Top 10 Hydroxytyrosol Manufacturers List and Guide: How To Solve …

Introduction: Navigating the Global Market for Hydroxytyrosol Manufacturers

In the rapidly evolving landscape of health and wellness, sourcing high-quality hydroxytyrosol from reliable manufacturers presents a significant challenge for international B2B buyers. This potent antioxidant, derived from olives, not only offers impressive health benefits but is also increasingly sought after for its applications in food supplements, cosmetics, and nutraceuticals. As the demand for hydroxytyrosol grows, understanding the nuances of the global market becomes crucial for businesses looking to capitalize on this trend.

This comprehensive guide delves into the essential aspects of the hydroxytyrosol manufacturing sector, providing insights into various types of hydroxytyrosol products, their diverse applications, and effective supplier vetting techniques. Additionally, it addresses cost considerations, regulatory compliance, and quality assurance measures, equipping buyers with the knowledge needed to make informed purchasing decisions.

By empowering B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in markets like Saudi Arabia and Nigeria—this guide serves as a valuable resource in navigating the complexities of sourcing hydroxytyrosol. With actionable insights and strategic recommendations, international buyers can confidently engage with suppliers, ensuring they secure the best products to meet their business needs.

Top 10 Hydroxytyrosol Manufacturers Manufacturers & Suppliers List

1. WACKER – HTEssence® Hydroxytyrosol

Domain: wacker.com

Registered: 1999 (26 years)

Introduction: Hydroxytyrosol is a constituent of olives and acts as an antioxidant in the body. It is considered one of the most effective antioxidants and is gaining commercial importance. WACKER’s HTEssence ® is a nature-identical hydroxytyrosol with a high safety profile, offering significant health benefits when used in food supplements. It supports cardiovascular health and healthy aging.

2. Enzo – Hydroxytyrosol Acetate

Domain: enzo.com

Registered: 1995 (30 years)

Introduction: Product Name: Hydroxytyrosol acetate

Alternative Name: HTS, 2-(3,4-Dihydroxyphenyl)-ethyl acetate

Catalog Number: ALX-350-404

Quantity: 50 mg

Price: $127.00

Appearance: White to off-white powder

CAS: 69039-02-7

Chemical Formula: C10H12O4

Molecular Weight: 196.2

Purity: ≥98% (HPLC)

Solubility: Freely soluble in organic solvents; slightly soluble in water (10mg/ml)

Source: Synthetic

Handling & Stora…

3. Olivetree People – I70 The Beauty Molecule

Domain: us.olivetreepeople.com

Registered: 2016 (9 years)

Introduction: I70 The Beauty Molecule is a 100% vegan beauty supercharger designed for cell protection. It contains Hydroxytyrosol combined with low and high molecular weight hyaluronic acid, infused with lavender, camu camu, and turmeric. The product is packaged in a 16.9 fl oz bottle and is priced at $94.95. It promotes a youthful, radiant complexion, tightens pores, protects from environmental factors, stren…

4. Patsnap – Hydroxytyrosol Insights

Domain: discovery.patsnap.com

Registered: 2006 (19 years)

Introduction: Hydroxytyrosol is a phenylethanoid, a type of phenolic phytochemical with antioxidant properties in vitro. It is found in olive leaf and olive oil, particularly in the form of oleuropein and its plain form after degradation.

