Top 4 Cable And Harness Manufacturers List and Guide: How To Solv…

Introduction: Navigating the Global Market for Cable and Harness Manufacturers

In an increasingly interconnected world, sourcing reliable cable and harness manufacturers can pose significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the complexities of global supply chains, varying quality standards, and the need for timely delivery can complicate procurement processes. This comprehensive guide aims to demystify the landscape of cable and harness manufacturing, providing insights into various types of assemblies, their applications across diverse industries, and effective strategies for supplier vetting.

From understanding the nuances of custom cable assemblies to evaluating the importance of certifications such as IPC and ISO, this guide equips you with the knowledge needed to make informed purchasing decisions. We delve into critical factors such as cost considerations, quality assurance practices, and logistical management, which are essential for optimizing your supply chain and ensuring product reliability.

By highlighting key trends and innovations in the cable and harness sector, this resource empowers B2B buyers to navigate the complexities of sourcing with confidence. With actionable insights tailored to your regional context, you will be better positioned to select partners who not only meet your specifications but also enhance your operational efficiency and competitiveness in the global market.

Top 10 Cable And Harness Manufacturers Manufacturers & Suppliers List

1. Avalontec – Precision Engineered Cable Wire Harnesses

Domain: avalontec.com

Registered: 2000 (25 years)

Introduction: Avalontec specializes in precision-engineered, high-quality cable wire harness manufacturing. Their offerings include:

– Coaxial and Triaxial Cables: For high-quality signal transmission with minimal interference.

– Flat Ribbon Cable Assembly: Space-saving design with efficient functionality.

– RF Cable Assembly: Reliable radio frequency transmission for telecommunications and broadcasting.

– Ove…

2. Custom Cord – Wire Harness Assemblies

Domain: customcord.com

Registered: 2000 (25 years)

Introduction: Custom Cord & Harness Assemblies specializes in contract manufacturing of commercial and industrial wire harness assemblies, multi conductor cable assemblies, and power cords. They offer custom wire harnesses, cable assemblies, and power cords for a diverse range of industries including appliance, refrigeration, HVAC, off-road vehicles, consumer products, commercial, industrial, and scientific app…

3. Force America – Custom Wire and Cable Harness Solutions

Domain: forceamerica.com

Registered: 1997 (28 years)

Introduction: Custom Manufactured Wire and Cable Harness Solutions. Specializes in designing and manufacturing a wide range of wire and cable harness solutions, from simple assemblies to complex custom solutions. Vast inventory of components for quick turnaround on custom prototypes and orders. Standard connectors and component inventory from top partners. Markets served include Agriculture, Construction, Fores…

4. Kato Cable – Wire Harnesses & Assemblies

Domain: katocable.com

Registered: 2006 (19 years)

Introduction: Kato Cable specializes in wire harnesses, cable assemblies, electro-mechanical assemblies, and battery cables built for performance and reliability. Their products are designed to meet the toughest industry standards and power critical applications across various markets. They offer comprehensive services including design, prototyping, manufacturing, and quality assurance, ensuring precision, reli…

Understanding Cable and Harness Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Cable Assemblies | Tailored to specific client requirements; often includes unique configurations. | Medical devices, aerospace, automotive, industrial applications. | Pros: Highly specialized; meets exact needs. Cons: Longer lead times; potentially higher costs. |

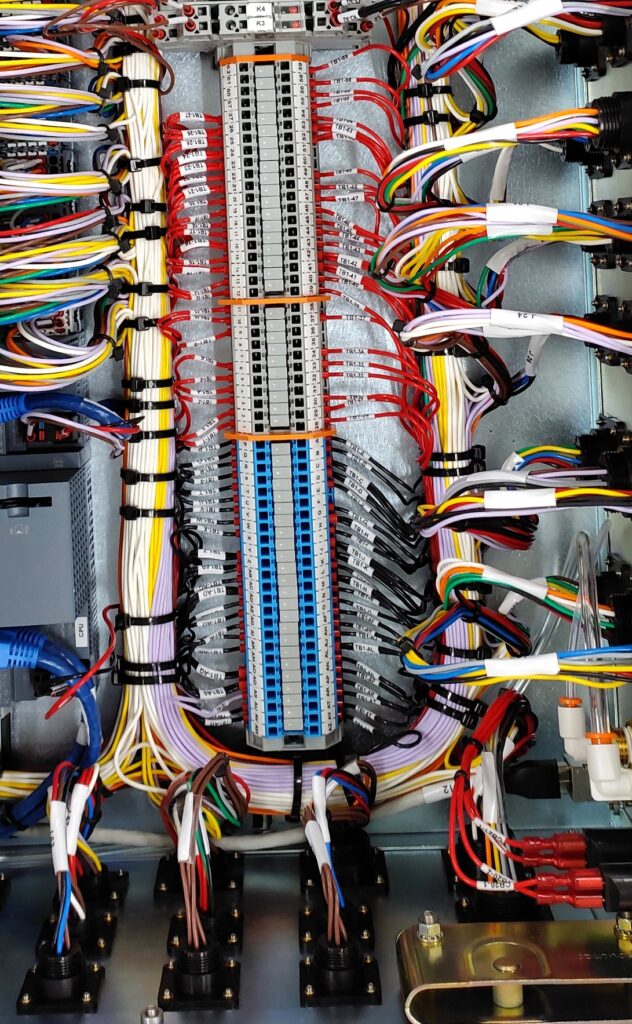

| Wire Harness Assemblies | Bundles multiple wires and connectors into a single unit; can handle complex circuitry. | Consumer electronics, automotive, industrial machinery. | Pros: Simplifies installation; reduces assembly time. Cons: Complexity can lead to higher failure rates if not properly designed. |

