Top 5 Plastic Cup Manufacturers List and Guide: How To Solve Scen…

Introduction: Navigating the Global Market for Plastic Cup Manufacturers

In an increasingly competitive global marketplace, sourcing reliable plastic cup manufacturers can be a daunting task for international B2B buyers. The challenge lies not only in identifying suppliers that meet quality standards but also in navigating the complexities of various materials, designs, and sustainability considerations. This guide provides a comprehensive overview of the plastic cup manufacturing landscape, covering essential aspects such as types of cups available, their applications across different industries, and effective strategies for supplier vetting.

B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—will find valuable insights tailored to their unique market needs. Whether you’re in Nigeria looking to source eco-friendly options or in Saudi Arabia seeking durable solutions for food service, this guide empowers you to make informed purchasing decisions. By understanding pricing structures, assessing quality control measures, and exploring innovative materials like PLA and recycled plastics, you can confidently engage with manufacturers that align with your business goals.

With actionable insights and detailed information at your fingertips, you will be well-equipped to streamline your sourcing process and enhance your supply chain efficiency, ensuring that your business remains competitive and responsive to consumer demands.

Top 10 Plastic Cup Manufacturers Manufacturers & Suppliers List

1. Custom Cup Factory – Disposable Dessert Supplies

Domain: customcupfactory.com

Registered: 2020 (5 years)

Introduction: Custom Printed and Generic Disposable Supplies including:

1. Frozen Dessert/Bakery:

– Paper Yogurt Cups

– Paper Ice Cream Cups

– Ice Cream Containers + Lids Combo

– PET Plastic Deli Container

– Dessert Cup Lids

– Desserts Spoons

– Foldable Cold Chain Insulation Boxes

– Paper Bakery Boxes

2. Cold Drink:

– PET Plastic Cups

– PP Plastic Cups

– Premium PP Injection P…

2. Epackage Supply – Disposable Cups

3. Berry Global – Drinking Cups

Domain: berryglobal.com

Registered: 2015 (10 years)

Introduction: Berry Global offers a wide variety of drinking cups designed for both hot and cold beverages. The cups are available in multiple sizes, including 6oz, 9.1oz, 10.3oz, 11.3oz, 12oz, 13.7oz, 15.24oz, 16oz, 17oz, 18.2oz, 19oz, 20oz, 20.1oz, 21oz, 24oz, 24.4oz, 26oz, 27oz, 30oz, 32oz, 35oz, 40oz, 50oz, and various milliliters. The cups are made from different materials, including PP (Polypropylene), PE…

4. Unicup – Custom Printed Paper Cups

Domain: unicup.com

Registered: 2004 (21 years)

Introduction: Manufacturer of full color custom printed paper cups. Offers custom disposable coffee cups, double wall paper cups, single wall paper cups, kraft paper cups with pad printing, and custom plastic cups. Minimum order quantities include: digital print on the label (min. 100 pcs in 24 hours), offset printing (min. 1000 pcs), digital printing (min. 5000 pcs), and pad printing (min. 500 pcs). Custom pap…

5. WinCup – Vio™ Biodegradable Foam Cups

Domain: wincup.com

Registered: 1995 (30 years)

Introduction: WinCup offers a range of disposable products, including the Vio™ Biodegradable Foam Cups and Phade® Marine Biodegradable Straws. The Vio™ Cup is designed to biodegrade 92% over 4 years under specific landfill conditions, tested using the ASTM D5511 method. However, it is not available for sale in California, Maryland, Washington, Colorado, and Minnesota. The Phade® straws are marine biodegradable …

Understanding Plastic Cup Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compostable Cups | Made from sustainable materials like PLA and sugarcane fiber; designed for commercial composting. | Food service, events, eco-friendly brands. | Pros: Environmentally friendly, biodegradable. Cons: May require specific composting facilities. |

| PET Cups | Lightweight, recyclable, and food-safe; clear options available for visibility. | Beverage service, retail, catering. | Pros: Durable, good clarity, widely accepted. Cons: Limited to cold beverages; recycling infrastructure varies. |

| PP Cups | Versatile in design, available in various colors and sizes; heat resistant. | Coffee shops, takeaway restaurants, events. | Pros: Suitable for hot and cold drinks, customizable. Cons: Less eco-friendly compared to compostable options. |

| Custom Printed Cups | Personalization options for branding; available in multiple materials. | Marketing events, brand promotions. | Pros: Enhances brand visibility, customizable. Cons: Higher initial investment, longer lead times. |

| HIPS Cups | Impact-resistant, lightweight; typically used for frozen desserts. | Ice cream shops, outdoor events. | Pros: Durable, suitable for cold applications. Cons: Limited to specific uses; may not be recyclable. |

What Are the Characteristics of Compostable Cups?

Compostable cups are crafted from renewable resources such as PLA (polylactic acid) and sugarcane fiber. They are designed to break down in commercial composting facilities, making them an eco-friendly choice for businesses focused on sustainability. Ideal for food service and events, these cups cater to environmentally conscious brands. When considering compostable options, buyers should evaluate local composting capabilities and potential cost implications, as these products may be more expensive than traditional plastic.

How Do PET Cups Stand Out in the Market?

PET (Polyethylene Terephthalate) cups are favored for their lightweight and recyclable properties, making them suitable for various applications, including beverage service and catering. Their clear design enhances product visibility, appealing to both consumers and retailers. While PET cups are durable and can withstand cold beverages, buyers should consider the recycling infrastructure in their region, as it can affect the environmental impact of these products.