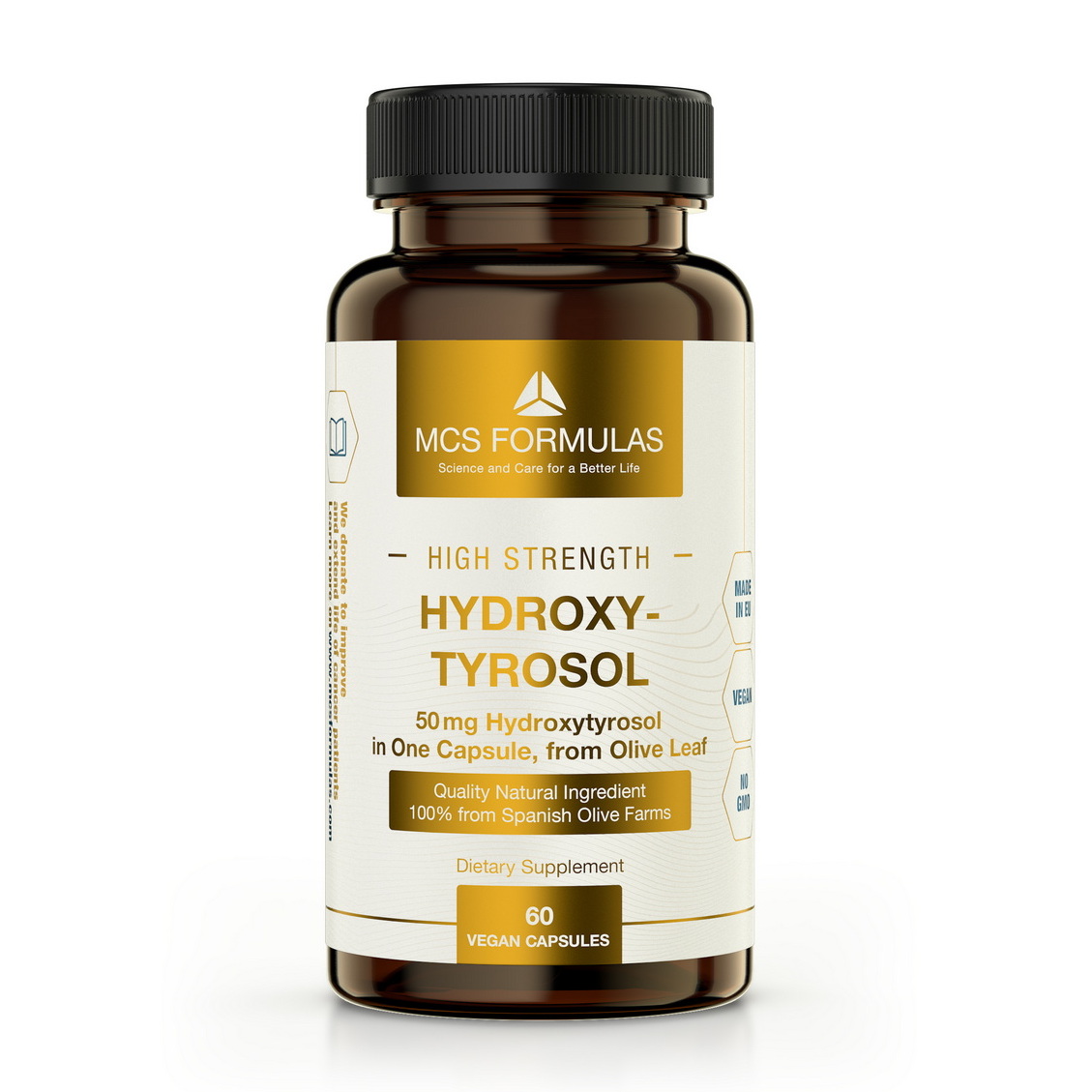

5. MCS Formulas – Hydroxytyrosol 50 mg

Domain: mcsformulas.com

Registered: 2019 (6 years)

Introduction: Hydroxytyrosol, 50 mg – MCS Formulas

Price: $34.37

In stock

Strength: 50 mg per capsule

Source: Extract of Olive Leaf from olive trees grown in Spain

Manufacturing: Capsules manufactured in the Netherlands

Additives: No unnecessary substances, simply pure

Capsule Type: Vegan capsules, vegan ingredients

SKU: HTY-1-MCS

Serving Size: 1 Capsule

Servings per Container: 60

Ingredients: Olive Leaf Extrac…

6. Hydroxytyrosol – Key Information

Domain: pharmacompass.com

Registered: 2014 (11 years)

Introduction: hydroxytyrosol – Uses, DMF, Dossier, Manufacturer, Supplier, Licensing, Distributor, Prices, News, GMP

7. HSF Biotech – Hydroxytyrosol Polyphenol

Domain: hsfbiotech.com

Registered: 2016 (9 years)

Introduction: Hydroxytyrosol is a powerful polyphenol sourced from olive leaves, with the following key details:

1. Source: Olive Leaf

2. Country of Origin: China

3. Testing Method: HPLC

4. CAS Registry No: 10597-60-1

5. Delivery Time: Around 3 working days

6. Payment Methods: TT, LC, DA

7. General Description: Hydroxytyrosol is an amphiphilic phenol with strong antioxidant properties, considered one of …

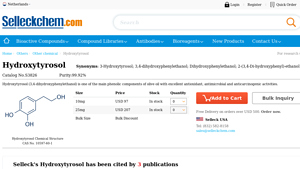

8. Selleckchem – Hydroxytyrosol

Domain: selleckchem.com

Registered: 2008 (17 years)

Introduction: Hydroxytyrosol | Purity: 99.92% (HPLC) | CAS No: 10597-60-1 | Catalog No: S3826 | In Stock | Synonyms: 3-Hydroxytyrosol, 3,4-dihydroxyphenylethanol, Dihydroxyphenylethanol, 2-(3,4-Di-hydroxyphenyl)-ethanol | Bioactive Compounds: Antioxidant, Antimicrobial, Anticarcinogenic activities | For research use only.

9. ChemFaces – Hydroxytyrosol 1-O-glucoside

Domain: chemfaces.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Hydroxytyrosol 1-O-glucoside”, “CAS”: “76873-99-9”, “Manufacturer”: “ChemFaces”, “Price”: “$318 / 10mg”, “Catalog No.”: “CFN95367”, “Molecular Formula”: “C14H20O8”, “Molecular Weight”: “316.3 g/mol”, “Purity”: “>=98%”, “Type of Compound”: “Phenols”, “Physical Description”: “Powder”, “Source”: “The herbs of Rhodiola rosea L.”, “Solvent”: “DMSO, Pyridine, Methanol, Ethanol, etc.”, …

10. Viablife – Hydroxytyrosol

Domain: en.viablife.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Hydroxytyrosol”, “CAS Number”: “10597-60-1”, “Synonyms”: [“3,4-Dihydroxyphenylethanol”, “3-Hydroxytyrosol”, “3,4-dihydroxyphenylethanol”, “Dihydroxyphenylethanol”, “2-(3,4-Di-hydroxyphenyl)-ethanol”], “IUPAC Name”: “4-(2-hydroxyethyl)-benzene-1,2-diol”, “Molecular Formula”: “C8H10O3”, “Molecular Weight”: “154.17”, “Appearance”: “Clear, faint yellow to light green liquid”, “Functi…

Understanding Hydroxytyrosol Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Hydroxytyrosol | Extracted directly from olives; high antioxidant potency. | Nutraceuticals, cosmetics | Pros: Naturally derived, high efficacy. Cons: Higher cost and variability in supply. |

| Synthetic Hydroxytyrosol | Lab-created, consistent purity and quality. | Pharmaceuticals, dietary supplements | Pros: Consistent quality, scalable production. Cons: May lack some natural benefits. |

| Hydroxytyrosol Acetate | Esterified form, enhanced stability and bioavailability. | Functional foods, health products | Pros: Higher absorption rates, versatile applications. Cons: Requires conversion to active form. |

| Hydroxytyrosol Blends | Formulated with other bioactive compounds for synergistic effects. | Beauty products, wellness supplements | Pros: Enhanced benefits, tailored formulations. Cons: Complexity in sourcing and formulation. |

| Hydroxytyrosol Concentrates | Highly concentrated extracts for maximum potency. | High-end supplements, research | Pros: Potent effects, small dosage required. Cons: Higher price point, potential for overuse. |

What are the Characteristics of Natural Hydroxytyrosol Manufacturers?

Natural hydroxytyrosol manufacturers focus on extracting the compound directly from olives, ensuring a product rich in antioxidants and other beneficial polyphenols. These products are often marketed for their health benefits, particularly in nutraceuticals and cosmetic applications. B2B buyers should consider the sourcing and quality assurance processes, as variability in olive quality can impact the final product. Additionally, while these products may have a higher cost, their natural origin can appeal to consumers seeking organic options.

