Top 6 Chair Manufacturers List and Guide: How To Solve Scenario 1…

Introduction: Navigating the Global Market for Chair Manufacturers

In today’s competitive landscape, sourcing high-quality chairs that cater to diverse needs—such as comfortable desk chairs for back pain relief—poses a significant challenge for international B2B buyers. The global market for chair manufacturers is vast and varied, with options ranging from ergonomic office seating to stylish residential designs. This comprehensive guide aims to navigate this complex landscape, providing insights into the types of chairs available, their applications across different sectors, and strategies for effective supplier vetting.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of chair procurement is crucial for making informed purchasing decisions. This guide empowers buyers by detailing cost considerations, identifying reputable manufacturers, and exploring innovative designs that meet specific market demands. Additionally, we highlight the importance of quality assurance, customization options, and sustainability practices—essential factors for today’s conscientious consumers.

By equipping buyers with actionable insights and a thorough understanding of the chair manufacturing landscape, this guide serves as a vital resource. It not only facilitates smarter sourcing strategies but also fosters partnerships with manufacturers that align with your business values and objectives, ensuring that you secure the best products for your needs.

Top 10 Chair Manufacturers Manufacturers & Suppliers List

1. Herman Miller – Modern Furniture Solutions

Domain: hermanmiller.com

Registered: 1996 (29 years)

Introduction: Herman Miller offers a wide range of modern furniture for both office and home environments. Key product categories include:

– **Seating**: Office Chairs, Side Chairs, Stacking Chairs, Nesting Chairs, ESD Seating, Stools, Lounge Seating, Benches.

– **Desks and Workspaces**: Workstations, Private Office setups, Collaborative Furniture, Sit-Stand options, and various types of desks.

– **Tables**: M…

2. Ashley Furniture – Diverse Home Furniture

Domain: keekea.com

Registered: 2021 (4 years)

Introduction: 1. Ashley Furniture Industries: Kitchen, dining, bedroom, and living room furniture; MOQ: 100; 800+ stores in North America. 2. Steelcase: Specializes in office furniture. 3. Bernhardt: Elegant chairs for offices and residential projects; sophisticated designs. 4. Herman Miller: Tables, chairs, storage furniture for office and residential; innovative and user-friendly. 5. Hooker Furniture: Stylish…

3. Hickory Chair – Key Furniture Collections

Domain: hickorychair.com

Registered: 1996 (29 years)

Introduction: Jules Swivel Chair (HC9509-SW), Laurent Dining Chair (HC1650-01), Laurent Counter Stool (HC1650-03), Kent M2m (HC123-51), Jupiter Swivel Chair (HC3423-27), Hervé Dresser (HC1572-70), Tuxedo Tall Cabinet (HC1569-70), Peony Console Table (HC7777-70), Candler King Bed (HC1555-10), Bess Dresser (HC5267-70), Haret Outdoor Chaise – Cloud White (HCD8900-37-W), Haret Outdoor Dining Chair – Cloud White (HC…

4. Sherrill Furniture – High-Quality American-Made Sofas and More

Domain: sherrillfurniture.com

Registered: 1997 (28 years)

Introduction: Sherrill Furniture is a USA manufacturer known for high-quality American-made furniture. They offer a variety of products including sofas, loveseats, chairs, sectionals, benches, and ottomans. Key product lines include the 9600/9700 Design Your Own series, the Truman Collection, and various design choices across multiple series. The furniture is customizable with options for fabrics, wood finishes…

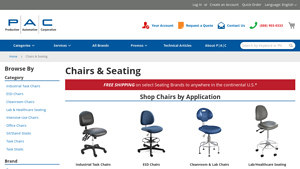

5. GoToPac – Task Chairs

Domain: gotopac.com

Registered: 2001 (24 years)

Introduction: Your Seating Experts | Task Chairs for Manufacturing, Cleanrooms, & More

6. Lee Industries – Home Furnishings

Domain: leeindustries.com

Registered: 1997 (28 years)

Introduction: Lee Industries offers a wide range of home furnishings including sofas, loveseats, sectionals, chairs (including swivel and glider chairs), desk chairs, relaxors, sleepers (traditional and trundle), ottomans, benches, chaises, beds, outdoor dining sets, and bar & counter stools. They also provide a variety of fabrics and leathers, including outdoor options and performance fabrics that are stain an…

Understanding Chair Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Office Chair Manufacturers | Ergonomic designs, adjustable features, and durable materials | Corporate offices, co-working spaces | Pros: Enhances productivity; Cons: Higher initial investment. |

| Residential Furniture Manufacturers | Diverse styles (traditional, modern), customizable options | Homes, hotels, and boutique accommodations | Pros: Aesthetic appeal; Cons: Longer lead times for customization. |

| Specialty Chair Manufacturers | Unique designs for specific needs (e.g., healthcare, gaming) | Healthcare facilities, gaming lounges | Pros: Tailored solutions; Cons: Limited availability in standard styles. |

| Outdoor Furniture Manufacturers | Weather-resistant materials, lightweight designs | Resorts, outdoor cafes, and gardens | Pros: Durability against elements; Cons: May require seasonal storage. |

| Custom Furniture Manufacturers | Bespoke designs, personalized features, and materials | High-end residential and commercial projects | Pros: Unique solutions; Cons: Higher costs and longer production times. |

What are the characteristics of Office Chair Manufacturers?