What Makes PP Cups a Versatile Choice?

Polypropylene (PP) cups are known for their versatility, available in numerous sizes and colors, and can handle both hot and cold beverages. They are commonly used in coffee shops and takeaway restaurants due to their heat resistance and customizable options. B2B buyers should weigh the benefits of customization against the environmental implications, as PP cups are less eco-friendly than compostable alternatives.

Why Invest in Custom Printed Cups?

Custom printed cups offer businesses an excellent opportunity to enhance brand visibility at events and marketing campaigns. These cups can be made from various materials, allowing for flexibility in design and function. However, the initial investment can be higher, and lead times may extend due to the customization process. Companies should assess their branding needs and budget constraints when considering this option.

What Are the Advantages of HIPS Cups for Specific Applications?

HIPS (High Impact Polystyrene) cups are lightweight and impact-resistant, making them ideal for serving frozen desserts like ice cream. Their durability ensures they can withstand outdoor events and high-traffic areas. However, they are limited to specific applications and may not be recyclable, which is a consideration for environmentally conscious buyers. Understanding the intended use and environmental policies will guide purchasing decisions in this category.

Key Industrial Applications of Plastic Cup Manufacturers

| Industry/Sector | Specific Application of Plastic Cup Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Disposable cups for beverages in restaurants and cafes | Cost-effective, convenient, and enhances customer experience | Compliance with food safety regulations, material sustainability, and customization options |

| Catering and Events | Bulk supply of plastic cups for events and parties | Streamlined service and reduced cleanup time | Volume discounts, durability for outdoor use, and branding options |

| Retail and Convenience | Branded plastic cups for on-the-go beverages | Increased brand visibility and customer loyalty | Custom printing capabilities, variety of sizes, and eco-friendly options |

| Healthcare | Single-use cups for medications and drinks | Hygiene and safety in patient care | Compliance with healthcare regulations, material safety, and ease of disposal |

| Education | Disposable cups for school cafeterias | Convenience and sanitation for large groups | Bulk purchasing options, variety in sizes, and affordability |

How Are Plastic Cups Used in the Food Service Industry?

Plastic cup manufacturers play a vital role in the food service sector by providing disposable cups that cater to both hot and cold beverages. Restaurants and cafes benefit from the convenience of single-use cups, which reduce the need for dishwashing and enhance the customer experience. Buyers in this sector must prioritize compliance with food safety regulations and consider sourcing cups made from recyclable or compostable materials to align with sustainability goals.

What is the Role of Plastic Cups in Catering and Events?

In catering and event management, plastic cups are essential for serving beverages at large gatherings. They streamline service and significantly reduce cleanup time, providing a practical solution for outdoor events where traditional glassware may pose risks. Businesses should focus on sourcing durable cups that can withstand varying temperatures and consider branding options to enhance visibility during events.

How Do Retailers Benefit from Custom-Branded Plastic Cups?

Retail and convenience stores utilize custom-branded plastic cups to serve on-the-go beverages, enhancing brand visibility and customer loyalty. These cups are lightweight and budget-friendly, making them ideal for high-volume sales environments. When sourcing, retailers should consider custom printing capabilities, a range of sizes, and the availability of eco-friendly materials to attract environmentally-conscious consumers.

Why Are Plastic Cups Important in Healthcare Settings?

Plastic cups find critical applications in healthcare, particularly for serving medications and drinks to patients. The focus here is on hygiene and safety, as single-use cups help prevent cross-contamination and maintain cleanliness. Buyers in this sector must ensure that the cups comply with healthcare regulations and are made from safe materials, while also considering ease of disposal to streamline operations.

How Do Educational Institutions Use Disposable Cups?

Educational institutions, such as schools and universities, often rely on disposable plastic cups for cafeterias and large gatherings. These cups offer convenience and sanitation, allowing for quick service to large groups of students. When sourcing, educational buyers should look for bulk purchasing options, a variety of sizes to suit different beverages, and affordability to manage tight budgets effectively.

3 Common User Pain Points for ‘Plastic Cup Manufacturers’ & Their Solutions

Scenario 1: Challenges with Sustainable Sourcing of Eco-Friendly Cups

The Problem:

As global awareness of environmental issues rises, B2B buyers are under increasing pressure to source sustainable products. For plastic cup manufacturers, this means offering eco-friendly options such as compostable or recyclable cups. However, many buyers, particularly from regions like Africa and South America, struggle to find reliable suppliers who can guarantee the sustainability credentials of their products. This often leads to confusion over certifications, product quality, and compliance with local regulations regarding waste management.

The Solution:

To effectively navigate this challenge, buyers should prioritize manufacturers who provide comprehensive documentation and certifications for their eco-friendly products. When sourcing plastic cups, look for suppliers that can demonstrate third-party certifications for compostability or recyclability, such as ASTM D6400 or EN 13432. Additionally, establishing clear communication with potential manufacturers about sourcing materials—like PLA from corn starch or sugarcane fiber—can help ensure that they meet your sustainability goals. Buyers should also consider engaging with suppliers who have a proven track record in environmentally conscious practices, as this will not only enhance brand reputation but also align with the increasing demand for sustainable options in the marketplace.

