the lock operates correctly under normal conditions.

- Durability Testing: Subjecting locks to wear and tear to assess their lifespan.

- Security Testing: Evaluating resistance to picking, bumping, or forced entry.

These tests help assure B2B buyers of the reliability and security of the locking mechanisms they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable insights:

-

Conduct Audits: Regular audits of suppliers can help assess their compliance with international quality standards. This includes reviewing their manufacturing processes, quality assurance measures, and adherence to safety standards.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and certifications. This transparency builds trust and confidence in their capabilities.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspectors can verify compliance with international standards and industry-specific requirements.

-

Understand Regional Certification Nuances: Different regions may have specific regulations or certifications that affect the quality and safety of locking mechanisms. Buyers should familiarize themselves with these nuances to ensure compliance and quality assurance.

What Should International Buyers Consider Regarding Quality Control?

When sourcing locking mechanisms from international suppliers, buyers should consider the following:

-

Cultural Differences: Be aware that quality control practices may vary significantly across regions. Understanding these differences can help buyers set realistic expectations and foster better communication with suppliers.

-

Supply Chain Reliability: Ensure that suppliers have a robust supply chain that can provide consistent quality. This is particularly important for buyers in Africa and South America, where supply chain disruptions may occur.

-

After-Sales Support: Quality assurance does not end with the sale. Buyers should look for suppliers that offer after-sales support, including warranty services and product training, to ensure long-term satisfaction with their purchases.

By focusing on these aspects, international B2B buyers can make informed decisions and secure reliable locking mechanisms that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘locking mechanisms’

Introduction

When sourcing locking mechanisms for your business, it is essential to follow a structured approach to ensure you select the most appropriate products for your needs. This checklist aims to guide B2B buyers from regions like Africa, South America, the Middle East, and Europe through the critical steps in the procurement process, focusing on technical specifications, supplier evaluation, and compliance requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before initiating the sourcing process. Consider the specific type of locking mechanism required—be it electronic locks, mechanical keyless locks, or rotary latches—based on your application.

- Identify security needs: Determine the level of security required for your facility or equipment.

- Assess environmental conditions: Ensure the locking mechanisms can withstand local climate factors, such as humidity or temperature variations.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and innovations in locking mechanisms to enhance your procurement strategy. Understanding the advancements in technology, such as smart locks or biometric systems, can provide your business with a competitive edge.

- Review industry publications: Subscribe to relevant journals and reports that highlight new products and technologies.

- Attend trade shows: Participate in industry exhibitions to see products firsthand and interact with manufacturers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, case studies, and references from other buyers in your industry or region.

- Check supplier certifications: Ensure that the suppliers meet international standards such as ISO certifications.

- Assess production capacity: Verify that the supplier can meet your order volume and delivery timelines.

Step 4: Request Samples and Test Performance

Obtaining samples of the locking mechanisms allows you to assess their quality and performance. This step is vital to ensure that the products meet your specifications and are fit for your intended use.

- Conduct functional tests: Evaluate ease of use, durability, and reliability under simulated conditions.

- Assess compatibility: Ensure the locks integrate seamlessly with your existing systems or infrastructure.

Step 5: Verify Compliance with Local Regulations

Compliance with local regulations is a crucial aspect of sourcing locking mechanisms, especially in different regions. Understanding these regulations helps avoid legal issues and ensures product safety.

- Research local safety standards: Familiarize yourself with requirements in your target market, such as fire safety regulations.

- Confirm import/export compliance: Ensure that the locking mechanisms adhere to the customs regulations of the countries involved.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, negotiate favorable terms and pricing. This step is essential to ensure you get the best value for your investment.

- Consider total cost of ownership: Evaluate not just the upfront costs but also maintenance and replacement costs over time.

- Negotiate payment terms: Aim for flexible payment options that align with your cash flow needs.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with your supplier can lead to better pricing, priority support, and access to new products.

- Communicate regularly: Keep the lines of communication open to address any issues or changes in requirements.

- Provide feedback: Share insights on product performance to help suppliers improve their offerings.

Following this checklist will enable B2B buyers to navigate the complexities of sourcing locking mechanisms effectively, ensuring that the final products meet their operational needs and security requirements.

Comprehensive Cost and Pricing Analysis for locking mechanisms Sourcing

What Are the Key Cost Components in Locking Mechanism Sourcing?

When sourcing locking mechanisms, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include steel, brass, and plastics, with stainless steel typically being more expensive due to its durability and corrosion resistance.