| Electromechanical Assemblies | Combines electrical and mechanical components; suitable for complex systems. | Robotics, automation, military applications. | Pros: Integrated solutions; versatile applications. Cons: Higher design and manufacturing complexity. |

| Battery Cables & Interconnects | Specialized for power distribution; often includes over-molding for durability. | Automotive, marine, recreational vehicles. | Pros: Ensures reliable power delivery; customizable. Cons: Limited to power applications; may require specific design considerations. |

| Over-Molded Cable Assemblies | Features protective over-molding to enhance durability; suitable for harsh environments. | Telecommunications, industrial equipment, medical devices. | Pros: Increased longevity and protection; good for harsh conditions. Cons: Can be more expensive due to added materials and processes. |

What Are the Key Characteristics of Custom Cable Assemblies?

Custom cable assemblies are designed to meet specific client requirements, often incorporating unique configurations tailored to the intended application. These assemblies are ideal for industries such as medical devices, aerospace, and automotive, where precision and reliability are crucial. When purchasing, buyers should consider the manufacturer’s ability to deliver quality prototypes and their experience in the relevant industry, as this can significantly impact the final product’s performance and compliance with standards.

How Do Wire Harness Assemblies Simplify Electrical Systems?

Wire harness assemblies bundle multiple wires and connectors into a single unit, which simplifies the installation process and enhances the organization of electrical systems. They are commonly used in consumer electronics, automotive, and industrial machinery. Buyers should evaluate the complexity of the harness required and the manufacturer’s expertise in handling intricate designs, as this can affect both performance and reliability.

Why Choose Electromechanical Assemblies for Complex Applications?

Electromechanical assemblies integrate electrical and mechanical components, making them suitable for complex systems such as robotics and automation. Their versatility allows them to serve various industries, including military applications. Buyers should focus on the manufacturer’s ability to manage the complexities involved in design and production, as well as their adherence to industry standards, to ensure optimal performance.

What Benefits Do Battery Cables & Interconnects Provide?

Battery cables and interconnects are specialized for power distribution, often featuring over-molding for enhanced durability. They are widely used in automotive, marine, and recreational vehicle applications. When considering these products, buyers should assess the manufacturer’s capability to customize solutions that meet specific power requirements while ensuring reliability and safety in demanding environments.

How Do Over-Molded Cable Assemblies Enhance Durability?

Over-molded cable assemblies include protective over-molding that enhances durability and provides resistance to environmental factors. They are particularly suitable for telecommunications, industrial equipment, and medical devices. Buyers should consider the quality of materials used in the over-molding process and the manufacturer’s experience in producing such assemblies, as this will influence the longevity and reliability of the final product in harsh conditions.

Key Industrial Applications of Cable and Harness Manufacturers

| Industry/Sector | Specific Application of Cable and Harness Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical | Custom cable assemblies for diagnostic equipment | Enhances reliability and accuracy in patient diagnostics | Compliance with medical standards (ISO 13485), prototyping capabilities, and on-time delivery. |

| Aerospace | Precision wire harnesses for avionics systems | Ensures safety and performance in critical flight systems | AS9100 certification, ITAR compliance, and experience in low-volume production. |

| Automotive | Complex wire harnesses for electric vehicles | Supports advanced vehicle technology and enhances safety features | Ability to scale production, durability against environmental factors, and customization options. |

| Industrial Equipment | Cable assemblies for automation and control systems | Improves operational efficiency and reduces downtime | Robustness for harsh environments, customization capabilities, and logistics management. |

| Defense/Military | Specialized harnesses for military communication systems | Guarantees secure and reliable communication in critical operations | Compliance with military specifications, proven track record, and rapid prototyping. |

How Are Cable and Harness Manufacturers Used in the Medical Industry?

In the medical sector, cable and harness manufacturers provide custom cable assemblies that are integral to diagnostic equipment, surgical devices, and patient monitoring systems. These assemblies need to meet stringent regulatory standards to ensure reliability and safety in critical healthcare applications. International buyers must prioritize suppliers who can demonstrate compliance with ISO 13485 and offer rapid prototyping services to adapt to evolving technologies. The ability to deliver high-quality products on time is crucial, as any delay can impact patient care.

What Role Do Cable and Harness Manufacturers Play in Aerospace Applications?

Aerospace applications rely heavily on precision-engineered wire harnesses for avionics systems, navigation, and communication. These components must withstand extreme conditions and meet stringent safety regulations, such as AS9100 certification and ITAR compliance. For international buyers, sourcing from manufacturers with proven expertise in low-volume, high-mix production is essential to ensure quality and reliability. The focus on meticulous quality control processes safeguards against failures that could jeopardize flight safety.

How Are Cable and Harness Manufacturers Transforming the Automotive Sector?