Office chair manufacturers focus on ergonomic designs that promote comfort and productivity in workplace settings. These chairs often feature adjustable components such as height, lumbar support, and armrests to accommodate various body types and preferences. B2B buyers should consider factors such as durability and warranty, as these chairs are typically used for extended periods. Investing in high-quality office chairs can lead to improved employee satisfaction and reduced health-related absences.

How do Residential Furniture Manufacturers differ in the market?

Residential furniture manufacturers offer a wide range of styles, from contemporary to traditional, appealing to various aesthetic preferences. They often provide customizable options, allowing B2B buyers in hospitality and retail sectors to select finishes and fabrics that align with their brand identity. When sourcing residential furniture, businesses should consider lead times for customization and the potential for bulk purchasing discounts, which can enhance profitability.

What makes Specialty Chair Manufacturers essential for specific industries?

Specialty chair manufacturers create unique seating solutions tailored to specific industries, such as healthcare or gaming. Their products are designed to meet the distinct needs of these sectors, offering features like easy-to-clean surfaces for medical environments or ergonomic designs for long gaming sessions. B2B buyers should assess the specific requirements of their industry, as well as compliance with any relevant regulations, to ensure they select the most appropriate seating solutions.

Why choose Outdoor Furniture Manufacturers for commercial spaces?

Outdoor furniture manufacturers produce chairs designed to withstand the elements, utilizing weather-resistant materials and lightweight designs for easy mobility. These products are ideal for commercial applications such as resorts, outdoor cafes, and public parks. Buyers should evaluate the durability of materials and maintenance requirements, as well as seasonal storage solutions, to ensure the longevity and aesthetic appeal of outdoor seating options.

How can Custom Furniture Manufacturers provide unique solutions?

Custom furniture manufacturers excel in creating bespoke designs that cater to the specific needs and preferences of B2B clients. This includes personalized features and the use of unique materials, making them a popular choice for high-end residential and commercial projects. While the costs and production times may be higher than standard options, the resulting uniqueness can significantly enhance a brand’s image and customer experience, making it a worthwhile investment for discerning buyers.

Key Industrial Applications of Chair Manufacturers

| Industry/Sector | Specific Application of Chair Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Office Furniture | Ergonomic office seating for corporate environments | Enhances employee productivity and comfort, reducing fatigue. | Assess ergonomic certifications, customization options, and bulk pricing. |

| Hospitality | Seating solutions for restaurants and hotels | Improves guest experience and ambiance, driving customer loyalty. | Evaluate durability, style compatibility, and maintenance requirements. |

| Education | Classroom and lecture hall seating | Facilitates learning through comfort and flexibility in seating arrangements. | Consider modular designs, durability, and ease of rearrangement. |

| Healthcare | Patient and visitor seating in clinics and hospitals | Ensures comfort for patients and supports healthcare staff efficiency. | Focus on hygiene, easy-to-clean materials, and compliance with health regulations. |

| Event Management | Chairs for conferences, exhibitions, and banquets | Provides a professional setting that enhances attendee experience. | Look for stackability, transportability, and aesthetic appeal. |

How Are Chair Manufacturers Applied in Office Settings?

In corporate environments, ergonomic office seating plays a crucial role in enhancing employee productivity. Chair manufacturers provide a range of ergonomic options designed to support long hours of sitting, helping to alleviate discomfort and fatigue. For international buyers, especially from regions like Europe and the Middle East, sourcing chairs that meet specific ergonomic certifications can be vital. Additionally, customization options such as adjustable features are essential to accommodate diverse body types and preferences, making it important to consider these factors when sourcing.

What Are the Benefits of Chair Manufacturers for the Hospitality Industry?

For the hospitality sector, chair manufacturers supply seating solutions that significantly impact guest experience. Well-designed chairs in restaurants and hotels not only enhance the ambiance but also encourage customer loyalty through comfort. Buyers from Africa and South America should prioritize durability and style compatibility, ensuring that the chosen furniture withstands high usage while aligning with the brand’s aesthetic. Maintenance requirements also play a critical role, as easy-to-clean materials can reduce operational costs and improve guest satisfaction.

Why Is Classroom Seating Important in Education?

In educational settings, the role of chair manufacturers extends to providing classroom and lecture hall seating that facilitates learning. Comfortable and flexible seating arrangements can significantly enhance the learning experience for students. International buyers, particularly from regions with diverse educational needs, should consider modular designs that allow for easy rearrangement to accommodate different teaching styles. Durability is also a key factor, as educational institutions often require furniture that can withstand heavy use over long periods.

How Do Chair Manufacturers Address Healthcare Needs?

Healthcare settings require specialized seating solutions for both patients and visitors. Chair manufacturers focus on creating comfortable seating that supports both patient recovery and healthcare staff efficiency. For buyers in the Middle East and Europe, sourcing chairs that comply with health regulations and are made from easy-to-clean materials is crucial. Additionally, the focus on hygiene and infection control means that manufacturers must provide options that facilitate cleanliness without compromising comfort.