How Does Synthetic Hydroxytyrosol Differ from Natural Variants?

Synthetic hydroxytyrosol is produced in a laboratory setting, allowing for consistent purity and quality across batches. This form is particularly useful in pharmaceuticals and dietary supplements where standardized dosages are crucial. Buyers should weigh the benefits of reliable supply and lower variability against the potential loss of some natural health benefits. Furthermore, synthetic options can often be produced at a larger scale, making them suitable for companies looking to meet high demand.

What are the Advantages of Hydroxytyrosol Acetate for B2B Buyers?

Hydroxytyrosol acetate is an esterified form that offers enhanced stability and bioavailability compared to its natural counterpart. This form is particularly effective in functional foods and health products, where absorption rates are critical. B2B purchasers should evaluate the conversion process required to activate the compound, as well as its applications in various formulations. The stability of this product can be a significant advantage in product development.

Why Consider Hydroxytyrosol Blends in Product Development?

Manufacturers of hydroxytyrosol blends combine this powerful antioxidant with other bioactive compounds to create products with enhanced effects, particularly in beauty and wellness sectors. These tailored formulations can attract a niche market interested in comprehensive health solutions. B2B buyers should consider the complexity of sourcing these blends and how they align with their product goals. While they offer unique benefits, the development process may require more extensive research and formulation expertise.

What are the Key Considerations for Hydroxytyrosol Concentrates?

Hydroxytyrosol concentrates are designed for maximum potency, making them ideal for high-end supplements and research applications. These products require careful dosing due to their strength, which can be both an advantage and a challenge for manufacturers. B2B buyers must evaluate the price point and ensure that their target market is willing to invest in premium products. Additionally, understanding the regulatory landscape for concentrated forms is crucial to ensure compliance and safety in usage.

Key Industrial Applications of Hydroxytyrosol Manufacturers

| Industry/Sector | Specific Application of Hydroxytyrosol Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Natural food preservatives and dietary supplements | Enhances product shelf-life and nutritional value | Quality certifications, sourcing of raw materials, and compliance with local regulations |

| Cosmetics & Personal Care | Anti-aging and skin health formulations | Increases product efficacy and market appeal | Stability and purity of ingredients, regulatory compliance, and packaging requirements |

| Pharmaceuticals | Antioxidant and anti-inflammatory agents | Potential for innovative therapeutic products | Clinical efficacy data, sourcing reliability, and regulatory approvals |

| Nutraceuticals | Health supplements targeting cardiovascular health | Differentiation in a competitive market | Ingredient traceability, quality assurance, and sourcing ethics |

| Agriculture | Natural pesticides and plant growth enhancers | Sustainable farming practices and crop yield improvement | Environmental impact assessments, compliance with agricultural regulations, and efficacy studies |

How is Hydroxytyrosol Used in the Food & Beverage Industry?

Hydroxytyrosol is increasingly utilized in the food and beverage sector as a natural preservative and dietary supplement. Its potent antioxidant properties help to enhance product shelf-life while also delivering health benefits, such as improved cardiovascular health. International buyers, especially from regions like Africa and South America, should focus on suppliers who can provide quality certifications and comply with local food safety regulations to ensure product integrity.

What Role Does Hydroxytyrosol Play in Cosmetics & Personal Care?

In the cosmetics industry, hydroxytyrosol is valued for its anti-aging properties and ability to promote skin health. Manufacturers incorporate it into serums, creams, and lotions to enhance the efficacy of their products. B2B buyers must prioritize sourcing from manufacturers who guarantee ingredient stability and purity, as well as adherence to cosmetic regulations in their respective markets, particularly in Europe and the Middle East.

How is Hydroxytyrosol Beneficial in Pharmaceuticals?

Hydroxytyrosol serves as a key ingredient in pharmaceutical formulations, particularly for its antioxidant and anti-inflammatory properties. It is being researched for its potential therapeutic benefits, including treatment for chronic diseases. Buyers in this sector should seek manufacturers that can provide robust clinical efficacy data and have the necessary regulatory approvals to ensure product safety and effectiveness.

What are the Applications of Hydroxytyrosol in Nutraceuticals?

In the nutraceuticals industry, hydroxytyrosol is used to formulate health supplements that target cardiovascular health and overall wellness. Its inclusion can help differentiate products in a saturated market. Buyers should consider the traceability of ingredients and the quality assurance processes of suppliers to ensure that they meet health claims and ethical sourcing standards.

How is Hydroxytyrosol Applied in Agriculture?

Hydroxytyrosol is being explored as a natural pesticide and plant growth enhancer in agriculture. Its properties can help improve crop yields while promoting sustainable farming practices. International buyers should assess the environmental impact of sourcing hydroxytyrosol and ensure compliance with agricultural regulations to maximize its benefits in crop production.

3 Common User Pain Points for ‘Hydroxytyrosol Manufacturers’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance Challenges

The Problem: B2B buyers in the hydroxytyrosol sector often grapple with the complexities of regulatory compliance. Different countries have varying regulations regarding the sourcing, production, and marketing of food ingredients like hydroxytyrosol. This becomes particularly challenging for companies operating across multiple regions, such as Africa, South America, and Europe, where specific claims about health benefits must align with local laws. Failure to comply can lead to costly fines, product recalls, and damaged reputations.

The Solution: To effectively navigate these regulatory hurdles, buyers should engage with hydroxytyrosol manufacturers who have a strong understanding of the local regulatory landscape. It is advisable to partner with manufacturers that provide comprehensive documentation, including Certificates of Analysis (CoA) and Safety Data Sheets (SDS), which detail compliance with local and international regulations. Additionally, buyers can benefit from consultations with regulatory experts or legal advisors who specialize in food safety and ingredient sourcing. Establishing a clear line of communication with suppliers about regulatory updates will help ensure that all products meet the required standards before they reach the market.