Scenario 2: Inconsistent Quality Across Product Lines

The Problem:

Quality assurance is a significant concern for B2B buyers when purchasing plastic cups, especially when dealing with large quantities. Fluctuations in product quality can lead to customer dissatisfaction and damage to brand reputation. For instance, a coffee shop in Saudi Arabia may find that the cups they ordered from a manufacturer are not consistently able to withstand hot beverages, resulting in leaks and spills. This inconsistency can arise from varying manufacturing processes or materials used, making it crucial for buyers to ensure that they are getting reliable products.

The Solution:

To mitigate this risk, B2B buyers should conduct thorough due diligence before finalizing orders. Request samples from manufacturers to assess the quality and suitability of the cups for specific applications. Establishing a robust quality assurance process is also essential; consider implementing a regular review of supplier performance based on product quality, delivery timelines, and responsiveness. Additionally, utilizing manufacturers that offer a warranty or guarantee on their products can provide peace of mind. Collaborating with suppliers who have established quality control measures, such as ISO certification, will also help ensure consistent product standards across all orders.

Scenario 3: Navigating Import Regulations and Customs Issues

The Problem:

For international buyers, especially those in Europe and the Middle East, navigating the complexities of import regulations can be a daunting task. Each country has its own set of customs requirements and tariffs for importing plastic products, which can delay shipments and increase costs. A buyer in Nigeria may find that a shipment of plastic cups is held up at customs due to missing documentation or unexpected tariffs, leading to operational disruptions and financial losses.

The Solution:

To avoid these pitfalls, B2B buyers should proactively educate themselves about the import regulations specific to their region and the products they intend to purchase. This includes understanding tariff codes, required documentation, and any potential restrictions on plastic imports. Working closely with a logistics partner who specializes in international shipping can streamline the process and provide insights into customs requirements. Additionally, building strong relationships with manufacturers can facilitate smoother communication regarding shipping logistics and documentation. Ensure that your suppliers are aware of the necessary paperwork and can provide it in a timely manner to avoid customs delays. Regularly reviewing and updating your knowledge of import regulations will also help you stay compliant and minimize disruptions in your supply chain.

Strategic Material Selection Guide for Plastic Cup Manufacturers

When selecting materials for plastic cup manufacturing, understanding the properties, advantages, and limitations of each material is crucial for B2B buyers. This guide analyzes four common materials used in the production of plastic cups: Polyethylene Terephthalate (PET), Polypropylene (PP), Polylactic Acid (PLA), and High-Impact Polystyrene (HIPS). Each of these materials offers unique characteristics that can influence the performance and suitability of the final product.

What Are the Key Properties of PET for Plastic Cups?

Polyethylene Terephthalate (PET) is widely recognized for its clarity and strength. It has a temperature tolerance of up to 60°C (140°F), making it suitable for cold beverages. PET is also resistant to impact and has excellent barrier properties, which helps preserve the quality of the contents.

Pros and Cons of PET: The main advantages of PET include its recyclability and lightweight nature, which reduces shipping costs. However, its lower temperature resistance limits its use for hot beverages, and it can be more expensive than other materials like PP.

Impact on Application: PET is ideal for cold drink applications, such as soft drinks and juices, where clarity and freshness are important. However, manufacturers must ensure compliance with local recycling regulations, especially in regions like Europe, where sustainability is a priority.

How Does Polypropylene (PP) Compare for Plastic Cup Manufacturing?

Polypropylene (PP) is another popular choice for plastic cups, known for its high melting point of around 100°C (212°F), making it suitable for hot beverages. PP is also resistant to chemical corrosion, which enhances its durability in various applications.

Pros and Cons of PP: The key advantage of PP is its versatility and ability to withstand higher temperatures, making it suitable for both hot and cold drinks. However, it is less transparent than PET, which may affect consumer perception. Additionally, while PP is recyclable, the recycling infrastructure may not be as robust in certain regions.

Impact on Application: PP cups are commonly used in coffee shops and takeaway restaurants. B2B buyers should consider local recycling capabilities and regulations, particularly in regions like Africa and the Middle East, where waste management practices may vary significantly.

What Are the Benefits of Using Polylactic Acid (PLA) in Plastic Cups?

Polylactic Acid (PLA) is a biodegradable alternative made from renewable resources like corn starch. It offers a temperature tolerance of up to 50°C (122°F) and is suitable for cold beverages.

Pros and Cons of PLA: The primary advantage of PLA is its eco-friendliness, appealing to businesses aiming for sustainable practices. However, its lower heat resistance limits its applications, and it may require specific composting conditions to break down effectively.

Impact on Application: PLA is increasingly popular among environmentally conscious brands in Europe and South America. Buyers should ensure that local composting facilities can handle PLA products, as this is not universally available.

What Role Does High-Impact Polystyrene (HIPS) Play in Plastic Cup Manufacturing?

High-Impact Polystyrene (HIPS) is known for its rigidity and impact resistance. It can withstand temperatures up to 70°C (158°F), making it suitable for a range of applications, including both hot and cold beverages.

Pros and Cons of HIPS: HIPS cups are durable and provide a good barrier against moisture. However, they are not as recyclable as PET or PP, which may be a concern for environmentally conscious buyers. The cost of HIPS is generally moderate, but its environmental impact may deter some buyers.