What Role Do Chair Manufacturers Play in Event Management?

In the event management sector, chair manufacturers provide versatile seating for conferences, exhibitions, and banquets. The ability to source stackable and transportable chairs is critical for organizers looking to maximize space and minimize setup time. Buyers from South America and Africa should prioritize aesthetic appeal alongside functionality, as the right seating can enhance the overall professional atmosphere of an event. Considering the balance between style, comfort, and practicality is essential for successful event planning.

3 Common User Pain Points for ‘Chair Manufacturers’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Chair Manufacturing

The Problem: B2B buyers often face significant hurdles when it comes to ensuring product quality and consistency from chair manufacturers. This challenge is particularly pronounced when sourcing from different regions, where varying manufacturing standards can lead to discrepancies in material quality, craftsmanship, and durability. For example, a buyer may order a bulk shipment of ergonomic office chairs only to discover that a significant portion does not meet the expected comfort standards, resulting in dissatisfaction from end-users and potential returns.

The Solution: To mitigate quality assurance issues, B2B buyers should implement a comprehensive vendor evaluation process. Start by defining clear quality standards and specifications that align with your business needs. When approaching manufacturers, request product samples and conduct thorough inspections to assess craftsmanship and materials firsthand. Additionally, consider establishing quality control checkpoints throughout the production process. This can include regular communication with the manufacturer and site visits if feasible. Leverage technology such as video calls for real-time inspections or third-party quality assurance services to validate compliance with your specifications before shipment. This proactive approach not only helps in maintaining high-quality standards but also fosters a stronger partnership with the manufacturer.

Scenario 2: Managing Lead Times and Delivery Issues

The Problem: Timely delivery of products is crucial for B2B buyers, especially in industries where furniture plays a key role in operational efficiency. Manufacturers often struggle with unpredictable lead times due to supply chain disruptions, production delays, or fluctuating demand. For instance, a buyer may place an order for office chairs to coincide with a new project launch, only to face unexpected delays, which can jeopardize the project timeline and strain client relationships.

The Solution: To address lead time challenges, buyers should establish transparent communication channels with their chair manufacturers. Discuss lead times upfront and inquire about potential risks that could affect delivery schedules. Implementing a Just-In-Time (JIT) inventory system can also be beneficial, allowing you to synchronize orders with your operational needs. Moreover, consider building a diversified supply chain by engaging multiple manufacturers across different regions. This strategy not only mitigates the risk of delays but also gives buyers greater flexibility to adapt to changing market demands. Regularly revisiting and refining agreements with manufacturers can ensure that both parties remain aligned on expectations and delivery timelines.

Scenario 3: Customization Limitations and Design Constraints

The Problem: Many B2B buyers encounter limitations when seeking customized chair designs that meet specific branding or ergonomic requirements. Manufacturers may offer a limited range of styles, colors, or materials, which can hinder a buyer’s ability to create a cohesive aesthetic across their workspace or meet unique user needs. For example, a corporate client may want chairs that reflect their brand colors while also providing ergonomic support, but find that the available options do not fulfill these criteria.

The Solution: To overcome customization limitations, buyers should engage in detailed discussions with manufacturers about their specific needs and preferences. It’s essential to understand the manufacturer’s capabilities regarding customization options. Seek manufacturers that offer flexible solutions, such as made-to-order chairs or modular designs that can be tailored to fit individual specifications. Additionally, utilize design software or 3D rendering tools provided by some manufacturers to visualize how customized products will look in your space. This not only aids in making informed decisions but also helps manufacturers understand your vision better. By establishing a collaborative relationship with manufacturers, buyers can drive innovation and creativity in product development, leading to unique solutions that enhance both functionality and brand identity.

Strategic Material Selection Guide for Chair Manufacturers

What Are the Key Properties of Common Materials Used by Chair Manufacturers?

When selecting materials for chair manufacturing, understanding their properties is crucial for ensuring product performance and longevity. Here, we analyze four common materials: wood, metal, plastic, and upholstery fabrics.

How Does Wood Perform as a Material in Chair Manufacturing?

Wood is a traditional material known for its aesthetic appeal and structural integrity. Key properties include its natural strength, temperature resistance, and ability to be shaped into various designs. However, wood can be susceptible to moisture and temperature changes, which may lead to warping or cracking over time.

Pros: Wood is durable and can last for decades if properly maintained. It also offers a classic look that appeals to many consumers.

Cons: The cost of high-quality wood can be significant, and manufacturing complexity increases with intricate designs. Additionally, it may require regular maintenance, such as polishing or sealing.

For international buyers, especially in regions with varying climates like Africa and South America, selecting the right type of wood is vital. Compliance with sustainability standards, such as the Forest Stewardship Council (FSC), is also a consideration.

What Advantages Does Metal Offer in Chair Manufacturing?

Metal, particularly steel and aluminum, is favored for its strength and durability. It has excellent pressure resistance and is often used in modern and industrial-style chairs. Metals can withstand heavy use and are less prone to damage from environmental factors.

Pros: Metal chairs are often lightweight, making them easy to transport. They are also resistant to pests and do not require much maintenance.