Scenario 2: Quality Assurance and Product Consistency

The Problem: Another common challenge faced by buyers is ensuring the quality and consistency of hydroxytyrosol products. Variability in raw materials, extraction methods, and production processes can lead to significant fluctuations in the potency and effectiveness of hydroxytyrosol. This inconsistency not only affects product performance but can also jeopardize brand integrity and consumer trust.

The Solution: To mitigate quality assurance issues, buyers should prioritize partnerships with manufacturers that implement stringent quality control measures throughout their production processes. This includes verifying that manufacturers adhere to Good Manufacturing Practices (GMP) and conduct regular testing for potency and purity. Buyers can also request samples for independent third-party testing to validate the quality claims made by the manufacturer. Establishing a robust feedback loop with the supplier, where performance data and consumer feedback are shared, can help manufacturers refine their processes and maintain consistent quality over time.

Scenario 3: Sourcing Challenges and Supply Chain Disruptions

The Problem: Many B2B buyers face sourcing challenges, especially in the context of global supply chain disruptions. The sourcing of hydroxytyrosol, which is primarily derived from olives, can be affected by agricultural factors such as climate change, pest infestations, and market fluctuations. Such disruptions can lead to shortages, increased costs, and delays in product delivery, ultimately impacting the buyer’s ability to meet customer demands.

The Solution: To combat sourcing challenges, buyers should consider diversifying their supplier base and not relying solely on a single manufacturer. Establishing relationships with multiple hydroxytyrosol suppliers across different geographical regions can create a safety net against potential supply chain disruptions. Additionally, buyers can engage in forward contracts or strategic partnerships to secure pricing and supply commitments. Staying informed about market trends and agricultural forecasts will enable buyers to anticipate potential disruptions and make proactive sourcing decisions. Regular communication with suppliers about their production capabilities and potential challenges will also help maintain a steady supply of hydroxytyrosol.

Strategic Material Selection Guide for Hydroxytyrosol Manufacturers

What Are the Key Materials Used in Hydroxytyrosol Manufacturing?

When selecting materials for hydroxytyrosol production, manufacturers must consider several factors, including chemical compatibility, processing conditions, and regulatory compliance. Below are analyses of four common materials used in the manufacturing process, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It is non-reactive, making it ideal for processing sensitive compounds like hydroxytyrosol.

Pros & Cons:

The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it can be more expensive than alternatives like carbon steel. The complexity of manufacturing and welding can also add to the overall costs.

Impact on Application:

Stainless steel is compatible with various solvents and does not leach harmful substances into the product, making it suitable for food and pharmaceutical applications.

Considerations for International Buyers:

Manufacturers in regions such as Africa and the Middle East should ensure compliance with local food safety standards and certifications. Common standards like ASTM and DIN may apply, and buyers should verify that suppliers meet these requirements.

2. Glass

Key Properties:

Glass is inert, non-reactive, and offers excellent visibility for monitoring contents. It can withstand a wide range of temperatures and is resistant to many chemicals.

Pros & Cons:

The primary advantage of glass is its chemical stability, which prevents contamination. However, it is fragile and can break easily, leading to potential safety hazards and increased shipping costs due to weight.

Impact on Application:

Glass containers are ideal for storing hydroxytyrosol, especially in laboratory settings where purity is paramount. They are also suitable for small-scale production.

Considerations for International Buyers:

Buyers should be aware of shipping regulations regarding glass products, particularly in regions with high humidity or temperature fluctuations. Compliance with international safety standards is crucial to prevent breakage during transit.

3. Polyethylene (PE)

Key Properties:

Polyethylene is a lightweight, flexible plastic known for its chemical resistance and durability. It is suitable for a range of temperatures and is often used in packaging.

Pros & Cons:

The low cost and ease of manufacturing make polyethylene a popular choice for packaging hydroxytyrosol products. However, it may not provide the same level of barrier protection against oxygen and light as glass or metal.

Impact on Application:

Polyethylene is suitable for bulk storage and transportation of hydroxytyrosol, but manufacturers should consider additional protective measures to maintain product integrity.

Considerations for International Buyers:

Buyers should ensure that polyethylene packaging complies with local regulations regarding food safety and environmental impact, particularly in regions like Europe where strict standards are enforced.

4. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can be anodized to enhance its protective properties.

Pros & Cons:

Aluminum offers a good balance between cost and performance, making it suitable for various applications. However, it may react with certain acidic compounds, which could affect hydroxytyrosol stability.

Impact on Application:

Aluminum containers can be used for storing hydroxytyrosol, but manufacturers must ensure that the product does not react with the material.

Considerations for International Buyers:

Compliance with international packaging standards is essential, especially in regions like South America and Africa, where regulations may vary significantly. Buyers should check for certifications that ensure the aluminum used meets safety and quality standards.

Summary Table

| Material | Typical Use Case for Hydroxytyrosol Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Processing equipment and storage tanks | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Glass | Laboratory storage and small-scale production | Chemical stability and purity | Fragile and heavy | Medium |

| Polyethylene | Bulk storage and transportation | Low cost and lightweight | Limited barrier protection | Low |

| Aluminum | Packaging and storage containers | Lightweight and corrosion-resistant | Potential reactivity with acidic compounds | Medium |

This strategic material selection guide provides hydroxytyrosol manufacturers with essential insights into the materials best suited for their production processes, ensuring compliance and product integrity in various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for Hydroxytyrosol Manufacturers

What Are the Key Stages in the Manufacturing Process of Hydroxytyrosol?

The production of hydroxytyrosol, a potent antioxidant derived from olives, involves several critical stages that ensure the quality and efficacy of the final product. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

-

Material Preparation

The initial step involves sourcing high-quality raw materials, primarily olive leaves and fruit, which are rich in oleuropein and other polyphenols. Suppliers must ensure that the olives are harvested at the right time to maximize polyphenol content. This often includes testing the raw materials for purity and quality, ensuring they meet international standards. -

Extraction Techniques

Various extraction methods can be employed to isolate hydroxytyrosol. Common techniques include:

– Solvent Extraction: Utilizing organic solvents to dissolve and separate hydroxytyrosol from the plant material.