Impact on Application: HIPS is often used in food service settings where durability is essential. Buyers should consider the environmental regulations in their region, particularly in Europe, where there is a strong push for sustainable materials.

| Material | Typical Use Case for Plastic Cup Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET | Cold beverages like soft drinks and juices | Excellent clarity and recyclability | Limited heat resistance | Medium |

| PP | Hot and cold beverages in cafes and restaurants | High temperature tolerance | Less transparency than PET | Medium |

| PLA | Eco-friendly cups for cold beverages | Biodegradable and made from renewable resources | Lower heat resistance and composting requirements | High |

| HIPS | Durable cups for food service | Good impact resistance | Not easily recyclable | Medium |

This strategic material selection guide provides insights for B2B buyers in diverse markets, helping them make informed decisions based on the unique properties and applications of each material. Understanding these factors will enable manufacturers to align their product offerings with market demands and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Plastic Cup Manufacturers

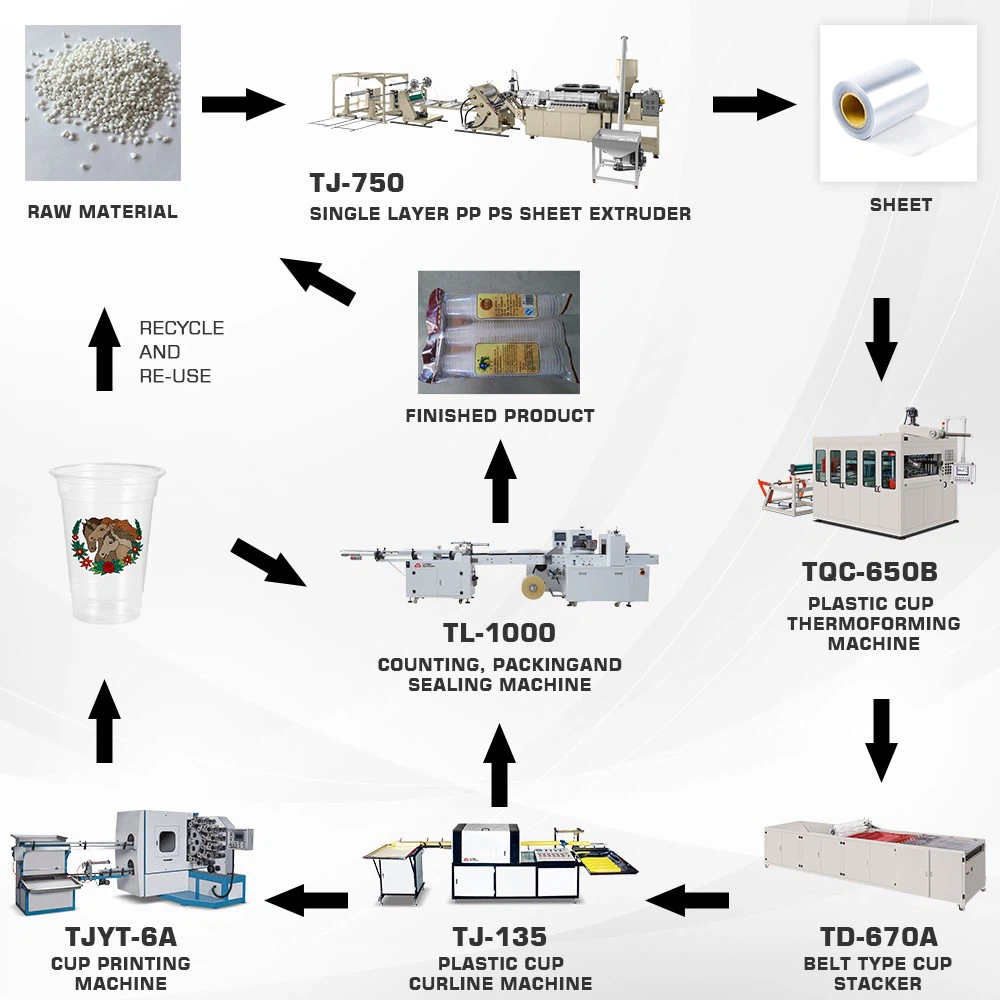

What Are the Key Stages in the Manufacturing Process of Plastic Cups?

The manufacturing of plastic cups involves several critical stages that ensure both efficiency and quality. Understanding these stages helps B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Raw Materials Are Used?

The first step in the production of plastic cups is the preparation of raw materials. Commonly used materials include Polyethylene Terephthalate (PET) and Polypropylene (PP). These plastics are chosen for their durability, food safety, and recyclability. The raw materials are often delivered in pellet form, which are then dried and pre-conditioned to remove moisture, ensuring optimal processing conditions.

2. Forming: How Are Plastic Cups Shaped?

The forming stage can involve several techniques, with the most common being injection molding and blow molding.

-

Injection Molding: This process involves injecting molten plastic into a mold, allowing it to cool and solidify into the desired shape. This method is particularly effective for creating cups with complex designs and features.

-

Blow Molding: In this process, a tube of molten plastic is inflated within a mold to form the cup shape. Blow molding is typically used for producing hollow items like disposable cups, as it allows for faster production rates and lower material costs.

These techniques are essential for achieving consistent wall thickness and structural integrity in the final product.

3. Assembly: What Happens After Forming?

Once the cups are formed, they may go through additional assembly steps, especially when lids or sleeves are involved. Automated systems often handle the attachment of lids to cups, ensuring a secure fit that meets consumer expectations. This stage may also include the printing of branding or product information on the cups, which is crucial for marketing purposes.