Cons: Metal can be more expensive than wood and may require additional treatments to prevent rust or corrosion, particularly in humid environments.

For B2B buyers in the Middle East, where humidity can be high, selecting corrosion-resistant metals, such as stainless steel, is essential. Compliance with international standards like ASTM for metal products is also important.

How Does Plastic Compare as a Material for Chair Manufacturers?

Plastic is increasingly popular due to its versatility and cost-effectiveness. It is lightweight and can be molded into various shapes and designs, making it suitable for both indoor and outdoor use. Key properties include good weather resistance and ease of cleaning.

Pros: Plastic chairs are generally low-cost and can be produced in large quantities. They are also resistant to fading and moisture, making them ideal for outdoor settings.

Cons: While durable, plastic can be less sturdy than wood or metal and may not have the same aesthetic appeal. Some plastics can degrade over time, especially under UV exposure.

International buyers should consider the environmental impact of plastic and look for options that comply with recycling standards. In regions like Europe, adherence to EU regulations on plastic materials is crucial.

What Role Do Upholstery Fabrics Play in Chair Manufacturing?

Upholstery fabrics are essential for comfort and aesthetics in chairs. Common materials include leather, vinyl, and various textiles. Key properties vary widely, with some fabrics offering high durability and stain resistance, while others may be more susceptible to wear.

Pros: Upholstered chairs provide comfort and can enhance the overall design of a space. High-quality fabrics can be very durable and easy to clean.

Cons: Upholstery can be expensive, and some materials may require special care to maintain their appearance. Additionally, the manufacturing process can be complex, especially for custom designs.

For B2B buyers, understanding the fabric’s fire resistance and compliance with standards such as the California Bureau of Home Furnishings’ regulations is vital. Preferences for specific fabrics may also vary by region, with leather being more popular in the Middle East compared to other regions.

Summary Table of Material Selection for Chair Manufacturers

| Material | Typical Use Case for Chair Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Traditional chairs, dining sets | Aesthetic appeal and durability | Susceptible to moisture and requires maintenance | Medium |

| Metal | Office chairs, outdoor seating | High strength and low maintenance | Higher cost and rust potential | High |

| Plastic | Casual and outdoor furniture | Lightweight and cost-effective | Less sturdy and aesthetic appeal | Low |

| Upholstery Fabrics | Lounge chairs, office seating | Comfort and design versatility | Expensive and care-intensive | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers, ensuring they make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Chair Manufacturers

What Are the Key Stages in Chair Manufacturing Processes?

The manufacturing of chairs involves several critical stages, each essential for ensuring quality and durability. The process typically unfolds in four main phases: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Chair Manufacturing?

The first step in chair manufacturing is material preparation. Depending on the chair design, manufacturers may use various materials, including wood, metal, plastics, and upholstery fabrics. For wooden chairs, the selection of high-quality timber is crucial. This involves sourcing wood from sustainable forests and ensuring that it meets specific moisture content standards to prevent warping.

Once the materials are selected, they undergo cutting and shaping. Advanced technologies such as CNC (Computer Numerical Control) machines are often employed to achieve precise cuts and shapes, minimizing waste and ensuring uniformity. For metal components, processes such as stamping or laser cutting are utilized to create the desired shapes.

What Techniques Are Used in the Forming Stage?

In the forming stage, the prepared materials are manipulated into their final shapes. For wooden chairs, this may involve steam bending or laminating techniques to create curves and ergonomic designs. Metal chairs might undergo processes such as welding or injection molding for plastics.

Innovative techniques like 3D printing are becoming increasingly popular in chair manufacturing, particularly for prototyping and custom designs. This allows manufacturers to create complex shapes that traditional methods may not easily achieve, providing a competitive edge in customization.

How Is the Assembly Process Conducted?

The assembly phase is where various components come together to form the finished product. This typically involves joining the seat, backrest, legs, and any additional features, such as armrests or upholstery. Manufacturers often utilize various fastening techniques, including screws, dowels, and adhesives, ensuring that the chair is robust and stable.

Quality assurance during assembly is critical. Many manufacturers implement automated assembly lines equipped with sensors and cameras to detect defects in real-time. This not only improves efficiency but also reduces the risk of human error.

What Finishing Techniques Enhance Chair Quality?

The final stage of chair manufacturing is finishing, which enhances both aesthetics and durability. This can include applying stains, paints, or varnishes to wooden surfaces or powder coating for metal components. Upholstery work involves selecting and applying fabric or leather, which is essential for comfort and style.

Quality control during the finishing stage is essential, as any flaws can affect the chair’s overall appearance and longevity. Many manufacturers use advanced techniques such as UV curing to ensure that finishes are durable and resistant to wear and tear.

What Quality Assurance Standards Should B2B Buyers Look For?

For B2B buyers, understanding quality assurance (QA) standards is crucial when sourcing chairs from manufacturers. Compliance with international standards such as ISO 9001 ensures that manufacturers follow systematic processes that enhance product quality and customer satisfaction.

Which International Standards Are Relevant for Chair Manufacturing?

ISO 9001 is a widely recognized quality management standard that outlines requirements for consistent product quality. For chair manufacturers, this means adhering to documented processes, conducting regular audits, and implementing continuous improvement practices.