– Supercritical Fluid Extraction (SFE): A more advanced method that uses supercritical CO2 as a solvent, providing higher yields and purity levels.

– Enzymatic Hydrolysis: This method involves using enzymes to break down oleuropein into hydroxytyrosol, enhancing the extraction efficiency while maintaining the bioactivity of the compound. -

Purification and Concentration

After extraction, the hydroxytyrosol undergoes purification processes, such as filtration, centrifugation, and chromatography. These steps are crucial for removing impurities and concentrating the active ingredient to desired levels. The final product may be standardized to ensure consistency in potency and quality. -

Formulation

The purified hydroxytyrosol can be formulated into various products, such as dietary supplements, beauty products, or functional foods. This stage might involve combining hydroxytyrosol with other ingredients, like hyaluronic acid in beauty formulations, to enhance its efficacy and market appeal. -

Finishing

The last stage involves packaging and labeling the final product. Packaging must protect the integrity of hydroxytyrosol, which is sensitive to light and air. Proper labeling is also essential for compliance with international regulations and to inform B2B buyers about the product’s benefits and usage.

How Is Quality Control Implemented in Hydroxytyrosol Manufacturing?

Quality control (QC) is paramount in the manufacturing of hydroxytyrosol, ensuring that the product meets both industry standards and customer expectations. Here’s a breakdown of the QC processes typically employed:

-

International Standards Compliance

Hydroxytyrosol manufacturers often adhere to international quality standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, certifications like CE (Conformité Européenne) for products sold in Europe and API (Active Pharmaceutical Ingredient) standards for health products are critical for regulatory compliance. -

Key QC Checkpoints

– Incoming Quality Control (IQC): This initial check involves testing raw materials upon arrival to ensure they meet specified criteria before production begins.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are taken to monitor critical parameters, such as extraction efficiency and purity levels.

– Final Quality Control (FQC): The final product is rigorously tested against predetermined specifications to confirm its quality and efficacy before it reaches the market. -

Common Testing Methods

Manufacturers typically utilize various analytical techniques to ensure quality, including:

– High-Performance Liquid Chromatography (HPLC): For quantifying hydroxytyrosol levels and checking for impurities.

– Mass Spectrometry: To analyze the molecular structure and verify the identity of the compound.

– Microbial Testing: To ensure the absence of harmful microorganisms, particularly in products intended for consumption.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are actionable steps to take:

-

Conduct Supplier Audits

Regular audits of suppliers can provide firsthand insights into their manufacturing and quality assurance practices. Buyers should assess compliance with international standards and evaluate the effectiveness of their QC systems. -

Request Quality Documentation

Buyers should ask for documentation such as Certificates of Analysis (CoA) for each batch of hydroxytyrosol. These documents provide detailed information about the product’s composition, purity, and safety, offering assurance of quality. -

Engage Third-Party Inspection Services

Utilizing independent third-party inspection services can enhance confidence in supplier quality. These services can conduct unannounced inspections and provide unbiased reports on manufacturing practices and product quality. -

Evaluate Regulatory Compliance

It’s important to ensure that suppliers comply with local and international regulations. Buyers should verify that the manufacturer holds relevant certifications and adheres to guidelines set forth by regulatory bodies in their target markets.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing hydroxytyrosol internationally, buyers must navigate various nuances in quality control and certification:

-

Regional Compliance Requirements

Different regions may have distinct regulatory requirements for health products. Buyers from Europe may need to ensure compliance with the European Food Safety Authority (EFSA) regulations, while those in the Middle East might focus on Gulf Standards Organization (GSO) compliance. -

Cultural and Market Considerations

Understanding cultural perceptions of quality can also influence purchasing decisions. For instance, buyers in Africa may prioritize suppliers with certifications recognized in their local markets, while European buyers may focus on sustainability and environmental impact. -

Traceability and Transparency

Buyers should look for suppliers that offer transparency in their supply chain and traceability of raw materials. This not only enhances trust but also ensures that the hydroxytyrosol is ethically sourced and produced under responsible conditions.

In conclusion, B2B buyers seeking hydroxytyrosol should prioritize suppliers who demonstrate robust manufacturing processes and stringent quality control measures. By understanding the intricacies of production and quality assurance, buyers can make informed decisions that align with their business needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Hydroxytyrosol Manufacturers’

In today’s global market, sourcing hydroxytyrosol effectively requires a strategic approach to ensure quality, compliance, and value. This checklist will guide B2B buyers through the essential steps to procure from reputable hydroxytyrosol manufacturers.

Step 1: Define Your Technical Specifications

Establish clear technical requirements for the hydroxytyrosol you need, including purity levels, form (liquid or powder), and intended application (nutraceutical, cosmetic, etc.). These specifications will help you filter potential suppliers and ensure that the products meet your quality standards. Being precise in your requirements also aids in avoiding miscommunications later in the procurement process.

Step 2: Research Market Trends and Regulations

Understanding the current market landscape and regulatory requirements is critical. Check the latest trends in hydroxytyrosol applications, especially in your target regions such as Africa, South America, the Middle East, and Europe. Familiarize yourself with local regulations regarding the importation and usage of hydroxytyrosol to ensure compliance, as these can vary significantly by country.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for manufacturers with established reputations and proven track records in delivering high-quality hydroxytyrosol. Pay attention to customer feedback and industry reviews, which can provide insight into a supplier’s reliability.

Step 4: Verify Supplier Certifications

Ensure that the manufacturers you are considering have the necessary certifications, such as ISO, GMP, and HACCP. These certifications indicate that the supplier adheres to strict quality control and safety standards. Additionally, check for any certifications specific to your region, as compliance with local regulations is paramount for smooth operations.

Step 5: Request Samples for Testing

Before making a bulk purchase, always request samples of hydroxytyrosol for quality assessment. Conduct tests to verify the product’s purity, concentration, and suitability for your intended use. This step is crucial in minimizing the risks associated with product quality and ensuring that the supplier can meet your specifications consistently.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in discussions regarding pricing, payment terms, minimum order quantities, and delivery schedules. Clear negotiation helps establish a mutually beneficial agreement and ensures that all parties understand their responsibilities. Be sure to address any potential issues, such as delays or quality discrepancies, within the contract to protect your interests.