In the automotive industry, particularly with the rise of electric vehicles, complex wire harnesses are essential for integrating advanced technology and ensuring safety features. Manufacturers must provide durable solutions that can withstand varying environmental conditions, as well as offer customization to meet specific vehicle designs. For buyers in regions like Africa and South America, sourcing from manufacturers who can scale production efficiently while maintaining quality standards is key to supporting their market demands.

Why Are Cable Assemblies Important for Industrial Equipment?

Cable assemblies are vital for automation and control systems within industrial equipment, enhancing operational efficiency and reducing downtime. Manufacturers must ensure that their products can withstand harsh environments, which often includes moisture, extreme temperatures, and mechanical stress. International buyers should seek suppliers with strong logistics management capabilities to ensure timely delivery and adequate inventory levels, particularly in markets where production schedules are tight.

How Do Cable and Harness Manufacturers Support Defense and Military Needs?

In the defense sector, specialized harnesses are crucial for military communication systems, where reliability and security are paramount. Manufacturers must comply with military specifications and demonstrate a proven track record in delivering products that meet rigorous standards. For international buyers, it is essential to partner with manufacturers who can offer rapid prototyping and modification capabilities to adapt to changing defense requirements quickly, thus maintaining operational readiness.

3 Common User Pain Points for ‘Cable and Harness Manufacturers’ & Their Solutions

Scenario 1: Difficulty in Customizing Cable Assemblies for Unique Applications

The Problem: B2B buyers often face challenges when sourcing custom cable assemblies that meet specific requirements for unique applications. This can occur in industries such as aerospace or medical technology, where precision and compliance with stringent standards are paramount. Buyers may struggle with finding manufacturers that can accommodate low-volume orders while still delivering high-quality, tailored solutions. Additionally, a lack of engineering expertise within the purchasing company may hinder effective communication of requirements, leading to misaligned expectations and costly revisions.

The Solution: To effectively address this challenge, buyers should prioritize manufacturers that offer comprehensive design support and prototyping services. Engage in early discussions with potential suppliers to explore their capabilities in customizing cable assemblies. Request samples and prototype builds to validate the manufacturer’s ability to meet specifications before committing to larger orders. Additionally, leveraging manufacturers with robust engineering teams can facilitate the translation of complex needs into practical solutions. Companies like Salt Lake Cable & Harness and PCA, known for their extensive experience in custom applications, can be particularly beneficial in these scenarios. Establishing clear lines of communication and setting detailed specifications upfront will ensure that the final product aligns closely with your expectations.

Scenario 2: Managing Supply Chain Disruptions for Cable and Harness Products

The Problem: Global supply chain disruptions can lead to significant delays in the procurement of cable and harness products, jeopardizing project timelines and operational efficiency. For companies operating in fast-paced industries, such as automotive or consumer electronics, any interruption can have cascading effects on production schedules. B2B buyers may find themselves grappling with increased lead times, higher costs, and even potential penalties for missed deadlines, all while trying to maintain quality and compliance standards.

The Solution: To mitigate supply chain risks, B2B buyers should adopt a proactive approach by diversifying their supplier base. This includes engaging multiple manufacturers across different regions to avoid reliance on a single source. Implementing an inventory management system, such as Vendor Managed Inventory (VMI) or Kanban, can also help maintain optimal stock levels and streamline reorder processes. It is advisable to collaborate closely with suppliers on logistics management, ensuring that they have robust contingency plans in place. Regularly reviewing and adjusting procurement strategies based on current market trends will further enhance resilience against future disruptions. Establishing long-term partnerships with manufacturers that have demonstrated reliability can provide added security in uncertain times.

Scenario 3: Ensuring Compliance with Industry Standards in Cable Manufacturing

The Problem: Compliance with industry standards, such as IPC 620 for cable assemblies, is critical for B2B buyers in regulated sectors like medical devices, aerospace, and automotive. However, many buyers may not fully understand the complexities of these standards or how they apply to their specific products. This lack of knowledge can lead to the selection of non-compliant components, resulting in product recalls, legal issues, and damage to reputation.

The Solution: B2B buyers should prioritize partnering with cable and harness manufacturers who have a deep understanding of industry regulations and quality standards. Engage manufacturers that can demonstrate compliance through certifications and quality assurance processes. During the sourcing process, buyers should inquire about the manufacturer’s quality control measures, testing protocols, and previous compliance certifications. Additionally, consider utilizing third-party auditors or consultants to evaluate supplier compliance independently. This proactive approach not only ensures that products meet necessary standards but also fosters a culture of quality and accountability within the supply chain. Regular training and updates on industry standards can also empower internal teams to make informed decisions when selecting components and manufacturers.

Strategic Material Selection Guide for Cable and Harness Manufacturers

What Are the Key Materials for Cable and Harness Manufacturing?

In the cable and harness manufacturing sector, selecting the right materials is crucial for ensuring product performance, reliability, and compliance with industry standards. Below, we analyze four common materials used in cable and harness manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

What Are the Key Properties of PVC in Cable and Harness Manufacturing?

Polyvinyl Chloride (PVC) is a widely used material in cable insulation and jacketing. It offers excellent electrical insulation properties and is resistant to moisture, chemicals, and abrasion. PVC can withstand temperatures ranging from -15°C to 70°C, making it suitable for various environments.