In addition to ISO 9001, industry-specific certifications like CE marking in Europe indicate that products meet safety and health standards. For manufacturers exporting to markets like Saudi Arabia and Brazil, understanding local regulations and certifications is vital to ensure compliance and market access.

What Are the Key Quality Control Checkpoints in Chair Manufacturing?

Quality control is integral to ensuring that chairs meet the required standards before they reach the market. There are several key checkpoints in the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. Ensuring that materials meet specified standards can prevent defects in the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, quality checks are performed at various stages. This could involve measuring dimensions, checking joinery, and assessing the integrity of components.

-

Final Quality Control (FQC): Before products are packaged and shipped, a thorough inspection is conducted. This may include checking for surface defects, ensuring proper assembly, and verifying that the finished product meets all specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensure reliability. Here are some actionable strategies:

What Audit Practices Should Buyers Implement?

Conducting supplier audits is an effective way to assess the manufacturing processes and quality assurance practices of potential partners. Buyers can request to visit manufacturing facilities to observe operations firsthand. During these audits, buyers should focus on the following:

-

Documentation Review: Ensure that the manufacturer has documented processes and quality management systems in place.

-

Employee Training: Evaluate the training programs for employees involved in production to ensure they are knowledgeable about quality standards.

-

Equipment and Technology: Inspect the machinery and technology used in manufacturing to ascertain whether they are up-to-date and suitable for producing high-quality chairs.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an additional layer of assurance for B2B buyers. These independent organizations can conduct comprehensive assessments of manufacturing processes, raw materials, and final products. Their objective reports can help buyers make informed decisions and mitigate risks associated with quality issues.

What Are the Quality Control Nuances for International Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying standards, regulations, and expectations regarding product quality.

-

Cultural Considerations: Buyers should be aware of cultural differences that may affect manufacturing practices and quality perceptions. Building strong relationships with suppliers can facilitate better communication regarding quality expectations.

-

Regulatory Compliance: Familiarize yourself with local regulations that may impact the quality standards of imported chairs. For example, certain materials may be restricted in specific markets, necessitating compliance from manufacturers.

-

Product Certifications: When sourcing from international suppliers, ensure that the products meet the necessary certifications for your target market. This not only ensures compliance but also enhances the credibility of the products in the eyes of customers.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and establish fruitful partnerships with chair manufacturers worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Chair Manufacturers’

When sourcing from chair manufacturers, a structured approach can streamline the process and ensure you partner with the right supplier. This guide provides a clear checklist to help international B2B buyers effectively navigate the procurement landscape for chairs, focusing on quality, reliability, and value.

Step 1: Define Your Requirements Clearly

Understanding your specific needs is fundamental. Determine the type of chairs you require, such as office, dining, or lounge chairs, and outline the material, design, and ergonomic standards essential for your target market. This clarity helps suppliers provide accurate proposals and reduces the chances of miscommunication.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify potential chair manufacturers. Look for companies with a proven track record, positive customer reviews, and a robust portfolio of products. Utilize trade shows, industry publications, and online directories to gather a diverse list of candidates that meet your quality and design criteria.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, including factory location, technology used, and workforce expertise, to ensure they can meet your volume and quality requirements.

- Production Capacity: Ensure the manufacturer can handle your order size without compromising quality.

- Lead Times: Inquire about production timelines to align with your business needs.

Step 4: Verify Compliance and Certifications

It’s essential to confirm that potential suppliers comply with relevant international standards and possess necessary certifications. Look for ISO certifications, safety standards, and environmental compliance, especially if you are sourcing for markets with stringent regulations. This step safeguards your business against potential legal issues and ensures product safety.

Step 5: Request Samples and Conduct Quality Checks

Before finalizing any order, request samples of the chairs you intend to purchase. This allows you to assess the quality, materials, and craftsmanship firsthand. Conduct quality checks to ensure the samples meet your specifications, and consider arranging a factory visit to observe the production process in person.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable manufacturer, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements on these factors help prevent misunderstandings later in the partnership. Ensure that both parties understand the terms to foster a transparent and mutually beneficial relationship.

Step 7: Establish Ongoing Communication

Maintaining effective communication with your supplier is vital throughout the production and delivery process. Set up regular check-ins to monitor progress, address any concerns, and ensure that the final products align with your expectations. Establishing a strong communication channel builds trust and enhances the partnership’s longevity.

By following this checklist, B2B buyers can make informed decisions and build successful relationships with chair manufacturers, ensuring they procure high-quality products that meet their market needs.

Comprehensive Cost and Pricing Analysis for Chair Manufacturers Sourcing

What Are the Key Cost Components in Chair Manufacturing?

When sourcing chairs from manufacturers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall price. Common materials include wood, metal, plastic, and upholstery fabrics. Higher-quality or sustainable materials often come at a premium.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the chair design. Skilled labor for craftsmanship, particularly in custom or designer chairs, can increase costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with the production process, such as utilities, rent, and administrative expenses. Efficient production processes can help minimize overhead.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, especially for custom designs. These costs are typically amortized over the production run.

-

Quality Control (QC): Ensuring that products meet specific quality standards incurs additional costs. Investments in quality control help prevent defects and returns, which can be more costly in the long run.