Step 7: Establish a Quality Assurance Process

After selecting a supplier, implement a robust quality assurance process to monitor product quality consistently. Regular audits and performance reviews will help ensure that the hydroxytyrosol you receive meets your specifications over time. Building a strong partnership with your supplier through open communication will further enhance product reliability and service quality.

By following these steps, B2B buyers can make informed decisions when sourcing hydroxytyrosol, ensuring they partner with manufacturers who can meet their quality and compliance needs effectively.

Comprehensive Cost and Pricing Analysis for Hydroxytyrosol Manufacturers Sourcing

What Are the Key Cost Components for Hydroxytyrosol Manufacturing?

Understanding the cost structure of hydroxytyrosol manufacturing is crucial for B2B buyers to make informed sourcing decisions. The primary cost components include:

- Materials: The raw materials for hydroxytyrosol production primarily come from olives or synthetic processes. The price of olives can fluctuate based on seasonality, quality, and sourcing locations, impacting the overall cost.

- Labor: Labor costs vary significantly across regions. Countries with lower labor costs may offer competitive pricing, but this can also affect the quality of the final product.

- Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient operations can minimize these costs, allowing for more competitive pricing.

- Tooling: Specialized equipment for extraction and processing can be a significant upfront investment. Manufacturers often spread these costs over large production runs to lower per-unit costs.

- Quality Control (QC): Ensuring compliance with international quality standards incurs costs for testing and certifications. This is particularly relevant for buyers in regulated markets.

- Logistics: Shipping costs, which can vary by region and transport mode, are critical. Factors like distance, freight rates, and local tariffs can significantly influence total costs.

- Margin: Manufacturers typically add a profit margin that reflects their operational costs, market demand, and competitive landscape.

How Do Price Influencers Impact Hydroxytyrosol Sourcing?

Several factors influence the pricing of hydroxytyrosol, making it essential for buyers to understand these nuances:

- Volume and Minimum Order Quantities (MOQs): Larger orders often yield lower per-unit costs. Buyers should negotiate MOQs that align with their consumption needs to benefit from economies of scale.

- Specifications and Customization: Custom formulations or specific purity levels can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected pricing changes.

- Materials Quality and Certifications: Higher-quality materials or those with certifications (e.g., organic, non-GMO) may come at a premium. Buyers should assess the value these certifications bring to their end products.

- Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Established suppliers may charge more but offer better quality and service.

- Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects the total cost by determining who bears shipping costs and risks. Buyers should negotiate terms that minimize their exposure to unexpected costs.

What Are the Best Tips for Negotiating Hydroxytyrosol Prices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings:

- Conduct Market Research: Understanding the market landscape, including competitor pricing and supplier capabilities, can empower buyers during negotiations.

- Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs, including shipping, storage, and potential wastage, rather than just the initial purchase price. This holistic view can lead to better decision-making.

- Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Regular communication and transparency about needs can foster goodwill and collaboration.

- Be Prepared for Pricing Nuances: International buyers may face additional costs such as tariffs, taxes, and currency fluctuations. Understanding these factors can help in negotiating more favorable terms.

- Request Samples: Before committing to large orders, request samples to evaluate quality. This helps ensure that the product meets specifications and reduces the risk of costly returns.

Disclaimer on Pricing

The prices discussed in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct their own due diligence and obtain quotes from multiple suppliers to ensure the best value.

Alternatives Analysis: Comparing Hydroxytyrosol Manufacturers With Other Solutions

Exploring Alternatives to Hydroxytyrosol Manufacturers

In the evolving landscape of health and wellness products, hydroxytyrosol has gained recognition for its potent antioxidant properties derived from olives. However, businesses seeking effective solutions may consider alternatives that offer comparable benefits. This analysis compares hydroxytyrosol with other viable options to help B2B buyers make informed decisions.

| Comparison Aspect | Hydroxytyrosol Manufacturers | Resveratrol | Curcumin |

|---|---|---|---|

| Performance | High antioxidant capacity | Comparable antioxidant effects | Strong anti-inflammatory properties |

| Cost | Premium pricing due to extraction | Moderate pricing | Generally low-cost |

| Ease of Implementation | Requires regulatory compliance | Simple integration in products | Easy to formulate into supplements |

| Maintenance | Stable under proper conditions | Requires careful storage | Low maintenance |

| Best Use Case | Nutraceuticals, skincare | Dietary supplements, cosmetics | Health supplements, functional foods |

What are the Pros and Cons of Resveratrol as an Alternative?

Resveratrol is a polyphenolic compound found in red wine and grapes, known for its antioxidant properties. Its performance is on par with hydroxytyrosol, particularly in cardiovascular health. The cost of resveratrol is generally moderate, making it accessible for many manufacturers. It can be easily integrated into dietary supplements and cosmetics, facilitating a straightforward implementation process. However, resveratrol requires careful storage to maintain efficacy, and its benefits can vary based on dosage and formulation. While effective, it may not provide the same level of cellular protection as hydroxytyrosol.

How Does Curcumin Compare to Hydroxytyrosol?

Curcumin, the active compound in turmeric, is celebrated for its anti-inflammatory and antioxidant properties. It offers strong health benefits, particularly in managing chronic inflammation and oxidative stress. One of curcumin’s key advantages is its lower cost, making it an attractive option for manufacturers. It is also relatively easy to formulate into various products, from supplements to functional foods. Maintenance is minimal, as curcumin is stable under proper storage conditions. However, curcumin’s bioavailability is a concern; it often requires additional compounds, like piperine, to enhance absorption, which can complicate formulations.

How Should B2B Buyers Choose Between These Solutions?