-

Labor: Labor costs vary based on the manufacturing location. Countries with lower labor costs, such as those in parts of Africa and South America, can offer competitive pricing. However, the skill level of the workforce also affects quality and cost.

-

Manufacturing Overhead: This encompasses expenses such as utilities, rent, and administrative costs. Efficient manufacturing processes can help minimize overhead.

-

Tooling: Initial investment in tooling can be significant, especially for custom locking mechanisms. Buyers should consider whether suppliers have the necessary equipment to produce the desired specifications.

-

Quality Control (QC): Implementing stringent QC processes ensures that the locking mechanisms meet required standards. While this may increase upfront costs, it can lead to lower failure rates and improved customer satisfaction over time.

-

Logistics: Transporting locking mechanisms involves shipping costs, tariffs, and handling fees. Incoterms play a crucial role in determining who bears these costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s pricing model can help buyers negotiate better.

How Do Price Influencers Affect Locking Mechanism Costs?

Several factors can influence pricing in the locking mechanism market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Customized locking mechanisms may incur additional costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: High-quality materials and certifications, such as ISO standards, can increase costs but may also enhance product reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they dictate the responsibilities for shipping and delivery, affecting the total cost.

What Tips Can Help Buyers Negotiate Better Prices?

Negotiating effectively can lead to significant savings. Here are some actionable tips for international B2B buyers:

-

Research Market Prices: Familiarize yourself with market rates for various locking mechanisms. This knowledge will empower you during negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and potential replacements. A higher upfront cost might be justified if the product lasts longer.

-

Leverage Relationships: Build strong relationships with suppliers. Long-term partnerships can lead to better pricing, priority service, and insights into market trends.

-

Ask for Volume Discounts: If planning to order in bulk, inquire about volume discounts. Suppliers are often willing to negotiate on larger orders.

-

Be Flexible with Specifications: If possible, be flexible with your specifications. Minor adjustments can lead to significant cost reductions.

What Should Buyers Keep in Mind About Pricing Nuances?

International B2B buyers should be aware of specific pricing nuances that can vary by region:

-

Currency Fluctuations: Exchange rates can impact costs. Consider locking in prices or using contracts that account for currency fluctuations.

-

Local Regulations and Tariffs: Import duties and local regulations can add to the cost. Understand the regulatory landscape in your region to avoid surprises.

-

Cultural Factors: Negotiation styles can differ across regions. Being culturally aware can improve communication and lead to better outcomes.

Disclaimer for Indicative Prices

Prices for locking mechanisms can vary widely based on the factors discussed above. It is essential for buyers to obtain quotes from multiple suppliers and conduct thorough market research to ensure they are getting a fair price. Always consider the specific needs of your business and the quality of the product being sourced.

Alternatives Analysis: Comparing locking mechanisms With Other Solutions

Understanding Alternatives to Traditional Locking Mechanisms

In the world of security solutions, traditional locking mechanisms are not the only option available to businesses. As technology advances, various alternatives have emerged that provide different levels of security, convenience, and cost-effectiveness. This section compares traditional locking mechanisms with electronic access control systems and biometric security systems, helping international B2B buyers make informed decisions based on their specific needs.

Comparison Table of Locking Mechanisms and Alternatives

| Comparison Aspect | Locking Mechanisms | Electronic Access Control Systems | Biometric Security Systems |

|---|---|---|---|

| Performance | Reliable for physical security | High efficiency, remote access | Extremely secure, unique identifiers |

| Cost | Generally low initial cost | Moderate to high initial cost | High initial cost, but low maintenance |

| Ease of Implementation | Simple installation | Requires wiring and setup | Complex installation, needs calibration |

| Maintenance | Low maintenance | Moderate maintenance required | Regular updates and calibration needed |

| Best Use Case | Small businesses, residential properties | Large facilities, offices | High-security areas, data centers |

What Are the Advantages and Disadvantages of Electronic Access Control Systems?

Electronic access control systems use keypads, RFID cards, or mobile applications to grant access.

Pros:

– Convenience: Offers remote access and control, allowing businesses to manage entry points from anywhere.

– Audit Trails: Provides tracking of who accessed what and when, which is essential for security audits.

Cons:

– Higher Initial Costs: Installation and setup can be costly, especially for larger facilities.

– Dependency on Power: Requires a reliable power source; outages can compromise security.