4. Finishing: How Are Plastic Cups Prepared for Distribution?

The finishing process encompasses several activities aimed at preparing the cups for packaging and distribution. This can include quality checks, surface treatments, and packaging. Surface treatments may enhance the cup’s durability or aesthetic appeal, while quality checks ensure that each cup meets industry standards.

What Quality Control Measures Are Essential for Plastic Cup Manufacturers?

Quality control (QC) is vital in the plastic cup manufacturing process to ensure product safety and compliance with international standards.

Relevant International Standards: Which Certifications Should Buyers Look For?

Plastic cup manufacturers often comply with several international quality standards, including:

-

ISO 9001: This standard emphasizes a quality management system that can enhance customer satisfaction through effective processes.

-

CE Marking: Particularly relevant in Europe, this certification indicates that products meet EU safety, health, and environmental protection standards.

-

API Standards: For manufacturers producing cups for specific industries, adherence to American Petroleum Institute (API) standards may be required.

These certifications not only ensure compliance but also enhance the manufacturer’s credibility in the global market.

What Are the Key Quality Control Checkpoints?

Quality control in plastic cup manufacturing typically involves multiple checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct inspections to monitor production parameters and product quality.

-

Final Quality Control (FQC): After production, a comprehensive inspection is conducted to ensure that the finished cups meet all design and quality specifications.

These checkpoints are crucial for identifying and rectifying any defects early in the process.

Common Testing Methods: How Are Plastic Cups Tested for Quality?

Plastic cups undergo various tests to verify their safety and performance. Common testing methods include:

-

Mechanical Testing: This assesses the strength and durability of the cups under various conditions.

-

Chemical Testing: Ensures that the materials used do not leach harmful substances into food or beverages.

-

Environmental Testing: Evaluates how the cups perform under different environmental conditions, such as temperature fluctuations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence to verify that suppliers adhere to quality control standards. Here are effective strategies:

Conducting Audits: What Should Buyers Look For?

Buyers should request audits of the manufacturing facility. An effective audit should cover:

- Compliance with international quality standards.

- Documentation of quality control processes.

- Evidence of regular training for staff on quality assurance practices.

Reviewing Quality Control Reports: What Information Is Essential?

Buyers can request quality control reports from suppliers. These reports should detail:

- Results from various testing methods.

- Records of any non-conformances and corrective actions taken.

- Continuous improvement initiatives related to quality.

Utilizing Third-Party Inspections: How Can Buyers Ensure Objectivity?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These inspections can be particularly beneficial for international buyers who may not have the capacity to conduct on-site audits.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulations regarding food safety and environmental standards. Buyers must ensure that suppliers comply with local regulations in their respective markets.

-

Cultural Differences: Understanding cultural attitudes towards quality and safety can help buyers navigate supplier relationships more effectively.

By carefully evaluating the manufacturing processes and quality control measures, B2B buyers can ensure they partner with reliable plastic cup manufacturers that meet their needs for quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Plastic Cup Manufacturers’

Introduction

Navigating the procurement of plastic cups from manufacturers can be a complex process, especially for international B2B buyers. This step-by-step checklist is designed to streamline your sourcing efforts, ensuring you make informed decisions while aligning with your specific business needs and sustainability goals.

1. Identify Your Requirements

Before you start searching for suppliers, clearly define what types of plastic cups you need. Consider factors such as:

– Material: Options like PET, PP, or compostable materials.

– Size and volume: Determine the specific sizes and capacities you require.

– Usage: Understand if the cups are for hot or cold beverages, or both.

2. Research Potential Suppliers

Conduct thorough research to identify potential manufacturers. Utilize online platforms and industry directories to compile a list of suppliers. Key aspects to focus on include:

– Reputation: Look for reviews and testimonials from other buyers.

– Product range: Ensure they offer a variety of cup types that meet your specifications.

3. Verify Supplier Certifications

It’s critical to ensure that potential suppliers comply with relevant safety and quality standards. Verify certifications such as:

– ISO certifications: Indicate adherence to international quality standards.

– Food safety compliance: Essential for products intended for food and beverage use.

4. Request Samples

Before making a bulk order, request product samples to evaluate quality firsthand. This step allows you to:

– Assess durability: Check if the cups meet your functional requirements.

– Evaluate design: Ensure the aesthetic aligns with your brand image.

5. Compare Pricing and Terms

Once you have a shortlist of potential suppliers, compare their pricing structures and payment terms. Be mindful of:

– Bulk discounts: Many manufacturers offer lower prices for larger orders.

– Shipping costs: Factor in these costs to get a true sense of overall pricing.

6. Engage in Negotiations

Don’t hesitate to negotiate terms with your selected suppliers. Key points to discuss include:

– Minimum order quantities: Find out if they can accommodate your order size.

– Lead times: Ensure they can meet your delivery schedules.

7. Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Set up a plan that includes:

– Regular updates: Request progress reports on your order.

– Point of contact: Designate a representative from both your side and the supplier’s side for smooth communication.

By following this checklist, you can enhance your sourcing strategy, ensuring that you select the right plastic cup manufacturers that align with your operational needs and sustainability goals.

Comprehensive Cost and Pricing Analysis for Plastic Cup Manufacturers Sourcing

What Are the Key Cost Components in Sourcing Plastic Cups from Manufacturers?

When sourcing plastic cups, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials like PET (Polyethylene Terephthalate) and PP (Polypropylene) are popular for their recyclability and food safety. Eco-friendly options, such as PLA (Polylactic Acid) and sugarcane fiber, may have higher initial costs but can appeal to environmentally-conscious consumers.