Pros & Cons: PVC is cost-effective and easy to manufacture, leading to lower production costs. However, it has limitations in high-temperature applications and can become brittle over time when exposed to UV light.

Impact on Application: PVC is compatible with a wide range of media, including water and various oils, making it suitable for industrial and automotive applications.

Considerations for International Buyers: Buyers should ensure that PVC products comply with local and international standards such as ASTM D3032 and IEC 60502. In regions like Africa and South America, understanding local regulations regarding chemical safety is essential.

What Are the Advantages of Using Silicone in Cable and Harness Assemblies?

Silicone is another popular material known for its flexibility and high-temperature resistance, with ratings typically between -60°C and 200°C. It is also resistant to UV light, ozone, and various chemicals, making it ideal for harsh environments.

Pros & Cons: The primary advantage of silicone is its durability and ability to maintain performance under extreme conditions. However, it is more expensive than PVC and can complicate manufacturing processes due to its unique properties.

Impact on Application: Silicone is particularly well-suited for applications in aerospace and medical devices, where reliability and safety are paramount.

Considerations for International Buyers: Compliance with standards such as ISO 9001 and ASTM D2000 is critical. Buyers in Europe and the Middle East should also consider REACH regulations regarding chemical safety.

Why Is Polyethylene a Preferred Material for Cable Insulation?

Polyethylene (PE) is commonly used for cable insulation due to its excellent dielectric properties and resistance to moisture and chemicals. It can operate effectively within a temperature range of -40°C to 90°C.

Pros & Cons: PE is lightweight and cost-effective, making it suitable for various applications. However, it has lower mechanical strength compared to other materials and can degrade under UV exposure unless treated.

Impact on Application: PE is ideal for outdoor applications and telecommunications, where moisture resistance is crucial.

Considerations for International Buyers: Buyers should ensure that PE cables comply with standards like IEC 60529 for ingress protection. Understanding local environmental regulations in regions like Brazil and Vietnam is also necessary.

What Role Does Teflon Play in High-Performance Cable Assemblies?

Teflon (PTFE) is known for its exceptional thermal stability and chemical resistance, with a temperature range of -200°C to 260°C. It is often used in high-performance applications such as aerospace and military.

Pros & Cons: Teflon offers superior performance in extreme conditions and is non-flammable. However, it is one of the most expensive materials and can be challenging to process.

Impact on Application: Teflon is particularly beneficial in applications requiring minimal friction and high thermal stability, such as in aerospace wiring.

Considerations for International Buyers: Buyers should be aware of compliance with military standards (e.g., MIL-W-5086) and other relevant certifications. Understanding the supply chain logistics for Teflon components is crucial for manufacturers in Africa and the Middle East.

Summary Table of Material Selection

| Material | Typical Use Case for Cable and Harness Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Insulation for automotive and industrial cables | Cost-effective and easy to manufacture | Limited high-temperature performance | Low |

| Silicone | Aerospace and medical device applications | High durability and temperature resistance | Higher cost and manufacturing complexity | High |

| Polyethylene | Outdoor telecommunications and moisture-resistant cables | Lightweight and excellent dielectric properties | Lower mechanical strength and UV degradation | Medium |

| Teflon | High-performance aerospace and military applications | Exceptional thermal stability and chemical resistance | High cost and challenging processing | High |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Cable and Harness Manufacturers

What Are the Main Stages of Manufacturing for Cable and Harness Manufacturers?

The manufacturing process for cable and harness assemblies involves several critical stages, each designed to ensure the final product meets the necessary specifications and quality standards. The main stages of production typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Cable and Harness Production?

The first step in manufacturing is material preparation, which involves sourcing high-quality raw materials such as wires, connectors, and insulation materials. Suppliers must ensure these materials conform to international standards, such as ISO 9001, which governs quality management systems. The materials are then cut to specified lengths, stripped of insulation, and readied for assembly. Proper inventory management systems, like Vendor Managed Inventory (VMI) or Kanban, help streamline this process, ensuring that materials are available when needed without excessive overstock.

What Techniques Are Used in Forming Cable and Harness Assemblies?

Once the materials are prepared, the forming stage begins. This involves bending and shaping the wires and connectors according to specific design requirements. Techniques such as injection molding and over-molding can be employed to create custom connectors that enhance durability and functionality. Advanced machinery, including automated cutting and stripping machines, is often used to improve precision and efficiency, allowing for the production of both simple and complex wire harnesses.

What Is the Assembly Process for Cable and Harness Products?

The assembly stage is where the prepared components are brought together. Skilled technicians or automated systems assemble the wires and connectors into harnesses, ensuring that each connection is secure and correctly aligned. This is a critical phase, as any errors in assembly can lead to product failures. Quality assurance checkpoints, such as In-Process Quality Control (IPQC), are implemented to monitor the assembly process, ensuring that any issues are identified and rectified immediately.

How Is the Finishing Process Handled in Cable and Harness Manufacturing?

Finishing involves a series of steps designed to prepare the cable assemblies for shipment and use. This may include applying protective coatings, labeling, and packaging. The finishing stage is crucial for ensuring that the products are not only functional but also aesthetically pleasing and ready for integration into larger systems. Stringent Final Quality Control (FQC) checks are performed during this stage to ensure that all products meet the required specifications before they leave the manufacturing facility.