How Do Biometric Security Systems Compare in Terms of Security and Cost?

Biometric security systems utilize unique physical characteristics, such as fingerprints or facial recognition, to grant access.

Pros:

– Enhanced Security: Difficult to bypass as they rely on individual traits, making unauthorized access nearly impossible.

– User Convenience: Eliminates the need for keys or cards, streamlining access for users.

Cons:

– High Initial Investment: The technology can be expensive to implement and maintain.

– Privacy Concerns: Collecting biometric data raises privacy issues that must be addressed.

Conclusion: How Can B2B Buyers Choose the Right Security Solution?

When selecting a security solution, international B2B buyers must evaluate their specific needs, taking into account factors such as the level of security required, budget constraints, and the operational environment. Traditional locking mechanisms may suffice for small businesses and residential properties, while electronic access control systems and biometric solutions offer advanced features for larger enterprises or high-security areas. By weighing the pros and cons of each option, buyers can make a strategic choice that aligns with their security objectives and operational demands.

Essential Technical Properties and Trade Terminology for locking mechanisms

What Are the Essential Technical Properties of Locking Mechanisms?

When sourcing locking mechanisms for B2B applications, understanding the technical properties is crucial for ensuring security, durability, and compliance with local standards. Here are some key specifications to consider:

1. Material Grade: How Does Material Affect Lock Performance?

The material used in locking mechanisms significantly impacts their strength and longevity. Common materials include stainless steel, brass, and zinc alloys. Stainless steel is favored for its corrosion resistance, making it suitable for outdoor applications, especially in humid climates found in parts of Africa and South America. Brass, while aesthetically pleasing, may not be as durable under harsh environmental conditions.

2. Tolerance: Why Is Precision Important in Lock Manufacturing?

Tolerance refers to the allowable deviation in the dimensions of lock components. Tight tolerances ensure that parts fit together correctly, which enhances the lock’s effectiveness and reduces the likelihood of tampering. For B2B buyers, specifying tight tolerances is vital when selecting locks for high-security environments, such as financial institutions or government facilities.

3. Locking Mechanism Type: Which Type Suits Your Needs?

Locking mechanisms come in various types, including pin tumbler, wafer, and electronic locks. Each type has unique benefits and security levels. For example, pin tumbler locks are widely used due to their balance of security and cost. In contrast, electronic locks offer advanced features such as remote access and audit trails, making them ideal for modern commercial applications.

4. Security Rating: What Level of Security Should You Look For?

Security ratings, such as those provided by organizations like Underwriters Laboratories (UL) or the European Norm (EN), help assess the effectiveness of locks against forced entry. Understanding these ratings allows B2B buyers to select locks that meet their specific security requirements, especially in regions facing high crime rates.

5. Operating Temperature Range: How Does Environment Affect Lock Functionality?

Locks must operate effectively in various environmental conditions. The operating temperature range specifies the temperatures within which the lock functions reliably. For international buyers, especially in regions with extreme temperatures, it is crucial to ensure that the chosen locking mechanism can withstand local climatic conditions without compromising performance.

What Are Common Trade Terms in the Locking Mechanism Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

1. OEM (Original Equipment Manufacturer): What Role Does OEM Play in Lock Supply Chains?

OEM refers to companies that manufacture products based on specifications provided by another company. In the locking mechanism industry, OEMs often produce locks for brands that may not have in-house manufacturing capabilities. Understanding OEM relationships can help buyers ensure quality and consistency in their product sourcing.

2. MOQ (Minimum Order Quantity): Why Is MOQ Important for Bulk Purchases?

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can significantly affect purchasing decisions and inventory management. Understanding the MOQ can help buyers negotiate better terms and avoid excess inventory.

3. RFQ (Request for Quotation): How Can RFQ Streamline Your Procurement Process?

An RFQ is a document used to invite suppliers to bid on a specific quantity of goods or services. For locking mechanisms, issuing an RFQ allows buyers to compare pricing, specifications, and delivery times, thus facilitating informed decision-making.

4. Incoterms: What Are the Most Relevant Incoterms for Locking Mechanism Imports?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping agreements. Understanding terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) can help B2B buyers from Africa, South America, the Middle East, and Europe manage shipping costs and risks effectively.

5. Lead Time: How Does Lead Time Impact Your Supply Chain?

Lead time refers to the time it takes from placing an order to receiving the product. For international buyers, understanding lead times is essential for effective inventory management and ensuring that projects remain on schedule, especially when sourcing locking mechanisms from overseas suppliers.