-

Logistics: Shipping and handling costs can vary based on location, volume, and mode of transport. Import duties and tariffs may also influence the final cost for international buyers.

-

Margin: Manufacturers apply a margin to cover their costs and generate profit. This can vary by manufacturer and may be influenced by brand reputation and market positioning.

How Do Pricing Influencers Impact Chair Sourcing?

Several factors can influence pricing when sourcing chairs:

-

Volume and Minimum Order Quantity (MOQ): Manufacturers often offer better pricing for larger orders. Understanding MOQ is essential for budgeting, as lower quantities may lead to higher per-unit costs.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Clear communication about specifications at the outset can help avoid unexpected charges.

-

Materials and Quality Certifications: Chairs made from premium materials or those that meet specific quality certifications (like ISO or ANSI) generally command higher prices. Buyers should weigh the benefits of certifications against budget constraints.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge more for their proven track record, while lesser-known manufacturers might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipment, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for calculating the total landed cost. These terms dictate who bears the cost and risk at various stages of transportation.

What Are the Best Negotiation Tips for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Leverage Volume: If possible, consolidate orders to meet MOQs for better pricing. This can lead to significant savings on a per-unit basis.

-

Explore Total Cost of Ownership (TCO): Rather than focusing solely on the initial purchase price, consider the long-term costs associated with maintenance, durability, and potential replacements. This approach can justify a higher initial investment if it leads to savings over time.

-

Understand Pricing Nuances: Be aware of currency fluctuations and their potential impact on pricing. Additionally, negotiate payment terms that align with your cash flow needs, such as extended payment terms or discounts for upfront payments.

-

Conduct Market Research: Familiarize yourself with the average pricing for similar chairs in your target market. This information can strengthen your negotiating position and ensure you are not overpaying.

Conclusion: How Can Buyers Navigate the Pricing Landscape Effectively?

While sourcing chairs, buyers must consider a multitude of factors that influence pricing. Understanding the cost structure, being aware of pricing influencers, and employing effective negotiation strategies can lead to more informed purchasing decisions. Keep in mind that prices can vary significantly, and it is advisable to request quotes from multiple suppliers to ensure competitive pricing. Always approach negotiations with a clear understanding of your needs and budget constraints, as this will empower you to secure the best possible deal for your organization.

Alternatives Analysis: Comparing Chair Manufacturers With Other Solutions

Exploring Alternative Solutions to Traditional Chair Manufacturers

In the evolving landscape of office and commercial furniture, buyers increasingly seek alternatives to traditional chair manufacturers. These alternatives can provide unique benefits tailored to specific needs, whether it’s for cost efficiency, sustainability, or innovative design. Here, we will compare traditional chair manufacturing with two alternative solutions: ergonomic office furniture rental services and modular furniture systems.

| Comparison Aspect | Chair Manufacturers | Ergonomic Office Furniture Rental Services | Modular Furniture Systems |

|---|---|---|---|

| Performance | High durability and quality | Good, but dependent on rental condition | Versatile and customizable |

| Cost | Typically higher upfront cost | Lower initial cost; ongoing rental fees | Moderate; depends on configuration |

| Ease of Implementation | Requires significant lead time | Quick setup and delivery | Moderate; may require assembly |

| Maintenance | Long-term maintenance needed | Minimal; rental service handles upkeep | Variable; user responsible for care |

| Best Use Case | Permanent installations in offices | Short-term needs, startups, or events | Dynamic spaces needing flexibility |

What Are the Benefits and Drawbacks of Ergonomic Office Furniture Rental Services?

Ergonomic office furniture rental services provide businesses with the flexibility to furnish their spaces without the financial burden of purchasing. This option is particularly beneficial for companies with short-term projects or fluctuating workforce needs. The main advantage is the reduced upfront cost, as businesses only pay for the duration of use. However, the performance can vary based on the condition of rented items, and businesses may face challenges with the consistency of ergonomic features across different rental providers.

How Do Modular Furniture Systems Compare?

Modular furniture systems represent another innovative alternative, offering customizable configurations that can adapt to various spaces and needs. This flexibility allows businesses to reconfigure their office layout as requirements change, making them ideal for dynamic work environments. While the initial investment can be moderate, the modular approach can save costs in the long run by eliminating the need for complete replacements. However, users may need to invest time in assembly and maintenance, which can be a drawback for some organizations.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between traditional chair manufacturers and alternative solutions like rental services or modular systems, B2B buyers should consider their specific needs, budget constraints, and the intended use of the furniture. For companies seeking permanence and high-quality design, investing in traditional manufacturers may be the best option. Conversely, businesses with fluctuating needs or those looking for cost-effective solutions might find rentals or modular systems more advantageous. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their organizational goals.

Essential Technical Properties and Trade Terminology for Chair Manufacturers

What Are the Key Technical Properties Relevant to Chair Manufacturing?

Understanding the technical properties of chairs is crucial for international B2B buyers, especially those sourcing from diverse regions like Africa, South America, the Middle East, and Europe. Here are several essential specifications:

1. Material Grade

The material grade refers to the quality and type of materials used in chair construction, such as wood, metal, or upholstery fabric. High-grade materials ensure durability, comfort, and aesthetic appeal. For B2B buyers, investing in chairs made from superior materials reduces replacement costs and enhances customer satisfaction.