What Quality Assurance Standards Are Relevant for Cable and Harness Manufacturers?

Quality assurance is a fundamental aspect of cable and harness manufacturing. Manufacturers often adhere to international standards such as ISO 9001, which outlines a framework for quality management systems. In addition, industry-specific standards like IPC/WHMA-A-620 for wire harness assemblies ensure that products meet rigorous performance and safety criteria.

For international buyers, understanding these standards is critical, as they can impact product reliability and compliance with local regulations. For instance, products sold in the European market may also need to meet CE marking requirements, while manufacturers supplying to the U.S. Department of Defense must comply with specific military standards.

What Are Common Quality Control Checkpoints in Cable and Harness Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and resolve issues before they escalate.

-

Final Quality Control (FQC): A thorough examination of the finished products to ensure they meet all design specifications and quality standards.

What Testing Methods Are Commonly Used in Cable and Harness Manufacturing?

Various testing methods are employed to ensure the reliability and performance of cable and harness assemblies. These may include:

-

Electrical Testing: To verify the integrity of connections and signal transmission capabilities.

-

Environmental Testing: Assessing the durability of products under extreme conditions, such as temperature variations and humidity.

-

Mechanical Testing: Evaluating the strength and flexibility of cables and harnesses to ensure they can withstand operational stresses.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure they are receiving reliable products. Here are some effective strategies:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes, quality control measures, and adherence to industry standards.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports and certifications.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s compliance with quality standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must be aware of the nuances associated with quality control and certification, particularly when dealing with suppliers from different regions. Variations in regulatory requirements, manufacturing practices, and quality standards can impact product reliability.

For example, buyers from Europe may prioritize CE certifications, while those in the Middle East may focus on compliance with local standards. Understanding these differences is crucial for mitigating risks associated with international procurement.

Conclusion: Ensuring Quality in Cable and Harness Manufacturing

The manufacturing processes and quality assurance protocols in cable and harness production are integral to delivering reliable and high-quality products. By understanding the stages of manufacturing, relevant standards, and effective QC measures, B2B buyers can make informed decisions when selecting suppliers. This is particularly important in international markets, where varying standards and practices can significantly impact product performance. By prioritizing quality in their procurement strategies, buyers can ensure they receive products that meet their specifications and enhance their operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Cable and Harness Manufacturers’

Introduction

This guide is designed to assist B2B buyers in effectively sourcing cable and harness manufacturers. With the right approach, businesses can ensure they partner with the most suitable suppliers, thereby enhancing their production capabilities and maintaining high-quality standards. The following checklist outlines essential steps to streamline the procurement process.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing cable and harness manufacturers. This includes determining the types of cables needed, such as coaxial or flat ribbon cables, and specifying any particular industry standards that must be met. A detailed specification helps suppliers provide accurate quotes and ensures that the final products will meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in cable and harness manufacturing. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Look for companies with experience in your specific industry to ensure they understand your unique requirements and challenges.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications. Key certifications such as ISO 9001, IPC standards, and industry-specific registrations (like AS9100 for aerospace) indicate a commitment to quality and compliance. Certifications ensure that the manufacturer follows established processes that enhance product reliability and safety.

Step 4: Review Manufacturing Capabilities

Assess the manufacturing capabilities of potential suppliers. Look for details on their production processes, technology used, and capacity for scaling production. Understanding their capabilities will help ensure they can meet your volume requirements and deliver products on time, which is crucial for maintaining your supply chain efficiency.

Step 5: Request Prototypes and Samples

Before finalizing your choice, request prototypes or samples of the products. This step is vital for evaluating the quality and functionality of the cable and harness assemblies. Testing samples allows you to identify any potential issues early and ensures that the supplier can meet your technical specifications.

Step 6: Understand Pricing and Payment Terms

Gain a clear understanding of pricing structures and payment terms from each supplier. This includes not only the base cost of products but also any additional fees for tooling, prototypes, or shipping. Transparent pricing helps you budget effectively and prevents unexpected costs that could impact your project timelines.

Step 7: Establish Communication Protocols

Finally, establish clear communication protocols with your chosen supplier. Determine how updates will be communicated, the frequency of check-ins, and who the key contacts will be on both sides. Effective communication is essential for resolving issues quickly and ensuring that both parties are aligned throughout the manufacturing process.

By following this checklist, B2B buyers can confidently navigate the sourcing process for cable and harness manufacturers, ensuring that they partner with the right suppliers to meet their production needs.

Comprehensive Cost and Pricing Analysis for Cable and Harness Manufacturers Sourcing

What Are the Key Cost Components in Cable and Harness Manufacturing?

Understanding the cost structure of cable and harness manufacturing is essential for B2B buyers aiming for efficient sourcing. The primary cost components include:

-

Materials: Raw materials such as copper, plastic, and insulation materials significantly impact costs. Prices fluctuate based on global supply and demand, which can vary considerably by region.

-

Labor: Labor costs depend on the skill level required for assembly and manufacturing. Regions with higher labor costs may result in more expensive products, while those with lower labor rates can provide cost savings.