-

Labor: Labor costs vary by region and manufacturing process. Automated production can reduce costs, but manual assembly may be necessary for custom designs, impacting the overall labor expenditure.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Manufacturers with streamlined operations may offer more competitive pricing.

-

Tooling: Custom molds for unique cup designs can be a significant upfront cost. However, if a buyer commits to large volumes, manufacturers often amortize these costs over the production run, reducing per-unit prices.

-

Quality Control (QC): Ensuring product quality is essential and can add to costs. Manufacturers with robust QC processes may charge more, but this investment can prevent costly defects and returns.

-

Logistics: Shipping costs depend on the location of the manufacturer, delivery speed, and the chosen shipping method. International buyers must consider customs duties and import taxes, which can add to total expenses.

-

Margin: Manufacturers typically add a profit margin to their costs. This margin can vary based on market competition and the perceived value of the product.

How Do Price Influencers Affect the Cost of Plastic Cups?

Several factors influence pricing in the plastic cup market:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing due to economies of scale. Negotiating MOQs can be beneficial for both parties.

-

Specifications and Customization: Custom designs, colors, or features can increase costs. Buyers should assess whether the added value justifies the higher price.

-

Materials Quality and Certifications: Cups that meet specific safety standards or certifications may command higher prices. Buyers should consider the implications of these certifications for their market.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers with a history of quality may charge more, but they can also offer assurance in terms of product reliability.

-

Incoterms: Understanding the delivery terms (Incoterms) is vital. Different terms (e.g., FOB, CIF) can affect the total cost, including who bears the risk and responsibility during transit.

What Tips Can Help Buyers Negotiate Better Prices for Plastic Cups?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes:

-

Conduct a Total Cost of Ownership Analysis: Go beyond upfront costs. Consider long-term expenses such as shipping, storage, and waste management when evaluating suppliers.

-

Leverage Volume Discounts: If possible, consolidate orders across multiple products or locations to meet higher MOQ thresholds for better pricing.

-

Negotiate Terms: Don’t hesitate to discuss payment terms, delivery schedules, and price adjustments based on market fluctuations.

-

Stay Informed About Market Trends: Understanding market dynamics can provide leverage in negotiations. For example, if a particular material is experiencing a price drop, use this information to negotiate.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms over time. Suppliers may be more willing to negotiate with trusted partners.

What Should Buyers Consider Regarding Pricing Nuances in International Markets?

International buyers should be aware of several nuances:

-

Currency Fluctuations: Prices may vary with exchange rates, so consider locking in rates when negotiating.

-

Regulatory Differences: Ensure compliance with local regulations, as these can impact pricing and sourcing strategies.

-

Cultural Factors: Understanding local business practices and negotiation styles can facilitate smoother transactions.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on current market conditions, supplier agreements, and specific buyer requirements. Always conduct thorough research and due diligence before finalizing any purchase agreements.

Alternatives Analysis: Comparing Plastic Cup Manufacturers With Other Solutions

Understanding Alternatives to Plastic Cup Manufacturing

In the competitive landscape of beverage service, businesses often face the decision of selecting the most suitable cup solution. While plastic cups are prevalent due to their convenience and low cost, alternatives are emerging that cater to environmental concerns and specific use cases. This analysis will compare plastic cup manufacturers with two viable alternatives: compostable cups and reusable cup systems.

Comparison Table

| Comparison Aspect | Plastic Cup Manufacturers | Compostable Cups | Reusable Cup Systems |

|---|---|---|---|

| Performance | Lightweight, durable, and food-safe | Strong and durable but may require specific disposal facilities | Highly durable, designed for multiple uses |

| Cost | Generally low cost per unit | Higher initial cost, but potentially lower long-term costs | Higher upfront investment, savings over time |

| Ease of Implementation | Easy to source and implement in operations | May require education on disposal methods | Requires infrastructure for cleaning and storage |

| Maintenance | Low maintenance, single-use | Minimal maintenance; proper composting is essential | Requires regular cleaning and maintenance |

| Best Use Case | High-volume, single-use applications | Eco-conscious businesses and events | Cafés and restaurants focused on sustainability |

Detailed Breakdown of Alternatives

Compostable Cups

Compostable cups are made from renewable resources like cornstarch or sugarcane fiber. They provide a sustainable alternative to traditional plastic, appealing to businesses looking to enhance their environmental responsibility. However, their effectiveness relies on the availability of commercial composting facilities, which may not be accessible in all regions. Additionally, while the upfront cost is typically higher than plastic cups, companies can save on waste disposal fees over time, making them a potentially cost-effective solution for eco-friendly brands.

Reusable Cup Systems

Reusable cup systems involve the use of durable cups that can be cleaned and reused multiple times. This method significantly reduces waste and can lead to substantial cost savings for businesses that experience high beverage turnover. However, implementing a reusable system requires investment in cleaning infrastructure and may involve initial training for staff and customers. This solution is ideal for cafés, restaurants, or events that emphasize sustainability and aim to minimize their environmental footprint.

Conclusion: Choosing the Right Solution for Your Business Needs

B2B buyers must evaluate their specific operational requirements, customer preferences, and environmental commitments when selecting a cup solution. Plastic cups offer a practical and cost-effective option for high-volume scenarios, while compostable cups present a compelling choice for brands looking to align with sustainable practices. Meanwhile, reusable systems may provide the best long-term benefits for establishments focused on reducing waste. By understanding the strengths and limitations of each option, businesses can make informed decisions that support their goals and resonate with their target audience.