When selecting between hydroxytyrosol, resveratrol, and curcumin, B2B buyers should consider several factors. The intended application is crucial; for skincare and high-potency nutraceuticals, hydroxytyrosol may be preferred due to its superior antioxidant properties. If cost is a significant factor, curcumin presents a budget-friendly alternative with strong health benefits. For those focused on cardiovascular health and ease of use, resveratrol is an excellent option. Ultimately, the choice should align with the specific health benefits desired, regulatory considerations, and cost constraints, ensuring that the selected ingredient meets both consumer demand and business objectives.

Essential Technical Properties and Trade Terminology for Hydroxytyrosol Manufacturers

What Are the Key Technical Properties of Hydroxytyrosol That B2B Buyers Should Consider?

When sourcing hydroxytyrosol, it’s crucial to understand its technical properties, as they directly impact product quality, efficacy, and compliance with regulatory standards. Here are some key specifications that hydroxytyrosol manufacturers should focus on:

-

Purity Level

Purity is a critical specification for hydroxytyrosol, typically quantified as a percentage. A purity level of ≥98% is often required for pharmaceutical and cosmetic applications. High purity ensures maximum efficacy and safety, making it essential for manufacturers to provide a Certificate of Analysis (CoA) to verify purity levels. Buyers must prioritize suppliers who can consistently meet these standards to ensure product integrity. -

Molecular Weight (MW)

Hydroxytyrosol has a molecular weight of approximately 196.2 g/mol. Understanding the molecular weight is important for formulation, especially when integrating hydroxytyrosol into dietary supplements or cosmetic products. It affects the bioavailability and absorption rate of the compound, influencing its antioxidant properties and overall effectiveness. -

Solubility

Hydroxytyrosol is freely soluble in organic solvents and slightly soluble in water (approximately 10 mg/ml). Solubility is crucial for manufacturers when developing formulations, as it affects how hydroxytyrosol can be incorporated into various products. Buyers should consider the solubility characteristics to ensure compatibility with other ingredients in their formulations. -

Chemical Stability

Hydroxytyrosol is sensitive to light and heat, necessitating proper handling and storage conditions, ideally at -20°C for long-term stability. Understanding these requirements is vital for buyers to ensure that they maintain the quality of hydroxytyrosol throughout the supply chain, from storage to final product formulation. -

Regulatory Status

Hydroxytyrosol is classified under various regulatory frameworks depending on its intended use (e.g., food supplements, cosmetics, pharmaceuticals). Buyers must ensure that the suppliers they engage with comply with local regulations and standards. This is particularly important in regions like the EU and the Middle East, where regulatory compliance can significantly affect market entry.

What Are Common Trade Terms That Hydroxytyrosol Manufacturers Should Know?

Navigating the procurement landscape for hydroxytyrosol involves familiarizing oneself with industry-specific terminology. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hydroxytyrosol, buyers may work with OEMs to create custom formulations or private-label products. Understanding OEM relationships can help streamline procurement and reduce lead times. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For hydroxytyrosol, MOQs can vary significantly based on the supplier and the purity level. Buyers should negotiate MOQs that align with their production needs without overcommitting capital. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to bid on specific products or services. For hydroxytyrosol, issuing an RFQ can help buyers compare prices, quality, and delivery terms from various suppliers, ensuring competitive sourcing. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for hydroxytyrosol manufacturers, as they dictate shipping costs, risks, and responsibilities. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps mitigate misunderstandings in international transactions. -

CoA (Certificate of Analysis)

A CoA is a document provided by manufacturers that confirms the product meets specified standards and contains the claimed ingredients. For hydroxytyrosol, a CoA is essential for verifying purity, potency, and compliance with regulatory standards, ensuring buyers receive a quality product.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing hydroxytyrosol, ultimately ensuring that they select suppliers that align with their quality and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the Hydroxytyrosol Manufacturers Sector

What Are the Key Trends Shaping the Hydroxytyrosol Manufacturers Market?

The hydroxytyrosol market is gaining momentum globally, driven by a surge in demand for natural antioxidants in various sectors, including dietary supplements, cosmetics, and food and beverages. One of the primary drivers is the growing awareness of health and wellness, particularly in regions like Africa, South America, and the Middle East, where consumers are increasingly prioritizing natural and organic products. The antioxidant properties of hydroxytyrosol, which outshine those of conventional compounds like resveratrol and vitamin C, are particularly appealing to health-conscious buyers.

Emerging technologies are reshaping sourcing trends in this sector. Manufacturers are leveraging advanced extraction techniques, such as supercritical CO2 extraction, which enhances yield while preserving the bioactive properties of hydroxytyrosol. Additionally, digital platforms are becoming essential for B2B transactions, streamlining procurement processes and enabling manufacturers to connect directly with international buyers. As e-commerce continues to evolve, suppliers who adopt these technologies will likely gain a competitive edge in the market.

Furthermore, regulatory frameworks are increasingly influencing market dynamics. Compliance with international standards regarding food safety and product efficacy is critical for manufacturers aiming to access diverse markets, especially in Europe and the Middle East. Buyers are encouraged to engage with suppliers who maintain transparency and adhere to stringent regulations, ensuring product quality and safety.

How Are Sustainability and Ethical Sourcing Impacting Hydroxytyrosol Manufacturers?

Sustainability is becoming a cornerstone of business strategy within the hydroxytyrosol manufacturing sector. With rising concerns about environmental degradation and resource depletion, manufacturers are under pressure to adopt sustainable practices. This includes sourcing raw materials responsibly, particularly olives, which are the primary source of hydroxytyrosol. Ethical sourcing not only mitigates environmental impact but also appeals to consumers and businesses alike, who are increasingly prioritizing brands with a commitment to sustainability.

Certifications such as organic, Fair Trade, and ISO 14001 are gaining traction among buyers looking to partner with manufacturers that prioritize ethical practices. These certifications serve as a mark of quality and responsibility, assuring buyers that the products they source contribute positively to social and environmental outcomes. For B2B buyers, aligning with manufacturers that uphold these standards can enhance their brand reputation and foster loyalty among increasingly eco-conscious consumers.