-

Manufacturing Overhead: This includes utilities, rent, equipment maintenance, and other indirect costs necessary for production. A facility’s operational efficiency can greatly affect overall pricing.

-

Tooling: The initial investment in tooling for custom designs can be substantial. However, this cost can be amortized over larger production runs, making volume a critical factor in pricing.

-

Quality Control (QC): Stringent QC processes are essential in ensuring product reliability, especially in industries like aerospace and medical. The costs associated with testing and certification can add to the final price.

-

Logistics: Shipping and handling costs, including customs duties and insurance, can vary widely based on the destination. Proximity to suppliers and transportation infrastructure play crucial roles in these expenses.

-

Margin: Manufacturers typically add a margin to cover their operational risks and profit. Understanding the industry standard margin can help buyers gauge the fairness of pricing.

How Do Price Influencers Affect Cable and Harness Sourcing?

Several factors influence pricing in the cable and harness manufacturing sector:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their production needs while minimizing costs.

-

Specifications and Customization: Custom designs usually incur higher costs due to the additional engineering and tooling required. Buyers should be clear about their specifications to avoid unnecessary expenses.

-

Materials Quality and Certifications: Higher-quality materials and certifications (like IPC standards) often lead to increased prices. Buyers must assess whether the added cost aligns with their quality requirements.

-

Supplier Factors: The reliability, reputation, and location of the supplier can influence pricing. Established manufacturers with a track record of quality and delivery can often command higher prices.

-

Incoterms: Different Incoterms can affect the total landed cost. Buyers should understand how terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) impact their final expenses.

What Are the Best Buyer Tips for Sourcing Cable and Harness Manufacturers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective sourcing strategies can yield significant cost efficiencies:

-

Negotiate Wisely: Leverage volume purchasing to negotiate better rates. Understanding the supplier’s cost structure can also provide leverage during discussions.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate long-term costs, including maintenance, durability, and potential downtime caused by failures.

-

Understand Pricing Nuances: Different regions have varying pricing structures based on local regulations, labor costs, and material availability. Buyers should conduct market research to gain insights into fair pricing.

-

Engage in Strategic Partnerships: Building long-term relationships with suppliers can lead to better pricing, improved communication, and priority service, especially during high-demand periods.

-

Request Samples and Prototypes: Before committing to large orders, request samples or prototypes to ensure the product meets your specifications and quality expectations.

Conclusion and Disclaimer

The pricing landscape for cable and harness manufacturing is multifaceted, influenced by various cost components and market dynamics. Buyers should approach sourcing with a comprehensive understanding of these factors to make informed decisions. Prices are subject to fluctuation based on market conditions and supplier capabilities, and this analysis serves as a guideline rather than a definitive pricing model.

Alternatives Analysis: Comparing Cable and Harness Manufacturers With Other Solutions

Introduction to Alternatives in Cable and Harness Solutions

In the rapidly evolving landscape of technology, selecting the right connectivity solution is crucial for businesses. While cable and harness manufacturers offer specialized products for various industries, alternative solutions exist that may better fit specific needs or constraints. Understanding these alternatives allows B2B buyers to make informed decisions based on performance, cost, and application requirements.

Comparison Table

| Comparison Aspect | Cable And Harness Manufacturers | Flexible Printed Circuit Boards (FPCBs) | Wireless Connectivity Solutions |

|---|---|---|---|

| Performance | High durability and reliability | Limited range but lightweight | Variable performance based on distance |

| Cost | Generally higher upfront investment | Lower production costs for high volumes | Lower initial costs, but variable long-term expenses |

| Ease of Implementation | Requires engineering expertise | Simplified production for complex layouts | Easy integration with existing systems |

| Maintenance | Regular inspection needed | Minimal maintenance required | Software updates may be necessary |

| Best Use Case | Industrial, aerospace, automotive | Consumer electronics, medical devices | IoT devices, short-range applications |

Detailed Breakdown of Alternatives

Flexible Printed Circuit Boards (FPCBs)

FPCBs are an innovative alternative that offers significant advantages in specific applications. They are lightweight and can be bent or folded, making them ideal for compact spaces such as consumer electronics or medical devices. However, their performance can be limited compared to traditional cable assemblies, particularly in high-stress environments. While FPCBs often come with lower production costs, they may not provide the same durability as wire harnesses, especially in industrial applications.

Wireless Connectivity Solutions

Wireless solutions represent a growing trend in connectivity, providing flexibility and ease of installation, particularly in Internet of Things (IoT) devices. They eliminate the need for physical connections, which can simplify design and reduce installation time. However, performance can vary based on distance and environmental factors, and while initial costs may be lower, ongoing expenses related to software and network management can accumulate. Wireless solutions are best suited for applications where mobility and ease of access are paramount, rather than high-performance requirements.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating cable and harness manufacturers against alternatives like FPCBs and wireless solutions, B2B buyers should consider their specific requirements, including performance, cost, and application context. Each option presents unique benefits and limitations, making it essential to align the choice with operational needs and strategic goals. A thorough assessment of the technical specifications and long-term implications of each solution will guide buyers toward the best fit for their projects, ensuring both efficiency and effectiveness in their connectivity strategies.