Essential Technical Properties and Trade Terminology for Plastic Cup Manufacturers

What Are the Key Technical Properties of Plastic Cups for Manufacturers?

When considering plastic cups for manufacturing, understanding critical technical properties is essential for ensuring product quality, performance, and compliance with industry standards. Here are some of the most significant specifications:

-

Material Grade

– Definition: The classification of plastic material based on its chemical composition and physical properties. Common materials include Polyethylene Terephthalate (PET), Polypropylene (PP), and Polylactic Acid (PLA).

– Importance: The choice of material affects the cup’s durability, transparency, recyclability, and suitability for hot or cold beverages. For instance, PET is favored for its clarity and strength, while PLA is chosen for its compostability, appealing to eco-conscious consumers. -

Tolerance

– Definition: The permissible limit of variation in a physical dimension of the cup, usually expressed in millimeters or inches.

– Importance: Tolerances are crucial in maintaining the integrity of the product during production and end-use. Accurate tolerances ensure that lids fit securely, preventing leaks and spills, which can enhance customer satisfaction and reduce waste. -

Capacity

– Definition: The volume of liquid a cup can hold, typically measured in ounces or milliliters.

– Importance: Offering various capacities allows manufacturers to cater to different market needs, from small portion cups for sauces to larger cups for beverages. Understanding market demand for specific sizes can drive sales and optimize inventory. -

Heat Resistance

– Definition: The ability of a cup to withstand high temperatures without deforming or compromising its structural integrity.

– Importance: For cups intended for hot beverages, high heat resistance is crucial. This property ensures safety and functionality, preventing the cup from melting or warping when filled with hot liquids. -

Barrier Properties

– Definition: The effectiveness of a material in preventing the passage of gases, moisture, and flavors.

– Importance: Cups with excellent barrier properties help maintain the quality of beverages by preventing contamination and extending shelf life. This is particularly important in markets where product freshness is critical. -

Compostability

– Definition: The ability of a material to decompose into natural substances under composting conditions.

– Importance: With increasing environmental awareness, manufacturers must consider compostability as a vital property. Cups made from compostable materials like PLA offer an eco-friendly alternative and can enhance brand reputation among environmentally conscious consumers.

What Are Common Trade Terms Used in the Plastic Cup Manufacturing Industry?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: In the context of plastic cups, OEMs often provide custom solutions tailored to specific client needs, allowing businesses to offer unique products without investing in manufacturing infrastructure. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ helps buyers gauge the feasibility of purchasing from a supplier, especially for startups or small businesses that may not need large quantities. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to invite suppliers to submit price proposals for specific products or services.

– Relevance: Submitting an RFQ is a standard practice in procurement, helping buyers compare costs and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce that delineate the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is crucial for international trade, as they clarify shipping responsibilities, risk management, and cost allocations, thereby preventing misunderstandings. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Relevance: Knowing the lead time is essential for planning inventory and meeting customer demand, particularly in markets with tight delivery schedules. -

Custom Printing

– Definition: The process of printing designs or branding on cups.

– Relevance: Custom printing allows manufacturers to differentiate their products and strengthen brand identity, a significant factor in competitive markets.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market strategies.

Navigating Market Dynamics and Sourcing Trends in the Plastic Cup Manufacturers Sector

What Are the Current Market Dynamics and Key Trends for Plastic Cup Manufacturers?

The global plastic cup manufacturing sector is witnessing significant shifts influenced by a combination of sustainability demands, technological advancements, and evolving consumer preferences. Key drivers include increased environmental awareness, which has prompted manufacturers to innovate with eco-friendly materials such as PLA (polylactic acid) and sugarcane fiber. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly seeking suppliers who can provide products that align with sustainability goals while also being budget-friendly.

Emerging B2B technology trends, including automated manufacturing processes and AI-driven supply chain management, are enhancing operational efficiency and reducing costs. These innovations enable manufacturers to respond quickly to market demands and customize products for niche markets, such as branded or event-specific cups. Furthermore, the rise of e-commerce platforms has simplified sourcing for international buyers, allowing them to compare products, prices, and suppliers more effectively.

Market dynamics are also influenced by regulatory changes aimed at reducing plastic waste, particularly in Europe, where stringent packaging directives are in place. Buyers in regions like Nigeria and Saudi Arabia are encouraged to stay abreast of these regulations as they can impact sourcing decisions and supplier relationships.

How Important Is Sustainability and Ethical Sourcing in the Plastic Cup Manufacturing Sector?

Sustainability and ethical sourcing have become paramount in the plastic cup manufacturing industry, with environmental impacts being a significant concern for businesses and consumers alike. The production and disposal of plastic cups contribute to pollution and waste, leading many companies to adopt sustainable practices. This includes utilizing biodegradable materials and implementing recycling programs to minimize their carbon footprint.

For B2B buyers, understanding the importance of ethical supply chains is critical. Suppliers that prioritize sustainability often hold certifications such as FSC (Forest Stewardship Council) or BPI (Biodegradable Products Institute), ensuring that their products meet rigorous environmental standards. These certifications not only enhance a brand’s reputation but also appeal to a growing base of environmentally-conscious consumers.