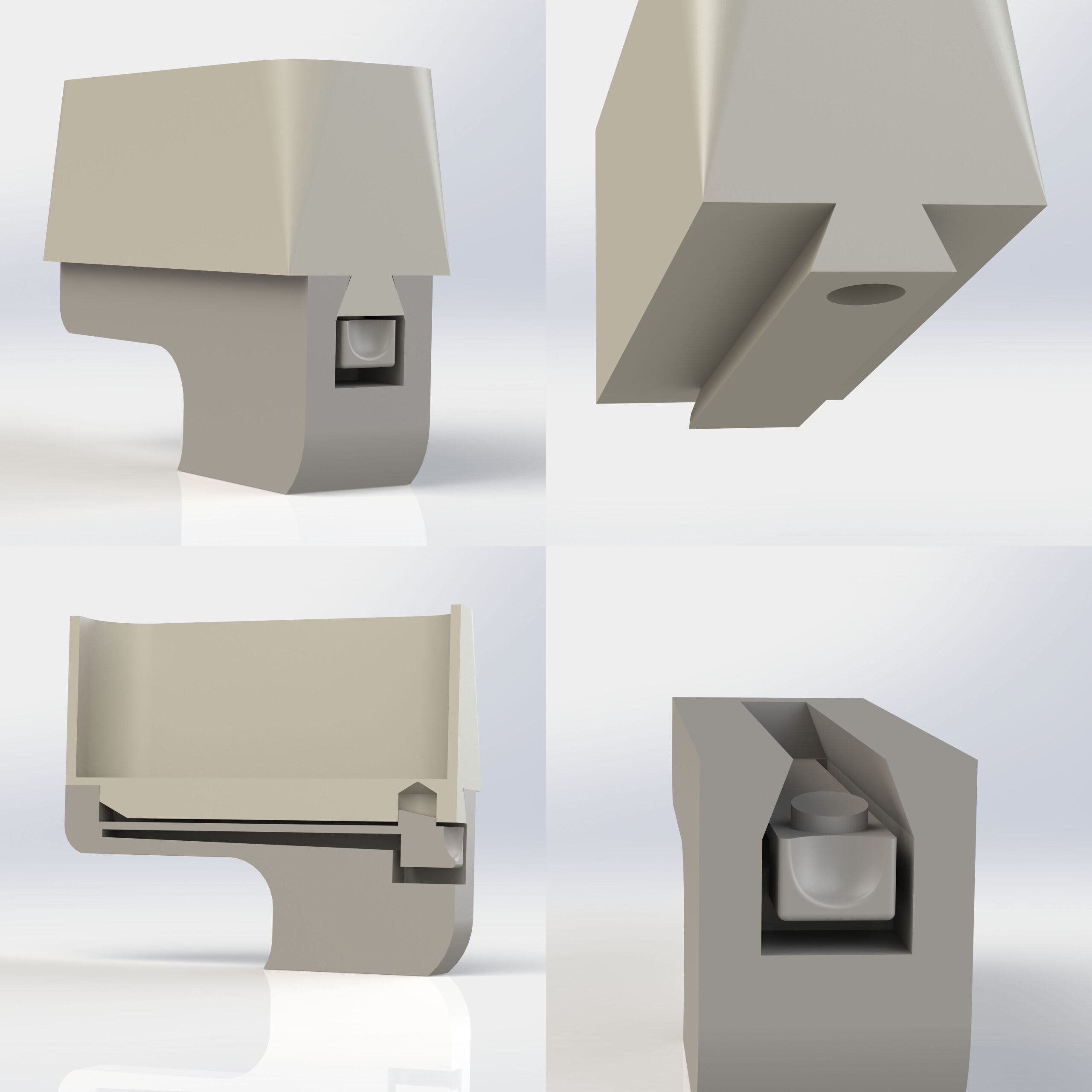

A stock image related to locking mechanisms.

By comprehensively understanding these technical properties and industry terms, international B2B buyers can make more informed decisions when sourcing locking mechanisms tailored to their specific needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the locking mechanisms Sector

What Are the Key Trends Shaping the Locking Mechanisms Market?

The locking mechanisms market is evolving rapidly, driven by several global trends that international B2B buyers need to understand. With increasing urbanization and the rise of smart cities, demand for advanced security solutions is surging across regions, particularly in Africa, South America, the Middle East, and Europe. Key trends include the growing adoption of electronic and smart locks, which offer enhanced security features such as remote access, real-time monitoring, and integration with smart home systems.