2. Load Capacity

Load capacity indicates the maximum weight a chair can safely support. This specification is vital for ergonomic and safety considerations. Buyers need to ensure that the chairs they purchase meet the expected user demographics, especially in commercial settings like offices or public spaces, to avoid liability issues.

3. Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension or measurement. In chair manufacturing, it is crucial for ensuring that parts fit together correctly and that the final product meets design specifications. For B2B buyers, understanding tolerances helps in assessing quality control processes and ensuring that products meet their specific requirements.

4. Finish and Coating

The finish and coating of a chair impact its appearance and longevity. This includes treatments such as varnishing, painting, or powder coating. Buyers should consider finishes that provide resistance to scratches, stains, and environmental conditions, especially for outdoor or high-traffic areas.

5. Ergonomic Design Features

Ergonomic design features include adjustable components like seat height, lumbar support, and armrests that enhance user comfort and posture. For B2B buyers, focusing on ergonomic features is essential for promoting employee well-being and productivity, particularly in office environments.

6. Warranty Period

The warranty period indicates the time frame during which the manufacturer guarantees the quality of their product. A longer warranty often reflects the manufacturer’s confidence in their craftsmanship and materials. Buyers should prioritize products with substantial warranty coverage to ensure long-term value.

What Are Common Trade Terms in Chair Manufacturing?

Navigating the chair manufacturing industry also involves understanding specific jargon and trade terms that facilitate communication and transactions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For chair manufacturers, this means they can provide customized products that align with a buyer’s brand or specifications. Understanding OEM relationships can help buyers find manufacturers capable of meeting their unique needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers who must consider their budget and inventory levels when placing orders. Knowing the MOQ can also help in negotiating prices and ensuring that the purchase aligns with demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products. In the chair manufacturing sector, issuing an RFQ allows buyers to compare costs, specifications, and delivery timelines from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers in a transaction. Understanding these terms helps B2B buyers clarify shipping responsibilities, insurance, and risk management, ensuring smooth logistics in international sourcing.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. This term is crucial for planning inventory and ensuring that supply chains remain efficient. Buyers should communicate their lead time expectations clearly to avoid disruptions.

6. CAD (Computer-Aided Design)

CAD refers to the use of software to create precise drawings and technical illustrations of products. In chair manufacturing, CAD is essential for prototyping and ensuring accurate specifications. B2B buyers can benefit from suppliers who utilize CAD, as it often results in higher quality and better-fitting products.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing chairs, leading to successful partnerships and optimal product selections.

Navigating Market Dynamics and Sourcing Trends in the Chair Manufacturers Sector

What Are the Key Trends Shaping the Global Chair Manufacturers Market?

The chair manufacturing sector is witnessing transformative changes driven by globalization, technological advancements, and evolving consumer preferences. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are navigating a marketplace characterized by several key trends. One significant driver is the increasing demand for ergonomic and multifunctional furniture as remote work becomes more prevalent. Manufacturers are responding by integrating innovative designs that prioritize comfort and adaptability, catering to diverse workspaces and lifestyles.

Moreover, digital transformation in sourcing processes is gaining traction. B2B buyers now leverage e-commerce platforms and virtual showrooms, allowing them to explore product options, access real-time inventory, and engage with suppliers from different parts of the globe. This shift towards digital procurement not only enhances efficiency but also enables buyers to compare prices and specifications seamlessly.

Sustainability is another crucial factor influencing market dynamics. As awareness of environmental issues rises, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This trend is particularly pronounced in Europe, where stringent regulations on environmental impact compel manufacturers to adopt eco-friendly materials and processes. As a result, the chair manufacturing sector is evolving to meet these demands, shaping a more responsible and responsive market landscape.

How Is Sustainability Influencing Sourcing Decisions in the Chair Manufacturing Sector?

Sustainability and ethical sourcing are becoming paramount in the chair manufacturing industry. The environmental impact of production methods and materials used is under scrutiny, prompting manufacturers to adopt greener practices. This includes utilizing sustainable materials such as reclaimed wood, recycled metals, and eco-friendly upholstery fabrics. B2B buyers are increasingly inclined to partner with manufacturers who demonstrate a commitment to sustainability, as this aligns with their own corporate social responsibility goals.

The importance of ethical supply chains cannot be overstated. Buyers are actively seeking suppliers who ensure fair labor practices and transparency in their sourcing processes. Certifications such as Forest Stewardship Council (FSC) for wood products and Global Organic Textile Standard (GOTS) for textiles are becoming essential indicators of a manufacturer’s commitment to sustainable practices. By prioritizing suppliers with these certifications, B2B buyers can mitigate risks associated with unethical sourcing and enhance their brand reputation.

Incorporating sustainable practices not only addresses environmental concerns but also resonates with consumers who are increasingly demanding eco-conscious products. This shift is not merely a trend; it represents a fundamental change in how businesses operate, emphasizing the need for long-term sustainability in the chair manufacturing sector.

What Is the Historical Context of Chair Manufacturing for B2B Buyers?