Essential Technical Properties and Trade Terminology for Cable and Harness Manufacturers

What Are the Key Technical Properties of Cable and Harness Manufacturing?

Understanding the essential technical properties of cable and harness manufacturing is crucial for B2B buyers seeking reliable and efficient solutions. Here are some critical specifications to consider:

1. Material Grade

The material used in cable and harness assemblies significantly affects their performance and longevity. Common materials include copper for conductors due to its excellent conductivity and various plastics (like PVC or Teflon) for insulation. Selecting the right material grade ensures that the product meets industry standards and application requirements, which is vital for sectors like aerospace and medical where safety and reliability are paramount.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of the cable or harness. High precision in manufacturing is essential, especially in applications where space is limited or performance is critical. Ensuring tight tolerances can prevent issues such as signal interference or mechanical failure, thus enhancing the overall reliability of the product.

3. Voltage Rating

The voltage rating indicates the maximum voltage the cable or harness can safely carry. This specification is crucial for preventing electrical failures and ensuring compliance with safety standards. Buyers need to match the voltage rating with their application’s requirements to avoid risks associated with over-voltage situations.

4. Current Carrying Capacity

This property defines the maximum amount of electrical current a cable can carry without overheating. Understanding current carrying capacity is essential for ensuring that the cable or harness will operate safely and efficiently under load. It helps in selecting the right gauge and configuration, which can significantly impact performance and safety.

5. Environmental Resistance

Cables and harnesses often operate in challenging environments. Environmental resistance properties, such as moisture, temperature extremes, and chemical exposure, are critical for determining the longevity and reliability of the assemblies. Selecting products with appropriate environmental ratings ensures they will function effectively in their intended applications.

What Are Common Trade Terms in Cable and Harness Manufacturing?

Familiarity with industry terminology can facilitate smoother transactions and clearer communication between buyers and manufacturers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of cable and harness manufacturing, OEMs often require custom solutions tailored to their specific equipment needs. Understanding OEM dynamics is crucial for buyers to ensure they receive products that meet their precise specifications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is particularly important for buyers looking to balance inventory costs with production needs. Understanding MOQ helps in planning purchases effectively, especially when dealing with custom cable and harness solutions.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. It typically includes detailed specifications, quantities, and delivery timelines. Issuing an RFQ is essential for B2B buyers to ensure they receive competitive pricing and terms from multiple manufacturers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers to mitigate risks and ensure smooth logistics in global supply chains.

5. Prototyping

Prototyping involves creating a preliminary model of a product to test its design and functionality. For cable and harness manufacturers, prototyping allows for adjustments before mass production. Buyers should prioritize suppliers that offer prototyping services to refine their designs and avoid costly errors in full-scale production.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right cable and harness solutions for their specific needs. This knowledge not only enhances procurement efficiency but also fosters stronger partnerships with manufacturers.

Navigating Market Dynamics and Sourcing Trends in the Cable and Harness Manufacturers Sector

What Are the Key Market Drivers for Cable and Harness Manufacturers?

The cable and harness manufacturing sector is witnessing significant transformations driven by technological advancements, global demand for connectivity, and the increasing complexity of electronic systems. With industries like automotive, aerospace, and telecommunications evolving rapidly, the need for custom and high-quality cable assemblies is paramount. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe must stay abreast of these trends to remain competitive.

Emerging technologies such as IoT, electric vehicles, and renewable energy sources are creating new markets and applications for cable and harness manufacturers. The demand for lightweight, durable, and high-performance materials is increasing, prompting manufacturers to invest in innovative production techniques and materials. Furthermore, automation and digitalization in manufacturing processes are enhancing efficiency, reducing lead times, and improving quality control.

How Are B2B Tech and Sourcing Trends Shaping the Industry?

The current landscape also reflects a shift towards integrated supply chain solutions. Manufacturers are increasingly adopting Vendor Managed Inventory (VMI) and Just-In-Time (JIT) methodologies to optimize inventory levels and reduce costs. Collaborative partnerships between manufacturers and suppliers are becoming essential for achieving seamless production and delivery, which is crucial for B2B buyers looking to mitigate risks associated with supply chain disruptions.

Additionally, the rise of e-commerce platforms tailored for B2B transactions is simplifying the sourcing process, allowing buyers to access a broader range of suppliers and negotiate better terms. As competition intensifies, international buyers must leverage these platforms for market intelligence, supplier evaluation, and procurement efficiency.

Why Is Sustainability and Ethical Sourcing Important in Cable and Harness Manufacturing?

As global awareness of environmental issues grows, sustainability has become a critical consideration in the cable and harness manufacturing sector. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using eco-friendly materials and implementing energy-efficient production processes.

The environmental impact of manufacturing operations is under scrutiny, with many companies striving to reduce their carbon footprint and waste. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential benchmarks for assessing supplier sustainability.

Ethical sourcing is equally important. Buyers are encouraged to engage suppliers that uphold fair labor practices and transparency throughout their supply chains. This not only mitigates reputational risks but also aligns with the growing consumer demand for ethically produced products.

What Are the Green Certifications and Materials in the Cable and Harness Sector?

In the cable and harness manufacturing sector, materials such as recyclable plastics and low-impact metals are gaining traction. Manufacturers are exploring alternatives like bio-based polymers and biodegradable materials to enhance their sustainability profile.