Moreover, the demand for compostable cups is rising, particularly in food service and catering businesses. As commercial composting facilities become more accessible, the availability of compostable cups will likely expand, allowing manufacturers to meet the needs of environmentally aware clients. Buyers should actively seek suppliers who are transparent about their sourcing practices and material usage to ensure alignment with their own sustainability goals.

What Is the Historical Context of Plastic Cup Manufacturing and Its Evolution?

The history of plastic cup manufacturing dates back to the mid-20th century, with the introduction of materials like polystyrene and polyethylene. Initially, plastic cups were favored for their convenience and low cost, quickly becoming staples in food service, catering, and events. Over the decades, the industry evolved with the introduction of new materials such as PET and PP, which offered improved safety and recyclability.

In recent years, the focus has shifted towards sustainability, driven by both regulatory pressures and consumer demand for environmentally friendly products. The evolution of technology has also played a crucial role, enabling manufacturers to create innovative designs and enhance the functionality of plastic cups. As the industry continues to adapt, B2B buyers must remain informed about these historical trends to better understand the current market landscape and make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of Plastic Cup Manufacturers

-

How do I choose the right plastic cup manufacturer for my business needs?

Selecting the right plastic cup manufacturer involves evaluating several key factors. First, assess the manufacturer’s range of products to ensure they offer the specific types of cups you require, such as biodegradable options or custom branding. Review their certifications and compliance with international standards, especially if you’re sourcing from regions with strict regulations. Finally, consider their production capacity, lead times, and customer service reputation, as these elements can significantly impact your supply chain efficiency. -

What are the benefits of using biodegradable plastic cups?

Biodegradable plastic cups are increasingly popular due to their environmental benefits. Made from renewable resources like PLA (polylactic acid) or sugarcane, these cups decompose more quickly than traditional plastic, reducing landfill waste. They also appeal to eco-conscious consumers, enhancing your brand’s reputation. Additionally, many manufacturers offer biodegradable options at competitive prices, making it easier to integrate sustainability into your business model without compromising on quality or cost. -

What is the minimum order quantity (MOQ) for plastic cups from manufacturers?

Minimum order quantities (MOQs) vary by manufacturer and depend on factors such as material, customization, and production capabilities. Typically, MOQs can range from a few hundred to several thousand units. When negotiating, consider your storage capacity and cash flow. Some manufacturers may offer flexibility on MOQs for new clients or bulk orders, so it’s advisable to communicate your specific needs and explore potential arrangements. -

How can I ensure quality assurance (QA) when sourcing plastic cups internationally?

To ensure quality assurance when sourcing plastic cups, conduct thorough supplier vetting. Request product samples to assess material quality and production standards. Verify that the manufacturer adheres to relevant quality certifications such as ISO 9001. Additionally, consider conducting factory audits or third-party inspections, especially for larger orders, to ensure compliance with your specifications and international standards. -

What payment terms should I expect when dealing with plastic cup manufacturers?

Payment terms can vary widely among plastic cup manufacturers, but common practices include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. For larger orders, some manufacturers may offer credit terms or extended payment plans. Always clarify payment methods accepted (e.g., bank transfer, letters of credit) and ensure that terms are documented in your contract to prevent misunderstandings. -

What shipping options are available for importing plastic cups?

When importing plastic cups, various shipping options are available, including air freight for faster delivery and ocean freight for cost-effectiveness on larger shipments. Consider factors such as delivery time, budget, and the fragility of the products. Additionally, inquire about the manufacturer’s experience with logistics, as they may have established partnerships with shipping companies that can streamline the import process and reduce costs. -

How can I customize plastic cups for my brand?

Customization options for plastic cups typically include printing your logo, selecting colors, and choosing specific sizes or shapes. Most manufacturers offer a range of printing techniques, such as screen printing or digital printing, to achieve the desired effect. To initiate the customization process, provide the manufacturer with your design specifications and discuss any minimum order requirements, as custom products may have higher MOQs. -

What should I consider regarding regulations when importing plastic cups?

When importing plastic cups, it’s crucial to understand the regulations and compliance standards in your destination country. Each region may have specific guidelines regarding materials used, food safety, and environmental impact. Research the relevant regulations, such as FDA or EU standards, and verify that your chosen manufacturer complies with these requirements. Additionally, ensure that all necessary documentation, such as safety data sheets and certificates of compliance, accompanies your shipment to avoid delays at customs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Plastic Cup Manufacturers

In today’s dynamic market, strategic sourcing has become a vital component for plastic cup manufacturers looking to thrive in the competitive landscape. As sustainability gains traction, options such as compostable and recyclable materials are not just trends but essential offerings that align with global environmental goals. Buyers are encouraged to consider suppliers that provide eco-friendly alternatives, as these products can enhance brand reputation and appeal to environmentally conscious consumers.

Furthermore, the diversity in materials—from PET and PP to innovative bioplastics—enables businesses to cater to various consumer preferences while ensuring food safety and compliance with international standards. By leveraging strategic partnerships with manufacturers, international buyers can access a wide range of customizable options, enhancing their product lines and market reach.

As we move forward, it is imperative for B2B buyers from regions such as Africa, South America, the Middle East, and Europe to actively seek suppliers that prioritize innovation, quality, and sustainability. Engage with manufacturers that can support your unique needs and help you stay ahead in this evolving industry. The future of disposable tableware is not just about convenience but also about responsibility and adaptability.