The chair manufacturing industry has evolved significantly over the past century, shaped by technological advancements and changing consumer preferences. Initially dominated by traditional craftsmanship, the sector saw a major transformation with the advent of industrialization in the early 20th century. Mass production techniques allowed for greater efficiency and affordability, making stylish and functional chairs accessible to a broader audience.

As the market matured, the latter part of the 20th century witnessed a surge in design innovation, with iconic brands like Herman Miller and Steelcase leading the way. These companies introduced ergonomic designs and modular furniture systems that catered to the modern workplace, setting new standards in functionality and aesthetics.

Today, the industry stands at the intersection of tradition and innovation, where heritage craftsmanship meets cutting-edge technology. This historical context is crucial for B2B buyers as they navigate the current market landscape, providing insights into the evolution of design and manufacturing practices that continue to shape the sector. Understanding this history enables buyers to make informed sourcing decisions that align with their business values and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of Chair Manufacturers

-

How do I ensure the quality of chairs from manufacturers?

To ensure quality when sourcing chairs from manufacturers, start by requesting samples of their products. Assess the materials, craftsmanship, and design. Additionally, check for certifications that adhere to international standards (like ISO or BIFMA for office furniture). Conducting factory visits or virtual tours can also provide insights into their production processes. Partnering with reputable manufacturers who have positive reviews or references from other B2B clients can further mitigate risks related to quality. -

What are the typical minimum order quantities (MOQs) for chair manufacturers?

Minimum order quantities (MOQs) can vary significantly between manufacturers. Generally, MOQs for chairs range from 50 to 500 units, depending on the manufacturer, product type, and customization options. Large manufacturers may have lower MOQs for standard products, while custom designs could require higher quantities. Always clarify MOQs during initial negotiations and consider the implications on inventory and cash flow for your business. -

What payment terms should I expect when dealing with chair manufacturers?

Payment terms with chair manufacturers can vary widely, typically ranging from 30% upfront and 70% upon delivery to net 30 or net 60 terms. Some manufacturers may offer discounts for early payments or larger orders. It’s crucial to negotiate terms that align with your cash flow needs. Always confirm the payment methods accepted (bank transfer, letter of credit, etc.) and ensure that you have a clear agreement in writing to avoid any disputes later. -

How can I customize my chair orders to meet specific needs?

Most chair manufacturers offer customization options, including material selection, color, size, and design modifications. Begin by discussing your requirements with the manufacturer’s sales or design team. Provide detailed specifications and reference images to ensure clarity. Some manufacturers may have online tools or design resources to visualize your customizations. Be mindful of potential lead times and MOQs associated with custom orders. -

What logistics considerations should I be aware of when importing chairs?

When importing chairs, consider shipping costs, customs duties, and delivery timelines. Choose a reliable logistics partner experienced in handling furniture shipments. Ensure compliance with your country’s import regulations and standards. Familiarize yourself with Incoterms (International Commercial Terms) to clarify responsibilities regarding shipping, insurance, and duties. Additionally, factor in the potential for damages during transport and consider insurance options. -

How can I vet potential chair manufacturers before placing an order?

Vetting potential chair manufacturers involves several steps. Start by researching their reputation through online reviews, industry forums, and references from other buyers. Request company profiles, production capabilities, and certifications. Schedule meetings or video calls to discuss your needs and assess their responsiveness. If possible, visit their facilities or request a third-party audit report to evaluate their production practices and quality control measures. -

What are the common challenges in sourcing chairs from international manufacturers?

Common challenges in sourcing chairs internationally include language barriers, cultural differences, varying quality standards, and longer lead times. Time zone differences can complicate communication and timely responses. Currency fluctuations may also impact pricing. To mitigate these challenges, establish clear communication channels, utilize professional translators if necessary, and ensure that all agreements are documented in a language both parties understand. -

What are the key trends influencing chair design and manufacturing today?

Current trends in chair design include ergonomic features, sustainability, and multifunctionality. Manufacturers are increasingly focusing on materials that are environmentally friendly and sustainable, such as recycled plastics and responsibly sourced woods. Additionally, the rise of remote work has led to increased demand for ergonomic office chairs that promote comfort and health. Understanding these trends can help buyers select products that are not only stylish but also aligned with market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Chair Manufacturers

In today’s competitive landscape, strategic sourcing remains a pivotal factor for chair manufacturers aiming to thrive in the global market. By aligning procurement strategies with emerging trends, such as sustainability and customization, manufacturers can enhance their operational efficiency and market responsiveness. The insights gathered highlight the importance of selecting suppliers who not only deliver quality products but also align with your business values and customer expectations.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics and consumer preferences is crucial. Establishing strong partnerships with reliable manufacturers can drive innovation and provide a competitive edge. It is essential to consider factors such as minimum order quantities, lead times, and logistical capabilities when sourcing.

Looking ahead, the chair manufacturing industry is poised for growth driven by evolving work environments and lifestyle changes. Buyers are encouraged to leverage the insights from this guide to make informed sourcing decisions. Embrace the opportunity to collaborate with manufacturers who prioritize quality, innovation, and sustainability, ensuring your business remains at the forefront of the market.