Green certifications, such as UL Environment and Energy Star, signify a manufacturer’s commitment to sustainability and can enhance a buyer’s brand reputation when sourcing products. Implementing a sustainable procurement strategy not only addresses environmental concerns but can also lead to cost savings and improved operational efficiency.

How Has the Cable and Harness Manufacturing Sector Evolved Over Time?

The evolution of cable and harness manufacturing can be traced back to the industrial revolution, where the need for electrical connectivity became paramount. Over the decades, the industry has shifted from simple wire harnesses to complex assemblies that integrate advanced technologies.

In recent years, the proliferation of electronic devices and the demand for reliable connections have driven innovations in materials and manufacturing processes. Today, manufacturers are leveraging automation, robotics, and advanced testing methodologies to ensure high quality and performance in their products.

This historical context underscores the importance for B2B buyers to understand the trajectory of the industry, as it informs current practices and future trends. By aligning with innovative manufacturers who prioritize quality, sustainability, and technological advancement, buyers can secure their position in a competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of Cable and Harness Manufacturers

-

How do I ensure quality when sourcing cable and harness manufacturers?

To ensure quality, start by verifying the manufacturer’s certifications such as ISO 9001 or IPC standards, which indicate adherence to quality management systems. Request samples of their products to evaluate workmanship and materials used. Additionally, consider their experience in your specific industry and ask for references from previous clients. Conducting a factory audit, if feasible, can also provide insights into their production capabilities and quality control processes. -

What is the best way to communicate my custom requirements to a cable manufacturer?

Clear communication is key to successful collaboration. Prepare detailed specifications, including diagrams, materials, dimensions, and any regulatory standards. Utilize CAD models if available, as they can convey complex designs more effectively. Schedule a meeting to discuss your needs directly with the manufacturer’s engineering team. Ensure that you establish a feedback loop to address any concerns or modifications during the design and prototyping phases. -

What are the typical minimum order quantities (MOQs) for cable and harness assemblies?

Minimum order quantities can vary significantly between manufacturers and depend on factors such as complexity, materials, and production methods. Generally, MOQs may range from a few hundred to several thousand units. It’s advisable to discuss your project requirements upfront and negotiate terms that align with your budget and timeline. Some manufacturers may offer lower MOQs for prototype runs or initial orders, which can be beneficial for startups and smaller businesses. -

What payment terms should I expect when working with international suppliers?

Payment terms can differ widely based on the supplier’s policies and the nature of the transaction. Common arrangements include net 30, 60, or 90 days after delivery. For international transactions, consider using letters of credit or escrow services to mitigate risks. Discuss payment milestones linked to production stages, especially for large orders, to ensure both parties are protected throughout the process. -

How can I vet a potential cable and harness supplier effectively?

Start by researching the supplier’s reputation within the industry through online reviews and testimonials. Request case studies that showcase their experience with similar projects. Evaluate their financial stability and operational capacity by reviewing their production facilities and workforce. If possible, visit their location or engage a third-party audit service to assess their compliance with quality and safety standards. -

What are the logistics considerations when importing cable assemblies from overseas?

Logistics involve several factors including shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with your supplier’s location and your destination country. Ensure that all documentation, such as invoices and packing lists, is prepared accurately to avoid customs delays. Factor in potential tariffs and duties that may apply to your products, and plan for sufficient lead time to accommodate any unforeseen delays. -

How important is after-sales support from cable and harness manufacturers?

After-sales support is crucial for addressing any issues that may arise post-delivery, such as product defects or compatibility concerns. A manufacturer that offers robust support can help troubleshoot problems, provide technical assistance, and facilitate replacements or repairs if necessary. Evaluate their warranty policies and responsiveness to customer inquiries during the selection process, as this can significantly impact your overall satisfaction and operational efficiency. -

What are the advantages of working with a manufacturer that offers prototyping services?

Prototyping services allow you to test and validate your designs before full-scale production, reducing the risk of costly errors. This iterative process enables you to refine specifications based on real-world testing and feedback. Working with a manufacturer that provides rapid prototyping can also accelerate your time to market, as it allows for quicker adjustments to designs and features based on market demands or regulatory requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Cable and Harness Manufacturers

In the rapidly evolving landscape of cable and harness manufacturing, strategic sourcing emerges as a critical component for businesses aiming to maintain competitiveness. By partnering with experienced manufacturers who offer custom solutions and advanced engineering capabilities, international buyers can ensure they receive high-quality products tailored to their specific needs. The ability to streamline production processes, manage logistics effectively, and engage in continuous innovation is paramount, particularly for companies in diverse sectors such as medical, aerospace, automotive, and industrial applications.

For B2B buyers in Africa, South America, the Middle East, and Europe, the implications of strategic sourcing extend beyond cost savings; it encompasses risk mitigation, enhanced supply chain resilience, and improved product reliability. As the demand for sophisticated cable assemblies and harnesses grows, embracing these sourcing strategies will position companies to capitalize on emerging market opportunities.

Looking ahead, the focus on quality and customization will only intensify. By aligning with manufacturers committed to excellence, you can drive your projects forward with confidence. Take the next step—explore partnerships that can elevate your business and meet the dynamic demands of the global marketplace.