Moreover, the shift towards contactless technology is gaining traction, especially in the wake of the COVID-19 pandemic, as businesses seek to minimize physical touchpoints. Additionally, the emphasis on sustainability is prompting manufacturers to innovate with eco-friendly materials and processes. As a result, B2B buyers must stay informed about these technological advancements and evaluate suppliers based on their ability to meet modern security needs while adhering to sustainable practices.

How Can Sustainability and Ethical Sourcing Impact Your Locking Mechanisms Procurement?

Sustainability and ethical sourcing are increasingly vital considerations for B2B buyers in the locking mechanisms sector. The environmental impact of manufacturing processes, particularly concerning waste management and resource consumption, is under scrutiny. Buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient production methods.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. Furthermore, transparency in the supply chain is crucial; buyers should ensure that their suppliers adhere to ethical labor practices and fair trade principles. By aligning procurement strategies with sustainability goals, businesses can not only enhance their brand image but also contribute positively to the global effort toward environmental stewardship.

What Is the Historical Context of Locking Mechanisms and Its Relevance Today?

The evolution of locking mechanisms dates back thousands of years, originating with simple pin tumbler designs in ancient civilizations. Over the centuries, advancements in materials and technology have significantly improved lock security. Notable innovations include the introduction of metal locks by the Romans and the development of complex mechanisms during the Middle Ages, which laid the foundation for modern locking systems.

Today, understanding this historical context is essential for B2B buyers. The legacy of security innovations informs current market offerings and trends, providing insights into the reliability and effectiveness of various locking solutions. Buyers can leverage this knowledge to make informed decisions when sourcing locking mechanisms that not only meet contemporary security demands but also reflect a long-standing commitment to quality and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of locking mechanisms

-

How do I choose the right locking mechanism for my business needs?

Choosing the right locking mechanism depends on several factors, including the level of security required, the environment where the lock will be used, and the type of access control needed. For example, electronic locks may be suitable for high-security areas due to their advanced features, while mechanical locks may suffice for less critical applications. Assess your specific requirements such as durability, weather resistance, and ease of use, and consult with suppliers to get expert recommendations tailored to your industry. -

What is the best locking mechanism for commercial applications?

The best locking mechanism for commercial applications often includes high-security options such as smart locks, electronic access control systems, or heavy-duty padlocks. Smart locks offer remote access and audit trails, which are beneficial for businesses with multiple users. For industries in high-crime areas, consider locks that meet specific security certifications. Engage with suppliers to evaluate the latest technologies that align with your operational needs and security protocols. -

What are the key considerations when sourcing locking mechanisms internationally?

When sourcing locking mechanisms internationally, consider the supplier’s reputation, compliance with local and international standards, and the quality of their products. Verify their certifications and seek references from other businesses in your region. Additionally, ensure that the supplier can provide support for installation and maintenance. Understanding customs regulations and import duties in your country is also crucial to avoid unexpected costs. -

How can I ensure the quality of locking mechanisms from suppliers?

To ensure quality, request samples before placing bulk orders and conduct thorough inspections upon receipt. Look for suppliers who offer warranties and have quality assurance processes in place. Certifications such as ISO 9001 can indicate a commitment to quality management. Additionally, consider conducting factory visits or audits to assess manufacturing practices and standards. -

What customization options are available for locking mechanisms?

Many suppliers offer customization options, including unique sizes, finishes, and functionalities tailored to your specific needs. You can request features such as key control systems, integrated alarms, or specific electronic interfaces. Discuss your requirements with suppliers to explore available customization options that enhance security and meet operational demands. -

What are the typical minimum order quantities (MOQs) for locking mechanisms?

Minimum order quantities (MOQs) for locking mechanisms can vary widely among suppliers, typically ranging from 100 to 1,000 units depending on the type and customization level. Larger suppliers may have more flexible MOQs, while specialized or custom manufacturers may require higher quantities. Always clarify MOQs during negotiations and assess how they align with your purchasing strategy. -

What payment terms should I expect when purchasing locking mechanisms internationally?