Moreover, incorporating green materials and processes into production can lead to cost efficiencies over time. Manufacturers who invest in sustainable practices may reduce waste and energy consumption, translating into lower operational costs and enhanced profitability. B2B buyers should consider these factors when sourcing hydroxytyrosol, as sustainable suppliers are likely to offer long-term value.

What Is the Historical Context of Hydroxytyrosol Production?

The journey of hydroxytyrosol from a natural compound found in olives to a commercially viable ingredient reflects a broader trend in the global food and health industries. Historically, hydroxytyrosol was primarily recognized for its health benefits in Mediterranean diets, but recent research has illuminated its potent antioxidant properties, leading to increased demand across various sectors.

As awareness of the health benefits of olive-derived compounds grew, so did the interest in hydroxytyrosol as a functional ingredient in dietary supplements and cosmetics. The 21st century has seen a significant shift towards extracting this compound through innovative methods that enhance purity and efficacy. This evolution not only underscores the growing importance of hydroxytyrosol but also signals a shift in consumer preferences towards natural and health-oriented products.

In summary, understanding the historical context of hydroxytyrosol production provides valuable insights for B2B buyers, allowing them to appreciate the compound’s significance in contemporary markets and its potential for future growth. As the market continues to evolve, staying informed about these trends will enable buyers to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of Hydroxytyrosol Manufacturers

-

How do I choose the right hydroxytyrosol manufacturer for my business needs?

When selecting a hydroxytyrosol manufacturer, consider factors such as product quality, production capacity, and certifications. Request samples to assess the product’s purity and effectiveness. It’s also essential to evaluate the manufacturer’s compliance with international regulations and quality standards, such as ISO certifications. Engage in discussions regarding their sourcing practices for raw materials, as this can impact the overall quality of the hydroxytyrosol. Lastly, check customer reviews and testimonials to gauge their reliability and service quality. -

What is the best application of hydroxytyrosol in health products?

Hydroxytyrosol is renowned for its potent antioxidant properties, making it an excellent ingredient in dietary supplements, functional foods, and cosmetics. Its applications range from promoting cardiovascular health to supporting skin rejuvenation and anti-aging benefits. For B2B buyers, understanding the specific health claims associated with hydroxytyrosol can help in marketing products effectively. Conducting market research on consumer preferences in your target regions, such as Europe or the Middle East, will aid in tailoring product formulations to meet demand. -

What are the minimum order quantities (MOQs) for hydroxytyrosol?

Minimum order quantities for hydroxytyrosol can vary significantly among manufacturers based on their production capacity and business model. Typically, MOQs can range from a few kilograms to several hundred kilograms. It’s advisable to discuss your specific needs with the manufacturer to negotiate terms that align with your business strategy. Some suppliers may offer flexible MOQs for first-time buyers or trial orders, allowing you to test the product in your market before committing to larger quantities. -

What payment terms should I expect when sourcing hydroxytyrosol?

Payment terms can vary by manufacturer, but common practices include upfront payments, partial payments upon order confirmation, or payment upon delivery. It is essential to clarify these terms before placing an order to avoid any misunderstandings. Additionally, inquire about accepted payment methods, as international transactions may involve wire transfers, letters of credit, or online payment platforms. Ensure that the terms are documented in a formal agreement to protect both parties. -

How can I ensure the quality of hydroxytyrosol products?

To guarantee quality, request a Certificate of Analysis (CoA) from the manufacturer for each batch of hydroxytyrosol. This document provides detailed information about the product’s purity, concentration, and compliance with relevant standards. Additionally, consider manufacturers that conduct third-party testing to validate their claims. Regular audits and site visits can also help assess the manufacturer’s quality control processes. Establishing a long-term relationship with suppliers who prioritize quality assurance will enhance your product offerings. -

What logistics considerations are important when importing hydroxytyrosol?

When importing hydroxytyrosol, logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder experienced in handling chemical products to ensure compliance with international shipping laws. Familiarize yourself with the import regulations of your target market, as different countries may have specific documentation or testing requirements. Additionally, plan for potential delays in customs clearance to maintain a smooth supply chain and avoid disruptions in your product availability. -

Can hydroxytyrosol be customized for specific applications?

Yes, many manufacturers offer customization options for hydroxytyrosol based on the intended application. This can include adjusting the concentration of hydroxytyrosol or formulating it with other complementary ingredients to enhance its benefits. Engage in discussions with potential suppliers about your specific requirements, and inquire if they have experience in creating tailored solutions for different industries, such as cosmetics or nutraceuticals. Custom formulations can provide a competitive edge in the marketplace. -

What regulatory considerations should I be aware of when sourcing hydroxytyrosol?

Regulatory considerations for sourcing hydroxytyrosol include compliance with local and international food safety and labeling regulations. In regions like Europe, ensure that the product meets the EU’s food safety standards and that any health claims are substantiated according to regulations such as EC No. 1924/2006. For markets in Africa and South America, familiarize yourself with specific country regulations regarding the import and sale of dietary supplements. Collaborating with legal experts or consultants can help navigate these complexities effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Hydroxytyrosol Manufacturers

In the rapidly evolving market for hydroxytyrosol, strategic sourcing emerges as a critical factor for international B2B buyers. By establishing robust relationships with reliable manufacturers, businesses can ensure a consistent supply of this potent antioxidant, known for its exceptional health benefits, including support for cardiovascular health and skin vitality. As demand for natural and effective ingredients rises across various sectors—especially in cosmetics, nutraceuticals, and functional foods—buyers must prioritize suppliers that demonstrate transparency, quality assurance, and compliance with regulatory standards.

Moreover, the diverse applications of hydroxytyrosol, from beauty products to dietary supplements, present significant opportunities for market expansion in regions such as Africa, South America, the Middle East, and Europe. Buyers should actively engage with manufacturers who can offer innovative formulations and tailored solutions that meet the unique needs of their markets.

Looking ahead, the hydroxytyrosol market is poised for growth, driven by increasing consumer awareness of health and wellness. Now is the time for B2B buyers to leverage strategic sourcing strategies to secure competitive advantages and access high-quality hydroxytyrosol products. Embrace the potential of this powerful ingredient and partner with industry leaders to drive your business forward.