Payment terms can vary depending on the supplier and the specific transaction. Common terms include partial upfront payments with the balance upon delivery, letters of credit, or net payment terms (e.g., net 30, net 60). It’s essential to negotiate terms that protect your cash flow while ensuring that the supplier is comfortable with the arrangement. Always ensure clarity on payment methods accepted, including wire transfers, credit cards, or escrow services. -

How does logistics impact the procurement of locking mechanisms?

Logistics plays a crucial role in the procurement of locking mechanisms, affecting delivery times, costs, and overall supply chain efficiency. Consider factors such as shipping methods, lead times, and customs clearance processes. Collaborate with suppliers who have reliable logistics partners and can provide transparent tracking information. Evaluate whether the supplier offers local warehousing options to reduce shipping times and costs, particularly for ongoing or bulk orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

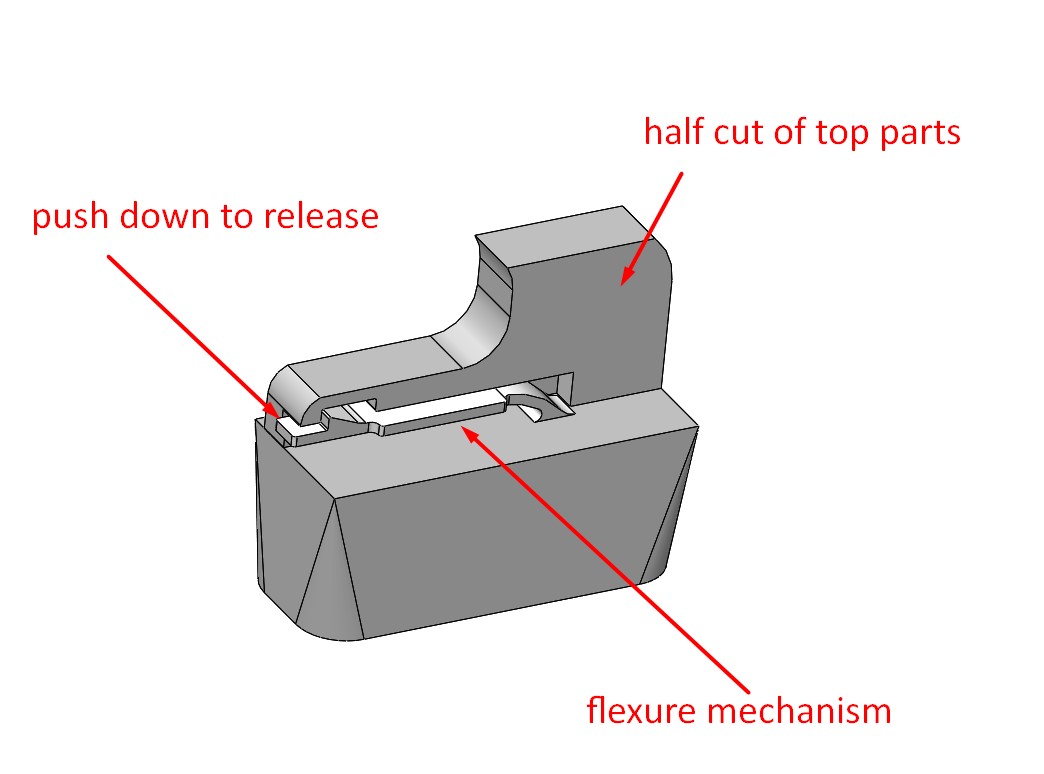

A stock image related to locking mechanisms.

Strategic Sourcing Conclusion and Outlook for locking mechanisms

In today’s rapidly evolving market, the importance of strategic sourcing for locking mechanisms cannot be overstated. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly prioritize security and reliability, understanding the diverse types of locking mechanisms—ranging from mechanical to electronic solutions—becomes essential. Buyers should carefully evaluate the materials, designs, and manufacturing processes that align with their specific security needs and industry requirements.

Investing in high-quality locking mechanisms not only enhances security but also contributes to operational efficiency and customer satisfaction. By fostering strong relationships with reputable suppliers, businesses can ensure access to innovative products that meet stringent safety standards. Additionally, exploring partnerships with manufacturers who demonstrate sustainability practices can provide a competitive edge in an environmentally conscious market.

Looking ahead, it is crucial for B2B buyers to stay informed about emerging technologies and trends in the locking mechanisms sector. Engaging with industry experts and attending trade shows can provide valuable insights. By embracing a proactive sourcing strategy, businesses can better navigate the complexities of security needs and position themselves for success in an increasingly interconnected global marketplace.